Energy-Efficient Optimization of Two-Sided Disassembly Line Balance Considering Parallel Operation and Uncertain Using Multiobjective Flatworm Algorithm

Abstract

1. Introduction

- The triangular fuzzy number is introduced into the two-sided disassembly line to simulate the uncertainty of parts disassembly time. This method can not only simulate the average disassembly time of parts, but also expresses the disassembly time of parts with good conditions (less than the average disassembly time) and parts with poor conditions (more than the average disassembly time), which increases the universality of uncertainty expression.

- The parallel operation constraint is introduced to imitate some large-volume components and parts that lay across the two-side disassembly line and that should be dismantled parallel in the same mated-station, which is significantly different from the straight one-sided disassembly line and U-shaped. For example, the removal of the engine cover of an EOL automobile requires the workers at the left and right stations of the same disassembly mated-station to work together to remove their respective fastening bolts due to its large size.

- A mixed-integer programming (MIP) model based on energy efficiency is established for the two-sided disassembly line balancing problem considering parallel operation and fuzzy processing times (TDLBP-POF), which is more realistic than the previous model, and a multiobjective flatworm algorithm (MOFA) is developed to solve the problem.

2. Model Construction of TDLBP-POF

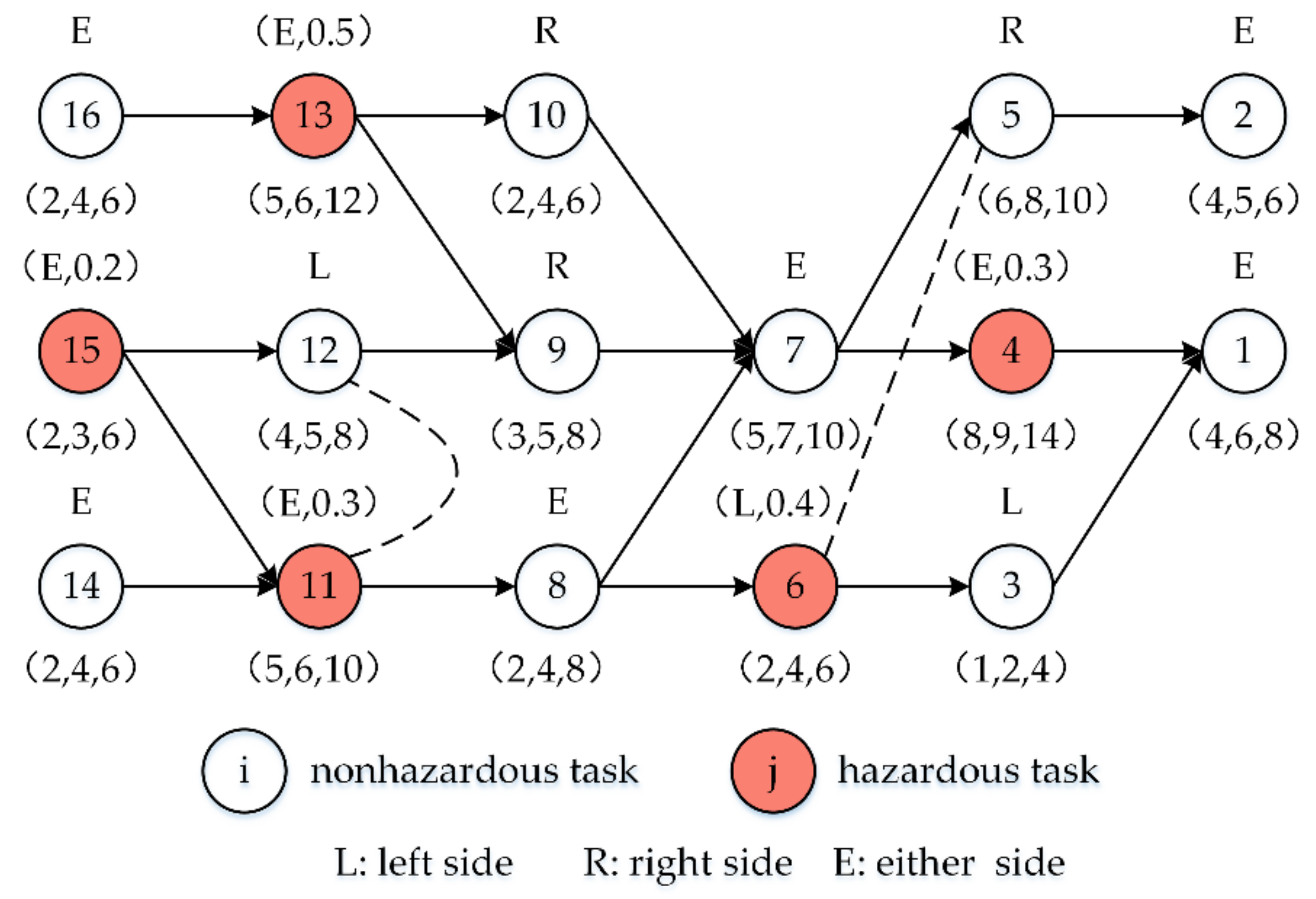

2.1. Problem Description

2.2. Parallel Operation Constraint

2.3. Approaches for Fuzzy Processing Times

2.4. Mathematical Model of TDLBP-POF

2.4.1. Notations

2.4.2. Objective Functions

2.4.3. Constrains

3. Multiobjective Flatworm Algorithm for TDLBP-POF

3.1. Solution Encoding

3.2. The Growth Process

3.3. The Splitting Process

3.4. The Regeneration Process

3.5. Solution Decoding

3.6. The Pareto-Optimal Solutions

4. Case Verification and Discussion

4.1. Fuzzy Straight One-Sided Disassembly Line Case with No Parallel Operation

4.2. Fuzzy Two-Sided Disassembly Line with Parallel Operation Tasks

4.3. Application Case Verification and Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xia, X.; Liu, W.; Zhang, Z.; Wang, L.; Cao, J.; Liu, X. A balancing method of mixed-model disassembly line in random working environment. Sustainability 2019, 11, 2304. [Google Scholar] [CrossRef]

- Meng, W.; Zhang, X. Optimization of remanufacturing disassembly line balance considering multiple failures and material hazards. Sustainability 2020, 12, 7318. [Google Scholar] [CrossRef]

