LCA and Exergo-Environmental Evaluation of a Combined Heat and Power Double-Flash Geothermal Power Plant

Abstract

1. Introduction

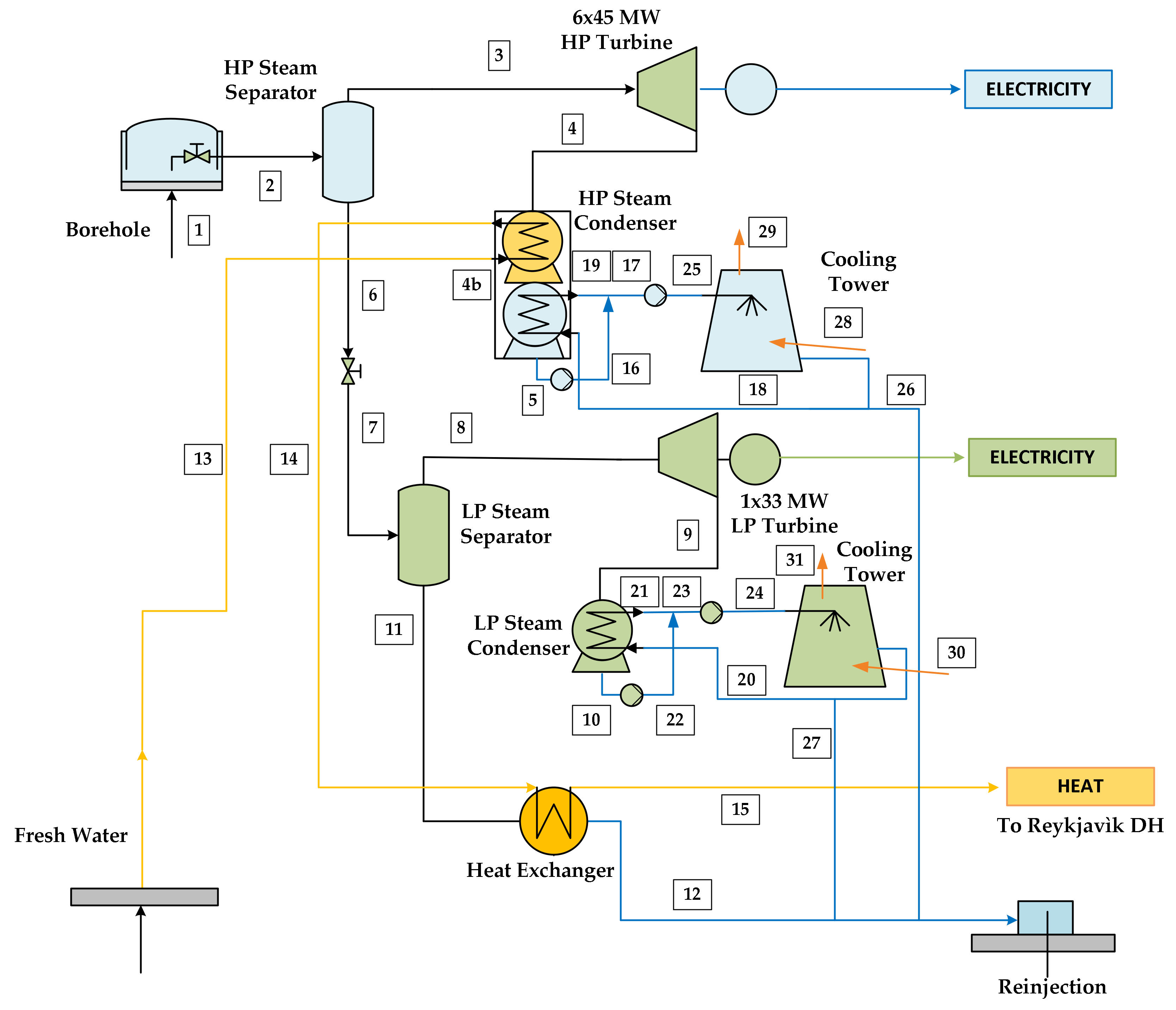

2. Description of the Reference Case

- Withdrawal of the geothermal fluid through the wells;

- Separation of the vapour phase and the liquid phase;

- Transport and heating of cold water (heat transfer fluid for cogeneration);

- Production of electricity;

- Connection to the national electricity grid and the Reykjavík district for heating.

