Managing Supply Chain Activities in the Field of Energy Production Focusing on Renewables

Abstract

:1. Introduction

2. SCM and RE Production

3. Methodology

3.1. Literature Refinement

3.2. Literature Ramification

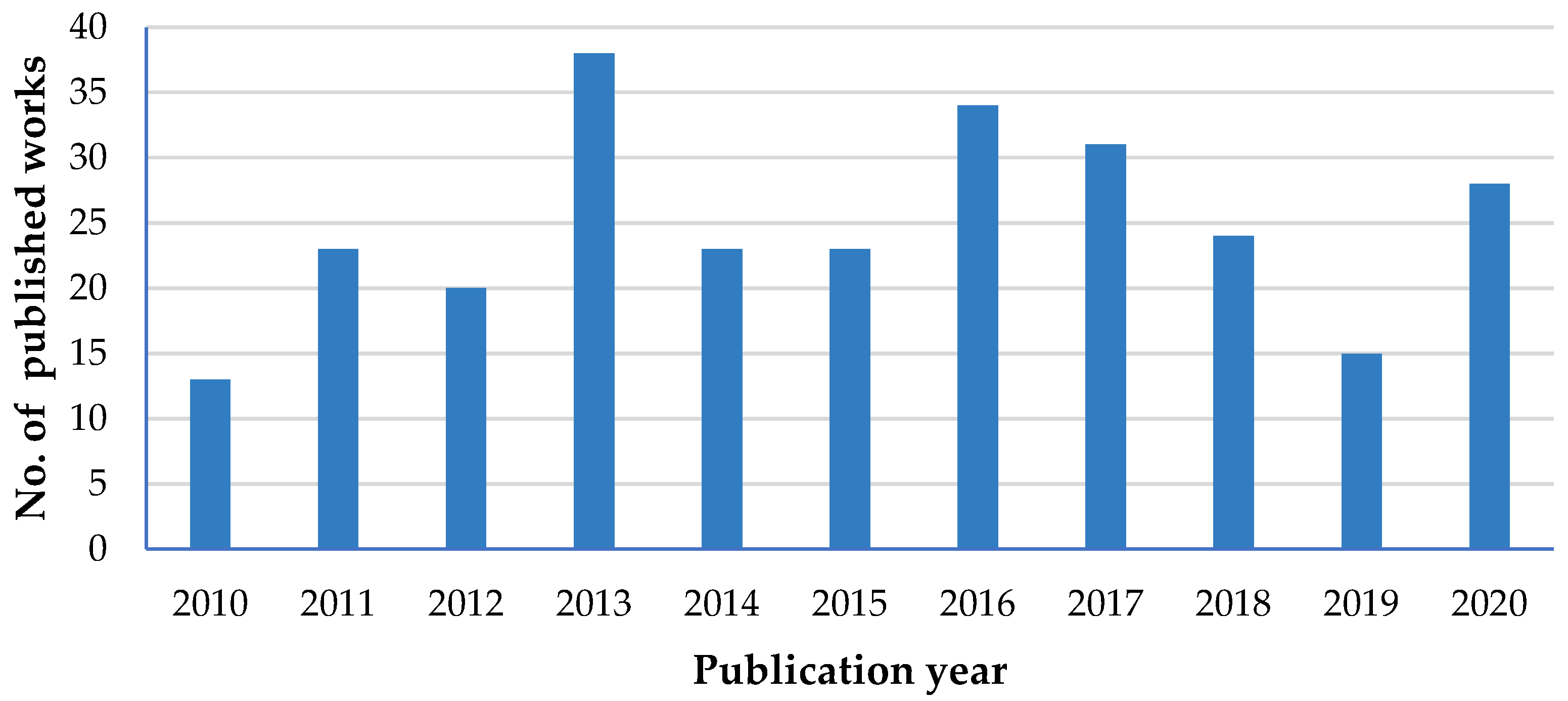

4. The Analysis and Results

4.1. Bio-Energy and Supply Chain (Stream 1—Category 1)

4.2. Renewables and Supply Chain (Stream 2—Category 1)

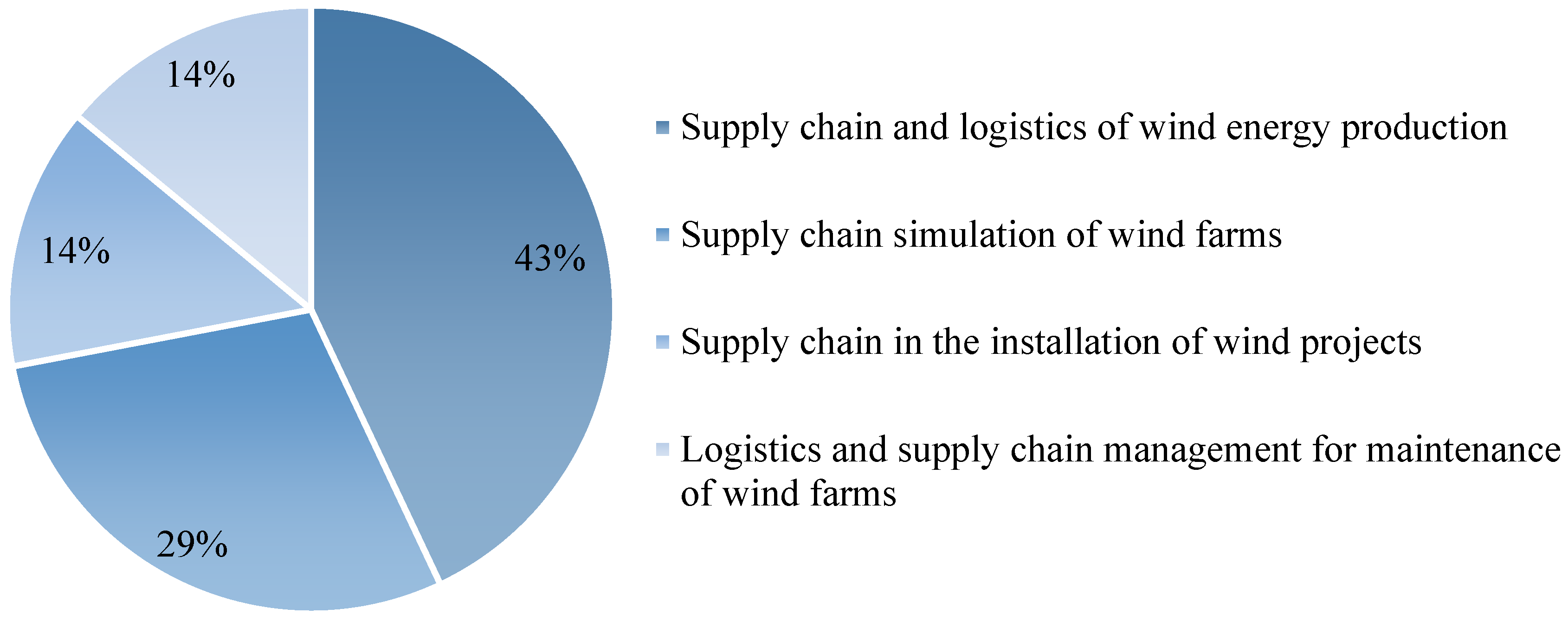

4.3. Wind Energy and Supply Chain (Stream 3—Category 1)

4.4. Solar Energy and Supply Chain (Stream 4—Category 1)

4.5. Hydrogen Energy and Supply Chain (Stream 5—Category 1)

4.6. HRES and Supply Chain (Category 2)

5. Limitations and Prospective Scopes

6. Practical and Managerial Implications

- Various aspects of the supply chain and logistics activities within the RE production field are adequately covered in the literature, such as managing, controlling, and modeling the supply chain for biomass, wind, and solar power production. However, it needs more attention for the rest of the renewables (i.e., geothermal, hydropower, and tidal).

