Structure of Green Supply Chain Management for Sustainability of Small and Medium Enterprises

Abstract

:1. Introduction

2. Theoretical Background

2.1. GSCM

2.2. Environmental Collaboration

2.3. Green Innovation Capacity

2.4. GSCM Performance

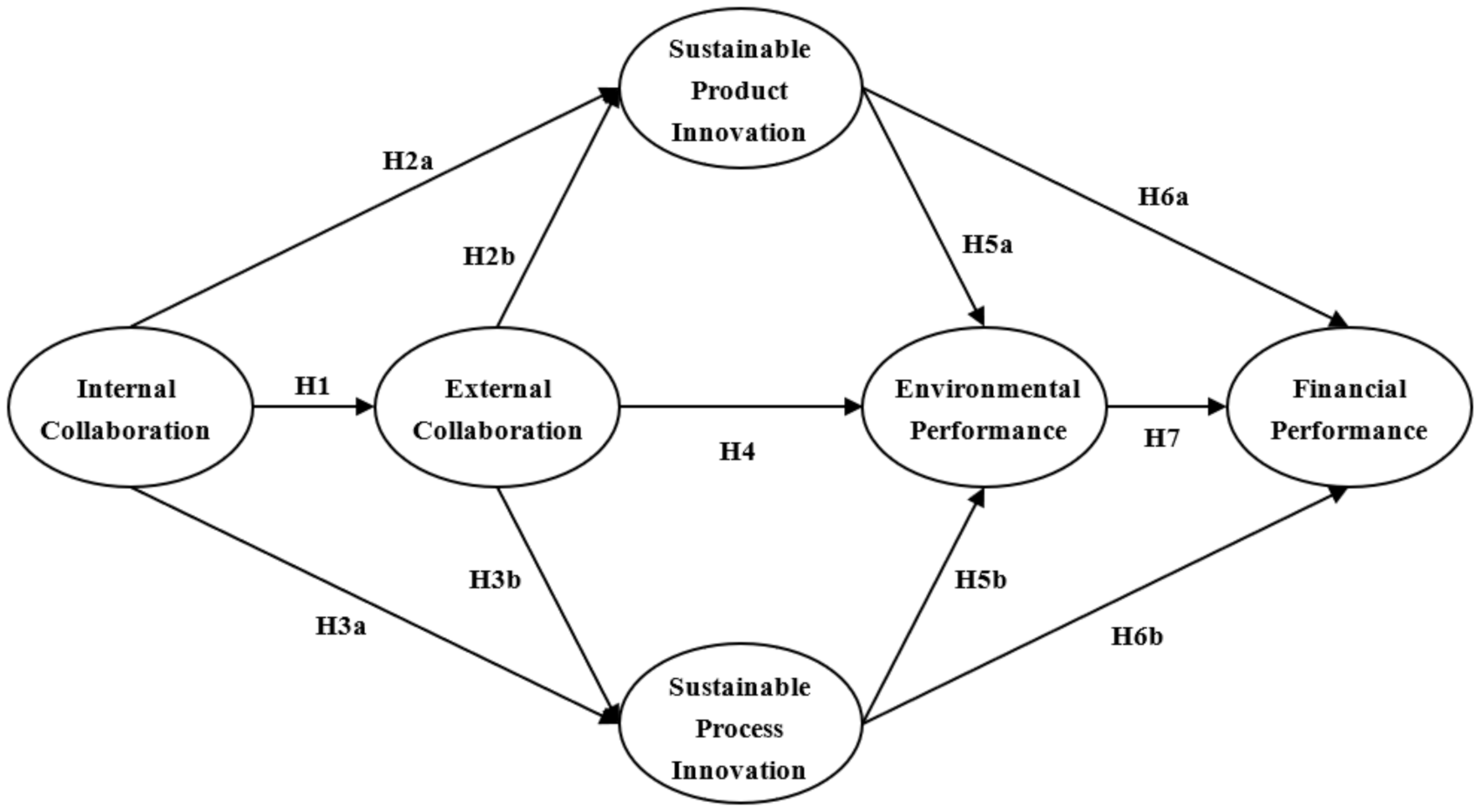

3. Research Model and Hypothesis

3.1. Research Model

3.2. Hypothesis Development

4. Research Method

4.1. Data Collection and Sample

4.2. Measures

5. Research Result

5.1. Analysis Method

5.2. Measurement Model

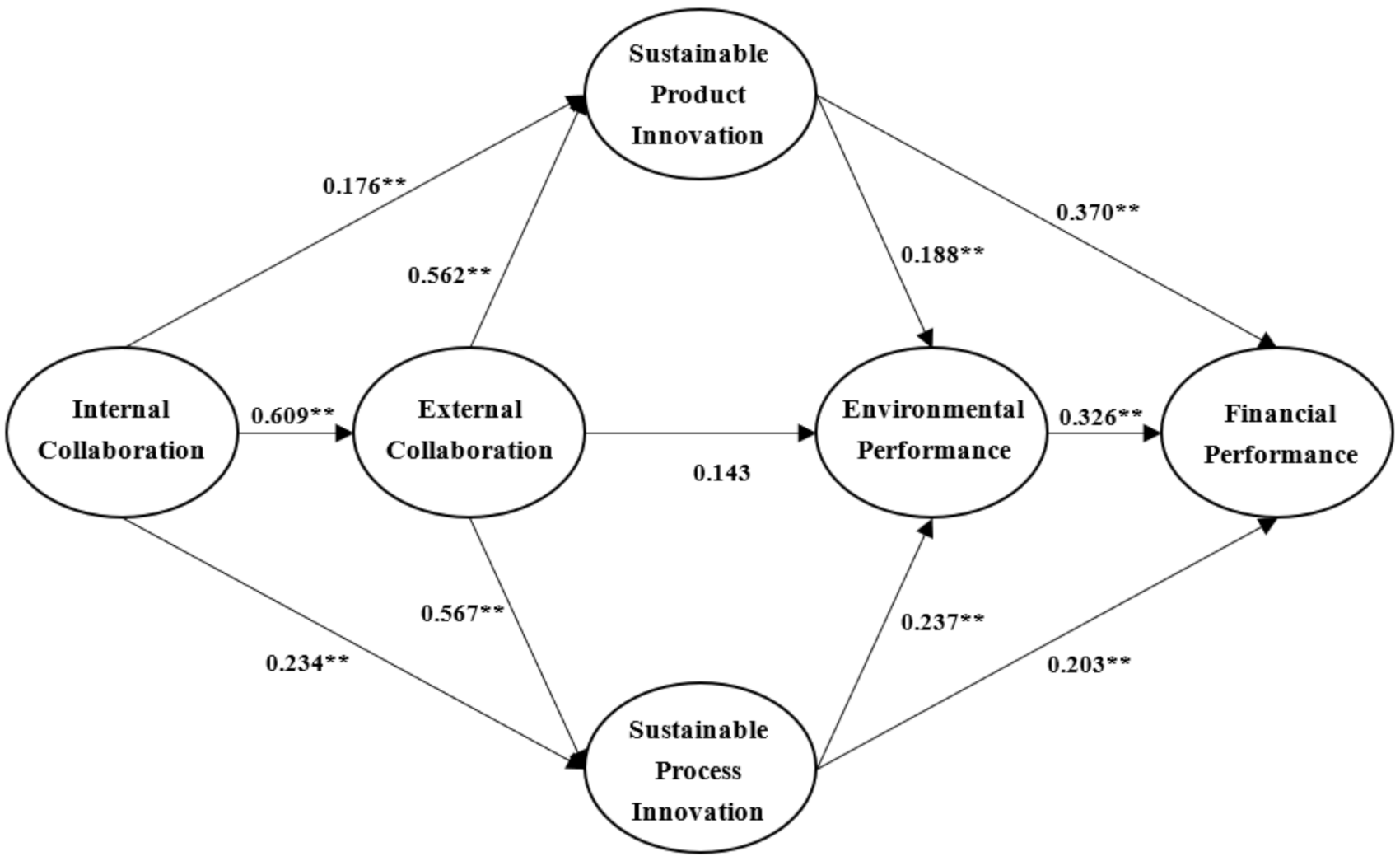

5.3. Structural Model

5.4. Hypotheses Test

6. Conclusions

6.1. Discussion of Results

6.2. Implications and Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Internal Collaboration | Cross-functional cooperation for environmental improvements | Zhu and Sarkis (2004) [64] Zhu et al. (2010) [65] Yu et al. (2014) [18] |

| Environmental compliance and auditing programs | ||

| Environmental management certification (e.g., ISO14000/ISO14001 certification) | ||

| Environmental management systems operating | ||

| External Collaboration | Collaborate with suppliers for environmental objectives | |

| Environmental audit for suppliers’ internal management | ||

| Collaborate with customers for eco-design | ||

