Utilization of Recycled Plastic Waste in Fiber Reinforced Concrete for Eco-Friendly Footpath and Pavement Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation and Testing

3. Results and Discussions

3.1. Mechanical Characteristics

3.2. Environmental Impacts

4. Conclusions

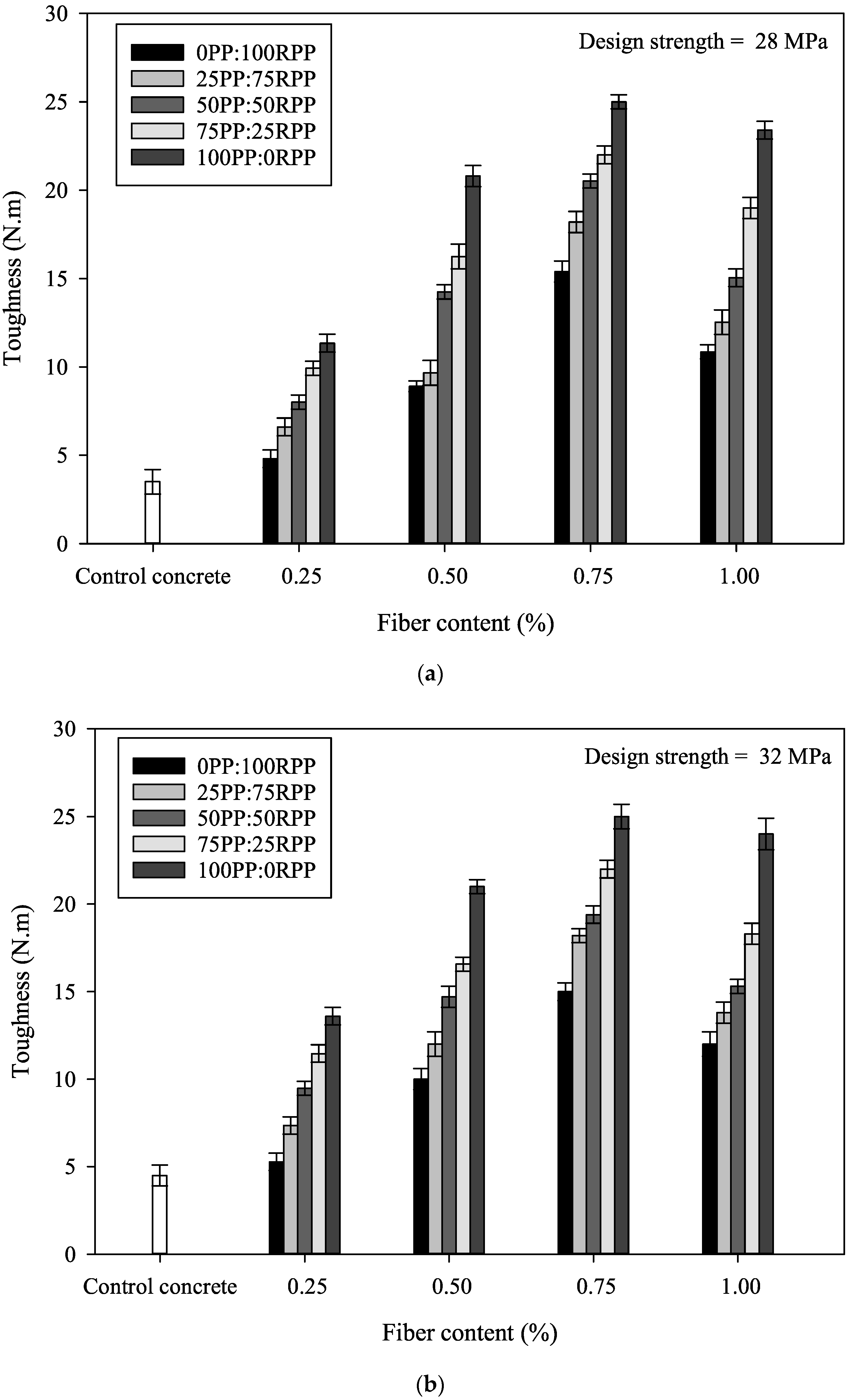

- Improvements in the compressive strength, flexural strength, and toughness of the samples with F were observed in comparison to the control concrete samples for design strengths of 28 and 32 MPa.

- The maximum compressive strengths of 28 and 32 MPa FRC, 31.3 and 34 MPa, respectively, were found at a fiber content of 0.25% and a PP:RPP ratio of 100:0, whereas, the maximum flexural strength and toughness of the 28 and 32 MPa FRC samples were found at an optimum F content of 0.75% for all PP:RPP ratios.