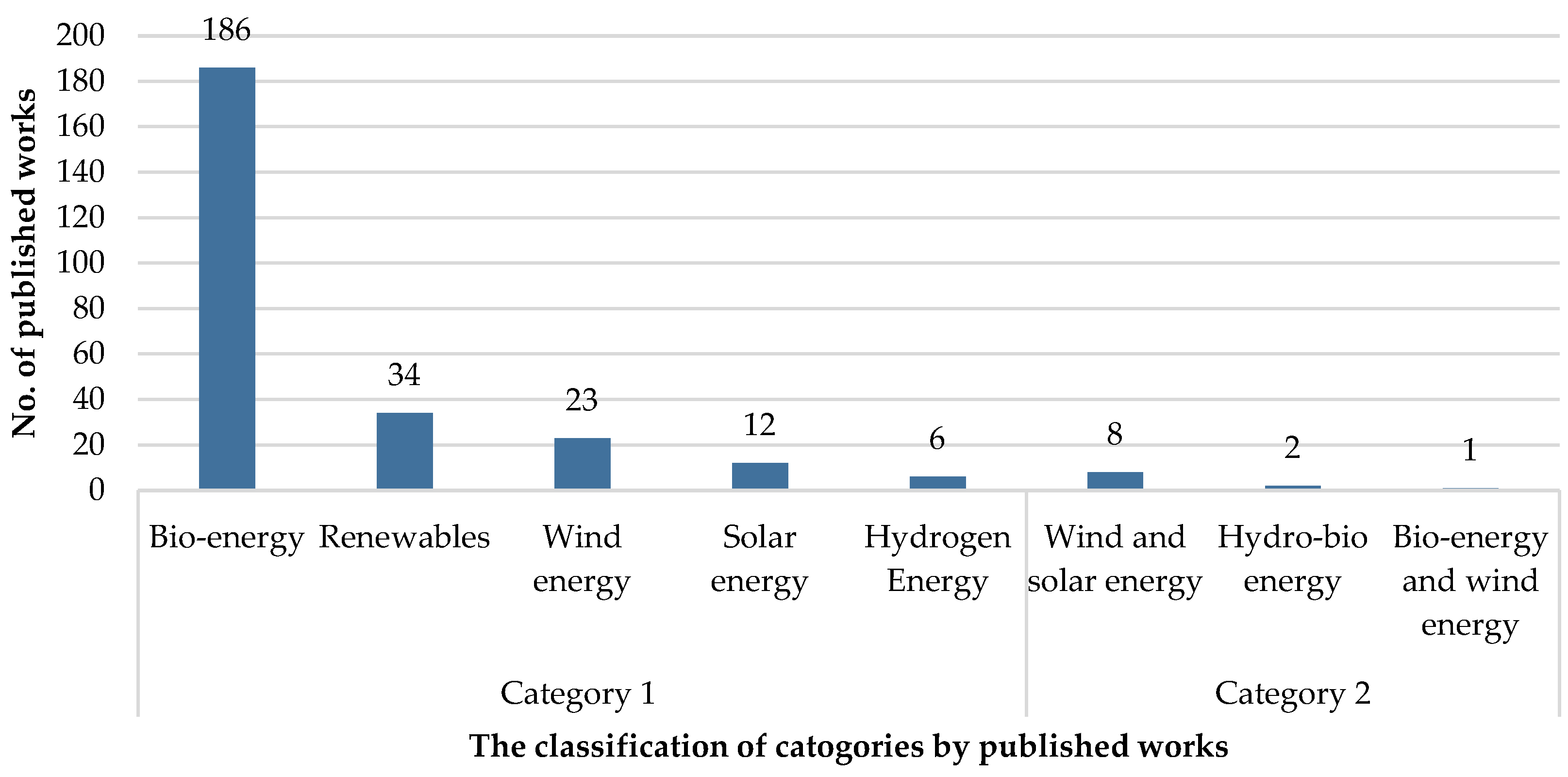

- Most of the studies concentrated on bioenergy, approximately 68% of the screened literature addresses this category. Additionally, managing the supply chain of biomass products to produce bioenergy such as bioethanol, biofuel, or biogas was the central theme within this category as it represented about 65% of the published works in this area. Hence, increasing the scientific contributions regarding the other disciplines is required, especially the intelligent logistics system for biomass production such as optimization and modeling, intelligent transportation systems, or blockchain and information control.

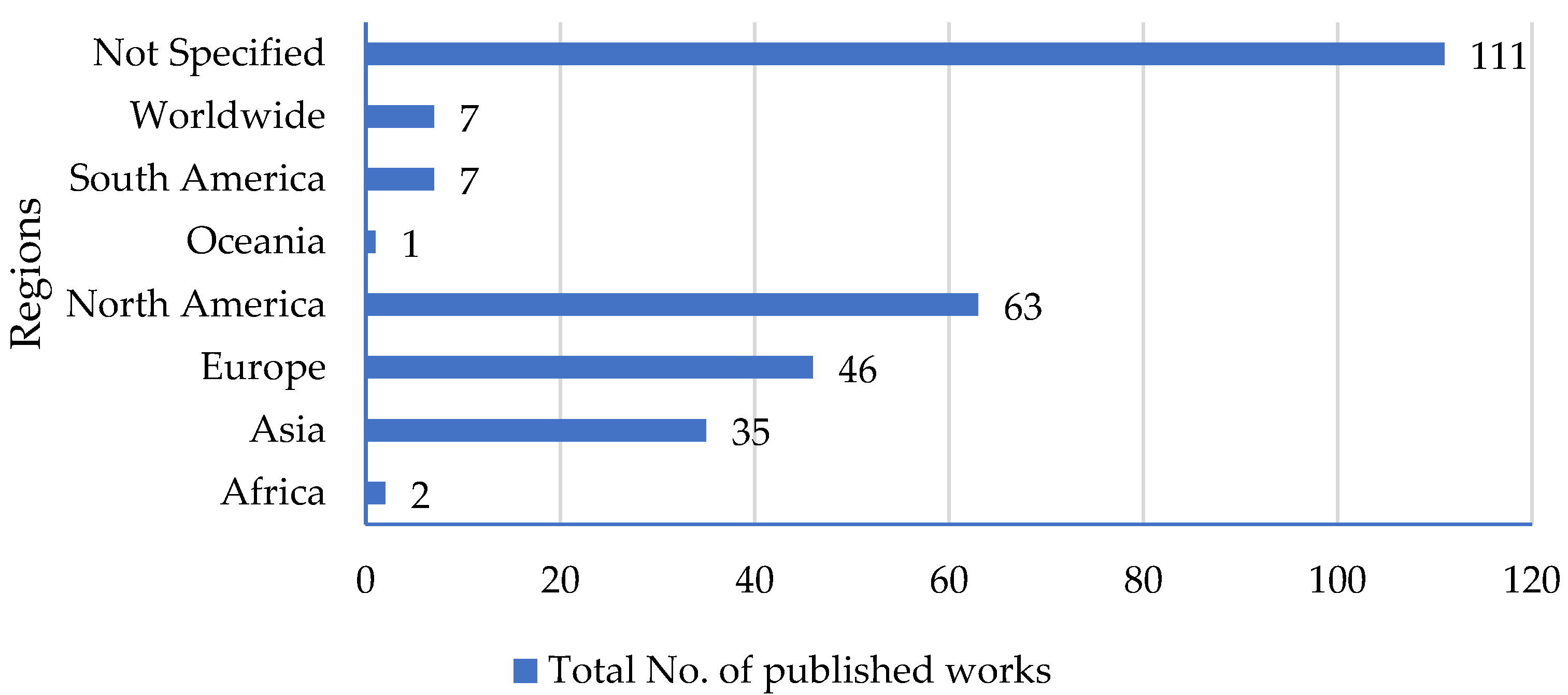

- Some regions were sufficiently studied, while others need more adequate research in such a field; for example, the highest ratio goes to North America and Europe. At the same time, in contrast, the West of Asia, the golf area, and Africa have the lowest research studies. However, those areas have good opportunities to establish and develop renewable energy farms. Moreover, due to their nature, location, and weather, they might also be hub areas in renewable energy production. Notwithstanding, most of these areas comprise developing countries, and most of them have a deficiency in energy resources.

- Transportation; as one of the logistics activities, it is covered only in biomass production because the biomass production scope is the only field that has physical movements, while the rest of RE transportation operations are via networking and grids, so no physical movements exist but only designs and planning for such networks that require engineering techniques. Nevertheless, the research community should contemplate supply chain activities of non-physical activities such as optimal network planning, network capacity optimization, and timely distribution and delivery.

7. Conclusion and Future Research Prospective

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Kenya | Alstone, P. (2015) [102] |

| South Africa | Batidzirai, B., et al. (2016) [103] |

| Asia generally | Foo, D.C., et al. (2013) [104] |

| China | Hu, Y. and H. Cheng (2013), Zhao, W., et al. (2019), Hensel, N.D. (2011), Zhang, Y., et al. (2012), Besha, P. (2013), and Lefevre-Marton, N. (2013) [5,87,105,106,107,108] |

| India | Gumte, K.M. and K. Mitra (2019) and Yadav, Y.S. and Y. Yadav (2016) [53,109] |

| Indonesia | Nugroho, Y.K. and L. Zhu (2019) [50] |

| Iran | Mahjoub, N. and H. Sahebi (2020), Rahemi, H., et al. (2020), Gilani, H., et al. (2020), Fattahi, M., et al. (2020), Shahbazbegian, V., et al. (2020), Manouchehrabadi, M.K., et al. (2020), and Dehghani, E., et al. (2020) [12,34,41,43,110,111,112] |

| Japan | Ishii, K., et al. (2016) [113] |

| Malay Peninsula | Yokoi, Y., et al. (2018) [59] |

| Malaysia | Lo, S.L.Y., et al. (2020), Aziz, N.I.H.A., et al. (2020), Ling, W.C., et al. (2019), Leong, H., et al. (2019), Zahraee, S.M., et al. (2019), Hong, B.H. and H.L. Lam (2015), Choo, Y.M., et al. (2011), Hassan, M.N.A. (2012), Lam, H.L., et al. (2013), Umar, M.S., et al. (2013), Bujang, B. and A. Safuan (2014), and Shaharudin, M.S. and Y. Fernando (2015) [38,46,51,52,57,70,114,115,116,117,118,119] |

| Pakistan | Amer, M., (2013) and Mun, K.G. (2016) [120,121] |

| South Korea | Seo, S.-K., et al. (2020) [122] |

| Thailand | Manakit, P. (2018) [123] |

| Europe generally | Sikkema, R., et al. (2010), Marinelli, A., et al. (2012), Lange, K., et al. (2012), Monforti, F., et al. (2013), López, E., et al. (2016), García-Galindo, D., et al. (2016), Arranz-Piera, P., et al. (2016), Pezdevšek Malovrh, Š., et al. (2017), Garcia, C.A. and G. Hora (2017), Korpinen, O.-J., et al. (2017), and Mastrocinque, E., et al. (2020) [23,100,124,125,126,127,128,129,130,131,132] |