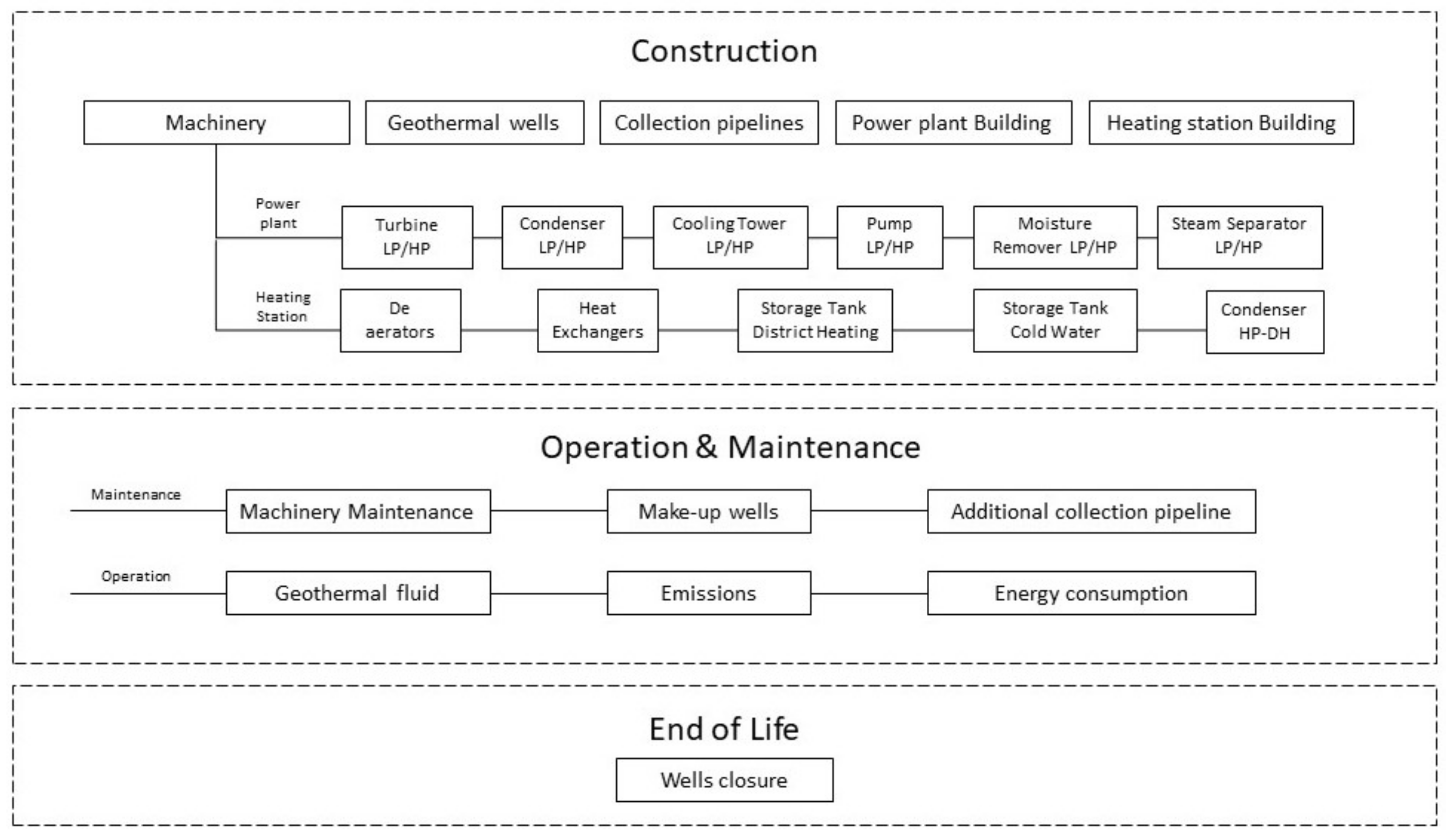

3. Life Cycle Analysis

3.1. Life Cycle Assessment

3.2. Goal and Scope

3.3. Functional Unit and General Setup of the LCA

3.4. Life Cycle Inventory

3.4.1. Life Cycle Inventory—Scenario 1

3.4.2. Life Cycle Inventory—Scenario 2

- The introduction of the CarbFix and SulFix gaseous effluent treatment system;

- The use of electric drilling machines instead of machines that consume diesel for the construction of geothermal wells.

