A Comprehensive Approach to the Design of a Renewable Energy Microgrid for Rural Ethiopia: The Technical and Social Perspectives

Abstract

- We employed renewable energy sources to design a microgrid for rural Ethiopia.

- We formulated a realistic energy demand plan based on social data.

- Crop security can be achieved under typical climatic conditions.

- The microgrid could enhance food and health security in the region.

- A sociological analysis reveals a positive local consensus toward the design.

1. Introduction

2. Data and Study Area

2.1. Study Domain: The Koga Irrigation Project

2.2. Meteorological Data

2.3. Groundwater and Crop Yield

3. Models and Methods

3.1. Estimation of Electricity Demand and Irrigation Water Needs

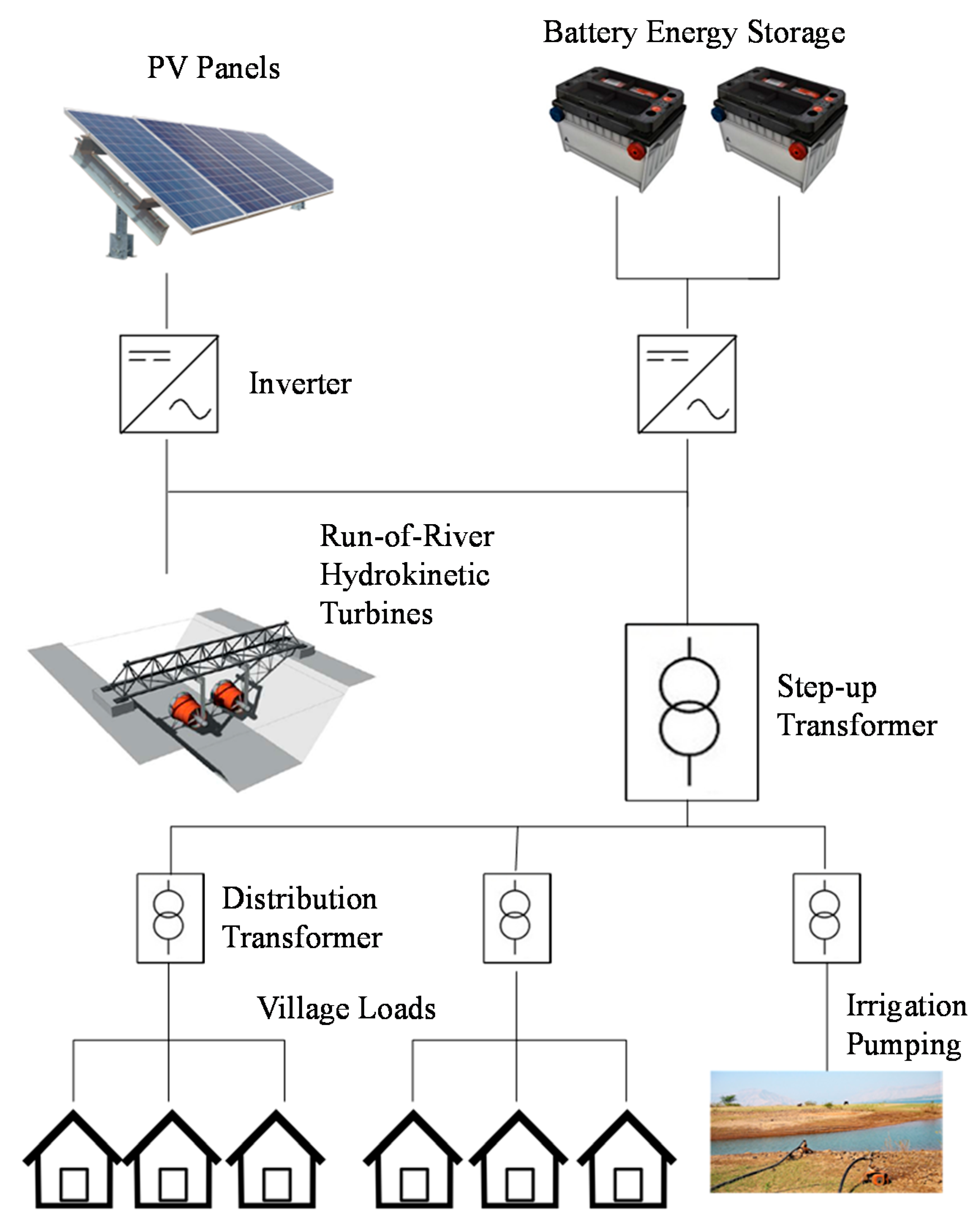

3.2. Microgrid Design and Capital Cost

3.3. Social Impact Assessment

4. Results

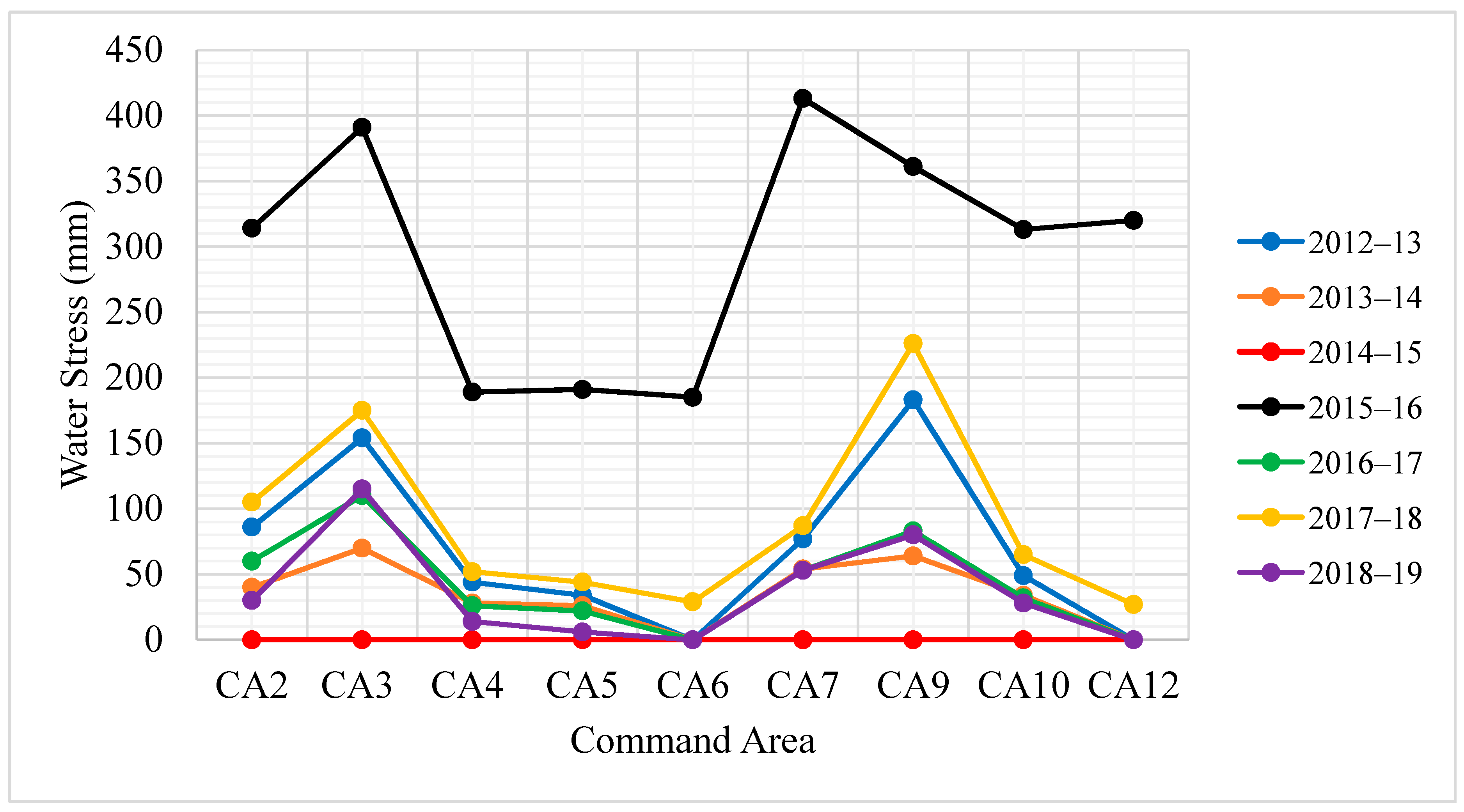

4.1. Crop Water Stress and Supplemental Irrigation

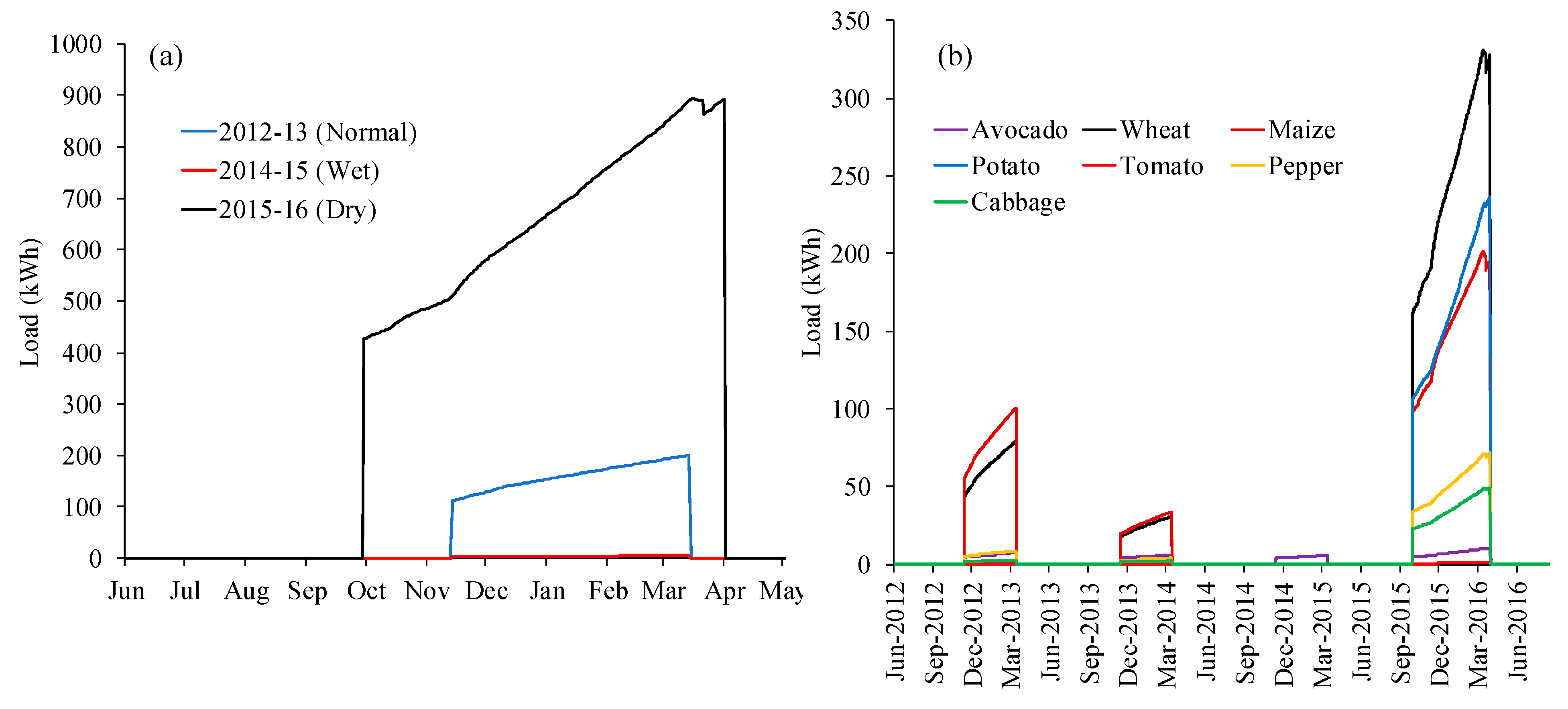

4.2. Electricity Demand

4.3. The Microgrid

4.4. Social and Economic Effects

4.5. Implementation and Interactions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mohtar, R.H.; Daher, B. Water, Energy, and Food: The Ultimate Nexus. In Encyclopedia of Agricultural, Food, and Biological Engineering, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2010; pp. 1–5. [Google Scholar] [CrossRef]