- All mixtures met the compressive strength requirements for concrete footpaths, except for those with F contents of 0.75 and 1% and a PP:RPP ratio of 0:100. Meanwhile, the 32 MPa FRC sample with F contents of 0.25 and 0.5% for all PP:RPP ratios met the minimum requirements for rigid pavement.

- The heavy metal contaminants in the 32 MPa FRC sample were within the allowable limits for all mixtures. The maximum CO2 emissions savings of 28 MPa and 32 MPa FRC were found at a fiber content of 0.5% and a PP:RPP ratio of 0:100. Future research should focus on the effect of F content and PP:RPP ratio on the strength and permeability of fiber-reinforced pervious concrete.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Toghroli, A.; Shariati, M.; Sajedi, F.; Ibrahim, Z.; Koting, S.; Mohamad, E.T.; Khorami, M. A review on pavement porous concrete using recycled waste materials. Smart Struct. Syst. 2018, 22, 433–440. [Google Scholar]

- Al-Kheetan, M.J.; Ghaffar, S.H.; Awad, S.; Chougan, M.; Byzyka, J.; Rahman, M.M. Microstructural, mechanical and physical assessment of Portland cement concrete pavement modified by sodium acetate under various curing conditions. Infrastructures 2021, 6, 113. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Woerden, F.V. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; World Bank Publications: Washington, DC, USA, 2018. [Google Scholar]

- Silva, T.R.; Azevedo, A.R.G.; Cecchin, D.; Marvila, M.T.; Amran, M.; Fediuk, R.; Vatin, N.; Karelina, M.; Klyuev, S.; Szelag, M. Application of Plastic Wastes in Construction Materials: A Review Using the Concept of Life-Cycle Assessment in the Context of Recent Research for Future Perspectives. Materials 2021, 14, 3549. [Google Scholar] [CrossRef]

- Marks, D.; Miller, M.A.; Vassanadumrongdee, S. The geopolitical economy of Thailand’s marine plastic pollution crisis. Asia Pac. Viewp. 2020, 61, 266–282. [Google Scholar] [CrossRef]

- Radusin, T.; Nilsen, J.; Larsen, S.; Annfinsen, S.; Waag, C.; Eikeland, M.S.; Petteren, M.K.; Fredriksen, S.B. Use of recycled materials as mid layer in three layered structures-new possibility in design for recycling. J. Clean. Prod. 2020, 259, 120876. [Google Scholar] [CrossRef]

- Mohammadinia, A.; Wong, Y.C.; Arulrajah, A.; Horpibulsuk, S. Strength. Evaluation of utilizing recycled plastic waste and recycled crushed glass in concrete footpaths. Constr. Build. Mater. 2019, 197, 489–496. [Google Scholar] [CrossRef]

- Siddique, R.; Khatib, J.; Kaur, I. Use of recycled plastic in concrete: A review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef]

- Yazdani, M.; Kabirifar, K.; Frimpong, B.E.; Shariati, M.; Mirmozaffari, M.; Boskabadi, A. Improving construction and demolition waste collection service in an urban area using a simheuristic approach: A case study in Sydney, Australia. J. Clean. Prod. 2021, 280, 124138. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Adesina, A. Plastic wastes to construction products: Status, limitations and future perspective. Case Stud. Constr. Mater. 2020, 12, e00330. [Google Scholar] [CrossRef]

- Faraj, R.H.; Ali, H.F.H.; Sherwani, A.F.H.; Hassan, B.R.; Karim, H. Use of recycled plastic in self-compacting concrete: A comprehensive review on fresh and mechanical properties. J. Build. Eng. 2020, 30, 101283. [Google Scholar] [CrossRef]

- Mehrabi, P.; Shariati, M.; Kabirifar, K.; Jarrah, M.; Rasekh, H.; Trung, N.T.; Jahandari, S. Effect of pumice powder and nano-clay on the strength and permeability of fiber-reinforced pervious concrete incorporating recycled concrete aggregate. Constr. Build. Mater. 2021, 287, 122652. [Google Scholar] [CrossRef]

- Toghroli, A.; Mehrabi, P.; Shariati, M.; Trung, N.T.; Jahandari, S.; Rasekh, H. Evaluating the use of recycled concrete aggregate and pozzolanic additives in fiber-reinforced pervious concrete with industrial and recycled fibers. Constr. Build. Mater. 2020, 252, 118997. [Google Scholar] [CrossRef]

