1. Introduction

Polymers currently represent one of the most important materials for society and they are used in the most diverse industrial segments, from the automotive to the packaging sectors. Food-contact polymers are a group of polymers used for food packages and may influence the food quality since they can release contaminants during food storage [

1]. Contaminants can be incorporated into polymers by the use of additives during manufacturing, such as stabilizers, plasticizers, lubricants, antimicrobial agents, antioxidizing agents, antistatic agents, pigments, and others [

2,

3]. Among these contaminants are elements such as Cd and Pb, which are of great concern because of their potential toxicity [

4]. Therefore, developing suitable methods for the determination of potentially toxic elements in food-contact polymers is of considerable importance.

Several techniques have been used for the determination of potentially toxic elements in polymers, such as flame and graphite furnace atomic absorption spectrometry (FAAS and GFAAS), inductively coupled plasma optical emission spectrometry (ICP-OES), and inductively coupled plasma mass spectrometry (ICP-MS) [

5,

6,

7,

8,

9]. However, these techniques usually require the sample to be in solution form. Consequently, routine procedures for polymer analysis rely on decomposition methods followed by determination. When considering polymer decomposition, the conversion of solid samples into suitable solutions is not a straightforward task because of the high chemical resistance of these materials [

6]. Usually, severe pressure and temperature conditions, as well as concentrated acids, are necessary for polymer digestion. Moreover, the sample preparation is the most critical step of analysis, since it is susceptible to contamination and analyte losses [

10].

In this sense, solid sampling methods are considered to be an interesting alternative for polymer analysis. By using this approach, the sample decomposition step can be avoided, minimizing the analysis time, the waste generation, and the sources of contamination, and even improving the limits of detection (LODs). In this context, techniques such as electrothermal vaporization (ETV) and laser ablation (LA), coupled with ICP-based techniques, can be used [

11,

12]. However, these techniques present relatively high acquisition and operational costs compared to other techniques, such as FAAS [

13]. Flame atomic absorption spectrometry is a widespread, robust, and cheap technique to operate, and is usually available in routine laboratories [

13,

14]. However, its major limitation is the relatively high LODs, which makes the application of this technique more difficult for trace analysis. Some studies have developed systems allowing solid sampling using FAAS (SS-FAAS) [

15,

16,

17,

18,

19,

20,

21], which minimizes the sample preparation step and reduces the LOD values. One example of this approach is the combination of microwave-induced combustion (MIC) with flame furnace atomic absorption spectrometry (MIC-FF-AAS) [

22,

23]. In this study, the sample was combusted in a domestic microwave oven, and the analyte gases were directed to a flame furnace atomizer positioned over the flame. However, this system presented some reproducibility issues, and it was hard to couple it to the FAAS equipment [

22,

23].

In order to overcome the MIC-FF-AAS limitations, in a previous study [

24], a portable microwave applicator device was developed and coupled with an FAAS spectrometer. This technique is called microwave-assisted solid sampling analysis coupled to flame furnace atomic absorption spectrometry (MW-SS-FF-AAS) and it was applied for Hg determination in polymer samples. In this case, the samples were weighed on a quartz boat, which contained a microcrystalline cellulose pellet moistened with 6 mol L

−1 NH

4NO

3 (igniter solution), and were introduced into the microwave system for combustion and further Hg determination. Calibration was performed with the reference solutions, and the obtained LOQ for the Hg was 0.7 μg g

−1. The accuracy was verified using certified reference materials (CRMs), and the proposed microwave-assisted solid sampling system was considered suitable for Hg determination in polymers. In addition, this system is portable, which makes its coupling with conventional atomic absorption spectrometers easy, thus increasing the application possibilities of this technique [

24].

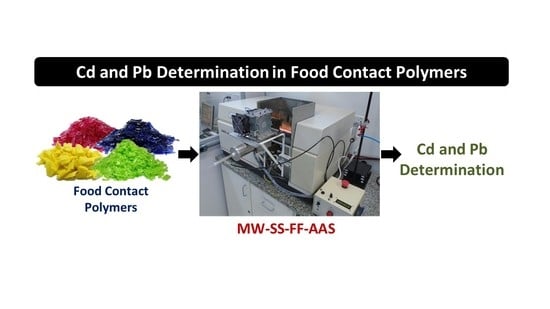

Considering the successful application of the MW-SS-FF-AAS system for Hg determination in polymers, which reduced reagent use and laboratory waste, the possibility of applying the same system for the determination of other elements was investigated. Thus, in this study, the MW-SS-FF-AAS system was applied, and the operational parameters of the proposed system were evaluated and optimized for the direct determination of Cd and Pb in food-contact polymers.