- Markantonis, V.; Reynaud, A.; Karabulut, A.; El Hajj, R.; Altinbilek, D.; Awad, I.M.; Bruggeman, A.; Constantianos, V.; Mysiak, J.; Lamaddalena, N.; et al. Can the Implementation of the Water-Energy-Food Nexus Support Economic Growth in the Mediterranean Region? The Current Status and the Way Forward. Front. Environ. Sci. 2019, 7, 84. [Google Scholar] [CrossRef]

- de Fraiture, C.; Wichelns, D. Satisfying future water demands for agriculture. Agric. Water Manag. 2010, 97, 502–511. [Google Scholar] [CrossRef]

- Hoekstra, A.Y.; Mekonnen, M.M. The water footprint of humanity. Proc. Natl. Acad. Sci. USA 2012, 109, 3232–3237. [Google Scholar] [CrossRef]

- Hoekstra, A.Y.; Wiedmann, T.O. Humanity’s unsustainable environmental footprint. Science 2014, 344, 1114–1117. [Google Scholar] [CrossRef] [PubMed]

- Rockström, J.; Falkenmark, M.; Karlberg, L.; Hoff, H.; Rost, S.; Gerten, D. Future water availability for global food production: The potential of green water for increasing resilience to global change. Water Resour. Res. 2009, 45. [Google Scholar] [CrossRef]

- Rosegrant, M.W.; Ringler, C.; Zhu, T. Water for Agriculture: Maintaining Food Security under Growing Scarcity. Annu. Rev. Environ. Resour. 2009, 34, 205–222. [Google Scholar] [CrossRef]