| Collaborate with customers for cleaner production | ||

| Product Innovations | Environmentally friendly material | Chen et al. (2008) [50] Chiou et al. (2011) [20] Huang and Li (2017) [21] |

| Environmentally friendly packaging | ||

| Recovery of products and recycling | ||

| Eco-labeling | ||

| Process Innovations | Energy savings | |

| Pollution prevention | ||

| Waste recycling | ||

| Less toxicity | ||

| Environmental Performance | Reduction of air emission/waste water/solid wastes | Zhu and Sarkis (2004) [64] Chiou et al. (2011) [20] Huang and Li (2017) [21] |

| Decrease of consumption for hazardous/harmful/toxic materials | ||

| Decrease of frequency for environmental accidents | ||

| Improve an enterprise’s environmental situation | ||

| Financial Performance | (Last 3 years) Sales growth | Purba (2002) [24] Cao and Zhang (2011) [66] Patel et al. (2013) [62] |

| (Last 3 years) Profit growth | ||

| (Last 3 years) Market share growth | ||

| (Last 3 years) Operational efficiency |

References

- Amel-Zadeh, A.; Serafeim, G. Why and how investors use ESG information: Evidence from a global survey. Financ. Anal. J. 2018, 74, 87–103. [Google Scholar] [CrossRef] [Green Version]