- Kazancoglu, Y.; Ozturkoglu, Y. Integrated framework of disassembly line balancing with Green and business objectives using a mixed MCDM. J. Clean. Prod. 2018, 191, 179–191. [Google Scholar] [CrossRef]

- Baykasoglu, A.; Tasan, S.O.; Tasan, A.S.; Akyol, S.D. Modeling and solving assembly line design problems by considering human factors with a real-life application. Hum. Factors Ergon. Manuf. 2017, 27, 96–115. [Google Scholar] [CrossRef]

- Wang, K.; Li, X.; Gao, L.; Garg, A. Partial disassembly line balancing for energy consumption and profit under uncertainty. Robot. Comput. Integr. Manuf. 2019, 59, 235–251. [Google Scholar] [CrossRef]

- Kalaycilar, E.G.; Azizoʇlu, M.; Yeralan, S. A disassembly line balancing problem with fixed number of workstations. Eur. J. Oper. Res. 2016, 249, 592–604. [Google Scholar] [CrossRef]

- Liang, J.; Guo, S.; Du, B.; Li, Y.; Guo, J.; Yang, Z.; Pang, S. Minimizing energy consumption in multi-objective two-sided disassembly line balancing problem with complex execution constraints using dual-individual simulated annealing algorithm. J. Clean. Prod. 2020, 284, 125418. [Google Scholar] [CrossRef]

- Zhu, L.; Zhang, Z.; Wang, Y. A Pareto firefly algorithm for multi-objective disassembly line balancing problems with hazard evaluation. Int. J. Prod. Res. 2018, 56, 7354–7374. [Google Scholar] [CrossRef]

- Wang, K.; Li, X.; Gao, L. A multi-objective discrete flower pollination algorithm for stochastic two-sided partial disassembly line balancing problem. Comput. Ind. Eng. 2019, 130, 634–649. [Google Scholar] [CrossRef]

- Gupta, S.M.; Gungor, A.; Pochampally, K.; Kamarthi, S.V. Complications in disassembly line balancing. Proc. SPIE Int. Conf. Environ. Concious Manuf. 2000, 4193, 289–298. [Google Scholar]

- McGovern, S.M.; Gupta, S.M. Combinatorial optimization analysis of the unary NP-complete disassembly line balancing problem. Int. J. Prod. Res. 2007, 45, 4485–4511. [Google Scholar] [CrossRef]

- Edis, E.B.; Ilgin, M.A.; Edis, R.S. Disassembly line balancing with sequencing decisions: A mixed integer linear programming model and extensions. J. Clean. Prod. 2019, 238, 117826. [Google Scholar] [CrossRef]

- Altekin, F.T. A comparison of piecewise linear programming formulations for stochastic disassembly line balancing. Int. J. Prod. Res. 2017, 55, 7412–7434. [Google Scholar] [CrossRef]

- Özceylan, E.; Paksoy, T. Reverse supply chain optimisation with disassembly line balancing. Int. J. Prod. Res. 2013, 51, 5985–6001. [Google Scholar] [CrossRef]