- Tarrass, F.; Benjelloun, M. The effects of water shortages on health and human development. Perspect. Public Health 2011, 132, 240–244. [Google Scholar] [CrossRef]

- Matson, P.A.; Parton, W.J.; Power, A.G.; Swift, M.J. Agricultural Intensification and Ecosystem Properties. Science 1997, 277, 504–509. [Google Scholar] [CrossRef] [PubMed]

- Pellegrini, P.; Fernández, R.J. Crop intensification, land use, and on-farm energy-use efficiency during the worldwide spread of the green revolution. Proc. Natl. Acad. Sci. USA 2018, 115, 2335–2340. [Google Scholar] [CrossRef]

- Kebebe, E. Bridging technology adoption gaps in livestock sector in Ethiopia: A innovation system perspective. Technol. Soc. 2019, 57, 30–37. [Google Scholar] [CrossRef]

- Thornton, P.K. Livestock production: Recent trends, future prospects. Philos. Trans. R. Soc. B Biol. Sci. 2010, 365, 2853–2867. [Google Scholar] [CrossRef]

- Noureldeen Mohamed, N. Water Energy Food Nexus. In Energy in Agriculture under Climate Change; SpringerBriefs in Climate Studies; Springer: Cham, Switzerland, 2020; pp. 47–59. [Google Scholar] [CrossRef]

- Pelletier, N.; Audsley, E.; Brodt, S.; Garnett, T.; Henriksson, P.; Kendall, A.; Kramer, K.J.; Murphy, D.; Nemecek, T.; Troell, M. Energy Intensity of Agriculture and Food Systems. Annu. Rev. Environ. Resour. 2011, 36, 223–246. [Google Scholar] [CrossRef]

