Analysis of Turbulent Flow Structure with Its Fluvial Processes around Mid-Channel Bar

Abstract

:1. Introduction

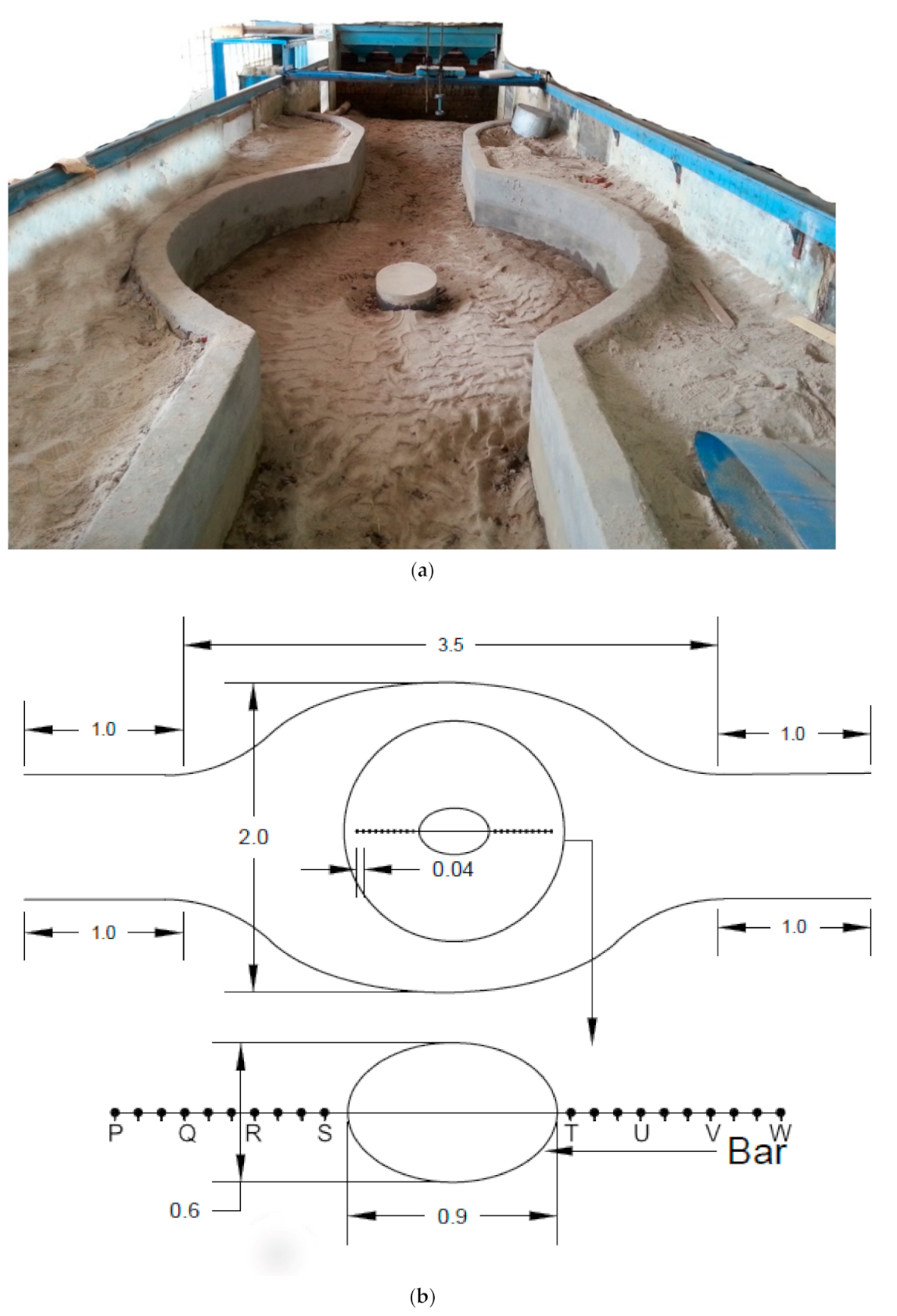

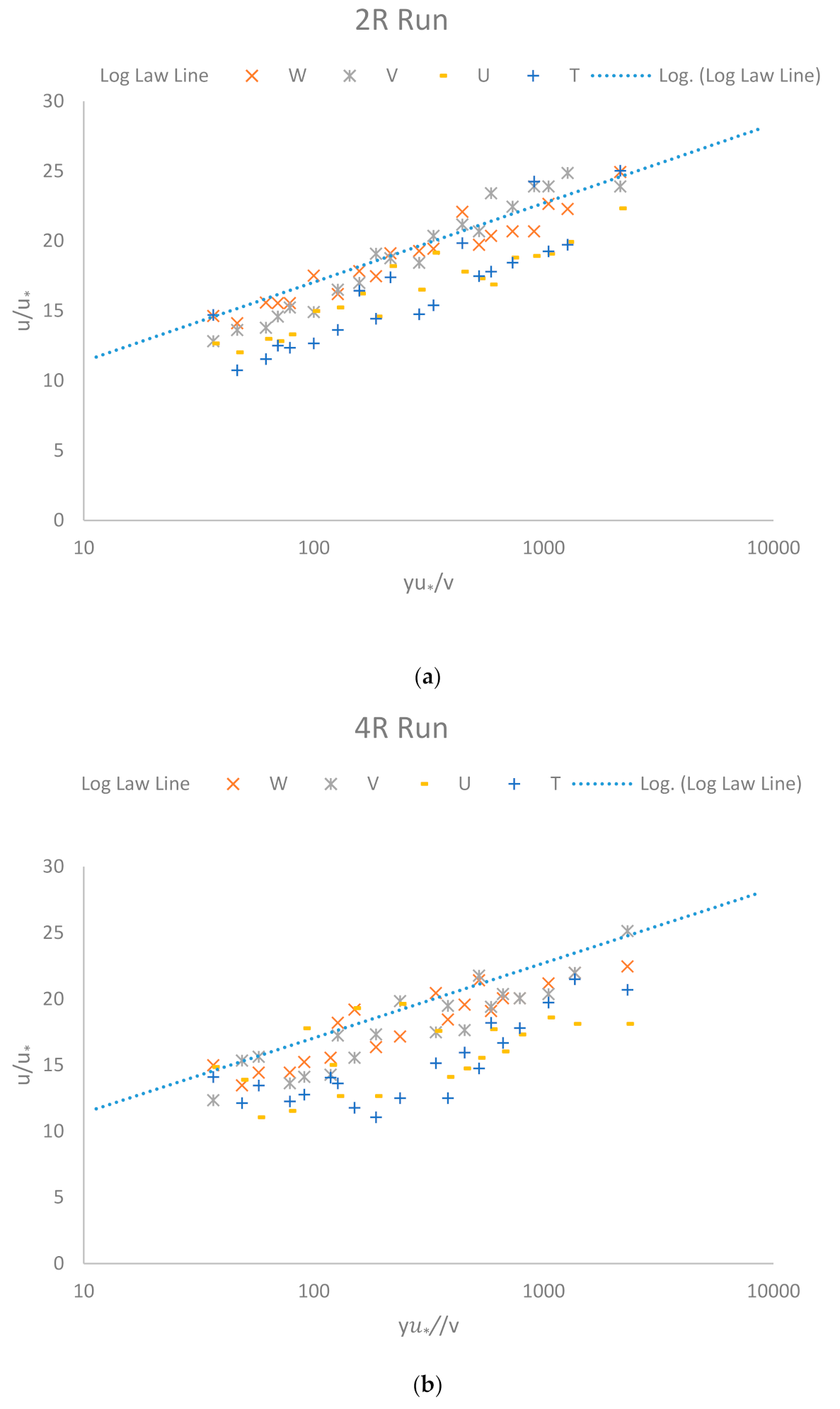

2. Experimental Program

3. Results and Discussion

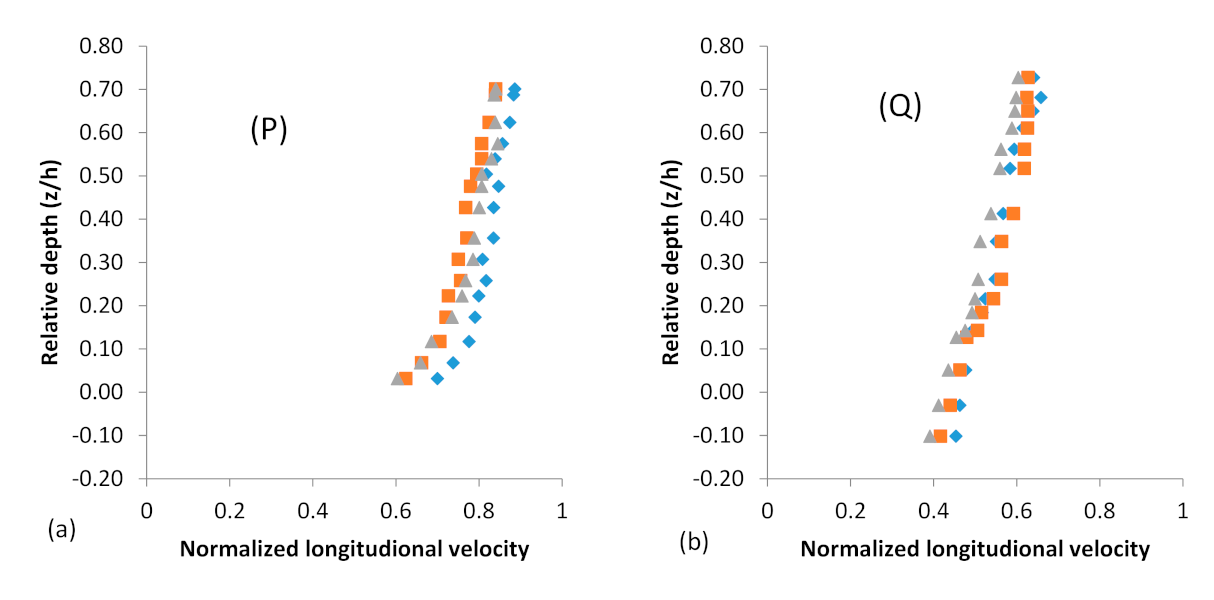

3.1. Wake Flow Analysis

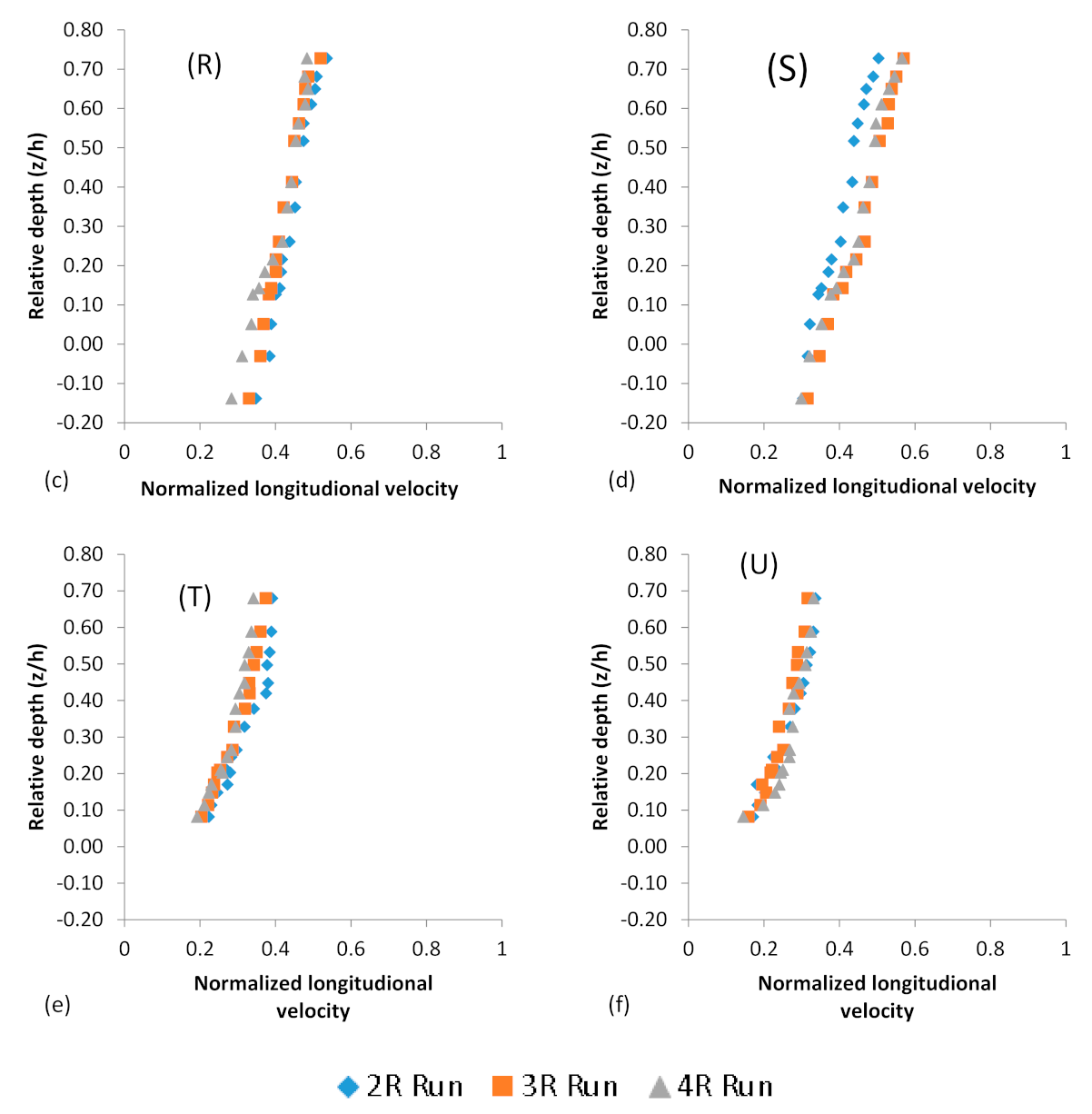

