Abstract

This study deals with small investors’ demands on thermal insulation systems when choosing the most suitable solution for a family house. By 2050, seventy percent of current buildings, including residential buildings, are still expected to be in operation. To reach carbon neutrality, it is necessary to reduce operational energy consumption and thus reduce the related cost of building operations and the cost of the life cycle of buildings. One solution is to adapt envelopes of buildings by proper insulation solutions. To choose an optimal thermal insulation system that will reduce energy consumption of building, it is necessary to consider the environmental cost of insulation materials in addition to the construction cost of the materials. The environmental cost of a material depends on the carbon footprint from the initial origin of the material. This study presents the results of a multi-criteria decision-making analysis, where five different contractors set the evaluation criteria for selection of the optimal thermal insulation system. In their decision-making, they involved the requirements of small investors. The most common requirements were selected: the construction cost, the construction time (represented by the total man-hours), the thermal conductivity coefficient, the diffusion resistance factor, and the reaction to fire. The confidences of the criteria were then determined with the help of the pairwise comparison method. This was followed by multi-criteria decision-making using the method of index coefficients, also known as the method of basic variant. The multi-criteria decision-making included thermal insulation systems based on polystyrene, mineral wool, thermal insulation plaster, and aerogels’ nanotechnology. As a result, it was concluded that, currently, in Slovakia, small investors emphasize the cost of material and the coefficient of thermal conductivity and they do not care as much about the carbon footprint of the material manufacturing, the importance of which is mentioned in this study.

1. Introduction

Architecture is destined to satisfy the human needs of both the individual and society as a whole. In addition to the visual and aesthetic function, a building’s architecture must ensure a suitable indoor climate. In older buildings, it is necessary to make intensive use of the heating system to maintain thermal comfort indoors [1]. This increases CO2 emissions. Today, a great emphasis is placed on sustainable architecture [2] in order to reach a good environment for future generations. This is only possible through a solid and honest approach to the global Paris Climate Agreement [3,4]. In connection with international commitments related to the Paris Climate Agreement, Slovakia, as a European Union member state, is expected to reduce its carbon footprint emissions in the coming years. In 2019, the Slovak Republic committed to start implementing actions aimed at achieving carbon neutrality. Carbon neutrality is to be achieved by 2050. In terms of achieving carbon neutrality, buildings are a major challenge of the construction sector as far as the entire life cycle is concerned. Up to 2030, the most important area for policy in Slovakia is the renovation of buildings, which constitutes the most important source of possible energy savings until 2030. According to several estimations, 70% of currently existing buildings will remain in the year 2050 [5]. However, these buildings will demand renovation.

To achieve a suitable indoor temperature and humidity climate, buildings consume a considerable amount of energy during their operation. Heating consumes a substantial volume of energy and emits a considerable amount of CO2 into the atmosphere. This is one of the reasons for global warming. Decreasing the energy consumption by providing a suitable external thermal insulation composite system is one of the possibilities to reverse the above-mentioned condition.

Adaptive architecture is a multi-disciplinary field concerned with buildings that are designed to adapt to their environments, their inhabitants, and their objects [6]. It makes it possible to better adapt buildings and their structures to the climate and natural and cultural environment [7]. Adaptation can be viewed as reforming the composition of a perimeter structure by adding a thermal insulation system. Adaptive architecture also includes adaptive building peripheral structures. This article discusses the adaptability at the level of perimeter wall construction, which is to respond to temperature changes so that it does not cool down quickly in the winter and does not warm up quickly in the summer. This can be achieved with a suitable thermal insulation system. Renovation of buildings plays a key role in the decarbonization of Europe. Renovation of the building envelope can potentially increase energy efficiency and reduce the carbon footprint during the operational phase. The carbon footprint during the manufacturing phase can be reduced by sound selection of insulating material.

1.1. Availability of Various Thermal Insulation Materials

Applied building materials may not be relatively new. Researchers have struggled to develop smart materials and form system solutions from conventional materials with improved properties. This leads to the creation of an adaptive building structure with a lower negative impact on the environment [8]. Within adaptive architecture, it is necessary to design and adapt such perimeter structures that would ensure lower demands on energy needs. Buildings and their structures adapt to physical changes in the external environment, such as a change in outdoor temperature.

The research study of Ahmed et al. [9] points to the adaptive facades. The aim of adaptive facades was to change both the shape and the material of building envelopes. This change will ensure that the building envelope meets the needs of users and maximizes the efficiency of the building’s operation. In Slovakia, thermal insulation of building envelopes is accomplished by common materials such as polystyrene insulation boards and insulation boards based on mineral wool. However, some new thermal insulation materials are evolved and tested abroad. With this approach, investigators are trying to reduce CO2 by processing new and partially recycled materials to form composites. As an example, a novel thermal insulation composite (NTIC) is prepared by combining industrial solid wastes with expanded polystyrene (EPS) beads to save energy in buildings [10]. The employability of waste expanded polystyrene foam (EPS) as a filling material in the plaster with resin-added gypsum by means of revaluation has also been examined. But not all modern materials can be used in external plaster. The examined material can only be used indoors, as research has demonstrated [11]. The use of this plaster material will prevent environmental pollution and will save building heating and cooling energy.

The research aimed at the development of thermal and sound insulation materials by the use of natural or recycled materials was advanced by the introduction of the sustainability concept in the process of building design. Several comparative analyses have mainly examined the thermal characteristics in terms of thermal conductivity, specific heat, and density [12]. Even if it is usually stated that energy consumption in buildings accounts for more than 30% of total global final energy consumption, not many studies have analyzed updated data on the current energy consumption in buildings and only a few analyses have concentrated on comparing different countries. In one study [13], the author analyzed the energy consumption of buildings in the US, the EU, and in the BRIC countries (Brazil, Russia, India, and China). According to the current scenario, by 2050, the global energy demand in buildings will at least double compared to today’s levels. To avoid this outcome, it is necessary to disseminate and accept cost-effective best practices and technologies as well as changes in behavior and lifestyle [13]. Therefore, it is necessary to evaluate the effect of thermal insulation parameters on the thermal performance of buildings [14]. Heat losses in buildings contribute significantly to buildings’ poor energy performance. One study [15] has observed the central problems with heat losses from buildings resulting in decreased energy efficiency. In particular, the problem involves the discovery of heat losses, thermal bridges, insulation problems, and other efficiency impairments.

Construction is one of the key consumers of energy in Europe. The European Union has adopted several directives that directly or indirectly address the energy performance of buildings in order to reduce their energy use. Renovation of buildings is often mentioned without discussing separately about historic buildings and their insulation in terms of ensuring energy efficiency [16].

1.2. Selected Properties of Available Thermal Insulation Materials

A multi-objective optimization algorithm regarding several factors (insulation material, thickness of insulation material, window type, window frame material, thermal resistance of the wall, and orientation to the world sides) is used for a suitable design of building insulation [17,18]. However, enlarging the thickness of the insulation material in the building envelope has consequences from energy, environmental, and economic points of view. In this context, efforts should be made to optimize the insulation thickness [19]. For example, the optimal insulation thicknesses, which have been determined by environmental impact analysis, are 0.15 and 0.064 m for glass wool and rockwool, respectively. The optimal insulation thicknesses determined by the life cycle cost analysis are 0.012 and 0.007 m for glass wool and rockwool, respectively [20]. These data are striking when compared with the currently used thicknesses of thermal insulation in Slovakia. The optimal solution of the thermal insulation thickness depends on energy, economic, and environmental aspects. In terms of the cost, EPS is the most promising thermal insulation material, and its best location is in the middle of the building envelope. Depending on the climatic zone and the typology of the building, the cost-optimal thickness is up to 10 cm [21,22].