- Chen, X.; Thorp, K.R.; Ouyang, Z.; Hou, Y.; Zhou, B.; Li, Y. Energy consumption due to groundwater pumping for irrigation in the North China Plain. Sci. Total Environ. 2019, 669, 1033–1042. [Google Scholar] [CrossRef]

- Soto-García, M.; Martin-Gorriz, B.; García-Bastida, P.; Alcon, F.; Martínez-Alvarez, V. Energy consumption for crop irrigation in a semiarid climate (south-eastern Spain). Energy 2013, 55, 1084–1093. [Google Scholar] [CrossRef]

- Amjath-Babu, T.; Krupnik, T.J.; Kaechele, H.; Aravindakshan, S.; Sietz, D. Transitioning to groundwater irrigated intensified agriculture in Sub-Saharan Africa: An indicator based assessment. Agric. Water Manag. 2016, 168, 125–135. [Google Scholar] [CrossRef]

- Villholth, K.G. Groundwater irrigation for smallholders in Sub-Saharan Africa—A synthesis of current knowledge to guide sustainable outcomes. Water Int. 2013, 38, 369–391. [Google Scholar] [CrossRef]

- Scott, C.A. Electricity for groundwater use: Constraints and opportunities for adaptive response to climate change. Environ. Res. Lett. 2013, 8, 035005. [Google Scholar] [CrossRef]

- Mulugetta, Y. Energy in Rural Ethiopia: Consumption Patterns, Associated Problems, and Prospects for a Sustainable Energy Strategy. Energy Sources 1999, 21, 527–539. [Google Scholar] [CrossRef]

- Koizumi, T. Biofuels and food security. Renew. Sustain. Energy Rev. 2015, 52, 829–841. [Google Scholar] [CrossRef]

- Mehdi, B.J.; Slim, B.Y. The role of renewable energy and agriculture in reducing CO2 emissions: Evidence for North Africa countries. Ecol. Indic. 2017, 74, 295–301. [Google Scholar] [CrossRef]

- Singh, A.K.; Poonia, S.; Santra, P.; Jain, D. Ensuring Energy and Food Security through Solar Energy Utilization. In Contemporary Environmental Issues and Challenges in Era of Climate Change; Springer: Singapore, 2020; pp. 199–218. [Google Scholar] [CrossRef]

- United Nations. Sustainable Development Goals: Goal 7. Department of Economic and Social Affais, Sustainable Development. 2021. Available online: https://sdgs.un.org/goals/goal7 (accessed on 16 March 2021).

- Alves, M.; Segurado, R.; Costa, M. On the road to 100% renewable energy systems in isolated islands. Energy 2020, 198, 117321. [Google Scholar] [CrossRef]

- Francois, B.; Borga, M.; Creutin, J.; Hingray, B.; Raynaud, D.; Sauterleute, J. Complementarity between solar and hydro power: Sensitivity study to climate characteristics in Northern-Italy. Renew. Energy 2016, 86, 543–553. [Google Scholar] [CrossRef]

- Schmidt, J.; Cancella, R.; Pereira, A.O. An optimal mix of solar PV, wind and hydro power for a low-carbon electricity supply in Brazil. Renew. Energy 2016, 85, 137–147. [Google Scholar] [CrossRef]

- Erbato, T.T.; Hartkopf, T. Smarter Micro Grid for energy solution to rural Ethiopia. In Proceedings of the 2012 IEEE PES Innovative Smart Grid Technologies (ISGT), Washington, DC, USA, 16–20 January 2012. [Google Scholar] [CrossRef]

- Fodhil, F.; Hamidat, A.; Nadjemi, O. Potential, optimization and sensitivity analysis of photovoltaic-diesel-battery hybrid energy system for rural electrification in Algeria. Energy 2019, 169, 613–624. [Google Scholar] [CrossRef]

- Maleki, A.; Pourfayaz, F.; Rosen, M.A. A novel framework for optimal design of hybrid renewable energy-based autonomous energy systems: A case study for Namin, Iran. Energy 2016, 98, 168–180. [Google Scholar] [CrossRef]

- Brandoni, C.; Bošnjaković, B. HOMER analysis of the water and renewable energy nexus for water-stressed urban areas in Sub-Saharan Africa. J. Clean. Prod. 2017, 155, 105–118. [Google Scholar] [CrossRef]

- Alvial-Palavicino, C.; Garrido-Echeverría, N.; Jiménez-Estévez, G.; Reyes, L.; Palma-Behnke, R. A methodology for community engagement in the introduction of renewable based smart microgrid. Energy Sustain. Dev. 2011, 15, 314–323. [Google Scholar] [CrossRef]

- Jimenez-Estevez, G.A.; Palma-Behnke, R.; Ortiz-Villalba, D.; Mata, O.N.; Montes, C.S. It Takes a Village: Social SCADA and Approaches to Community Engagement in Isolated Microgrids. IEEE Power Energy Mag. 2014, 12, 60–69. [Google Scholar] [CrossRef]

- Rahmann, C.; Núñez, O.; Valencia, F.; Arrechea, S.; Sager, J.; Kammen, D. Methodology for Monitoring Sustainable Development of Isolated Microgrids in Rural Communities. Sustainability 2016, 8, 1163. [Google Scholar] [CrossRef]

- Power Africa. Off-Grid Solar Market Assessment; US Agency of International Development (USAID): Washington, DC, USA, 2019; pp. 1–47.