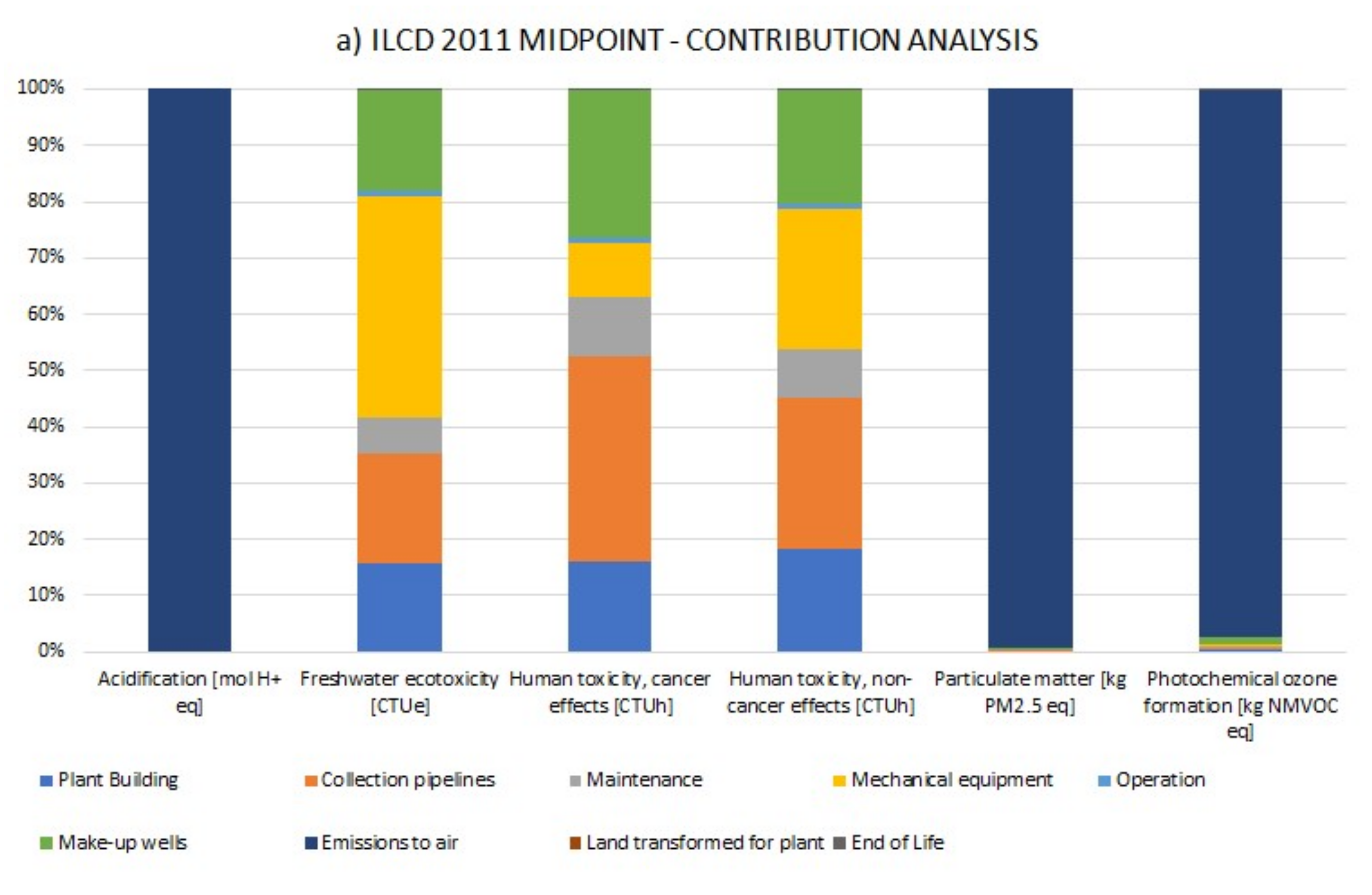

3.5. Life Cycle Impact Assessment (LCIA)—Benchmarking of Methods

3.5.1. ReCiPe 2016 vs ILCD 2011

3.5.2. CML Versus ILCD and ReCiPe

- Acidification

- Eutrophication

- Global warming

- Ozone layer depletion

- Human toxicity

- Marine aquatic ecotoxicity

- Terrestrial ecotoxicity

3.6. LCA Comparison of Scenario 1 and Scenario 2

3.7. Calculation of Single Score Values

4. Exergo-Environmental Assessment

- I.

- Environmental impact of exergy destruction occurring inside each component:

- II.

- Total environmental impact associated with a component allowing to determine the largest environmental impact:

- III.

- The exergo-environmental factor , representing the percentage contribution of compared to the total , that expresses the primary source of the environmental impact of these components:

- IV.

- The relative difference of the specific environmental impacts (Products-to Fuel) for the k-th component allows identifying the potential for improvement:

5. Discussion & Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Environmental impact rate | LCIA | Life Cycle Impact Assessment | |

| Environmental impact of exergy destruction | LCT | Life Cycle Thinking | |

| Component relate environnemental impact rate | LP | Low Pressure | |

| b | Environment impact per unit of exergy | Mwe | Mega Watt electric |

| CHP | Cogeneration of Heat and Power | MWt | Mega Watt thermal |

| CI | Impact category | NCG | Non condensable gases |

| DH | District Heating | NI | Normalized value |

| EEvA | Exergo-environmental Analysis | O&M | Operation and maintenance |

| EF | Environmental Footprint | ODS | Ozone Depleting Substance |

| EGS | Enhanced geothermal system | ORC | Organic Rankine Cycle |

| EoL | End of Life | θ | Carnot factor |

| EP | Eco Point | Q | Heat |

| EPA | Environmental Protection Agency | r | Relative difference of specific environmental impacts |

| EU | European Union | RES | Renewable energy sources |

| Ex | Exergy | s | Entropy |

| f | Exergo-environmental factor | T | Temperature |

| HP | High Pressure | w | Weighting factor |

| LCA | Life Cycle Analysis | W | Power |

| LCI | Life Cycle Inventory | z | Exergy destruction ratio |

References

- Shortall, R.; Davidsdottir, B.; Axelsson, G. Development of a sustainability assessment framework for geothermal energy projects. Energy Sustain. Dev. 2015, 27, 28–45. [Google Scholar] [CrossRef]