- Friede, G.; Busch, T.; Bassen, A. ESG and financial performance: Aggregated evidence from more than 2000 empirical studies. J. Sustain. Financ. Investig. 2015, 5, 210–233. [Google Scholar] [CrossRef] [Green Version]

- Galbreath, J. ESG in focus: The Australian evidence. J. Bus. Ethics 2013, 118, 529–541. [Google Scholar] [CrossRef]

- Haden, S.S.P.; Oyler, J.D.; Humphreys, J.H. Historical, practical, and theoretical perspectives on green management: An exploratory analysis. Manag. Decis. 2009, 47, 1041–1055. [Google Scholar] [CrossRef]

- Klassen, R.D.; McLaughlin, C.P. The impact of environmental management on firm performance. Manag. Sci. 1996, 42, 1199–1214. [Google Scholar] [CrossRef]

- Sarkis, J.; Zhu, Q.; Lai, K. An organizational theoretic review of green supply chain management literature. Int. J. Prod. Econ. 2011, 130, 1–15. [Google Scholar] [CrossRef]

- Woo, C.; Kim, M.G.; Chung, Y.; Rho, J.J. Suppliers’ communication capability and external green integration for green and financial performance in Korean construction industry. J. Clean. Prod. 2016, 112, 483–493. [Google Scholar] [CrossRef]

- Lee, S.Y.; Klassen, R.D.; Furlan, A.; Vinelli, A. The green bullwhip effect: Transferring environmental requirements along a supply chain. Int. J. Prod. Econ. 2014, 156, 39–51. [Google Scholar] [CrossRef]

