Condition Assessment of Joints in Steel Truss Bridges Using a Probabilistic Neural Network and Finite Element Model Updating

Abstract

1. Introduction

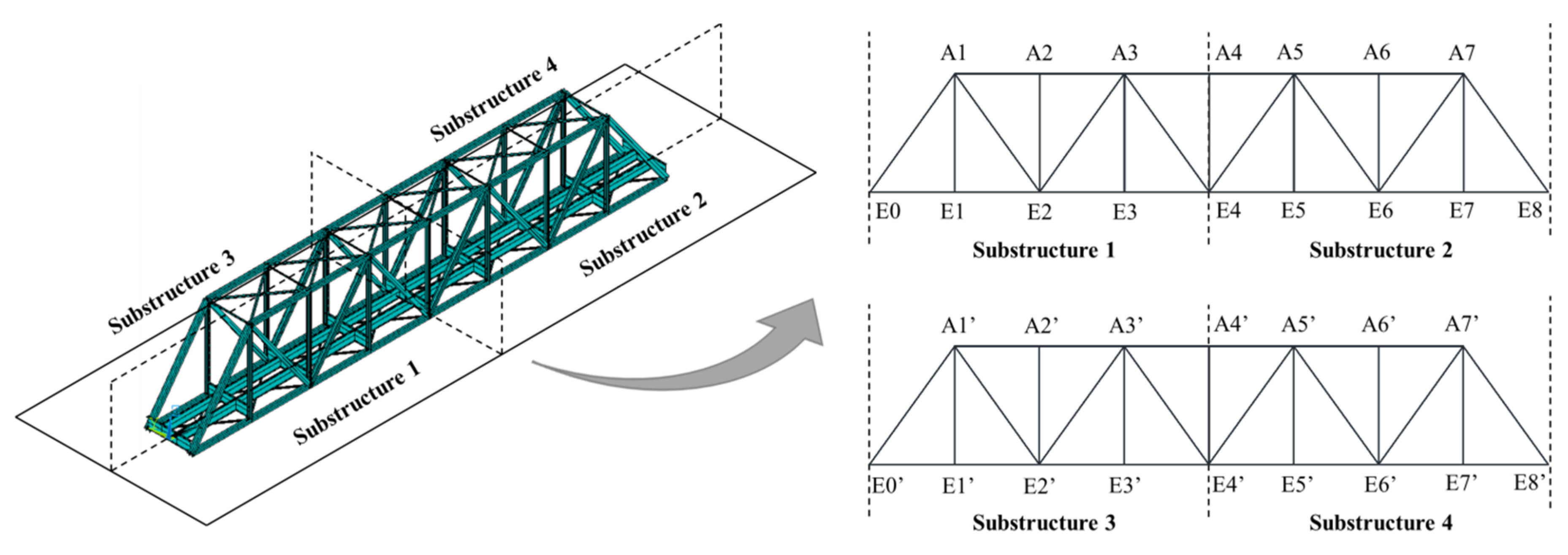

2. Bridge Description

3. Methodology

3.1. Simplified Simulation of Joint Damage

3.2. Damage Localization Using PNN

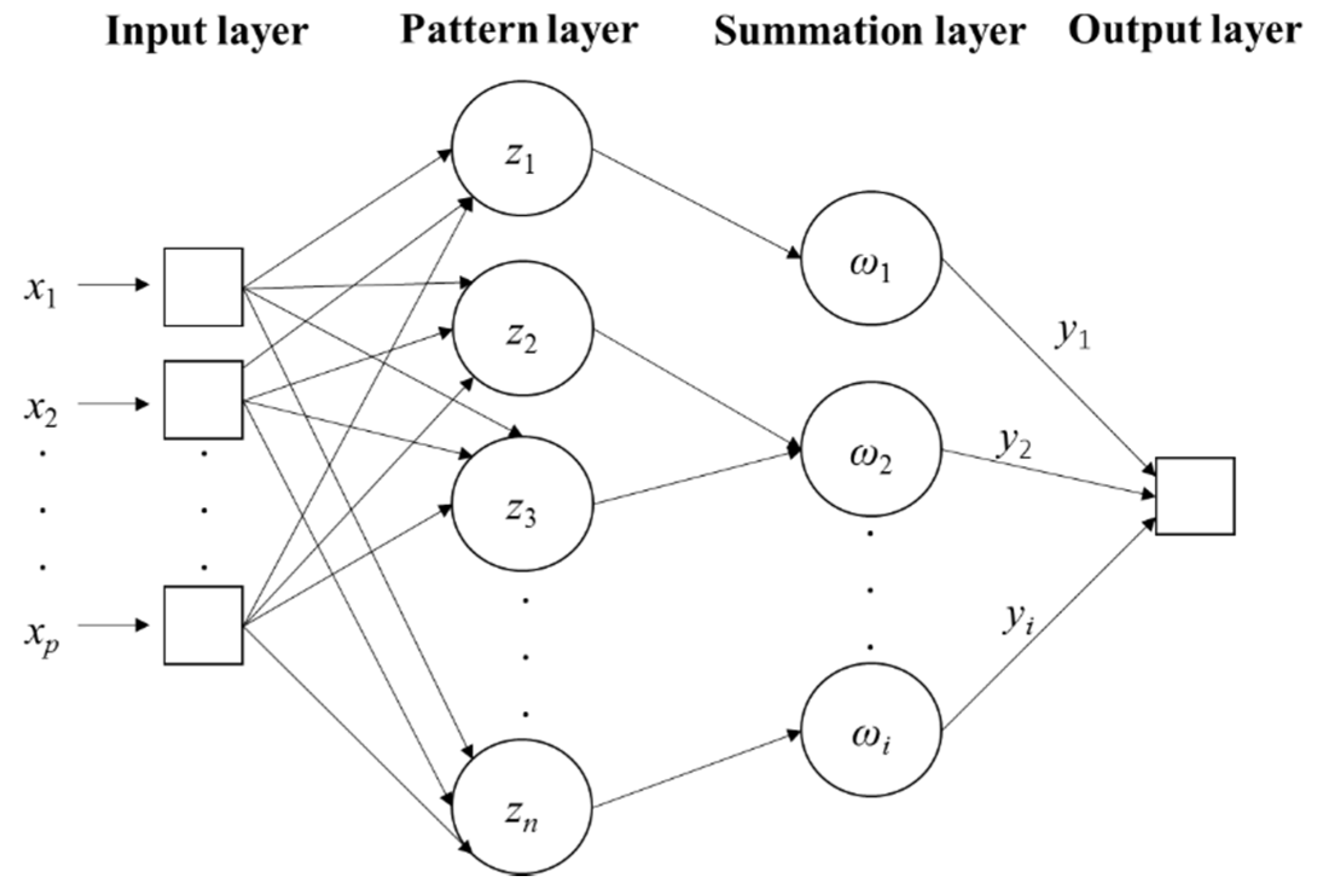

3.2.1. Probabilistic Neural Network

3.2.2. Input Selection and Testing Method

3.3. Quantitative Damage Severity Assessment Using FE Model Updating

3.3.1. FE Model Updating Parameters

3.3.2. Objective Function and Optimization Algorithm

3.4. Two-Step Damage Identification Process

- Subdivide the steel truss bridge into several substructures and use the CRMCs as the inputs for the PNN.

- Establish FE models of the bridge with and without damage, and calculate and normalize the inputs for different damage cases to generate the sample sets for the neural network.

- Select samples to train the neural network, and use the remaining samples for testing and obtaining the optimum training pattern. Input the modal curvatures obtained from the field measurements into the neural network to localize the damage in a certain substructure.

- 4.

- Construct the objective function based on the modal curvatures. Identify the end-stiffness reduction coefficients, α, of members in the substructure by the iterative model updating method.

4. Results

4.1. Verification of Input Sensitivity

4.2. Damage Localization

4.2.1. Generation of Training and Testing Samples

4.2.2. Testing of Trained Neural Networks for Damage Localization

- High accuracy can be achieved when 16 training samples are used for single damage cases. A slight improvement can be achieved by including more training samples.

