1. Introduction

According to international trends, several countries have argued against the possibility of economic expansion without increasing CO

2 emissions. Specifically, it has become a hot topic whether it is genuinely possible to achieve steady economic growth without increasing energy consumption or greenhouse gas emissions [

1]. Significant growth in infrastructure, agriculture, and industry boosts GDP (gross domestic product) and increases energy usage [

2]. With a rise in GDP, the economy tends to grow, leading to significantly increased energy consumption [

3]. Since energy is recognized as the primary source of a country’s production and industrial sectors, it plays a prominent role in national economic growth. As a result, understanding energy policy and regulations are essential for understanding the connection between economic growth and energy usage [

4]. Furthermore, Indonesia aspires to be a developed country by 2045, and GDP must be increased to achieve the targeted status [

5]. Currently, rapid developments in different sectors have been boosted to support the national income target. However, this development requires tons of energy, mainly sourced from fossil fuels. The industrial and transportation sectors are projected to consume 333.93 million GJ of diesel oil and 8430.74 million GJ of gasoline annually by 2030, respectively [

6]. Therefore, sustainable and cleaner production needs to be implemented to minimize the risk to the environment [

7,

8].

Since the 1990s, carbon emissions generated by energy usage have increased dramatically in newly industrialized countries compared to developed countries. As a result, environmental degradation has reached alarming proportions, prompting fears of climate change and global warming [

9]. Global warming is currently occurring at an alarming rate across the planet, and Southeast Asia is one of the world’s most climate-vulnerable regions. Although it is not the world’s largest producer of carbon dioxide (CO

2), its emissions will become significant if no action is taken [

10]. The growth of sustainability forces many countries to take action on climate change mitigation. Due to international pressure and its vulnerability to the effects of climate change, Indonesia needs to undertake significant reforms. The use of fossil fuels for energy must be decreased, and CO

2 emissions in Indonesia must be minimized [

11]. Meanwhile, Indonesia, a developing country with abundant natural resources, is the world’s sixth-highest emitter of greenhouse gases. These natural resources, including both fossil and renewable resources, could promote the country’s economic development. [

12]. However, the impact of greenhouse gas emissions as a consequence of economic growth needs to be assessed, particularly since CO

2 emissions increase exponentially [

10].

Currently, the global petroleum industry is still considered a valuable industry for fulfilling global energy demand. Petroleum-based energy is still considered the primary energy source in global economic growth. As a result, several efforts to reduce greenhouse gas emissions have been introduced, including replacing coal-burning with natural gas burning as an energy transition fuel [

13]. Nevertheless, the dependency on petroleum-based energy is projected to remain high since it is the backbone of the global energy supply [

14,

15,

16]. In addition, the drastic growth of the global economy both increases the usage of fossil fuel in the downstream sector (household, transport, and other human activities) [

17,

18,

19,

20] and drives industries’ development in every sector for fulfilling the economic trend, leading to an excess of CO

2 emissions [

21]. Thus, elementary industries, such as heavy industries (the iron and steel industry), generate tons of CO

2 emissions while fulfilling the demand for infrastructure growth [

22,

23]. This trend will trigger an increase of CO

2 emissions in the upstream (exploration) operations of the petroleum industries [

24,

25]. The petroleum industry is one of Indonesia’s most important industrial sectors as it produces the country’s greatest revenue and is one of the world’s largest exporters [

26]. Indonesia’s petroleum industry has a history of more than 100 years and a well-understood regulatory structure for supporting the national energy demand. Indonesia has been a global leader in several policies, including the production sharing contract (PSC) model and LNG (liquefied natural gas) industrialization. Indonesia’s petroleum industry continues to be an essential sector contributing to national income (including 12 percent of the average national budget) and national economic growth [

27]. Since energy availability and supply are essential factors for maintaining Indonesia’s economic development, the energy and petroleum industry is listed as a national strategic industry. The government aims to increase domestic natural gas usage in response to Indonesia’s rapid economic growth, as stated in the 2014 Energy Law. It targets a 22% share of natural gas in the national energy mix by 2025, equivalent to 8300 MMSCFD, or a 3000 MMSCFD increase in gas supply above the current domestic supply [

26]. However, law enforcement related to sustainable production and net-zero carbon policy enforce the upstream petroleum field to reduce their carbon emissions.