- Chu, S.; Yang, H.; Lee, M.; Park, S. The impact of institutional pressures on green supply chain management and firm performance: Top management roles and social capital. Sustainability 2017, 9, 764. [Google Scholar] [CrossRef] [Green Version]

- Joo, H.Y. The Causal Relationship Between Environmental Collaboration and Export Performance. Korea Trade Rev. 2015, 40, 137–160. [Google Scholar]

- Choi, S.B.; Min, H.; Joo, H.Y.; Choi, H.B. Assessing the impact of green supply chain practices on firm performance in the Korean manufacturing industry. Int. J. Logist. Res. Appl. 2018, 20, 129–145. [Google Scholar] [CrossRef]

- Rha, J.S. A Study on the Research Trends in Supply Chain Management in Korea using Network Text Analysis. J. Korea Ind. Inf. Syst. Res. 2020, 25, 41–53. [Google Scholar]

- Liu, S.; Chang, Y.T. Manufacturers’ closed-loop orientation for green supply chain management. Sustainability 2017, 9, 222. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Confirmation of a measurement model for green supply chain management practices implementation. Int. J. Prod. Econ. 2008, 111, 261–273. [Google Scholar] [CrossRef]

- Li, D.; Zheng, M.; Cao, C.; Chen, X.; Ren, S.; Huang, M. The impact of legitimacy pressure and corporate profitability on green innovation: Evidence from China top 100. J. Clean. Prod. 2017, 141, 41–49. [Google Scholar] [CrossRef] [Green Version]

- Jafarzadeh-Ghoushchi, S. Qualitative and Quantitative Analysis of Green Supply Chain Management (GSCM) Literature From 2000 to 2015. Supply Chain Manag. Int. J. 2018, 7, 77–86. [Google Scholar]

- Green, K.W., Jr.; Zelbst, P.J.; Meacham, J.; Bhadauria, V.S. Green supply chain management practices: Impact on performance. Supply Chain Manag. Int. J. 2012, 17, 290–305. [Google Scholar] [CrossRef]

- Yu, W.; Chavez, R.; Feng, M.; Wiengarten, F. Integrated green supply chain management and operational performance. Supply Chain Manag. Int. J. 2014, 19, 683–696. [Google Scholar] [CrossRef]

- Luzzini, D.; Brandon-Jones, E.; Brandon-Jones, A.; Spina, G. From sustainability commitment to performance: The role of intra-and inter-firm collaborative capabilities in the upstream supply chain. Int. J. Prod. Econ. 2015, 165, 51–63. [Google Scholar] [CrossRef] [Green Version]

- Chiou, T.Y.; Chan, H.K.; Lettice, F.; Chung, S.H. The influence of greening the suppliers and green innovation on environmental performance and competitive advantage in Taiwan. Transp. Res. E Logist. Transp. Rev. 2011, 47, 822–836. [Google Scholar] [CrossRef]

- Huang, J.W.; Li, Y.H. Green innovation and performance: The view of organizational capability and social reciprocity. J. Bus. Ethics 2017, 145, 309–324. [Google Scholar] [CrossRef]

- Saunila, M.; Ukko, J.; Rantala, T. Sustainability as a driver of green innovation investment and exploitation. J. Clean. Prod. 2018, 179, 631–641. [Google Scholar] [CrossRef]

- Carter, C.R.; Kale, R.; Grimm, C.M. Environmental purchasing and firm performance: An empirical investigation. Transp. Res. E Logist. Transp. Rev. 2000, 36, 219–228. [Google Scholar] [CrossRef]

- Purba, R. Greening the Supply Chain: A New Initiative in South East Asia. Int. J. Oper. Prod. Manag. 2002, 22, 632–655. [Google Scholar]

