Postharvest Losses of Pomegranate Fruit at the Packhouse and Implications for Sustainability Indicators

Abstract

:1. Introduction

Trends in Production and Trade of Pomegranate Fruit in South Africa and Globally

2. Materials and Methods

2.1. Study Settings

2.2. Method of Data Collection

2.3. Data Collection

2.4. Historical Packhouse Data

2.5. Statistical Analysis

3. Results

3.1. Magnitude of Fruit Losses and Waste

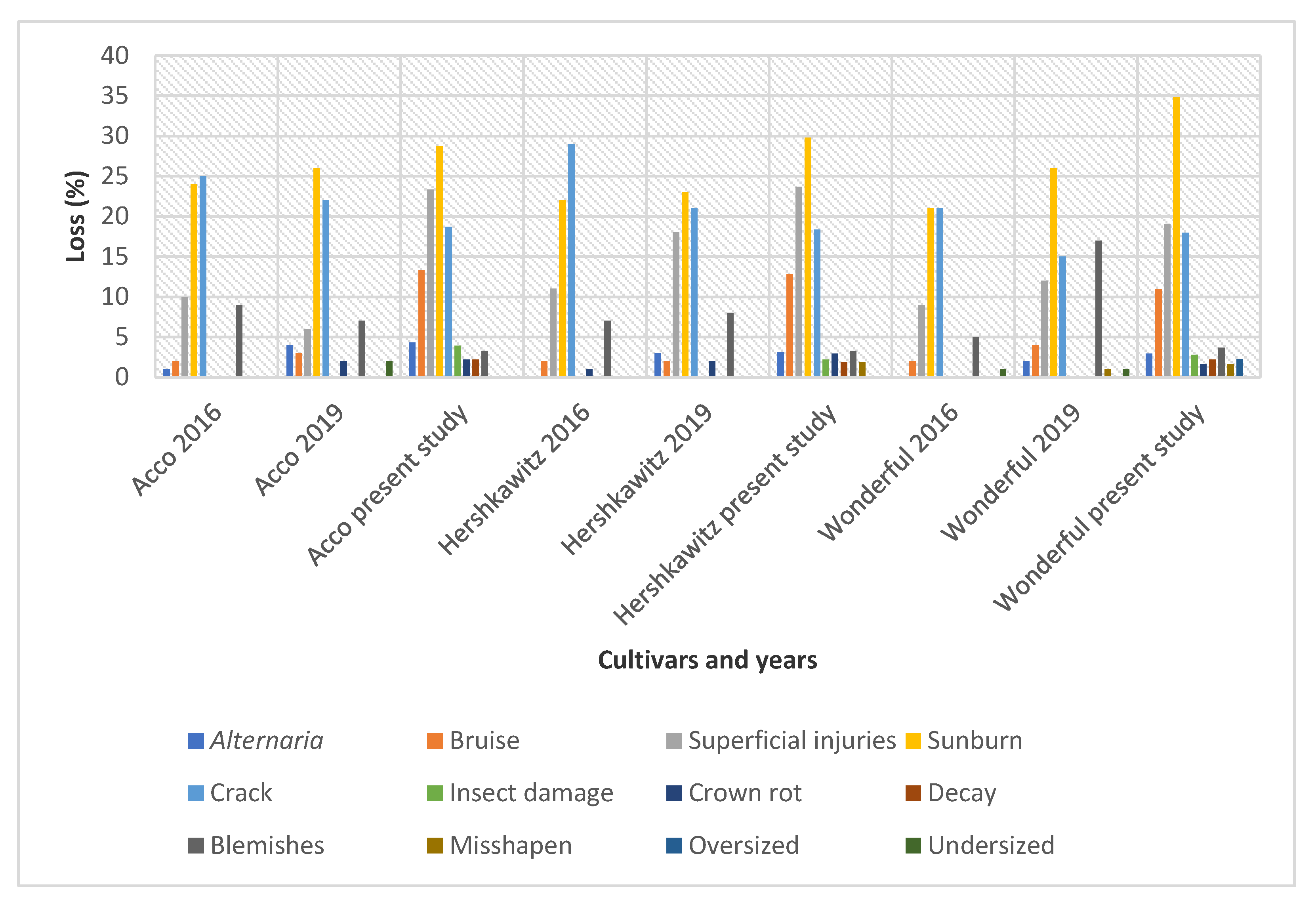

3.2. Causes of Packhouse Pomegranate Fruit Losses

3.2.1. Environmental Stress (Sunburn, Cracks, and Splits)

Sunburn

Cracks and Splits

