Synergistic Study of Solid Lubricant Nano-Additives Incorporated in canola oil for Enhancing Energy Efficiency and Sustainability

Abstract

1. Introduction

2. Experimental Details

2.1. Materials and Methods

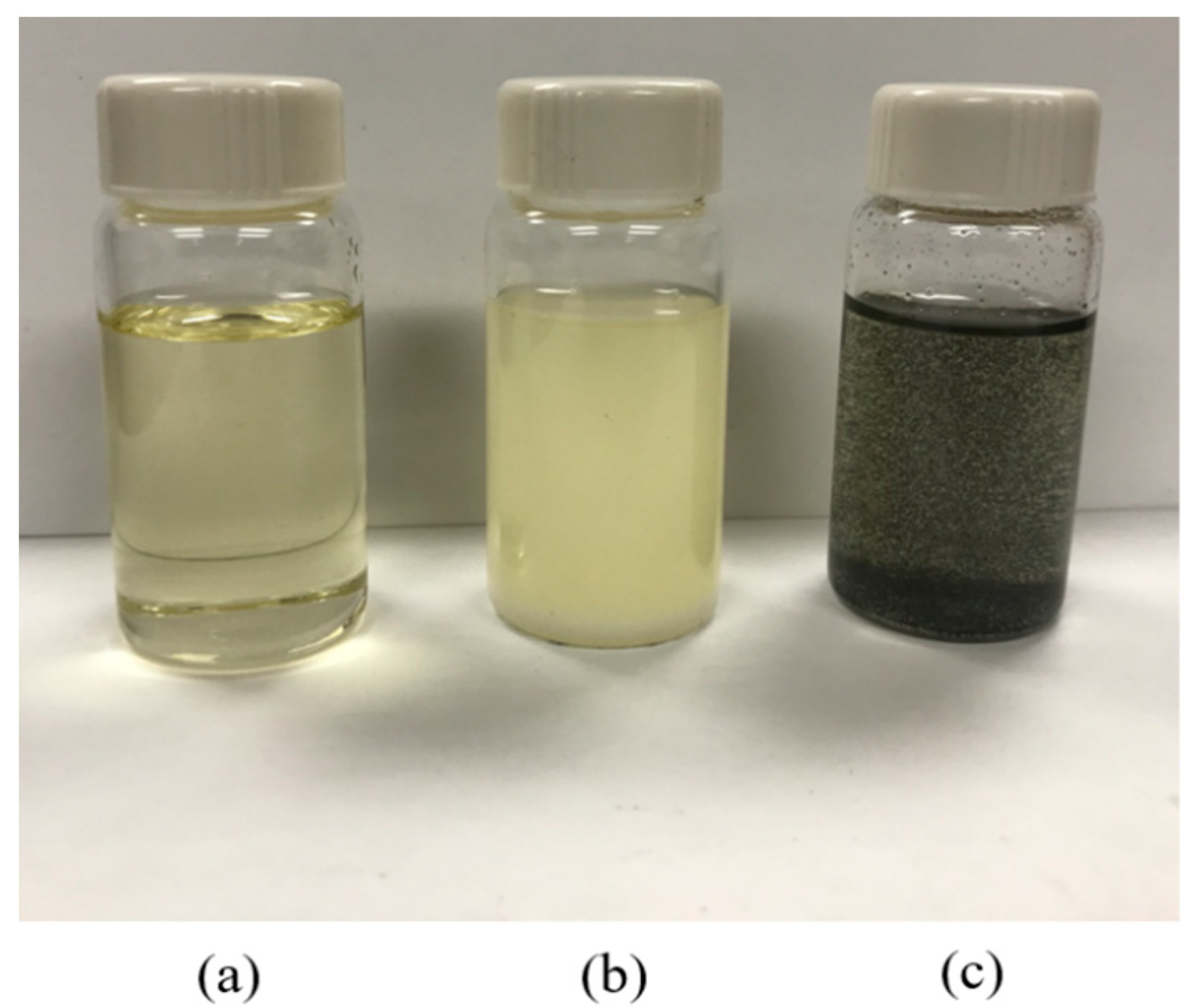

2.2. Preparation of Nano Lubricants

3. Results and Discussion

3.1. Viscosity and pH of the Lubricants

3.2. FTIR Analysis

3.3. Friction Analysis

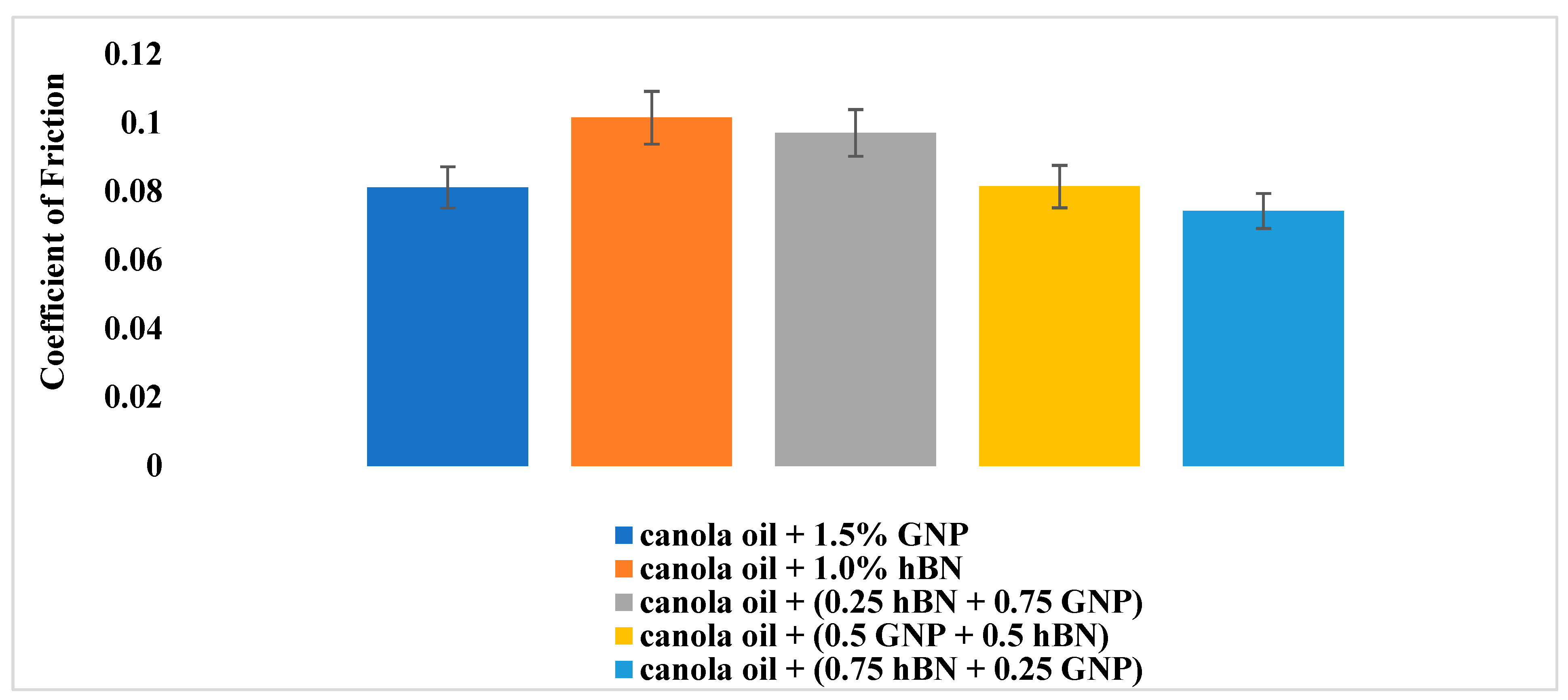

3.4. Wear Volume Analysis

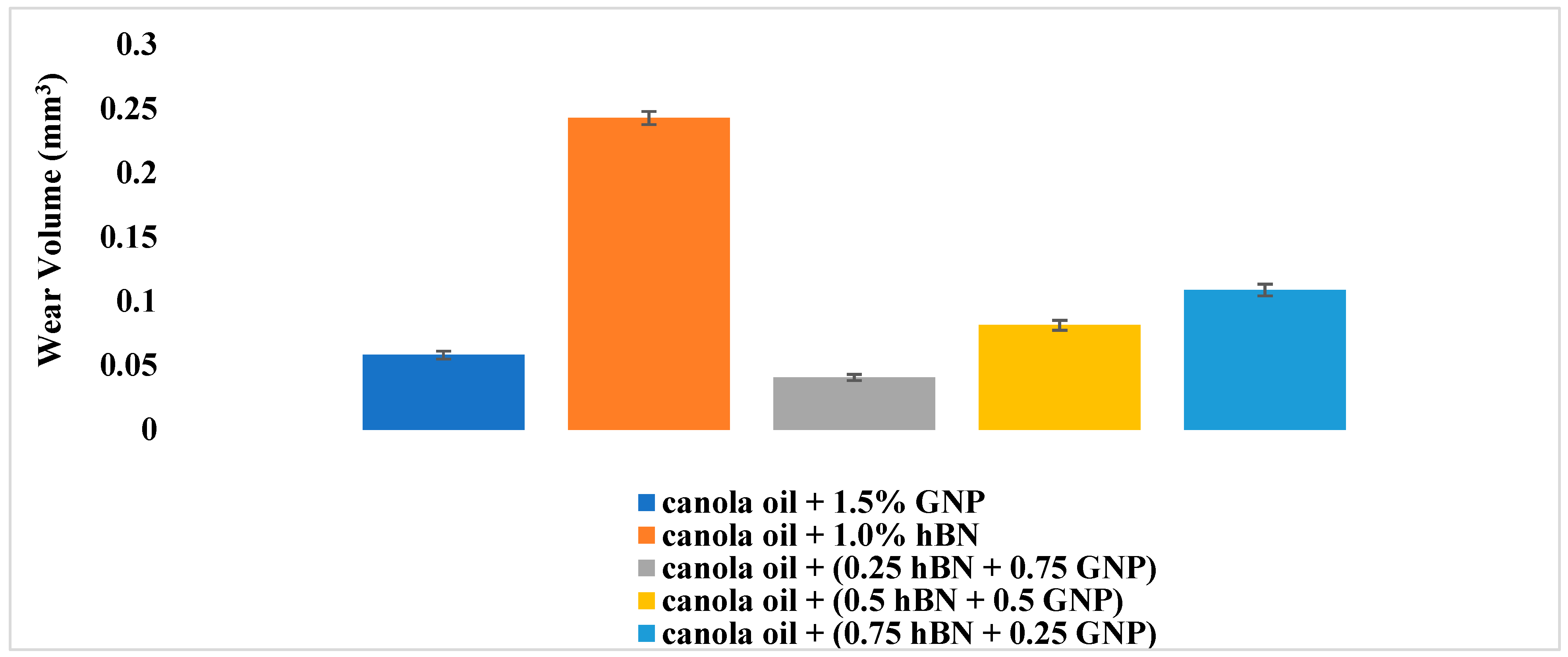

3.5. Worn Surface Analysis

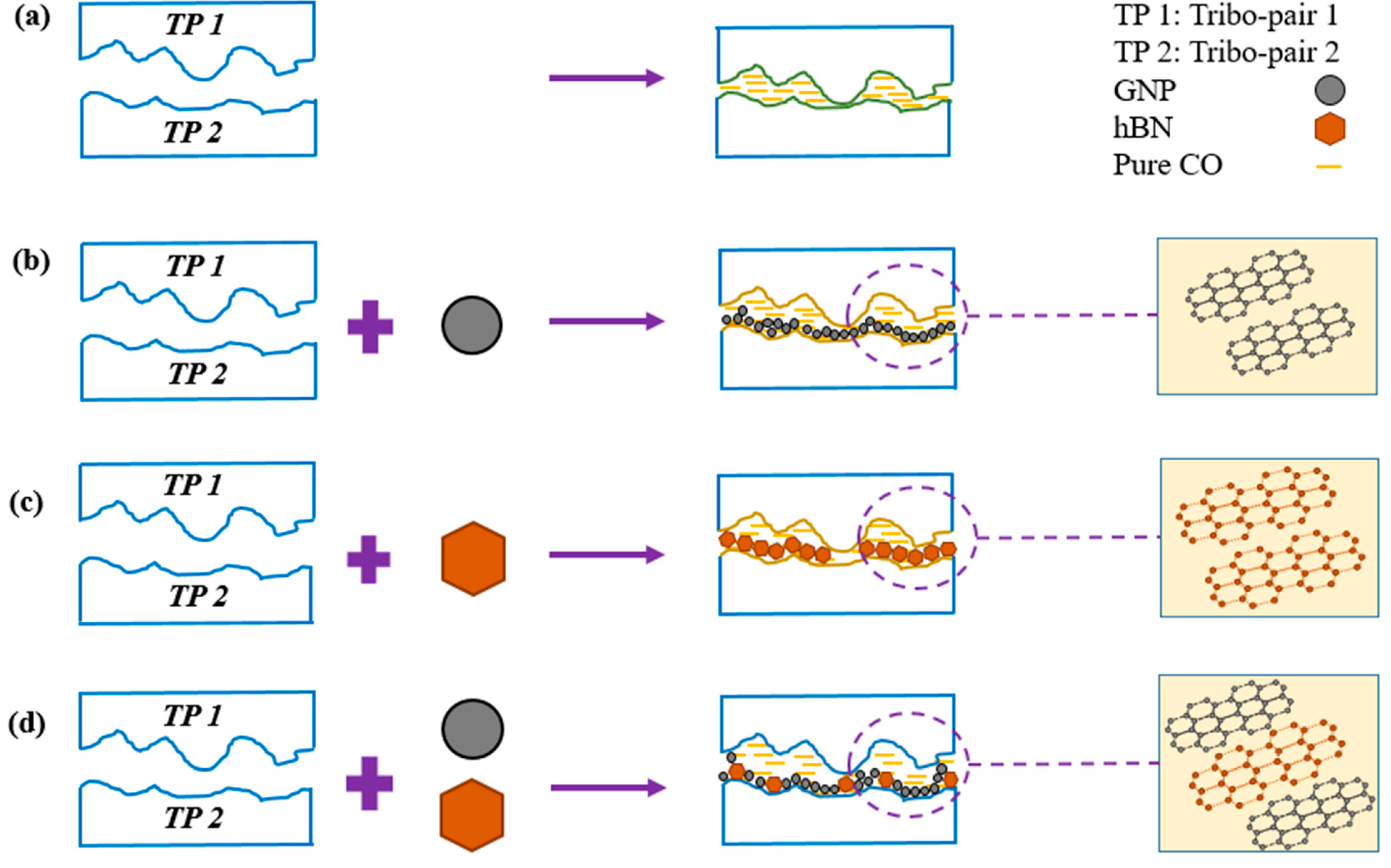

4. Friction and Wear Mechanisms

5. Summary

