The Potential for Hydrolysed Sheep Wool as a Sustainable Source of Fertiliser for Irish Agriculture

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

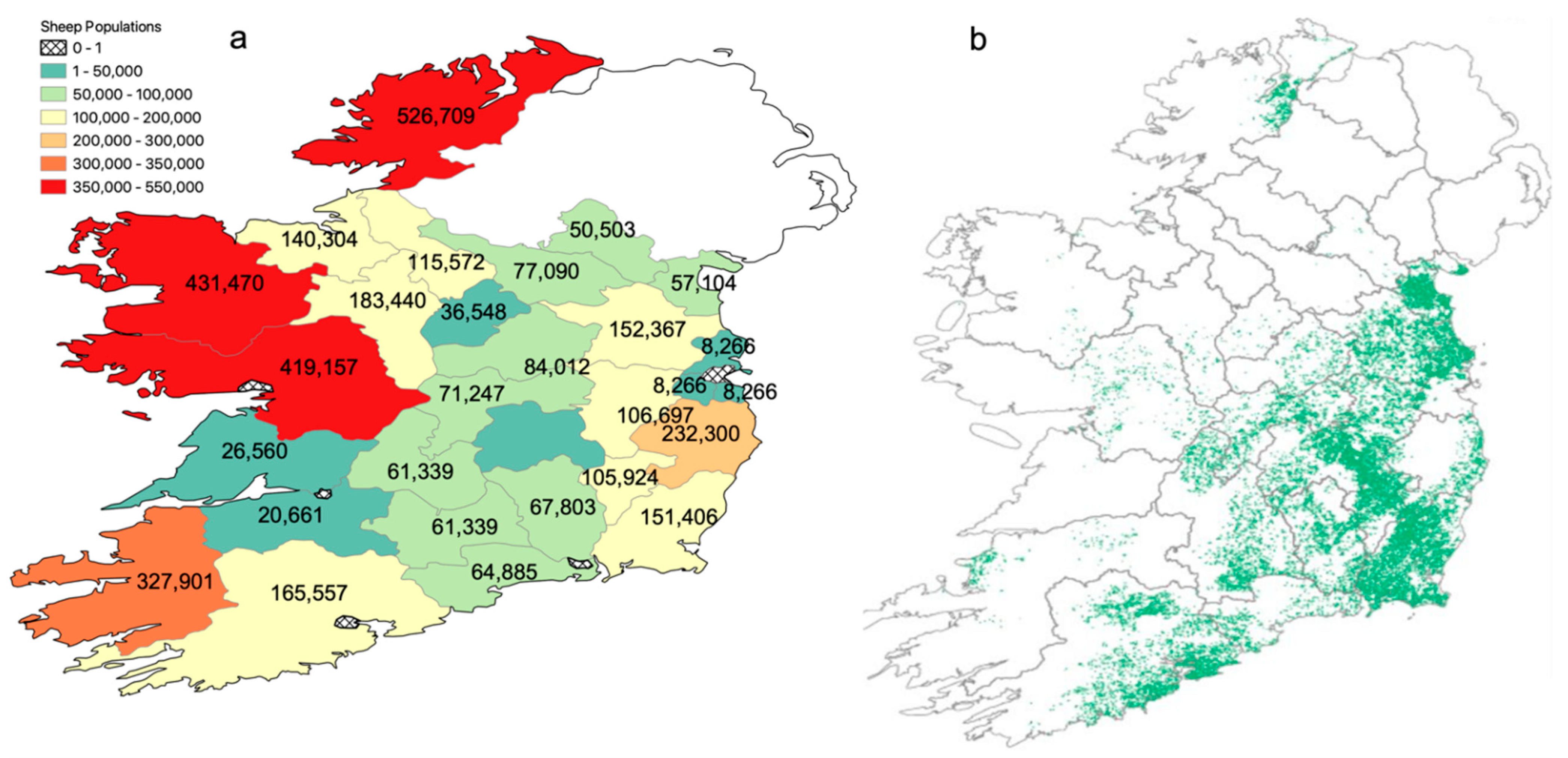

3.1. Amendment Quantity

3.2. Location of Processing Site

3.3. Economic Analysis

3.4. Future Work

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Byrne, T.; Amer, P.; Fennessy, P.; Cromie, A.; Keady, T.; Hanrahan, J.; McHugh, M.; Wickham, B. Breeding objectives for sheep in Ireland: A bio-economic approach. Livest. Sci. 2010, 132, 135–144. [Google Scholar] [CrossRef]