| Austria | Kanzian, C. and M. Kühmaier (2017) [133] |

| Denmark | Koch, C., et al. (2017) and Sambra, A., et al. (2018) [134,135] |

| Finland | Kc, R., et al. (2020), Korpinen, O.J., et al. (2016), Karttunen, K., et al. (2012), Tahvanainen, T. and P. Anttila (2011), Palander, T. (2011), Karttunen, K., et al. (2013), and Tuominen, R., et al. (2018) [39,68,77,78,79,136,137] |

| France | Annevelink, E., et al. (2016) [138] |

| Germany | Vojdani, N. and F. Lootz (2012), Richter, A., et al. (2012), and Reuß, M., et al. (2019) [99,139,140] |

| Ireland | Sosa, A., et al. (2015) [141] |

| Italy | Garofalo, P., et al. (2020), Gnoni, M., et al. (2011), Dal-Mas, M., et al. (2011), Pari, L., et al. (2013), Pantaleo, A., et al. (2013), and Cannemi, M., et al. (2014) [42,142,143,144,145,146] |

| Serbia | Perić, M., et al. (2020) [35] |

| Spain | Velazquez-Marti, B. and E. Fernandez-Gonzalez (2010), Serrano, A., et al. (2015), Pari, L., et al. (2016), Annevelink, B., et al. (2017), and Jeong, J.S. and Á. Ramírez-Gómez (2018) [83,147,148,149,150] |

| Turkey | Şengül, Ü., et al. (2015), and Durmaz, Y.G. and B. Bilgen (2020) [14,45] |

| United Kingdom | Nowak, J.W. (2014), Dunnett, A. (2011), Irawan, C.A., et al. (2018), Abad, A.V., et al. (2015), Yu, M. (2015), and Khan, S.A.R. and D. Qianli (2017) [2,81,96,151,152,153] |

| Canada | Chavez, H., et al. (2017), Alam, M. (2014), Shabani, N. and T. Sowlati (2013), Calvert, K. (2013), Chávez, H., et al. (2017), and Weldu, Y.W. (2017) [65,154,155,156,157,158] |

| Mexico | Díaz-Trujillo, L.A. and F. Nápoles-Rivera (2019) [54] |

| United States of America | Arent, D., et al. (2014), Li, Y., et al. (2020), Vance, L., et al. (2012), Saghaei, M., et al. (2020), Kang, S., et al. (2020), Esmaeili, S.A.H., et al. (2020), Roni, M.S., et al. (2017), Poudel, S.R. (2017) Lin, T., et al. (2016), Hartley, D.S. (2014), Kazemzadeh, N. and G. Hu (2013), Dhanju, A. (2010), Brathwaite, N.H. (2010), Parker, N., et al. (2010), Tun-Hsiang, E.Y., et al. (2011), An, H. (2011), Han, S.-K. (2011), Parker, N.C. (2011), Vimmerstedt, L.J., et al. (2012), de Bourgeois, W. (2012), Okwo, A. (2012), Sharma, B. (2012), Zhang, J., et al. (2013), Leahy, J. and L. Lindenfeld (2013), Awudu, I.K. (2013), Bai, Y. (2013), Emery, I.R. (2013), Lin, T. (2014), Shah, A. (2013), Argo, A.M., et al. (2013), Osmani, A. and J. Zhang (2014), Tallaksen, J. and T.S. Kush (2014), Aitken, M.L. (2014), Jenkins, T.L. (2014), Marufuzzaman, M. (2014), Memisoglu, G. (2014), Zhang, F. (2011), Lee, J.H. (2014), Osmani, A. and J. Zhang (2014), Caffrey, K.R. (2015), Field, J.L. (2015), Tong, W. (2015), Zhang, L. (2015), Angelis, S. (2016), Campbell, R.M. (2016), Chen, M. (2016), Pokharel, R. (2016), Reyes, G. (2016), Beach, R.H., et al. (2017), Mooney, D.F. (2017), Seel, J. (2017), Sampat, A.M., et al. (2018), Li, Y. (2018), and Ozkan, D. (2011) [3,16,30,33,40,44,63,64,67,71,76,159,160,161,162,163,164,165,166,167,168,169,170,171,172,173,174,175,176,177,178,179,180,181,182,183,184,185,186,187,188,189,190,191,192,193,194,195,196,197,198,199,200,201,202,203] |

| Australia | Ghaffariyan, M.R., et al. (2016) [204] |

| Argentina | Bragado, M.V., et al. (2019) and Rodríguez, M.A., et al. (2016) [56,205] |

| Brazil | Herrera, M.M., et al. (2020) and Bradshaw, A. (2018) [95,206] |

| Ecuador | Aseffe, J.A.M., et al. (2020) [47] |

| Peru | Barreto, C.M. (2015) [207] |

| Venezuela | Pietrosemoli, L. and C.R. Monroy (2013) [91] |

Appendix B

| Reference | Year | The General Purpose of the Study | Method/Approach | Geographical Area (if Any) | The Main Findings/Results of the Study |

|---|---|---|---|---|---|

| Bioenergy | |||||

| [28] | 2020 | It aims to form data-oriented modeling to improve SCM related to forest and biomass. | Data-oriented modeling | None | The main results of this study revealed that promising prospects for data-driven tools are big data technologies. |

| [33] | 2020 | Offers solutions to reduce the electricity production costs from woody biomass. | Mixed-integer non-linear programming | USA | It is concluded that the proposed Improved Cross-Entropy achieves better compared to conventional Cross-Entropy by 5.6%. |

| [7] | 2020 | Proposes a structure of biomass-based supply chain for power generation. | System Dynamics | None | The results detected the significant variables to biomass supply chain development by a causal diagram. |

| [34] | 2020 | It offers a framework that addresses land-use sustainability and optimal bioethanol supply chain development. | Mixed-integer linear programming | Iran | The main results of this study concluded that the planned integrated land planning-network design problems for bioethanol supply chain planning are solved. |

| [35] | 2020 | Focuses on the environmental impact of fuel consumption on several phases of the woody biomass supply chain. | Qualitative approach | Serbia | The results indicated that chipping was the most environmentally exhausting because of the expected practice productivity and high level of diesel consumption in out-of-date types of machinery. |

| [36] | 2020 | Reviews all publications on modeling a supply chain for biomass production. | Review | None | The key results of this review revealed that the examination of several different variables must be included for energy supply chain models, also the main disadvantages of its use. |

| [37] | 2020 | Presents the biomass network integration for the energy supply chain designs. | Optimization model | None | The main results revealed that a decrease in the emissions cost of up to 4.32% is realizable on the integrated network of 5–8% for the biomass energy supply chain designs. |

| [38] | 2020 | Provides a synopsis of the diverse methodologies used for the viability evaluation of biomass-based engineering. | Review | Malaysia | It was found that the mathematical modeling with optimization represents 78% of the literature reviewed. |

| [16] | 2020 | Examines the biofuel supply chain from economic performance and an environmental impact point of view. | Mathematical model | USA | The bioethanol production from co-fermentation of cellulosic biomass has been proposed. |

| [39] | 2020 | Optimizes the dynamic features of the forest biomass supply chain for environmental sustainability. | Mathematical model | Finland | This study revealed that depending on which kind of biomass and its source, the forest biomass supply chain incarnated GHG emissions from 2.72 to 3.46 kg CO2-eq per MWh. |

| [40] | 2020 | It offers a framework for proposing a biofuel supply chain. | Optimization model | USA | The main results revealed that the lowest fuel price of microalgae-based biodiesel is $10.92/gal biodiesel, about three times higher than the recent biodiesel price of $3.51/gal biodiesel. |

| [41] | 2020 | Proposes bioethanol production from sugarcane. | Optimization model | Iran | The suggested model encourages more convenient decisions than the deterministic model via average and standard deviation of objective values. |

| [42] | 2020 | It aims at assessing the energy crop of sugar beet suitability. | Mathematical model | Italy | This paper describes the multi-composite metric built on ad hoc modules. |

| [43] | 2020 | Uses various technologies to develop a supply chain system for biomass power production. | Mathematical model | Iran | The economic viability, the sustainability characteristics, and the required arrangement for the supply chain system design have been proved by computational results. |

| [44] | 2020 | Analyses the effects of two different financial inducements inspiring first-generation bioethanol manufacturers to use second-generation biomass. | Linear programming models | USA | The key results of this review concluded that first-generation bioethanol manufacture is more effective than second-generation bioethanol. |

| [45] | 2020 | Provides the network of the biomass supply chain using the optimal design and planning. | Mixed-integer linear programming | Turkey | The results concluded that the key control on decisions and financial returns is the maximum distance parameter and purchasing prices. |

| [46] | 2020 | It aims at examining the biogas supply chain sustainability. | Conceptual framework | Malaysia | The conceptual framework of biogas production based on environmental sustainability using life cycle assessment has been proposed |

| [47] | 2020 | Assesses the environmental performance of the seed-corn supply chain by energy recovery from corncob residues | Experimental analysis | Ecuador | The results determine a technical alternative for converting the corncob supply chain by integrated thermochemical conversion processes. |