- The dynamic viscosity of pure canola oil increases with the incorporation of nano additives.

- The FTIR data provides an idea of the various chemical functional groups present in the canola oil.

- The-ball-on-disk test shows that 1.5 wt.% GNP nano lubricant exhibited the lowest COF and wear volume. Similarly, the 1.0 wt.% hBN nano lubricant exhibits the lowest COF and wear volume.

- When hBN and GNP are mixed and incorporated into the canola oil, they exhibit significant improvement in friction and wear behavior.

- A synergistic effect between hBN and GNP takes place when incorporated into the canola oil to form a hybrid nano lubricant mixture (especially the mixture containing higher hBN) pertaining to the COF. On the other hand, the hybrid mixture containing higher GNP exhibited the lowest wear volume.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lovell, M.R.; Kabir, M.; Menezes, P.L.; Higgs, C.F., III. Influence of boric acid additive size on green lubricant performance. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2010, 368, 4851–4868. [Google Scholar] [CrossRef] [PubMed]

- Fox, N.J.; Tyrer, B.; Stachowiak, G.W. Boundary Lubrication Performance of Free Fatty Acids in Sunflower Oil. Tribol. Lett. 2004, 16, 275–281. [Google Scholar] [CrossRef]

- Erhan, S.Z.; Sharma, B.K.; Liu, Z.; Adhvaryu, A. Lubricant base stock potential of chemically modified vegetable oils. J. Agric. Food Chem. 2008, 56, 8919–8925. [Google Scholar] [CrossRef]

- Lundgren, S.M.; Persson, K.; Mueller, G.; Kronberg, B.; Clarke, J.; Chtaib, M.; Claesson, P.M. Unsaturated fatty acids in alkane solution: Adsorption to steel surfaces. Langmuir 2007, 23, 10598–10602. [Google Scholar] [CrossRef]

- Reeves, C.J.; Menezes, P.L. Advancements in eco-friendly lubricants for tribological applications: Past, present, and future. In Ecotribology; Springer: Berlin/Heidelberg, Germany, 2016; pp. 41–61. [Google Scholar]