In a general way, architects and engineers use the information provided by the manufacturer in the material specification for their building’s physical design. Such data are obtained from laboratory measurements, where it may not be possible to simulate the effects of weathering at the respective intensity. For example, the properties of mineral wool can get worse by up to 40% because of moisture [23]. For both manufacturers and customers, examining the thermal properties of building materials, such as effective thermal conductivity, is particularly important. The generally used thermal insulating materials involve the plastic foamy and mineral wool materials as well as nanotechnological insulators. The new generation of insulation materials is represented by the nanotechnological insulators, particularly aerogel and hollow nanospheres. The boards based on silica-aerogel technology are promising for the future [24]. Various prototype insulation solutions have also appeared, such as special perlite boards or the above-mentioned aerogel composite materials [25]. When insulating, care must be taken to ensure that the material does not degenerate during installation. Otherwise, it is not possible to prevent the spread of moisture in the materials. Installation of insulation in foundations, underground floors, and plinths belongs to typical examples [26]. In Slovakia, Romania, and other surrounding countries, the most used thermal envelope systems are based on polystyrene (EPS). Similar to our study, other researchers have determined a comparative solution of the building envelope for a masonry two-story house [27]. The authors of another study [28] have also stated that expanded polystyrene is mostly used for external thermal insulation systems. However, they have pointed out that this material is based on fossil resources. Moreover, they have compared a multi-active façade system based on recycled paper with a traditional external thermal insulation composite system (ETICS) utilizing EPS. The evaluation during the operational phase alone resulted in a similar ecological footprint of both systems. However, life cycle analysis has provided a clear positive response for the multi-active façade system, although with higher construction costs [28]. The environmental costs of building materials and the need for a life cycle analysis are not yet included in the Slovak legislation. As to environmental impact, the clients are not forced to take responsibility for selected building materials. Similar to our study, other researchers [29] have dealt with the analysis of the optimal thermal insulation system based on EPS and based on mineral wool for apartment buildings.

2. Materials and Methods

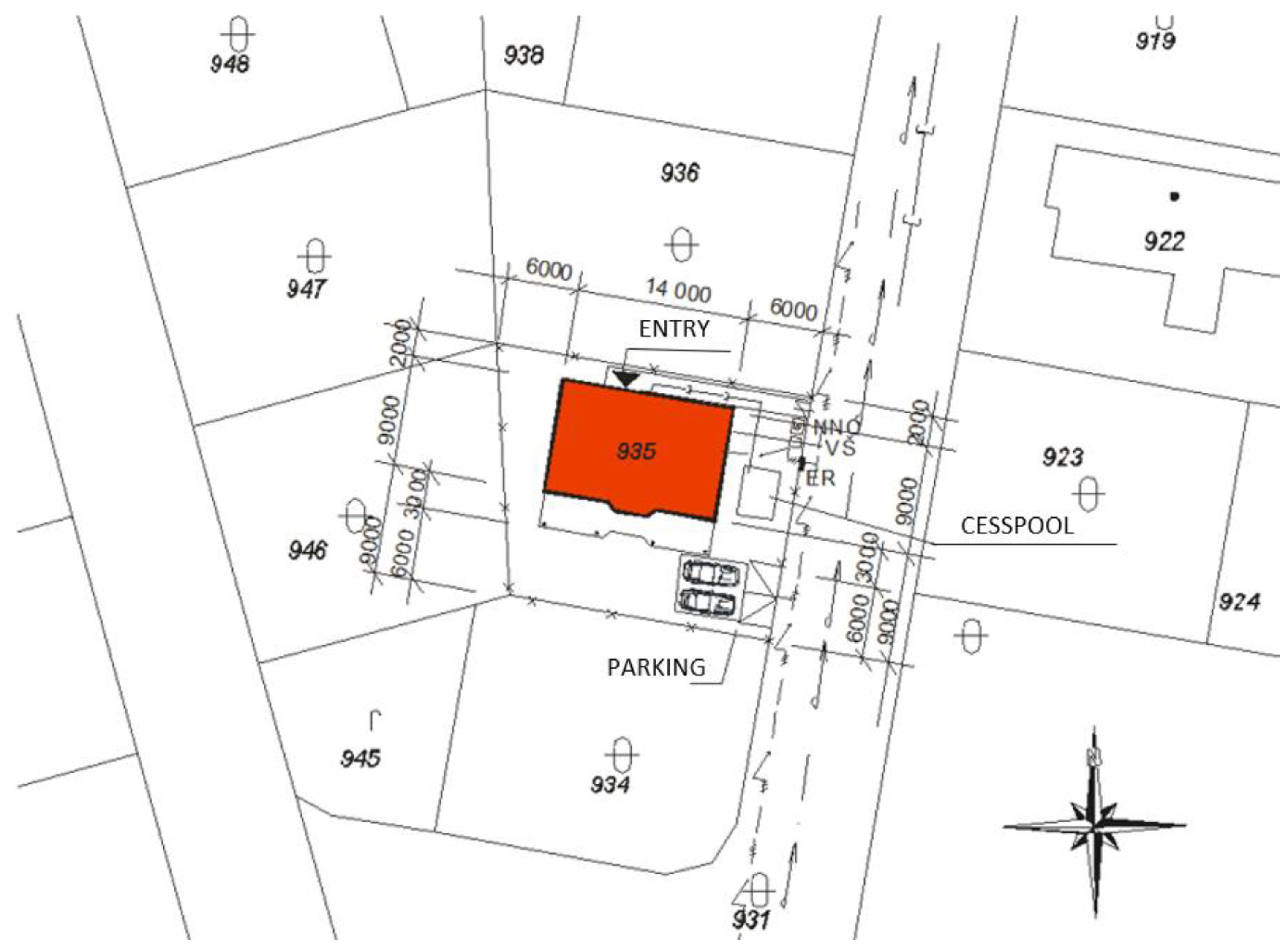

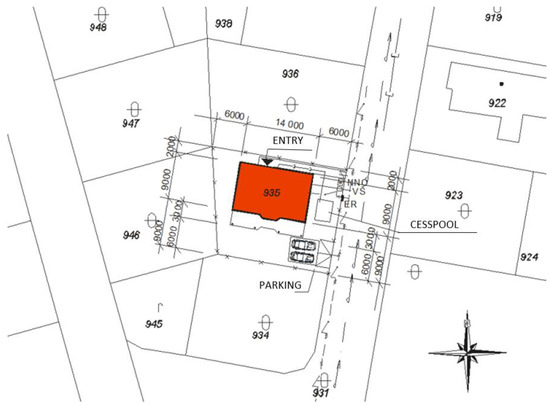

The object of the research was represented by evaluation parameters of thermal insulation systems that are required by small investors of a one-apartment residential building. The aim of the research was to prove whether these requirements are in accordance with sustainable development and in line with monitoring of the life cycle of the house construction. The one-apartment building is a one-story family house without a residential attic (see Figure 1 and Figure 2). The family house is of a medium size category for a family of four. Natural gas is the source of heating. The perimeter walls of the family house are made of Porfix 500 mm × 250 mm × 300 mm blocks. The blocks are made of white autoclaved aerated concrete based on silica sand. The weight of one block is 24 kg. The interior plasters are lime-cement stucco. The external plasters are lime-cement smooth, provided with Baumit facade paint. The façade paint is a diffusion open coloured paint with a microscopically smooth nano-crystalline surface. The mineral paint is water-soluble, highly vapor-permeable and resistant to contamination. The façade paint consists of mineral binders, silicates, mineral fillers, organic binders, colour and white pigments, additives, and water. The windows and exterior doors are plastic. The ceiling of the family house is prefabricated and made of the ceramic Miako system. The Miako system is a system product for ceramic beam ceilings that are composed of ceramic ceiling inserts and ceramic-concrete ceiling beams reinforced with a welded lattice girder. The roofing is made of the concrete Bramac system. The Bramac concrete roofing is made of high-quality raw materials, namely sand, water, Portland cement, and iron oxide pigments. The strengths of the concrete roofing increase over time, which means a guarantee of its long life and functionality.