A data-driven approach which relies on factual information can help to predict the future pattern, avoiding false assumptions and increasing the model’s reliability. Compared to the analysis-based approach which relies on anecdotal and observation evidence, the data-driven approach promises excellent and reliable result analysis. There is no sufficient empirical research discussing possible inquiries to reduce greenhouse gas in the upstream field. Numerous studies have determined greenhouse gas emissions in different parts of the petroleum industry [

24,

25,

28], but the inquiry for reducing greenhouse gas in the upstream petroleum field is rarely discussed. This research aims to identify the inquiry needed for reducing greenhouse gas emissions in the upstream petroleum field using panel data analysis. Based on the emission–energy–production relationship found in this study, policies that could efficiently lead to greenhouse gas reductions are further recommended. The focus is on the upstream petroleum industry and the sector pertaining to the primary extraction process. The contribution is extended toward industrial decarbonization strategies involving upstream processes to fulfill the net-zero carbon policy. This finding implies that energy usage in the main process is the key factor in maintaining production stability and further reducing greenhouse gases.

2. Literature Review

Greenhouse gas is a major global issue, and many scholars are studying greenhouse gas from different perspectives. The existing literature provides extensive studies of greenhouse gas patterns, which have been examined using various approaches and statistical methods.

The major environmental hazard posed by the current energy system is climate change due to carbon dioxide emissions from the use of fossil fuels [

29]. Carbon dioxide (CO

2), hydrofluorocarbons (HFCs), nitrous oxide (N

2O), perfluorocarbons (PFCs), methane (CH

4), and sulfur hexafluoride (SF

6) are greenhouse gases (GHGs) that contribute to global warming, which is regarded as the most pressing concern of the twenty-first century, according to the 1998 Kyoto Protocol [

10]. Global average heat and fossil fuel emissions continue to climb, and global CO

2 emissions from fossil fuels increased by roughly 2% from 2017 to 2019 [

30]. In developing countries, including Indonesia, greenhouse gases are mainly produced from fossil fuel usage [

31]. Specifically, greenhouse gas emissions in Indonesia are generated from electricity production, manufacturing industries and construction, transportation, domestic buildings (commercial and public services), and other sources, which contribute 37.7%, 34%, 19.7%, 6.3%, and 2.3%, respectively [

10].

The contribution and connection between energy usage and greenhouse gas emissions have been researched among countries and industries [

2,

3,

9,

23,

24,

29,

32,

33,

34]. In several countries, it is widely accepted that fossil fuel energy usage is correlated with economic productivity growth, while natural gas consumption has been identified as showing bi-directional causality correlations and strong casualty effects in Brazil, Russia, and Turkey [

35]. Energy consumption has a long-term positive and statistically significant impact on greenhouse gas emissions, although greenhouse gas emissions and economic growth have a non-linear relationship, which is consistent with the environmental Kuznets curve [

32]. Say and Yücel [

36] found a strong relationship between energy usage and greenhouse gas emissions in Turkey. Research using data collected from 1975 to 2011 showed that Indonesia’s economic advancement and energy consumption influenced greenhouse gas emissions, and the variables cointegrated in a long-run relationship [

37]. Another empirical result showed that a 1% increase in crop production index and livestock production index caused a 28% proportional increase in greenhouse gas emissions [

38].

Several methods have been developed to study the relationship between energy usage, oil and gas production, and greenhouse gas emissions, including the life cycle assessment (LCA) and statistical models [

29,

32,

39,

40]. The statistical multivariate regression model involves multiple data variables from different scales and factors and is commonly used to define the relationship between independent and dependent variables for analysis [

41]. A panel data model is an empirical model that is mainly used to identify the trend involving time series and cross-sectional data that analyzes behaviors across individuals and over time. It is suitable for holistic environmental policy analysis in different types and scales of countries and industries [

42]. In terms of estimating methods, the panel data model aids in producing more efficient estimates by considering both the time and cross-section dimensions of the dataset [

22,

33,

43,

44,

45]. For example, energy consumption and activity added by the industrial sector in 30 different areas across China resulted in a rise and a vast difference in regional variations of carbon emissions caused by industrial structure differences [

44]. Therefore, this method is strongly recommended since it can explain the multiple traits of carbon emission data [

45]. Recent studies have examined the factors contributing to CO

2 emission using a multivariate regression model including the panel data model run at national [

9,

21,

35] and industry levels [

23,

33]. Several panel data studies at the country level showed that investment, urbanization, trade, and economic growth significantly contribute to greenhouse gas emissions [

21,

46,

47]. Other panel data studies have discussed the impact of various primary industries on greenhouse gas emissions in different regions [

23,

33,

48,

49]. The factors contributing to greenhouse gas emissions were strongly related to fossil fuel energy usage [

50] due to higher oil and gas production in the upstream extraction fields.