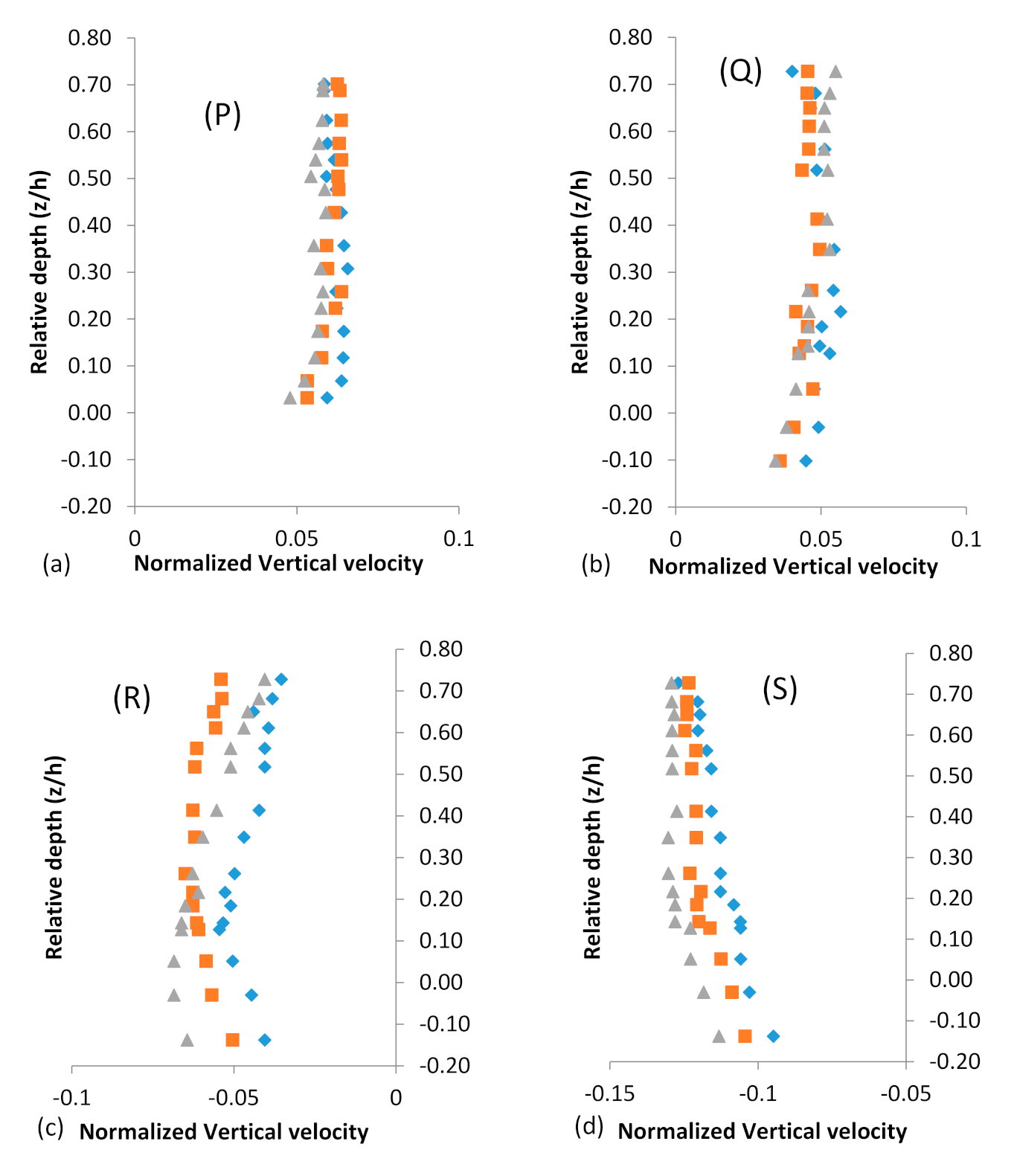

3.2. Flow Velocity Analysis

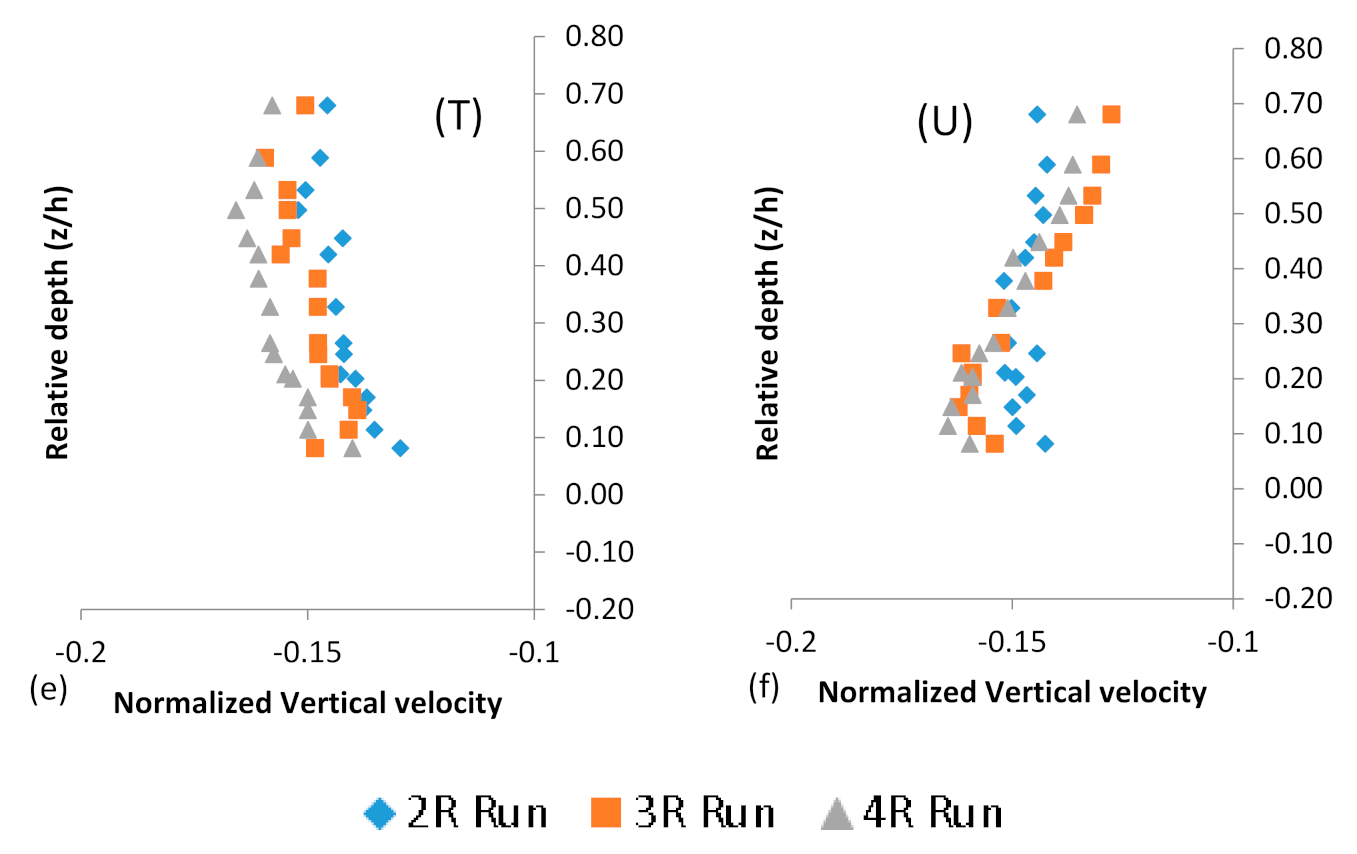

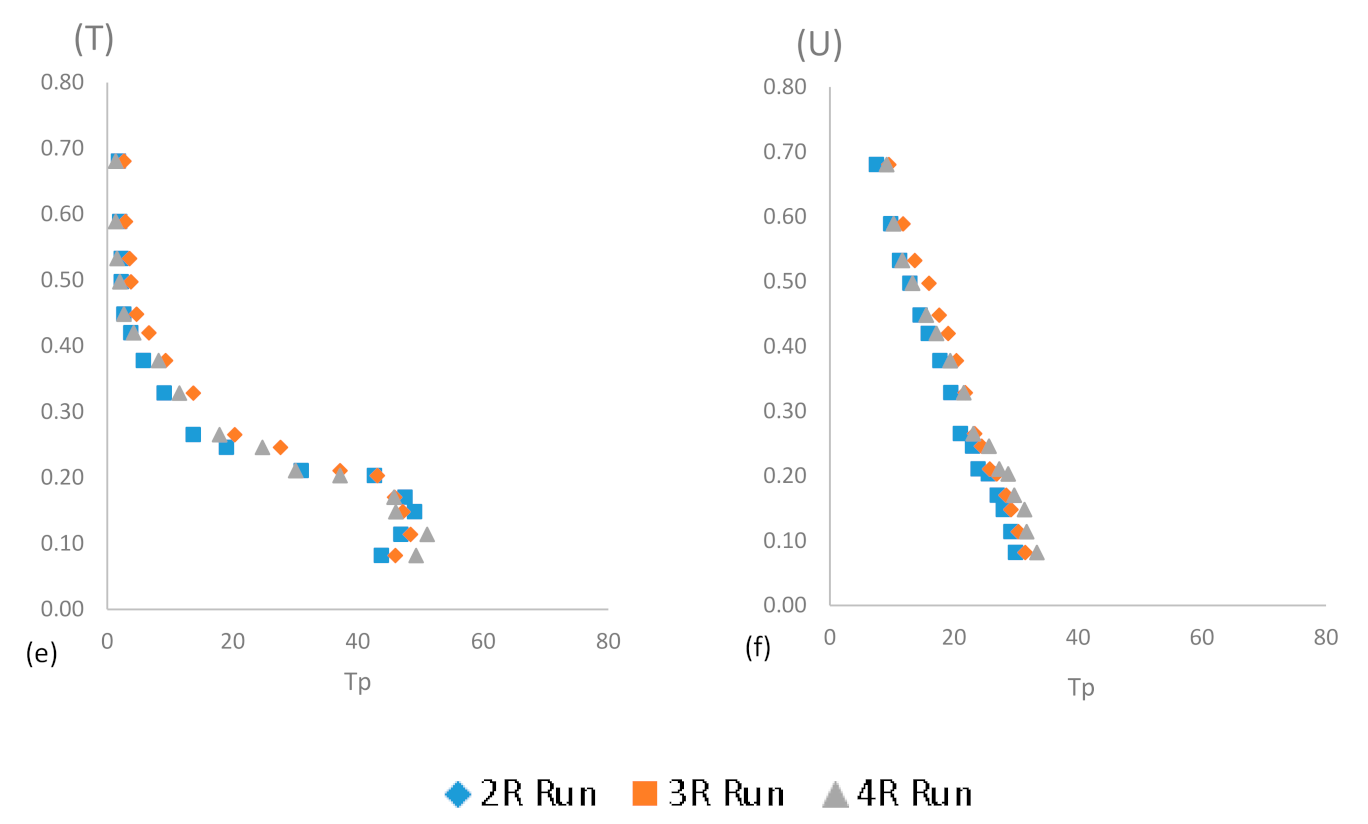

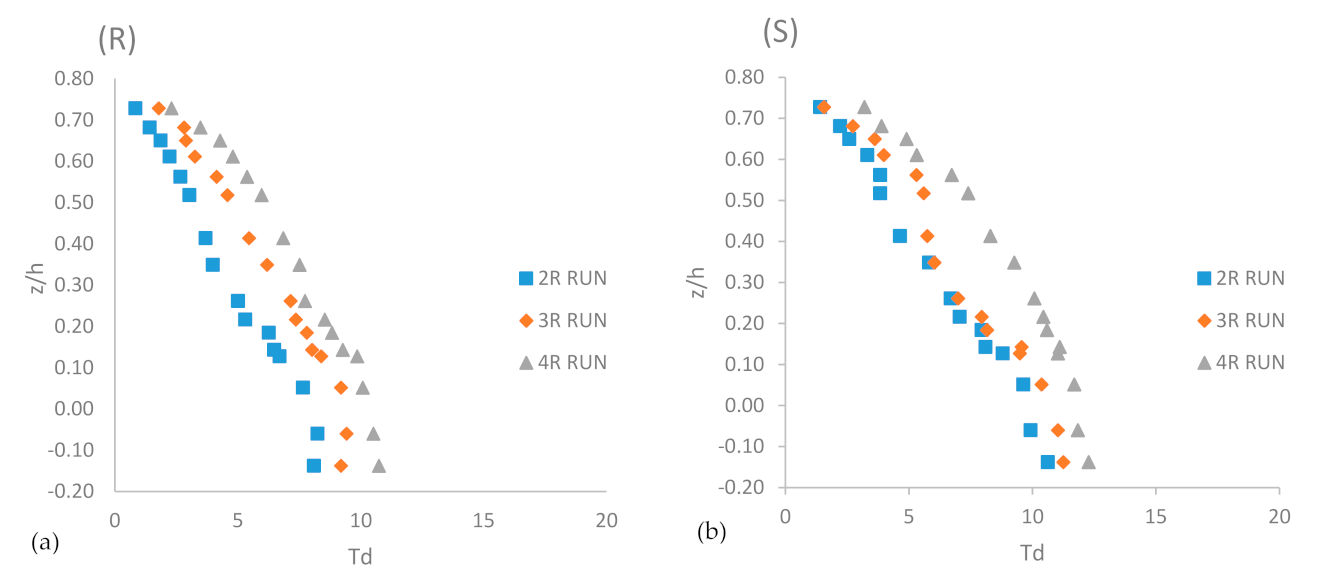

3.3. Effect of Bar Submergence on Channel Bed Elevations

3.4. Third-Order Moments of Fluctuating Velocity Signals

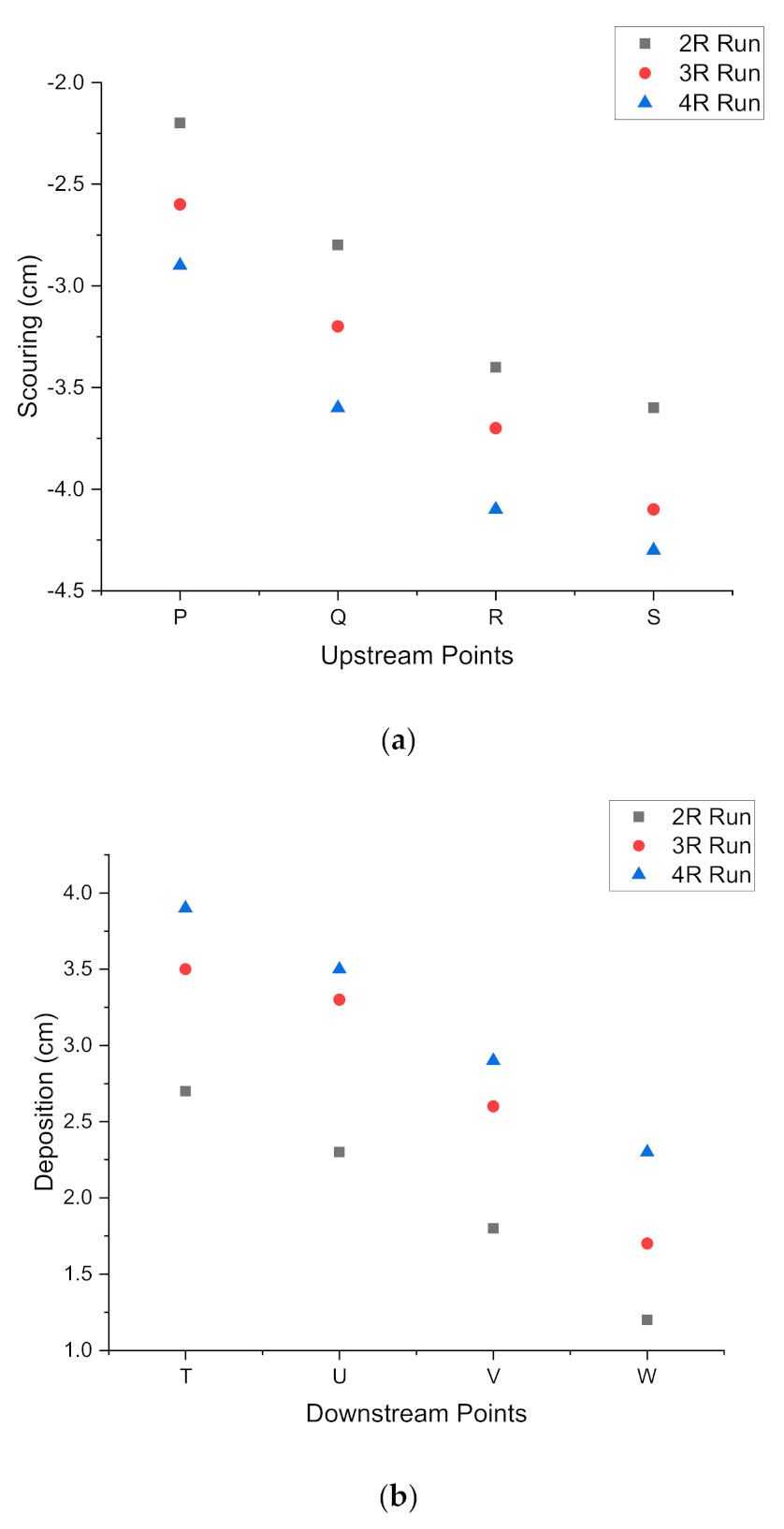