Figure 1.

The 3D visualization of the studied family house.

Figure 2.

The siting of the studied family house.

This study deals with the analysis of the significance of environmental, cost, and technological parameters of selected thermal insulation systems. The analysis was intent to choose an optimal thermal insulation system for the studied family house. The following thermal insulation systems were examined in the analysis: Baumit OPEN System, Knauf SMARTwall, ThermoUm SATSYS technology, Knauf ECOSE® Technology, and Aerogels’ Spaceloft® (see Table 1).

Table 1.

The list of the thermal insulation systems.

The Baumit OPEN facade insulation boards are made of stabilized expanded polystyrene with reduced flammability. It is the system component of Baumit OPEN external thermal insulation systems. These are highly vapor-permeable white perforated polystyrene insulation boards with good thermal insulation properties, characterized by dimensional and volume stability.

The Knaufinsulation SMARTwall NC1 ETICS includes mineral insulation boards with silicate spray and thermal insulation properties designed for thermal insulation of external walls as part of a contact thermal insulation system for family houses. The product increases the passive fire safety of buildings, absorbs noise from the exterior, and is vapor permeable.

The thermal insulation plaster ThermoUm SATSYS Technology is applicable for plastering brick, aerated concrete, concrete, and other types of bases. It has hydrophobic and air-permeable properties, which help to remove moisture, prevent the formation of mold on the surface of the walls and inside the structure, and create a healthy and safe environment in living spaces. The natural structure of ThermoUm materials ensures sound insulation and actively helps to create an acoustic environment that prevents echoes in the space. The plaster has a low bulk density and a low modulus of elasticity.

Insulation material ECOSE® Technology TP 435 B is made of mineral glass fibers. It is a contactless technology. The material is treated on one side with black non-woven fabric. The use of its thermal insulation properties and sound absorption properties is mainly in lightweight facade claddings, primarily as an insulation of ventilated facades. When applied to a structure, the material is installed with a black non-woven fabric towards the exterior. The black non-woven fabric serves as a thermal insulation material to minimize airflow cooling in the ventilated gap.

ETICS Aerogels’ Spaceloft® Nanotechnology—the aerogel is an exceptionally fine, porous foam structure, comparable to solidified cigarette smoke. The pore size of the structure is so small that the air molecules in the pores become trapped and cannot, to the extent as without foam, transfer kinetic and vibrational energy to each other, which is the essence of diffuse heat flow. In addition to heat conduction, a radiant component is also used here, but this is absorbed by aerogel and its share in the total heat transfer is also significantly smaller.

When deciding which thermal insulation system or product is the best solution, it is often necessary to work with a large number of parameters or criteria. In order to determine the confidence of the regarded parameters, contractor companies providing the construction of thermal insulation systems were addressed. These companies most often encounter small investors’ requirements in regard to thermal insulation. Determining the confidence (the importance of criteria) in the decision-making process is mostly based on the subjective opinion of the evaluator. To reach an objective opinion, we need to involve more independent evaluators in the decision-making process. Using several optimizing methods and a sufficient number of independent valuation experts participating in the decision-making process, it is possible to objectively determine the weights of the importance of individual criteria.