| [48] | 2019 | Concerns about the cost of a bio-methane gas optimization supply chain. | Mixed-integer mathematical model | None | The model impacts both technological improvement and the economic value of biogas energy production. |

| [49] | 2019 | Offers a mathematical optimization model for the costs of logistics and carbon footprints of the RESC. | Mathematical model | None | The model integrates the effect of carbon emissions as a cost parameter in the supply chain of mixed-refinery bio-oil. |

| [50] | 2019 | Develops an optimization and planning platform of biofuel _under sustainable supply chain planning_ that unifies biofuel products, operations, and network structures. | Mathematical model | Indonesia | The results indicate an optimal region of the composition ratio between different biomass products. |

| [51] | 2019 | Synthesizes a mathematical optimization method for a bio-electricity supply chain grid. | Mathematical model | Malaysia | The result revealed that, at the various seasons of supply and demand diversities, the decision-makers could conclude the possibilities of the upcoming bio-electricity projects. |

| [52] | 2019 | Develops a hybrid optimization methodology of Bio-energy Supply Chain Network (BSCN). | Mathematical model | Malaysia | The analysis indicates the optimal power plant methodologies combined heat and power systems. |

| [53] | 2019 | Develops an optimization model for optimizing the Net Present Value (NPV) using supply chain networks. | Mixed-integer linear programming | India | The results show the influence of different constraints such as transportation modes, available areas, global fuel price fluctuations, and feedstock availability on the NPV. |

| [54] | 2019 | Presents the lowest environmental effect and the optimal profit by a multi-objective optimization method applied to a biogas supply chain. | Optimization model | Mexico | The main results of this study revealed that the model implementation produces key environmental and economic enhancement because of the synchronous growth in the total yearly profit and carbon footprint reduction. |

| [55] | 2019 | Conducts a review on detailed modeling of the biomass supply chain designing, planning, and management. | Review | None | This review concluded that it is essential to comprise sustainability and uncertainty research schemes into large-scale systems optimization. |

| [56] | 2019 | It offers a model that achieves the optimal profits and picks the uttermost biomass supply chain. | Mathematical model | Argentina | The model indicates that the utmost value was achieved by delivering the available stuff of lower market value, then the rest of higher value stuff but with reasonable logistics costs. |

| [57] | 2019 | Assesses the Biomass Supply Chain (BSC) from an environmental sustainability perspective. | Simulation modeling | Malaysia | The results show that for a sustainable improvement of palm biomass, transportation enhancement and production effectiveness should have the priority to work on BSC. |

| [58] | 2019 | Reviews all publications on the optimization methodologies for the adequate supply chains managing and controlling forest biomass. | Review | None | Upcoming research should provide cohesive frameworks that achieve the optimal biomass supply chain at the different management levels. |

| [59] | 2018 | Analyses and designs a sustainable Empty Fruit Bunch (EFB) supply chain. | Case study | Malay Peninsula | The EFB can be competitive when comparing its performances with various fuels. |

| [60] | 2018 | Demonstrates the technicality of animal waste (horse manure) for energy conversion supply chains. | Qualitative approach | None | The findings confirmed that the horse manure-to-energy at all phases of the supply chain has discrete features. |

| [61] | 2018 | Presents optimization models for bio-power supply chains to help design and administrational sustainability. | Optimization models | None | The proposed models could use by utility enterprises to realize some techniques to advance bio-power production and have enhanced environmental impacts. |

| [62] | 2018 | Evolves pruning biomass supply chain using the Smart Logistics System (SLS) applications. | Qualitative approach | None | The SLS enhances the pruning biomass supply chain performance and saves logistics costs. |

| [63] | 2017 | Designs a model that captured the balance achieved of supplying bio-fuels between costs, social, and environmental aspects. | Multi-objective hub-and-spoke model | USA | The results help policy-makers to propose procedures that inspire renewables production. |

| [64] | 2017 | Analyses two vital problems in the biomass supply chain network field: the pre-disaster planning problem and the inbound feedstock supply uncertainty of bio-energy supply chain networks. | Models and algorithms | USA | The results revealed that the congestion cost plays a substantial part in picking the size and location of the multimodal facilities in bio-energy supply chain networks. |

| [65] | 2017 | Proposes a biomass quality and cost optimizing model to ensure conversion technology components. | Simulation-based Multi-Objective Optimization | Canada | The results demonstrate that this method is eligible for discovering an efficient assortment of non-dominated solutions. |

| [66] | 2016 | Addresses multi-scale supply chain optimization of biomass-to-bioenergy. | Models and algorithms | None | The proposed models can be reformed to cover more styles of supply chains, and the proposed solution algorithms are general and not limited to specific applications. |

| [67] | 2016 | Compares the delivery costs using biomass pre-processing techniques, using two different transport means. | Optimization model | USA | The proposed findings revealed that the transport costs of biomass could pursue the design of coal transport. Transforming biomass to ethanol regionally and transporting it for long distances is economically efficient, the same as the existing grain-based biofuel system. |

| [68] | 2016 | Presents dynamic modeling methods for inspecting prospects for cost savings in biomass logistics. | Static and dynamic modeling | Finland | Backhauling and High-capacity-truck Transportation (HCT) are distinctive schemes in biomass transportation by road, creating the best competition in long-distance transport. |

| [69] | 2016 | Develops a model for a viable scheme with thermal energy storage of biomass supply chains and District Heating Systems (DHS). | Fuzzy optimization approaches | None | The results revealed that the model could efficiently support decision-makers to design an energy production system effectively. |

| [70] | 2015 | Proposes a waste-to-energy supply network using a multiple biomass corridor concept. | Mathematical model | Malaysia | The potential central processing hubs are allocated, and the ideal technics network of the processing hub is specified. |

| [71] | 2014 | Examines existing woody bio-energy facilities to explain the drivers of establishing bioenergy projects. | Quantitative approach | USA | The proposed tactic enhances the provincial economy by decreasing energy costs, job opportunities creation, and local improvement. |

| [72] | 2014 | Improves an operative model for the supply chain network for biogas production. | Mixed-integer linear programming model | None | The recommended method correctly identifies the supply of biomass and product distribution decisions. Besides, strategic decisions like determining the quantities, sizes, and sites of bio-gas factories and required biomass warehouses. |

| [73] | 2013 | Develops a framework for different kinds of customers concerning torrefaction configuration from a supply chain point of view. | Conceptual approach | None | The suggested framework clarifies various components of torrefaction supply and demand. |

| [74] | 2013 | Describes energy requirements, energy objects, conversion practices, biofuel feedstocks, and a complete review of the Biomass Supply Chain (BSC). | Review | None | The results provide the starting points for the realization of biomass feedstocks, biofuel production, and a complete study of the BSC planning and modeling. |

| [75] | 2013 | Promotes a GIS-based approach for biomass supply chain models. | Mathematical programming model | None | The developed method generates input data to biomass supply chain models by more efficient biomass residue availability data. |

| [76] | 2013 | Assigns an optimized scheme for the biofuel refineries supply chain. | Mathematical programming framework | USA | The developed approaches focus on maximizing the predictable profit and the qualification of system risk in various circumstances. |

| [77] | 2012 | Analyses the cost of biomass transport operations in Finland’s Lake Saimaa area. | Discrete-event simulation | Finland | According to the simulation study results, the waterway transportation of forest chips had a competitive cost compared with road transportation by trucks after 100–150 km. |

| [78] | 2011 | Creates a GIS-based approach to simulate the cost for some supply chains regarding woody biomass. | Mathematical programming model | Finland | The results revealed that the most cost-competitive chain comparing various distances using road and rail transport. |

| [79] | 2011 | Considers a multiple objective model for scheduling problems applied to the industrial energy supply chain. | Dynamic multiple objective programming model | Finland | The results illustrate the potential electricity production effects in Finland. |

| [80] | 2011 | Presents a literature review of articles that screened the interface of the production of bio-energy and matters of logistics. | Review | None | The results classify the issues and challenges that ensure a balanced and competitively priced feedstock supply for bioenergy facilities. |

| [81] | 2011 | Presents a SCM optimization model for the infrastructures of the bio-energy, using a spatially distinct modeling framework. | Optimization model | UK | The innovative dynamic model formulation offered, driving technicality of the spatial-dynamic growth of the bioenergy infrastructures. |

| [82] | 2011 | Presents an approach regarding biorefineries production optimization planning and facility location. | Optimization model | None | The model proposes the optimal choice of various patterns considering the specific location configuration, selection of biomass, and processing infrastructures. |

| [83] | 2010 | Presents a method to choose the authentic points for the locations of a bioenergy factory. | Mathematical algorithm | Spain | The findings determine the workshop locations that convert biomass into bioenergy for a set of cities. Besides, the workshop location points are considered destinations in the network when the logistics models are concluded. |

| [84] | 2010 | Presents the essential elements of various kinds of biomass supply chains. | Linear mixed-integer modeling | None | The results present the supply, node, dryer, and storage schemes for the existing cases in this study. |

| [85] | 2010 | Improves efficient biomass-to-biorefinery supply chains for creating biofuels as a feasible alternative. | Optimization models | None | The solution algorithms provided will help researchers efficiently resolve the multi-commodity supply chain plan and management difficulties for biorefineries. |