2. Materials and Methods

2.1. Instrumentation

For the Cd and Pb determination, the MW-SS-FF-AAS system, developed in a previous study [

24], was placed in front of the flame atomic absorption spectrometer (AAS Vario 6, Analytik Jena, Germany). The MW-SS-FF-AAS system (

Figure 1) comprises a quartz tube (9-mm i.d., 400-mm length) located inside a metallic waveguide (110-mm length, 65-mm width, 185-mm height) equipped with a magnetron (700 W of power). An injector tube (3-mm i.d., 80-mm length) was attached to the quartz tube end to allow connection with the FF atomizer (9-mm i.d., 100-mm length) positioned over the AAS flame [

24]. The FF atomizer was developed from a metallic bar (72% Ni, 15% Cr, 8% Fe, 0.5% Cu, and 0.3% Tl). A distance of 4 mm was kept between the burner and the FF atomizer. The background correction was performed using a deuterium lamp, and the Cd and Pb hollow-cathode lamps were operated at 4 and 10 mA, respectively. The monitored wavelengths were 288.8 nm (Cd) and 283.3 nm (Pb), and a 1.2-nm spectral resolution was used for both elements.

For the comparison of the results, samples were digested using a microwave oven (Multiwave 3000®, Anton Paar, Austria) equipped with quartz vessels (80 mL, maximum temperature of 280 °C, and maximum pressure of 80 bar). A Pb and Cd determination in digests was performed using an inductively coupled plasma mass spectrometer (Elan DRC II, PerkinElmer) with a concentric nebulizer (Meinhard Associates, USA) and a cyclonic spray chamber (Glass Expansion Inc., Australia). The radiofrequency (RF) power and the plasma, auxiliary, and nebulizer gas flow rates were set at 1400 W, 15.0, 1.2, and 1.05 L min−1, respectively. The Cd and Pb were determined by monitoring the 111Cd and 208Pb isotopes.

Microcrystalline cellulose pellets were made using a manual hydraulic press (Specac, UK) [

25]. An analytical microbalance (M2P, Sartorius, Germany) with a resolution of 0.001 mg, and a balance (AY 220, Shimadzu, Japan) with a resolution of 0.0001 g were used.

2.2. Reagents

Purified water (18.2 MΩ cm, Millipore, Burlington, MA, USA) was used to prepare the standards and diluted reagents. Nitric acid (65%, Merck, Darmstadt, Germany) and hydrochloric acid (37%, Merck) were purified in a distillation system (DuoPur, Milestone, Sorisole, Italy). A solution of NH4NO3 (Merck, 6 mol L−1) was used for the MW-SS-FF-AAS. Cadmium and Pb standard solutions (1000 mg L−1, Merck), microcrystalline cellulose, and filter paper with low ash content (Schleicher and Schuell GmbH, Dassel, Germany) were used for the MW-SS-FF-AAS. Argon (99.998%, White Martins, Rio De Janeiro, Brazil) was used for the ICP-MS. Oxygen (99.6%, White Martins, Brazil) and acetylene (99.8%, White Martins, Brazil) were used for the MW-SS-FF-AAS.

2.3. Samples and Sample Preparation

Food-contact polymer samples (high-density polyethylene (HDPE), polyethylene terephthalate (PET), polypropylene (PP), and polyvinyl chloride (PVC)) were bought in a local market. The polymers were previously washed with neutral detergent and ultrapure water and were then cut into pieces (3 × 3 mm). The samples were milled for digestion using a cryogenic mill (Spex Certiprep, USA). Certified reference materials of low-density polyethylene (LDPE) from the European Reference Materials (ERM) were used for the accuracy evaluation (ERM EC 680k and ERM EC 681k).

The polymer samples were also decomposed by microwave-assisted wet digestion (MAWD), according to previous studies [

6,

7]. For this, 300 mg of sample were weighted inside the quartz vessels, and reagents were added according to the polymer class: for the HDPE and PVC, 7 mL of HNO

3; and for the PET and PP, 7 mL of HNO

3 + 1 mL of HCl. The heating program used for the HDPE was: (i) 700 W for 45 min (5 min of ramp); and (ii) 0 W for 20 min (cooling). The heating program for the PET and PP was: (i) 800 W for 30 min (15 min of ramp); and (ii) 0 W for 20 min (cooling). The heating program for the PVC was: (i) 400 W for 10 min (10 min of ramp); (ii) 1000 W for 10 min (10 min of ramp); and (iii) 0 W for 20 min (cooling) [

6,

7].

