Ergonomics Risk Assessment for Manual Material Handling of Warehouse Activities Involving High Shelf and Low Shelf Binning Processes: Application of Marker-Based Motion Capture

Abstract

1. Introduction

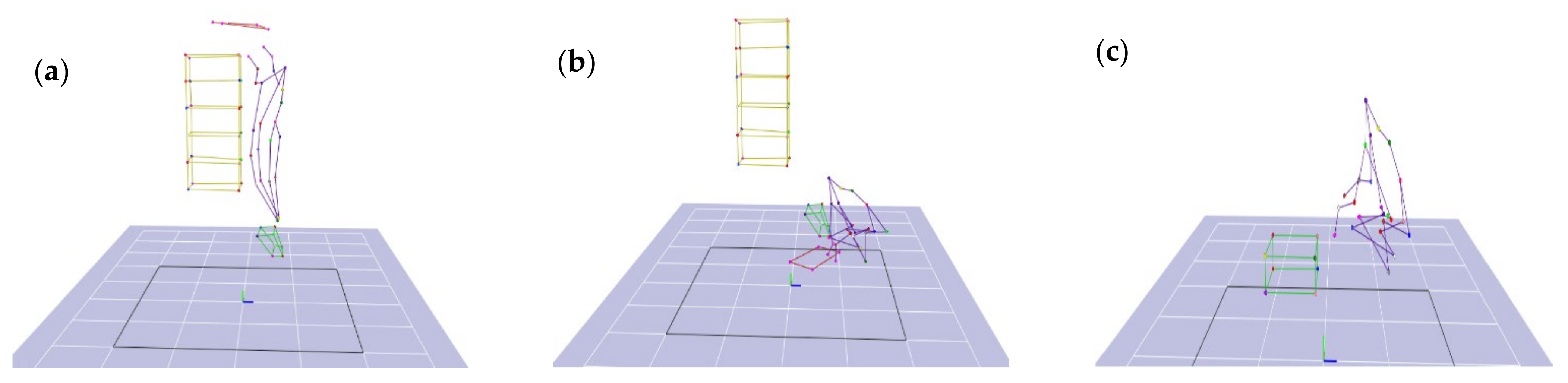

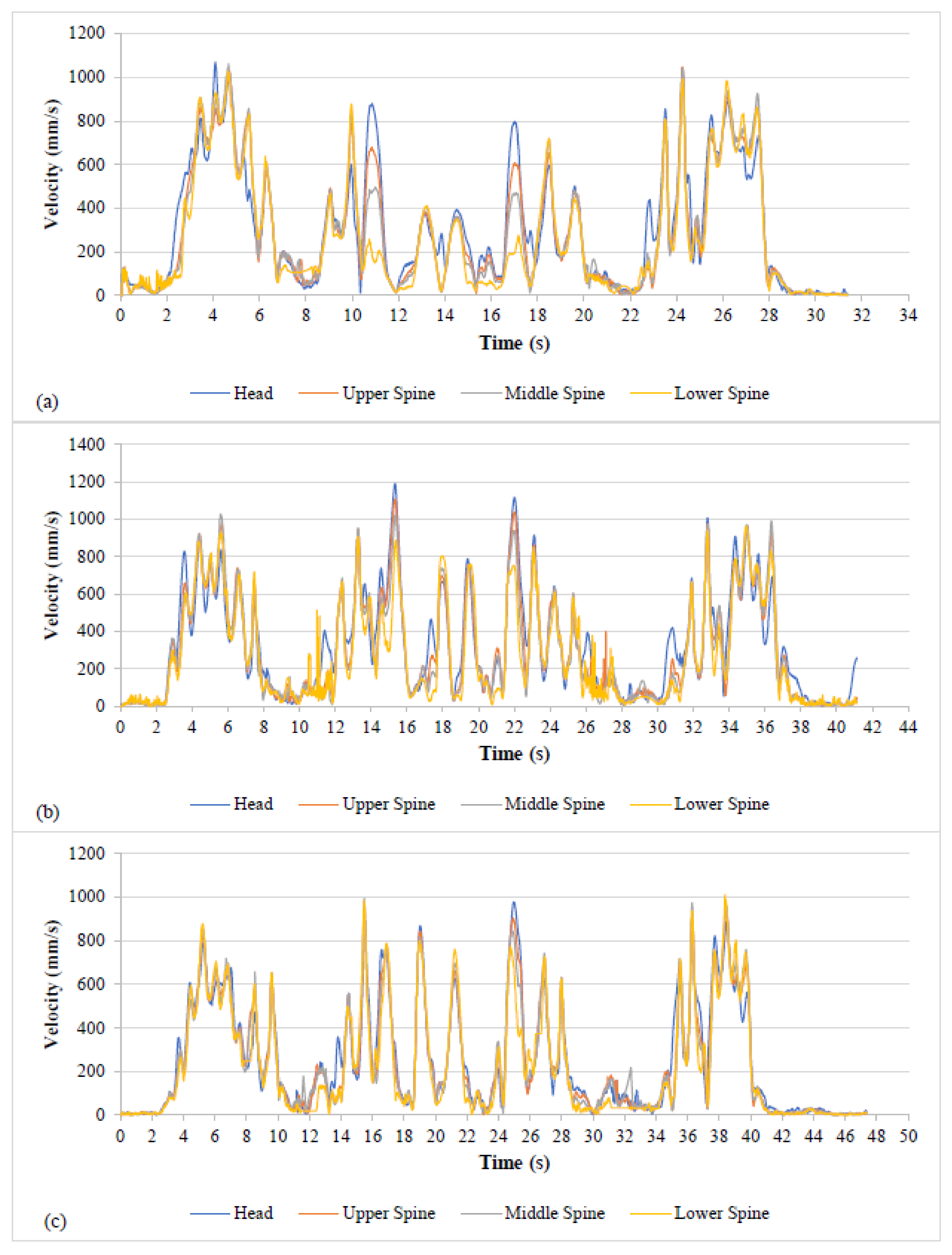

2. Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- CDC. Work-Related Musculoskeletal Disorders & Ergonomics. Centers for Disease Control and Prevention. 2020. Available online: https://www.cdc.gov/workplacehealthpromotion/health-strategies/musculoskeletal-disorders/index.html (accessed on 14 February 2022).

- Ge, H.; Sun, X.; Liu, J.; Zhang, C. The status of musculoskeletal disorders and its influence on the working ability of Oilworkers in Xinjiang, China. Int. J. Environ. Res. Public Health 2018, 15, 842. [Google Scholar] [CrossRef] [PubMed]

- Al-Hadidi, F.; Bsisu, I.; Haddad, B.; AlRyalat, S.A.; Shaban, M.; Matani, N.; Dehidi, S.; Khater, Y.; Shahrouri, R.; Muzayen, T.; et al. The prevalence of low back pain among female hospital staff at childbearing age. PeerJ 2020, 8, e9199. [Google Scholar] [CrossRef] [PubMed]

- Parida, R.; Ray, P.K. Biomechanical Modelling of Manual Material Handling Tasks: A Comprehensive Review. Procedia Manuf. 2015, 3, 4598–4605. [Google Scholar] [CrossRef][Green Version]

- Hazana Abdullah, N.; Aziati Abdul Hamid, N.; Wahab, E.; Shamsuddin, A.; Asmawi, R. Work-related Musculoskeletal Disorder (WRMD) among Production Operators: Studies of Differences in Age and Gender. J. Phys. Conf. Ser. 2018, 1049, 012023. [Google Scholar] [CrossRef]

- Fernandes, P.R.; Hurtado, A.L.B.; Batiz, E.C. Ergonomics management with a proactive focus. Procedia Manuf. 2015, 3, 4509–4516. [Google Scholar] [CrossRef]