| Renewables | |||||

| [86] | 2020 | Studies the agreement of long-term service in the supply chain of electricity. | Game theory and the dynamic programming | None | The results show that the utility firm’s optimal conventional capacity decision follows a two-threshold policy, exhibiting a hysteresis phenomenon. |

| [87] | 2019 | Investigates policy special effects under various supply chain network arrangements. | Theoretical model | China | The results pinpointed the following aspects: firstly, the total profits of the renewables producing firm have been dwindled because of the rises in the share obligation and the permit price; secondly, the charged price flexibility of a retailer has been risen by the differential pricing once confronting in the permit price, and the shared commitment rose; and finally, the totaled profits of the supply chain have been expressively increased by the collaboration between the renewables producing firm and the retailer. |

| [6] | 2019 | Delivers an inclusive bibliometric investigation that offers a complete grasp of the supply chain performance and renewables field. | Review | None | Providing a prospective scheme for the research community in this field. |

| [1] | 2018 | Provides study for the existing and prospecting published works in RESC detecting the core features of the modeling methods for the supply chain using system dynamics. | Review | None | The findings disclosed a lack of system dynamics usage in the renewables supply chain. Furthermore, modeling the macro view of renewable energies has not been explored yet. It also requires more consideration of the social aspects of the supply chain in sustainability concepts. |

| [88,89] | 2018 | Explores the significance of RE and green actions in logistics practices. | - Ordinary Least Square (OLS) [89] - Generalized Method of Moments (GMM) [88] | None | The results revealed that renewables are motivating factors of green logistics practices that foster environmental and economic sustainability. |

| [90] | 2016 | Provides a conceptual model applied to renewable energy projects (RES) that can provide a dimensioned agreement between logistic chain links. | Multicriteria analysis methods (AHP) and management programs (DBR and SAP-MRP) | None | The cooperation between supply chain activities in the execution of renewable energy projects offers new improvement opportunities, collaboration, and support an economic advantage for energy produced from RES to reach sustainable development goals. |

| [3] | 2014 | Discovers various scenarios of the effects of acquiring higher standards of clean electric power. | Case study | USA | GHG emissions could be decreased by using renewable sources such as water. |

| [91] | 2013 | It underlines the fundamental issues that facilitate the supply of renewables worldwide, which is incredibly convenient for developing countries. | Case study | Venezuela | The result demonstrates an organizational limitation in supporting knowledge generation. Sharing and reusing such valuable resources could be stimulated to solve some of the construction problems described in this study. |

| [5] | 2013 | Presents a synopsis of the status and development of renewables to generate electricity and debates the various obstacles that limited the progression of the Chinese renewables industry. | Review | China | The long-distance transmission networks are required to spatial disharmony in renewable energy supply. Also, more research and technology improvement and financial procedures should be elaborated to support the sustained development of renewable electricity generation. |

| [29] | 2013 | Investigates literature that considers the benefits of performance upgrading and overcomes obstacles to renewables supply chain enhancement. | Review | None | From an economic view, support the distribution channels by the technological side, energy efficiency, and advanced storage. From an environmental image, improve production processes with low emissions. Finally, from a social perspective, encourage the involvement of inhabitants to generate new job opportunities. |

| [92] | 2013 | Recognizes crucial areas of the business to let new actors from engineering, business, and policy to enter the renewables industry effectively. | Business model | None | The model leads to determine the 7 sides that could help the new actors in the renewables business, which are (strategic, resource, technology, feasibility analysis, value creation, customer and market, and stakeholder). |

| [9] | 2012 | Evaluates renewable energies from a supply chain point of view with the current electric system. | Qualitative approach | None | The managerial perceptions of researchers, governments, and stakeholders for introducing renewable electric energy usage are provided. |

| [93] | 2011 | Discusses the approaches to addressing Wind, Water, and Sun (WWS) to ensure the stability between the power supply and its demand. | Qualitative approach | None | The results confirmed that obstacles to all conversions to WWS power worldwide are predominantly social and political, not technical or economic issues. |

| [94] | 2010 | Presents a novel method to optimize the renewables supply for regional energy. | P-graph framework | None | A new clusters supply chain algorithm of the energy is revealed. |

| Wind energy | |||||

| [95] | 2020 | Assesses the alternatives of simulation modeling to improve the wind energy supply chain | Simulation model | Brazil | The proposed model represents the core time delays in the wind energy supply chain. |

| [96] | 2018 | Proposes a combined model to set up the offshore wind turbine farms using port selection criteria and SC optimization. | Integer Linear Programming | UK | The results determine the utmost appropriate installation port for the case study offshore wind farm and figure the total transportation costs of the overall SC costs. |

| [97] | 2017 | Investigates offshore wind logistics practices in Europe and China to analyze the capability of SC to guarantee green practices. | Qualitative approach | Europe and China | This study discovers the respective capacities of the SC where global association and experience transfer may expedite positioning. |

| [98] | 2015 | Reviews the literature that covers the maintenance logistics of the offshore wind system. | Review | None | The findings revealed that the literature on maintenance logistics strategic decisions had gained the peak consideration, then the tactical and operational decisions. |

| [99] | 2012 | Presents offshore wind farms methodologies to design SC networks. | Qualitative approach | Germany | The findings could be used to improve more methods to assess the prospective influence of professional logistics on offshore wind systems. |

| [100] | 2012 | Develops a simulation model that cerebrates several logistics characteristics of wind energy. | Simulation model | Europe | The simulation tool developed in this study considers different logistical characteristics of the maritime supply chain in offshore wind farms. |

| [101] | 2010 | Analyses the fundamental conditions and current conflicts of supply chains for offshore wind installations. | Mixed-integer linear programming | None | The resulting calculations clarify an optimum installation schedule for offshore wind turbines by detecting various weather conditions. Besides, it can also be used to shrink vessel operation times independence on seasonal or updated weather forecasts. |

| Solar energy | |||||

| [110] | 2020 | Proposes a supply chain network and reverse logistics to design and optimize a thin-film photovoltaic. | Bi-objective model | Iran | The results confirmed that using an optimistic approach to face uncertainty decreases the costs by 20% compared with the usage of a pessimistic approach. |

| [23] | 2020 | Develops a sustainable supply chain approach in the solar energy industry. | Multi-criteria decision-making framework | Europe | The framework offers a dominant tool to decision-makers for making decisions for sustainable investment in the photovoltaic energy industry. |

| [111] | 2020 | Develops a two-echelon (multi-period and multi-product) for the solar cell supply chain. | Mathematical model | Iran | The proposed model determines which scenario to be selected and defines how many solar panels of two kinds should be installed. |

| [112] | 2020 | It aims at reducing the environmental footprints and conventional cost objective of the concerned supply chain. | Mathematical model | Iran | The proposed model offers splendid practical and managerial insights into the solar energy supply chain. |

| [208] | 2020 | Explores a solar industry of contemporary trade conflict between China and the USA. | Game-theoretical modeling | China and USA | The results determine that the Free Trade policy would be the leading solution and SCM for developing solar energy sustainability. |

| Hydrogen energy | |||||

| [122] | 2020 | Involves a hydrogen supply chain construction. | Optimization model | South Korea | The results show that a hydrogen supply chain centralized storage structure advanced the phase transition of central hydrogen production plants. |

| [209] | 2020 | Investigates the evolution of publications on hydrogen research and the collaboration network of the international scientific community. | Review | None | The analysis of international collaboration networks is listed. |

| [140] | 2019 | Executes an infrastructure assessment via spatial resolution for hydrogen energy infrastructures. | Spatially resolved infrastructure | Germany | The findings indicate that salt caverns and transmission pipelines are the main techniques for prospect hydrogen infrastructure schemes. |

| [210] | 2019 | Reviews the scientific works that scrutinize the Hydrogen Supply Chain Network Design (HSCND) systems. | Review | None | The prospective (HSCND) model problems for the upcoming study are explained. |

| [211] | 2018 | Discusses the main inspirations of hydrogen as a future alternative fuel, presenting current directions in hydrogen production and challenges for the upcoming supply chain of hydrogen energy. | Mathematical models | None | The book helps recognize the approaches used to evaluate the viability of developing a hydrogen supply chain, infrastructures, and safety performance. |

| Reference | Year | The General Purpose of the Study | Method/Approach | Geographical Area (if Any) | The Main Findings/Results of the Study |

|---|---|---|---|---|---|

| Solar and wind energy | |||||

| [212] | 2018 | Provides a net-zero carbon production-inventory system regarding energy prosumerism. | Optimization model | None | The results revealed that a net-zero carbon production-inventory system is achievable and affordable, provided the photovoltaic setting up cost is well-matched with wind generation. |

| [213] | 2018 | Presents a complete framework for handling stored energy in micro-grids, focusing on renewable resources’ pure uncertainty. | Mathematical models | None | The results revealed significant enhancements in the Stochastic Dual Dynamic Programming (SDDP) algorithm and other regularization structures. |

| [214] | 2017 | Investigates the feasibility of controlling overall supply chain networks with net-zero-carbon on-site farms for wind and solar energy. | Optimization model | None | The experiments prove that a net-zero-carbon is technically and economically feasible according to the supply chain operation given in this study. |

| [8] | 2016 | Carries out a complete review of several phases of the solar-wind energy scheme. | Review | None | The study explains the prefeasibility analysis, optimal size, modeling, control characteristics, and reliability concerns regarding the solar-wind energy scheme. |

| Hydro-bio energy | |||||

| [12] | 2020 | It aims at developing a bioenergy supply chain model for network design to assess the hybrid system. | Case study | Iran | The results revealed that the microalgae/Jatropha is more feasible than livestock manure and agricultural residues for energy production. |

| [121] | 2016 | Develops coal-based energy supply chains gradually over time and applies the supply chain management concept to water resource development, finally offering the end-to-end and active views required to expand the hydropower network for energy security. | Mathematical model | Pakistan | The results demonstrate the value of the supply chain in hydropower network expansion and provide visions of the prorated performance between popular practices and various strategies on the mix and sequence of sites with multiple forms and capacities. |

| Bio-energy and wind energy | |||||

| [179] | 2014 | Considers the network layout and optimal allocation of electric biomass and wind energy supply chain. | Stochastic programming model | USA | The model shows that the key effect on the decisions is the subsidy level for renewable electricity production. |