- Food and Agriculture Organization. Ethiopia at a Glance. FAO in Ethiopia. 2020. Available online: http://www.fao.org/ethiopia/fao-in-ethiopia/ethiopia-at-a-glance/en/ (accessed on 20 May 2020).

- Lewis, K. Understanding climate as a driver of food insecurity in Ethiopia. Clim. Chang. 2017, 144, 317–328. [Google Scholar] [CrossRef]

- Ethiopia Ministry of Water for Irrigation and Electricity. Second Growth and Transformation National Plan for the Water Supply and Sanitation Sub-Sector; Ethiopia Ministry of Water for Irrigation and Electricity: Addis Ababa, Ethiopia, 2015; pp. 1–4.

- Falchetta, G.; Pachauri, S.; Parkinson, S.; Byers, E. A high-resolution gridded dataset to assess electrification in sub-Saharan Africa. Sci. Data 2019, 6, 110. [Google Scholar] [CrossRef]

- Fereres, E.; Orgaz, F.; Gonzalez-Dugo, V. Reflections on food security under water scarcity. J. Exp. Bot. 2011, 62, 4079–4086. [Google Scholar] [CrossRef] [PubMed]

- Ethiopia National Planning Commission. Growth and Transformation Plan (GTP II), 2015/16—2019/20; Ethiopia National Planning Commission: Addis Ababa, Ethiopia, 2016; Volume 1, pp. 1–2.

- Hirmer, S.; Guthrie, P. The benefits of energy appliances in the off-grid energy sector based on seven off-grid initiatives in rural Uganda. Renew. Sustain. Energy Rev. 2017, 79, 924–934. [Google Scholar] [CrossRef]

- Karekezi, S.; Kithyoma, W. Renewable energy strategies for rural Africa: Is a PV-led renewable energy strategy the right approach for providing modern energy to the rural poor of sub-Saharan Africa? Energy Policy 2002, 30, 1071–1086. [Google Scholar] [CrossRef]

- DANAS Electrical Engineering. Electric Enjera Mitad: Energy Efficiency Standards and Labeling. Available online: https://www.viennaenergyforum.org/sites/default/files/documents/Development%20of%20Energy%20efficint%20local%20bread%20making%20%20MITAD%20Ehiopia%20Getahun%20Moges.pdf (accessed on 1 April 2021).

- Barnes, D.; Golumbeanu, R.; Diaw, I. Beyond Electricity Access: Output-Based Aid and Rural Electrification in Ethiopia; World Bank: Washington, DC, USA, 2016; pp. 1–118. [Google Scholar]

- Lam, N.L.; Smith, K.R.; Gauthier, A.; Bates, M.N. Kerosene: A Review of Household Uses and their Hazards in Low- and Middle-Income Countries. J. Toxicol. Environ. Health Part B 2012, 15, 396–432. [Google Scholar] [CrossRef] [PubMed]

- Khandker, S.R.; Barnes, D.F.; Samad, H. Welfare Impacts of Rural Electrification: Evidence from Vietnam; World Bank: Washington, DC, USA, 2009. [Google Scholar]

- Gillard, R.; Oates, L.; Kasaija, P.; Sudmant, A.; Gouldson, A. Sustainable Urban Infrastructure for All: Lessons on Solar Powered Streetlights from Kampala and Jinja, Uganda; Coalition for Urban Transitions: Washing, DC, USA; London, UK, 2019; pp. 1–20. [Google Scholar]

- MacDonald, M. Koga Irrigation Scheme Manual: Operation and Maintenance. Part A: General Procedures. Volume I; Ministry of Water Resources: Addis Ababa, Ethiopia, 2008.

- Lijalem, G.A. Irrigation Performance Evaluation Using GIS and Remote Sensing, Case of Koga Irrigation Area, Upper Blue Nile Basin. Master’s Thesis, Bahir Dar University, Bahir Dar, Ethiopia, 2018. [Google Scholar]

- Muñoz Sabater, J. ERA5-Land Hourly Data from 1981 to Present. Copernicus Climate Change Service (C3S) Climate Data Store (CDS). 2019. Available online: https://doi.org/10.24381/cds.e2161bac (accessed on 12 July 2020).

- Wang, J.; Hong, Y.; Li, L.; Gourley, J.J.; Khan, S.I.; Yilmaz, K.K.; Adler, R.F.; Policelli, F.S.; Habib, S.; Irwn, D.; et al. The coupled routing and excess storage (CREST) distributed hydrological model. Hydrol. Sci. J. 2011, 56, 84–98. [Google Scholar] [CrossRef]

- Reynolds, B. Variability and Change in Koga Reservoir Volume, Blue Nile, Ethiopia; Uppsala University: Uppsala, Sweden, 2013. [Google Scholar]

- Khadim, F.K.; Dokou, Z.; Bagtzoglou, A.C.; Yang, M.; Lijalem, G.A.; Anagnostou, E. A numerical framework to advance agricultural water management under hydrological stress conditions in a data scarce environment. Agric. Water Manag. 2021. (under review). [Google Scholar]

