FoodSQRBlock: Digitizing Food Production and the Supply Chain with Blockchain and QR Code in the Cloud

Abstract

:1. Introduction

- We propose FoodSQRBlock, a BT and QR code based framework to digitise food production information and retrieval;

- A large-scale integration of FoodSQRBlock in the cloud and related experimental evaluational in the Google Cloud Platform.;

- The analysis and limitations of the large-scale integration of FoodSQRBlock in the cloud.

2. Preliminaries

2.1. Blockchain Technology

- Public: In this network, everyone can check and verify the transaction made. The network is also open to anyone who wants to participate in the consensus process.

- Private: In this type of network, strict restrictions are applied on data access, and the nodes (user/entity) have restricted access to specific block chains, which are monitored by a governing body.

- Consortium: Nodes in this type of network can form a partnership with businesses or other authorities. This type of network may be public or private, and hence, this could be seen as a hybrid approach as it is partly decentralized.

- Decentralized: Blockchain data can be recorded, stored, updated and distributed without dependence on a central authority or node.

- Transparency: Data recorded and stored are transparent and visible, therefore leveraging trust among its users.

- Open source: The source code, as well as most of the blockchain dependent systems are open to view, free to use and provide the ease of extension to other applications.

- Autonomous: Blockchain updates are consensus based, and thus, data can be updated securely from a single user to the whole system. This feature provides autonomy to the system to update data securely.

- Immutability: All data in the blockchain are reserved forever.

- Anonymity: Blockchain also provides anonymity to its users and makes the system more trustworthy by only using the users’ blockchain addresses instead of their personal information.

2.2. QR Code

2.3. Cloud Computing

- On-demand self-service: For cloud computing, capabilities can be provided automatically when needed, without requiring any human interaction between the consumer and the service provider.

- Broad network access: In this type of service, computing capabilities are available over the network and accessible through several mechanisms disposable for a wide range of consumer platforms such as workstations, laptops and smartphones.

- Resource pooling: In the cloud, computing resources are pooled to accommodate multiple consumers, hence dynamically allocating and deallocating them according to the consumers’ demand. Moreover, the provider resources are location independent, i.e., the consumer does not have any knowledge or control of their exact location.

- Rapid elasticity: In the cloud, the computing capabilities can be provided flexibly and released to scale in and out according to the consumer’s demand. Therefore, the consumer has the perception of unlimited, and always adequate, computing capabilities.

- Measured service: In the cloud, resource usage can be monitored and reported according to the type of service being offered. This is particularly relevant in pay-per-use or pay-per-user services because it grants great transparency between the provider and the consumer of such services.

3. Related Work

- Improving the storage capacity of blockchain data while not increasing the computational power requirement.

- Making the BT based food production framework more accessible to consumers such that the food items can be verified easily at any point in the supply chain.

4. Proposed Framework: FoodSQRBlock

- Production: This is the primary production phase, which represents all the activities related to agriculture within the farm.

- Processing: In this phase, harvesting the produce and turning it into products are performed. The preparation and packaging of the produce is also performed in this phase, where each package is uniquely identified trough a production batch code.

- Distribution: In this phase, once the product is packaged and labelled, it is released for distribution to different warehouses and other distribution centres for product storage.

- Retailing: In this phase, the products are delivered to the retailers, who sell the products to the consumers, from the distribution centres.

- Consumption: The consumer is the end user of the food supply chain, where she/he buys the product, requires the quality standards verifying the traceability and accesses other relevant data about the product such as the expiry date.

- Physical layer: This layers consists of different food products from different farmers and producers within the supply chain.

- Digital data layer: This layer includes are digital data associated with the produce belonging to the physical layer, which will be used for traceability and accessibility. One example of the data of the produce could be the expiry date of the food product.

- Cloud layer: In this layer, the digital data are processed in the cloud using BT, which is used for traceability and accessibility.