3.2.2. Mechanical and Physical Damage (Superficial Injuries, Bruise Damage, and Blemishes)

Superficial Injuries

Bruise Damage

Blemish

3.2.3. Biological Damage (Insect Damage)

Insect Damage

3.2.4. Microbial and Pathological Spoilage (Decay and Rots, Alternaria, Crown Rot)

Decay and Rots

Alternaria

Crown Rot

3.2.5. Irregular Fruit Size and Shape (Oversized and Misshapen)

Oversized

Misshapen

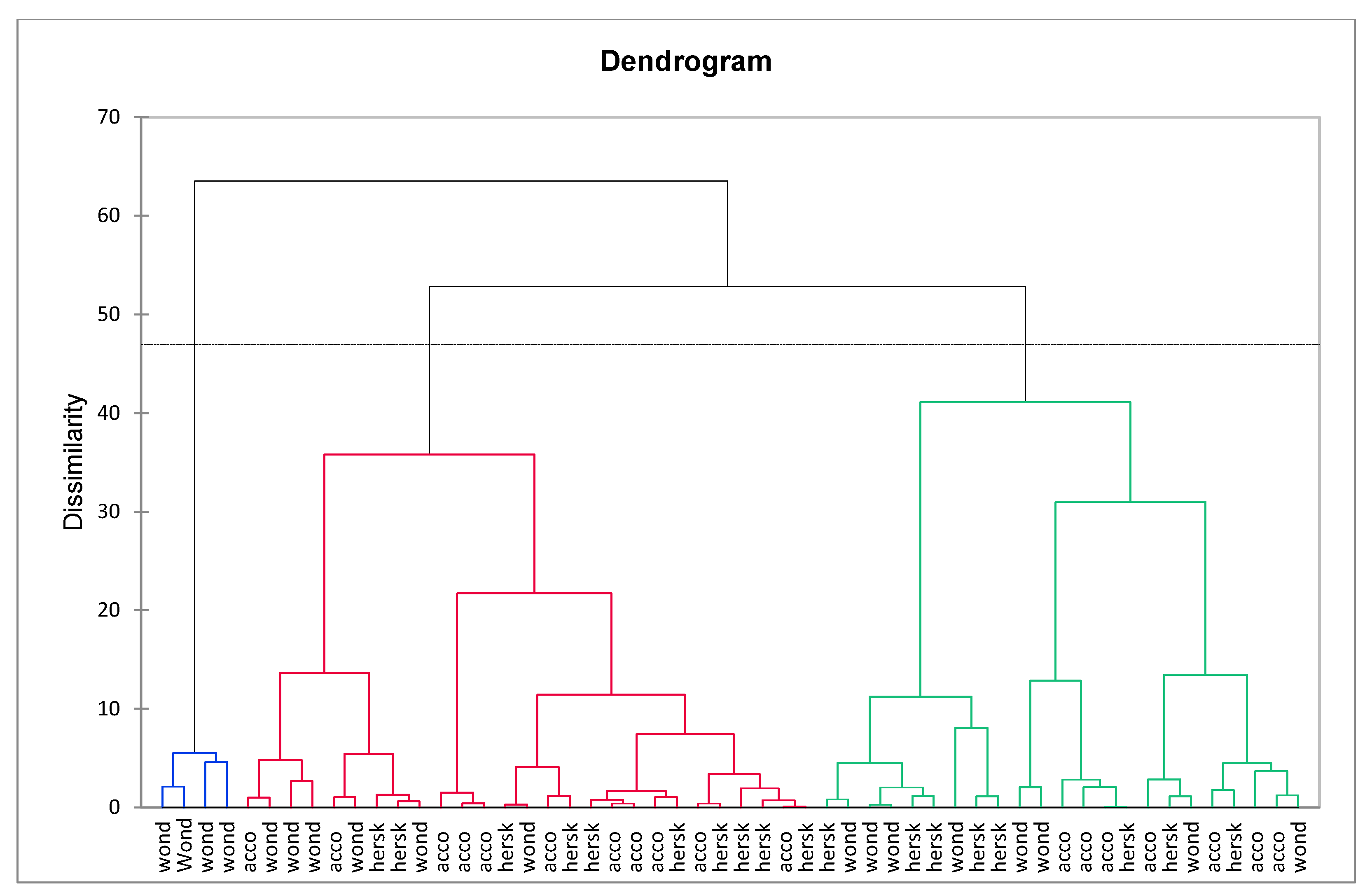

3.3. Comparative Analysis of Pomegranate Fruit Based on Defects

4. Discussion

4.1. Historical Packhouse Data on Pomegranate Fruit Losses at Case Study Packhouse in Wellington, Western Cape, South Africa