References

- Fontes, C.H.; Freires, F.G. Sustainable and renewable energy supply chain: A system dynamics overview. Renew. Sustain. Energy Rev. 2018, 82, 247–259. [Google Scholar]

- Nowak, J.W. Quantitative Risk Assessment for a National Renewable Energy Target; The George Washington University: Washington, DC, USA, 2014. [Google Scholar]

- Arent, D.; Pless, J.; Mai, T.; Wiser, R.; Hand, M.; Baldwin, S.; Heath, G.; Macknick, J.; Bazilian, M.; Schlosser, A.; et al. Implications of high renewable electricity penetration in the US for water use, greenhouse gas emissions, land-use, and materials supply. Appl. Energy 2014, 123, 368–377. [Google Scholar] [CrossRef]

- Zhao, J. A Simulation-Based Decision Support System for Electric Power Demand Management Considering Social Network Interactions; The University of Arizona: Ann Arbor, MI, USA, 2013; p. 264. [Google Scholar]

- Hu, Y.; Cheng, H. Development and bottlenecks of renewable electricity generation in China: A critical review. Environ. Sci. Technol. 2013, 47, 3044–3056. [Google Scholar] [CrossRef] [PubMed]

- Azevedo, S.G.; Santos, M.; Antón, J.R. Supply chain of renewable energy: A bibliometric review approach. Biomass Bioenergy 2019, 126, 70–83. [Google Scholar] [CrossRef]

- García-Alcaraz, J.L.; Sánchez-Ramírez, C.; Avelar-Sosa, L.; Alor-Hernández, G. Systemic Approach for the Design of Renewable Energy Supply Chain Generated from Biomass. In Techniques, Tools and Methodologies Applied to Global Supply Chain Ecosystems; Springer: Cham, Switzerland, 2020; pp. 259–283. [Google Scholar]

- Khare, V.; Nema, S.; Baredar, P. Solar–wind hybrid renewable energy system: A review. Renew. Sustain. Energy Rev. 2016, 58, 23–33. [Google Scholar] [CrossRef]

- Wee, H.M.; Yang, W.H.; Chou, C.W.; Padilan, M.V. Renewable energy supply chains, performance, application barriers, and strategies for further development. Renew. Sustain. Energy Rev. 2012, 16, 5451–5465. [Google Scholar] [CrossRef]

- Erdinc, O.; Uzunoglu, M. Optimum design of hybrid renewable energy systems: Overview of different approaches. Renew. Sustain. Energy Rev. 2012, 16, 1412–1425. [Google Scholar] [CrossRef]

- Qi, W. Design and Management of Networked Energy and Logistics Systems; University of California: Berkeley, CA, USA, 2015. [Google Scholar]

- Mahjoub, N.; Sahebi, H. The water-energy nexus at the hybrid bioenergy supply chain: A sustainable network design model. Ecol. Indic. 2020, 119, 106799. [Google Scholar] [CrossRef]

- Mardani, A.; Jusoh, A.; Zavadskas, E.K.; Cavallaro, F.; Khalifah, Z. Sustainable and renewable energy: An overview of the application of multiple criteria decision making techniques and approaches. Sustainability 2015, 7, 13947–13984. [Google Scholar] [CrossRef] [Green Version]

- Şengül, Ü.; Eren, M.; Shiraz, S.E.; Gezder, V.; Şengül, A.B. Fuzzy TOPSIS method for ranking renewable energy supply systems in Turkey. Renew. Energy 2015, 75, 617–625. [Google Scholar] [CrossRef]

- Little, S. A Delphi Study on Risk and Uncertainty Decision Making for Renewable Energy Green Supply Chain Management; Northcentral University: Scottsdale, AZ, USA, 2017. [Google Scholar]

- Li, Y.; Kesharwani, R.; Sun, Z.; Qin, R.; Dagli, C.; Zhang, M.; Wang, D. Economic viability and environmental impact investigation for the biofuel supply chain using co-fermentation technology. Appl. Energy 2020, 259, 114235. [Google Scholar] [CrossRef]

- IRENA. Future of Wind: Deployment, Investment, Technology, Grid Integration and Socio-Economic Aspects. 2019. Available online: https://www.irena.org/publications/2019/Oct/Future-of-wind (accessed on 29 March 2022).

- Qu, Y.; Yu, Y.; Appolloni, A.; Li, M.; Liu, Y. Measuring green growth efficiency for Chinese manufacturing industries. Sustainability 2017, 9, 637. [Google Scholar] [CrossRef] [Green Version]

- Venturi, P.; Gigler, J.K.; Huisman, W. Economical and technical comparison between herbaceous (Miscanthus x giganteus) and woody energy crops (Salix viminalis). Renew. Energy 1999, 16, 1023–1026. [Google Scholar] [CrossRef]

- Jelti, F.; Allouhi, A.; Büker, M.S.; Saadani, R.; Jamil, A. Renewable power generation: A supply chain perspective. Sustainability 2021, 13, 1271. [Google Scholar] [CrossRef]

- Fernando, Y.; Bee, P.S.; Jabbour, C.J.; Thomé, A.M. Understanding the effects of energy management practices on renewable energy supply chains: Implications for energy policy in emerging economies. Energy Policy 2018, 118, 418–428. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Esposito, E. Environmental sustainability and energy-efficient supply chain management: A review of research trends and proposed guidelines. Energies 2018, 11, 275. [Google Scholar] [CrossRef] [Green Version]

- Mastrocinque, E.; Ramírez, F.J.; Honrubia-Escribano, A.; Pham, D.T. An AHP-based multi-criteria model for sustainable supply chain development in the renewable energy sector. Expert Syst. Appl. 2020, 150, 113321. [Google Scholar] [CrossRef]

- Haiyun, C.; Zhixiong, H.; Yüksel, S.; Dinçer, H. Analysis of the innovation strategies for green supply chain management in the energy industry using the QFD-based hybrid interval valued intuitionistic fuzzy decision approach. Renew. Sustain. Energy Rev. 2021, 143, 110844. [Google Scholar] [CrossRef]

- Grosvold, J.; Hoejmose, S.U.; Roehrich, J.K. Squaring the circle: Management, measurement and performance of sustainability in supply chains. Supply Chain Manag. Int. J. 2014, 19, 292–305. [Google Scholar] [CrossRef]

- Gawusu, S.; Zhang, X.; Jamatutu, S.A.; Ahmed, A.; Amadu, A.A.; Djam Miensah, E. The dynamics of green supply chain management within the framework of renewable energy. Int. J. Energy Res. 2022, 46, 684–711. [Google Scholar] [CrossRef]

- Halldorsson, A.; Svanberg, M. Energy resources: Trajectories for supply chain management. Supply Chain Manag. Int. J. 2013, 18, 66–73. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J.; Vance, J.; Wang, Y.; Wu, J.; Hartley, D. Data Analytics for Enhancement of Forest and Biomass Supply Chain Management. Curr. For. Rep. 2020, 6, 129–142. [Google Scholar] [CrossRef]

- Cucchiella, F.; D’Adamo, I. Issue on supply chain of renewable energy. Energy Convers. Manag. 2013, 76, 774–780. [Google Scholar] [CrossRef]

- Vance, L.; Cabezas, H.; Heckl, I.; Bertok, B.; Friedler, F. Synthesis of sustainable energy supply chain by the P-graph framework. Ind. Eng. Chem. Res. 2012, 52, 266–274. [Google Scholar] [CrossRef]

- Appolloni, A.; D’Adamo, I.; Gastaldi, M.; Yazdani, M.; Settembre-Blundo, D. Reflective backward analysis to assess the operational performance and eco-efficiency of two industrial districts. Int. J. Product. Perform. Manag. 2021. [Google Scholar] [CrossRef]

- Bouazzaoui, M.; Wu, H.J.; Roehrich, J.K.; Squire, B.; Roath, A.S. Justice in inter-organizational relationships: A literature review and future research agenda. Ind. Mark. Manag. 2020, 87, 128–137. [Google Scholar] [CrossRef]

- Saghaei, M.; Ghaderi, H.; Soleimani, H. Design and optimization of biomass electricity supply chain with uncertainty in material quality, availability and market demand. Energy 2020, 197, 117165. [Google Scholar] [CrossRef]

- Rahemi, H.; Torabi, S.A.; Avami, A.; Jolai, F. Bioethanol supply chain network design considering land characteristics. Renew. Sustain. Energy Rev. 2020, 119, 109517. [Google Scholar] [CrossRef]