- Li, W.; Kong, X.H.; Ruan, M.; Ma, F.M.; Jiang, Y.F.; Liu, M.Z.; Chen, Y.; Zuo, X.H. Green waxes, adhesives and lubricants. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2010, 368, 4869–4890. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Jayadas, N.; Nair, K.P. Coconut oil as base oil for industrial lubricants—Evaluation and modification of thermal, oxidative and low temperature properties. Tribol. Int. 2006, 39, 873–878. [Google Scholar] [CrossRef]

- Liu, Y.; Binks, B.P. Foams of vegetable oils containing long-chain triglycerides. J. Colloid Interface Sci. 2021, 583, 522–534. [Google Scholar] [CrossRef]

- Salih, N.; Salimon, J.; Yousif, E. The physicochemical and tribological properties of oleic acid based triester biolubricants. Ind. Crop. Prod. 2011, 34, 1089–1096. [Google Scholar] [CrossRef]

- Omrani, E.; Menezes, P.L.; Rohatgi, P.K. Effect of micro-and nano-sized carbonous solid lubricants as oil additives in nanofluid on tribological properties. Lubricants 2019, 7, 25. [Google Scholar] [CrossRef]

- Reeves, C.J.; Menezes, P.L.; Lovell, M.R.; Jen, T.-C. The size effect of boron nitride particles on the tribological performance of biolubricants for energy conservation and sustainability. Tribol. Lett. 2013, 51, 437–452. [Google Scholar] [CrossRef]

- Singh, Y.; Farooq, A.; Raza, A.; Mahmood, M.A.; Jain, S. Sustainability of a non-edible vegetable oil based bio-lubricant for automotive applications: A review. Process. Saf. Environ. Prot. 2017, 111, 701–713. [Google Scholar] [CrossRef]

- Panchal, T.M.; Patel, A.; Chauhan, D.; Thomas, M.; Patel, J.V. A methodological review on bio-lubricants from vegetable oil based resources. Renew. Sustain. Energy Rev. 2017, 70, 65–70. [Google Scholar] [CrossRef]

- Chowdary, K.; Kotia, A.; Lakshmanan, V.; Elsheikh, A.H.; Ali, M.K.A. A review of the tribological and thermo-physical mechanisms of bio-lubricants based nanomaterials in automotive applications. J. Mol. Liq. 2021, 339, 116717. [Google Scholar] [CrossRef]

- Bartz, W.J. Ecotribology: Environmentally acceptable tribological practices. Tribol. Int. 2006, 39, 728–733. [Google Scholar] [CrossRef]

- Reeves, C.J.; Menezes, P.L. Evaluation of boron nitride particles on the tribological performance of avocado and canola oil for energy conservation and sustainability. Int. J. Adv. Manuf. Technol. 2016, 89, 3475–3486. [Google Scholar] [CrossRef]

- Gulzar, M.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Zulkifli, N.W.M.; Mufti, R.A.; Zahid, R. Tribological performance of na-noparticles as lubricating oil additives. J. Nanoparticle Res. 2016, 18, 1–25. [Google Scholar] [CrossRef]

- Reeves, C.J.; Siddaiah, A.; Menezes, P.L. A review on the science and technology of natural and synthetic bio-lubricants. J. Bio-Tribo-Corros. 2017, 3, 11. [Google Scholar] [CrossRef]

- Omrani, E.; Siddaiah, A.; Moghadam, A.D.; Garg, U.; Rohatgi, P.; Menezes, P.L. Ball Milled Graphene Nano Additives for Enhancing Sliding Contact in Vegetable Oil. Nanomaterials 2021, 11, 610. [Google Scholar] [CrossRef] [PubMed]

- Reeves, C.J.; Menezes, P.L.; Lovell, M.R.; Jen, T.-C. The influence of surface roughness and particulate size on the tribological performance of bio-based multi-functional hybrid lubricants. Tribol. Int. 2015, 88, 40–55. [Google Scholar] [CrossRef]

- John, M.; Menezes, P.L. Self-Lubricating Materials for Extreme Condition Applications. Materials 2021, 14, 5588. [Google Scholar] [CrossRef]

- Lisuzzo, L.; Hueckel, T.; Cavallaro, G.; Sacanna, S.; Lazzara, G. Pickering emulsions based on wax and halloysite nanotubes: An ecofriendly protocol for the treatment of archeological woods. ACS Appl. Mater. Interfaces 2020, 13, 1651–1661. [Google Scholar] [CrossRef] [PubMed]