- Kannan, D.; Garg, K.; Jha, P.C.; Diabat, A. Integrating disassembly line balancing in the planning of a reverse logistics network from the perspective of a third party provider. Ann. Oper. Res. 2017, 253, 353–376. [Google Scholar] [CrossRef]

- Cao, J.; Xia, X.; Wang, L.; Zhang, Z.; Liu, X. A Novel Multi-Efficiency Optimization Method for Disassembly Line Balancing Problem. Sustainability 2019, 11, 6969. [Google Scholar] [CrossRef]

- Li, J.; Chen, X.; Zhu, Z.; Yang, C.; Chu, C. A branch, bound, and remember algorithm for the simple disassembly line balancing problem. Comput. Oper. Res. 2019, 105, 47–57. [Google Scholar] [CrossRef]

- Li, Z.; Çil, Z.A.; Mete, S.; Kucukkoc, I. A fast branch, bound and remember algorithm for disassembly line balancing problem. Int. J. Prod. Res. 2020, 58, 3220–3234. [Google Scholar] [CrossRef]

- Seidi, M.; Saghari, S. The balancing of disassembly line of automobile engine using Genetic Algorithm (GA) in fuzzy environment. Ind. Eng. Manag. Syst. 2016, 15, 364–373. [Google Scholar] [CrossRef]

- Ding, L.P.; Feng, Y.X.; Tan, J.R.; Gao, Y.C. A new multi-objective ant colony algorithm for solving the disassembly line balancing problem. Int. J. Adv. Manuf. Technol. 2010, 48, 761–771. [Google Scholar] [CrossRef]

- Kalayci, C.B.; Gupta, S.M. A particle swarm optimization algorithm with neighborhood-based mutation for sequence-dependent disassembly line balancing problem. Int. J. Adv. Manuf. Technol. 2013, 69, 197–209. [Google Scholar] [CrossRef]

- Fang, Y.; Ming, H.; Li, M.; Liu, Q.; Pham, D.T. Multi-objective evolutionary simulated annealing optimisation for mixed-model multi-robotic disassembly line balancing with interval processing time. Int. J. Prod. Res. 2019, 58, 1–17. [Google Scholar] [CrossRef]

- Liu, J.; Wang, S. Balancing disassembly line in product recovery to promote the coordinated development of economy and environment. Sustainability 2017, 9, 309. [Google Scholar] [CrossRef]

- Ren, Y.; Yu, D.; Zhang, C.; Tian, G.; Meng, L.; Zhou, X. An improved gravitational search algorithm for profit-oriented par-tial disassembly line balancing problem. Int. J. Prod. Res. 2017, 55, 7302–7316. [Google Scholar] [CrossRef]

- Kucukkoc, I. Balancing of two-sided disassembly lines: Problem definition, MILP model and genetic algorithm approach. Comput. Oper. Res. 2020, 124, 105064. [Google Scholar] [CrossRef]

- Mete, S.; Çil, Z.A.; Özceylan, E.; Ağpak, K.; Battaïa, O. An optimisation support for the design of hybrid production lines including assembly and disassembly tasks. Int. J. Prod. Res. 2018, 56, 7375–7389. [Google Scholar] [CrossRef]

- Zheng, F.; He, J.; Chu, F.; Liu, M. A new distribution-free model for disassembly line balancing problem with stochastic task processing times. Int. J. Prod. Res. 2018, 56, 7341–7353. [Google Scholar] [CrossRef]

- He, J.; Chu, F.; Zheng, F.; Liu, M.; Chu, C. A multi-objective distribution-free model and method for stochastic disassembly line balancing problem. Int. J. Prod. Res. 2019, 58, 1–17. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, K.; Zhu, L.; Wang, Y. A Pareto improved artificial fish swarm algorithm for solving a multi-objective fuzzy disassembly line balancing problem. Expert Syst. Appl. 2017, 86, 1339–1351. [Google Scholar] [CrossRef]

- Kalayci, C.B.; Hancilar, A.; Gungor, A.; Gupta, S.M. Multi-objective fuzzy disassembly line balancing using a hybrid discrete artificial bee colony algorithm. J. Manuf. Syst. 2015, 37, 672–682. [Google Scholar] [CrossRef]

- Chutima, P.; Chimklai, P. Multi-objective two-sided mixed-model assembly line balancing using particle swarm optimisation with negative knowledge. Comput. Ind. Eng. 2012, 62, 39–55. [Google Scholar] [CrossRef]

- Lee, T.O.; Kim, Y.; Kim, Y.K. Two-sided assembly line balancing to maximize work relatedness and slackness. Comput. Ind. Eng. 2001, 40, 273–292. [Google Scholar] [CrossRef]

- Tsaura, S.H.; Chang, T.Y.; Yen, C.H. The evaluation of airline service quality by fuzzy MCDM. Tour. Manag. 2002, 23, 107–115. [Google Scholar] [CrossRef]