- Perić, M.; Antonijević, D.; Komatina, M.; Bugarski, B.; Rakin, M. Life cycle assessment of wood chips supply chain in Serbia. Renew. Energy 2020, 155, 1302–1311. [Google Scholar] [CrossRef]

- Nunes, L.J.; Causer, T.P.; Ciolkosz, D. Biomass for energy: A review on supply chain management models. Renew. Sustain. Energy Rev. 2020, 120, 109658. [Google Scholar] [CrossRef]

- Murele, O.C.; Zulkafli, N.I.; Kopanos, G.; Hart, P.; Hanak, D.P. Integrating biomass into energy supply chain networks. J. Clean. Prod. 2020, 248, 119246. [Google Scholar] [CrossRef]

- Lo, S.L.; How, B.S.; Leong, W.D.; Teng, S.Y.; Rhamdhani, M.A.; Sunarso, J. Techno-economic analysis for biomass supply chain: A state-of-the-art review. Renew. Sustain. Energy Rev. 2020, 135, 110164. [Google Scholar] [CrossRef]

- Kc, R.; Aalto, M.; Korpinen, O.J.; Ranta, T.; Proskurina, S. Lifecycle Assessment of Biomass Supply Chain with the Assistance of Agent-Based Modelling. Sustainability 2020, 12, 1964. [Google Scholar] [CrossRef] [Green Version]

- Kang, S.; Heo, S.; Realff, M.J.; Lee, J.H. Three-stage design of high-resolution microalgae-based biofuel supply chain using geographic information system. Appl. Energy 2020, 265, 114773. [Google Scholar] [CrossRef]

- Gilani, H.; Sahebi, H.; Oliveira, F. Sustainable sugarcane-to-bioethanol supply chain network design: A robust possibilistic programming model. Appl. Energy 2020, 278, 115653. [Google Scholar] [CrossRef]

- Garofalo, P.; Mastrorilli, M.; Ventrella, D.; Vonella, A.V.; Campi, P. Modelling the suitability of energy crops through a fuzzy-based system approach: The case of sugar beet in the bioethanol supply chain. Energy 2020, 196, 117160. [Google Scholar] [CrossRef]

- Fattahi, M.; Govindan, K.; Farhadkhani, M. Sustainable supply chain planning for biomass-based power generation with environmental risk and supply uncertainty considerations: A real-life case study. Int. J. Prod. Res. 2021, 59, 3084–3108. [Google Scholar] [CrossRef]

- Esmaeili, S.A.H.; Szmerekovsky, J.; Sobhani, A.; Dybing, A.; Peterson, T.O. Sustainable biomass supply chain network design with biomass switching incentives for first-generation bioethanol producers. Energy Policy 2020, 138, 111222. [Google Scholar] [CrossRef]

- Durmaz, Y.G.; Bilgen, B. Multi-objective optimization of sustainable biomass supply chain network design. Appl. Energy 2020, 272, 115259. [Google Scholar] [CrossRef]

- Aziz, N.I.H.A.; Hanafiah, M.M.; Gheewala, S.H.; Ismail, H. Bioenergy for a Cleaner Future: A Case Study of Sustainable Biogas Supply Chain in the Malaysian Energy Sector. Sustainability 2020, 12, 3213. [Google Scholar] [CrossRef] [Green Version]

- Aseffe, J.A.M.; González, A.M.; Jaén, R.L.; Lora, E.E.S. The corn cob gasification-based renewable energy recovery in the life cycle environmental performance of seed-corn supply chain: An Ecuadorian case study. Renew. Energy 2020, 163, 1523–1535. [Google Scholar] [CrossRef]

- Sarker, B.R.; Wu, B.; Paudel, K.P. Modeling and optimization of a supply chain of renewable biomass and biogas: Processing plant location. Appl. Energy 2019, 239, 343–355. [Google Scholar] [CrossRef]

- Sadeghi, J.; Haapala, K.R. Optimizing a sustainable logistics problem in a renewable energy network using a genetic algorithm. OPSEARCH 2019, 56, 73–90. [Google Scholar] [CrossRef]

- Nugroho, Y.K.; Zhu, L. Platforms planning and process optimization for biofuels supply chain. Renew. Energy 2019, 140, 563–579. [Google Scholar] [CrossRef]

- Ling, W.C.; Verasingham, A.B.; Andiappan, V.; Wan, Y.K.; Chew, I.M.; Ng, D.K. An integrated mathematical optimisation approach to synthesise and analyse a bioelectricity supply chain network. Energy 2019, 178, 554–571. [Google Scholar] [CrossRef]

- Leong, H.; Leong, H.; Foo, D.C.; Ng, L.Y.; Andiappan, V. Hybrid approach for carbon-constrained planning of bioenergy supply chain network. Sustain. Prod. Consum. 2019, 18, 250–267. [Google Scholar] [CrossRef]

- Gumte, K.M.; Mitra, K. Bio-Supply Chain Network Design to tackle ethanol deficiency in India: A mathematical framework. J. Clean. Prod. 2019, 234, 208–224. [Google Scholar] [CrossRef]

- Díaz-Trujillo, L.A.; Nápoles-Rivera, F. Optimization of biogas supply chain in Mexico considering economic and environmental aspects. Renew. Energy 2019, 139, 1227–1240. [Google Scholar] [CrossRef]

- Agustina, F.; Vanany, I.; Siswanto, N. Biomass Supply Chain Design, Planning and Management: A Review of Literature. In Proceedings of the 2018 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Bangkok, Thailand, 16–19 December 2018; pp. 884–888. [Google Scholar]

- Bragado, M.V.; Broz, D.; Dondo, R. Design and optimization of a supply chain for cogeneration of electrical and thermal energy from forest biomass. In Proceedings of the Simposio Argentino de Informática Industrial e Investigación Operativa SIIO 2018—47 Jornadas Argentinas de Informática JAIIO 2018, Buenos Aires, Argentina, 5–7 September 2018; pp. 29–40. [Google Scholar]

- Zahraee, S.M.; Golroudbary, S.R.; Shiwakoti, N.; Kraslawski, A.; Stasinopoulos, P. An investigation of the environmental sustainability of palm biomass supply chains via dynamic simulation modeling: A case of Malaysia. J. Clean. Prod. 2019, 237, 117740. [Google Scholar] [CrossRef]

- Acuna, M.; Sessions, J.; Zamora, R.; Boston, K.; Brown, M.; Ghaffariyan, M.R. Methods to Manage and Optimize Forest Biomass Supply Chains: A Review. Curr. For. Rep. 2019, 5, 124–141. [Google Scholar] [CrossRef]

- Yokoi, Y.; Furubayashi, T.; Nakata, T.; Kasai, H.; Ochi, Y. Multifaceted analysis and integrated design for global supply chain of empty fruit bunch. Eur. Biomass Conf. Exhib. Proc. 2018, 2018, 855–866. [Google Scholar]

- Svanberg, M.; Finnsgård, C.; Flodén, J.; Lundgren, J. Analyzing animal waste-to-energy supply chains: The case of horse manure. Renew. Energy 2018, 129, 830–837. [Google Scholar] [CrossRef]

- Karimi, H. Optimization Models for Sustainable Design and Management of Biopower Supply Chains; Clemson University: Clemson, SC, USA, 2018. [Google Scholar]

- Gebresenbet, G.; Bosona, T.; Olsson, S.-O.; Garcia, D. Smart System for the optimization of logistics performance of the pruning biomass value chain. Appl. Sci. 2018, 8, 1162. [Google Scholar] [CrossRef] [Green Version]

- Roni, M.S.; Eksioglu, S.D.; Cafferty, K.G.; Jacobson, J.J. A multi-objective, hub-and-spoke model to design and manage biofuel supply chains. Ann. Oper. Res. 2017, 249, 351–380. [Google Scholar] [CrossRef]

- Poudel, S.R. Models and Algorithms to Solve a Reliable and Congested Biomass Supply Chain Network Designing Problem under Uncertainty; Mississippi State University: Starkville, MS, USA, 2017. [Google Scholar]

- Chavez, H.; Castillo-Villar, K.K.; Webb, E. Development of the IBSAL-SimMOpt Method for the Optimization of Quality in a Corn Stover Supply Chain. Energies 2017, 10, 1137. [Google Scholar] [CrossRef] [Green Version]

- Yue, D. Multi-Scale Optimization of Biomass-to-Bioenergy Supply Chains; Northwestern University: Evanston, IL, USA, 2016. [Google Scholar]

- Lin, T.; Rodríguez, L.F.; Davis, S.; Khanna, M.; Shastri, Y.; Grift, T.; Long, S.; Ting, K. Biomass feedstock preprocessing and long-distance transportation logistics. Gcb Bioenergy 2016, 8, 160–170. [Google Scholar] [CrossRef]

- Korpinen, O.J.; Venäläinen, P.; Aalto, M.; Ranta, T. Advanced solutions for biomass transportation by road—How to evaluate their performance? In Proceedings of the 24th European Biomass Conference and Exhibition Proceedings, Amsterdam, The Netherlands, 6–9 June 2016; pp. 1681–1685. [Google Scholar]

- Balaman, Ş.Y.; Selim, H. Sustainable design of renewable energy supply chains integrated with district heating systems: A fuzzy optimization approach. J. Clean. Prod. 2016, 133, 863–885. [Google Scholar] [CrossRef]