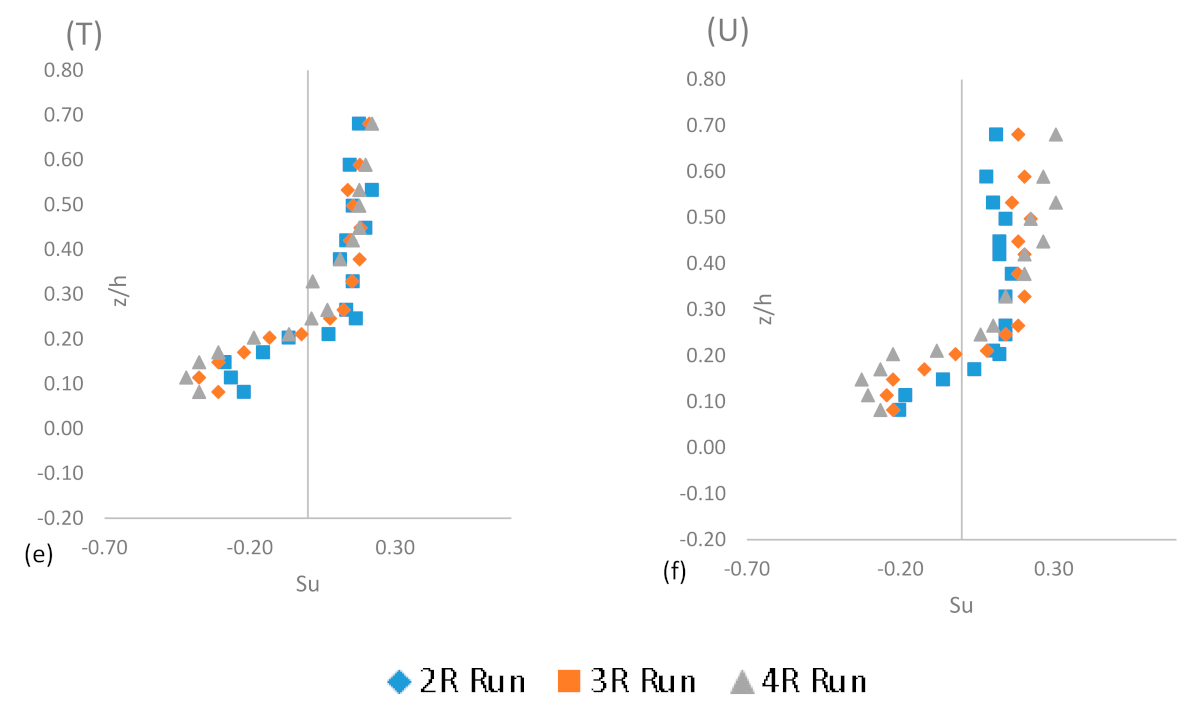

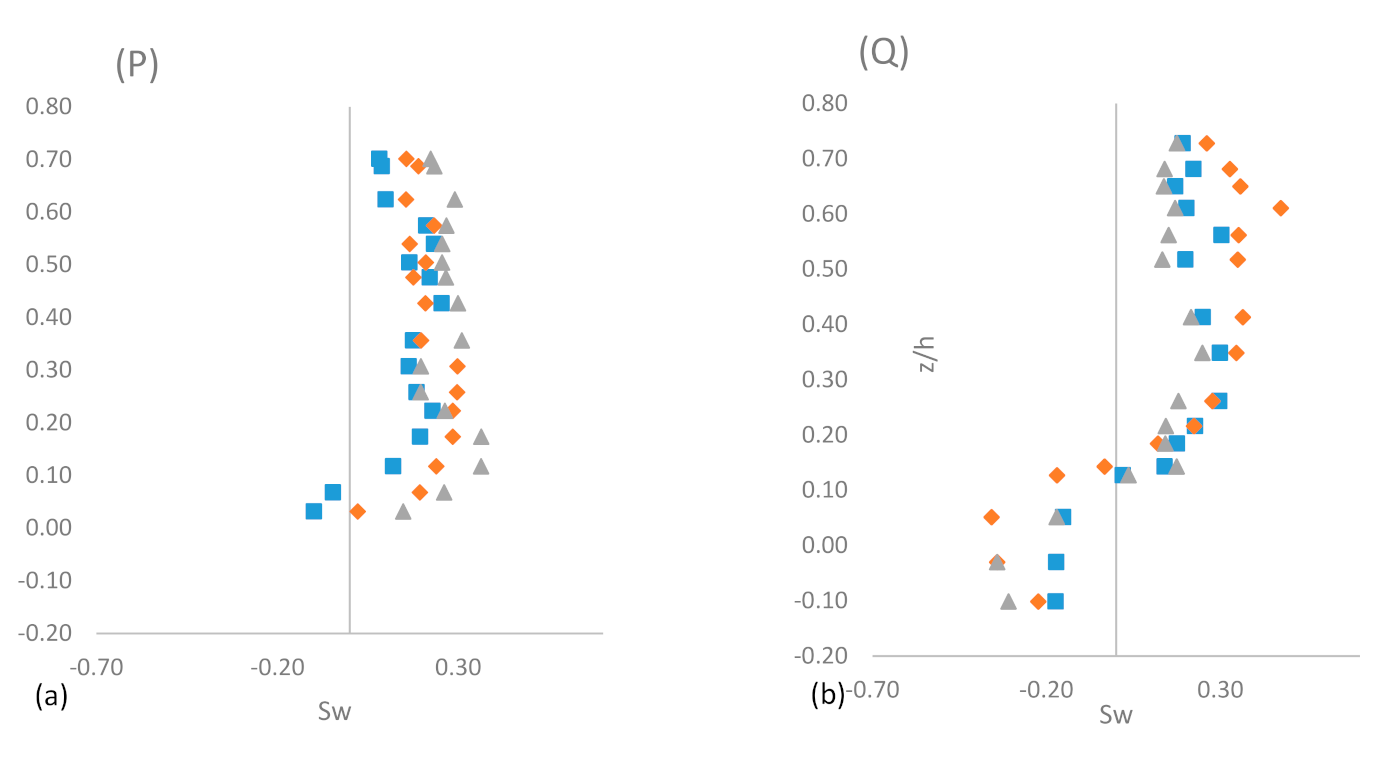

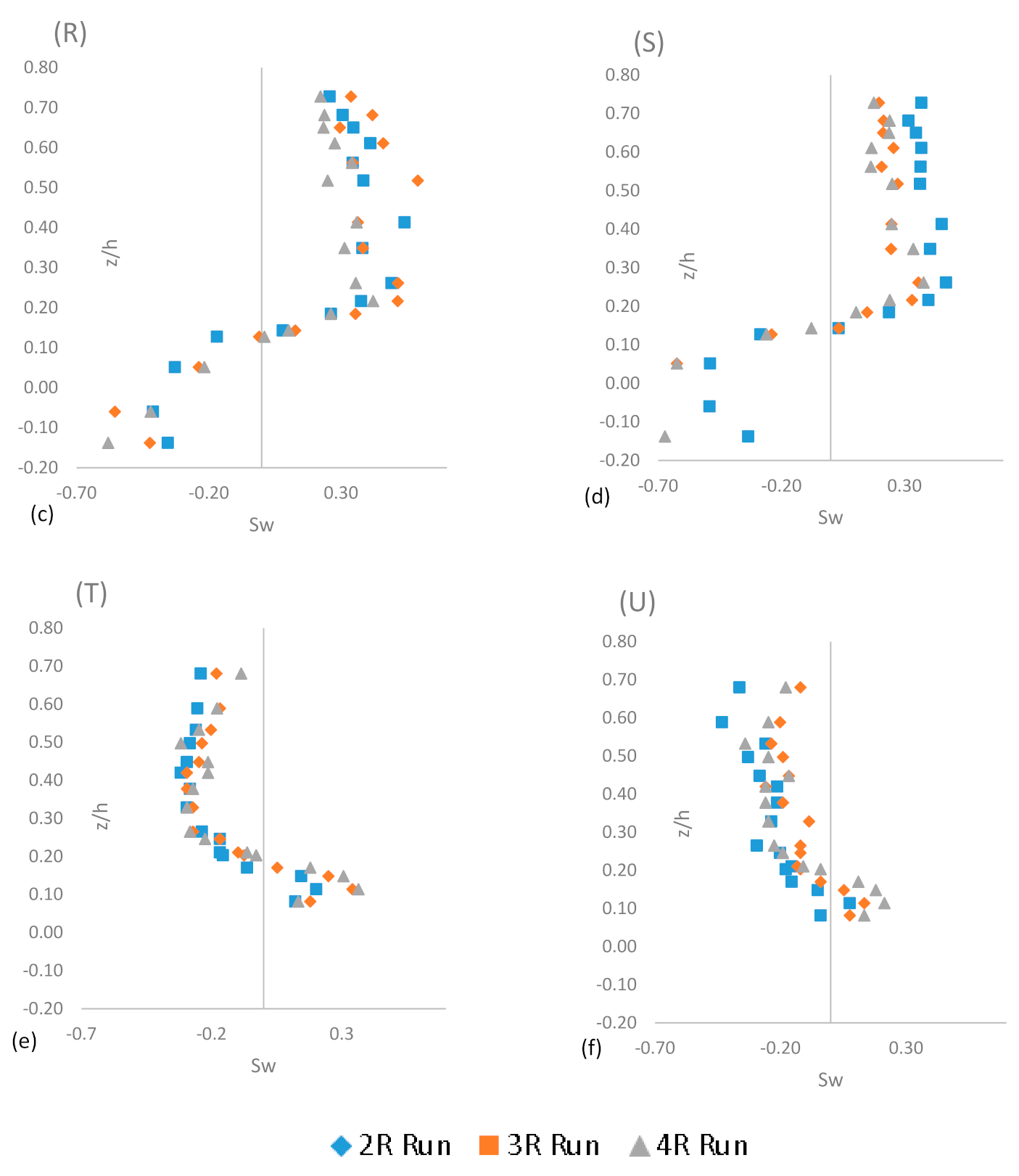

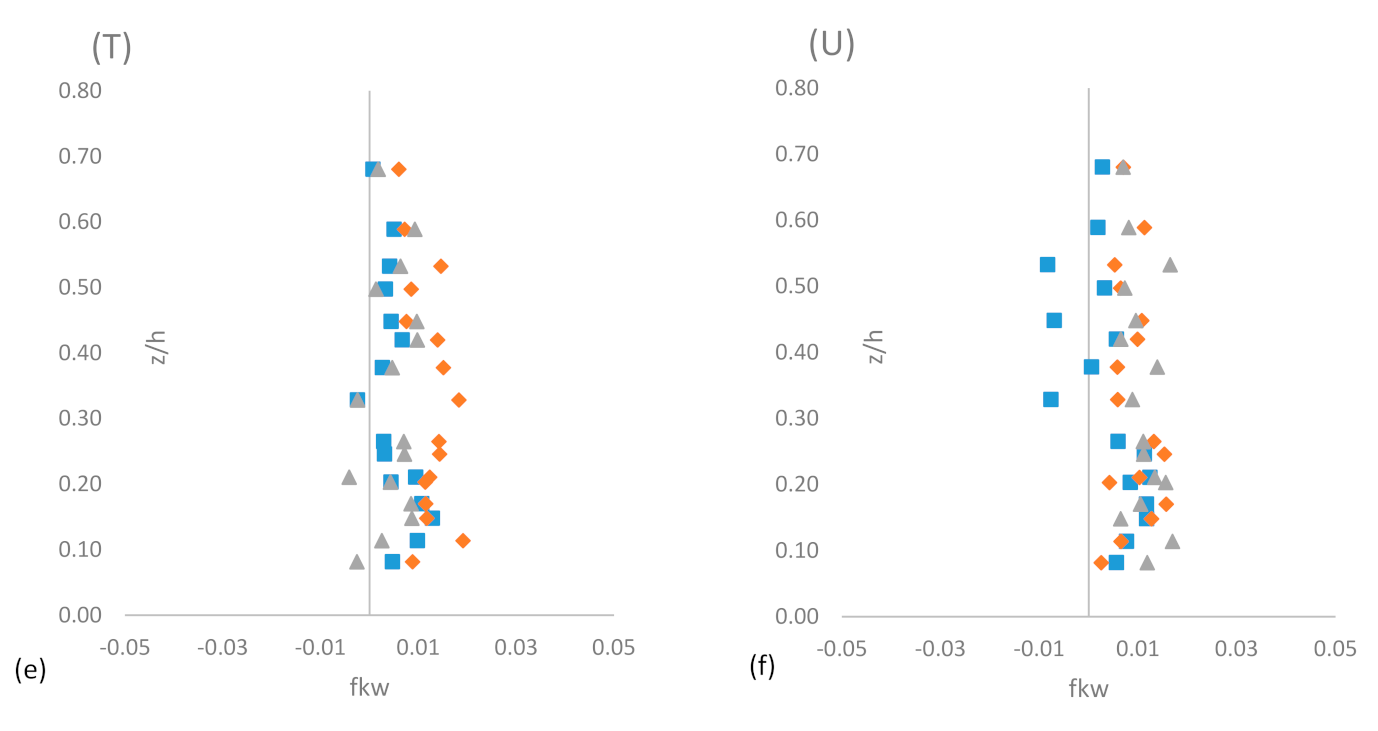

3.4.1. Skewness Coefficients

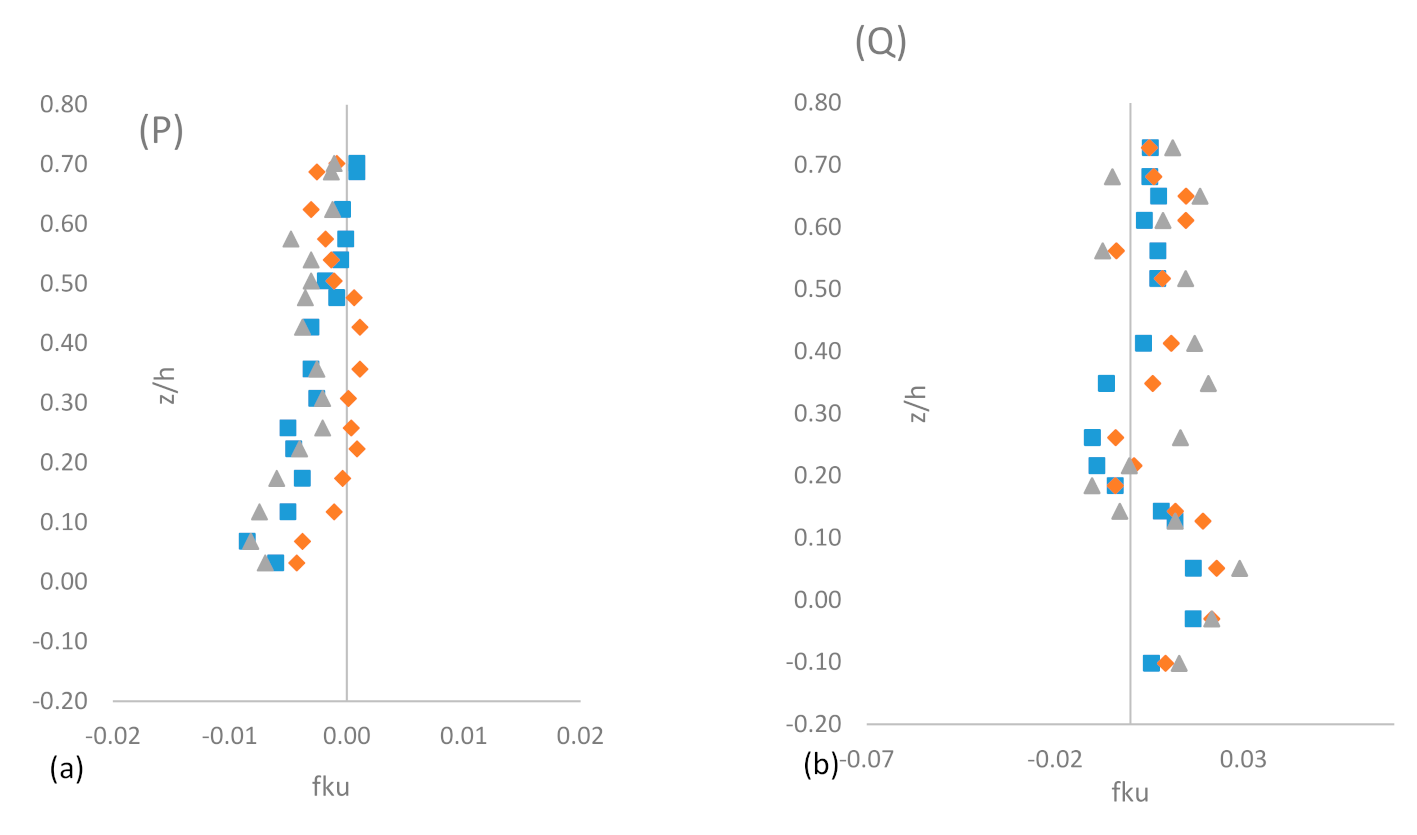

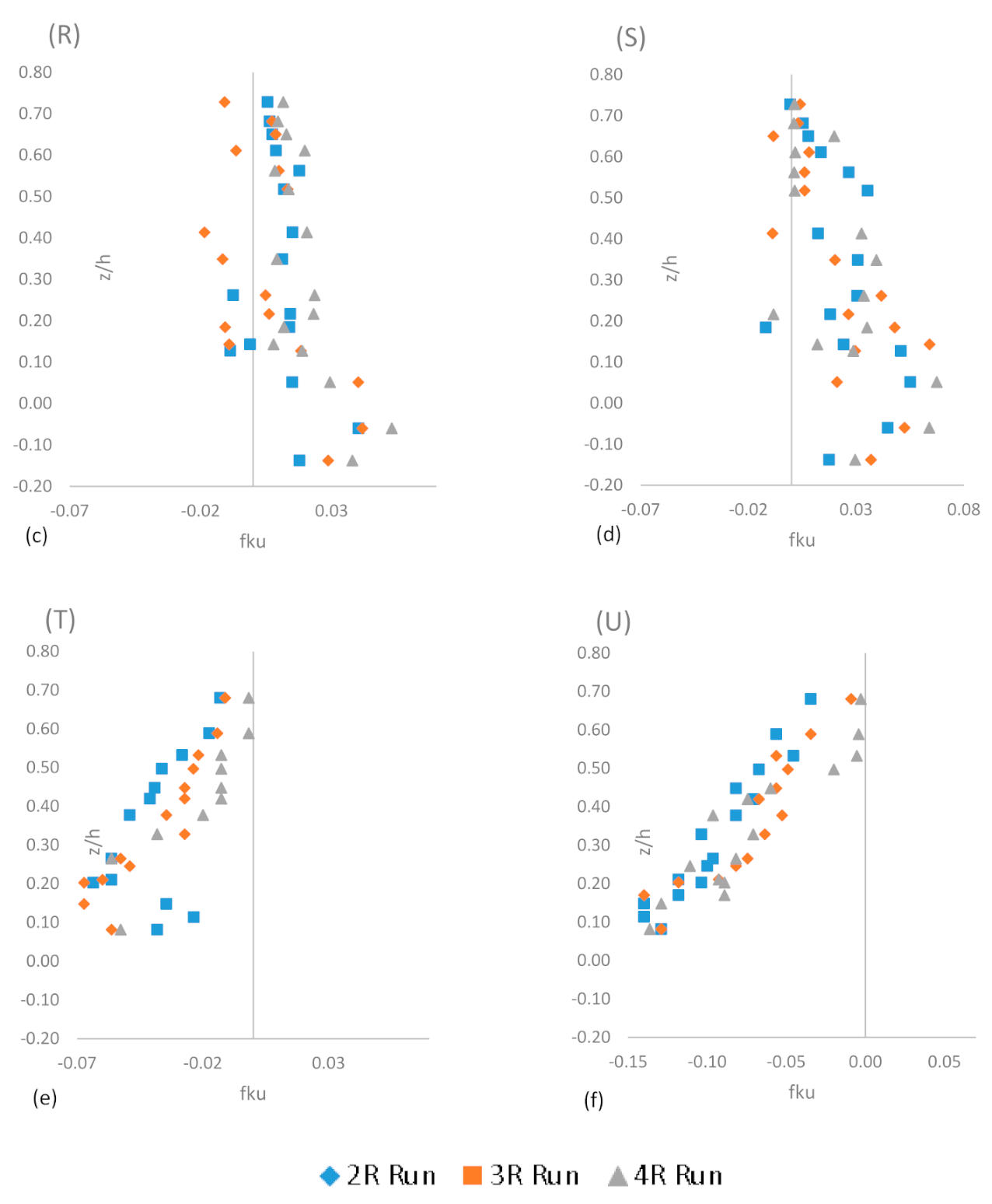

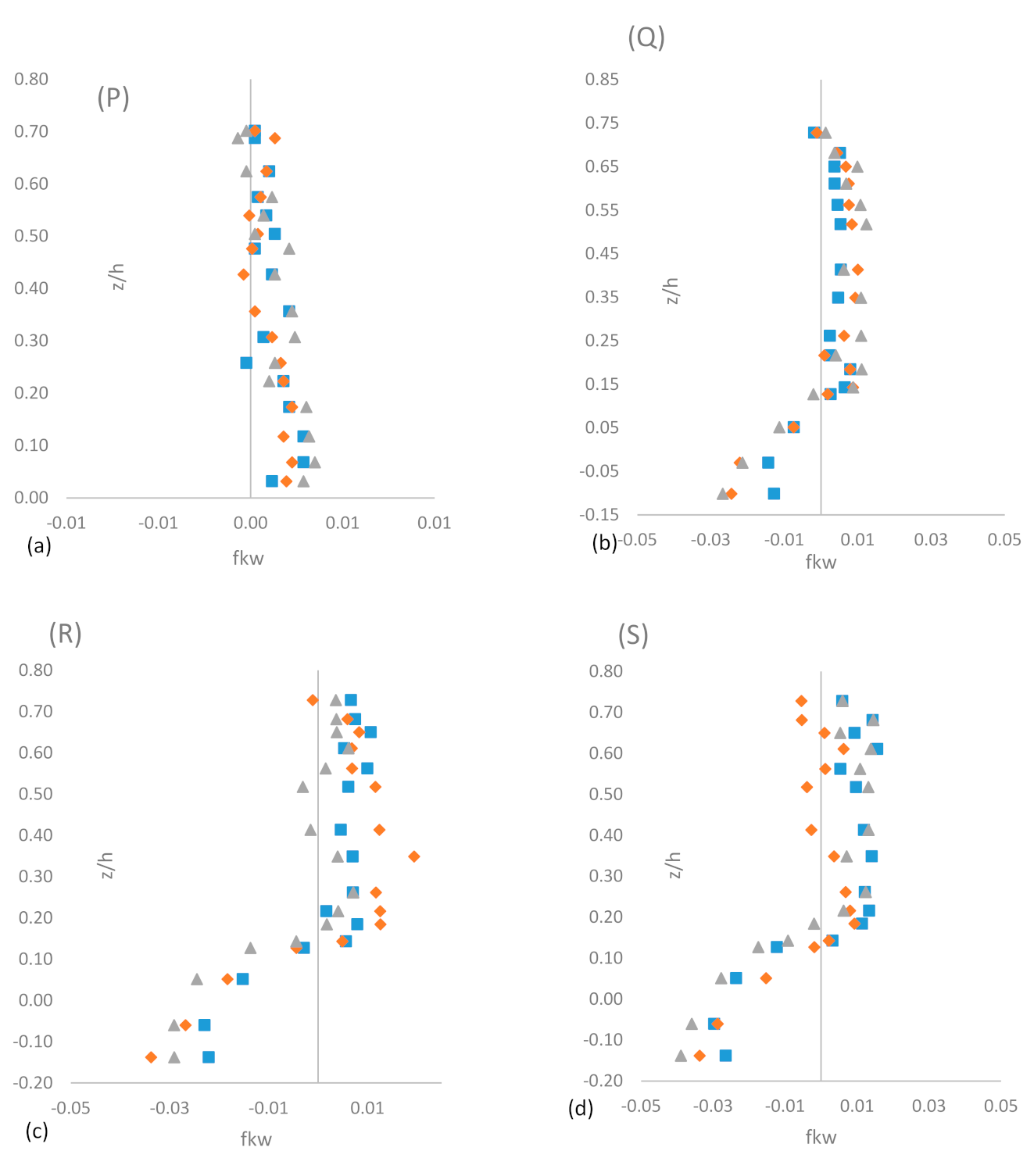