2.4. MW-SS-FF-AAS Procedure

The food-contact polymers were weighed and placed on a quartz boat, which contained a cellulose pellet moistened with igniter solution (20 µL of 6 mol L

−1 NH

4NO

3). The boat was then inserted into the MW-SS-FF-AAS system for sample combustion. The standard solutions used for optimization and further calibration were pipetted directly onto the cellulose pellet. Inside the quartz tube, a continuous oxygen flow was applied for sample combustion and to carry the combustion gases to the atomizer. The microwave was activated only until the start of the sample combustion (about 5 s). Integrated absorbance was used for measurements (integration of 40 s) [

24]. The operational parameters of the system were evaluated, including the possibility of calibration using reference solutions.

3. Results and Discussion

Potentially toxic elements (e.g., Cd and Pb) present in polymers that are directly in contact with human or animal food are a problem to be further evaluated, and severe regulations need to be implemented. In this sense, analytical methods, especially those involving the reduction of reagents, and the consequent laboratory waste, are welcome. To evaluate the use of the MW-SS-FF-AAS system for the food-contact polymer analysis, some operation parameters must be optimized. The next sections aim to elucidate how the optimization was carried out, as well as to expose the complexities regarding the analysis of such complex matrices.

3.1. Combustion Parameters

Sample combustion parameters, such as the type of combustion aid, the platform position inside the MW applicator, and the igniter volume, were based in a previous study [

24]. Therefore, in all evaluations, the platform was positioned centrally inside the microwave applicator, and 20 µL of 6 mol L

−1 NH

4NO

3 were pipetted onto a pellet of 20 mg of cellulose for combustion.

3.2. Flame Furnace

The gases generated during the sample combustion inside the MW-SS system were directed to the FF atomizer positioned over the AAS burner. The FF atomizer can be used to increase the atom density in the optical path, leading to higher sensitivity when compared with conventional FAAS systems [

22,

24]. Moreover, the design used for the FF tube can directly affect analyte atomization and sensitivity, since it can cause changes in the temperature and chemical environment for atomization processes. Previous studies report the use of holes, or even a longitudinal slit, in order to increase the FF temperature and promote different atomization mechanisms (e.g., either collisional or via radical formation) [

22,

26,

27,

28]. Therefore, different FF designs were evaluated: a tube without holes; a tube with 6 or 12 holes (2 mm i.d.); and a tube with a longitudinal slit (2 × 100 mm). For this, reference solutions containing 100 ng of Cd, 200 ng of Pb, and 5 mg of the CRM, ERM EC 681k, were applied. The results are presented as the characteristic masses (m

0) and are shown in

Figure 2. It is important to highlight that the lower the characteristic mass, the higher the sensitivity [

13].

For the Cd, lower characteristic masses were obtained using an FF with 12 holes or a longitudinal slit, than for an FF without holes or with 6 holes. In addition, when the FFs with 6 holes and without holes were used, the analytical signal did not return to the baseline, leading to higher characteristic mass values. Thus, those FF designs were considered unsuitable for Cd determination in food-contact polymers. The characteristic mass values obtained for the FFs with 12 holes and with a longitudinal slit were very similar (221 and 230 pg, respectively, for the CRM). However, the FF with a longitudinal slit was chosen for the following optimizations because of the similarity of the characteristic mass values between the reference solutions and the solid CRM.

For the Pb, the sensitivity was higher when using the FF with 12 holes (m0 = 4046 pg for the reference solution, and m0 = 5415 pg for the ERM, EC 681k) and the FF with a longitudinal slit (m0 = 4330 pg for the reference solution, and m0 = 4090 pg for the ERM, EC 681k). This is probably due to the increase in temperature where the atomization takes place, caused by the flame gases inside the FF. Moreover, when using the FF with a longitudinal slit, no statistical difference (t-test, 95% of confidence level) was observed for the characteristic mass values for the reference solution and the CRM. Therefore, the FF with a longitudinal slit was used in the following experiments.