- Cavallaro, G.; Milioto, S.; Nigamatzyanova, L.; Akhatova, F.; Fakhrullin, R.F.; Lazzara, G. Pickering Emulsion Gels Based on Halloysite Nanotubes and Ionic Biopolymers: Properties and Cleaning Action on Marble Surface. ACS Appl. Nano Mater. 2019, 2, 3169–3176. [Google Scholar] [CrossRef]

- Yu, L.; Li, S.; Stubbs, L.P.; Lau, H.C. Characterization of clay-stabilized, oil-in-water Pickering emulsion for potential conformance control in high-salinity, high-temperature reservoirs. Appl. Clay Sci. 2021, 213, 106246. [Google Scholar] [CrossRef]

- Suresha, B.; Hemanth, G.; Rakesh, A.; Adarsh, K. Tribological behaviour of neem oil with and without graphene nanoplatelets using four-ball tester. Adv. Tribol. 2020, 2020, 1984931. [Google Scholar] [CrossRef]

- Dai, W.; Kheireddin, B.; Gao, H.; Liang, H. Roles of nanoparticles in oil lubrication. Tribol. Int. 2016, 102, 88–98. [Google Scholar] [CrossRef]

- Talib, N.; Sasahara, H.; Rahim, E.A. Evaluation of modified jatropha-based oil with hexagonal boron nitride particle as a biolubricant in orthogonal cutting process. Int. J. Adv. Manuf. Technol. 2017, 92, 371–391. [Google Scholar] [CrossRef]

- Suresha, B.; Hemanth, G.; Padmanabha, A.; Prasanna, S.I.; Kulkarni, G.; Charan, M.R.S.; Amith, R. Tribological characteristics of mahua oil with graphene nanoplatelets as anti-wear and extreme pressure additive. Surf. Topogr. Metrol. Prop. 2021, 9, 045008. [Google Scholar] [CrossRef]

- Bhaumik, S.; Paleu, V.; Pathak, R.; Maggirwar, R.; Katiyar, J.K.; Sharma, A.K. Tribological investigation of r-GO additived biodegradable cashew nut shells liquid as an alternative industry lubricant. Tribol. Int. 2019, 135, 500–509. [Google Scholar] [CrossRef]

- Bhaumik, S.; Datta, S.; Pathak, S.D. Analyses of tribological properties of castor oil with various carbonaceous micro- and nano-friction modifiers. J. Tribol. 2017, 139, 061802. [Google Scholar] [CrossRef]

- Bahari, A.; Lewis, R.; Slatter, T. Friction and wear phenomena of vegetable oil–based lubricants with additives at severe sliding wear conditions. Tribol. Trans. 2018, 61, 207–219. [Google Scholar] [CrossRef]

- Kasar, A.K.; Menezes, P.L. Synthesis and recent advances in tribological applications of graphene. Int. J. Adv. Manuf. Technol. 2018, 97, 3999–4019. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene: A new emerging lubricant. Mater. Today 2014, 17, 31–42. [Google Scholar] [CrossRef]

- Talib, N.; Nasir, R.; Rahim, E. Tribological behaviour of modified jatropha oil by mixing hexagonal boron nitride nanoparticles as a bio-based lubricant for machining processes. J. Clean. Prod. 2017, 147, 360–378. [Google Scholar] [CrossRef]

- Gupta, M.K.; Bijwe, J.; Kadiyala, A.K. Tribo-investigations on oils with dispersants and hexagonal boron nitride particles. J. Tribol. 2018, 40, 441–456. [Google Scholar] [CrossRef]

- Düzcükoğlu, H.; Sahin, Ö.S. Investigation of wear performance of canola oil containing boric acid under boundary friction condition. Tribol. Trans. 2010, 54, 57–61. [Google Scholar] [CrossRef]

- Caballero, B. (Ed.) Encyclopedia of Food Sciences and Nutrition, 2nd ed.; Academic Press: Cambridge, MA, USA, 2003. [Google Scholar]

- Dhanola, A.; Garg, H. Dispersion stability and rheology study of canola oil containing TiO2 nanoadditives for tribological applications: An experimental approach. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 235, 1350650120973793. [Google Scholar] [CrossRef]

- Wu, Y.; Li, W.; Wang, X. The influence of oxidation on the tribological performance of diester lubricant. Lubr. Sci. 2014, 26, 55–65. [Google Scholar] [CrossRef]