4.2. Economic, Environmental, and Resource Impacts

4.3. Nutritional Impacts

4.4. Possible Solutions to Overcome and Limit Fruit Loss at the Packhouse

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kahramanoglu, I. Trends in pomegranate sector: Production, postharvest handling and marketing. Int. J. Agric. For. Life Sci. 2019, 3, 239–246. [Google Scholar]

- Kahramanoglu, I.; Usanmaz, S. Pomegranate Production and Marketing, 1st ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Middha, S.K.; Usha, T.; Pande, V. A review on antihyperglycemic and antihepatoprotective activity of eco-friendly Punica granatum peel waste. Evid. Based Complement. Altern. Med. 2013, 656172, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Pareek, S.; Valero, D.; Serrano, M. Postharvest biology and technology of pomegranate. J. Sci. Food Agric. 2015, 95, 2360–2379. [Google Scholar] [CrossRef]

- Fawole, O.A.; Opara, U.L. Seasonal variation in chemical composition, aroma volatiles and antioxidant capacity of pomegranate during fruit development. Afri. J. Biotechnol. 2013, 12, 4006–4019. [Google Scholar]

- Al-Said, F.A.; Opara, L.A.; Al-Yahyai, R.A. Physico-chemical and textural quality attributes of pomegranate cultivars (Punica granatum L.) grown in the Sultanate of Oman. J. Food Eng. 2009, 90, 129–134. [Google Scholar] [CrossRef]

- de Oliveira, F.L.; Arruda, T.Y.P.; da Silva Lima, R.; Casarotti, S.N.; Morzelle, M.C. Pomegranate as a natural source of phenolic antioxidants: A review. J. Food Bioact. 2020, 9, 10–22. [Google Scholar] [CrossRef] [Green Version]

- Faria, A.; Calhau, C. The bioactivity of pomegranate: Impact on health and disease. Crit. Rev. Food Sci. Nutr. 2011, 51, 626–634. [Google Scholar] [CrossRef]

- Mphahlele, R.R.; Fawole, O.A.; Opara, U.L. Influence of packaging system and long term storage on physiological attributes, biochemical quality, volatile composition and antioxidant properties of pomegranate fruit. Sci. Hort. 2016, 211, 140–151. [Google Scholar] [CrossRef]

- Heber, D.; Schulman, R.N.; Seeram, N.P. (Eds.) Pomegranates: Ancient Roots to Modern Medicine; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Kang, N.J.; Shin, S.H.; Lee, H.J.; Lee, K.W. Polyphenols as small molecular inhibitors of signaling cascades in carcinogenesis. Pharmacol. Ther. 2011, 130, 310–324. [Google Scholar] [CrossRef] [PubMed]

- Katz, S.R.; Newman, R.A.; Lansky, E.P. Punica granatum: Heuristic treatment for diabetes mellitus. J. Med. Food 2007, 10, 213–217. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, Q.; Hou, H.; Liu, Z.; Wang, L.; Rasekhmagham, R.; Kord-Varkaneh, H.; Santos, H.O.; Yao, G. The effects of pomegranate supplementation on biomarkers of inflammation and endothelial dysfunction: A meta-analysis and systematic review. Complement. Ther. Med. 2020, 49, 1–8. [Google Scholar] [CrossRef]

- Işık Özgüven, A.; Gültekin, U.; Gözlekçi, S.; Yilmaz, I.; Yilmaz, C.; Küçük, E.; Imrak, B.; Korkmaz, C. A review of the economics and the marketing of the pomegranate industry in turkey. Acta Hortic. 2015, 1089, 221–228. [Google Scholar] [CrossRef]

- Rymon, D. Mapping features of the global pomegranate market. Acta Hortic. 2011, 890, 599–602. [Google Scholar] [CrossRef]

- Pomegranate Producers Association of South Africa (POMASA). Pomegranate Industry Overview: Statistics and Information. 2019. Available online: https://www.sapomegranate.co.za/statistics-and-information/pomegranate-industry-overview/ (accessed on 12 March 2020).