3.3. Flame Stoichiometry

The proportion between the gases that form the flame (air and acetylene) was evaluated, since it influences the temperature, which affects the atomization of the analytes [

26,

27,

29]. The flame stoichiometry can also promote atomization mechanisms by collisions or via radical formation. These collisional and radical mechanisms can be even more important when systems with FFs are used, especially models that allow the flame gases to enter (e.g., tubes with holes or longitudinal slits), since the internal temperature of the FF is usually lower than the temperature of the flame [

26,

27,

29]. To evaluate the flame stoichiometry influence on analyte atomization, a flow rate of 100 L h

−1 was used for acetylene gas, and the air flow rate was changed from 400 to 700 L h

−1. The results are shown in

Figure 3.

The flame stoichiometry did not have a high influence on the Cd characteristic mass value for the reference solution. However, increases in the characteristic mass values, as well as in the relative standard deviations (RSDs), were observed for the solid CRM when air-flow rates of 400 or 700 L h−1 were used (RSDs > 20%). On the other hand, lower RSDs (<7%) were obtained using an air flow rate of 500 or 600 L h−1. In addition, when using the air+acetylene flow rate of 500 + 100 L h−1, a good agreement was observed for the characteristic mass between the reference solution and the solid CRM. Therefore, this condition was chosen for the following experiments. The lead presented lower characteristic mass values and RSDs (<10%) when using air flow rates of 500 and 600 L h−1. These conditions also presented higher similarity between the characteristic mass of the solution and the solid CRM, which is an important aspect when calibration is performed using aqueous reference solutions. In this sense, the selected air + acetylene flow rates for the Pb determination were 600 + 100 L h−1.

3.4. Cellulose Mass

The mass of the microcrystalline cellulose, used as a combustion aid, was evaluated from 10 to 40 mg. The use of cellulose facilitates sample combustion inside the MW-SS-FF-AAS system, and allows for similar behavior between the reference solutions and the solid samples. The results are shown in

Figure 4.

As can be observed in

Figure 4, when cellulose masses from 10 to 30 mg were used, the characteristic mass values for Cd and Pb presented no statistical difference (one-way ANOVA, 95% confidence level). Additionally, the behavior of the analytes in the reference solution and in the solid CRM was very similar for all conditions. However, when using 40 mg of cellulose, higher characteristic mass values and higher RSDs were obtained for both analytes. This occurs possibly because water is generated during cellulose combustion. As water tends to condensate inside the combustion tube, it could lead to analyte absorption. The cellulose masses were selected on the basis of the lowest RSDs; thus, 20 mg for Cd, and 10 mg for Pb.

3.5. Oxygen Flow Rate

In the MW-SS-FF-AAS system, an oxygen flow is used for sample combustion, but it is also responsible for carrying the combustion gases to the FF atomizer. A higher oxygen flow rate can increase sample combustion efficiency, but it may also lead to a reduction in sensitivity, due to the reduction in the atom density in the optical path. Thus, in order to establish a compromise condition, the oxygen flow rate was evaluated from 0.2 to 1.0 L min

−1 (

Figure 5). Oxygen flow rates <0.2 L min

−1 and >1 L min

−1 were not used because the sample combustion was not reproducible.

As was expected, an increase in the characteristic mass values (decrease in sensitivity) was observed with the increase in the oxygen flow rate, probably due to the diffusional losses inside the FF atomizer. However, when oxygen flow rates of 0.2 and 0.4 L min−1 were used, the combustion was incomplete, leading to residues on the platform. In addition, when using 0.2 L min−1 of O2, a higher characteristic mass was also observed, possibly because this flow rate was too low to transport the analytes to the FF atomizer. As a compromise condition, an oxygen flow rate of 0.6 L min−1 was used for both analytes.

3.6. Analysis of Food-Contact Polymer Samples

After establishing the best conditions for the proposed system, the Cd and Pb determination was performed in food-contact polymers. Each condition was chosen to obtain higher sensitivity (lower values of characteristic mass) and similar analyte behavior between the reference solutions and the solid samples, in order to enable calibration with solutions and to avoid the use of expensive CRMs. Calibration curves were prepared by pipetting reference Cd and Pb solutions onto the cellulose pellets. For the Cd, masses from 5 to 250 ng were evaluated and the calibration was linear, from 10 to 175 ng. When 5 ng of Cd was tested, overestimated values and high RSDs were obtained (m

0 of 190 ± 77 pg, RSD of 40%). In addition, when Cd masses higher than 175 ng were used, the analytical signal did not return to the baseline, leading to underestimated results. For Pb, 75 to 1300 ng was evaluated and the calibration was considered linear, from 100 to 1000 ng, since masses outside of this range led to underestimated results.