- The damage severity of the training samples used has little effect on the accuracy of damage localization regardless of whether single or multiple damage detection is attempted.

- Using a portion of single damage training samples cannot achieve good identification results for multiple damage localization. However, with adequate numbers of training samples, a high accuracy of multiple damage localization can be accomplished.

- Using single damage samples to train the PNN can effectively achieve damage localization for either single or multiple damage cases, which indicates that the trained PNN has a strong generalization ability.

4.3. Quantitative Damage Severity Assessment

4.3.1. Detection of Single Damage

- For the single damage cases, the damage extent of different members can all be accurately identified with a maximum error of less than 3.3% between the identified results and real values.

- Although some non-existent damage is identified in some members, the corresponding end-stiffness reduction coefficients, α, are relatively small, less than 0.1. The false damage identification can be eliminated by ignoring the results with α less than 0.1 in actual applications.

- As shown in Figure 18, the objective function converges after about 12 iterations, which proves the high efficiency of the proposed method.

4.3.2. Detection of Multiple Damages

- When a case of multiple damage occurs in a substructure, it can be effectively identified by the proposed model updating method, including Case 7, despite larger errors (14.25%) compared to other cases.

- Compared to the single damage cases, the total number of false damage identifications in multiple damage cases is greater. The incorrect α values are, nevertheless, still all less than 0.1.

- The numbers of steps the method takes to converge in multiple damage cases are generally consistent with the single damage cases, which again validates the high computational efficiency of the proposed method.

4.4. Noise Effect

5. Discussion

6. Conclusions

- The simplified simulation method of joint damage and substructuring technique were found to be very efficient for reducing the complexity of joint condition evaluation in steel truss bridges.

- The CRMC has a high sensitivity to local damage. Using only the CRMCs of the fundamental vertical bending mode measured at lower chord nodes as the inputs of the PNN can correctly identify the damaged substructure.

- Using single damage cases to train the PNN can achieve very high accuracy of joint damage localization for either single or multiple damage detection cases. The damage severity of the training samples adopted for training has little effect on the accuracy of the subsequent unknown damage localization.

- The proposed model updating method can effectively quantify the joint deterioration with high iteration efficiency and has some robustness to noise.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Salem, H.M.; Helmy, H.M. Numerical investigation of collapse of the Minnesota I-35W bridge. Eng. Struct. 2014, 59, 635–645. [Google Scholar] [CrossRef]

- National Transportation Safety Board. Collapse of I-35W Highway Bridge, Minneapolis, Minnesota, August 1, 2007. Highway Accident Report NTSB/HAR-08/03; Washington, DC, USA. 2008. Available online: http://www.dot.state.mn.us/i35wbridge/pdf/ntsb-report.pdf (accessed on 29 January 2021).

- Federal Highway Administration. National Bridge. Inspection Standards; Federal Register, FHWA: Washington, DC, USA, 2004. [Google Scholar]

- Jiang, T.; Li, Y.; Song, G. Detection of High-Strength Bolts Looseness Using Lead Zirconate Titanate Due to Wavelet Packet Analysis. In Proceedings of Earth and Space 2018: Engineering for Extreme Environments, Cleveland, Ohio, USA, 9–12 April 2018; ASCE: Reston, VA, USA, 2018. [Google Scholar]

- Phares, B.M.; Washer, G.A.; Rolander, D.D.; Graybeal, B.A.; Moore, M. Routine highway bridge inspection condition documentation accuracy and reliability. J. Bridge. Eng. 2004, 9, 403–413. [Google Scholar] [CrossRef]

- Nikravesh, S.M.Y.; Goudarzi, M. A review paper on looseness detection methods in bolted structures. Lat. Am. J. Solids Struct. 2017, 14, 2153–2176. [Google Scholar] [CrossRef]

- Kong, X.; Li, J. Image Registration-Based Bolt Loosening Detection of Steel Joints. Sensors 2018, 18, 1000. [Google Scholar] [CrossRef] [PubMed]