- Bohan, A.; Shalloo, L.; Creighton, P.; Berry, D.; Boland, T.; O’Brien, A.; Pabiou, T.; Wall, E.; McDermott, K.; McHugh, N. Deriving economic values for national sheep breeding objectives using a bio-economic model. Livest. Sci. 2019, 227, 44–54. [Google Scholar] [CrossRef]

- McLaren, A.; McHugh, N.; Lambe, N.; Pabiou, T.; Wall, E.; Boman, I. Factors affecting ewe longevity on sheep farms in three European countries. Small Rumin. Res. 2020, 189, 106145. [Google Scholar] [CrossRef]

- Rippon, J.A.; Christoe, J.R.; Denning, R.J.; Evans, D.J.; Huson, M.G.; Lamb, P.R.; Millington, K.R.; Pierlot, A.P. Wool: Structure, Properties, and Processing. In Encyclopedia of Polymer Science and Technology; Wiley: Hoboken, NJ, USA, 2016; pp. 1–46. [Google Scholar]

- Khan, M.J.; Abbas, A.; Ayaz, M.; Naeem, M.; Akhter, M.S.; Soomro, M.H. Factors affecting wool quality and quantity in sheep. Afr. J. Biotechnol. 2012, 11, 13761–13766. [Google Scholar] [CrossRef]

- Corscadden, K.; Biggs, J.; Stiles, D. Sheep’s wool insulation: A sustainable alternative use for a renewable resource? Resour. Conserv. Recycl. 2014, 86, 9–15. [Google Scholar] [CrossRef]

- Stiles, D.; Corscadden, K. Food/fibre/fuel: Exploring value chains through wool. In Proceedings of the Conference for the Avalon Agriculture Advantage: Growing Opportunities, Salmonier, NL Canada, 24 March 2011. [Google Scholar]

- CSO. Central Statistics Office. 2020. Available online: https://www.cso.ie/en/releasesandpublications/er/aypc/areayieldandproductionofcrops2019/ (accessed on 5 January 2021).

- Alyousef, R.; Alabduljabbar, H.; Mohammadhosseini, H.; Mohamed, A.M.; Siddika, A.; Alrshoudi, F.; Alaskar, A. Utilization of sheep wool as potential fibrous materials in the production of concrete composites. J. Build. Eng. 2020, 30, 101216. [Google Scholar] [CrossRef]

- Dénes, O.; Florea, I.; Manea, D.L. Utilization of Sheep Wool as a Building Material. Procedia Manuf. 2019, 32, 236–241. [Google Scholar] [CrossRef]

- Parlato, M.C.; Porto, S.M. Organized Framework of Main Possible Applications of Sheep Wool Fibers in Building Components. Sustainabilty 2020, 12, 761. [Google Scholar] [CrossRef] [Green Version]

- Zach, J.; Korjenic, A.; Petránek, V.; Hroudová, J.; Bednar, T. Performance evaluation and research of alternative thermal insulations based on sheep wool. Energy Build. 2012, 49, 246–253. [Google Scholar] [CrossRef]

- Bhavsar, P.; Zoccola, M.; Patrucco, A.; Montarsolo, A.; Mossotti, R.; Rovero, G.; Giansetti, M.; Tonin, C. Superheated Water Hydrolysis of Waste Wool in a Semi-Industrial Reactor to Obtain Nitrogen Fertilizers. ACS Sustain. Chem. Eng. 2016, 4, 6722–6731. [Google Scholar] [CrossRef]

- Holkar, C.R.; Jadhav, A.J.; Bhavsar, P.S.; Kannan, S.; Pinjari, D.V.; Pandit, A.B. Acoustic Cavitation Assisted Alkaline Hydrolysis of Wool Based Keratins to Produce Organic Amendment Fertilizers. ACS Sustain. Chem. Eng. 2016, 4, 2789–2796. [Google Scholar] [CrossRef]