Table 1 shows the linear calibration ranges, linear equations, and the coefficients of determination (R

2) obtained for each analyte.

To avoid under- or overestimated results, the effect of the sample mass-introduced into the MW-SS system was also evaluated [

30,

31]. This evaluation was performed by weighing the masses of ERM, EC 680k, from 0.5 to 10 mg for Cd, and from 5.5 to 33 mg for Pb. The measured concentrations in these experiments were within the linear calibration range (shown in

Table 1). Furthermore, masses higher than 35 mg of ERM 680k were considered unsuitable, since carbonaceous residues were observed on the platform and in the combustion tube, indicating incomplete combustion. As can be observed in

Figure 6, the average Cd and Pb concentrations calculated for all the evaluated masses were 19.8 ± 2.5 and 13.7 ± 1.8 μg g

−1, respectively. These results were in agreement with the certified values of the CRM, ERM EC 680k (19.6 ± 1.4 μg g

−1 for Cd, and 13.6 ± 0.5 μg g

−1 for Pb). Thus, the accuracy of the proposed method can be guaranteed using up to 10 mg for Cd determination, and up to 33 mg for Pb determination in polymers. The obtained RSDs considering all the evaluated masses were lower than 15%, which is appropriate for solid sampling analysis [

13].

Figure 7 presents the Cd and Pb analytical signal profiles from a reference solution and for the CRM, ERM EC 681k, under optimized conditions. Low background signals were observed for both analytes, possibly because the combustion system allows for the conversion of the polymer matrix to more simple compounds (e.g., CO

2 and H

2O). Thus, in this case, the deuterium lamp correction system was considered suitable for background correction.

The MW-SS-FF-AAS system was applied for Cd and Pb determination in food-contact polymers purchased at a local market. For a comparison of the results, these samples were also digested by MAWD, followed by Cd and Pb determination by ICP-MS [

6,

7]. In addition, two polymer CRMs were also analyzed. The results are shown in

Table 2.

As can be observed from

Table 2, the results for the Cd and Pb obtained for the CRMs by MW-SS-FF-AAS (ERM EC 680k and ERM EC 681k) presented no statistical differences (

t-test, 95% of confidence level) with the certified values. A good precision was also observed, and the RSDs were, in general, lower than 15%. Moreover, the Cd and Pb results obtained for the PP sample were in agreement (

t-test, 95% of confidence level), with results obtained by ICP-MS after MAWD. However, the analyte concentrations in the PET and PVC samples were lower than the LOQs of the MW-SS-FF-AAS method. For the HDPE, an agreement of only 55% was obtained with the results after MAWD. This is probably due to the presence of additives used as flame retardants, since a white residue was observed on the platform after combustion. This additive probably affected the sample combustion, as well as impaired the release of analytes from the matrix. In general, good results were obtained by the proposed MW-SS-FF-AAS method, which indicates its suitability for Cd and Pb determination in food-contact polymers.

4. Conclusions

The applicably of the MW-SS-FF-AAS system for Cd and Pb determination in food-contact polymers was demonstrated, minimizing the consumption of toxic, or otherwise harmful reagents, and the consequent laboratory waste generation. Polymers can be considered hard-to-digest samples and solid sampling methods are an excellent alternative for their analysis. The system was optimized in order to achieve high sensitivity (low characteristic mass) and similar behavior between the solid samples and the reference solutions (which made the calibration with the reference solutions possible). The limits of quantification obtained by the MW-SS-FF-AAS were considered suitable for Cd and Pb determination at relatively low concentrations (1.7 and 4.6 μg g−1 for Cd and Pb, respectively). Moreover, in comparison with the conventional FAAS technique, the sensitivity for the proposed system was improved 11 and 14 times for Cd and Pb, respectively. The accuracy was assessed by analyzing polymer CRMs and by a comparison with the results obtained by ICP-MS after MAWD. The results for the CRMs by MW-SS-FF-AAS presented no statistical difference with the certified values. Additionally, good agreement was observed with the results of the digestion method for food-contact polymers. Therefore, the proposed MW-SS-FF-AAS method can be considered a suitable alternative for Cd and Pb determination in food-contact polymers, as it is in agreement with the current recommendations for minimizing reagent consumption and the generation of effluents in analytical laboratories.