- Wang, K.; Li, X.; Gao, L.; Li, P. Energy consumption and profit-oriented disassembly line balancing for waste electrical and electronic equipment. J. Clean. Prod. 2020, 265, 121829. [Google Scholar] [CrossRef]

- Li, D.; Zhang, C.; Tian, G.; Shao, X.; Li, Z. Multiobjective program and hybrid imperialist competitive algorithm for the mixed-model two-sided assembly lines subject to multiple constraints. IEEE Trans. Syst. Man Cybern. Syst. 2018, 48, 119–129. [Google Scholar] [CrossRef]

- Yuan, B.; Zhang, C.; Shao, X. A late acceptance hill-climbing algorithm for balancing two-sided assembly lines with multiple constraints. J. Intell. Manuf. 2013, 26, 159–168. [Google Scholar] [CrossRef]

- Tseng, H.E.; Huang, Y.M.; Chang, C.C.; Lee, S.C. Disassembly sequence planning using a Flatworm algorithm. J. Manuf. Syst. 2020, 57, 416–428. [Google Scholar] [CrossRef]

- Deb, K.; Agrawal, S.; Pratap, A.; Meyarivan, T. A fast elitist non-dominated sorting genetic algorithm for multi-objective optimization: NSGA-II. In Lecture Notes in Computer Science; Parallel Problem Solving from Nature PPSN VI, PPSN 2000; Schoenauer, M., Ed.; Springer: Berlin/Heidelberg, Germany, 2000; Volume 1917. [Google Scholar] [CrossRef]

| Solution | f1 | f2 | f3 | f4 | |||

|---|---|---|---|---|---|---|---|

| 1 | 11 | 10.714 | 79 | 908 | (0.551, 0.891, 1) | (0, 7.616, 27.622) | (0, 18, 89) |

| 2 | 11 | 10.960 | 75 | 908 | (0.551, 0.891, 1) | (0, 8.000, 27. 839) | (0, 18, 89) |

| 3 | 12 | 15.239 | 73 | 882 | (0.505, 0.817, 1) | (3, 12.845, 32.265) | (0, 33, 107) |

| 4 | 12 | 16.422 | 76 | 856 | (0.505, 0.817, 1) | (3, 14.799, 33.091) | (3, 33, 107) |

| 5 | 13 | 20.887 | 71 | 873 | (0.466, 0.754, 1) | (9.055, 18.868, 36.756) | (14, 48, 125) |

| Solution | Task Assignment Schemes |

|---|---|

| 1 | {4}-{5,2}-{1,10,11,12,3}-{8}-{6}-{7}-{9}-{13,14,17,21,22}-{25,15,18,16,20}-{19}-{23,24} |

| 2 | {2,4}-{1,5}-{10,11,12,3}-{7}-{6}-{9}-{8}-{14,13,17,15,18,16}-{19,21}-{25,22,20}-{23,24} |

| 3 | {2,4}-{1,5}-{10,11,12,3}-{8}-{7}-{6}-{9}-{14,13,17,21,25}-{22,15,18,16}-{19}-{23}-{20,24} |

| 4 | {2,1}-{7}-{6}-{5,3}-{9}-{8}-{14,13,17,21,25}-{22,4}-{16,23}-{10,11,12,15,18}-{19}-{20,24} |

| 5 | {2,5}-{1,4}-{10,11,12,3}-{8}-{6}-{7}-{9}-{14,13,17,21,25}-{22,16}-{23,15}-{18}-{19}-{20,24} |

| Solution | f1 | f2 | f3 | f4 | |||

|---|---|---|---|---|---|---|---|

| 1 | 9 | 39.12 | 271 | 2372 | (0.72, 0.91, 1) | (0, 30.56, 95.35) | (0, 80, 278) |

| 2 | 9 | 39.96 | 263 | 2335 | (0.72, 0.91, 1) | (0, 32.28, 95.27) | (0, 80, 278) |

| 3 | 9 | 40.28 | 264 | 2325 | (0.72, 0.91, 1) | (0, 32.77, 95.58) | (0, 80, 278) |

| 4 | 9 | 45.43 | 261 | 2334 | (0.72, 0.91, 1) | (9.00, 38.08, 96.58) | (9, 80, 278) |

| 5 | 10 | 71.01 | 259 | 2330 | (0.65, 0.82, 1) | (14.93, 69.70, 129.69) | (27, 184, 388) |

| 6 | 10 | 74.00 | 261 | 2313 | (0.65, 0.82, 1) | (21.42, 71.96, 130.66) | (33, 184, 388) |

| 7 | 10 | 79.18 | 257 | 2322 | (0.65, 0.82, 1) | (29.41, 77.06, 133.21) | (47, 184, 388) |