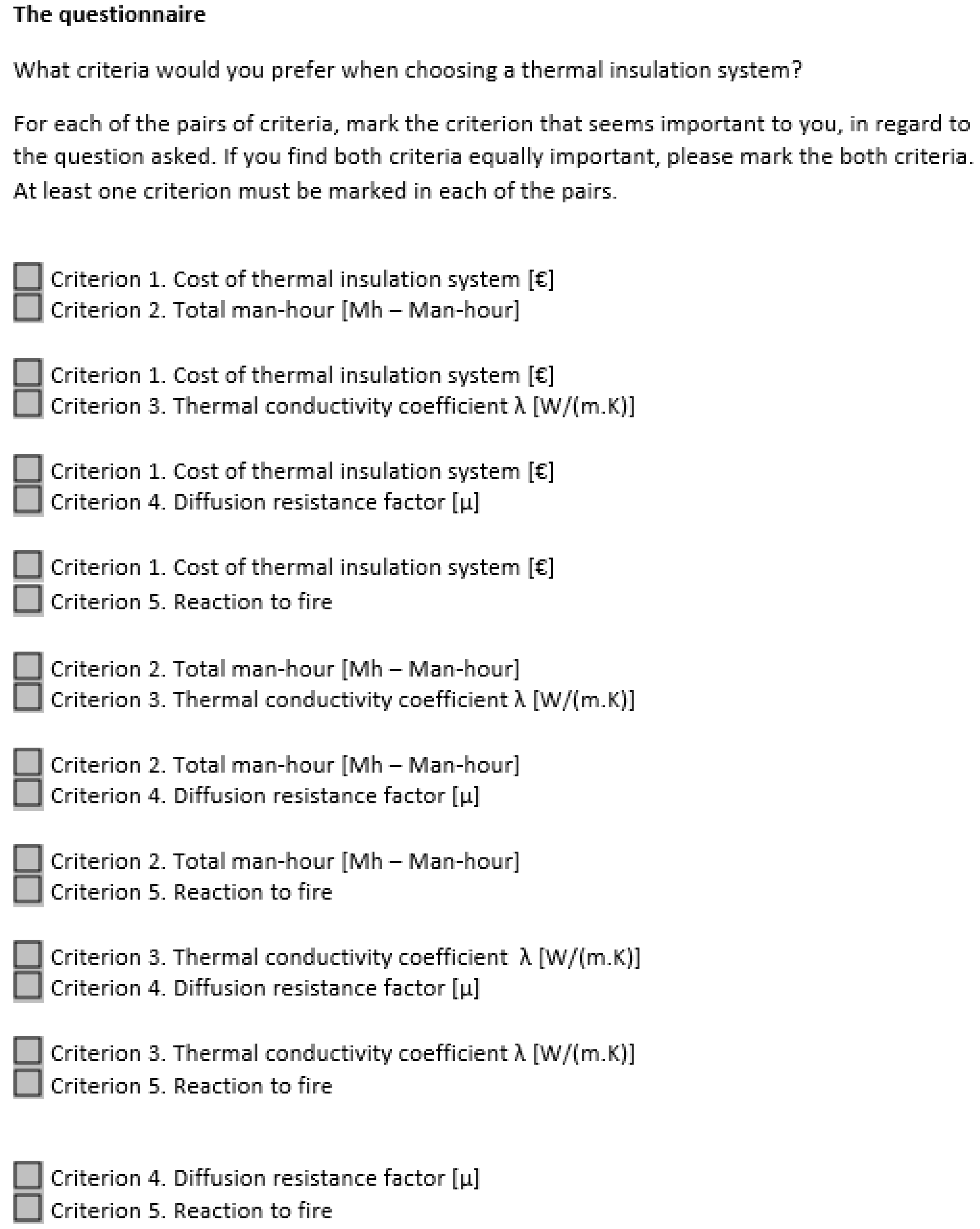

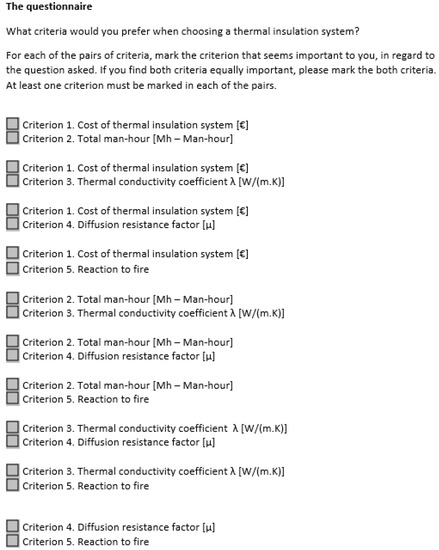

By the pairwise comparison method, it is possible to determine the weights (importance) of individual criteria and then calculate the confidence coefficient of the criteria. A consecutive comparison of the importance of each criterion with all other criteria is the basis of the pairwise comparison method. The importance of the criteria is obtained from the developed questionnaire with paired questions that represent a combination of criteria, which is filled in by the evaluator—an expert in the area of thermal insulation systems.

The pairs of criteria are calculated by the formula:

N = m.(m − 1)/2

N—number of pairs of criteria,

m—number of criteria

Figure 3.

The questionnaire for pairwise comparison of selection criteria.

Table 2.

The criteria set according to the requirements of small investors.

The determination of the parameters, on the basis of which the selection of the thermal insulation system was carried out, is based on the analysis of small investors’ demands imposed on contractors who are responsible for insulation’s execution on sites. Based on the current awareness and small investors’ demands imposed on contractors, the criteria presented in Table 2 were defined. The cost of the thermal insulation system was obtained by calculating construction works and materials in the Cenkros plus software. The total construction time of the thermal insulation system was obtained from the schedules that were developed by the MS Project software. The thermal conductivity coefficient λ (W/(m·K)) was determined based on the manufacturer’s technical data sheets. In principle, the lower the coefficient, the better the thermal insulation properties of the insulation material. The coefficient of thermal conductivity is defined as the ability of a material to conduct heat.

The diffusion resistance factor μ (-) is defined as the ability of a material to transmit water vapor by diffusion. It reflects the relative ability of a material to transmit water vapor. It indicates how many times the diffusion resistance of a given substance is greater than an equally thick layer of air at the same temperature. The reaction to fire class is the ability of building materials to withstand the temperatures of ignition, smolder, or combustion. The values of these criteria were determined based on the manufacturer’s technical data sheets (EN 13501-1:2010). The score is presented in Table 3.

Table 3.

The flammability classification score.

A questionnaire was developed to determine the confidence of individual criteria (see Figure 3). The questionnaire was filled in by contractors (evaluators). Each evaluator has indicated their preferred order of the submitted parameters. The principle of evaluating the questionnaire is to mark at least one of the pair of criteria that is of the greatest importance to the evaluator. The preferences of individual criteria are written in a table (matrix) of relationships. The confidence coefficient is determined based on the calculation of the partial weights of the different evaluators.

The determination of the criteria confidence was then followed by multi-criteria decision-making with the help of the method of index coefficients, also known as the method of the basic variant. By the method, the partial evaluation of individual criteria was determined through calculating the partial confidence coefficients (Bj). The confidence coefficients were determined by comparing the value of the criterion (parameter) of the evaluated variant with the values of the basic variant. The basic variant is a simulated variant, which contains the theoretically worst or best values of partial weights. In the calculation, two groups of the criteria were distinguished. The cost-type criteria were in the first criteria group. The cost-type criteria were those whose lower values in terms of efficiency were most preferred by the evaluator over higher values. These are the criterion-value-minimizing type. The higher the value of the sub-criterion, the worse the rating. The revenue-type criteria represent the second group of criteria. The revenue-type criteria were those whose higher value in terms of efficiency was most preferred by the evaluator over lower values. These are the criterion-value-maximizing type. The lower the value of the sub-criterion, the worse the rating.

Then, the confidence coefficient of the Bj criteria was calculated. The confidence coefficient is the basic parameter when used in various methods of multi-criteria decision-making. The confidence coefficient of the Bj criteria is determined by the formula:

Bj = γj/p

- γj—the sum of the partial weights of the criteria assigned to the criterion of all evaluators.

- γkj—partial weights assigned to the kth evaluator of the jth criterion.

- Bj—the coefficient of the criteria confidence.

- Υj—the sum of the partial weights of the criteria assigned to the criterion of all evaluators.

- p—the number of evaluators.

The process of the multi-criteria decision-making by the method of index coefficients (the method of the basic variant):

1. The forming of the matrix of variants and criteria—in this case, the variants were different thermal insulation systems designed for thermal insulation of the family houses and the criteria involved the cost of the thermal insulation system per 1 m2, the construction time of the thermal insulation system, the thermal conductivity coefficient (λ), the diffusion resistance factor (μ), and the reaction to fire class.

If some values of the variant criteria were the same when ranking the criteria, the order was determined as the average of the sum of the orders belonging to the identical parameters.

2. Determination of the types of criteria (revenue and cost). Creation of the simulated (basic) variant.

For cost-type criteria:

For revenue-type criteria:

where:

zij—the fictive value of the partial criterion of the variant confidence.

hbj—the value of the jth criterion in the fictive (basic) variant.

hij—the real value of the jth criterion in the ith variant.

Bj—the confidence coefficient.

For each variant, the value of relative confidence (Sj) was determined.

where:

Sj—the total relative value of the sub-criteria of the variants’ confidence.

zij—the fictive value of the sub-criterion of the variant confidence.

During evaluation (Vj) of the confidence variants, the variant with the smallest number of relative confidence came first.