- Yang, M.; Wang, G.; Lazin, R.; Shen, X.; Anagnostou, E. Impact of planting time soil moisture on cereal crop yield in the Upper Blue Nile Basin: A novel insight towards agricultural water management. Agric. Water Manag. 2021, 243, 106430. [Google Scholar] [CrossRef]

- Jones, J.W.; Antle, J.M.; Basso, B.; Boote, K.J.; Conant, R.T.; Foster, I.; Godfray, H.C.J.; Herrero, M.; Howitt, R.E.; Janssen, S.; et al. Toward a new generation of agricultural system data, models, and knowledge products: State of agricultural systems science. Agric. Syst. 2017, 155, 269–288. [Google Scholar] [CrossRef]

- Jones, J.W.; Antle, J.M.; Basso, B.; Boote, K.J.; Conant, R.T.; Foster, I.; Godfray, H.C.J.; Herrero, M.; Howitt, R.E.; Janssen, S.; et al. Brief history of agricultural systems modeling. Agric. Syst. 2017, 155, 240–254. [Google Scholar] [CrossRef]

- Jones, J.W.; Hoogenboom, G.; Porter, C.H.; Boote, K.J.; Batchelor, W.D.; Hunt, L.A.; Wilkens, P.W.; Singh, U.; Gijsman, A.J.; Ritchie, J.T. The DSSAT cropping system model. Eur. J. Agron. 2003, 18, 235–265. [Google Scholar] [CrossRef]

- Yamazaki, D.; Ikeshima, D.; Tawatari, R.; Yamaguchi, T.; O’Loughlin, F.; Neal, J.C.; Sampson, C.C.; Kanae, S.; Bates, P.B. A high-accuracy map of global terrain elevations. Geophys. Res. Lett. 2017, 44, 5844–5853. [Google Scholar] [CrossRef]

- Hautot, S.; Whaler, K.; Gebru, W.; Desissa, M. The structure of a Mesozoic basin beneath the Lake Tana area, Ethiopia, revealed by magnetotelluric imaging. J. Afr. Earth Sci. 2006, 44, 331–338. [Google Scholar] [CrossRef]

- Kebede, S. Groundwater in Ethiopia: Features, Numbers and Opportunities; Springer Science & Business Media: Addis Ababa, Ethiopia, 2012; ISBN 978-3-642-30390-6. [Google Scholar] [CrossRef]

- Beck, H.E.; Van Dijk, A.I.J.M.; Levizzani, V.; Schellekens, J.; Miralles, D.G.; Martens, B.; De Roo, A. MSWEP: 3-hourly 0.25° global gridded precipitation (1979–2015) by merging gauge, satellite, and reanalysis data. Hydrol. Earth Syst. Sci. 2017, 21, 589–615. [Google Scholar] [CrossRef]

- Huffman, G.J.; Bolvin, D.T.; Braithwaite, D.; Hsu, K.L.; Joyce, R.J.; Kidd, C.; Nelkin, E.J.; Sorooshian, S.; Stocker, E.F.; Tan, J.; et al. Integrated Multi-satellite Retrievals for the Global Precipitation Measurement (GPM) Mission (IMERG). In Satellite Precipitation Measurement; Levizzani, V., Kidd, C., Kirschbaum, D., Kummerow, C., Nakamura, K., Turk, F., Eds.; Advances in Global Change Research; Springer: Cham, Switzerland, 2020; Volume 67, pp. 343–353. [Google Scholar] [CrossRef]

- Lazin, R.; Shen, X.; Koukoula, M.; Anagnostou, E. Evaluation of the Hyper-Resolution Model-Derived Water Cycle Components Over the Upper Blue Nile Basin. J. Hydrol. 2020, 590, 125231. [Google Scholar] [CrossRef]

- Dokou, Z.; Khadim, F.K.; Zhou, W.; Flamig, Z.; Moges, M.; Tilahun, S.; Azage, M.; Moges, S.; Li, B.; Mellor, J.; et al. Citizen Science at the Source of the Blue Nile: Promoting Public Participation in Science for Ensuring Food and Water Security in Ethiopia. 2019. Available online: https://pire.engr.uconn.edu/wp-content/uploads/sites/2414/2019/01/Poster_AGU2018_Dokou-FINAL.pdf (accessed on 1 April 2021).

- Koch, F.D. Avocado Grower’s Handbook, 1st ed.; Bonsall Publications: Bonsall, CA, USA, 1983; ISBN 0-9675198-0-2. [Google Scholar]

- CSA. Agricultural Sample Survey. Stat. Bull. 2016, 1, 1–111. [Google Scholar]

- Yang, M.; Wang, G.; Ahmed, K.F.; Adugna, B.; Eggen, M.; Atsbeha, E.; You, L.; Koo, J.; Anagnostou, E. The role of climate in the trend and variability of Ethiopia’s cereal crop yields. Sci. Total Environ. 2020, 723, 137893. [Google Scholar] [CrossRef]

- Niswonger, R.G.; Prudic, D.E.; Regan, R.S. Documentation of the unsaturated-zone flow (UZF1) package for modeling unsaturated flow between the land surface and the water table with MODFLOW-2005. In U.S. Geological Survey Techniques and Methods; USGS: Reston, VA, USA, 2006. [Google Scholar]