3.4.2. Turbulent Kinetic Energy Flux

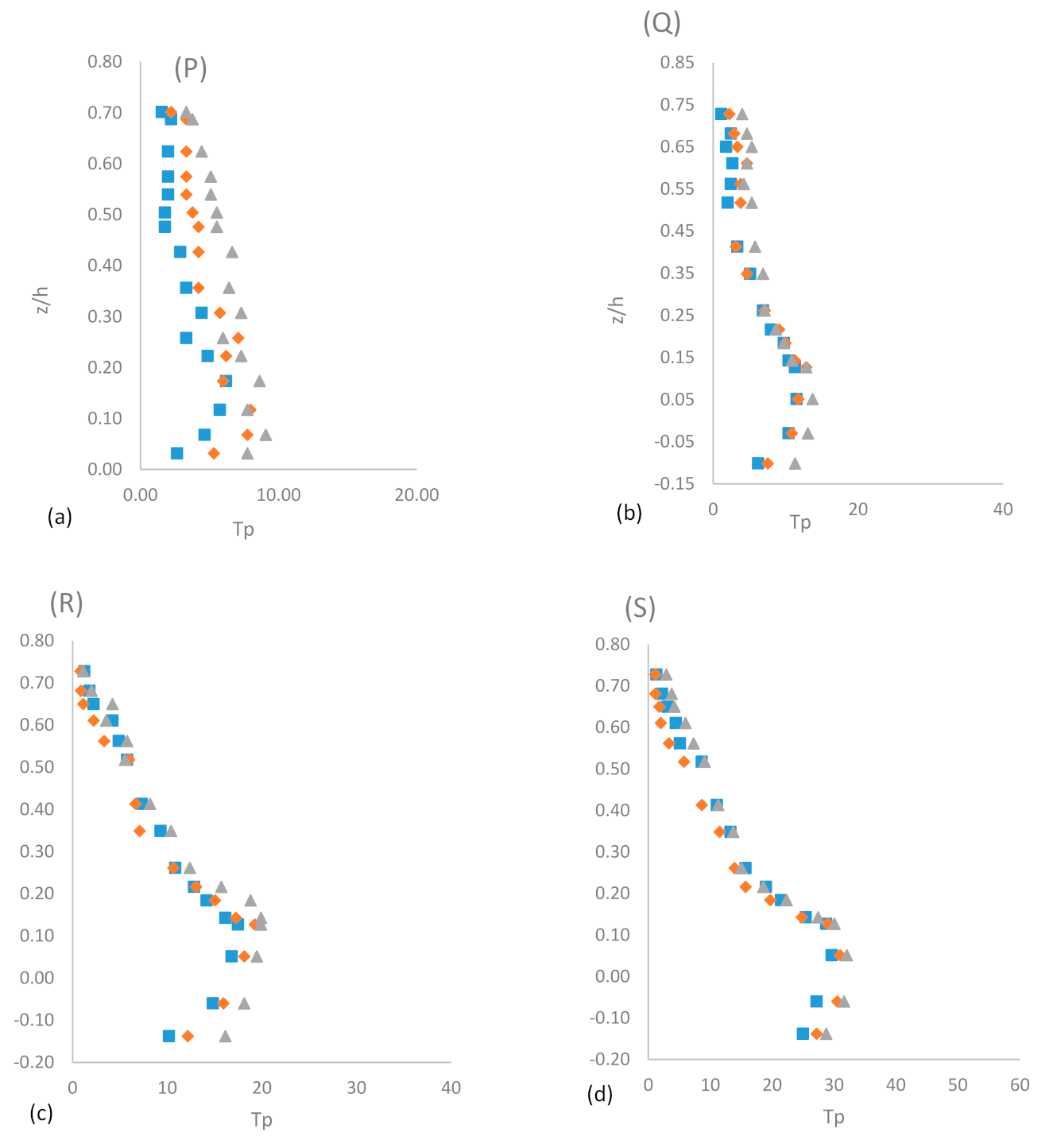

3.4.3. Turbulent Kinetic Energy Production and Dissipation

4. Potential Use of the Present Research in Braided Alluvial Rivers

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahmed, F.; Rajaratnam, N. Flow around bridge piers. J. Hydraul. Eng. 1998, 124, 288–300. [Google Scholar] [CrossRef]

- Ashmore, P.E. Laboratory modelling of gravel braided stream morphology. Earth Surf. Processes Landf. 1982, 7, 201–225. [Google Scholar] [CrossRef]

- Ashmore, P.E. How do gravel-bed rivers braid? Can. J. Earth Sci. 1991, 28, 326–341. [Google Scholar] [CrossRef] [Green Version]

- Ashworth, P.J. Mid-channel bar growth and its relationship to local flow strength and direction. Earth Surf. Processes Landf. 1996, 21, 103–123. [Google Scholar] [CrossRef]

- Balachandar, R.; Bhuiyan, F. Higher-order moments of velocity fluctuations in an open-channel flow with large bottom roughness. J. Hydraul. Eng. 2007, 133, 77–87. [Google Scholar] [CrossRef]

- Balachandar, R.; Patel, V. Velocity measurements in a developed open channel flow in the presence of an upstream perturbation. J. Hydraul. Res. 2005, 43, 258–266. [Google Scholar] [CrossRef]

- Barman, K.; Debnath, K.; Mazumder, B.S. Higher-order turbulence statistics of wave–current flow over a submerged hemisphere. Fluid Dyn. Res. 2017, 49, 025504. [Google Scholar] [CrossRef]