| 8 | 11 | 129.08 | 260 | 2311 | (0.59, 0.75, 0.97) | (93.77, 125.90, 170.76) | (134, 288, 498) |

| 9 | 11 | 144.90 | 259 | 2303 | (0.59, 0.75, 0.97) | (117.69, 141.63, 178.66) | (192, 288, 498) |

| Solution | Task Assignment Schemes |

|---|---|

| 1 | {5,13,14,19,15,16,17,18,47}-{20,21,22,23,24}-{25,8,9,10,11,1,6}-{26,27}-{2,3,28,29,30,31,4}-{32}-{33,34,35,36,43,44,12,45}-{37,46,7,38}-{39,40,41,42} |

| 2 | {5,13,14,19,15,16,17,18,47}-{20,22,21,24,23}-{25,8,9,10,11,1}-{26}-{2,3,27,28,29,30,31}-{32}-{33,34,35,36,43,44,45,46,6}-{12,7,37,38,4}-{39,40,41,42} |

| 3 | {5,13,14,19,15,16,17,18,47}-{20,22,21,24,23}-{25,8,9,10,11,1}-{26,27}-{28,29,30,31,2,3}-{32}-{33,34,35,36,43,44,45,46,12}-{6,7,37,38,4}-{39,40,41,42} |

| 4 | {5,13,14,19,15,16,17,18,47,22}-{20,21,23,24,25}-{1,2,3,8,9}-{26}-{10,11,27,28,29,30,31}-{32}-{33,34,35,36,43,44,45,46,12}-{6,7,37,38,4}-{39,40,41,42} |

| 5 | {5,13,14,19,15,16,17,18,47,22}-{20,21,23,24,25}-{1,2,3,8,9}-{26}-{10,11,27,28,29,30,31}-{32}-{33,34,35,36,43,44,6}-{37,38}-{39,40}-{45,46,12,41,42,4,7} |

| 6 | {5,13,14,19,15,16,17,18,47,22}-{20,21,23,24,25}-{8,9,10,11,1}-{26,27}-{28,29,30,31,2,3}-{32}-{33,34,35,36,43,44}-{37,38}-{39,40,6}-{45,46,12,41,42,4,7} |

| 7 | {5,13,14,19,15,16,17,18,47,22}-{20,21,23,24,25}-{1,2,3,8,10}-{9,11,26}-{27,28,29,30,31}-{32}-{33,34,35,36,43,44}-{37,38}-{39,40}-{45,46,12,41,42,6,4,7} |

| 8 | {5,13,14,19,15,16,17,18,47,22}-{20,21,23,24,25}-{8,9,10,11}-{26,27}-{28,29,1,30,31,2}-{3}-{32}-{33,34,35,36,43,44,6}-{37,38}-{39,40}-{45,46,12,41,42,4,7} |

| 9 | {5,13,14,19,15,16,17,18,47,22}-{20,21,23,24,25}-{8,9,10,11}-{26,27}-{28,29,1,30,31,2}-{3}-{32}-{33,34,35,36,43,44,45,46,12}-{37,38}-{39,40,41,42}-{6,4,7} |