- Zailani, S.; Govindan, K.; Iranmanesh, M.; Shaharudin, M.R.; Chong, Y.S. Green innovation adoption in automotive supply chain: The Malaysian case. J. Clean. Prod. 2015, 108, 1115–1122. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. Green supply chain management innovation diffusion and its relationship to organizational improvement: An ecological modernization perspective. J. Eng. Technol. Manag. 2012, 29, 168–185. [Google Scholar] [CrossRef]

- Govindan, K.; Kaliyan, M.; Kannan, D.; Haq, A.N. Barriers analysis for green supply chain management implementation in Indian industries using analytic hierarchy process. Int. J. Prod. Econ. 2014, 147, 555–568. [Google Scholar] [CrossRef]

- Min, H.; Kim, I. Green supply chain research: Past, present, and future. Logis. Res. 2012, 4, 39–47. [Google Scholar] [CrossRef]

- Kannan, D.; de Sousa Jabbour, A.B.L.; Jabbour, C.J.C. Selecting green suppliers based on GSCM practices: Using fuzzy TOPSIS applied to a Brazilian electronics company. Eur. J. Oper. Res. 2014, 233, 432–447. [Google Scholar] [CrossRef]

- Tseng, M.L.; Lin, R.J.; Lin, Y.H.; Chen, R.H.; Tan, K. Close-loop or open hierarchical structures in green supply chain management under uncertainty. Expert. Syst. Appl. 2014, 41, 3250–3260. [Google Scholar] [CrossRef]

- Wu, G.C.; Ding, J.H.; Chen, P.S. The effects of GSCM drivers and institutional pressures on GSCM practices in Taiwan’s textile and apparel industry. Int. J. Prod. Econ. 2012, 135, 618–636. [Google Scholar] [CrossRef]

- Caniato, F.; Caridi, M.; Crippa, L.; Moretto, A. Environmental sustainability in fashion supply chains: An exploratory case based research. Int. J. Prod. Econ. 2012, 135, 659–670. [Google Scholar] [CrossRef]

- Bowen, F.E.; Cousins, P.D.; Lamming, R.C.; Farukt, A.C. The role of supply management capabilities in green supply. Prod. Oper. Manag. 2001, 10, 174–189. [Google Scholar] [CrossRef]

- Bourdieu, P. Distinction: A Social Critique of the Judgement of Taste; Harvard University Press: Cambridge, MA, USA, 1987. [Google Scholar]

- Adler, P.S.; Kwon, S.W. Social capital: Prospects for a new concept. Acad. Manag. Rev. 2002, 27, 17–40. [Google Scholar] [CrossRef] [Green Version]

- Carey, S.; Lawson, B.; Krause, D.R. Social capital configuration, legal bonds and performance in buyer–supplier relationships. J. Oper. Manag. 2011, 29, 277–288. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.; Pagell, M. Balancing priorities: Decision-making in sustainable supply chain management. J. Oper. Manag. 2011, 29, 577–590. [Google Scholar] [CrossRef]

- Modi, S.B.; Mabert, V.A. Supplier development: Improving supplier performance through knowledge transfer. J. Oper. Manag. 2007, 25, 42–64. [Google Scholar] [CrossRef]

- Vachon, S.; Klassen, R.D. Environmental management and manufacturing performance: The role of collaboration in the supply chain. Int. J. Prod. Econ. 2008, 111, 299–315. [Google Scholar] [CrossRef]

- Chin, T.A.; Tat, H.H.; Sulaiman, Z. Green supply chain management, environmental collaboration and sustainability performance. Procedia Cirp. 2015, 26, 695–699. [Google Scholar] [CrossRef] [Green Version]

- Flynn, B.B.; Huo, B.; Zhao, X. The impact of supply chain integration on performance: A contingency and configuration approach. J. Oper. Manag. 2010, 28, 58–71. [Google Scholar] [CrossRef]

- Barratt, M. Understanding the meaning of collaboration in the supply chain. Supply Chain Manag. Int. J. 2004, 9, 30–42. [Google Scholar] [CrossRef]