- Goerner-Hu, X.; Scott, E.L.; Seeger, T.; Schneider, O.; Bitter, J.H. Reaction Stages of Feather Hydrolysis: Factors That Influence Availability for Enzymatic Hydrolysis and Cystine Conservation during Thermal Pressure Hydrolysis. Biotechnol. Bioprocess Eng. 2020, 25, 749–757. [Google Scholar] [CrossRef]

- Qiu, J.; Wilkens, C.; Barrett, K.; Meyer, A.S. Microbial enzymes catalyzing keratin degradation: Classification, structure, function. Biotechnol. Adv. 2020, 44, 107607. [Google Scholar] [CrossRef]

- Gogos, A.; Evangelou, M.; Schaffer, A.; Schulin, R. Hydrolysed wool: A novel soil amendment for zinc and iron biofortification of wheat. N. Z. J. Agric. Res. 2013, 56, 130–141. [Google Scholar] [CrossRef]

- Gousterova, A.; Nustorova, M.; Goshev, I.; Christov, P.; Braikova, D.; Tishinov, K.; Haertle, T.; Nedkov, P. Alkaline Hydrolysate of Waste Sheep Wool Aimed as Fertilizer. Biotechnol. Biotechnol. Equip. 2003, 17, 140–145. [Google Scholar] [CrossRef]

- Montanarella, L.; Panagos, P. The relevance of sustainable soil management within the European Green Deal. Land Use Policy 2021, 100, 104950. [Google Scholar] [CrossRef]

- DAFM. DAFM Sheep and Goat Census. 2020. Available online: https://data.cso.ie/table/AAA06 (accessed on 12 March 2021).

- De Barbieri, I.; Hegarty, R.; Li, L.; Oddy, V. Association of wool growth with gut metabolism and anatomy in sheep. Livest. Sci. 2015, 173, 38–47. [Google Scholar] [CrossRef]

- Mounter, S.W.; Griffith, G.R.; Piggott, R.R.; Fleming, E.M.; Zhao, X. Composition of the National Sheep Flock and Specification of Equilibrium Prices and Quantities for the Australian Sheep and Wool Industries, 2002–03 to 2004–05. In Economic Research Report No. 37; NSW Department of Primary Industries: Orange, Australia, 2007. [Google Scholar]

- Zoccola, M.; Montarsolo, A.; Mossotti, R.; Patrucco, A.; Tonin, C. Green Hydrolysis as an Emerging Technology to Turn Wool Waste into Organic Nitrogen Fertilizer. Waste Biomass Valorization 2015, 6, 891–897. [Google Scholar] [CrossRef]

- Robards, G. Regional and Seasonal Variation in Wool Growth Throughout Australia; The University of New England Publishing Unit: Armidale, NSW, Australia, 1998; pp. 1–42. [Google Scholar]

- Connolly, L. Competitiveness in Irish Sheep Production; Teagasc, Ed.; Teagasc: Galway, Ireland, 1999. [Google Scholar]

- Donnellan, T.; Moran, B.; Lennon, J.; Dillon, E. Teagasc National Farm Survey 2019; Teagasc: Carlow, Ireland, 2020. [Google Scholar]

- Rajabinejad, H.; Zoccola, M.; Patrucco, A.; Montarsolo, A.; Rovero, G.; Tonin, C. Physiochemical properties of keratin extracted from wool by various methods. Text. Res. J. 2017, 88, 2415–2424. [Google Scholar] [CrossRef]

- Roques, S.; Kendall, S.; Smith, K.; Price, P.N.; Berry, P. A Review of the Non-NPKS Nutrient Requirements of UK Cereals and Oilseed Rape; AHDB, Ed.; AHDB: Warwickshire, UK, 2013. [Google Scholar]

- Rehman, A.; Farooq, M.; Ozturk, L.; Asif, M.; Siddique, K.H.M. Zinc nutrition in wheat-based cropping systems. Plant Soil 2017, 422, 283–315. [Google Scholar] [CrossRef]

- Kumar, V.; Pandita, S.; Sidhu, G.P.S.; Sharma, A.; Khanna, K.; Kaur, P.; Bali, A.S.; Setia, R. Copper bioavailability, uptake, toxicity and tolerance in plants: A comprehensive review. Chemosphere 2021, 262, 127810. [Google Scholar] [CrossRef]

- Grace, N.D.; Lee, J. Influence of high zinc intakes, season, and staple site on the elemental composition of wool and fleece quality in grazing sheep. N. Z. J. Agric. Res. 1992, 35, 367–377. [Google Scholar] [CrossRef]