| Task | α = 0 | α = 0.3 | α = 0.5 | α = 0.7 | α = 1 |

|---|---|---|---|---|---|

| 1 | (4, 6, 8) | (4.6, 6, 7.4) | (5, 6, 7) | (5.4, 6, 6.6) | 6 |

| 2 | (4, 5, 6) | (4.3, 5, 5.7) | (4.5, 5, 5.5) | (4.7, 5, 5.3) | 5 |

| 3 | (1, 2, 4) | (1.3, 2, 3.4) | (1.5, 2, 3) | (1.7, 2, 2.6) | 2 |

| 4 | (8, 9, 14) | (8.3, 9, 12.5) | (8.5, 9, 11.5) | (8.7, 9, 10.5) | 9 |

| 5 | (6, 8, 10) | (6.6, 8, 9.4) | (7, 8, 9) | (7.4, 8, 8.6) | 8 |

| 6 | (2, 4, 6) | (2.6, 4, 5.4) | (3, 4, 5) | (3.4, 4, 4.6) | 4 |

| 7 | (5, 7, 10) | (5.6, 7, 9.1) | (6, 7, 8.5) | (6.4, 7, 7.9) | 7 |

| 8 | (2, 4, 8) | (2.6, 4, 6.8) | (3, 4, 6) | (3.4, 4, 5.2) | 4 |

| 9 | (3, 5, 8) | (3.6, 5, 7.1) | (4, 5, 6.5) | (4.4, 5, 5.9) | 5 |

| 10 | (2, 4, 6) | (2.6, 4, 5.4) | (3, 4, 5) | (3.4, 4, 4.6) | 4 |

| 11 | (5, 6, 10) | (5.3, 6, 8.8) | (5.5, 6, 8) | (5.7, 6, 7.2) | 6 |

| 12 | (4, 5, 8) | (4.3, 5, 7.1) | (4.5, 5, 6.5) | (4.7, 5, 5.9) | 5 |

| 13 | (5, 6, 12) | (5.3, 6, 10.2) | (5.5, 6, 9) | (5.7, 6, 7.8) | 6 |

| 14 | (2, 4, 6) | (2.6, 4, 5.4) | (3, 4, 5) | (3.4, 4, 4.6) | 4 |

| 15 | (2, 3, 6) | (2.3, 3, 5.1) | (2.5, 3, 4.5) | (2.7, 3, 3.9) | 3 |

| 16 | (2, 4, 6) | (2.6, 4, 5.4) | (3, 4, 5) | (3.4, 4, 4.6) | 4 |

| 0 | (0, 8.89, 63.46) | (0, 16.00, 1643.00) | (113.01, 149.37, 207.97) |

| (0, 16.33, 59.29) | (0, 74.00, 1023.00) | (127.99, 167.33, 228.91) | |

| (0, 21.90, 59.29) | (0, 109.00, 997.00) | (127.96, 167.29, 228.86) | |

| 0.3 | (0, 8.89, 52.64) | (0, 16.00, 863.21) | (123.92, 149.37, 190.39) |

| (0, 21.15, 46.61) | (12.25, 96.00, 422.41) | (155.82, 185.48, 230.77) | |

| (0, 19.61, 53.86) | (0, 106.00, 969.59) | (123.84, 149.28, 190.27) | |

| 0.5 | (0, 8.89, 43.50) | (0, 16.00, 482.25) | (131.19, 149.37, 178.67) |

| (0, 14.58, 42.08) | (1, 66.00, 449.75) | (131.11, 149.28, 178.56) | |

| 0.7 | (0, 8.89, 34.30) | (0.18, 20, 264.29) | (138.41, 149.31, 166.89) |

| (0, 14.58, 32.52) | (3.38, 46.00, 233.35) | (138.38, 149.28, 166.85) | |

| 1 | 14.58 | 42.00 | 149.33 |

| 14.58 | 46.00 | 149.31 | |

| 14.58 | 66.00 | 149.28 |

| 0 | (0, 14.58, 60.42) | (0, 56.00, 1275.00) | (113.06, 149.43, 208.09) |

| (0, 14.58, 63.46) | (0, 48.00, 1647.00) | (112.97, 149.31, 207.89) | |

| (0, 21.90, 59.29) | (0, 99.00, 995.00) | (128.02, 167.37, 229.00) | |

| 0.3 | (0, 14.58, 50.23) | (0, 56.00, 720.51) | (123.91, 149.35, 190.38) |

| (0, 14.58, 53.26) | (0, 48.00, 912.99) | (123.88, 149.31, 190.32) | |

| (0, 21.90, 50.19) | (0, 101.00, 617.32) | (139.92, 167.48, 210.67) | |

| (0, 21.90, 50.19) | (0, 101.00, 617.32) | (139.92, 167.48, 210.67) | |

| 0.5 | (0, 8.89, 43.50) | (0, 18.00, 483.75) | (131.29, 149.48, 178.82) |

| (0, 14.58, 42.08) | (4.00, 66.00, 458.75) | (131.21, 149.39, 178.71) | |

| (0, 14.58, 47.35) | (0, 52.00, 666.75) | (131.21, 149.39, 178.70) | |

| (0, 19.61, 46.12) | (0.25, 84.00, 606.75) | (131.17, 149.35, 178.66) | |

| 0.7 | (0, 8.89, 32.15) | (0, 18.00, 214.23) | (152.16, 163.78, 182.09) |

| (0, 14.58, 32.52) | (2.18, 44.00, 227.39) | (138.45, 149.35, 166.93) | |

| (0, 14.58, 32.52) | (14.89, 66.00, 246.75) | (138.37, 149.28, 166.84) | |

| 1 | 8.89 | 24.00 | 163.89 |

| 14.58 | 44.00 | 149.38 | |

| 19.61 | 84.00 | 149.35 |

| 0 | (0, 8.89, 60.42) | (0, 22.00, 1277.00) | (125.04, 163.80, 224.84) |

| (0, 8.89, 63.46) | (0, 16.00, 1643.00) | (113.01, 149.37, 207.97) | |

