Quantifying Environmental Burdens of Plasters Based on Natural vs. Flue Gas Desulfurization (FGD) Gypsum

Abstract

1. Introduction

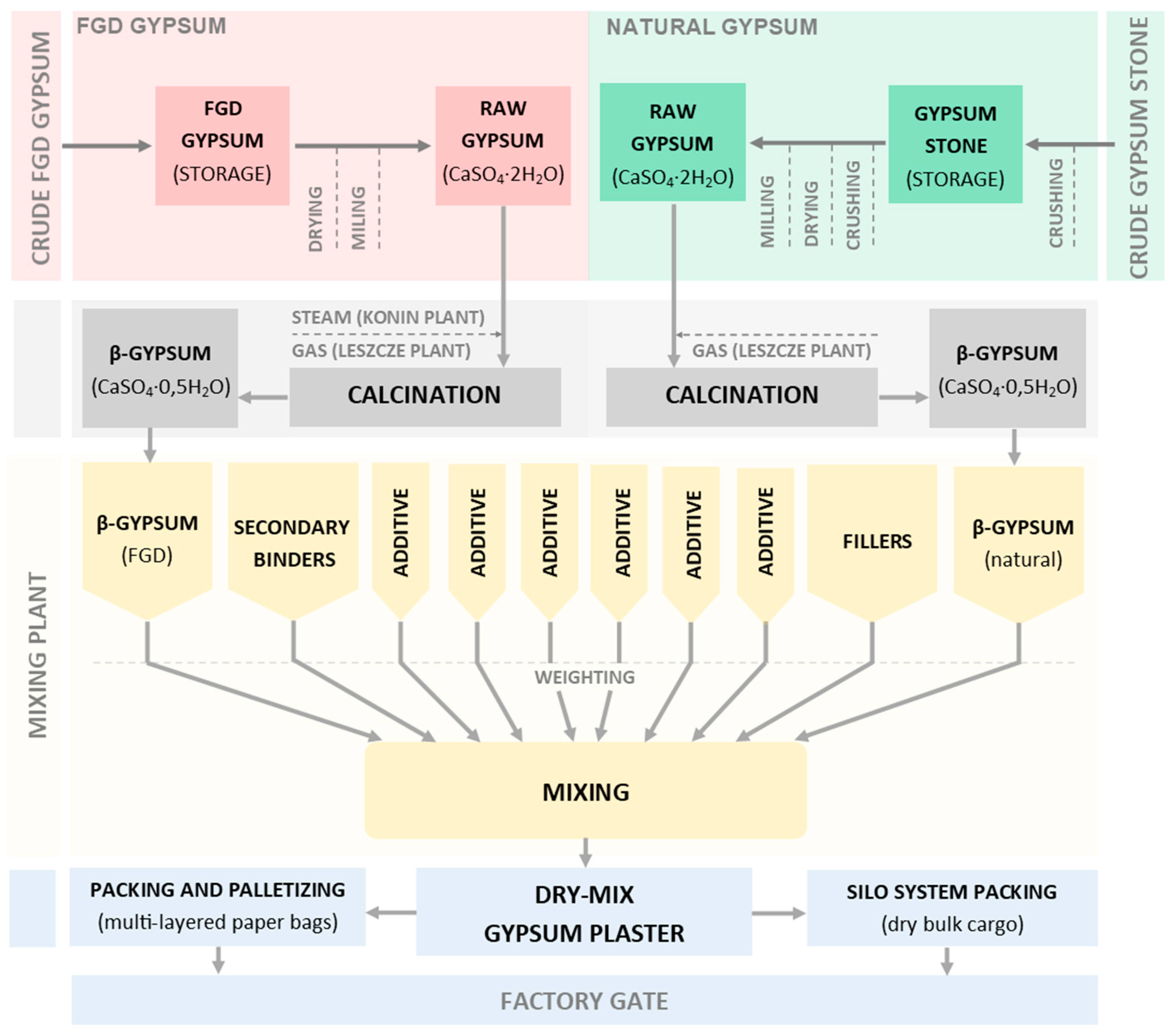

2. Materials and Methods

2.1. Gypsum

2.2. Gypsum Plasters

2.3. Life Cycle Assessment (LCA)—General Rules Applied

3. Results

- Global warming potential (GWP);

- Depletion potential of the stratospheric ozone layer (ODP);

- Acidification potential of soil and water (AP);

- Eutrophication potential (EP);

- Formation potential of tropospheric ozone (POCP);

- Abiotic depletion potential (ADP-elements; ADP-el.) for nonfossil resources;

- Abiotic depletion potential (ADP-fossil fuels; ADP-ff.) for fossil resources;

- Total use of renewable primary energy resources (primary energy and primary energy resources used as raw materials) (PERT);

- Total use of nonrenewable primary energy resources (primary energy and primary energy resources used as raw materials) (PENRT).