- Rahman, H.; Bhoi, P.R.; Saha, A.; Patil, V.; Adhikari, S. Thermo-catalytic co-pyrolysis of biomass and high-density polyethylene for improving the yield and quality of pyrolysis liquid. Energy 2021, 225, 120231. [Google Scholar] [CrossRef]

- Reeves, C.J.; Menezes, P.L.; Jen, T.C.; Lovell, M.R. The influence of fatty acids on tribological and thermal properties of natural oils as sustainable biolubricants. Tribol. Int. 2015, 90, 123–134. [Google Scholar] [CrossRef]

- Ahammed, N.; Asirvatham, L.G.; Wongwises, S. Effect of volume concentration and temperature on viscosity and surface tension of graphene–water nanofluid for heat transfer applications. J. Therm. Anal. Calorim. 2016, 123, 1399–1409. [Google Scholar] [CrossRef]

- Chakraborty, S.; Panigrahi, P.K. Stability of nanofluid: A review. Appl. Therm. Eng. 2020, 174, 115259. [Google Scholar] [CrossRef]

- Ali, I.; Basheer, A.A.; Kucherova, A.; Memetov, N.; Pasko, T.; Ovchinnikov, K.; Pershin, V.; Kuznetsov, D.; Galunin, E.; Grachev, V.; et al. Advances in carbon nanomaterials as lubricants modifiers. J. Mol. Liq. 2019, 279, 251–266. [Google Scholar] [CrossRef]

- Talib, N.; Rahim, E. Performance of modified jatropha oil in combination with hexagonal boron nitride particles as a bio-based lubricant for green machining. Tribol. Int. 2018, 118, 89–104. [Google Scholar] [CrossRef]

- Qi, S.; Geng, Z.; Lu, Z.; Zhang, G.; Wu, Z. Synergistic Lubricating Behaviors of 3D Graphene and 2D Hexagonal Boron Nitride Dispersed in PAO4 for Steel/Steel Contact. Adv. Mater. Interfaces 2020, 7, 1901893. [Google Scholar] [CrossRef]

- Azman, N.F.; Samion, S. Dispersion Stability and Lubrication Mechanism of Nanolubricants: A Review. Int. J. Precis. Eng. Manuf. Technol. 2019, 6, 393–414. [Google Scholar] [CrossRef]

- Anand, R.; Raina, A.; Haq, M.I.U.; Mir, M.J.; Gulzar, O.; Wani, M.F. Synergism of TiO2 and Graphene as Nano-Additives in Bio-Based Cutting Fluid—An Experimental Investigation. Tribol. Trans. 2021, 64, 350–366. [Google Scholar] [CrossRef]

- Ahmed Abdalglil Mustafa, W.; Dassenoy, F.; Sarno, M.; Senatore, A. A review on potentials and challenges of nanolubricants as promising lubricants for electric vehicles. Lubr. Sci. 2021, 34, 1–29. [Google Scholar] [CrossRef]

- Leven, I.; Krepel, D.; Shemesh, O.; Hod, O. Robust Superlubricity in Graphene/h-BN Heterojunctions. J. Phys. Chem. Lett. 2013, 4, 115–120. [Google Scholar] [CrossRef]

- Mandelli, D.; Leven, I.; Hod, O.; Urbakh, M. Sliding friction of graphene/hexagonal–boron nitride heterojunctions: A route to robust superlubricity. Sci. Rep. 2017, 7, 10851. [Google Scholar] [CrossRef]

| Lubricant Sample | Additives | Tribological Equipment Set-Up | Observation from Results | Mechanism | References |

|---|---|---|---|---|---|

| Canola Oil | Graphene | Pin on disk | Coefficient of friction improved by 11 to 26 %. Wear rate improved by 47 to 83% | Protective film formation | [10] |

| Avocado Oil | Hexagonal boron nitride | Pin on disk | Coefficient of friction improved by 8 to 64%. Wear volume improved by 13 to 72% | Protective transfer film formation | [16] |

| Modified Jatropha Oil | Hexagonal boron nitride | Four ball tester with ASTM D4172 standards | Coefficient of friction improved by 20 to 57%. However, wear scar diameter increased | Rolling effect and protective film formation | [27] |

| Mahua Oil | Graphene | Four ball tester with ASTM D4172 standards | Coefficient of friction improved by 17.07% and wear scar diameter by 15.15% | Protective film formation | [28] |