- Eberle, A.; Heath, G.A.; Petri, A.C.C.; Nicholson, S.R. Systematic Review of Life Cycle Greenhouse Gas Emissions from Geothermal Electricity. Systematic Review of Life Cycle Greenhouse Gas. Emissions from Geothermal Electricity; National Renewable Energy Laboratory: Golden, CO, USA, 2017. [Google Scholar]

- Asdrubali, F.; Baldinelli, G.; D’Alessandro, F.; Scrucca, F. Life cycle assessment of electricity production from renewable energies: Review and results harmonization. Renew. Sustain. Energy Rev. 2015, 42, 1113–1122. [Google Scholar] [CrossRef]

- Basosi, R.; Bonciani, R.; Frosali, D.; Manfrida, G.; Parisi, M.L.; Sansone, F. Life Cycle Analysis of a Geothermal Power Plant: Comparison of the Environmental Performance with Other Renewable Energy Systems. Sustainability 2020, 12, 2786. [Google Scholar] [CrossRef]

- Karlsdóttir, M.R.; Palsson, O.P.; Pálsson, H.; Maya-Drysdale, L. Life cycle inventory of a flash geothermal combined heat and power plant located in Iceland. Int. J. Life Cycle Assess. 2015, 20, 503–519. [Google Scholar] [CrossRef]

- Paulillo, A.; Striolo, A.; Lettieri, P. The environmental impacts and the carbon intensity of geothermal energy: A case study on the Hellisheiði plant. Environ. Int. 2019, 133, 105226. [Google Scholar] [CrossRef]

- Heberle, F.; Schifflechner, C.; Brüggemann, D. Life cycle assessment of Organic Rankine Cycles for geothermal power generation considering low-GWP working fluids. Geothermics 2016, 64, 392–400. [Google Scholar] [CrossRef]

- Frick, S.; Kaltschmitt, M.; Schröder, G. Life cycle assessment of geothermal binary power plants using enhanced low-temperature reservoirs. Energy 2010, 35, 2281–2294. [Google Scholar] [CrossRef]

- Pratiwi, A.; Ravier, G.; Genter, A. Life-cycle climate-change impact assessment of enhanced geothermal system plants in the Upper Rhine Valley. Geothermics 2018, 75, 26–39. [Google Scholar] [CrossRef]

- Parisi, M.L.; Douziech, M.; Tosti, L.; Pérez-López, P.; Mendecka, B.; Ulgiati, S.; Fiaschi, D.; Manfrida, G.; Blanc, I. Definition of LCA Guidelines in the Geothermal Sector to Enhance Result Comparability. Energies 2020, 13, 3534. [Google Scholar] [CrossRef]

- Blanc, I.; Damen, L.; Douziech, M.; Fiaschi, D.; Manfrida, G.; Parisi, M.L.; Lopez, P.P.; Ravier, G.; Tosti, L.; Mendecka, B. First Version of Harmonized Guidelines to Perform Environmental Assessment for Geothermal Systems Based on LCA and non LCA Impact Indicators: LCA Guidlines for Geothermal Installations. Deliverable 3.2, GEOENVI Project. 2020. Available online: https://www.geoenvi.eu/wp-content/ (accessed on 10 February 2021).

- Singh, R.K.; Murty, H.; Gupta, S.; Dikshit, A. An overview of sustainability assessment methodologies. Ecol. Indic. 2012, 15, 281–299. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). International Standard ISO 14044 Environmental management—Life cycle assessment—Requirements and Guidelines Management, 1 ed; ISO: Geneva, Swizterland, 2006; pp. 1–46. [Google Scholar]

- Huppes, G.; van Oers, L. Evaluation of Weighting Methods for Measuring the EU-27 Overall Environmental Impact. JRC Sci. Tech. Reports 2011. [Google Scholar]

- Pizzol, M.; Laurent, A.; Sala, S.; Weidema, B.; Verones, F.; Koffler, C. Normalisation and weighting in life cycle assessment: Quo vadis? Int. J. Life Cycle Assess. 2017, 22, 853–866. [Google Scholar] [CrossRef]

- Meyer, L.; Tsatsaronis, G.; Buchgeister, J.; Schebek, L. Exergoenvironmental analysis for evaluation of the environmental impact of energy conversion systems. Energy 2009, 34, 75–89. [Google Scholar] [CrossRef]

- Cavalcanti, E.J.C. Exergoeconomic and exergoenvironmental analyses of an integrated solar combined cycle system. Renew. Sustain. Energy Rev. 2017, 67, 507–519. [Google Scholar] [CrossRef]