5. Experimental Evaluation: Case Study and Large-Scale Integration of FoodSQRBlock

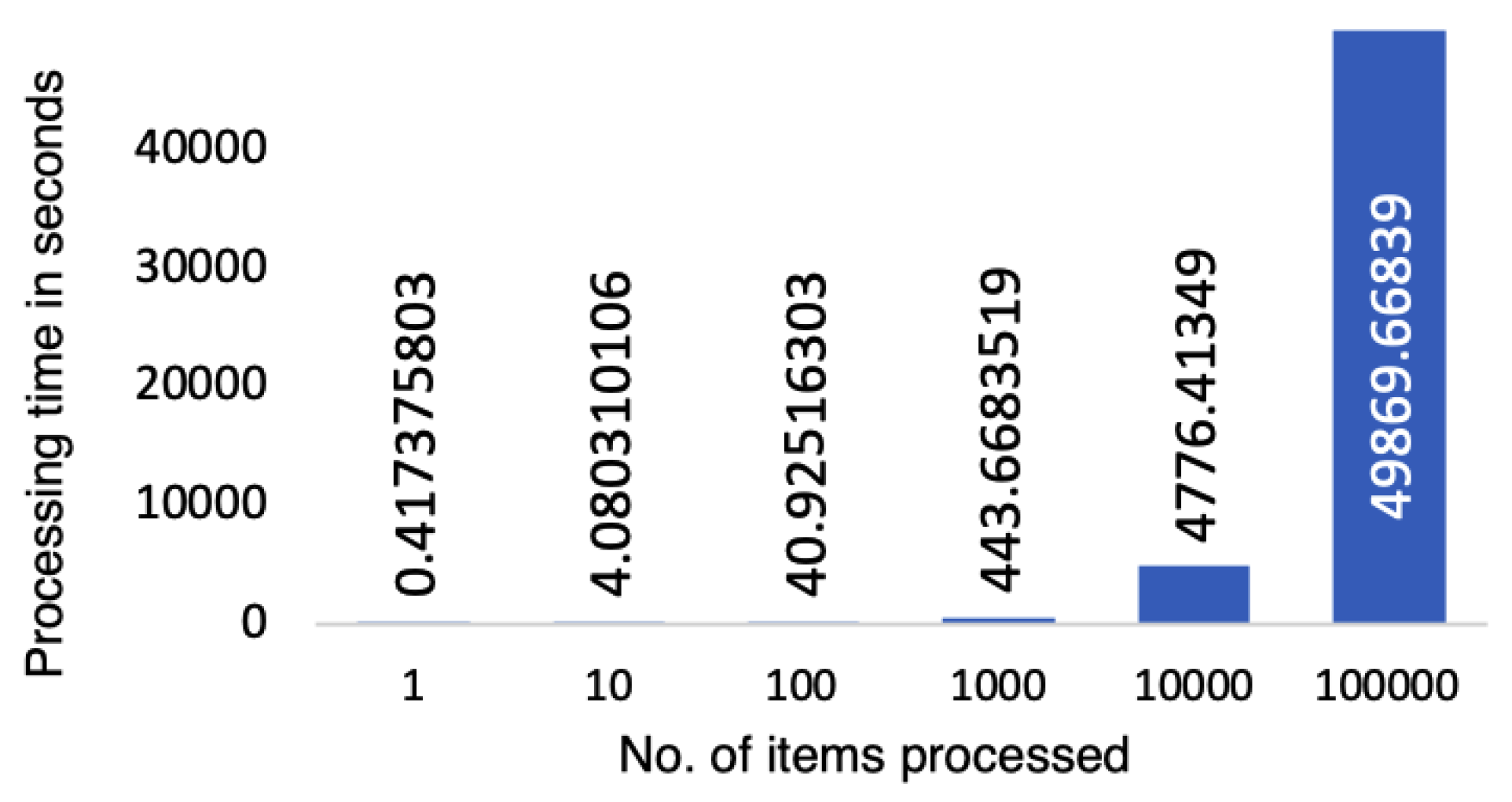

5.1. Experimental Evaluation

5.2. Analysis and Discussion

6. Conclusions

7. Code Availability

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yiannas, F. A new era of food transparency powered by blockchain. Innov. Technol. Gov. Glob. 2018, 12, 46–56. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, S.; Lopez, C.; Lu, H.; Elgueta, S.; Chen, H.; Boshkoska, B.M. Blockchain technology in agri-food value chain management: A synthesis of applications, challenges and future research directions. Comput. Ind. 2019, 109, 83–99. [Google Scholar] [CrossRef]

- Tian, F. An agri-food supply chain traceability system for China based on RFID & blockchain technology. In Proceedings of the 2016 13th International Conference on Service Systems and Service Management (ICSSSM), Kunming, China, 24–26 June 2016; pp. 1–6. [Google Scholar]

- General Food Law. Available online: https://ec.europa.eu/food/safety/general_food_law_en (accessed on 26 June 2020).