- Pham, H.C.; Ta, Q.-B.; Kim, J.-T.; Ho, D.-D.; Tran, X.-L.; Huynh, T.-C. Bolt-Loosening Monitoring Framework Using an Image-Based Deep Learning and Graphical Model. Sensors 2020, 20, 3382. [Google Scholar] [CrossRef]

- An, Y.; Li, B.; Ou, J. An algorithm for damage localization in steel truss structures: Numerical simulation and experimental validation. J. Intell. Mater. Syst. Struct. 2013, 24, 1683–1698. [Google Scholar] [CrossRef]

- An, Y.; Ou, J. Experimental and numerical studies on damage localization of simply supported beams based on curvature difference probability method of waveform fractal dimension. J. Intell. Mater. Syst. Struct. 2012, 23, 415–426. [Google Scholar] [CrossRef]

- Yang, J.N.; Xia, Y.; Loh, C.H. Damage identification of bolt connections in a steel frame. J. Struct. Eng. 2014, 140, 04013064. [Google Scholar] [CrossRef]

- Li, J.; Hao, H. Health monitoring of joint conditions in steel truss bridges with relative displacement sensors. Measurement 2016, 88, 360–371. [Google Scholar] [CrossRef]

- Tan, Z.X.; Thambiratnam, D.P.; Chan, T.H.T.; Gordan, M.; Razak, H.A. Damage detection in steel-concrete composite bridge using vibration characteristics and artificial neural network. Struct. Infrastruct. Eng. 2020, 16, 1247–1261. [Google Scholar] [CrossRef]

- Chun, P.J.; Yamane, T.; Izumi, S.; Kuramoto, N. Development of a Machine Learning-Based Damage Identification Method Using Multi-Point Simultaneous Acceleration Measurement Results. Sensors 2020, 20, 2780. [Google Scholar] [CrossRef] [PubMed]

- Padil, K.H.; Bakhary, N.; Hao, H. The use of a non-probabilistic artificial neural network to consider uncertainties in vibration-based-damage detection. Mech. Syst. Signal. Process. 2017, 83, 194–209. [Google Scholar] [CrossRef]

- Abdeljaber, O.; Avci, O.; Kiranyaz, S.; Gabbouj, M.; Inman, D.J. Real-time vibration-based structural damage detection using one-dimensional convolutional neural networks. J. Sound Vib. 2017, 388, 154–170. [Google Scholar] [CrossRef]

- Chun, P.J.; Yamashita, H.; Furukawa, S. Bridge damage severity quantification using multipoint acceleration measurement and artificial neural networks. Shock Vib. 2015, 2015, 1–11. [Google Scholar] [CrossRef]

- Figueiredo, E.; Park, G.; Farrar, C.R.; Worden, K.; Figueiras, J. Machine learning algorithms for damage detection under operational and environmental variability. Struct. Health Monit. 2011, 10, 559–572. [Google Scholar] [CrossRef]

- Liu, H.B.; Jiao, Y.B. Application of genetic algorithm-support vector machine (GA-SVM) for damage identification of bridge. Inter. J. Comput. Intell. Appl. 2011, 10, 383–397. [Google Scholar] [CrossRef]

- Yam, L.H.; Yan, Y.J.; Jiang, J.S. Vibration-based damage detection for composite structures using wavelet transform and neural network identification. Compos. Struct. 2003, 60, 403–412. [Google Scholar] [CrossRef]

- Mehrjoo, M.; Khaji, N.; Moharrami, H.; Bahreininejad, A. Damage detection of truss bridge joints using Artificial Neural Networks. Expert Syst. Appl. 2008, 35, 1122–1131. [Google Scholar] [CrossRef]

- Yin, T.; Zhu, H.P. Probabilistic Damage Detection of a Steel Truss Bridge Model by Optimally Designed Bayesian Neural Network. Sensors 2018, 18, 3371. [Google Scholar] [CrossRef]

- Palomino, L.V.; Steffen, V., Jr.; Neto, R.M.F. Probabilistic Neural Network Applied to Impedance-Based Structural Health Monitoring for Damage Classification. In Proceedings of the 8th International Conference on Structural Dynamics, EURODYN 2011, Leuven, Belgium, 4–6 July 2011. [Google Scholar]