As a major perpetrator of greenhouse gas emissions, and even though petroleum is a non-renewable energy source, many petroleum industries are constantly improving procedures for more efficient exploration of oil resources [

51]. Previous studies identified greenhouse gas emissions in different sectors of the petroleum industry [

24,

25,

28,

52]. Johansson et al. (2012) [

25] found that petroleum oil refineries account for approximately 8% of all industrial greenhouse gas emissions in the European regions (EU). Another study conducted by Abella and Bergerson [

53] found that greenhouse gas emissions in petroleum refineries range from 4 to 18 g CO

2eq/MJ of petroleum product (23–110 kg CO

2 eq/bbl of crude oil). The potential greenhouse gas emissions from liquid gas transportation was studied in the Indian Himalayas. It was estimated that hauling a 14.2 kg cylinder produces 60 g of greenhouse gas emissions per kilometer [

39]. In the upstream petroleum industry, natural gas and crude oil extraction in China is projected to generate 9.65 and 94.50 million tons of greenhouse gas emissions by 2030 [

54]. An impact assessment study conducted by Sulistyawanti et al. [

55] on the oil and gas exploration fields showed that greenhouse gas emissions were nearly 48,947.35 tons CO

2eq in 2015.

The current study examines the relationship between CO2 emissions and significant contributing factors such as oil and gas production and energy consumption in the oil and gas exploration industries. By adopting the panel data model, which is widely used in environmental policy research, the statistical pattern of contributing factors and CO2 emissions in the oil and gas exploration industries may be explained by describing the supporting and constraint variables with more precise correlation and low deviation.