- Food Safety Modernization Act (FSMA). Available online: https://www.fda.gov/food/guidance-regulation-food-and-dietary-supplements/food-safety-modernization-act-fsma (accessed on 26 June 2020).

- Dey, S. A Proof of Work: Securing Majority-Attack in Blockchain Using Machine Learning and Algorithmic Game Theory. Int. J. Wirel. Microw. Technol. 2018, 8, 1–9. [Google Scholar] [CrossRef]

- Dey, S. Securing majority-attack in blockchain using machine learning and algorithmic game theory: A proof of work. In Proceedings of the 2018 10th Computer Science and Electronic Engineering (CEEC), Colchester, UK, 19–21 September 2018; pp. 7–10. [Google Scholar]

- Astill, J.; Dara, R.A.; Campbell, M.; Farber, J.M.; Fraser, E.D.; Sharif, S.; Yada, R.Y. Transparency in food supply chains: A review of enabling technology solutions. Trends Food Sci. Technol. 2019, 91, 240–247. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Sharma, R. Modeling the blockchain enabled traceability in agriculture supply chain. Int. J. Inf. Manag. 2020, 52, 101967. [Google Scholar] [CrossRef]

- Teach ICT—Barcodes. Available online: https://biturl.top/QJzuYz (accessed on 7 July 2020).

- Drobnik, O. Barcodes with iOS: Bringing Together the Digital and Physical Worlds; Manning: Shelter Island, NY, USA, 2015. [Google Scholar]

- UPC 704660784002 Lookup. Available online: https://www.barcodespider.com/704660784002 (accessed on 7 July 2020).

- nosh—Food Stock Management. Available online: https://nosh.tech (accessed on 7 July 2020).

- NoWaste—Food Inventory List. Available online: https://www.nowasteapp.com (accessed on 7 July 2020).

- Blockchain Is Useful for a Lot More than Bitcoin. Available online: http://theconversation.com/blockchain-is-useful-fora-lot-more-than-just-bitcoin-58921 (accessed on 7 July 2020).

- How Could Blockchain Be Used in the Enterprise. Available online: https://www.computerworlduk.com/galleries/security/how-could-blockchain-be-used-the-enterprise3628558/ (accessed on 7 July 2020).

- Dey, S.; Mondal, K.; Nath, J.; Nath, A. Advanced Steganography Algorithm Using Randomized Intermediate QR Host Embedded With Any Encrypted Secret Message: ASA_QR Algorithm. Int. J. Mod. Educ. Comput. Sci. 2012, 4, 59. [Google Scholar] [CrossRef] [Green Version]

- Huang, P.C.; Chang, C.C.; Li, Y.H.; Liu, Y. Efficient QR code secret embedding mechanism based on Hamming code. IEEE Access 2020, 8, 86706–86714. [Google Scholar] [CrossRef]

- Dey, S. Sd-eqr: A new technique to use qr codestm in cryptography. arXiv 2012, arXiv:1205.4829. [Google Scholar]

- Dey, S.; Agarwal, S.; Nath, A. Confidential encrypted data hiding and retrieval using qr authentication system. In Proceedings of the 2013 International Conference on Communication Systems and Network Technologies, Gwalior, India, 6–8 April 2013; pp. 512–517. [Google Scholar]

- Dey, A.S.; Nath, B.J.; Nath, C.A. A New Technique to Hide Encrypted Data in QR Codes (TM). In Proceedings of the International Conference on Internet Computing (ICOMP), Las Vegas, NV, USA, 16–19 July 2012; p. 1. [Google Scholar]