- Ben Meftah, M.; Mossa, M. Scour holes downstream of bed sills in low-gradient channels. J. Hydraul. Res. 2006, 44, 497–509. [Google Scholar] [CrossRef]

- Bennett, S.J.; Best, J.S. Mean flow and turbulence structure over fixed, two-dimensional dunes: Implications for sediment transport and bedform stability. J. Int. Assoc. Sedimentol. 1995, 42, 491–513. [Google Scholar] [CrossRef]

- Bey, A.; Faruque, M.; Balachandar, R. Two-dimensional scour hole problem: Role of fluid structures. J. Hydraul. Eng. 2007, 133, 414–430. [Google Scholar] [CrossRef]

- Calomino, F.; Alfonsi, G.; Gaudio, R.; D’Ippolito, A.; Lauria, A.; Tafarojnoruz, A.; Artese, S.J.W. Experimental and numerical study of free-surface flows in a corrugated pipe. Water 2018, 10, 638. [Google Scholar] [CrossRef] [Green Version]

- Dey, S.; Raikar, R.V.; Roy, A. Scour at submerged cylindrical obstacles under steady flow. J. Hydraul. Eng. 2008, 134, 105–109. [Google Scholar] [CrossRef]

- Gad-el-Hak, M.; Bandyopadhyay, P.R. Reynolds number effects in wall-bounded turbulent flows. Appl. Mech. Rev. 1994, 47, 307–365. [Google Scholar] [CrossRef]

- Goring, D.G.; Nikora, V.I. Despiking acoustic Doppler velocimeter data. J. Hydraul. Eng. 2002, 128, 117–126. [Google Scholar] [CrossRef] [Green Version]

- Guan, D.; Melville, B.W.; Friedrich, H. Flow patterns and turbulence structures in a scour hole downstream of a submerged weir. J. Hydraul. Eng. 2014, 140, 68–76. [Google Scholar] [CrossRef]

- Keirsbulck, L.; Labraga, L.; Mazouz, A.; Tournier, C. Influence of surface roughness on anisotropy in a turbulent boundary layer flow. Exp. Fluids 2002, 33, 497–499. [Google Scholar] [CrossRef]

- Khan, M.A.; Sharma, N. Analysis of turbulent flow characteristics around bar using the conditional bursting technique for varying discharge conditions. KSCE J. Civ. Eng. 2018, 22, 2315–2324. [Google Scholar] [CrossRef]

- Khan, M.A.; Sharma, N.; Singhal, G.E. Experimental study on bursting events around a bar in physical model of a braided channel. J. Hydraul. Eng. 2017, 23, 63–70. [Google Scholar] [CrossRef]

- Khan, M.A.; Sharma, N.; Pandey, M.; Qamar, M. Turbulent characteristics of flow in the vicinity of mid-channel braid bar. Can. J. Civ. Eng. 2021, 48. [Google Scholar]

- Kothyari, U.C.; Garde, R.C.J.; Raju, K.G.R. Temporal variation of scour around circular bridge piers. J. Hydraul. Eng. 1992, 118, 1091–1106. [Google Scholar] [CrossRef]

- Krogstadt, P.-Å.; Antonia, R. Surface roughness effects in turbulent boundary layers. Exp. Fluids 1999, 27, 450–460. [Google Scholar] [CrossRef]

- Kumar, A.; Kothyari, U.C.; Raju, K.G.R. Flow structure and scour around circular compound bridge piers–A review. J. Hydro-Environ. Res. 2012, 6, 251–265. [Google Scholar] [CrossRef]

- Lacey, R.W.J.; Rennie, C. Laboratory investigation of turbulent flow structure around a bed-mounted cube at multiple flow stages. J. Hydraul. Eng. 2012, 138, 71–84. [Google Scholar] [CrossRef]

- Lauria, A.; Alfonsi, G.; Tafarojnoruz, A. Flow Pressure Behavior Downstream of Ski Jumps. Fluids 2020, 5, 168. [Google Scholar] [CrossRef]

- Leopold, L.B.; Wolman, M.G. River channel patterns. In Fluv Geom: Geom Crit Conc; Water Department: San Deigo, CA, USA, 1957; Volume 3. [Google Scholar]

- Lohrmann, A.; Cabrera, R.; Kraus, N.C. Acoustic-Doppler velocimeter (ADV) for laboratory use. In Fundamentals and Advancements in Hydraulic Measurements and Experimentation; American Society of Civil Engineering: San Diego, CA, USA, 1994. [Google Scholar]

- Melville, B.W.; Raudkivi, A.J. Flow characteristics in local scour at bridge piers. J. Hydraul. Res. 1977, 15, 373–380. [Google Scholar] [CrossRef]

- Nagano, Y.; Tagawa, M. Statistical characteristics of wall turbulence with a passive scalar. J. Fluid Mech. 1988, 196, 157–185. [Google Scholar] [CrossRef]

- Nezu, I.; Nakagawa, H.; Jirka, G.H. Turbulence in open-channel flows. J. Hydraul. Eng. 1994, 120, 1235–1237. [Google Scholar] [CrossRef]

- Raupach, M.R. Conditional statistics of Reynolds stress in rough-wall and smooth-wall turbulent boundary layers. J. Fluid Mech. 1981, 108, 363–382. [Google Scholar] [CrossRef]

- Sarkar, A.; Ratha, D. Flow around submerged structures subjected to shallow submergence over plane bed. J. Fluids Struct. 2014, 44, 166–181. [Google Scholar] [CrossRef]

- Sarkar, K.; Chakraborty, C.; Mazumder, B. Variations of bed elevations due to turbulence around submerged cylinder in sand beds. Environ. Fluid Mech. 2016, 16, 659–693. [Google Scholar] [CrossRef]

- Shamloo, H.; Rajaratnam, N.; Katopodis, C. Hydraulics of simple habitat structures. J. Hydraul. Res. 2001, 39, 351–366. [Google Scholar] [CrossRef]

- Tafarojnoruz, A.; Lauria, A. Large eddy simulation of the turbulent flow field around a submerged pile within a scour hole under current condition. Coast. Eng. J. 2020, 62, 489–503. [Google Scholar] [CrossRef]

- van Rijn, L.C.; Kroon, A. Sediment transport by currents and waves. Coast. Eng. 1992, 12, 2613–2628. [Google Scholar]

- Vijayasree, B.; Eldho, T.; Mazumder, B.; Viswanadham, B.J.S. Effectiveness of combinations of raft foundation with aprons as a protection measure against bridge pier scour. Sadhana 2018, 43, 21. [Google Scholar] [CrossRef] [Green Version]

| Measurement Time (Min) | Standard Deviation (%) |

|---|---|

| 1 | 9 |

| 2 | 7 |

| 3 | 5 |

| 4 | 4 |

| 5 | 4 |

| Experimental Code | Bar Size (L × B × Hb) (cm) | Flow Depth (cm) | Submergence Ratio |

|---|---|---|---|

| IR | 90 by 70 by 7.5 | 30 | 0.25 |

| 2R | 90 by 70 by 11 | 30 | 0.37 |

| 3R | 90 by 70 by 15 | 30 | 0.5 |

| 4R | 90 by 70 by 19 | 30 | 0.63 |

| 5R | 90 by 70 by 21 | 30 | 0.7 |

| 6R | 90 by 70 by 24 | 30 | 0.8 |

| S. No. | Sections | 2R RUN | 3R RUN | 4R RUN |

|---|---|---|---|---|

| 1 | P | −2.2 | −2.6 | −2.9 |

| 2 | Q | −3.1 | −3.2 | −3.6 |

| 3 | R | −3.4 | −3.7 | −4.1 |

| 4 | S | −3.6 | −4.1 | −4.3 |

| 5 | T | 2.7 | 3.5 | 3.9 |

| 6 | U | 2.3 | 3.3 | 3.5 |

| 7 | V | 1.8 | 2.6 | 2.9 |

| 8 | W | 1.2 | 1.7 | 2.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, M.A.; Sharma, N.; Pu, J.; Alfaisal, F.M.; Alam, S.; Khan, W.A. Analysis of Turbulent Flow Structure with Its Fluvial Processes around Mid-Channel Bar. Sustainability 2022, 14, 392. https://doi.org/10.3390/su14010392

Khan MA, Sharma N, Pu J, Alfaisal FM, Alam S, Khan WA. Analysis of Turbulent Flow Structure with Its Fluvial Processes around Mid-Channel Bar. Sustainability. 2022; 14(1):392. https://doi.org/10.3390/su14010392

Chicago/Turabian StyleKhan, Md. Amir, Nayan Sharma, Jaan Pu, Faisal M. Alfaisal, Shamshad Alam, and Wahaj Ahmad Khan. 2022. "Analysis of Turbulent Flow Structure with Its Fluvial Processes around Mid-Channel Bar" Sustainability 14, no. 1: 392. https://doi.org/10.3390/su14010392