- Khadim, F.K.; Dokou, Z.; Lazin, R.; Moges, S.; Bagtzoglou, A.C.; Anagnostou, E. Groundwater modeling in data scarce aquifers: The case of Gilgel-Abay, Upper Blue Nile, Ethiopia. J. Hydrol. 2020, 590, 125214. [Google Scholar] [CrossRef]

- Bal, S.K.; Mukherjee, J.; Choudhury, B.U.; Dhawan, A.K. Advances in Crop Environment Interaction; Springer Nature Singapore Pte Ltd.: Singapore, 2018. [Google Scholar] [CrossRef]

- Lambert, T.; Gilman, P.; Lilienthal, P. Micropower system modeling with Homer. In Integration of Alternative Sources of Energy; Farret, F.A., Simões, M.G., Eds.; John Wiley & Sons: Hoboken, NJ, USA, December 2005; ISBN 0471712329. [Google Scholar]

- Bahramara, S.; Moghaddam, M.P.; Haghifam, M. Optimal planning of hybrid renewable energy systems using HOMER: A review. Renew. Sustain. Energy Rev. 2016, 62, 609–620. [Google Scholar] [CrossRef]

- Dawood, F.; Shafiullah, G.; Anda, M. Stand-Alone Microgrid with 100% Renewable Energy: A Case Study with Hybrid Solar PV-Battery-Hydrogen. Sustainability 2020, 12, 2047. [Google Scholar] [CrossRef]

- Ajayi, C.; Oyawale, F.; Afolalu, S.A. Optimization and Performance Evaluation of Blender-Hammer Mill. J. Phys. Conf. Ser. 2019, 1378, 032023. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 2nd ed.; Wiley: New York, NY, USA, 1991; ISBN 100471510564. [Google Scholar]

- Chow, V.T. Open-Channel Hydraulics; McGraw-Hill: New York, NY, USA, 1959; 680p, ISBN 9780070107762. [Google Scholar]

- Mondal, A.H.; Bryan, E.; Ringler, C.; Mekonnen, D.; Rosegrant, M. Ethiopian energy status and demand scenarios: Prospects to improve energy efficiency and mitigate GHG emissions. Energy 2018, 149, 161–172. [Google Scholar] [CrossRef]

- Borgstein, E.; Wade, K.; Mekonnen, D. Capturing the Productive Use Dividend: Valuing the Synergies between Rural Electrification and Smallholder Agriculture in Ethiopia; Rocky Mountain Institute: Basalt, CO, USA, 2020. [Google Scholar]

- Padam, G.; Rysankova, D.; Portale, E.; Koo, B.; Keller, S.; Fleurantin, G. Ethiopia beyond Connection: Energy Access Diagnostic Report Based on the Multi-Tier Framework; World Bank: Washington, DC, USA, 2018; pp. 1–64. [Google Scholar]

- Adem, K.D.; Ambie, D.A.; Arnavat, M.P.; Henriksen, U.B.; Ahrenfeldt, J.; Thomsen, T.P. First enjera baking biomass gasifier stove to reduce indoor air pollution, and fuel use. Aims Energy 2019, 7, 227–245. [Google Scholar] [CrossRef]

- Alemayehu, Y.A. Status and Benefits of Renewable Energy Technologies in the Rural Areas of Ethiopia: A Case Study on Improved Cooking Stoves and Biogas Technologies. Int. J. Renew. Energy Dev. 2015, 4, 103–111. [Google Scholar] [CrossRef]

- IEG (Independent Evaluation Group). The Welfare Impact of Rural Electrification: A Reassessment of the Costs and Benefits; Impact Evaluation Report; World Bank: Washington, DC, USA, 2008. [Google Scholar]

| List | Planned | Wheat | Maize | Potato | Cabbage | Tomato | Pepper | Avocado |

|---|---|---|---|---|---|---|---|---|

| CA1 | 329 | 184 | 1 | 136 | 2 | 1 | 3 | 4 |

| CA2 | 599 | 321 | 8 | 167 | 19 | 23 | 59 | 4 |

| CA3 | 696 | 594 | 22 | 34 | 20 | 1 | 16 | 9 |

| CA4 | 672 | 469 | 22 | 72 | 52 | 9 | 43 | 6 |

| CA5 | 598 | 264 | 35 | 207 | 38 | 11 | 38 | 6 |

| CA6 | 368 | 255 | 27 | 39 | 19 | 11 | 11 | 6 |

| CA7 | 477 | 315 | 18 | 95 | 24 | 4 | 16 | 6 |

| CA8 | 451 | 334 | 32 | 51 | 4 | 2 | 14 | 14 |

| CA9 | 258 | 173 | 48 | 13 | 7 | 4 | 12 | 3 |

| CA10 | 463 | 327 | 113 | 7 | 2 | 2 | 7 | 5 |

| CA11 | 787 | 473 | 95 | 194 | 2 | 7 | 13 | 4 |

| CA12 | 814 | 556 | 105 | 79 | 12 | 4 | 50 | 8 |

| Total | 6512 | 4265 | 523 | 1091 | 200 | 78 | 280 | 75 |

| Year | Mean (kWh/m2) | Standard Deviation (kWh/m2) | Coefficient of Variation |