- Basha, S.I.; Ali, M.R.; Al-Dulaijan, S.U.; Maslehuddin, M. Mechanical and thermal properties of lightweight recycled plastic aggregate concrete. J. Build. Eng. 2020, 32, 101710. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A.; Lucchetti, M.C.; Petrucci, E. Recycled Fibers in Reinforced Concrete: A systematic literature review. J. Clean. Prod. 2019, 248, 119207. [Google Scholar] [CrossRef]

- Małek, M.; Jackowski, M.; Łasica, W.; Kadela, M. Characteristics of Recycled Polypropylene Fibers as an Addition to Concrete Fabrication Based on Portland Cement. Materials 2020, 13, 1827. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Francioso, V.; Moro, C.; Castillo, A.; Velay-Lizancos, M. Effect of elevated temperature on flexural behavior and fibers-matrix bonding of recycled PP fiber-reinforced cementitious composite. Constr. Build. Mater. 2021, 269, 121243. [Google Scholar] [CrossRef]

- Bhogayata, A.C.; Arora, N.K. Impact strength, permeability and chemical resistance of concrete reinforced with metalized plastic waste fibers. Constr. Build. Mater. 2018, 161, 254–266. [Google Scholar] [CrossRef]

- Abu-Saleem, M.; Zhuge, Y.; Hassanli, R.; Ellis, M.; Rahman, M.M.; Levett, P. Microwave radiation treatment to improve the strength of recycled plastic aggregate concrete. Case Stud. Constr. Mater. 2021, 15, e00728. [Google Scholar] [CrossRef]

- Abd-Elaal, E.; Al-Bataineh, S.A.; Mills, J.; Whittle, J.; Zhuge, Y. Enhancing Mechanical Properties of Rubberised Concrete with Non-thermal Plasma Treatment. ACMSM25; Springer: Berlin/Heidelberg, Germany, 2020; pp. 23–32. [Google Scholar]

- Sukontasukkul, P.; Chindaprasirt, P.; Pongsopha, P.; Phoo-Ngernkham, T.; Tangchirapat, W.; Banthia, N. Effect of fly ash/silica fume ratio and curing condition on mechanical properties of fiber-reinforced geopolymer. J. Sustain. Cem.-Based Mater. 2020, 9, 218–232. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Jamnam, S.; Sappakittipakorn, M.; Fujikake, K.; Chindaprasirt, P. Residual flexural behavior of fiber reinforced concrete after heating. Mater. Struct. 2018, 51, 98. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Pongsopha, P.; Chindaprasirt, P.; Songpiriyakij, S. Flexural performance and toughness of hybrid steel and polypropylene fibre reinforced geopolymer. Constr. Build. Mater. 2018, 161, 37–44. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Boonbamrung, T.; Poolsong, A.; Kroehong, W. Effect of elevated temperature on polypropylene fiber reinforced alkali-activated high calcium fly ash paste. Case Stud. Constr. Mater. 2021, 15, e00554. [Google Scholar] [CrossRef]

- Khoury, G.A. Polypropylene fibres in heated concrete. Part 2: Pressure relief mechanisms and modelling criteria. Mag. Concr. Res. 2008, 60, 189–204. [Google Scholar] [CrossRef]

- López-Buendía, A.M.; Romero-Sánchez, M.D.; Climent, V.; Guillem, C. Surface treated polypropylene (PP) fibres for reinforced concrete. Cem. Concr. Res. 2013, 54, 29–35. [Google Scholar] [CrossRef]

- Yoosuk, P.; Suksiripattanapong, C.; Sukontasukkul, P.; Chindaprasirt, P. Properties of polypropylene fiber reinforced cellular lightweight high calcium fly ash geopolymer Mortar. Case Stud. Constr. Mater. 2021, 15, e00730. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Shanks, R.A.; Collister, T.; Combe, M.; Jacob, M.; Tian, M.; Sivakugan, N. Fiber preparation and mechanical properties of recycled polypropylene for reinforcing concrete. J. Appl. Polym. Sci. 2015, 132, 41866. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Collister, T.; Combe, M.; Sivakugan, N.; Deng, Z. Post-cracking performance of recycled polypropylene fibre in concrete. Constr. Build. Mater. 2015, 101, 1069–1077. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Riella, J.; Chung, D.; Collister, T.; Combe, M.; Sivakugan, N. Comparative evaluation of virgin and recycled polypropylene fibre reinforced concrete. Constr. Build. Mater. 2016, 114, 134–141. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Sheehan, M.; Combe, M.; Collister, T. A life cycle assessment of recycled polypropylene fibre in concrete footpaths. J. Clean. Prod. 2016, 112, 2231–2242. [Google Scholar] [CrossRef]

- ASTM C127-15; Standard Test Method for Relative Density (Specific Gravity) And Absorption of Coarse Aggregate. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- ASTM C136-14; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. American Society for Testing and Materials: West Conshohocken, PA, USA, 2014.