- Petrosyan, T.; Dunoyan, A.; Mkrtchyan, H. Application of Motion Capture Systems in Ergonomic Analysis. Armen. J. Spec. Educ. 2020, 1, 107–117. [Google Scholar] [CrossRef]

- Ong, Z.C.; Seet, Y.C.; Khoo, S.Y.; Noroozi, S. Development of an economic wireless human motion analysis device for quantitative assessment of human body joint. Meas. J. Int. Meas. Conf. 2018, 115, 306–315. [Google Scholar] [CrossRef]

- Ro, D.H.; Han, H.S.; Lee, D.Y.; Kim, S.H.; Kwak, Y.H.; Lee, M.C. Slow gait speed after bilateral total knee arthroplasty is associated with suboptimal improvement of knee biomechanics. Knee Surg. Sport Traumatol. Arthrosc. 2018, 26, 1671–1680. [Google Scholar] [CrossRef]

- Halilaj, E.; Rajagopal, A.; Fiterau, M.; Hicks, J.L.; Hastie, T.J.; Delp, S.L. Machine learning in human movement biomechanics: Best practices, common pitfalls, and new opportunities. J. Biomech. 2018, 81, 1–11. [Google Scholar] [CrossRef]

- Li, X.; Komeili, A.; Gül, M.; El-Rich, M. A framework for evaluating muscle activity during repetitive manual material handling in construction manufacturing. Autom. Constr. 2017, 79, 39–48. [Google Scholar] [CrossRef]

- D’hooge, R.; Hodges, P.; Tsao, H.; Hall, L.; MacDonald, D.; Danneels, L. Altered trunk muscle coordination during rapid trunk flexion in people in remission of recurrent low back pain. J. Electromyogr. Kinesiol. 2013, 23, 173–181. [Google Scholar] [CrossRef]

- Patrizi, A.; Pennestrì, E.; Valentini, P.P. Comparison between low-cost marker-less and high-end marker-based motion capture systems for the computer-aided assessment of working ergonomics. Ergonomics 2016, 59, 155–162. [Google Scholar] [CrossRef]