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- World Meteorological Organization. State of the Global Climate 2020. Provisional Report. Available online: https://library.wmo.int/doc_num.php?explnum_id=10444 (accessed on 27 December 2020).

- Le Quéré, C.; Jackson, R.B.; Jones, M.W.; Smith, A.J.; Abernethy, S.; Andrew, R.M.; De-Gol, A.J.; Willis, D.R.; Shan, Y.; Canadell, J.G.; et al. Temporary reduction in daily global CO2 emissions during the COVID-19 forced confinement. Nat. Clim. Chang. 2020, 10, 647–653. [Google Scholar] [CrossRef]

- World Meteorological Organization. WMO Greenhouse Gas Bulletin–No. 16: The State of Greenhouse Gases in the Atmosphere Based on Global Observation through 2019. Available online: https://library.wmo.int/doc_num.php?explnum_id=10437 (accessed on 27 December 2020).

- Krausmann, F.; Gingrich, S.; Eisenmenger, N.; Erb, K.H.; Haberl, H.; Fischer-Kowalski, M. Growth in global materials use, GDP and population during the 20th century. Ecol. Econ. 2009, 68, 2696–2705. [Google Scholar] [CrossRef]

- Global Alliance for Buildings and Construction, International Energy Agency and the United Nations Environment Programme. 2019 Global Status Report for Buildings and Construction: Towards a Zero-emission, Efficient and Resilient Buildings and Construction Sector. Available online: https://www.worldgbc.org/news-media/2019-global-status-report-buildings-and-construction (accessed on 27 December 2020).

- United Nations Environment Programme. 2020 Global Status Report for Buildings and Construction: Towards a Zero-emission, Efficient and Resilient Buildings and Construction Sector. Available online: https://globalabc.org/news/launched-2020-global-status-report-buildings-and-construction (accessed on 27 December 2020).

- Peters, G.P.; Andrew, R.M.; Canadell, J.G.; Friedlingstein, P.; Jackson, R.B.; Korsbakken, J.I.; Le Quéré, C.; Peregon, A. Carbon dioxide emissions continue to grow amidst slowly emerging climate policies. Nat. Clim. Chang. 2020, 10, 3–6. [Google Scholar] [CrossRef]

- Pomponi, F.; Crawford, R.; Stephan, A.; Hart, J.; D’Amico, B. The ‘building paradox’: Research on building-related environmental effects requires global visibility and attention. Emerald Open Res. 2020, 2, 50. [Google Scholar] [CrossRef]

- Röck, M.; Saade, M.R.M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG emissions of buildings–The hidden challenge for effective climate change mitigation. Appl. Energy 2020, 258, 114107. [Google Scholar] [CrossRef]

- United Nations. World Urbanization Prospects: The 2018 Revision. Available online: https://www.un.org/en/events/citiesday/assets/pdf/the_worlds_cities_in_2018_data_booklet.pdf (accessed on 27 December 2020).

- Scherz, M.; Passer, A.; Kreiner, H. Challenges in the achievement of a Net Zero Carbon Built Environment–A systemic approach to support the decision-aiding process in the design stage of buildings. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 032034. [Google Scholar] [CrossRef]

- Regulation (EU) No. 305/2011 of the European Parliament and of the Council. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32011R0305 (accessed on 28 December 2020).

- European Commission. M/350 EN Standardisation Mandate to CEN. In Development of Horizontal Standardized Methods for Assessment of the Integrated Environmental Performance of Buildings; European Commission: Brussels, Belgium, 2004. [Google Scholar]

- European Committee for Standardization (CEN). EN 15978:2011 Sustainability of Construction Works-Assessment of Environmental Performance of Buildings-Calculation Method; European Committee for Standardization (CEN): Brussels, Belgium, 2012. [Google Scholar]

- European Committee for Standardization (CEN). EN 15804:2012 Sustainability of Construction Works-Environmental Product Declarations-Core Rules for the Product Category of Construction Product; European Committee for Standardization (CEN): Brussels, Belgium, 2012. [Google Scholar]