| Cashew nutshell liquid | Reduced graphene oxide | Four ball tester with ASTM D4172 standards | Significant improvement in reduction of coefficient of friction and wear scar diameter | Protective film formation | [29] |

| Castor oil | Graphene | Four ball tester with ASTM D4172 standards | Significant improvement in reduction of coefficient of friction and wear scar diameter | Protective film formation | [30] |

| Soyabean oil (SBO), Palm oil (PO) | Hexagonal Boron Nitride | Ball on flat set-up | Coefficient of friction increased for both SBO and PO but a loss of mass reduced by 12 and 5% | Protective film formation | [31] |

| Alloy | Fe | Cr | C | Mn | Si | S | P | Al | Mg | Cu |

|---|---|---|---|---|---|---|---|---|---|---|

| Al 6061 | - | 0.20 | - | - | 0.6 | - | - | 97.9 | 1.0 | 0.28 |

| 52,100 | 96.5–97.32 | 1.3–1.6 | 0.98–1.1 | 0.25–0.45 | 0.15–0.3 | 0.025 | 0.025 | - | - | - |

| Additive | Thickness (nm) | Purity (%) | Density (g/cm3) | Shape | Color |

|---|---|---|---|---|---|

| hBN | 70 | 99.85 | 2.30 | hexagonal | white |

| GNP | 2–10 | 99.90 | 2.25 | layered | grey |

| Test Specifications | Numerical Value |

|---|---|

| Sliding distance | 100 m |

| Angular velocity | 21.5 rpm |

| Normal Load | 30 N |

| Test duration | 2700 s |

| Maximum hertzian contact pressure | 0.314 GPa |

| Chemical Compounds | Frequency Range (cm−1) | Functional Group | Pure Canola Oil | Canola Oil + GNP | Canola Oil + hBN | Canola Oil + hBN+ GNP |

|---|---|---|---|---|---|---|

| Zone 1 | 3700–3200 | |||||

| Alcohol | 3650–3200 | -O-H | × | × | × | × |

| Alkyne | 3340–3250 | ≡C-H | × | × | × | × |

| Zone 2 | 3200–2690 | |||||

| Aryl or Vinyl sp2 C-H bond | 3100–3000 | ≡C-H | × | × | × | × |

| Alkyl sp3 C-H bond | 2960–2850 | ≡C-H | √ | √ | √ | √ |

| Carboxylic acid | 3000–2500 | -COOH | √ | √ | √ | √ |

| Zone 3 | 2380–1990 | |||||

| Alkyne | 2260–2000 | -C≡C- | × | × | × | × |

| Zone 4 | 1850–1650 | |||||

| Ketone | 1750–1705 | =C=O | √ | √ | √ | √ |

| Aldehyde | 1740–1720 | >C=O | × | × | × | × |

| Zone 5 | 1650–1450 | |||||

| Alkene | 1650–1620 | =C=C= | × | × | × | × |

| Benzene | ~1600 and ~1500 | Benzene ring | × | × | × | × |

| C-H bond stretching vibration in presence of alkenes | 1470–1450 | ≡C-H | √ | √ | √ | √ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sikdar, S.; Rahman, M.H.; Menezes, P.L. Synergistic Study of Solid Lubricant Nano-Additives Incorporated in canola oil for Enhancing Energy Efficiency and Sustainability. Sustainability 2022, 14, 290. https://doi.org/10.3390/su14010290

Sikdar S, Rahman MH, Menezes PL. Synergistic Study of Solid Lubricant Nano-Additives Incorporated in canola oil for Enhancing Energy Efficiency and Sustainability. Sustainability. 2022; 14(1):290. https://doi.org/10.3390/su14010290

Chicago/Turabian StyleSikdar, Soumya, Md Hafizur Rahman, and Pradeep L. Menezes. 2022. "Synergistic Study of Solid Lubricant Nano-Additives Incorporated in canola oil for Enhancing Energy Efficiency and Sustainability" Sustainability 14, no. 1: 290. https://doi.org/10.3390/su14010290

APA StyleSikdar, S., Rahman, M. H., & Menezes, P. L. (2022). Synergistic Study of Solid Lubricant Nano-Additives Incorporated in canola oil for Enhancing Energy Efficiency and Sustainability. Sustainability, 14(1), 290. https://doi.org/10.3390/su14010290