- Perrott, M.A.; Pizzari, T.; Cook, J.; McClelland, J.A. Comparison of lower limb and trunk kinematics between markerless and marker-based motion capture systems. Gait Posture 2017, 52, 57–61. [Google Scholar] [CrossRef]

- Lau, B.Y.S.; Ting, H.Y.; Tan, Y.W.D. Cost-Benefit Analysis Reference Framework for Human Motion Capture and Analysis Systems. Adv. Sci. Lett. 2018, 24, 1249–1253. [Google Scholar] [CrossRef]

- Schmitz, A.; Ye, M.; Boggess, G.; Shapiro, R.; Yang, R.; Noehren, B. The measurement of in vivo joint angles during a squat using a single camera markerless motion capture system as compared to a marker based system. Gait Posture 2015, 41, 694–698. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, L.; Teng, Q.; He, J.; Wu, H. DanHAR: Dual attention network for multimodal human activity recognition using wearable sensors. Appl. Soft Comput. 2021, 111, 107728. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, L.; Gao, W.; Min, F.; He, J. Shallow convolutional neural networks for human activity recognition using wearable sensors. IEEE Trans. Instrum. Meas. 2021, 70, 2510811. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, L.; Huang, W.; Min, F.; He, J.; Song, A. Deep neural networks for sensor-based human activity recognition using selective kernel convolution. IEEE Trans. Instrum. Meas. 2021, 70, 2512313. [Google Scholar] [CrossRef]

- He, J.; Zhang, Q.; Wang, L.; Pei, L. Weakly supervised human activity recognition from wearable sensors by recurrent attention learning. IEEE Sens. J. 2018, 19, 2287–2297. [Google Scholar] [CrossRef]