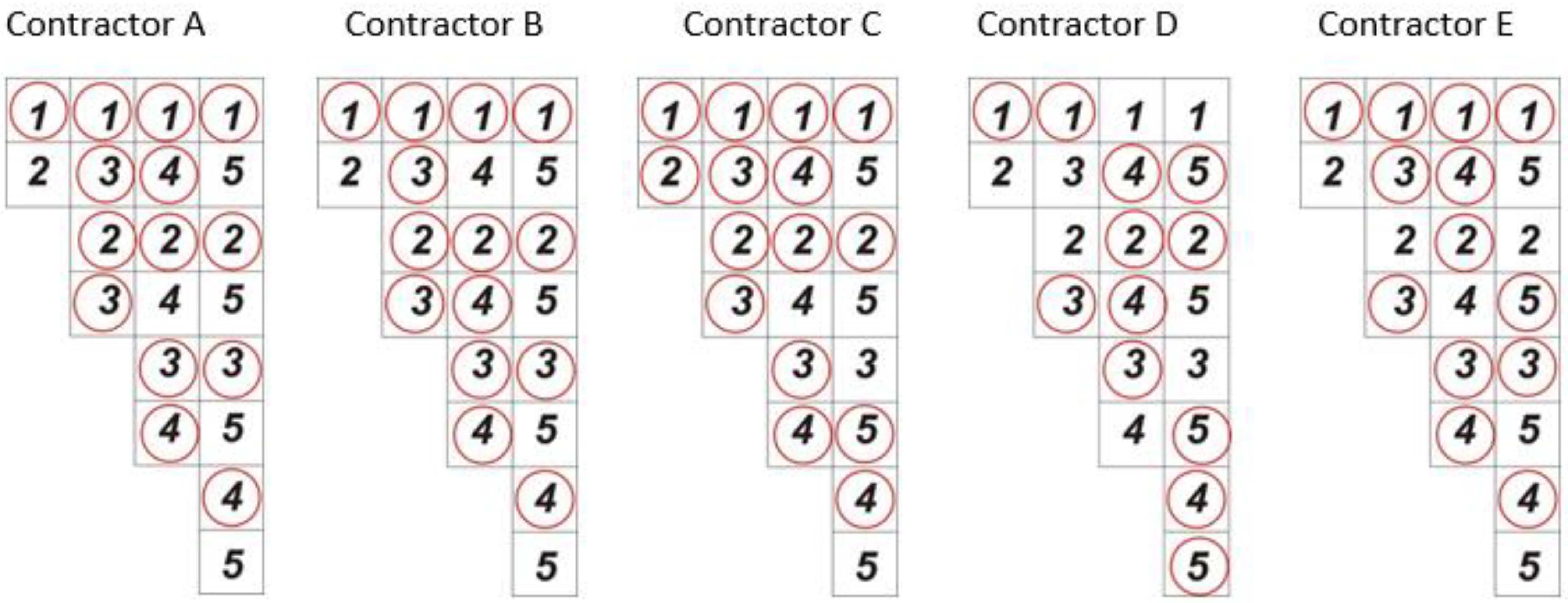

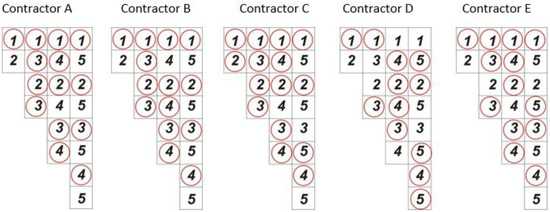

The aim of implementing the multi-criteria decision-making methods was to determine the optimal choice of thermal insulation system for the family house. The variants of thermal insulation system represent the object of the decision-making process. The group of evaluators/contractors who deal with the construction of thermal insulation, the manufacturers of thermal insulation materials, and the sellers of thermal insulation systems and materials were the subject of the decision-making process. In their answers, they followed the preferred parameters of small investors, who they usually encounter in their practice. The method of Fuller’s triangle was applied to evaluate the outputs of the questionnaires. It is a method of pairwise comparison of criteria. Each pair has 1 point. Each criterion gets as many points as were marked by the evaluators. If both criteria were marked in any pair, both criteria get half a point. The trade names of the companies’ evaluators, A–E, are not listed in the study. The authors may provide these names upon request.

3. Results

3.1. The Questionnaire Evaluation: Fuller’s Triangle

The calculation results of the weights of the confidence criteria by evaluator A:

1. criterion: 1.0 + 0.5 + 0.5 + 1.0 = 3.0

2. criterion: 0.5 + 1.0 + 1.0 = 2.5

3. criterion: 0.5 + 1 + 0.5 + 0.5 = 2.5

4. criterion: 0.5 + 0.5 + 1.0 = 2.0

5. criterion: 0 = 0

The same calculation was made to evaluate the weights of the confidence criteria by other evaluators/contractors. Ten pairs of criteria have come from the evaluation. The results of the questionnaire filled in by evaluators A–E are shown in the pairwise comparison triangles in the figure (see Figure 4).

Figure 4.

The pairwise comparison of the criteria by the evaluators/contractors (A–E).

The resulting weights of the criteria by different evaluators, coming from the Fuller’s triangles are presented in the table (see Table 4).

Table 4.

The results of the criteria evaluating.

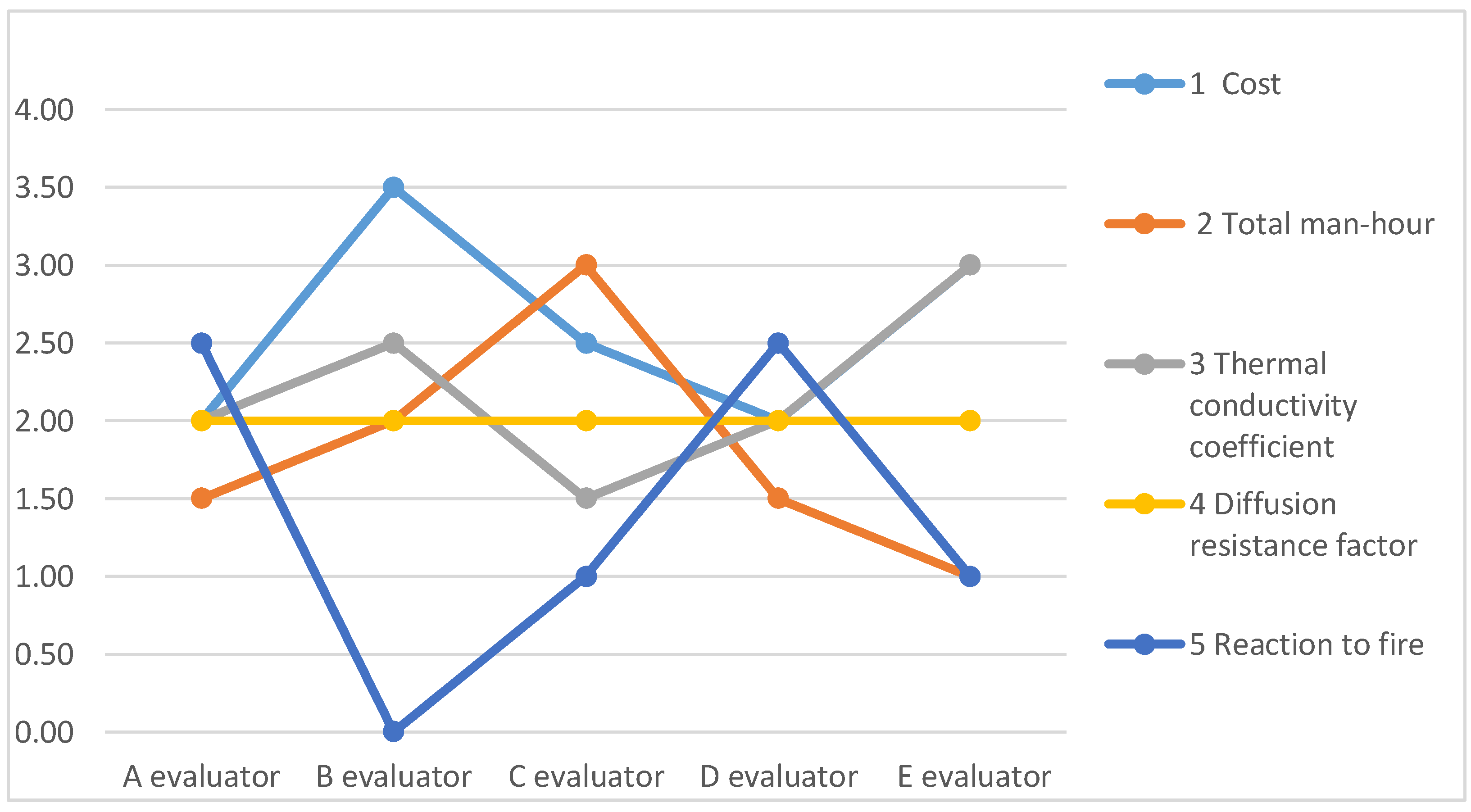

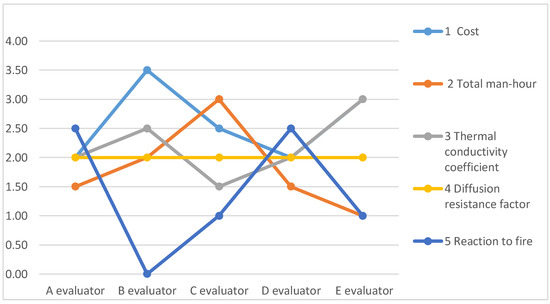

Then, the coefficient of the criteria confidence Bj was calculated. The confidence coefficient is a basic parameter when used in various methods of multi-criteria decision-making (see Table 5 and Figure 5).