5. Conclusions and Policy Implications

There are various greenhouse gas emissions studies in the petroleum industry [

25,

54,

55,

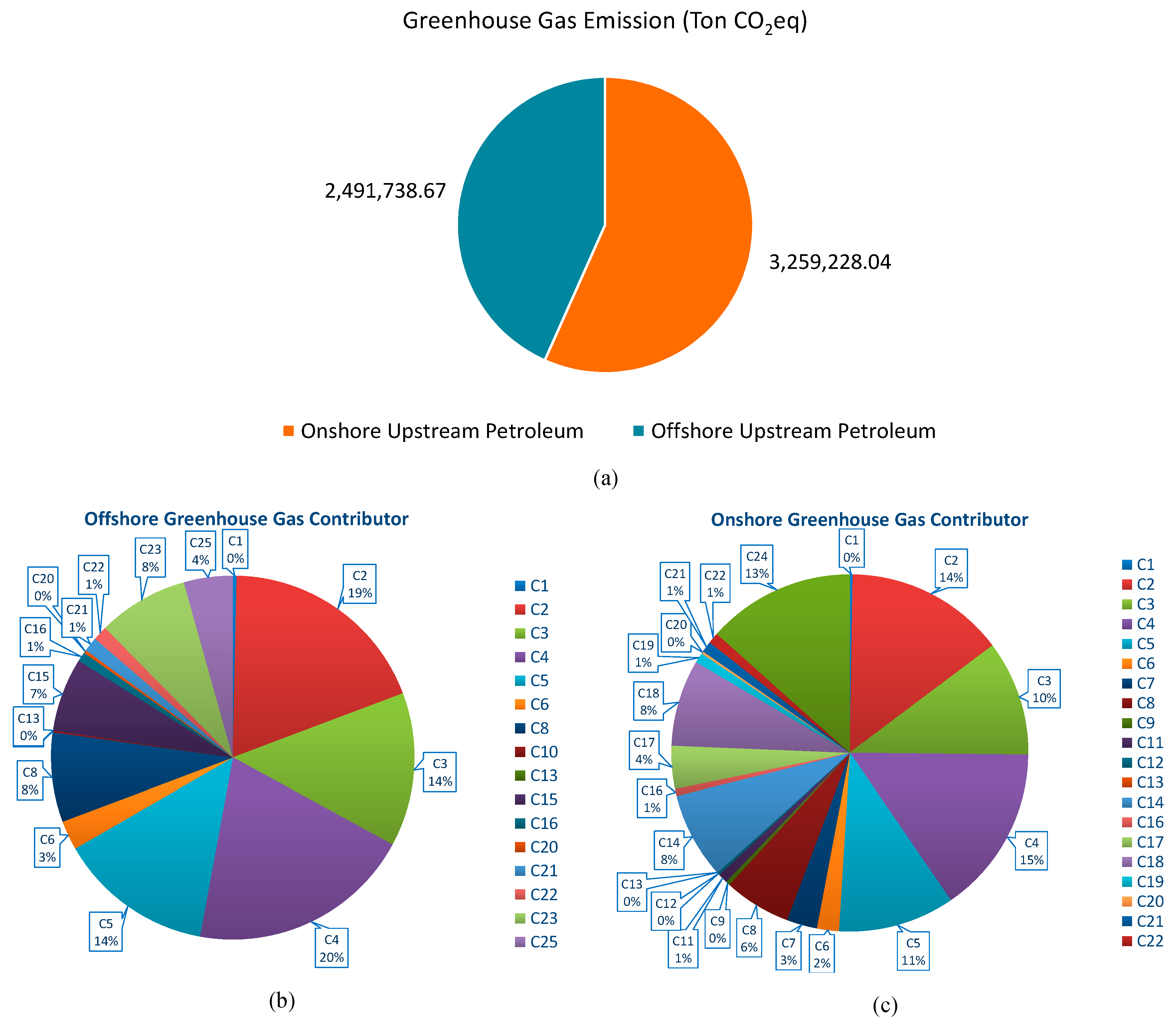

66]. However, there has been limited use of panel data investigation in the upstream petroleum industry thus far. Given this limitation, our research aims to understand the relationship between oil and gas production, energy usage, and greenhouse gas emissions at 25 Indonesian upstream petroleum fields and their main processes. The panel data regression shows that energy usage, natural gas, and crude oil production negatively affect greenhouse gas emissions. Similar regression patterns were identified for the petroleum fields and main process models. The correlation test also presents moderate and low significant correlations between variables.

There are several policy implications generated from this study. First, most energy usage occurs during the main oil and gas production process and is attributed to the lifting pump, transfer pump, the natural gas purification process, and other utilities. Since most upstream petroleum fields are located in remote areas, energy performance is an important requirement for crude oil and natural gas production. Therefore, an improved greenhouse gas reduction policy and scenario could be initiated by targeting the main oil and gas production stage. Second, the environmental policy and roadmap for environmental protection in the upstream petroleum industry should include energy management for the target production. In addition, the production policy and greenhouse gas reduction policy should not be separated since the factors influence each other. Optimizing existing energy usage in the production stage at upstream petroleum fields will boost oil and gas production. At the same time, the existing production efficiency will lead to greater greenhouse gas reduction. Third, an indirectly profitable green policy for reducing greenhouse gas would be more appealing to the decision-makers in upstream petroleum companies. Potential greenhouse gas reduction, which can be integrated with production profit, varies based on energy usage management. The main factors associated with oil and gas production performance that are profitable for greenhouse gas reduction in the upstream petroleum fields include powerplant efficiency, pump maintenance, utility optimization, and gas flare reuse. These factors may be included in profitable, sustainable green policies.

From the government’s policy perspective, encouraging the upstream petroleum industry to boost the energy efficiency of their target production is an important policy for minimizing greenhouse gas emissions before making upstream companies cope with general greenhouse gas reduction plans. Moreover, energy efficiency will be a priority since it may lower oil and gas production expenses. Therefore, an improved greenhouse gas reduction policy can be formulated to achieve a well-balanced and more profitable low-carbon implementation.

This study has a few limitations. Firstly, the data collected from the companies are limited to production monitoring and cannot represent all activities in the petroleum fields. Thus, further research could be conducted to investigate GHG mitigation and petroleum field behavior to mitigate GHG. Secondly, the data set may be relatively small compared to that of a national policymaker since only a four-year time series was considered in this study. Therefore, the result and policy implication may apply limited to the studied upstream petroleum field. Thirdly, although our findings suggest the opposite, it is theoretically possible that an increase in production will also increase greenhouse gas emissions. This may be caused by differences in production mechanisms at the petroleum fields. However, to test this theory for national policy evaluation, a longer time series data set is required to validate the panel model’s coefficient and statistical patterns.

Finally, this study contributes to the literature by identifying the relationships between greenhouse gas emissions, energy usage, and oil and gas production in Indonesia’s upstream petroleum fields using short panel data analysis, which has not been previously investigated. The result successfully identifies the interaction of the studied variables at the petroleum fields. The regression model shows a significant coefficient for independent variables, which may be used for greenhouse gas projection in the observed fields. Finally, this study may trigger further studies regarding a similar topic in the upstream petroleum fields since the fields are open for environmental improvement.