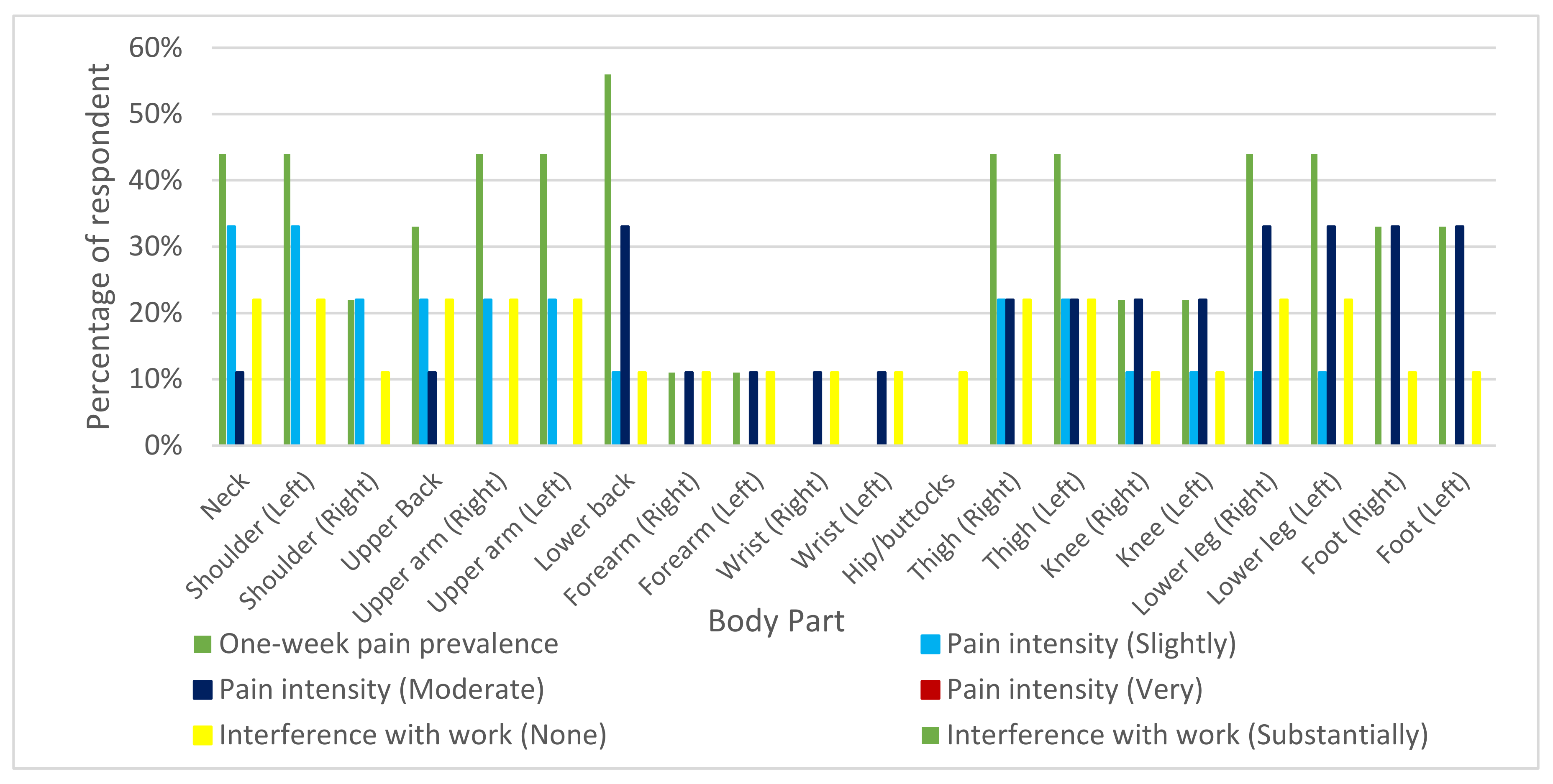

- Basahel, A.M. Investigation of Work-related Musculoskeletal Disorders (MSDs) in Warehouse Workers in Saudi Arabia. Procedia Manuf. 2015, 3, 4643–4649. [Google Scholar] [CrossRef][Green Version]

- Rahman, M.N.A.; Zuhaidi, M.F.A. Musculoskeletal symptoms and ergonomic hazards among material handlers in grocery retail industries. IOP Conf. Ser. Mater. Sci. Eng. 2017, 226, 012027. [Google Scholar] [CrossRef]

- Ray, P.K.; Parida, R.; Saha, E. Status Survey of Occupational Risk Factors of Manual Material Handling Tasks at a Construction Site in India. Procedia Manuf. 2015, 3, 6579–6586. [Google Scholar] [CrossRef]

- Dabholkar, T.; Yardi, S.; Dabholkar, Y.G.; Velankar, H.K.; Ghuge, G. A survey of work-related musculoskeletal disorders among otolaryngologists. Indian J. Otolaryngol. Head Neck Surg. 2017, 69, 230–238. [Google Scholar] [CrossRef]

- Syu, Y.-S.; Chen, L.; Tu, Y.-F. A Case Study of Digital Preservation of Motion Capture for Bā Jiā Jiāng Performance, Taiwan Religious Performing Arts. Euro-Mediterr. Conf. 2018, 11197, 103–110. [Google Scholar]

- Soh, A.A.S.A.; Jafri, M.Z.M.; Azraai, N.Z. Power estimation of martial arts movement with different physical, mood, and behavior using motion capture camera. In Optics for Arts, Architecture, and Archaeology VI; International Society for Optics and Photonics: San Diego, CA, USA, 2017; Volume 10331, p. 103310X. [Google Scholar]

- Yunus, M.N.H.; Jaafar, M.H.; Mohamed, A.S.A.; Azraai, N.Z.; Hossain, M.S. Implementation of kinetic and kinematic variables in ergonomic risk assessment using motion capture simulation: A review. Int. J. Environ. Res. Public Health 2021, 18, 8342. [Google Scholar] [CrossRef] [PubMed]

- Antwi-Afari, M.F.; Li, H.; Edwards, D.J.; Pärn, E.A.; Seo, J.; Wong, A.Y.L. Biomechanical analysis of risk factors for work-related musculoskeletal disorders during repetitive lifting task in construction workers. Autom. Constr. 2017, 83, 41–47. [Google Scholar] [CrossRef]

- Akhavian, R.; Behzadan, A.H. Smartphone-based construction workers’ activity recognition and classification. Autom. Constr. 2016, 71, 198–209. [Google Scholar] [CrossRef]

- Chung, K.L.; Lai, J.Y. An efficient law-of-cosine-based search for vector quantization. Pattern Recognit. Lett. 2004, 25, 1613–1617. [Google Scholar] [CrossRef]

- Hoozemans, M.J.M.; Knelange, E.B.; Frings-Dresen, M.H.W.; Veeger, H.E.J.; Kuijer, P.P.F.M. Are pushing and pulling work-related risk factors for upper extremity symptoms? A systematic review of observational studies. Occup. Environ. Med. 2014, 71, 788–795. [Google Scholar] [CrossRef]

- Blache, Y.; Desmoulins, L.; Allard, P.; Plamondon, A.; Begon, M. Effects of height and load weight on shoulder muscle work during overhead lifting task. Ergonomics 2015, 58, 748–761. [Google Scholar] [CrossRef]

- Manap, M.; Amat, H.; Sharif, S.; Yusoff, N.; Rahman, N. Guideline for Manual Handling at Workplace; Department of Occupational Safety and Health: Kuala Lumpur, Malaysia, 2017. [Google Scholar]

- Deros, B.M.; Daruis, D.D.I.; Basir, I.M. A study on ergonomic awareness among workers performing manual material handling activities. Procedia Soc. Behav. Sci. 2015, 195, 1666–1673. [Google Scholar] [CrossRef][Green Version]

- Palmer, K.T.; Smedley, J. Work relatedness of chronic neck pain with physical findings—A systematic review. Scand. J. Work Environ. Health 2007, 33, 165–191. [Google Scholar] [CrossRef]