- Specht, D.F. Probabilistic neural networks. Neural Netw. 1990, 3, 109–118. [Google Scholar] [CrossRef]

- Wasserman, P.D. Advanced Methods in Neural Computing; Van Nostrand, R., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1993. [Google Scholar]

- Lee, J.-J.; Yun, C.-B. Damage Localization for Bridges Using Probabilistic Neural Networks. KSCE J. Civ. Eng. 2007, 11, 111–120. [Google Scholar] [CrossRef]

- Li, P. Structural damage localization using probabilistic neural networks. Math. Comput. Model. 2011, 54, 965–969. [Google Scholar] [CrossRef]

- Zhou, X.T.; Ni, Y.Q.; Zhang, F.L. Damage localization of cable-supported bridges using modal frequency data and probabilistic neural network. Math. Probl. Eng. 2014, 2014, 837963. [Google Scholar] [CrossRef]

- Vagnoli, M.; Remenyte-Prescott, R.; Andrews, J. Railway bridge structural health monitoring and fault detection: State-of-the-art methods and future challenges. Struct. Health Monit. 2018, 17, 971–1007. [Google Scholar] [CrossRef]

- Pandey, A.K.; Biswas, M.; Samman, M.M. Damage detection from changes in curvature mode shapes. J. Sound Vib. 1991, 145, 321–332. [Google Scholar] [CrossRef]

- Ministry of Railways of the People’s Republic of China. China Railway Industry Standard. Code for Rating Existing Railway Bridges. 2004. Available online: http://m.wdfxw.net/Fulltext49716052.htm (accessed on 29 January 2021).

- Mazzotti, M.; Mao, Q.; Bartoli, I.; Livadiotis, S. A multiplicative regularized Gauss-Newton method with trust region Sequential Quadratic Programming for structural model updating. Mech. Syst. Signal. Process. 2019, 131, 417–433. [Google Scholar] [CrossRef]

- MATLAB 2017b. MATLAB Version R2017b; The Mathworks, Inc.: Natick, MA, USA, 2017. [Google Scholar]

| Component of Main Truss | Cross-Sectional Property | Material Property | ||||

|---|---|---|---|---|---|---|

| Section Type | Cross-Sectional Area (m2) | Moment of Inertia (m4) | Young’s Modulus (GPa) | Poisson’s Ratio (-) | Mass Density (kg/m3) | |

| Lower chords | H-shaped | 0.0154 | 0.623×10−3 | 205 | 0.3 | 7850 |

| Upper chords | H-shaped | 0.02344 | 0.965×10−3 | 205 | 0.3 | 7850 |

| Vertical rods | H-shaped | 0.0106 | 0.382×10−3 | 205 | 0.3 | 7850 |

| Diagonal rods | H-shaped | 0.019 | 0.791×10−3 | 205 | 0.3 | 7850 |

| Diagonal rods at both ends | H-shaped | 0.02904 | 1.236×10−3 | 205 | 0.3 | 7850 |

| Case No. | Member with Bolt Looseness | Member Location | End-Stiffness Reduction Coefficient, α |

|---|---|---|---|

| 1 | E3-E4 | Lower chord | 0.5 |

| 2 | A2–A3 | Upper chord | 0.5 |

| 3 | A1–E1 | Vertical chord | 0.5 |

| 4 | A3-E2 | Diagonal chord | 0.5 |

| Damage Type | Single damage | Double damage | Triple damage | |||||||||||

| Sample Set No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | ||

| End-stiffnessReduction Coefficient, α | 0.3 | 0.4 | 0.5 | 0.6 | 0.3 | 0.4 | 0.5 | 0.6 | 0.3 | 0.4 | 0.5 | 0.6 | ||

| Numberof Samples | 58 | 58 | 58 | 58 | 394 | 394 | 394 | 394 | 1638 | 1638 | 1638 | 1638 | ||

| Case No. | Damage Type | End-Stiffness Reduction Coefficient, α | Number of Training Samples |