- International Organization for Standardization (ISO). ISO 14040:2006 Environmental Management-Life Cycle Assessment-Principles and Framework; ISO 14040:2006; International Organization for Standardization (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization (ISO). ISO 14044:2006 Environmental Management-Life Cycle Assessment-Requirements and Guidelines; ISO 14040:2006; International Organization for Standardization (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization (ISO). ISO 14025:2006 Environmental Labels and Declarations-Type III Environmental Declarations-Principles and Procedure; ISO 14040:2006; International Organization for Standardization (ISO): Geneva, Switzerland, 2006. [Google Scholar]

- Bovea, M.D.; Ibáñez-Forés, V.; Agustí-Juan, I. Environmental product declaration (EPD) labeling of construction and building materials. In Eco-Efficient Construction and Building Materials: Life Cycle Assessment (LCA), Eco-Labelling and Case Studies; Woodhead Publishing: New York, NY, USA, 2014; pp. 125–150. ISBN 9780857097675. [Google Scholar]

- Brinkmann, T.; Metzger, L. Ecological assessment based on environmental product declarations. In Progress in Life Cycle Assessment; Springer: Cham, Switzerland, 2018; pp. 21–31. [Google Scholar]

- Rocha, C.; Camocho, D.; Sampaio, J.; Alexandre, J. Product-Service Development for Circular Economy and Sustainability Course; LNEG–Laboratório Nacional de Energia e Geologia, I.P.: Amodora, Portugal, 2020; ISBN 978-989-675-063-3. [Google Scholar]

- Anderson, J.; Moncaster, A. Embodied carbon of concrete in buildings, Part 1: Analysis of published EPD. Build. Cities 2020, 1, 198–217. [Google Scholar] [CrossRef]

- Waldman, B.; Huang, M.; Simonen, K. Embodied carbon in construction materials: A framework for quantifying data quality in EPDs. Build. Cities 2020, 1, 625–636. [Google Scholar] [CrossRef]

- Durão, V.; Silvestre, J.D.; Mateus, R.; De Brito, J. Economic valuation of life cycle environmental impacts of construction products—A critical analysis. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 012147. [Google Scholar] [CrossRef]

- Miller, T.R.; Gregory, J.; Kirchain, R. Critical Issues When Comparing Whole Building & Building Product Environmental Performance; MIT Concrete Sustainability Hub: Cambridge, MA, USA, 2016. [Google Scholar]

- Passer, A.; Lasvaux, S.; Allacker, K.; De Lathauwer, D.; Spirinckx, C.; Wittstock, B.; Kellenberger, D.; Gschösser, F.; Wall, J.; Wallbaum, H. Environmental product declarations entering the building sector: Critical reflections based on 5 to 10 years’ experience in different European countries. Int. J. Life Cycle Assess. 2015, 20, 1199–1212. [Google Scholar] [CrossRef]

- Bitsiou, E.; Giarma, C. Parameters related to building components’ life-cycle analysis in methods for buildings’ environmental performance assessment. IOP Conf. Ser. Earth Environ. Sci. 2020, 410, 012066. [Google Scholar] [CrossRef]

- Andersen, S.C.; Larsen, H.F.; Raffnsøe, L.; Melvang, C. Environmental product declarations (EPDs) as a competitive parameter within sustainable buildings and building materials. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 012145. [Google Scholar] [CrossRef]

- Gelowitz, M.D.C.; McArthur, J.J. Investigating the efect of environmental product declaration adoption in LEED® on the construction industry: A case study. Procedia Eng. 2016, 145, 58–65. [Google Scholar] [CrossRef]

- Berardi, U. Sustainability assessment in the construction sector: Rating systems and rated buildings. Sustain. Dev. 2012, 20, 411–424. [Google Scholar] [CrossRef]

- Galindro, B.M.; Welling, S.; Bey, N.; Olsen, S.I.; Soares, S.R.; Ryding, S.-O. Making use of life cycle assessment and environmental product declarations. A survey with practitioners. J. Ind. Ecol. 2020, 24, 1–11. [Google Scholar] [CrossRef]

- European Commission. Single Market for Green Products Initiative. Available online: https://ec.europa.eu/environment/eussd/smgp/index.htm (accessed on 28 December 2020).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A New Circular Economy Action Plan for a Cleaner and More Competitive Europe; European Commission: Brussels, Belgium, 2020; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1583933814386&uri=COM:2020:98:FIN (accessed on 28 December 2020).