- Aitchison, L.P.; Cui, C.K.; Arnold, A.; Nesbitt-Hawes, E.; Abbott, J. The ergonomics of laparoscopic surgery: A quantitative study of the time and motion of laparoscopic surgeons in live surgical environments. Surg. Endosc. 2016, 30, 5068–5076. [Google Scholar] [CrossRef]

- Oliveira, A.B.; Silva, L.C.C.B.; Coury, H.J.C.G. How do low/high height and weight variation affect upper limb movements during manual material handling of industrial boxes? Rev. Bras. Fisioter. Rev. Bras. Fisioter. 2011, 15, 494–502. [Google Scholar] [CrossRef]

- Kingston, D.C.; Tennant, L.M.; Chong, H.C.; Acker, S.M. Peak activation of lower limb musculature during high flexion kneeling and transitional movements. Ergonomics 2016, 59, 1215–1223. [Google Scholar] [CrossRef]

- Zelle, J.; Barink, M.; De Waal Malefijt, M.; Verdonschot, N. Thigh-calf contact: Does it affect the loading of the knee in the high-flexion range? J. Biomech. 2009, 42, 587–593. [Google Scholar] [CrossRef]

- Mikkelsen, S.; Pedersen, E.B.; Brauer, C.; Møller, K.L.; Alkjær, T.; Koblauch, H.; Simonsen, E.B.; Thygesen, L.C. Knee osteoarthritis among airport baggage handlers: A prospective cohort study. Am. J. Ind. Med. 2019, 62, 951–960. [Google Scholar] [CrossRef]

- Baker, P.; Reading, I.; Cooper, C.; Coggon, D. Knee disorders in the general population and their relation to occupation. Occup. Environ. Med. 2003, 60, 794–797. [Google Scholar] [CrossRef]

- Loh, P.Y.; Nakashima, H.; Muraki, S. Median nerve behavior at different wrist positions among older males. PeerJ 2015, 3, e928. [Google Scholar] [CrossRef]

- Ezugwu, U.A.; Egba, E.N.; Igweagu, P.C.; Eneje, L.E.; Orji, S.; Ugwu, U.C. Awareness of Awkward Posture and Repetitive Motion as Ergonomic Factors Associated with Musculoskeletal Disorders by Health Promotion Professionals. Glob. J. Health Sci. 2020, 12, 128. [Google Scholar] [CrossRef]

- Yoon, J.; Shiekhzadeh, A.; Nordin, M. The effect of load weight vs. pace on muscle recruitment during lifting. Appl. Ergon. 2012, 43, 1044–1050. [Google Scholar] [CrossRef]

- Greenland, K.O.; Merryweather, A.S.; Bloswick, D.S. The effect of lifting speed on cumulative and peak biomechanical loading for symmetric lifting tasks. Saf. Health Work 2013, 4, 105–110. [Google Scholar] [CrossRef]

- Vahdat, I.; Rostami, M.; Tabatabai Ghomsheh, F.; Khorramymehr, S.; Tanbakoosaz, A. Effects of external loading on lumbar extension moment during squat lifting. Int. J. Occup. Med. Environ. Health 2017, 30, 665. [Google Scholar] [CrossRef]

- Marras, W.S.; Knapik, G.G.; Ferguson, S. Loading along the lumbar spine as influence by speed, control, load magnitude, and handle height during pushing. Clin. Biomech. 2009, 24, 155–163. [Google Scholar] [CrossRef]

- Hlavenka, T.M.; Christner, V.F.K.; Gregory, D.E. Neck posture during lifting and its effect on trunk muscle activation and lumbar spine posture. Appl. Ergon. 2017, 62, 28–33. [Google Scholar] [CrossRef]

- Lin, C.J.; Cheng, C.-F. Lifting speed preferences and their effects on the maximal lifting capacity. Ind. Health 2017, 55, 27–34. [Google Scholar] [CrossRef]

- Tetteh, E.; Mirka, G. Effect of Time on the Variability of Lifting Kinematics in a Repetitive Lifting Task. Proc. Hum. Factors Ergon. Soc. Annu. Meet. 2018, 62, 910–914. [Google Scholar] [CrossRef]

- Pavlova, A.V.; Meakin, J.R.; Cooper, K.; Barr, R.J.; Aspden, R.M. Variation in lifting kinematics related to individual intrinsic lumbar curvature: An investigation in healthy adults. BMJ Open Sport Exerc. Med. 2018, 4, e000374. [Google Scholar] [CrossRef]

- Pan, F.; Firouzabadi, A.; Zander, T.; Schmidt, H. Sex-dependent differences in lumbo-pelvic coordination for different lifting tasks: A study on asymptomatic adults. J. Biomech. 2020, 102, 109505. [Google Scholar] [CrossRef]