- Wyrostek, A.; Kinal, S.; Patkowska-Sokoła, B.; Bodkowski, R.; Cholewińska, P.; Czyż, K. The influence of zinc-methionine bioplex supplementation to pregnant and lactating sheep on selected wool parameters. Arch. Anim. Breed. 2019, 62, 99–105. [Google Scholar] [CrossRef]

- Ragaišienė, A.; Rusinavičiūtė, J.; Milašienė, D.; Ivanauskas, R. Comparison of Selected Chemical Properties of Fibres from Different Breeds of Dogs and German Blackface Sheep. Fibres Text. East. Eur. 2016, 24, 21–28. [Google Scholar] [CrossRef]

- Sahoo, A.; Soren, N. Nutrition for Wool Production. Webmed Cent. Nutr. 2011, 2, WMC002384. [Google Scholar]

- Hawkins, D.; Ragnarsdóttir, K. The Cu, Mn and Zn concentration of sheep wool: Influence of washing procedures, age and colour of matrix. Sci. Total Environ. 2009, 407, 4140–4148. [Google Scholar] [CrossRef] [PubMed]

- Scott, G.; Glimp, H.A. Sheepman’s Production Handbook; Sheep Industry Development Program: Englewood, CO, USA, 1975. [Google Scholar]

- Patkowska-Sokoła, B.; Dobrzański, Z.; Osman, K.; Bodkowski, R.; Zygadlik, K. The content of chosen chemical elements in wool of sheep of different origins and breeds. Arch. Anim. Breed. 2009, 52, 410–418. [Google Scholar] [CrossRef]

- Solcova, O.; Knapek, J.; Wimmerova, L.; Vavrova, K.; Kralik, T.; Rouskova, M.; Sabata, S.; Hanika, J. Environmental aspects and economic evaluation of new green hydrolysis method for waste feather processing. Clean Technol. Environ. Policy 2021, 23, 1863–1872. [Google Scholar] [CrossRef]

- Argo, E.; Keshwani, D.R. Techno-Economic Implications of Fed-Batch Enzymatic Hydrolysis. Processes 2019, 7, 847. [Google Scholar] [CrossRef] [Green Version]

- Baroni, M.V.; Podio, N.S.; Badini, R.G.; Inga, M.; Ostera, H.A.; Cagnoni, M.; Gallegos, E.; Gautier, E.; Peral-García, P.; Hoogewerff, J.; et al. How Much Do Soil and Water Contribute to the Composition of Meat? A Case Study: Meat from Three Areas of Argentina. J. Agric. Food Chem. 2011, 59, 11117–11128. [Google Scholar] [CrossRef]

- Ashraf, M.T.; Schmidt, J.E. Process simulation and economic assessment of hydrothermal pretreatment and enzymatic hydrolysis of multi-feedstock lignocellulose—Separate vs combined processing. Bioresour. Technol. 2018, 249, 835–843. [Google Scholar] [CrossRef] [PubMed]

- Abdallah, A.; Ugolini, F.; Baronti, S.; Maienza, A.; Camilli, F.; Bonora, L.; Martelli, F.; Primicerio, J.; Ungaro, F. The potential of recycling wool residues as an amendment for enhancing the physical and hydraulic properties of a sandy loam soil. Int. J. Recycl. Org. Waste Agric. 2019, 8, 131–143. [Google Scholar] [CrossRef] [Green Version]

| County | Region | N Flocks | Average Flock Size | Ewes > 12 Months | Rams | Other Sheep | Total Sheep | % of National Flock |

|---|---|---|---|---|---|---|---|---|

| Carlow | South East | 689 | 154 | 71,492 | 2139 | 32,293 | 105,924 | 2.78 |

| Cavan | Border | 943 | 82 | 50,182 | 1900 | 25,008 | 77,090 | 2.02 |

| Clare | Mid-West | 573 | 46 | 17,443 | 775 | 8342 | 26,560 | 0.69 |

| Cork | South West | 1684 | 98 | 117,530 | 3454 | 44,573 | 165,557 | 4.35 |

| Donegal | Border | 6032 | 87 | 354,058 | 11,603 | 161,048 | 526,709 | 13.83 |

| Dublin | Mid-East and Dublin | 201 | 123 | 18,150 | 654 | 5996 | 24,800 | 0.65 |