- Başoğul, Y. Environmental assessment of a binary geothermal sourced power plant accompanied by exergy analysis. Energy Convers. Manag. 2019, 195, 492–501. [Google Scholar] [CrossRef]

- Nasruddin, N.; Saputra, I.D.; Mentari, T.; Bardow, A.; Marcelina, O.; Berlin, S. Exergy, exergoeconomic, and exergoenvironmental optimization of the geothermal binary cycle power plant at Ampallas, West Sulawesi, Indonesia. Therm. Sci. Eng. Prog. 2020, 19, 100625. [Google Scholar] [CrossRef]

- Ecoinvent Database 3.6. 2020. Available online: https://www.ecoinvent.org/database/older-versions/ecoinvent-36/ecoinvent-36.html (accessed on 1 December 2020).

- Di Pippo, R. Geothermal Power Generation: Developments and Innovation. Elsevier: Amsterdam, The Netherlands, 2016; ISBN 9780081003442. [Google Scholar]

- Hallgrímsdóttir, E.; Ballzus, C.; Hrólfsson, I. The Geothermal Power Plant at Nesjavellir, Iceland. GRC Trans. 2012, 36, 3109–3114. [Google Scholar]

- Karlsdottir, M.R.; Heinonen, J.; Palsson, H.; Palsson, O.P. Life cycle assessment of a geothermal combined heat and power plant based on high temperature utilization. Geothermics 2020, 84, 101727. [Google Scholar] [CrossRef]

- Tosti, L.; Ferrara, N.; Basosi, R.; Parisi, M.L. Complete Data Inventory of a Geothermal Power Plant for Robust Cradle-to-Grave Life Cycle Assessment Results. Energies 2020, 13, 2839. [Google Scholar] [CrossRef]

- Snæbjörnsdóttir, S.Ó.; Sigfússon, B.; Marieni, C.; Goldberg, D.; Gislason, S.R.; Oelkers, E.H. Carbon dioxide storage through mineral carbonation. Nat. Rev. Earth Environ. 2020, 1, 90–102. [Google Scholar] [CrossRef]

- Clark, D.E.; Oelkers, E.H.; Gunnarsson, I.; Sigfússon, B.; Snæbjörnsdóttir, S.Ó.; Aradóttir, E.S.; Gíslason, S.R. CarbFix2: CO2 and H2S mineralization during 3.5 years of continuous injection into basaltic rocks at more than 250 °C. Geochim. Cosmochim. Acta 2020, 279, 45–66. [Google Scholar] [CrossRef]

- OpenLCA 1.10, GreenDelta. Available online: https://www.openlca.org/download/ (accessed on 10 February 2021).

- Unisim® Design R471; Honeywell International Sàrl: Rolle, Swutzerland, 2019.

- Gunnarsson, I.; Aradóttir, E.S.; Oelkers, E.H.; Clark, D.E.; Arnarson, M.; Sigfússon, B.; Snæbjörnsdóttir, S.Ó.; Matter, J.M.; Stute, M.; Júlíusson, B.M.; et al. The rapid and cost-effective capture and subsurface mineral storage of carbon and sulfur at the CarbFix2 site. Int. J. Greenh. Gas. Control. 2018, 79, 117–126. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Universiteit Leiden CML-IA Characterisation Factors. Institude Environ. Sci. 2015, 20, 709–721.

- EC-JRC-Institute for Environment and Sustainability. Characterisation Factors of the ILCD Recommended Life Cycle Impact Assessment Methods: Database and Supporting Information; EC-JRC-Institute for Environment and Sustainability: Brussels, Belgium, 2012; ISBN 9789279227271. [Google Scholar]

- Castellani, V.; Diaconu, E.; Fazio, S.; Sala, S.; Schau, E.; Secchi, M.; Zampori, L. ; European Commission; Joint Research Centre. Supporting Information to the Characterisation Factors of Recommended EF Life Cycle Impact Assessment Methods: New Methods and Differences with ILCD.; European Commission: Brussels, Belgium, 2018; ISBN 978-92-79-76742-5. [Google Scholar]

- Bejan, A.; Tsatsaronis, G.; Moran, M.J.; Seshadri, K. Thermal Design and Optimization; John Wiley & Sons: Hoboken, NJ, USA, 2003; Volume 21, ISBN 978-0-471-58467-4. [Google Scholar]

- Lazzaretto, A.; Tsatsaronis, G. SPECO: A systematic and general methodology for calculating efficiencies and costs in thermal systems. Energy 2006, 31, 1257–1289. [Google Scholar] [CrossRef]

- Talluri, L.; Manfrida, G.; Fiaschi, D. Thermoelectric energy storage with geothermal heat integration—Exergy and exergo-economic analysis. Energy Convers. Manag. 2019, 199, 111883. [Google Scholar] [CrossRef]