- Thun, J.H.; Müller, A. An empirical analysis of green supply chain management in the German automotive industry. Expert. Syst. Appl. 2010, 19, 119–132. [Google Scholar] [CrossRef]

- Wong, W.P.; Tseng, M.L.; Tan, K.H. A business process management capabilities perspective on organisation performance. Total Qual. Manag. Bus. 2014, 25, 602–617. [Google Scholar] [CrossRef]

- Chen, Y.S.; Lai, S.B.; Wen, C.T. The influence of green innovation performance on corporate advantage in Taiwan. J. Bus. Ethics 2006, 67, 331–339. [Google Scholar] [CrossRef]

- Li, Y. Environmental innovation practices and performance: Moderating effect of resource commitment. J. Clean. Prod. 2014, 66, 450–458. [Google Scholar] [CrossRef]

- Chen, Y.S.; Chang, C.H.; Lin, Y.H. The determinants of green radical and incremental innovation performance: Green shared vision, green absorptive capacity, and green organizational ambidexterity. Sustainability 2014, 6, 7787–7806. [Google Scholar] [CrossRef] [Green Version]

- Luthra, S.; Garg, D.; Haleem, A. The impacts of critical success factors for implementing green supply chain management towards sustainability: An empirical investigation of Indian automobile industry. J. Clean. Prod. 2016, 121, 142–158. [Google Scholar] [CrossRef]

- Fraj, E.; Martínez, E.; Matute, J. Green marketing in B2B organisations: An empirical analysis from the natural-resource-based view of the firm. J. Bus. Ind. Mark. 2013, 28, 396–410. [Google Scholar] [CrossRef]

- Chen, Y.S. The driver of green innovation and green image–green core competence. J. Bus. Ethics 2008, 81, 531–543. [Google Scholar] [CrossRef]

- Zhao, X.; Huo, B.; Selen, W.; Yeung, J.H.Y. The impact of internal integration and relationship commitment on external integration. J. Oper. Manag. 2011, 29, 17–32. [Google Scholar] [CrossRef]

- Swink, M.; Narasimhan, R.; Wang, C. Managing beyond the factory walls: Effects of four types of strategic integration on manufacturing plant performance. J. Oper. Manag. 2007, 25, 148–164. [Google Scholar] [CrossRef]

- Koufteros, X.; Vonderembse, M.; Jayaram, J. Internal and external integration for product development: The contingency effects of uncertainty, equivocality, and platform strategy. Decis. Sci. 2005, 36, 97–133. [Google Scholar] [CrossRef]

- Yang, C.S.; Lu, C.S.; Haider, J.J.; Marlow, P.B. The effect of green supply chain management on green performance and firm competitiveness in the context of container shipping in Taiwan. Transp. Res. E Logist. Transp. Rev. 2013, 55, 55–73. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K.H. Institutional-based antecedents and performance outcomes of internal and external green supply chain management practices. J. Purch. Supply. Manag. 2013, 19, 106–117. [Google Scholar] [CrossRef]

- Laari, S.; Töyli, J.; Solakivi, T.; Ojala, L. Firm performance and customer-driven green supply chain management. J. Clean. Prod. 2016, 112, 1960–1970. [Google Scholar] [CrossRef]

- Huang, Y.C.; Wu, Y.C. The effects of organizational factors on green new product success-evidence from high-tech industries in Taiwan. Manag. Decis. 2010, 48, 1539–1567. [Google Scholar] [CrossRef]

- Roscoe, S.; Cousins, P.; Lamming, R. Developing eco-innovations: A three stage typology of supply networks. J. Clean. Prod. 2016, 112, 1948–1959. [Google Scholar] [CrossRef]

- Kong, T.; Feng, T.; Ye, C. Advanced manufacturing technologies, green innovation: The role of internal environmental collaboration. Sustainability 2016, 8, 1056. [Google Scholar] [CrossRef] [Green Version]