| Galway | West | 4057 | 103 | 277,951 | 9262 | 131,944 | 419,157 | 11.00 |

| Kerry | South West | 2457 | 133 | 243,025 | 6617 | 78,259 | 327,901 | 8.61 |

| Kildare | Mid-East and Dublin | 652 | 164 | 68,771 | 2172 | 35,754 | 106,697 | 2.80 |

| Kilkenny | South East | 464 | 146 | 44,997 | 1394 | 21,412 | 67,803 | 1.78 |

| Laois | Midlands | 424 | 110 | 28,852 | 1057 | 16,786 | 46,695 | 1.23 |

| Leitrim | Border | 1142 | 101 | 82,451 | 2715 | 30,406 | 115,572 | 3.03 |

| Limerick | Mid-West | 219 | 94 | 13,079 | 416 | 7166 | 20,661 | 0.54 |

| Longford | Midlands | 421 | 87 | 25,106 | 903 | 10,539 | 36,548 | 0.96 |

| Louth | Mid-East and Dublin | 361 | 158 | 35,170 | 1141 | 20,793 | 57,104 | 1.49 |

| Mayo | West | 4842 | 89 | 310,069 | 9459 | 111,942 | 431,470 | 11.33 |

| Meath | Mid-East and Dublin | 989 | 154 | 100,413 | 3262 | 48,701 | 152,376 | 4.00 |

| Monaghan | Border | 503 | 100 | 30,093 | 1178 | 19,232 | 50,503 | 1.33 |

| Offaly | Midlands | 559 | 127 | 44,544 | 1370 | 25,333 | 71,247 | 1.87 |

| Roscommon | West | 1779 | 103 | 122,399 | 3820 | 57,221 | 183,440 | 4.82 |

| Sligo | Border | 1588 | 88 | 101,350 | 3391 | 35,563 | 140,304 | 3.68 |

| Tipperary | Mid-West | 880 | 139 | 75,764 | 2283 | 44,630 | 122,677 | 3.22 |

| Waterford | South East | 409 | 159 | 45,559 | 1244 | 18,052 | 64,855 | 1.70 |

| Westmeath | Midlands | 737 | 114 | 55,108 | 2200 | 26,704 | 84,012 | 2.21 |

| Wexford | South East | 1035 | 146 | 85,001 | 2827 | 63,578 | 151,406 | 3.97 |

| Wicklow | Mid-East and Dublin | 1298 | 179 | 152,313 | 4819 | 75,168 | 232,300 | 6.10 |

| Total | - | 34,938 | 119 | 2570,870 | 82,055 | 1156,443 | 3809,368 | 100 |

| Author | References | Minimum Yield | Maximum Yield |

|---|---|---|---|

| DeBarbieri | [21] | 3.8 | 5.1 |

| Mounter | [22] | 3.5 | 6.2 |

| Zoccola | [23] | 1.5 | 3 |

| Parlato | [11] | 1.5 | - |

| Corscadden | [6] | 2.3 | 3.6 |

| Robards | [24] | 2 | 5 |

| Connolly | [25] | - | 5.8 |

| www.iwto.org 1 | - | - | 4.5 |

| Alyousef | [9] | 2.3 | 3.6 |

| Source | References | Nitrogen | Sulphur | Phosphorus | Potassium | Calcium | Zinc | Iron | Copper |