|---|---|---|---|

| 1 | Single damage | 0.3 | 8 |

| 2 | Single damage | 0.3 | 16 |

| 3 | Single damage | 0.3 | 24 |

| 4 | Single damage | 0.3 | 58 |

| 5 | Single damage | 0.4 | 58 |

| 6 | Single damage | 0.5 | 58 |

| 7 | Single damage | 0.6 | 58 |

| Case No. | Damage Type | Member with Joint Damage (Member No.) | End-Stiffness Reduction Coefficient, α |

|---|---|---|---|

| 1 | Single damage | A2–A3 (6) | 0.3 |

| 2 | A1–E1 (8) | 0.6 | |

| 3 | E4–E5 (15) | 0.4 | |

| 4 | A5–E6 (27) | 0.5 | |

| 5 | Multiple damage | A3–A4, A3–E4 (7, 14) | 0.2, 0.7 |

| 6 | E4–E5, A5–E5 (15, 23) | 0.4, 0.6 | |

| 7 | E3–E4, A2–A3, A3–E2 (4, 6, 13) | 0.2, 0.4, 0.6 | |

| 8 | A4–E4, A5–E4, A7–E6 (22, 26, 28) | 0.5, 0.7, 0.3 |

| Case No. | Member with Joint Damage | Real Value | Identified Value | Relative Error (%) |

|---|---|---|---|---|

| 1 | 6 | 0.3 | 0.290 | −3.33 |

| 2 | 8 | 0.6 | 0.597 | −0.50 |

| 3 | 15 | 0.4 | 0.397 | −0.75 |

| 4 | 27 | 0.5 | 0.500 | 0 |

| Case No. | Member with Joint Damage | Real Value | Identified Value | Relative Error (%) |

|---|---|---|---|---|

| 5 | 7, 14 | 0.2, 0.7 | 0.185, 0.702 | −7.50, 0.29 |

| 6 | 15, 23 | 0.4, 0.6 | 0.395, 0.592 | −1.25, −1.33 |

| 7 | 4, 6, 13 | 0.2, 0.4, 0.6 | 0.181, 0.343, 0.597 | −9.50, −14.25, −0.50 |

| 8 | 22, 26, 28 | 0.5, 0.7, 0.3 | 0.492, 0.700, 0.301 | −1.50, 0, 0.33 |

| Case No. | Member with Joint Damage (Member No.) | End-Stiffness Reduction Coefficient, α | Signal-to-Noise Ratio (SNR) (dB) |

|---|---|---|---|

| 9 | A2–A3 (6) | 0.5 | 10 |

| 10 | 20 | ||

| 11 | 30 | ||

| 12 | 40 |

| Noise Level | Member with Joint Damage | Real Value | Identified Value | Relative Error (%) |

|---|---|---|---|---|

| 10 dB | 6 (A2–A3) | 0.5 | 0.760 | 52.00 |

| 20 dB | 0.012 | 97.60 | ||

| 30 dB | 0.581 | 16.20 | ||

| 40 dB | 0.502 | 0.40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhan, J.; Wang, C.; Fang, Z. Condition Assessment of Joints in Steel Truss Bridges Using a Probabilistic Neural Network and Finite Element Model Updating. Sustainability 2021, 13, 1474. https://doi.org/10.3390/su13031474

Zhan J, Wang C, Fang Z. Condition Assessment of Joints in Steel Truss Bridges Using a Probabilistic Neural Network and Finite Element Model Updating. Sustainability. 2021; 13(3):1474. https://doi.org/10.3390/su13031474

Chicago/Turabian StyleZhan, Jiawang, Chuang Wang, and Zhiheng Fang. 2021. "Condition Assessment of Joints in Steel Truss Bridges Using a Probabilistic Neural Network and Finite Element Model Updating" Sustainability 13, no. 3: 1474. https://doi.org/10.3390/su13031474

APA StyleZhan, J., Wang, C., & Fang, Z. (2021). Condition Assessment of Joints in Steel Truss Bridges Using a Probabilistic Neural Network and Finite Element Model Updating. Sustainability, 13(3), 1474. https://doi.org/10.3390/su13031474