- European Commission. The European Green Deal; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Durão, V.; Silvestre, J.D.; Mateus, R.; de Brito, J. Assessment and communication of the environmental performance of construction products in Europe: Comparison between PEF and EN 15804 compliant EPD schemes. Resour. Conserv. Recycl. 2020, 156, 104703. [Google Scholar] [CrossRef]

- European Commission. Amendment of Standardisation Mandate M/350 to CEN. Available online: https://www.constructionproducts.org.uk/media/25413/scc-16-04-mandate_m350_2016-02-05_ec_final_version-002.pdf (accessed on 28 December 2020).

- European Committee for Standardization (CEN). EN 15804:2012+A2:2019 Sustainability of Construction Works-Environmental Product Declarations-Core Rules for the Product Category of Construction Product; European Committee for Standardization (CEN): Brussels, Belgium, 2019. [Google Scholar]

- Benachio, G.L.F.; Freitas, M.D.C.D.; Tavares, S.F. Circular economy in the construction industry: A systematic literature review. J. Clean. Prod. 2020, 260, 121046. [Google Scholar] [CrossRef]

- Vinante, C.; Sacco, P.; Orzes, G.; Borgianni, Y. Circular Economy Metrics: Literature Review and Company-Level Classification Framework. J. Clean. Prod. 2020, 288, 125090. [Google Scholar] [CrossRef]

- Kylili, A.; Fokaides, P.A. Policy trends for the sustainability assessment of construction materials: A review. Sustain. Cities Soc. 2017, 35, 280–288. [Google Scholar] [CrossRef]

- Tomaszewska, J. Polish Transition towards Circular Economy: Materials Management and Implications for the Construction Sector. Materials 2020, 13, 5228. [Google Scholar] [CrossRef] [PubMed]

- Ströbele, B.; Lützkendorf, T. Communicating environmental information: Rethinking options for construction products. Build. Res. Inf. 2019, 47, 681–696. [Google Scholar] [CrossRef]

- Mjakuškina, S.; Kavosa, M.; Lapiņa, I. Achieving Sustainability in the Construction Supervision Process. J. Open Innov. Technol. Mark. Complex. 2019, 5, 47. [Google Scholar] [CrossRef]

- Meschede, C. The Sustainable Development Goals in Scientific Literature: A Bibliometric Overview at the Meta-Level. Sustainability 2020, 12, 4461. [Google Scholar] [CrossRef]

- Czernik, S.; Marcinek, M.; Michałowski, B.; Piasecki, M.; Tomaszewska, J.; Michalak, J. Environmental Footprint of Cementitious Adhesives—Components of ETICS. Sustainability 2020, 12, 8998. [Google Scholar] [CrossRef]

- Czarnecki, L.; Gemert, D. Innovation in construction materials engineering versus sustainable development. Bull. Pol. Acad. Sci. Tech. Sci. 2017, 65, 765–771. [Google Scholar] [CrossRef][Green Version]

- Szlugaj, J.; Naworyta, W. Analiza zmian podaży gipsu w Polsce w świetle rozwoju odsiarczania spalin w elektrowniach konwencjonalnych/Analysis of the Changes in Polish Gypsum Resources in the Context of Flue Gas Desulfurization in Conventional Power Plants. Gospod. Surowcami Miner. Miner. Resour. Manag. 2015, 31, 93–108. [Google Scholar] [CrossRef]

- Chrzanowski, Z.; Baran, B.; Dudziak, M.; Katzor, R. Polska jako potencjalne źródło ubocznych produktów spalania (UPS) dla rynków europejskich. In Proceedings of the XXVI Międzynarodowa Konferencja Popioły z Energetyki, Sopot, Poland, 8–10 October 2019. (In Polish). [Google Scholar]

- European Coal Combustion Products Association e.V. Production and Utilisation of CCPs in 2016 in Europe. 2020. Essen. Available online: http://www.ecoba.com/ecobaccpprod.html (accessed on 29 December 2020).

- Kowalczyk, G. Mniej Spalonego Węgla to Problem dla Branży Budowlanej. dziennik.pl. Available online: https://gospodarka.dziennik.pl/news/artykuly/7797527,wegiel-branza-budowlana-gips-cement.html (accessed on 15 January 2021).