- Fiaschi, D.; Manfrida, G.; Petela, K.; Talluri, L. Thermo-Electric Energy Storage with Solar Heat Integration: Exergy and Exergo-Economic Analysis. Energies 2019, 12, 648. [Google Scholar] [CrossRef]

- Fiaschi, D.; Manfrida, G.; Petela, K.; Rossi, F.; Sinicropi, A.; Talluri, L. Exergo-economic and enviromental analysis of a solar integrated thermo-electric storage. Energies 2020, 13, 2484. [Google Scholar]

| Cooling Towers CTLP | kg | |

|---|---|---|

| Number | 1 | - |

| Expected lifetime | 30 | - |

| Stainless steel | - | 1651.78 |

| Steel | - | 844.41 |

| Copper | - | 119.72 |

| Plastic | - | 367.34 |

| GRP | - | 92,809.80 |

| Cooling Towers CTHP | kg | |

| Number | 6 | - |

| Expected lifetime | 30 | - |

| Stainless steel | - | 9910.7 |

| Steel | - | 5066.41 |

| Copper | - | 718.31 |

| Plastic | - | 2204.02 |

| GRP | - | 556,858.80 |

| Efficiencies | CH4 | CO2 | H2S | Hydrogen | Nitrogen |

|---|---|---|---|---|---|

| 1_stage (Section 1) | 0.780 | 0.320 | 0.680 | 0.910 | 0.264 |

| 2_ stage (Section 2) | 0.800 | 0.338 | 0.714 | 0.934 | 0.267 |

| Gas Composition (mol) | CH4 | CO2 | H2S | Hydrogen | Nitrogen |

| 1_stage (Section 1) | 0.004 | 0.5450 | 0.2270 | 0.1590 | 0.0544 |

| 2_ stage (Section 2) | 0.0083 | 0.5270 | 0.0172 | 0.3440 | >0.0872 |

| Equipment | N° | kW | |||

| Absorption Tower compressor | 2 | 2 × 250 | |||

| Absorption Tower pump | 1 | 50 | |||

| Cooling pump | 1 | 35 | |||

| NCG Compressors | Inlet | Outlet | Recovery Pump | Inlet | Outlet |

|---|---|---|---|---|---|

| Temperature [°C] | 38.05 | 40.01 | Temperature [°C] | 20.29 | 20.32 |

| Pressure [bar] | 4.91 | 5.009 | Pressure [bar] | 6.002 | 9 |

| Mass Flow [kg/s] | 249.4 | 249.4 | Mass Flow [kg/s] | 35.47 | 35.47 |

| Compressor type | Centrifugal | Total Power [kW] | 7.059 | ||

| Compressor Speed [rpm] | 3000 | ||||

| Non-Water Soluble Gases | CO2 [kg/s] | H2S [kg/s] | CH4 [kg/s] | H2 [kg/s] | N2 [kg/s] |

|---|---|---|---|---|---|

| 249.9 kg/s total | - | - | - | - | - |

| 0.154 m3/s exhaust gas | 0.0811 | 0.0026 | 0.00128 | 0.530 | 0.0134 |

| Gases | |||||

| Gas-charged water | CO2 [kg/s] | H2S [kg/s] | CH4 [kg/s] | H2 [kg/s] | N2 [kg/s] |