Table 5.

The results of Υj and Bj.

Figure 5.

The graphical representation of the criteria confidence based on the contractors’ evaluation.

Based on the results, the most highly weighted pair of criteria that was evaluated by the contractors as best preferred was: the cost of thermal insulation system (€) and the total man-hours (Mh). The winning pair of the criteria was then followed by these pairs: the total man-hours (Mh) and the thermal conductivity coefficient λ, and the cost of the thermal insulation system (€) and reaction to fire.

Based on the evaluation of contractors’ responses, the criteria were ranked with reference to the significance. This ranking was then applied in the optimizing method of index coefficients, also known as the method of the basic variant.

3.2. The Optimizing Method of Index Coefficients

The set of criteria must meet the basic requirements: completeness, minimum scope, operationality (clarity and explicitness for the evaluator), measurability, non-redundancy (avoidance of duplication of criteria). Some requirements are often contradictory, so a compromise or balanced solution needs to be adopted in practice when establishing sets of criteria.

At first, the fictive basic values were calculated for individual criteria. Example calculation of the fictive value for criterion no. 1 (the cost of the thermal insulation system):

hBj1 = (47.878 + 43.672 + 46.469 + 74.364 + 110.404)/5 = 64.5574

The calculation of other values was made in a similar way. The results of the fictive basic variant, hBj, are presented in the table (see Table 6).

Table 6.

The results of the fictive basic variant.

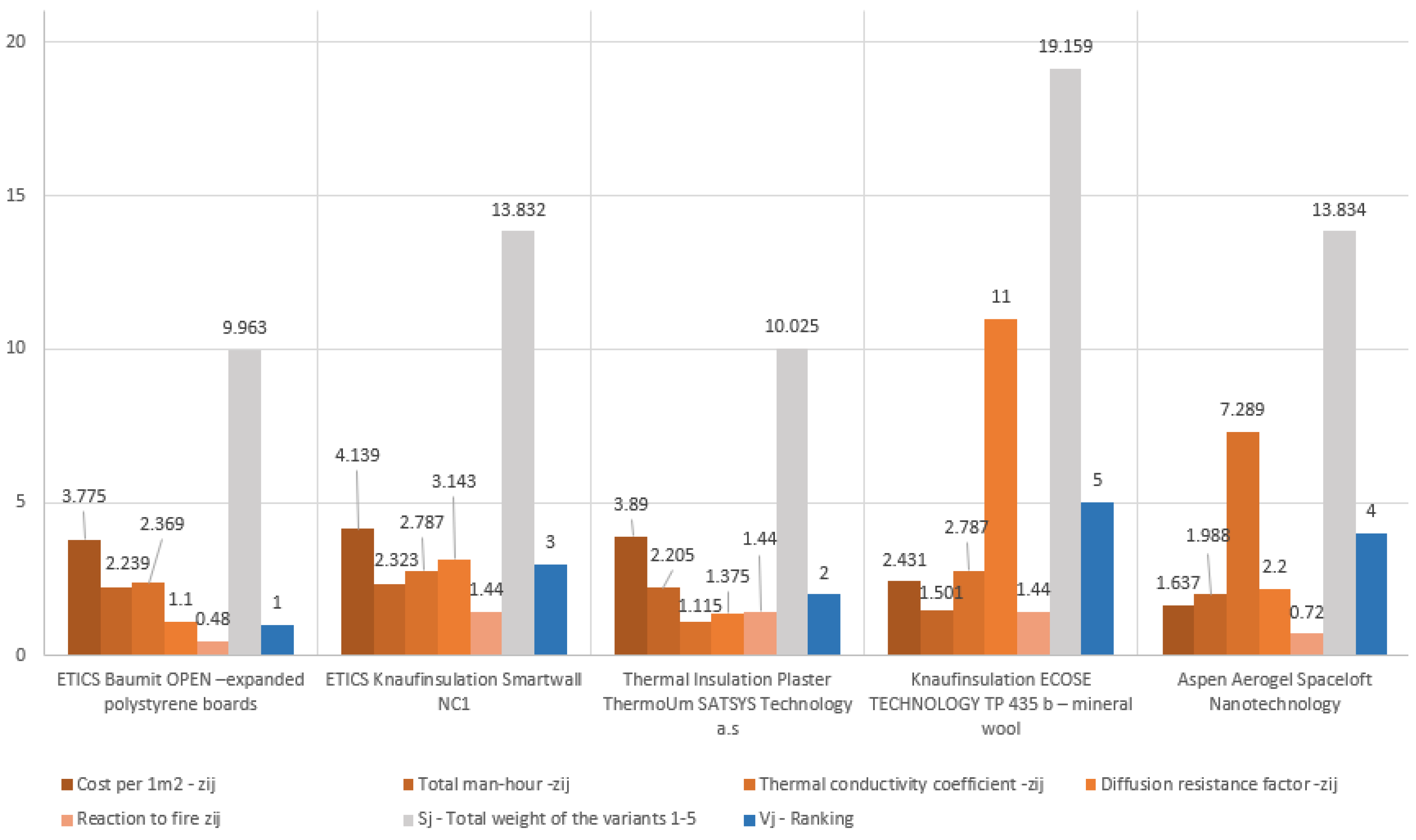

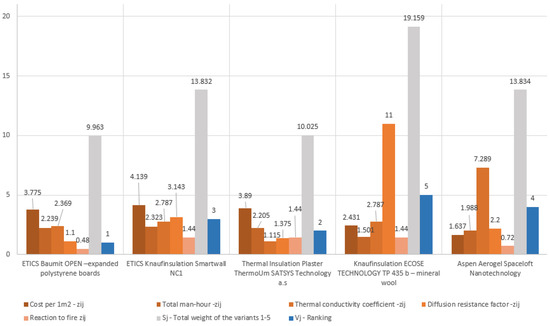

The individual weights of the variants’ criteria were determined and the total weights of the variants were concluded (Sj). With reference to the confidence, the ranking of the variants was determined from the smallest value to the largest one (see Table 7 and Figure 6).

Table 7.

The resulting weights of the variants’ criteria, zij, and the total weights of the variants, Sj.

Figure 6.

The weights of the variants’ criteria zi, the total weight of the variants, Sj, and ranking of the optimal solutions.

Using the method of index coefficients, the ranking of the variants of thermal insulation systems for the family house was determined. The weights of the criteria, having regard for small investors’ demands and resulting from the survey, were the most important in the ranking development. By determining the ranking of suitable thermal insulation solutions, an optimal solution for the house with respect to the requirements of small investors was found. However, the optimal solution may not be in line with the current trend of sustainability, to which attention must be paid. The above analyses of the case study show that the Baumit OPEN system with expanded polystyrene boards is the optimal solution for the family house’s thermal insulation system. The total weight of the variant criteria Sj = 9,963. Based on this multi-criteria decision-making of the optimal variant, the thermal insulation plaster with the value Sj = 10.025 is in second place. These variants are then followed by the Knaufinsulation SMARTwall NC1 system with the value Sj = 13,832 and the Aspen Aerogels’ Spaceloft® Nanotechnology system with an almost identical value of the weight of the variant criteria (Sj). The Knaufinsulation ECOSE® TECHNOLOGY TP 435 b system with the mineral wool appeared to be the least optimal for the family house in the case study. The results are presented in a table (see Table 7) and in a graph (see Figure 6).