- Pomegranate Producers Association of South Africa (POMASA). Pomegranate Industry Overview: Statistics and Information. 2018. Available online: https://www.sapomegranate.co.za/statistics-and-information/pomegranate-industry-overview/ (accessed on 12 March 2020).

- Venter, E.; Lennox, C.L.; Meitz-Hopkins, J.C. First report of Cytospora punicae causing post-harvest fruit rot on pomegranate in South Africa. Plant Dis. 2017, 101, 631. [Google Scholar] [CrossRef]

- Munhuweyi, K.; Lennox, C.L.; Meitz-Hopkins, J.C.; Caleb, O.J.; Opara, U.L. Major diseases of pomegranate (Punica granatum L.), their causes and management—A review. Sci. Hortic. 2016, 211, 126–139. [Google Scholar] [CrossRef]

- Hussein, Z.; Fawole, O.A.; Opara, U.L. Harvest and postharvest factors affecting bruise damage of fresh fruits. Hortic. Plant J. 2019, 6, 1–13. [Google Scholar] [CrossRef]

- Lufu, R.; Ambaw, A.; Opara, U.L. The contribution of transpiration and respiration processes in the mass loss of pomegranate fruit (cv. Wonderful). Postharvest Biol. Technol. 2019, 157, 1–10. [Google Scholar] [CrossRef]

- Lufu, R.; Ambaw, A.; Opara, U.L. Water loss of fresh fruit: Influencing pre-harvest, harvest and postharvest factors. Sci. Hortic. 2020, 272, 1–16. [Google Scholar] [CrossRef]

- Fadiji, T.; Berry, T.M.; Coetzee, C.J.; Opara, U.L. Mechanical design and performance testing of corrugated paperboard packaging for the postharvest handling of horticultural produce. Biosyst. Eng. 2018, 171, 220–244. [Google Scholar] [CrossRef]

- POMASA (Pomegranate Association of South Africa). Pomegranate Production Guidelines. Available online: https://www.sapomegranate.co.za/wp-content/uploads/2017/08/POMASA-Technical-Production-Manual-1.pdf. (accessed on 29 March 2021).

- Johnson, L.K.; Dunning, R.D.; Bloom, J.D.; Gunter, C.C.; Boyette, M.D.; Creamer, N.G. Estimating on-farm food loss at the field level: A methodology and applied case study on a North Carolina farm. Resour. Conserv. Recycl. 2018, 137, 243–250. [Google Scholar] [CrossRef]

- Johnson, L.K.; Dunning, R.D.; Gunter, C.C.; Bloom, J.D.; Boyette, M.D.; Creamer, N.G. Field measurement in vegetable crops indicates need for reevaluation of on-farm food loss estimates in North America. Agric. Syst. 2018, 167, 136–142. [Google Scholar] [CrossRef]

- Schneider, F.; Part, F.; Göbel, C.; Nina Langen, N.; Gerhards, C.; Kraus, G.F.; Ritter, G. A methodological approach for the on-site quantification of food losses in primary production: Austrian and German case studies using the example of potato harvest. Waste Manag. 2019, 86, 106–113. [Google Scholar] [CrossRef]

- Fernandez-Zamudio, M.-A.; Barco, H.; Schneider, F. Direct Measurement of Mass and Economic Harvest and Post-Harvest Losses in Spanish Persimmon Primary Production. Agriculture 2020, 10, 581. [Google Scholar] [CrossRef]

- Usanmaz, S.; Kahramanoğlu, I.; Yılmaz, N. Yield and pomological characteristics of three pomegranate (Punica granatum L.) cultivars: Wonderful, Acco and Herskovitz. Am. J. Agric. For. 2014, 2, 61–65. [Google Scholar] [CrossRef] [Green Version]

- Bryman, A.; Bell, E.; Hirschsohn, P.; Dos Santos, A.; Du Toit, J.; Masenge, A.; Aardt, I.; Wagner, C. Research Methodology: Business and Management Contexts; Oxford University Press Southern Africa: Cape Town, South Africa, 2014. [Google Scholar]