- Paulraj, A.; Jayaraman, V.; Blome, C. Complementarity effect of governance mechanisms on environmental collaboration: Does it exist? Int. J. Prod. Res. 2014, 52, 6989–7006. [Google Scholar] [CrossRef]

- Dong, Y.; Wang, X.; Jin, J.; Qiao, Y.; Shi, L. Effects of eco-innovation typology on its performance: Empirical evidence from Chinese enterprises. J. Eng. Technol. Manag. 2014, 34, 78–98. [Google Scholar] [CrossRef]

- Patel, P.C.; Azadegan, A.; Ellram, L.M. The effects of strategic and structural supply chain orientation on operational and customer-focused performance. Decis. Sci. 2013, 44, 713–753. [Google Scholar] [CrossRef]

- Forsman, H. Environmental innovations as a source of competitive advantage or vice versa? Expert Syst. Appl. 2013, 22, 306–320. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J. Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Zhu, Q.; Geng, Y.; Lai, K.H. Circular economy practices among Chinese manufacturers varying in environmental-oriented supply chain cooperation and the performance implications. J. Environ. Manag. 2010, 91, 1324–1331. [Google Scholar] [CrossRef]

- Cao, M.; Zhang, Q. Supply chain collaboration: Impact on collaborative advantage and firm performance. J. Oper. Manag. 2011, 29, 163–180. [Google Scholar] [CrossRef]

- Wall, T.D.; Michie, J.; Patterson, M.; Wood, S.J.; Sheehan, M.; Clegg, C.W.; West, M. On the validity of subjective measures of company performance. Pers. Psychol. 2004, 57, 95–118. [Google Scholar] [CrossRef]

- Vij, S.; Bedi, H.S. Are subjective business performance measures justified? Int. J. Prod. Perform. Manag. 2016, 65, 603–621. [Google Scholar] [CrossRef]

- Tarsakoo, P.; Charoensukmongkol, P. Dimensions of social media marketing capabilities and their contribution to business performance of firms in Thailand. J. Asia Bus. Stud. 2019, 14, 441–461. [Google Scholar] [CrossRef]

- Vaitoonkiat, E.; Charoensukmongkol, P. Interaction effect of entrepreneurial orientation and stakeholder orientation on the business performance of firms in the steel fabrication industry in Thailand. J. Entrep. Emerg. Econ. 2020, 12, 453–473. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E.; Tatham, R.L. Multivariate Data Analysis, 6th ed.; Pearson University Press: New Jersey, NJ, USA, 2006. [Google Scholar]