| 35.47 kg/s | 0.145 | 0.127 | 0 | 5.02 × 10−6 | 2.12 × 10−4 |

| ILCD Categories | Impact Result | Normalization (%) |

|---|---|---|

| Acidification [molc H+ eq] | 1.16 × 101 | 45.97% |

| Particulate matter [kg PM2.5 eq] | 5.43 × 10−1 | 23.82% |

| Human toxicity, cancer effects [CTUh] | 1.02 × 10−6 | 18.24% |

| Freshwater ecotoxicity [CTUe] | 8.77 × 101 | 5.21% |

| Photochemical ozone formation [kg NMVOC eq] | 7.36 × 10−1 | 3.61% |

| Human toxicity, non-cancer effects [CTUh] | 1.37 × 10−6 | 1.96% |

| Other categories | - | 1.18% |

| ReCiPe Midpoint Categories | Impact Result | Normalization (%) |

|---|---|---|

| Marine ecotoxicity [kg 1,4-DCB] | 3.32 × 10−1 | 25.48% |

| Human carcinogenic toxicity [kg 1,4-DCB] | 6.09 × 10−1 | 17.40% |

| Terrestrial acidification [kg SO2 eq] | 8.85 × 100 | 17.10% |

| Freshwater ecotoxicity [kg 1,4-DCB] | 2.54 × 10−1 | 16.36% |

| Water consumption [m3] | 3.91 × 101 | 11.62% |

| Fine particulate matter formation [kg PM2.5 eq] | 2.57 × 100 | 7.96% |

| Terrestrial ecotoxicity [kg 1,4-DCB] | 2.38 × 101 | 1.82% |

| Human non-carcinogenic toxicity [kg 1,4-DCB] | 3.18 × 100 | 1.69% |

| Other categories | - | 0.57% |

| CML-IA Baseline Categories. | Impact Results | Normalization (%) |

|---|---|---|

| Acidification [kg SO2 eq] | 1.06 × 101 | 60.14% |

| Photochemical oxidation [kg C2H4 eq] | 4.26 × 10−1 | 23.44% |

| Marine aquatic ecotoxicity [kg 1,4-DB eq] | 5.25 × 103 | 11.25% |

| Human toxicity [kg 1,4-DB eq] | 1.49 × 101 | 2.85% |

| Fresh water aquatic ecotox [kg 1,4-DB eq] | 3.88 × 100 | 1.77% |

| Other categories | - | 0.55% |

| CML-IA Baseline | Amount | ILCD 2011 Midpoint | |

|---|---|---|---|

| Global warming (GWP100a) [kg CO2eq] | 2.21 × 101 | 2.20 × 101 | Climate change [kg CO2eq] |

| Ozone layer depletion (ODP) [kg CFC-11 eq] | 2.90 × 10−7 | 2.90 × 10−7 | Ozone depletion [kg CFC-11 eq] |

| Human toxicity [kg 1,4-DB eq] | 1.49 × 101 | 1.02 × 10−6 | Human toxicity, cancer effects [CTUh] |

| 1.37 × 10−6 | Human toxicity, non-cancer effects [CTUh] | ||

| Eutrophication [kg PO4---eq] (Eutrophication [kg P-PO4eq] | 5.83 × 10−3 1.19 × 10−3 | 1.13 × 10−3 | Freshwater eutrophication [kg p eq] |

| CML-IA Baseline | Amount | ReCiPe 2016 Midpoint | |

|---|---|---|---|

| Acidification [kg SO2eq] | 1.06 × 101 | 8.85 × 100 | Terrestrial acidification [kg SO2eq] |

| Eutrophication [kg PO4--- eq] | 5.83 × 10−3 | 1.12 × 10−3 | Freshwater eutrophication [kg P eq] |

| (GWP100a) [kg CO2eq] | 2.21 × 101 | 2.23 × 101 | Global Warming [kg CO2eq] |

| Human toxicity [kg 1,4-DB eq] | 1.49 × 101 | 6.09 × 10−1 | Human carcinogenic toxicity [kg 1,4-DCB] |

| 3.18 × 100 | Human non-carcinogenic toxicity [kg 1,4-DCB] | ||

| Marine aquatic ecotoxicity [kg 1,4-DB eq] | 5.25 × 103 | 3.32 × 10−1 | Marine ecotoxicity [kg 1,4-DB eq] |

| Ozone layer depletion (ODP) [kg CFC-11 eq] | 2.90 × 10−7 | 1.25 × 10−6 | Stratospheric Ozone depletion [kg CFC-11 eq] |

| Terrestrial ecotoxicity [kg 1,4-DB eq] | 2.17 × 10−2 | 2.38 × 101 | Terrestrial ecotoxicity [kg 1,4-DB eq] |

| Single Score, EP | Single Score, EP | ||||

|---|---|---|---|---|---|

| Main Components | [Pt] | Common Components | [Pt] | ||

| HP Steam Separator | HPS | 1.40 × 103 | Moisture remover | HPM | 8.00 × 102 |

| HP Turbines | HPTG | 5.06 × 104 | Moisture remover | LPM | 7.79 × 102 |

| DH condenser HP | HPC-DH | 6.78 × 102 | Deaerator | DA | 5.45 × 102 |

| HP Condenser | HPC | 1.13 × 104 | Cold water tank | CWT | 5.75 × 100 |

| Pump 1 | PHP1 | 7.12 × 101 | District Heating tank | DHT | 2.87 × 100 |

| Pump 2 | PHP2 | 1.93 × 103 | Wells | WLL | 1.35 × 105 |

| HP Cooling tower | HPCT | 1.35 × 104 | Pipelines | PP | 1.77 × 105 |

| LP Steam Separator | LPS | 1.33 × 102 | Building Power Plant | BPP | 6.37 × 104 |

| LP Turbine | LPTG | 6.18 × 103 | Building Heating Station | BHS | 2.73 × 104 |

| Condenser LP | LPC | 1.43 × 103 | Land Use | LU | 7.59 × 102 |

| Pump 3 | PLP1 | 1.10 × 101 | Emission | Emi | 1.56 × 106 |

| Pump 4 | PLP2 | 4.55 × 102 | Operation | Ope | 5.27 × 103 |

| LP Cooling tower | LPCT | 2.24 × 103 | Maintenance | Man | 5.32 × 104 |

| HE for DH | DHHX | 2.20 × 103 | End of Life | EoL | 1.48 × 103 |

| Component | Environmental Balance Equation | Auxiliary Equation |

|---|---|---|

| Wells + Main Valve | ||

| HP Steam Separator | ||

| HP Turbines | ||

| DH condenser HP | ||

| Condenser HP | ||

| Pump1 | ||

| Mixing Point1 | - | |

| Pump2 | ||

| HP Cooling tower | ||

| Valve 2 | - | |

| LP Steam Separator | ||

| LP Turbine | ||

| Condenser LP | ||

| Pump 3 | ||

| Mixing Point2 | - | |

| Pump 4 | ||

| LP Cooling tower | ||

| HE for DH |

| Component | Single Score, EP [Pts] | Ẏk [Pts/s] | ḂD,k [Pts/s] | ḂTOT,k [Pts/s] | fb,k [%] | rb,k [–] |