- Dome, M.M.; Prusty, S. Determination of vegetable postharvest loss in the last-mile supply chain in Tanzania: A lean perspective. Int. J. Logist. Syst. Manag. 2017, 27, 133–150. [Google Scholar] [CrossRef]

- Munhuweyi, K.; Opara, U.L.; Sigge, G. Postharvest losses of cabbages from retail to consumer and the socio-economic and environmental impacts. Br. Food J. 2016, 118, 286–300. [Google Scholar] [CrossRef]

- Opara, U.L.; Al-Ani, M.R. Antioxidant contents of pre-packed fresh-cut versus whole fruit and vegetables. Br. Food J. 2010, 112, 797–810. [Google Scholar] [CrossRef]

- González, A.D.; Frostell, B.; Carlsson-Kanyama, A. Protein efficiency per unit energy and per unit greenhouse gas emissions: Potential contribution of diet choices to climate change mitigation. Food Policy 2011, 36, 562–570. [Google Scholar] [CrossRef]

- Mekonnen, M.M.; Hoekstra, A.Y. The green, blue and grey water footprint of crops and derived crop products. Hydrol. Earth Syst. Sci. 2011, 15, 1577–1600. [Google Scholar] [CrossRef] [Green Version]

- Spiker, M.L.; Hiza, H.A.; Siddiqi, S.M.; Neff, R.A. Wasted food, wasted nutrients: Nutrient loss from wasted food in the United States and comparison to gaps in dietary intake. J. Acad. Nutr. Diet. 2017, 117, 1031–1040. [Google Scholar] [CrossRef] [Green Version]

- Paul, D.K.; Shaha, R.K. Nutrients, vitamins and minerals content in common citrus fruits in the northern region of Bangladesh. Pak. J. Biol. Sci. 2004, 7, 238–242. [Google Scholar] [CrossRef]

- Hanson, C.; Lipinski, B.; Robertson, K.; Dias, D.; Gavilan, I.; Gréverath, P.; Ritter, S.; Fonseca, J.; Van Otterdijk, R.; et al.; World Resource Institute Food Loss and Waste Accounting and Reporting Standard. 2016. Available online: https://www.wri.org/publication/food-loss-and-waste-accounting-and-reporting-standard (accessed on 29 March 2020).

- Atanda, S.A.; Pessu, P.O.; Agoda, S.; Isong, I.U.; Ikotun, I. The concepts and problems of post–harvest food losses in perishable crops. Afr. J. Food Sci. 2011, 5, 603–613. [Google Scholar]

- Pomegranate Producers Association of South Africa (POMASA). Pomegranate Industry Overview: Statistics and Information. 2017. Available online: https://www.sapomegranate.co.za/statistics-and-information/pomegranate-industry-overview/ (accessed on 12 March 2020).

- Bond, R. Carrot Loss during Primary Production: Field Waste and Pack House Waste. Master’s Thesis, Hedmark University, Hedmark, Norway, 4 May 2016. [Google Scholar]

- Bantayehu, M.; Alemayehu, M.; Abera, M.; Bizuayehu, S. Postharvest Losses Assessment of Tropical Fruits in the Market Chain of North Western Ethiopia. Food Sci. Qual. Manag. 2017, 66, 1–12. [Google Scholar]

- Bhattarai, D.R.; Subedi, G.D.; Gautam, I.P.; Chauhan, S. Posthavest Supply Chain Study of Carrot in Nepal. Int. J. Hortic. 2017, 7, 239–245. [Google Scholar] [CrossRef]

- Weerakkody, P.; Jobling, J.; Infante, M.M.V.; Rogers, G. The effect of maturity, sunburn and the application of sunscreens on the internal and external qualities of pomegranate fruit grown in Australia. Sci. Hortic. 2010, 124, 57–61. [Google Scholar] [CrossRef]

- Yazici, K.; Kaynak, L. Effects of air temperature, relative humidity and solar radiation on fruit surface temperatures and sunburn damage in pomegranate (Punica granatum L. cv. Hicaznar). Acta Hortic. 2006, 818, 181–186. [Google Scholar] [CrossRef]

- Ghanbarpour, E.; Rezaei, M.; Lawson, S. Reduction of cracking in pomegranate fruit after foliar application of humic acid, calcium-boron and kaolin during water stress. Erwerbs-Obstbau 2019, 61, 29–37. [Google Scholar] [CrossRef]