4. Discussion and Conclusions

Due to a constant push to reduce energy consumption for the operation of constructions, the investors are led to choose a thermal insulation material to insulate their buildings. When choosing a thermal insulation system, small investors prefer the cheapest variant. The demands on thermal insulation materials are becoming more rigid. There are several research studies [30,31,32] focused mainly on the physical and technical properties of insulation materials in accordance with legislative requirements. The work of Alsayed and Tayeh [33] deals with an optimization of insulation thickness in buildings’ external walls. The life cycle costing approach was applied in the optimization. For the climatic conditions of Palestine, the optimal insulation thickness (polystyrene and polyurethane) varied between 0.4 and 9 cm. However, unlike our work, constructions were analyzed by a different methodology in their study. The authors examined annual energy savings, which varied between 4 and 8 dollars per m2 per year (between 4 and 8 $/m2/year). Similar to our work, Aïssani et al. [34] and Dombayci et al. [35] have argued that the performance of an insulated construction depends mainly on the thickness and the properties of the used insulation material, even though the performance is subjected to various uncertainties related, for instance, to the manufacturing process of the material. Liu et al. [36] have also dealt with reducing the life cycle cost of a building. Their results have demonstrated that the total life cycle cost of an exterior wall using expanded polystyrene as an insulation material is lower than using extruded polystyrene (XPS) as insulation. This indicated that EPS is more economical than XPS. The optimum thickness of XPS was found to be between 0.053 and 0.069 m and the optimum thickness of EPS was found to be between 0.081 and 0.105 m. With respect to the climatic conditions of Slovakia, a comparable thickness of EPS insulation (0.14 m) was examined in our research study. A similar research study was conducted by Norwegian researchers [37]. Various combinations of insulation thicknesses were assessed to identify which combination is most efficient in lowering lifetime carbon emissions. Vrbka and Tichá [38] analyzed the costs of thermal insulation systems to reduce the energy consumption of family houses. In their research, calculation methodologies to determine construction costs were used in the form of itemized budgets. The methodology of construction costs estimation with the help of itemized budgets was also applied in our study.

The life cycle costs (LCC) of buildings were also examined by other authors. Plebankiewicz et al. [39] have proposed a model that allows the investor to compare buildings in terms of the LCC already in the early stages of planning a construction project. According to our study, in the initial stage of a construction project, it is possible to replace the thermal insulation system and, thus, it is possible to change the costs of the whole life cycle of a building. In this way, the phase of the building material production can be considered. We can say that they only monitored construction cost when trying to reach energy savings during the use phase of the building. They did not consider the production of some insulating materials, such as, for example, polystyrene, which can negatively impact the environment for many decades. However, when choosing another, mostly more expensive thermal insulation material, the environment could be less burdened. The possibility of such a selection requires the existence of a database of building materials, which would list the amount of emissions that are emitted into nature and the environment during the production of the material. An example of such a database is the international Environmental Product Declaration (EPD) system. So far, Slovak legislation does not require the entry of manufacturers of building materials in the database. Even on its own initiative, there is no Slovak company in the EPD database, which reflects the awareness of the calculation of environmental costs of building materials in Slovakia. Of course, political will and legislation are needed to start the process in order to meet the requirements of the Paris Climate Agreement, to which the Slovak Republic has also committed itself.

The authors of the article consider it especially important not only to raise awareness about the environmental costs of building materials but also to introduce the need to calculate the environmental costs into the legislation of the Slovak Republic. It is necessary to consider the entire life cycle of the construction and calculate the costs of the entire life cycle of the construction. Currently, only the procurement cost of construction is considered. It is necessary to evoke the responsibility of investors for the constructions provided by them. This involves responsibility for the sustainable extraction of raw materials, for the building materials used, for sustainable construction, for the sustainable operation of the building, and also involves the responsibility for the demolition of constructions and the recycling of construction waste at the end of the building life cycle. The investor must therefore decide on a more environmentally friendly solution. Ultimately, this will not only provide the investor with a reduction in the environmental cost but also a reduction in the cost of the construction life cycle. It is also one of the ways to achieve carbon neutrality, reduce energy consumption and the generation of construction waste on Earth, and stop global warming.

In our work, we examined small investors’ demands on thermal insulation systems to insulate a family house. It was found that the lowest cost and the lowest coefficient of thermal conductivity are the most important requests of small investors when choosing an optimal solution for a thermal insulation system. Furthermore, it was found that small investors are not interested in the degree of environmental impact of the material production in the factory. The environmental cost of building materials, which depends on the carbon footprint from the initial origin of the materials, are not fully included in the price of thermal insulation materials. It is common for environmentally friendly materials (also known as biomaterials) to be more expensive than materials that are more harmful to the environment. This situation should be changed, even if some changes in legislation are needed. In this way, it will be possible to implement measures aimed at achieving carbon neutrality.

Our work tried to point out the need to deal with the monitoring of emissions already in the production phase of thermal insulation materials. In addition to efforts to reduce emissions in the phase of use of an insulated building, this is one of ways to move towards the desired carbon neutrality by 2050.

Author Contributions

Conceptualization, A.T. and Z.S.; methodology, A.T. and Z.S.; software, A.T.; validation, A.T.; formal analysis, Z.S.; investigation, A.T. and Z.S.; resources, A.T.; data curation, Z.S.; writing—original draft preparation, Z.S.; writing—review and editing, Z.S.; visualization, A.T.; supervision, M.K.; project administration, Z.S.; funding acquisition, M.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data sharing not applicable.

Acknowledgments

This paper was elaborated with the financial support of the research project VEGA 1/0557/18 of the Scientific Grant agency, the Ministry of Education, Science, Research, and Sport of the Slovak Republic, and the Slovak Academy of Sciences.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Caro, R.; Sendra, J.J. Are the dwellings of historic Mediterranean cities cold in winter? A field assessment on their indoor environment and energy performance. Energ. Build. 2021, 230, 110567. [Google Scholar] [CrossRef]

- Sposito, C.; Violano, A. Sustainable Architecture. In Technological Design. The Innovation in the Method, 1st ed.; Palermo University Press: Palermo, Italy, 2018; p. 159. [Google Scholar]

- Policies, Information and Services, Energy/Topics/Buildings/Energy Efficiency/Buildings. Available online: https://ec.europa.eu/energy/en/topics/energy-efficiency/buildings (accessed on 2 December 2020).

- Towards Reaching the 20% Energy Efficiency Target for 2020 and Beyond. Available online: http://europa.eu/rapid/press-release_MEMO-17-162_en.htm (accessed on 4 December 2020).