| Category and Items | Sample Size | Ratio (%) | |

|---|---|---|---|

| Operating Years | Less than 5 years | 38 | 11.6 |

| 5–10 years | 76 | 23.1 | |

| 10–20 years | 130 | 39.5 | |

| 20–30 years | 48 | 14.6 | |

| More than 30 years | 37 | 11.2 | |

| Annual Sales | Less than USD 10 M | 26 | 7.9 |

| USD 10–USD 30 M | 41 | 12.5 | |

| USD 30–USD 50 M | 100 | 30.4 | |

| USD 50–USD 100 M | 107 | 32.5 | |

| More than USD 100 M | 55 | 16.7 | |

| Industry | Textile/Clothing | 27 | 8.2 |

| Machinery/Steel/Metal | 60 | 18.2 | |

| Petroleum/Chemical/Plastics | 54 | 16.4 | |

| Electric/Electronic/Communication | 119 | 36.2 | |

| Bio/Medical | 46 | 14.0 | |

| Etc. | 23 | 7.0 | |

| Measurement Item | Factor L.D. | C.R. | AVE | Crb. Alpha | |

|---|---|---|---|---|---|

| Internal Collaboration | EIC1 | 0.763 | 0.902 | 0.697 | 0.856 |

| EIC2 | 0.781 | ||||

| EIC3 | 0.796 | ||||

| EIC4 | 0.756 | ||||

| External Collaboration | EEC1 | 0.714 | 0.887 | 0.664 | 0.794 |

| EEC2 | 0.696 | ||||

| EEC3 | 0.704 | ||||

| EEC4 | 0.686 | ||||

| Sustainable Product Innovation | PDI1 | 0.751 | 0.931 | 0.773 | 0.863 |

| PDI2 | 0.770 | ||||

| PDI3 | 0.858 | ||||

| PDI4 | 0.822 | ||||

| Sustainable Process Innovation | PCI1 | 0.746 | 0.924 | 0.754 | 0.876 |

| PCI2 | 0.773 | ||||

| PCI3 | 0.832 | ||||

| PCI4 | 0.779 | ||||

| Environmental Performance | EVP1 | 0.692 | 0.890 | 0.730 | 0.772 |

| EVP2 | 0.815 | ||||

| EVP4 | 0.687 | ||||

| Financial Performance | EPP1 | 0.844 | 0.916 | 0.788 | 0.821 |

| EPP2 | 0.877 | ||||

| EPP3 | 0.641 | ||||

| Variable | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| 1. Internal Collaboration | 0.697 ** | □ | □ | □ | □ | □ |

| 2. External Collaboration | 0.464 * | 0.664 ** | □ | □ | □ | □ |

| 3. Sustainable Product Innovation | 0.326 * | 0.434 * | 0.773 ** | □ | □ | □ |

| 4. Sustainable Process Innovation | 0.386 * | 0.473 * | 0.416 * | 0.754 ** | □ | □ |

| 5. Environmental Performance | 0.377 * | 0.288 * | 0.316 * | 0.349 * | 0.730 ** | □ |

| 6. Financial Performance | 0.246 * | 0.294 * | 0.386 * | 0.325 * | 0.324 * | 0.788 ** |

| Hypothesis Path | Estimate (β) | C.R. (t) | Results | |||

|---|---|---|---|---|---|---|

| H1 | Internal Collaboration | → | External Collaboration | 0.609 | 9.202 ** | Supported |

| H2a | Internal Collaboration | → | Sustainable Product Innovation | 0.176 | 2.321 * | Supported |

| H2b | External Collaboration | → | Sustainable Product Innovation | 0.562 | 5.776 ** | Supported |

| H3a | Internal Collaboration | → | Sustainable Process Innovation | 0.234 | 3.118 ** | Supported |

| H3b | External Collaboration | → | Sustainable Process Innovation | 0.567 | 5.891 ** | Supported |

| H4 | External Collaboration | → | Environmental Performance | 0.143 | 1.453 | Not Supported |

| H5a | Sustainable Product Innovation | → | Environmental Performance | 0.188 | 2.633 ** | Supported |

| H5b | Sustainable Process Innovation | → | Environmental Performance | 0.237 | 3.238 ** | Supported |

| H6a | Sustainable Product Innovation | → | Financial Performance | 0.370 | 4.991 ** | Supported |

| H6b | Sustainable Process Innovation | → | Financial Performance | 0.203 | 2.831 ** | Supported |

| H7 | Environmental Performance | → | Financial Performance | 0.326 | 3.091 ** | Supported |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jo, D.; Kwon, C. Structure of Green Supply Chain Management for Sustainability of Small and Medium Enterprises. Sustainability 2022, 14, 50. https://doi.org/10.3390/su14010050

Jo D, Kwon C. Structure of Green Supply Chain Management for Sustainability of Small and Medium Enterprises. Sustainability. 2022; 14(1):50. https://doi.org/10.3390/su14010050

Chicago/Turabian StyleJo, Donghyuk, and Chulhwan Kwon. 2022. "Structure of Green Supply Chain Management for Sustainability of Small and Medium Enterprises" Sustainability 14, no. 1: 50. https://doi.org/10.3390/su14010050

APA StyleJo, D., & Kwon, C. (2022). Structure of Green Supply Chain Management for Sustainability of Small and Medium Enterprises. Sustainability, 14(1), 50. https://doi.org/10.3390/su14010050