- Opara, L.U.; Studman, C.J.; Banks, N.H. Fruit skin splitting and cracking. Hortic. Rev. 1997, 19, 217–262. [Google Scholar]

- Abd El-Rhman, I.E. Physiological studies on cracking phenomena of pomegranates. J. Appl. Sci. Res. 2010, 6, 696–703. [Google Scholar]

- Singh, A.; Shukla, A.K.; Meghwal, P.R. Fruit Cracking in Pomegranate: Extent, Cause, and Management—A Review. Int. J. Fruit Sci. 2020, 1784074, S1234–S1253. [Google Scholar] [CrossRef]

- Hussein, Z.; Fawole, O.A.; Opara, U.O. Effects of bruising and storage duration on physiological response and quality attributes of pomegranate fruit. Sci. Hortic. 2020, 267, 1–7. [Google Scholar] [CrossRef]

- Hussein, Z.; Fawole, O.A.; Opara, U.L. Preharvest factors influencing bruise damage of fresh fruits–a review. Sci. Hortic. 2018, 229, 45–58. [Google Scholar] [CrossRef]

- Czieczor, L.; Bentkamp, C.; Damerow, L.; Blanke, M. Non-invasive determination of the quality of pomegranate fruit. Postharvest Biol. Technol. 2018, 136, 74–79. [Google Scholar] [CrossRef]

- Swilling, M.; Annecke, E. Just Transitions: Explorations of Sustainability in an Unfair World; UCT Press: Cape Town, South Africa, 2012. [Google Scholar]

- U.S. DOE (Department of Energy, Energy Information Administration). Method for Calculating Carbon Sequestration by Trees in Urban and Suburban Settings. Voluntary Reporting of Greenhouse Gases, U.S. 1998. Available online: https://www3.epa.gov/climatechange/Downloads/method-calculating-carbon-sequestration-trees-urban-and-suburban-settings.pdf. (accessed on 17 July 2020).

- Gleick, P.H.; Iwra, M. Basic water requirements for human activities: Meeting basic needs. Water Int. 1996, 21, 83–92. [Google Scholar] [CrossRef]

- Muller, J.C. Pomegranate waste record. In Personal Communication; Sonlia Fruit Packhouse: Wellington, South Africa, 2020. [Google Scholar]

- Keatinge, J.D.; Waliyar, F.; Jamnadas, R.H.; Moustafa, A.; Andrade, M.; Drechsel, P.; Hughes, J.D.A.; Kadirvel, P.; Luther, K. Relearning old lessons for the future of food—by bread alone no longer: Diversifying diets with fruit and vegetables. Crop. Sci. 2010, 50, 51–62. [Google Scholar] [CrossRef] [Green Version]

- Beretta, C.; Stoessel, F.; Baier, U.; Hellweg, S. Quantifying food losses and the potential for reduction in Switzerland. Waste Manag. 2013, 33, 764–773. [Google Scholar] [CrossRef] [Green Version]

- Medici, M.; Canavari, M.; Toselli, M. Interpreting environmental impacts resulting from fruit cultivation in a business innovation perspective. Sustainability 2020, 12, 1–14. [Google Scholar]

- Wright, H.J.; Ochilo, W.; Pearson, A.; Finegold, C.; Oronje, M.; Wanjohi, J.; Kamau, R.; Holmes, T.; Rumsey, A. Using ICT to strengthen agricultural extension systems for Plant health. J. Agric. Food Inf. 2016, 17, 23–36. [Google Scholar] [CrossRef] [Green Version]

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; Van Otterdijk, R.; Meybeck, A. Global Food Losses and Food Waste; FAO: Rome, Italy, 2011; pp. 1–38. [Google Scholar]

- Porat, R.; Lichter, A.; Terry, L.A.; Harker, R.; Buzby, J. Postharvest losses of fruit and vegetables during retail and in consumers’ homes: Quantifications, causes, and means of prevention. Postharvest Biol. Technol. 2018, 139, 135–149. [Google Scholar] [CrossRef] [Green Version]

| Pomegranate Cultivar | Fruit Put through the Processing Line (Bins) | Discarded Fruit (Bins) | Loss (%) |