- Elsayed, W.; Farrag, A.; El-Sayyad, M.; Marras, W. Changes in muscular activity and lumbosacral kinematics in response to handling objects of unknown mass magnitude. Hum. Mov. Sci. 2015, 40, 315–325. [Google Scholar] [CrossRef]

- Tsang, S.M.H.; Szeto, G.P.Y.; Li, L.M.K.; Wong, D.; Yip, M.M.P.; Lee, R.Y.W. The effects of bending speed on the lumbo-pelvic kinematics and movement pattern during forward bending in people with and without low back pain. BMC Musculoskelet. Disord. 2017, 18, 157. [Google Scholar] [CrossRef] [PubMed]

| Variables | Levels or Conditions | ||

|---|---|---|---|

| Independent variable | HS binning process | Weight of bin | 18 kg |

| Reaching height | 210 cm–235 cm | ||

| LS binning process | Weight of bin | 2.1 kg | |

| Lowering height | 40 cm–50 cm | ||

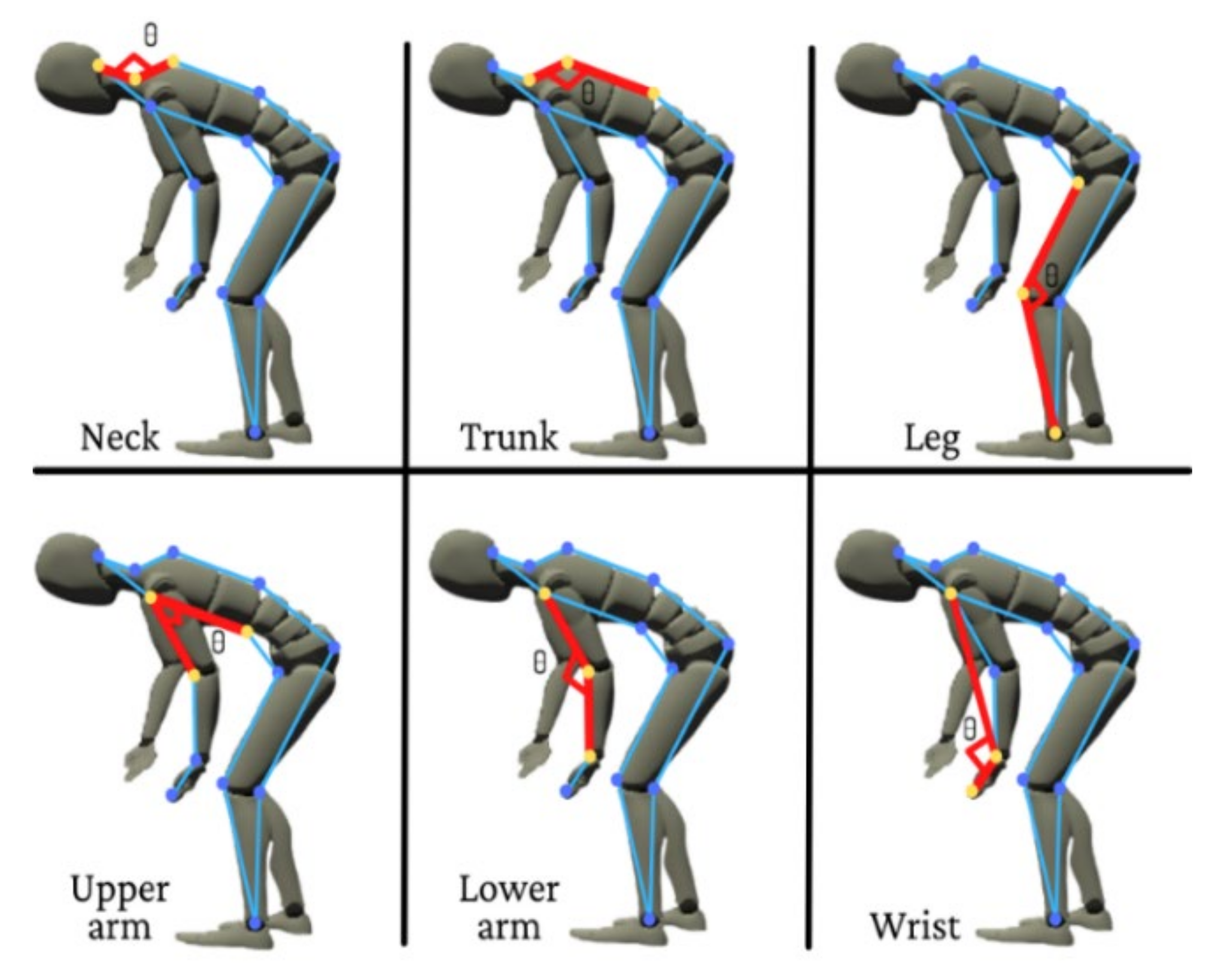

| Dependent variable | - | Angle of deviation for specific body parts (θ) | - |

| - | Movement time (s) | - | |

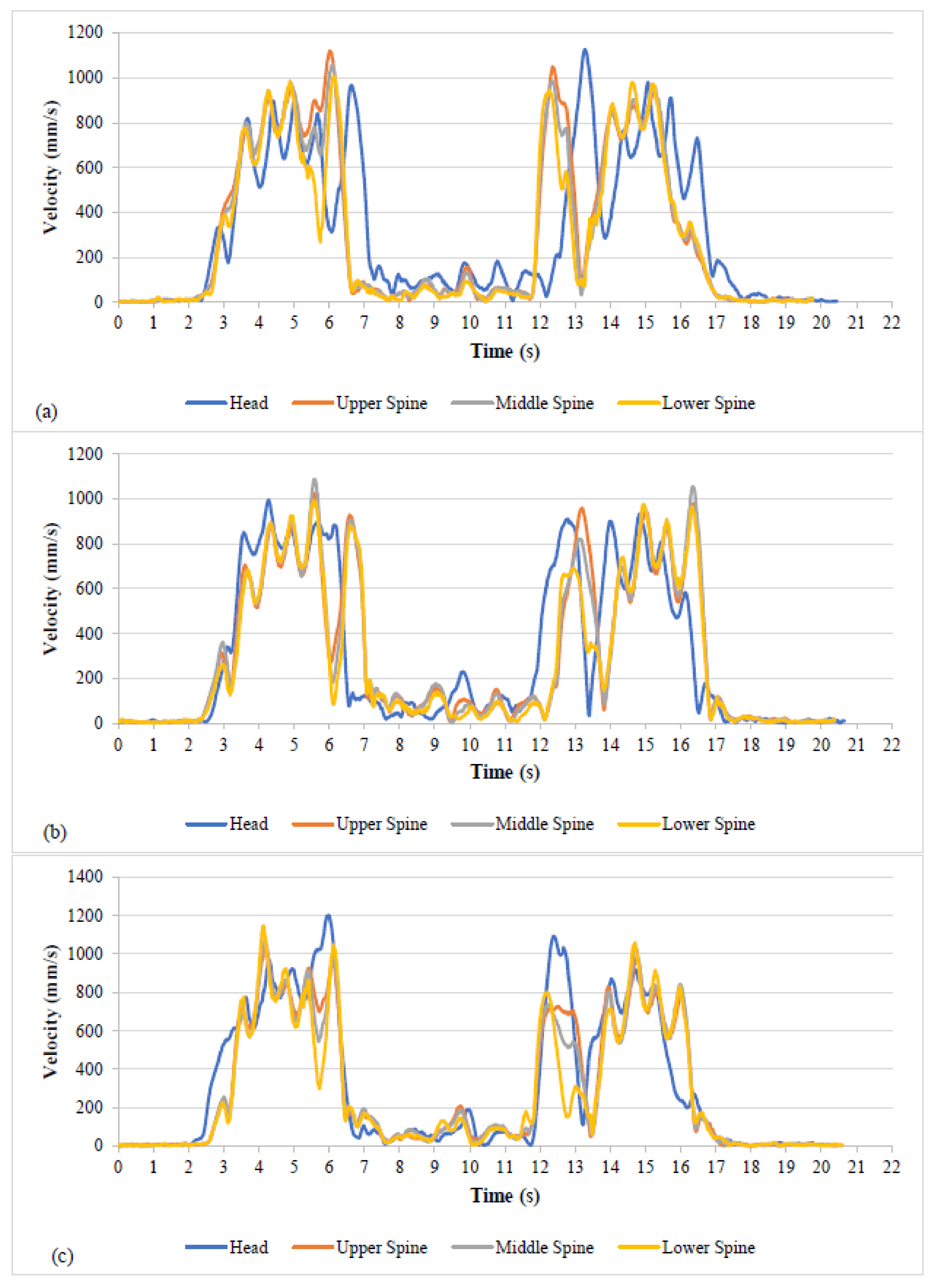

| - | Movement velocities (mm/s) | - | |

| Constant variable | - | Equipment | Medium duty bin |

| (61.5 cm × 42 cm × 23.5 cm) | |||

| Light duty bin | |||

| (50 cm × 31 cm × 17 cm) | |||

| Step ladder | |||

| (49 cm × 50 cm × 44 cm) | |||

| REBA Score | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Task | Participant | A | B | C | Max. Score | ||||

| Body Part | Reaching | Crouching | Reaching | Crouching | Reaching | Crouching | |||