- ASTM C128-15; Standard Test Method for Relative Density (Specific Gravity) And Absorption of Fine Aggregate. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- ASTM C33-16; Standard Specification for Concrete Aggregates. American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. American Society for Testing and Materials: West Conshohocken, PA, USA, 2014.

- ACI PRC-211.1-91; Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2009; pp. 1–38.

- ASTM C39-16; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

- ASTM C78M-18; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). American Society for Testing and Materials: West Conshohocken, PA, USA, 2018.

- United State EPA. Toxicity Characteristic Leaching Procedure (TCLP); SW-846, Appendix II-Method 1311; U.S. Environmental Protection Agency: Washington, DC, USA, 1992.

- Austroads. Guide to Pavement Technology Part 2: Pavement Structural Design; Austroads: Sydney, Australia, 2019. [Google Scholar]

- DH-S309/2544; Standards for Highway Construction. Department of Highways: Bangkok, Thailand, 1996.

- Tabyang, W.; Suksiripattanapong, C.; Wonglakorn, N.; Laksanakit, C.; Chusilp, N. Utilization of municipal solid waste incineration fly ash for non-bearing masonry units containing coconut fiber. J. Nat. Fibers 2022. [Google Scholar] [CrossRef]

- JSCE SF-4; Method of Test for Flexural Strength and Flexural Toughness of Fiber Reinforced Concrete. Japan Society of Civil Engineering: Tokyo, Japan, 1983; pp. 58–66.

- EPA. National Primary Drinking Water Standards; Environment Protection Agency: Washington, DC, USA, 1999.

- EPA. Soil Hazard Categorisation and Management, Industrial Waste Resource Guidelines; Publication No. IWRG 621; Environmental Protection Agency of Victoria: Carlton, Australia, 2009.

- EPA. Solid Industrial Waste Hazard Categorization and Management, Industrial Waste Resource Guidelines; Publication No. IWRG 631; Environmental Protection Agency of Victoria: Carlton, Australia, 2009.

- Tabyang, W.; Suksiripattanapong, C.; Phetchuay, C.; Laksanakit, C.; Chusilp, N. Evaluation of municipal solid waste incineration fly ash based geopolymer for stabilised recycled concrete aggregate as road material. Road Mater. Pavement Des. 2021. [Google Scholar] [CrossRef]

- Suksiripattanapong, C.; Sakdinakorn, R.; Tiyasangthong, S.; Wonglakorn, N.; Phetchuay, C.; Tabyang, W. Properties of soft Bangkok clay stabilized with cement and fly ash geopolymer for deep mixing application. Case Stud. Constr. Mater. 2022, 16, e01081. [Google Scholar] [CrossRef]

- Suksiripattanapong, C.; Uraikhot, K.; Tiyasangthong, S.; Wonglakorn, N.; Tabyang, W.; Jomnonkwao, S.; Phetchuay, C. Performance of asphalt concrete pavement reinforced with high-density polyethylene plastic waste. Infrastructures 2022, 7, 72. [Google Scholar] [CrossRef]

- Eriksson, O.; Finnveden, G. Plastic waste as a fuel—CO2-neutral or not? Energy Environ. Scr. 2009, 2, 907–914. [Google Scholar] [CrossRef]

- Turner, D.A.; Williams, I.D. Greenhouse gas emission factors for recycling of source-segregated waste materials. Resour. Conserv. Recycl. 2015, 105, 186–197. [Google Scholar] [CrossRef] [Green Version]

| Chemical Compositions | OPC (%) |

|---|---|

| SiO2 | 19.88 |

| Al2O3 | 4.88 |

| Fe2O3 | 3.18 |

| CaO | 66.53 |

| MgO | 1.48 |

| SO3 | 2.91 |

| K2O | 0.20 |

| LOI | 0.96 |

| Item | Cement (kg/m3) | Fine Aggregate (kg/m3) | Coarse Aggregate (kg/m3) | Water (kg/m3) | Fiber Content (%wt) | Fiber Content (kg/m3) |