|---|---|---|---|---|---|---|---|---|---|

| Parlato | [11] | 250,000 | 30,000 | - | - | - | - | - | - |

| Holkar | [14] | 165,000 | 35,000 | - | - | - | - | - | - |

| Gogos | [17] | 21,000 | 86,000 | - | 310 | 400 | 44 | 4.8 | - |

| Gogos | [17] | 38,000 | 320,000 | - | 710 | 670 | 63 | 5.8 | - |

| Zoccola | [23] | 165,000 | 35,000 | - | - | - | - | - | - |

| Grace | [31] | - | - | - | - | - | 80 | - | - |

| Grace | [31] | - | - | - | - | - | 300 | - | - |

| Wyrostek | [32] | - | - | - | - | - | 86 | - | - |

| Wyrostek | [32] | - | - | - | - | - | 98 | - | - |

| Ragaisiene | [33] | 148,000 | 10,000 | - | - | - | - | - | - |

| Sahoo | [34] | - | 31,000 | 120 | 3300 | 323 | 114 | 42 | 3 |

| Hawkins | [35] | - | - | - | - | - | 670 | - | 5 |

| Hawkins | [35] | - | - | - | - | - | 2200 | - | 9 |

| Scott | [36] | - | - | - | - | - | 195 | - | - |

| Patkowska-Sokola | [37] | - | - | 148 | 643 | 1790 | 74 | 22 | 5 |

| Patkowska-Sokola | [37] | - | - | 284 | 755 | 2900 | 89 | 510 | 10 |

| Minimum | 21,000 | 10,000 | 120 | 310 | 323 | 44 | 4.8 | 3 | |

| Average | 131,167 | 78,143 | 184 | 1144 | 1217 | 334 | 117 | 6.5 | |

| Maximum | 250,000 | 320,000 | 284 | 3300 | 2900 | 2200 | 510 | 10 | |

| SD a | 86,615 | 109,135 | 88 | 1218 | 1110 | 613 | 220 | 3 | |

| N | 6 | 7 | 3 | 5 | 5 | 12 | 5 | 5 |

| Crop | Area (ha) | Na (kg ha−1) b | Nreq (t) | % Replaced |

|---|---|---|---|---|

| Winter Wheat | 35,000 | 190 | 6650 | 26.9 |

| Winter Barley | 51,500 | 166 | 8549 | 20.9 |

| Winter Oats | 8300 | 146 | 1212 | 147.3 |

| Spring Wheat | 11,500 | 130 | 1495 | 119.7 |

| Spring Barley | 141,700 | 125 | 17,713 | 10.1 |

| Spring Oats | 17,200 | 105 | 1806 | 99.1 |

| Total | 265,200 | - | 37,424 | 4.78 |

| Input | Amount | Cost | Cost | Cost | Cost |

|---|---|---|---|---|---|

| Fleece Price | - | 0 | 1 | 2 | 3 |

| Feedstock Costs b | 340 | 0 | 55–227 | 109–453 | 164–680 |

| Natural Gas | 0.71 (MWh) | 27.7 | 27.7 | 27.7 | 27.7 |

| Water | 2.5 (m3) | 4 | 4 | 4 | 4 |

| Electricity | 100 (kWh) | 8 | 8 | 8 | 8 |

| Malic Acid | 18 (kg) | 75 | 75 | 75 | 75 |

| Other Costs | - | 2 | 2 | 2 | 2 |

| Total Costs b | - | 116.7 | 172–343 | 226–570 | 281–796 |

| Nutrient | Price Point 1 | Price Point 2 | Price Point 3 |

|---|---|---|---|

| N | 1 | 1.5 | 2 |

| S | 0.4 | 0.6 | 0.8 |

| P | 2 | 3 | 4 |

| K | 0.83 | 1.25 | 1.7 |

| Ca | 0.5 | 0.75 | 1 |

| Zn | 2.5 | 3.4 | 5.1 |

| Fe | 0.17 | 0.25 | 0.34 |

| Cu | 7.7 | 11.5 | 15.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gillespie, G.D.; Dada, O.; McDonnell, K.P. The Potential for Hydrolysed Sheep Wool as a Sustainable Source of Fertiliser for Irish Agriculture. Sustainability 2022, 14, 365. https://doi.org/10.3390/su14010365

Gillespie GD, Dada O, McDonnell KP. The Potential for Hydrolysed Sheep Wool as a Sustainable Source of Fertiliser for Irish Agriculture. Sustainability. 2022; 14(1):365. https://doi.org/10.3390/su14010365

Chicago/Turabian StyleGillespie, Gary D., Oyinlola Dada, and Kevin P. McDonnell. 2022. "The Potential for Hydrolysed Sheep Wool as a Sustainable Source of Fertiliser for Irish Agriculture" Sustainability 14, no. 1: 365. https://doi.org/10.3390/su14010365

APA StyleGillespie, G. D., Dada, O., & McDonnell, K. P. (2022). The Potential for Hydrolysed Sheep Wool as a Sustainable Source of Fertiliser for Irish Agriculture. Sustainability, 14(1), 365. https://doi.org/10.3390/su14010365