| (0, 8.89, 66.07) | (0, 27.00, 2085.00) | (112.93, 149.26, 207.81) | |

| (0, 14.58, 60.42) | (0, 46.00, 1275.00) | (112.99, 149.33, 207.93) | |

| (0, 16.33, 59.29) | (0, 74.00, 1023.00) | (127.99, 167.33, 228.91) | |

| 0.3 | (0, 8.89, 52.64) | (0, 16.00, 863.21) | (123.92, 149.37, 190.39) |

| (0, 8.89, 55.39) | (0, 20, 1088.69) | (123.88, 149.31, 190.32) | |

| (0, 14.58, 50.23) | (0, 42.00, 720.79) | (123.89, 149.33, 190.34) | |

| 0.5 | (0, 8.89, 37.39) | (0, 18.00, 294.75) | (131.20, 149.38, 178.69) |

| (0, 8.89, 43.50) | (0, 16.00, 482.25) | (131.19, 149.37, 178.67) | |

| (0, 14.58, 42.08) | (0, 42.00, 437.75) | (131.16, 149.33, 178.63) | |

| (0, 14.58, 42.08) | (0, 46.00, 447.75) | (131.11, 149.28, 178.56) | |

| 0.7 | (0, 8.89, 27.39) | (0.04, 18.00, 138.75) | (138.47, 149.38, 166.96) |

| (0, 8.89, 32.15) | (0, 16.00, 212.41) | (138.46, 149.37, 166.95) | |

| (0, 8.89, 34.30) | (0.18, 20, 264.29) | (138.41, 149.31, 166.89) | |

| (0, 14.58, 32.52) | (3.38, 46.00, 233.35) | (138.38, 149.28, 166.85) | |

| (0, 14.58, 34.65) | (1.37, 50, 278.93) | (138.36, 149.26, 166.82) | |

| 1 | 8.89 | 16.00 | 149.37 |

| 8.89 | 20.00 | 149.31 | |

| 14.58 | 44.00 | 149.27 | |

| 14.58 | 50.00 | 149.26 |

| Task | Description | h | K | TPO | S | |

|---|---|---|---|---|---|---|

| 1 | Engine cover left bolt | (30,36,41) | 0 | L | 2 | 3 |

| 2 | Engine cover right bolt | (30,36,41) | 0 | R | 1 | 3 |

| 3 | Engine cover | (22,30,36) | 0 | E | 5,7 | |

| 4 | Air bag | (160,185,200) | 1 | L | ||

| 5 | Battery | (66,73,85) | 0.8 | R | 6 | |

| 6 | Waste fluid | (151,162,190) | 0.5 | E | ||

| 7 | Waste oil | (200,225,252) | 0.7 | E | ||

| 8 | Left wheels | (112,128,136) | 0 | L | 10 | |

| 9 | Right wheels | (112,128,136) | 0 | R | 11 | |

| 10 | Left fender | (50,56,65) | 0 | L | 12 | |

| 11 | Right fender | (50,56,65) | 0 | R | 13 | |

| 12 | Left front bumper | (42,49,57) | 0 | L | 13 | 14 |

| 13 | Right front bumper | (42,49,57) | 0 | R | 12 | 14 |

| 14 | Front bumper | (30,34,41) | 0 | E | 15,16,17 | |

| 15 | Air intake grille | (41,46,53) | 0 | E | 26,27,28,29 | |

| 16 | Left mirrors and lamps | (55,70,79) | 0 | L | ||

| 17 | Right mirrors and lamps | (55,70,79) | 0 | R | ||

| 18 | Left door | (107,127,139) | 0 | L | 37 | |

| 19 | Right door | (87,97,109) | 0 | R | 38 | |

| 20 | Left trunk cover hinge | (22,25,30) | 0 | L | 21 | 22 |

| 21 | Right trunk cover hinge | (22,25,30) | 0 | R | 20 | 22 |

| 22 | Trunk cover | (31,36,42) | 0 | E | ||

| 23 | Left behind bumper | (55,61,72) | 0 | L | 24 | 25 |

| 24 | Right behind bumper | (55,61,72) | 0 | R | 23 | 25 |

| 25 | Behind bumper | (23,26,35) | 0 | E | 16,17 | |

| 26 | Radiator | (90,97,110) | 0 | E | 56 | |

| 27 | Condenser | (101,106,121) | 0 | E | 56 | |

| 28 | Coolant tank | (103,112,127) | 0.3 | E | 56 | |

| 29 | Air cleaner | (57,63,70) | 0 | E | 56 | |

| 30 | Wiper | (47,51,59) | 0 | E | 33,36 | |

| 31 | Front glass left sealant | (60,67,75) | 0 | L | 32 | 33 |

| 32 | Front glass right sealant | (60,67,75) | 0 | R | 31 | 33 |

| 33 | Front glass | (32,39,46) | 0.3 | E | 41,44 | |

| 34 | Behind glass left sealant | (40,47,57) | 0 | L | 35 | 36 |

| 35 | Behind glass right sealant | (40,47,57) | 0 | R | 34 | 36 |

| 36 | Behind glass | (25,28,35) | 0.2 | E | ||