|---|---|---|---|---|---|---|

| 28 MPa control concrete | 353.24 | 739.91 | 1007.98 | 210 | 0 | 0 |

| 28 MPa Concrete + 0.25% F | 353.24 | 739.91 | 1007.98 | 210 | 0.25 | 0.88 |

| 28 MPa Concrete + 0.50% F | 353.24 | 739.91 | 1007.98 | 210 | 0.50 | 1.77 |

| 28 MPa Concrete + 0.75% F | 353.24 | 739.91 | 1007.98 | 210 | 0.75 | 2.65 |

| 28 MPa Concrete + 1.0% F | 353.24 | 739.91 | 1007.98 | 210 | 1.00 | 3.53 |

| 32 MPa control concrete | 390.77 | 708.73 | 1007.98 | 210 | 0 | 0 |

| 32 MPa Concrete + 0.25% F | 390.77 | 708.73 | 1007.98 | 210 | 0.25 | 0.98 |

| 32 MPa Concrete + 0.50% F | 390.77 | 708.73 | 1007.98 | 210 | 0.50 | 1.95 |

| 32 MPa Concrete + 0.75% F | 390.77 | 708.73 | 1007.98 | 210 | 0.75 | 2.93 |

| 32 MPa Concrete + 1.0% F | 390.77 | 708.73 | 1007.98 | 210 | 1.00 | 3.90 |

| Contaminant | Control Concrete (mg/L) | Concrete with 100PP:0RPP Ratio (mg/L) | Concrete with 0PP:100RPP Ratio (mg/L) | Drinking Water Standard | Industrial Waste Standard |

|---|---|---|---|---|---|

| Arsenic | <0.001 | 0.004 | 0.007 | 0.05 | 0.35 |

| Cadmium | BDL | 0.001 | 0.002 | 2.0 | 35 |

| Chromium | 0.009 | 0.011 | 0.013 | 0.1 | 2.5 |

| Copper | BDL | BDL | BDL | 1.3 | 100 |

| Lead | BDL | BDL | BDL | 0.015 | 0.5 |

| Mercury | BDL | BDL | BDL | 0.002 | 0.05 |

| Zinc | BDL | 0.099 | 0.573 | - | 150 |

| Item | PP:RPP Ratio | ||||

|---|---|---|---|---|---|

| 100:0 | 75:25 | 50:50 | 25:75 | 0:100 | |

| 28 MPa Concrete + 0.50% F; Incineration | 0 | 0.25 | 0.5 | 0.75 | 1.00 |

| 28 MPa Concrete + 0.50% F; Landfill disposal | 0 | 0.12 | 0.24 | 0.36 | 0.48 |

| 32 MPa Concrete + 0.50% F; Incineration | 0 | 0.28 | 0.56 | 0.83 | 1.11 |

| 32 MPa Concrete + 0.50% F; Landfill disposal | 0 | 0.13 | 0.27 | 0.40 | 0.53 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Suksiripattanapong, C.; Phetprapai, T.; Singsang, W.; Phetchuay, C.; Thumrongvut, J.; Tabyang, W. Utilization of Recycled Plastic Waste in Fiber Reinforced Concrete for Eco-Friendly Footpath and Pavement Applications. Sustainability 2022, 14, 6839. https://doi.org/10.3390/su14116839

Suksiripattanapong C, Phetprapai T, Singsang W, Phetchuay C, Thumrongvut J, Tabyang W. Utilization of Recycled Plastic Waste in Fiber Reinforced Concrete for Eco-Friendly Footpath and Pavement Applications. Sustainability. 2022; 14(11):6839. https://doi.org/10.3390/su14116839

Chicago/Turabian StyleSuksiripattanapong, Cherdsak, Taweerat Phetprapai, Witawat Singsang, Chayakrit Phetchuay, Jaksada Thumrongvut, and Wisitsak Tabyang. 2022. "Utilization of Recycled Plastic Waste in Fiber Reinforced Concrete for Eco-Friendly Footpath and Pavement Applications" Sustainability 14, no. 11: 6839. https://doi.org/10.3390/su14116839

APA StyleSuksiripattanapong, C., Phetprapai, T., Singsang, W., Phetchuay, C., Thumrongvut, J., & Tabyang, W. (2022). Utilization of Recycled Plastic Waste in Fiber Reinforced Concrete for Eco-Friendly Footpath and Pavement Applications. Sustainability, 14(11), 6839. https://doi.org/10.3390/su14116839