- Lin, P.Y. Distributed secret sharing approach with cheater prevention based on QR code. IEEE Trans. Ind. Inform. 2016, 12, 384–392. [Google Scholar] [CrossRef]

- Dey, S. New generation of digital academic-transcripts using encrypted QR code™: Use of encrypted QR code™ in mark-sheets (academic transcripts). In Proceedings of the 2013 International Mutli-Conference on Automation, Computing, Communication, Control and Compressed Sensing (iMac4s), Kottayam, India, 22–23 March 2013; pp. 313–317. [Google Scholar]

- De Donno, M.; Tange, K.; Dragoni, N. Foundations and evolution of modern computing paradigms: Cloud, iot, edge, and fog. IEEE Access 2019, 7, 150936–150948. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F. A smart manufacturing service system based on edge computing, fog computing, and cloud computing. IEEE Access 2019, 7, 86769–86777. [Google Scholar] [CrossRef]

- Bohn, R.B.; Messina, J.; Liu, F.; Tong, J.; Mao, J. NIST cloud computing reference architecture. In Proceedings of the 2011 IEEE World Congress on Services, Washington, DC, USA, 4–9 July 2011; pp. 594–596. [Google Scholar]

- Ali, A.Q.; Sultan, A.B.M.; Abd Ghani, A.A.; Zulzalil, H. A Systematic Mapping Study on the Customization Solutions of Software as a Service Applications. IEEE Access 2019, 7, 88196–88217. [Google Scholar] [CrossRef]

- Li, D.; Kehoe, D.; Drake, P. Dynamic planning with a wireless product identification technology in food supply chains. Int. J. Adv. Manuf. Technol. 2006, 30, 938–944. [Google Scholar] [CrossRef]

- Foroglou, G.; Tsilidou, A.L. Further applications of the blockchain. In Proceedings of the 12th Student Conference on Managerial Science and Technology, Athens, Greece, 14 May 2015; pp. 1–8. [Google Scholar]

- Bogner, A.; Chanson, M.; Meeuw, A. A decentralised sharing app running a smart contract on the ethereum blockchain. In Proceedings of the 6th International Conference on the Internet of Things, Stuttgart, Germany, 7–9 November 2016; pp. 177–178. [Google Scholar]

- Kumar, R.; Tripathi, R. Traceability of counterfeit medicine supply chain through Blockchain. In Proceedings of the 2019 11th International Conference on Communication Systems & Networks (COMSNETS), Bengaluru, India, 7–11 January 2019; pp. 568–570. [Google Scholar]

- Baralla, G. Ensure traceability in European food supply chain by using a blockchain system. In Proceedings of the 2019 IEEE/ACM 2nd International Workshop on Emerging Trends in Software Engineering for Blockchain (WETSEB), Montreal, QC, Canada, 27 May 2019. [Google Scholar]

- Irving, G.; Holden, J. How blockchain-timestamped protocols could improve the trustworthiness of medical science. F1000Research 2016, 5, 222. [Google Scholar] [CrossRef] [PubMed]

- Krishnan, S.; Gonzalez, J.L.U. Building Your Next Big Thing with Google Cloud Platform: A Guide for Developers and Enterprise Architects; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dey, S.; Saha, S.; Singh, A.K.; McDonald-Maier, K. FoodSQRBlock: Digitizing Food Production and the Supply Chain with Blockchain and QR Code in the Cloud. Sustainability 2021, 13, 3486. https://doi.org/10.3390/su13063486

Dey S, Saha S, Singh AK, McDonald-Maier K. FoodSQRBlock: Digitizing Food Production and the Supply Chain with Blockchain and QR Code in the Cloud. Sustainability. 2021; 13(6):3486. https://doi.org/10.3390/su13063486

Chicago/Turabian StyleDey, Somdip, Suman Saha, Amit Kumar Singh, and Klaus McDonald-Maier. 2021. "FoodSQRBlock: Digitizing Food Production and the Supply Chain with Blockchain and QR Code in the Cloud" Sustainability 13, no. 6: 3486. https://doi.org/10.3390/su13063486