|---|---|---|---|

| ‘Acco’ | 89.00 | 6.00 | 6.74 |

| ‘Hershkawitz’ | 84.00 | 6.00 | 7.14 |

| ‘Wonderful’ | 78.00 | 6.00 | 7.69 |

| Total | 251.00 | 18.00 | 21.5 |

| Mean | 83.60 | 6.00 | 7.16 |

| Cultivar | |||

|---|---|---|---|

| Fruit Defect | ‘Acco’ (Loss %) | ‘Hershkawitz’ (Loss %) | ‘Wonderful’ (Loss %) |

| Alternaria | 4.30 | 3.10 | 2.96 |

| Bruise | 13.33 | 12.80 | 10.94 |

| Injury | 23.33 | 23.70 | 19.07 |

| Sunburn | 28.70 | 29.80 | 34.81 |

| Crack | 18.70 | 18.34 | 17.96 |

| Insect damage | 3.90 | 2.20 | 2.77 |

| Crown rot | 2.22 | 2.96 | 1.67 |

| Decay | 2.22 | 1.90 | 2.22 |

| Blemish | 3.30 | 3.30 | 3.70 |

| Misshapen | 0.00 | 1.90 | 1.66 |

| Oversized | 0.00 | 0.00 | 2.24 |

| Defects | Alternaria | Oversized | Bruise | Injury | Sunburn | Crack | Insect Damage | Crown Rot | Decay | Blemish | Misshapen |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Alternaria | 1 | ||||||||||

| Oversized | −0.267 | 1 | |||||||||

| Bruise | −0.248 | −0.179 | 1 | ||||||||

| Injury | 0.157 | −0.356 | −0.170 | 1 | |||||||

| Sunburn | −0.020 | 0.376 | −0.179 | −0.267 | 1 | ||||||

| Crack | −0.246 | −0.112 | −0.230 | −0.184 | −0.402 | 1 | |||||

| Insect damage | 0.116 | −0.133 | −0.157 | −0.219 | −0.208 | 0.157 | 1 | ||||

| Crown rot | 0.067 | −0.218 | −0.093 | 0.042 | −0.181 | −0.063 | 0.003 | 1 | |||

| Decay | −0.088 | 0.108 | −0.209 | 0.041 | −0.208 | −0.076 | 0.055 | −0.011 | 1 | ||

| Blemish | −0.362 | 0.131 | −0.100 | −0.112 | −0.094 | 0.096 | −0.124 | −0.160 | −0.008 | 1 | |

| Misshapen | −0.088 | 0.201 | −0.007 | −0.327 | −0.007 | 0.126 | −0.257 | −0.130 | 0.002 | 0.011 | 1 |

| Cultivar | ||||||||

|---|---|---|---|---|---|---|---|---|

| Defects | Acco (Mean) | Acco (Total) | Hershkawitz (Mean) | Hershkawitz (Total) | Wonderful (Mean) | Wonderful (Total) | Total | Loss (%) |

| Biological | ||||||||

| Insect damage (mean) | 3.50 ± 0.72 e,* | 21 | 2.00 ± 0.68 e,f | 12 | 2.50 ± 0.43 d | 15 | ||

| Total | 21 | 12 | 15 | 48 | 2.96 | |||

| Irregular fruit size and shape | ||||||||

| Misshapen | 0.00 ± 0.00 f | 0 | 1.67 ± 0.42 e,f | 10 | 1.50 ± 0.43 d | 9 | ||

| Oversized | 0.00 ± 0.00 f | 0 | 0.00 ± 0.00 f | 0 | 2.00 ± 0.63 d | 12 | ||

| Total | 0 | 10 | 21 | 31 | 1.92 | |||

| Mechanical damage | ||||||||

| Bruise damage | 12.00 ± 1.61 d | 72 | 11.50 ± 0.43 d | 69 | 9.83 ± 1.08 c | 59 | ||

| Superficial injuries | 21.00 ± 0.73 b | 126 | 21.33 ± 0.80 b | 128 | 17.17 ± 0.54 b | 103 | ||

| Blemish | 3.00 ± 0.52 e | 18 | 3.00 ± 0.37 e | 18 | 3.33 ± 0.42 d | 20 | ||

| Total | 216 | 215 | 182 | 613 | 37.84 | |||

| Environmental stress | ||||||||

| Sunburn | 25.83 ± 0.87 a | 155 | 26.83 ± 1.47 a | 161 | 31.33 ± 0.61 a | 188 | ||

| Cracks and splits | 16.83 ± 1.08 c | 101 | 16.50 ± 1.28 c | 99 | 16.17 ± 1.14 b | 97 | ||