| 37 | Left seat | (201,225,246) | 0 | L | 39 | |

| 38 | Right seat | (200,216,235) | 0 | R | 39 | |

| 39 | Armrest box | (90,98,117) | 0 | E | 41 | |

| 40 | Fuel tank | (95,106,121) | 0.2 | R | ||

| 41 | Steering wheel | (120,132,150) | 0 | L | 45 | |

| 42 | Dashboard left bolt | (94,102,110) | 0 | L | 43 | 44 |

| 43 | Dashboard right bolt | (69,75,86) | 0 | R | 42 | 44 |

| 44 | Dashboard | (70,75,85) | 0 | E | 45 | |

| 45 | Instrument | (87,98,110) | 0 | L | 48 | |

| 46 | Shift handle | (105,121,139) | 0 | E | 47 | |

| 47 | Brake rigging | (70,78,88) | 0 | L | 48 | |

| 48 | Clutch pedal | (59,65,78) | 0 | L | 49 | |

| 49 | Accelerator pedal | (55,60,72) | 0 | L | 61 | |

| 50 | Air conditioner | (125,138,153) | 0 | E | 51 | |

| 51 | Carbon canister | (35,41,50) | 0.4 | E | 61,62 | |

| 52 | Bottom guard board | (56,61,77) | 0 | E | 53 | |

| 53 | Ternary catalysis | (101,120,136) | 0.7 | E | 54 | |

| 54 | Exhaust pipe | (104,118,127) | 0.5 | E | 55 | |

| 55 | Transmission shaft | (230,258,280) | 0 | E | 56 | |

| 56 | Electric generator | (124,135,154) | 0 | E | 57 | |

| 57 | Engine | (450,475,499) | 0 | E | 58 | |

| 58 | Transmission | (207,228,244) | 0 | E | 59 | |

| 59 | Front suspension | (221,239,256) | 0 | E | 60 | |

| 60 | Behind suspension | (229,248,268) | 0 | E | 61,62 | |

| 61 | Left body accessories | (129,138,152) | 0.1 | L | ||

| 62 | Right body accessories | (100,117,131) | 0.1 | R |

| Source | Type III Sum of Squares | df | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|

| Corrected Model | 337312.773 a | 18 | 18739.598 | 4.341 | 7.45 × 10−6 |

| Intercept | 10307942906.242 | 1 | 10307942906 | 2388057.884 | 7.05 × 10−145 |

| n | 78530.084 | 2 | 39265.042 | 9.097 | 3.43 × 10−4 |

| s | 48637.008 | 2 | 24318.504 | 5.634 | 0.006 |

| p | 17303.642 | 2 | 8651.821 | 2.004 | 0.143 |

| n ·s | 130419.706 | 4 | 65209.854 | 15.107 | 0.002 |

| n ·p | 28153.932 | 4 | 14076.966 | 3.261 | 0.435 |

| s ·p | 34268.4 | 4 | 17134.199 | 3.969 | 0.292 |

| Error | 267620.171 | 62 | 4316.454 | ||

| Total | 10308547839 | 81 | |||

| Corrected Total | 604932.944 | 80 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, J.; Guo, S.; Zhang, Y.; Liu, W.; Zhou, S. Energy-Efficient Optimization of Two-Sided Disassembly Line Balance Considering Parallel Operation and Uncertain Using Multiobjective Flatworm Algorithm. Sustainability 2021, 13, 3358. https://doi.org/10.3390/su13063358

Liang J, Guo S, Zhang Y, Liu W, Zhou S. Energy-Efficient Optimization of Two-Sided Disassembly Line Balance Considering Parallel Operation and Uncertain Using Multiobjective Flatworm Algorithm. Sustainability. 2021; 13(6):3358. https://doi.org/10.3390/su13063358

Chicago/Turabian StyleLiang, Junyong, Shunsheng Guo, Yunfei Zhang, Wenfang Liu, and Shengwen Zhou. 2021. "Energy-Efficient Optimization of Two-Sided Disassembly Line Balance Considering Parallel Operation and Uncertain Using Multiobjective Flatworm Algorithm" Sustainability 13, no. 6: 3358. https://doi.org/10.3390/su13063358

APA StyleLiang, J., Guo, S., Zhang, Y., Liu, W., & Zhou, S. (2021). Energy-Efficient Optimization of Two-Sided Disassembly Line Balance Considering Parallel Operation and Uncertain Using Multiobjective Flatworm Algorithm. Sustainability, 13(6), 3358. https://doi.org/10.3390/su13063358