|---|---|---|---|---|---|---|

| Wells + Main Valve | 907,964 | 1.13 × 10−3 | 2.05 × 10−4 | 1.33 × 10−3 | 0.847 | 0.214 |

| HP Steam Separator | 1400 | 1.74 × 10−6 | 0.00 × 100 | 1.74 × 10−6 | 1 | 0.002 |

| HP Turbines | 513,868 | 6.39 × 10−4 | 1.49 × 10−4 | 7.88 × 10−4 | 0.811 | 1.34 |

| DH condenser HP | 28,462 | 3.54 × 10−5 | 8.95 × 10−6 | 4.43 × 10−5 | 0.798 | 13.6 |

| Condenser HP | 435,391 | 5.41 × 10−4 | 1.37 × 10−4 | 6.78 × 10−4 | 0.799 | 10.2 |

| Pump1 | 102.5 | 1.28 × 10−7 | 2.35 × 10−8 | 1.51 × 10−7 | 0.844 | 0.638 |

| Mixing Point1 | 2826 | 3.51 × 10−6 | 9.34 × 10−6 | 1.29 × 10−5 | 0.274 | 0.017 |

| Pump2 | 2807 | 3.49 × 10−6 | 6.59 × 10−7 | 4.15 × 10−6 | 0.841 | 0.650 |

| HP Cooling tower | 145,049 | 1.80 × 10−4 | 4.32 × 10−4 | 6.12 × 10−4 | 0.295 | 1.84 |

| Valve 2 | 59,352 | 7.38 × 10−5 | 1.91 × 10−5 | 9.29 × 10−5 | 0.794 | 0.496 |

| LP Steam Separator | 133 | 1.65 × 10−7 | 0.00 × 100 | 1.65 × 10−7 | 1 | 0.00103 |

| LP Turbine | 34,018 | 4.23 × 10−5 | 1.34 × 10−5 | 5.57 × 10−5 | 0.759 | 0.521 |

| Condenser LP | 58,619 | 7.29 × 10−5 | 2.76 × 10−5 | 1.00 × 10−4 | 0.726 | 8.92 |

| Pump 3 | 15.97 | 1.99 × 10−8 | 3.73 × 10−9 | 2.36 × 10−8 | 0.842 | 0.644 |

| Mixing Point2 | 353.4 | 4.40 × 10−7 | 1.57 × 10−6 | 2.01 × 10−6 | 0.218 | 0.0181 |

| Pump 4 | 670.7 | 8.34 × 10−7 | 1.62 × 10−7 | 9.96 × 10−7 | 0.837 | 0.663 |

| LP Cooling tower | 12,832 | 1.60 × 10−5 | 4.54 × 10−5 | 6.14 × 10−5 | 0.260 | 0.875 |

| HE for DH | 48,816 | 6.07 × 10−5 | 2.25 × 10−5 | 8.32 × 10−5 | 0.730 | 2.39 |

| Total | 2,252,679.6 | 2.80 × 10−3 | 1.07 × 10−3 | 3.87 × 10−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colucci, V.; Manfrida, G.; Mendecka, B.; Talluri, L.; Zuffi, C. LCA and Exergo-Environmental Evaluation of a Combined Heat and Power Double-Flash Geothermal Power Plant. Sustainability 2021, 13, 1935. https://doi.org/10.3390/su13041935

Colucci V, Manfrida G, Mendecka B, Talluri L, Zuffi C. LCA and Exergo-Environmental Evaluation of a Combined Heat and Power Double-Flash Geothermal Power Plant. Sustainability. 2021; 13(4):1935. https://doi.org/10.3390/su13041935

Chicago/Turabian StyleColucci, Vitantonio, Giampaolo Manfrida, Barbara Mendecka, Lorenzo Talluri, and Claudio Zuffi. 2021. "LCA and Exergo-Environmental Evaluation of a Combined Heat and Power Double-Flash Geothermal Power Plant" Sustainability 13, no. 4: 1935. https://doi.org/10.3390/su13041935

APA StyleColucci, V., Manfrida, G., Mendecka, B., Talluri, L., & Zuffi, C. (2021). LCA and Exergo-Environmental Evaluation of a Combined Heat and Power Double-Flash Geothermal Power Plant. Sustainability, 13(4), 1935. https://doi.org/10.3390/su13041935