| Total | 256 | 260 | 285 | 801 | 49.44 | |||

| Microbial and pathological | ||||||||

| Alternaria | 3.83 ± 0.83 e | 23 | 2.83 ± 0.70 e | 17 | 2.67 ± 0.33 d | 16 | ||

| Crown rot | 2.00 ± 0.26 e,f | 12 | 2.67 ± 0.61 e | 16 | 1.50 ± 0.50 d | 9 | ||

| Decay and rots | 2.00 ± 0.37 e,f | 12 | 1.67 ± 0.21 e,f | 10 | 2.00 ± 0.63 d | 12 | ||

| Total | 47 | 43 | 37 | 127 | 7.84 |

| Factors | Case Study Packhouse | South Africa | Global |

|---|---|---|---|

| Production volume (tonnes) * | 4592.00 | 32,572.11 | 3139 × 103 |

| Average loss (%) | 7.16 | 7.16 | 7.16 |

| Retail price (ZAR/kg) a | 89.99 | 89.99 | 89.99 |

| Estimated physical and economic losses | |||

| Physical loss (tonnes) | 328.79 | 2,332.16 | 224,792.50 |

| Monetary loss (ZAR) | 29 × 106 | 209 × 106 | 20,229 × 106 |

| Environmental impacts | |||

| Estimated GHG emission (CO2 eq) b | 157 × 103 | 1 × 106 | 107 × 106 |

| Estimated energy used (MJ) c | 2 × 106 | 14 × 106 | 1371 × 106 |

| Resource impact | |||

| Water footprint (m3) d | 299 × 103 | 2122 × 103 | 204,561 × 103 |

| Equivalent land used to produce lost fruit (ha) | 8.54 | 60.58 | 5838.77 |

| Case Study Packhouse | National (South Africa) | Global | ||||

|---|---|---|---|---|---|---|

| Nutrition factor | Amount lost (mg100−1 g) * | Nutritional loss (per capita/day) ** | Amount lost (mg100−1 g) * | Nutritional loss (per capita/day) ** | Amount lost (mg100−1 g) * | Nutritional loss (per capita/day) ** |

| Fibre | 164.39 ## | 7.00 | 1166.08 ## | 47.00 | 112 × 103 ## | 4496.00 |

| Carbohydrate | 3255.02 ## | 25.00 | 23,088.38 ## | 178.00 | 222 × 104 ## | 17,119.00 |

| Protein | 460.30 ## | 10.00 | 3265.02 ## | 71.00 | 314 × 103 ## | 6842.00 |

| Iron | 98.64 | 5.00 | 699.65 | 39.00 | 67 × 103 | 3747.00 |

| Ascorbic acid | 4931.85 | 66.00 | 34,982.40 | 466.00 | 337 × 104 | 44,959.00 |

| Calcium | 9863.70 | 10.00 | 69,964.80 | 70.00 | 674 × 104 | 6744.00 |

| Magnesium | 3945.48 | 13.00 | 27,985.92 | 90.00 | 269 × 104 | 8702.00 |

| Sodium | 1315.16 | 1.00 | 9328.64 | 5.00 | 899 × 103 | 450.00 |

| Potassium | 56,223.09 | 12.00 | 398,799.40 | 85.00 | 384 × 105 | 8179.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Opara, I.K.; Fawole, O.A.; Opara, U.L. Postharvest Losses of Pomegranate Fruit at the Packhouse and Implications for Sustainability Indicators. Sustainability 2021, 13, 5187. https://doi.org/10.3390/su13095187

Opara IK, Fawole OA, Opara UL. Postharvest Losses of Pomegranate Fruit at the Packhouse and Implications for Sustainability Indicators. Sustainability. 2021; 13(9):5187. https://doi.org/10.3390/su13095187

Chicago/Turabian StyleOpara, Ikechukwu Kingsley, Olaniyi Amos Fawole, and Umezuruike Linus Opara. 2021. "Postharvest Losses of Pomegranate Fruit at the Packhouse and Implications for Sustainability Indicators" Sustainability 13, no. 9: 5187. https://doi.org/10.3390/su13095187

APA StyleOpara, I. K., Fawole, O. A., & Opara, U. L. (2021). Postharvest Losses of Pomegranate Fruit at the Packhouse and Implications for Sustainability Indicators. Sustainability, 13(9), 5187. https://doi.org/10.3390/su13095187