- Ministry of State Assets. Available online: https://www.gov.pl/web/aktywa-panstwowe/w-katowicach-o-transformacji-gornictwa (accessed on 29 December 2020).

- Sadowski, R.F.; Kosieradzka-Federczyk, A. Paradoksy ekologiczne. In Odpady Miarą Sukcesu i Porażki Cywilizowanej Ludzkości; Krajowa Szkoła Administracji Publicznej: Warszawa, Poland, 2020; ISBN 9788361713197. [Google Scholar]

- Yichao, Z.; Ying, W.; Jinghai, Z.; Jiaxi, L.; Tong, L. Basic characteristics and comprehensive utilization of FGD gypsum. IOP Conf. Ser. Earth Environ. Sci. 2020, 510, 052002. [Google Scholar] [CrossRef]

- Ma, Y.; Nie, Q.; Xiao, R.; Hu, W.; Han, B.; Polaczyk, P.A.; Huang, B. Experimental investigation of utilizing waste flue gas desulfurized gypsum as backfill materials. Constr. Build. Mater. 2020, 245, 118393. [Google Scholar] [CrossRef]

- Lushnikova, N.; Dvorkin, L. Sustainability of gypsum products as a construction material. In Sustainability of Construction Materials; Woodhead Publishing: New York, NY, USA, 2016; pp. 643–681. ISBN 9780081009956. [Google Scholar]

- Watts, D.B.; Dick, W.A. Sustainable uses of FGD gypsum in agricultural systems: Introduction. J. Environ. Qual. 2014, 43, 246–252. [Google Scholar] [CrossRef]

- European Committee for Standardization (CEN). EN 13279-1:2008 Gypsum Binders and Gypsum Plasters–Part 1: Definitions and Requirements; European Committee for Standardization (CEN): Brussels, Belgium, 2008. [Google Scholar]

- Dolina Nidy. Environmental Product Declaration, Gypsum Plasters Alfa, Beta, Gamma, Zeta, Sprint, Tempo, Certificate No. 083/2019; Dolina Nidy: Warsaw, Poland, 2019. [Google Scholar]

- European Committee for Standardization (CEN). EN 15804:2012+A1:2013 Sustainability of Construction Works-Environmental Product Declarations-Core Rules for the Product Category of Construction Product; European Committee for Standardization (CEN): Brussels, Belgium, 2013. [Google Scholar]

- Building Research Institute (ITB). ITB-EPD General PCR Annex A v1.4 PN-EN 15804+A1:2014-04 Based; Building Research Institute (ITB): Warsaw, Poland, 2014. [Google Scholar]

- Gypsum Industries Ltd. Environmental Product Declaration, Gyproc Finish Plaster; Gypsum Industries Ltd.: Dublin, Ireland, 2014. [Google Scholar]

- Dalsan Alçı. Environmental Product Declaration, Gypsum Plasters; Dalsan Alçı: Ankara, Turkey, 2015. [Google Scholar]

- Gips Geliştirilmiş İnşaat Malzemeleri Tic. A.Ş. Environmental Product Declaration, Gypsum Based Plasters; Gips Geliştirilmiş İnşaat Malzemeleri Tic. A.Ş.: Istanbul, Turkey, 2016. [Google Scholar]

- Fořt, J.; Černý, R. Carbon footprint analysis of calcined gypsum production in the Czech Republic. J. Clean. Prod. 2018, 177, 795–802. [Google Scholar] [CrossRef]

- Lee, J.C.; Bradshaw, S.L.; Edil, T.B.; Benson, C.H. Quantifying the benefits of flue gas desulfurization gypsum in sustainable wallboard production. In Proceedings of the World of Coal Ash (WOCA) Conference, Denver, CO, USA, 9–12 May 2011; pp. 9–12. [Google Scholar]

- Peng, Z.G.; Ma, L.L.; Gong, X.Z. Comparison of life cycle environmental impacts between natural gypsum board and FGD gypsum board. Key Eng. Mater. 2014, 599, 15–18. [Google Scholar] [CrossRef]

- Gawlicki, M. Belite in cements with low emission of CO2 during clinker formation. Cement Wapno Beton 2020, 25, 348–357. [Google Scholar]

- Pedreño-Rojas, M.A.; Fořt, J.; Černý, R.; Rubio-de-Hita, P. Life cycle assessment of natural and recycled gypsum production in the Spanish context. J. Clean. Prod. 2020, 253, 120056. [Google Scholar] [CrossRef]