|---|---|---|---|

| 2000 | 5.147 | 0.821 | 0.1595 |

| 2001 | 5.096 | 0.909 | 0.1785 |

| 2002 | 5.097 | 0.909 | 0.1784 |

| 2003 | 5.097 | 0.909 | 0.1784 |

| 2004 | 5.096 | 0.908 | 0.1782 |

| 2005 | 5.096 | 0.909 | 0.1785 |

| 2006 | 5.097 | 0.909 | 0.1784 |

| 2007 | 5.097 | 0.909 | 0.1784 |

| 2008 | 5.096 | 0.908 | 0.1782 |

| 2009 | 5.096 | 0.909 | 0.1785 |

| 2010 | 5.097 | 0.909 | 0.1784 |

| 2011 | 5.097 | 0.909 | 0.1784 |

| 2012 | 5.096 | 0.908 | 0.1782 |

| 2013 | 5.096 | 0.909 | 0.1785 |

| 2014 | 5.097 | 0.909 | 0.1784 |

| 2015 | 5.097 | 0.909 | 0.1784 |

| 2016 | 5.096 | 0.908 | 0.1782 |

| 2017 | 5.096 | 0.909 | 0.1785 |

| 2018 | 5.097 | 0.909 | 0.1784 |

| 2019 | 5.097 | 0.909 | 0.1784 |

| Base Load and Electric Stove | |||

|---|---|---|---|

| Outage Percentages | 5% | 8% | 10% |

| PV Panels (kW) | 446.0 | 379.0 | 372.0 |

| Tesla–BESS (Qty) | 5.0 | 4.0 | 4.0 |

| Converter (kW) | 225.0 | 218.0 | 205.0 |

| Hydrokinetic (Qty) | 0.0 | 8.0 | 4.0 |

| Cap Cost (USD) | 12.3 M | 10.5 M | 10.3 M |

| Base Load and Electric Stove + Injera Baking | |||

|---|---|---|---|

| Outage Percentages | 5% | 8% | 10% |

| PV Panels (kW) | 832.0 | 826.0 | 817.0 |

| Tesla–BESS (Qty) | 15.0 | 7.0 | 6.0 |

| Converter (kW) | 199.0 | 271.0 | 246.0 |

| Hydrokinetic (Qty) | 8.0 | 8.0 | 8.0 |

| Cap Cost (USD) | 24.2 M | 22.3 M | 21.9 M |

| Base Load and Electric Stove + Milling Machine | |||

|---|---|---|---|

| Outage Percentages | 5% | 8% | 10% |

| PV Panels (kW) | 450.0 | 433.0 | 424.0 |

| Tesla–BESS (Qty) | 5.0 | 4.0 | 4.0 |

| Converter (kW) | 199.0 | 208.0 | 231.0 |

| Hydrokinetic (Qty) | 8.0 | 4.0 | 4.0 |

| Cap Cost (USD) | 12.5 M | 11.9 M | 11.6 M |

| Base Load and Electric Stove + Injera Baking and Milling Machine | |||

|---|---|---|---|

| Outage Percentages | 5% | 8% | 10% |

| PV Panels (kW) | 938.0 | 934.0 | 892.0 |

| Tesla–BESS (Qty) | 7.0 | 8.0 | 12.0 |

| Converter (kW) | 212.0 | 244.0 | 309.0 |

| Hydrokinetic (Qty) | 8.0 | 4.0 | 8.0 |

| Cap Cost (USD) | 25.1 M | 25.1 M | 25.0 M |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Emmanouil, S.; Philhower, J.; Macdonald, S.; Khadim, F.K.; Yang, M.; Atsbeha, E.; Nagireddy, H.; Roach, N.; Holzer, E.; Anagnostou, E.N. A Comprehensive Approach to the Design of a Renewable Energy Microgrid for Rural Ethiopia: The Technical and Social Perspectives. Sustainability 2021, 13, 3974. https://doi.org/10.3390/su13073974

Emmanouil S, Philhower J, Macdonald S, Khadim FK, Yang M, Atsbeha E, Nagireddy H, Roach N, Holzer E, Anagnostou EN. A Comprehensive Approach to the Design of a Renewable Energy Microgrid for Rural Ethiopia: The Technical and Social Perspectives. Sustainability. 2021; 13(7):3974. https://doi.org/10.3390/su13073974

Chicago/Turabian StyleEmmanouil, Stergios, Jason Philhower, Sophie Macdonald, Fahad Khan Khadim, Meijian Yang, Ezana Atsbeha, Himaja Nagireddy, Natalie Roach, Elizabeth Holzer, and Emmanouil N. Anagnostou. 2021. "A Comprehensive Approach to the Design of a Renewable Energy Microgrid for Rural Ethiopia: The Technical and Social Perspectives" Sustainability 13, no. 7: 3974. https://doi.org/10.3390/su13073974

APA StyleEmmanouil, S., Philhower, J., Macdonald, S., Khadim, F. K., Yang, M., Atsbeha, E., Nagireddy, H., Roach, N., Holzer, E., & Anagnostou, E. N. (2021). A Comprehensive Approach to the Design of a Renewable Energy Microgrid for Rural Ethiopia: The Technical and Social Perspectives. Sustainability, 13(7), 3974. https://doi.org/10.3390/su13073974