| HS Binning Process | Neck | 2 | 2 | 3 | 2 | 3 | 2 | 3 | |

| Trunk | 1 | 2 | 2 | 3 | 2 | 2 | 5 | ||

| Leg | 4 | 1 | 1 | 3 | 1 | 4 | 4 | ||

| Upper arm | 4 | 2 | 5 | 3 | 5 | 2 | 6 | ||

| Lower arm | 2 | 2 | 2 | 2 | 2 | 2 | 2 | ||

| Wrist | 2 | 2 | 2 | 2 | 3 | 1 | 3 | ||

| Load | 0 | 0 | 0 | 0 | 0 | 0 | 4 | ||

| Neck, trunk, leg posture | 5 | 3 | 4 | 6 | 4 | 6 | 9 | ||

| Arm and wrist posture | 8 | 3 | 8 | 5 | 8 | 2 | 9 | ||

| Entire Body posture | 8 | 3 | 8 | 8 | 8 | 6 | 12 | ||

| Activity Score | 1 | 1 | 1 | 1 | 1 | 1 | 3 | ||

| Grand Score | 8 | 4 | 9 | 9 | 9 | 7 | 15 | ||

| LS Binning Process | Neck | - | 2 | - | 2 | - | 2 | 3 | |

| Trunk | - | 1 | - | 1 | - | 2 | 5 | ||

| Leg | - | 4 | - | 4 | - | 4 | 4 | ||

| Upper arm | - | 4 | - | 3 | - | 4 | 6 | ||

| Lower arm | - | 2 | - | 1 | - | 1 | 2 | ||

| Wrist | - | 2 | - | 2 | - | 3 | 3 | ||

| Load | - | 2 | - | 2 | - | 2 | 4 | ||

| Neck, trunk, leg posture | - | 7 | - | 7 | - | 8 | 9 | ||

| Arm and wrist posture | - | 6 | - | 4 | - | 5 | 9 | ||

| Entire Body posture | - | 9 | - | 8 | - | 10 | 12 | ||

| Activity Score | - | 1 | - | 1 | - | 1 | 3 | ||

| Grand Score | - | 10 | - | 9 | - | 11 | 15 | ||

| Deviation of Angle (°) | |||||||

|---|---|---|---|---|---|---|---|

| Task | Posture | Participant | A | B | C | Median | |

| Body Part | |||||||

| HS Binning Process | Crouching | Neck | 38.24 | 24.63 | 27.08 | 27.08 | |

| Trunk | 11.47 | 4.87 | 2.39 | 4.87 | |||

| Knee | 27.36 | 130.1 | 120.12 | 120.12 | |||

| Upper arm | 32.78 | 54.29 | 22.45 | 32.78 | |||

| Lower arm | 44.32 | 40.21 | 8.44 | 40.21 | |||

| Wrist | 21.4 | 23.92 | 6.69 | 21.4 | |||

| Reaching | Neck | 8.87 | 1.67 | 8.03 | 8.03 | ||

| Trunk | 14.38 | 10.92 | 12.77 | 12.77 | |||

| Knee | 67.2 | 8.72 | 9.07 | 9.07 | |||

| Upper arm | 89.55 | 92.84 | 90.9 | 90.90 | |||

| Lower arm | 40.15 | 23.93 | 49.15 | 40.15 | |||

| Wrist | 7.73 | 0.58 | 24.75 | 7.73 | |||

| LS Binning Process | Crouching | Neck | 18.60 | 9.60 | 22.99 | 18.60 | |

| Trunk | 6.05 | 4.90 | 1.91 | 4.90 | |||

| Knee | 117.09 | 124.50 | 127.03 | 124.5 | |||

| Upper arm | 65.22 | 37.74 | 51.24 | 51.24 | |||

| Lower arm | 11.79 | 65.20 | 66.04 | 65.20 | |||

| Wrist | 3.67 | 0.69 | 44.05 | 3.67 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.S.; Jaafar, M.H.; Mohamed, A.S.A.; Azraai, N.Z.; Amil, N. Ergonomics Risk Assessment for Manual Material Handling of Warehouse Activities Involving High Shelf and Low Shelf Binning Processes: Application of Marker-Based Motion Capture. Sustainability 2022, 14, 5767. https://doi.org/10.3390/su14105767

Zhao YS, Jaafar MH, Mohamed ASA, Azraai NZ, Amil N. Ergonomics Risk Assessment for Manual Material Handling of Warehouse Activities Involving High Shelf and Low Shelf Binning Processes: Application of Marker-Based Motion Capture. Sustainability. 2022; 14(10):5767. https://doi.org/10.3390/su14105767

Chicago/Turabian StyleZhao, Yong Sze, Mohd Hafiidz Jaafar, Ahmad Sufril Azlan Mohamed, Nur Zaidi Azraai, and Norhaniza Amil. 2022. "Ergonomics Risk Assessment for Manual Material Handling of Warehouse Activities Involving High Shelf and Low Shelf Binning Processes: Application of Marker-Based Motion Capture" Sustainability 14, no. 10: 5767. https://doi.org/10.3390/su14105767

APA StyleZhao, Y. S., Jaafar, M. H., Mohamed, A. S. A., Azraai, N. Z., & Amil, N. (2022). Ergonomics Risk Assessment for Manual Material Handling of Warehouse Activities Involving High Shelf and Low Shelf Binning Processes: Application of Marker-Based Motion Capture. Sustainability, 14(10), 5767. https://doi.org/10.3390/su14105767