- Stowarzyszenie Producentów Cementu. Environmental Product Declaration, Cements CEM I, CEM II, CEM III, CEM IV, CEM V Produced in Poland, Certificate No 116/2020; Stowarzyszenie Producentów Cementu: Cracow, Poland, 2020. [Google Scholar]

- Jiménez-Rivero, A.; García-Navarro, J. Management of end-of-life gypsum in a circular economy. In Advances in Construction and Demolition Waste Recycling; Woodhead Publishing: New York, NY, USA, 2020; pp. 69–79. [Google Scholar]

| Designation | Notation |

|---|---|

| Gypsum plaster | B |

| Gypsum building plaster | B1 |

| Gypsum-based building plaster | B2 |

| Gypsum–lime building plaster | B3 |

| Lightweight gypsum building plaster | B4 |

| Lightweight gypsum-based building plaster | B5 |

| Lightweight gypsum–lime building plaster | B6 |

| Gypsum plaster for plasterwork with enhanced surface hardness | B7 |

| Gypsum plaster for special purposes | C |

| Gypsum plaster for fibrous plasterwork | C1 |

| Gypsum mortar | C2 |

| Gypsum plaster | C3 |

| Thermal insulation plaster | C4 |

| Fire protection plaster | C5 |

| Thin coat plaster, finishing product | C6 |

| Finishing product | C7 |

| Indicator (Unit) | A1–A3 | ||

|---|---|---|---|

| FGD Gypsum-Based Plaster (Konin Plant) | FGD Gypsum-Based Plaster (Leszcze Plant) | Natural Gypsum-Based Plaster (Leszcze Plant) | |

| Environmental impacts, 1 kg of product | |||

| GWP (kg CO2 eq.) | 6.73 × 10−2 | 7.32 × 10−2 | 1.36 × 10−1 |

| ODP (kg CFC 11 eq.) | 8.67 × 10−9 | 8.67 × 10−9 | 8.45 × 10−9 |

| AP (kg SO2 eq.) | 2.26 × 10−4 | 1.87 × 10−4 | 2.18 × 10−4 |

| EP (kg (PO4)3− eq.) | 7.57 × 10−6 | 4.66 × 10−6 | 4.93 × 10−6 |

| POCP (kg Ethene eq.) | 2.86 × 10−5 | 2.16 × 10−5 | 3.34 × 10−5 |

| ADP-el. (kg SB eq.) | 3.23 × 10−4 | 3.23 × 10−4 | 2.94 × 10−4 |

| ADP-ff. (MJ) | 6.82 × 10−1 | 7.61 × 10−1 | 1.24 × 100 |

| Environmental aspects related to the consumption of raw materials, 1 kg of product | |||

| PERT (MJ) | 8.76 × 10−1 | 7.19 × 10−1 | 3.06 × 10−2 |

| PENRT (MJ) | 7.49 × 10−1 | 8.33 × 10−1 | 1.31 × 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baran, E.; Czernik, S.; Hynowski, M.; Michałowski, B.; Piasecki, M.; Tomaszewska, J.; Michalak, J. Quantifying Environmental Burdens of Plasters Based on Natural vs. Flue Gas Desulfurization (FGD) Gypsum. Sustainability 2021, 13, 4298. https://doi.org/10.3390/su13084298

Baran E, Czernik S, Hynowski M, Michałowski B, Piasecki M, Tomaszewska J, Michalak J. Quantifying Environmental Burdens of Plasters Based on Natural vs. Flue Gas Desulfurization (FGD) Gypsum. Sustainability. 2021; 13(8):4298. https://doi.org/10.3390/su13084298

Chicago/Turabian StyleBaran, Edyta, Sebastian Czernik, Mariusz Hynowski, Bartosz Michałowski, Michał Piasecki, Justyna Tomaszewska, and Jacek Michalak. 2021. "Quantifying Environmental Burdens of Plasters Based on Natural vs. Flue Gas Desulfurization (FGD) Gypsum" Sustainability 13, no. 8: 4298. https://doi.org/10.3390/su13084298

APA StyleBaran, E., Czernik, S., Hynowski, M., Michałowski, B., Piasecki, M., Tomaszewska, J., & Michalak, J. (2021). Quantifying Environmental Burdens of Plasters Based on Natural vs. Flue Gas Desulfurization (FGD) Gypsum. Sustainability, 13(8), 4298. https://doi.org/10.3390/su13084298