- Detesová, K.; Szalai, P. Zmena Klímy 2019; Euroactiv: Bratislava, Slovakia, 2019; pp. 1–16. [Google Scholar]

- Schnädelbach, H. Adaptive Architecture—A Conceptual Framework. In Proceedings of the MediaCity Conference, Bauhaus-Universität, Weimar, Germany, 29–31 October 2010; pp. 523–557. [Google Scholar]

- Ngo, L.M.; Kieu, L.T.; Hoang, H.Y.; Nguyen, H.B. Experiences of Housing Adapted to Sea Level Rise and Applicability for Houses in the Can Gio District, Ho Chi Minh City, Vietnam. Sustainability 2020, 12, 3743. [Google Scholar] [CrossRef]

- Al-Alwan, H.A.S.; Abdullah, Y.S. Smart Material Systems and Adaptiveness in Architecture. Ain Shams Eng. J. 2019, 10, 623–638. [Google Scholar]

- Ahmed, A.; Okba, E.; Badawy, E. Designing bio-inspired adaptive climatic façades and its effect on daylighting performance of building. Int. J. Eng. Technol. 2020, 12, 41–51. [Google Scholar] [CrossRef][Green Version]

- Shi, G.; Liu, T.; Li, G.; Wang, Z. A novel thermal insulation composite fabricated with industrial solid wastes and expanded polystyrene beads by compression method. J. Clean. Prod. 2021, 279, 123420. [Google Scholar] [CrossRef]

- Bicer, A.; Kar, F. Thermal and mechanical properties of gypsum plaster mixed with expanded polystyrene and tragacanth. Therm. Sci. Eng. Prog. 2017, 1, 59–65. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Berardi, U. A cross-country comparison of the building energy consumptions and their trends. Resour. Conserv. Recycl. 2017, 123, 230–241. [Google Scholar] [CrossRef]

- Neya, I.; Yamegueu, D.; Coulibaly, Y.; Messan, A.; Ouedraogo, A.L.S.-N. Impact of insulation and wall thickness in compressed earth buildings in hot and dry tropical regions. J. Build. Eng. 2021, 33, 101612. [Google Scholar] [CrossRef]

- Yosifova, V. Methods and means for analyzing heat-loss in buildings for increasing their energy efficiency. Adv. Intell. Syst. Comput. 2020, 1252, 45–54. [Google Scholar]

- Mazzarella, L. Energy retrofit of historic and existing buildings. The legislative and regulatory point of view. Energy Build. 2015, 95, 23–31. [Google Scholar] [CrossRef]

- Azari, R.; Garshasbi, S.; Amini, P.; Rashed-Ali, H.; Mohammadi, Y. Multi-objective optimization of building envelope design for life cycle environmental performance. Energy Build. 2016, 126, 524–534. [Google Scholar] [CrossRef]

- Azari, R. Integrated energy and environmental life cycle assessment of office building envelopes. Energy Build. 2014, 82, 156–162. [Google Scholar] [CrossRef]

- Braulio-Gonzalo, M.; Bovea, M.D. Environmental and cost performance of building’s envelope insulation materials to reduce energy demand: Thickness optimisation. Energy Build. 2017, 150, 527–545. [Google Scholar] [CrossRef]

- Özel, G.; Açikkalp, E.; Görgün, B.; Yamik, H.; Caner, N. Optimum insulation thickness determination using the environmental and life cycle cost analyses based entransy approach. Sustain. Energy Technol. Assess. 2015, 11, 87–91. [Google Scholar] [CrossRef]

- Raimundo, A.M.; Saraiva, N.B.; Oliveira, A.V.M. Thermal insulation cost optimality of opaque constructive solutions of buildings under Portuguese temperate climate. Build. Environ. 2020, 182, 107107. [Google Scholar] [CrossRef]

- Brandão De Vasconcelos, A.; Pinheiro, M.D.; Manso, A.; Cabaço, A. EPBD cost-optimal methodology: Application to the thermal rehabilitation of the building envelope of a Portuguese residential reference building. Energy Build. 2016, 111, 12–25. [Google Scholar] [CrossRef]

- Nagy, B.; Simon, T.K.; Nemes, R. Effect of built-in mineral wool insulations durability on its thermal and mechanical performance. J. Therm. Anal. Calorim. 2020, 139, 169–181. [Google Scholar] [CrossRef]

- Lakatos, Á. Effect of the placement of aerogel insulation in the heat transfer properties. J. Therm. Anal. Calorim. 2018, 133, 321–327. [Google Scholar] [CrossRef]

- Galliano, R.; Ghazi Wakili, K.; Stahl, T.; Binder, B.; Daniotti, B. Performance evaluation of aerogel-based and perlite-based prototyped insulations for internal thermal retrofitting: HMT model validation by monitoring at demo scale. Energy Build. 2016, 126, 275–286. [Google Scholar] [CrossRef]

- Pilný, O.; Kalousek, L. Absorbent Properties of Polystyrene with Closed Outer Structure in Case of Failure of the External Surface of the Board. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Code 157867. [Google Scholar]

- Ciprian Maties, I.; Muntean, D.M. Cost and energy efficient envelope systems for a single-family house in Timisoara, Romania. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Code 152111. [Google Scholar]

- Sattler, S.; Österreicher, D. Assessment of sustainable construction measures in building refurbishment-life cycle comparison of conventional and Multi-Active Façade systems in a social housing complex. Sustainability 2019, 11, 4487. [Google Scholar] [CrossRef]

- Husain Jafri, S.A.; Bharti, P.K. Analyzing optimum thickness for combination of two thermal insulation materials for building walls. In IOP Conference Series: Materials Science and Engineeringe; IOP Publishing: Bristol, UK, 2018; Code 14009. [Google Scholar]

- Katunsky, D.; Katunska, J. Assessment of Thermal Insulation Properties of Envelope Structures of a Burgher House in Kosice. Lect. Notes Civ. Eng. 2021, 100, 166–173. [Google Scholar]

- Hoxha, V. Measuring energy heating performance of apartment buildings in Kosovo built after 2003. Facilities 2019, 38, 395–420. [Google Scholar] [CrossRef]

- Katunský, D.; Farárik, M. The Impact of Various Factors on the Energy Performance of Selected Types of Family Houses. Appl. Mech. Mater. 2019, 887, 109–116. [Google Scholar] [CrossRef]

- Alsayed, M.F.; Tayeh, R.A. Life cycle cost analysis for determining optimal insulation thickness in Palestinian buildings. J. Build. Eng. 2019, 22, 101–112. [Google Scholar] [CrossRef]

- Aïssani, A.; Chateauneuf, A.; Fontaine, J.-P.; Audebert, P. Cost model for optimum thicknesses of insulated walls considering indirect impacts and uncertainties. Energy Build. 2014, 84, 21–32. [Google Scholar] [CrossRef]

- Dombayci, Ö.; Ozturk, H.; Atalay, Ö.; Acar, Ş.; Ulu, E. The Impact of Optimum Insulation Thickness of External Walls to Energy Saving and Emissions of CO2 and SO2 for Turkey Different Climate Regions. Energy Power Eng. 2016, 8, 327–348. [Google Scholar] [CrossRef]

- Liu, X.; Chen, Y.; Ge, H.; Fazio, P.; Chen, G. Determination of Optimum Insulation Thickness of Exterior Wall with Moisture Transfer in Hot Summer and Cold Winter Zone of China. Procedia Eng. 2015, 121, 1008–1015. [Google Scholar] [CrossRef]

- Totland, M.; Kvande, T.; Bohne, R.A. The effect of insulation thickness on lifetime CO2 emissions. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 323, p. 012033. [Google Scholar]

- Vrbka, M.; Tichá, A. Accuracy of a parametrically determined price offer for low-energy and passive family houses. In Proceedings of the International Multidisciplinary Scientific Geo Conference Surveying Geology and Mining Ecology Management, SGEM, STEF 92 Technology, Albena, Bulgaria, 28 June–7 July 2019; Volume 19, pp. 335–342. [Google Scholar]

- Plebankiewicz, E.; Zima, K.; Wieczorek, D. Original Model for Estimating the Whole Life Costs of Buildings and its Verification. Arch. Civ. Eng. 2019, 65, 163–179. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).