- Hong, B.H.; Lam, H.L. Novel approach for integrated biomass supply chain. Chem. Eng. Trans. 2015, 45, 475–480. [Google Scholar]

- Hartley, D.S. Modeling and Optimization of Woody Biomass Harvest and Logistics in the Northeastern United States; West Virginia University: Morgantown, WV, USA, 2014. [Google Scholar]

- Balaman, Ş.Y.; Selim, H. A network design model for biomass to energy supply chains with anaerobic digestion systems. Appl. Energy 2014, 130, 289–304. [Google Scholar] [CrossRef]

- Svanberg, M.; Halldórsson, Á. Supply chain configuration for biomass-to-energy: The case of torrefaction. Int. J. Energy Sect. Manag. 2013, 7, 65–83. [Google Scholar] [CrossRef]

- Sharma, B.; Ingalls, R.G.; Jones, C.L.; Khanchi, A. Biomass supply chain design and analysis: Basis, overview, modeling, challenges, and future. Renew. Sustain. Energy Rev. 2013, 24, 608–627. [Google Scholar] [CrossRef]

- Martinez-Kawas, A. A Feasibility Study of Postharvest Handling, Storage and Logistics of Bioenergy Crops; Kansas State University: Manhattan, KS, USA, 2013. [Google Scholar]

- Kazemzadeh, N.; Hu, G. Optimization models for biorefinery supply chain network design under uncertainty. J. Renew. Sustain. Energy 2013, 5, 053125. [Google Scholar] [CrossRef] [Green Version]

- Karttunen, K.; Väätäinen, K.; Asikainen, A.; Ranta, T. The operational efficiency of waterway transport of forest chips on Finland’s Lake Saimaa. Silva Fenn. 2012, 3, 395–413. [Google Scholar] [CrossRef] [Green Version]

- Tahvanainen, T.; Anttila, P. Supply chain cost analysis of long-distance transportation of energy wood in Finland. Biomass Bioenergy 2011, 35, 3360–3375. [Google Scholar] [CrossRef]

- Palander, T. Modelling renewable supply chain for electricity generation with forest, fossil, and wood-waste fuels. Energy 2011, 36, 5984–5993. [Google Scholar] [CrossRef]

- Gold, S.; Seuring, S. Supply chain and logistics issues of bio-energy production. J. Clean. Prod. 2011, 19, 32–42. [Google Scholar] [CrossRef]

- Dunnett, A. Spatially Explicit Modelling and Optimisation of Bioenergy Supply—Chain Infrastructures; Imperial College London: London, UK, 2011. [Google Scholar]

- Bowling, I.M.; Ponce-Ortega, J.M.; El-Halwagi, M.M. Facility location and supply chain optimization for a biorefinery. Ind. Eng. Chem. Res. 2011, 50, 6276–6286. [Google Scholar] [CrossRef]

- Velazquez-Marti, B.; Fernandez-Gonzalez, E. Mathematical algorithms to locate factories to transform biomass in bioenergy focused on logistic network construction. Renew. Energy 2010, 35, 2136–2142. [Google Scholar] [CrossRef]

- Van Dyken, S.; Bakken, B.H.; Skjelbred, H.I. Linear mixed-integer models for biomass supply chains with transport, storage and processing. Energy 2010, 35, 1338–1350. [Google Scholar] [CrossRef] [Green Version]

- Acharya, A.M. Biomass-to-Biofuels’ Supply Chain Design and Management; Mississippi State University: Starkville, MS, USA, 2010. [Google Scholar]

- Kouvelis, P.; Matsuo, H.; Xiao, Y.; Yuan, Q. Long-Term Service Agreement in Electricity Supply Chain with Renewable Energy Penetration; Elsevier Inc.: New York, NY, USA, 2020; SSRN 3433943. [Google Scholar]

- Zhao, W.; Bao, X.; Yuan, G.; Wang, X.; Bao, H. The Equilibrium Model for the Coexistence of Renewable Portfolio Standards and Emissions Trading: The Supply Chain Analysis. Energies 2019, 12, 439. [Google Scholar] [CrossRef] [Green Version]

- Khan, S.A.R.; Zhang, Y.; Anees, M.; Golpîra, H.; Lahmar, A.; Qianli, D. Green supply chain management, economic growth and environment: A GMM based evidence. J. Clean. Prod. 2018, 185, 588–599. [Google Scholar] [CrossRef]

- Yu, Z.; Golpîra, H.; Khan, S. The relationship between green supply chain performance, energy demand, economic growth and environmental sustainability: An empirical evidence from developed countries. LogForum 2018, 14, 479–494. [Google Scholar] [CrossRef]

- Badea, A.; Prostean, G.; Tamasila, M.; Taucean, I.M. Conceptual Model In Supply Chain Collaboration For Renewable Energy Resources Projects. In Proceedings of the 5th International Management Conference, Politehnica University of Timisoara, Timisoara, Romania, 25–27 May 2016; pp. 66–73. [Google Scholar]

- Pietrosemoli, L.; Monroy, C.R. The impact of sustainable construction and knowledge management on sustainability goals. A review of the Venezuelan renewable energy sector. Renew. Sustain. Energy Rev. 2013, 27, 683–691. [Google Scholar] [CrossRef] [Green Version]

- Aslani, A.; Mohaghar, A. Business structure in renewable energy industry: Key areas. Renew. Sustain. Energy Rev. 2013, 27, 569–575. [Google Scholar] [CrossRef]

- Delucchi, M.A.; Jacobson, M.Z. Providing all global energy with wind, water, and solar power, Part II: Reliability, system and transmission costs, and policies. Energy Policy 2011, 39, 1170–1190. [Google Scholar] [CrossRef]

- Lam, H.L.; Varbanov, P.S.; Klemeš, J.J. Optimisation of regional energy supply chains utilising renewables: P-graph approach. Comput. Chem. Eng. 2010, 34, 782–792. [Google Scholar] [CrossRef]

- Herrera, M.M.; Uriona, M.; Dyner, I. Dynamics performance of the wind-power supply chain with transmission capacity constraints. Int. J. Electr. Comput. Eng. 2020, 10, 1142–1148. [Google Scholar] [CrossRef]

- Irawan, C.A.; Akbari, N.; Jones, D.F.; Menachof, D. A combined supply chain optimisation model for the installation phase of offshore wind projects. Int. J. Prod. Res. 2018, 56, 1189–1207. [Google Scholar] [CrossRef] [Green Version]

- Poulsen, T.; Lema, R. Is the supply chain ready for the green transformation? The case of offshore wind logistics. Renew. Sustain. Energy Rev. 2017, 73, 758–771. [Google Scholar] [CrossRef]

- Shafiee, M. Maintenance logistics organization for offshore wind energy: Current progress and future perspectives. Renew. Energy 2015, 77, 182–193. [Google Scholar] [CrossRef]

- Vojdani, N.; Lootz, F. Designing supply chain networks for the offshore wind energy industry. Int. J. Bus. Perform. Supply Chain Model. 2012, 4, 271–284. [Google Scholar] [CrossRef]

- Lange, K.; Rinne, A.; Haasis, H.-D. Planning maritime logistics concepts for offshore wind farms: A newly developed decision support system. In International Conference on Computational Logistics; Springer: Berlin/Heidelberg, Germany, 2012; pp. 142–158. [Google Scholar]

- Scholz-Reiter, B.; Lütjen, M.; Heger, J.; Schweizer, A. Planning and control of logistics for offshore wind farms. In Proceedings of the 12th WSEAS International Conference on Mathematical and Computational Methods in Science and Engineering, Faro, Portugal, 3–5 November 2010; pp. 242–247. [Google Scholar]

- Alstone, P. Connections beyond the Margins of the Power Grid: Information Technology and the Evolution of Off-Grid Solar Electricity in the Developing World; University of California: Berkeley, CA, USA, 2015. [Google Scholar]

- Batidzirai, B.; Junginger, M.; Klemm, M.; Schipfer, F.; Thrän, D. Biomass Supply and Trade Opportunities of Preprocessed Biomass for Power Generation. In Developing the Global Bioeconomy; Elsevier: Amsterdam, The Netherlands, 2016; pp. 91–114. [Google Scholar]

- Foo, D.C.; Tan, R.R.; Lam, H.L.; Aziz, M.K.A.; Klemeš, J.J. Robust models for the synthesis of flexible palm oil-based regional bioenergy supply chain. Energy 2013, 55, 68–73. [Google Scholar] [CrossRef]

- Hensel, N.D. Economic challenges in the clean energy supply chain: The market for rare earth minerals and other critical inputs. Bus. Econ. 2011, 46, 171–184. [Google Scholar] [CrossRef]

- Zhang, Y.; Bao, X.; Ren, G.; Cai, X.; Li, J. Analysing the status, obstacles and recommendations for WCOs of restaurants as biodiesel feedstocks in China from supply chain’perspectives. Resour. Conserv. Recycl. 2012, 60, 20–37. [Google Scholar] [CrossRef]

- Besha, P. National, Regional and Sectoral Innovation Systems in China: General Overview and Case Studies of Renewable Energy and Space Technology Sectors. Ph.D. Thesis, The George Washington University, Ann Arbor, MI, USA, 2013. [Google Scholar]

- Lefevre-Marton, N. Catching up: The Rise of the Chinese Wind Turbine Industry; Princeton University: Princeton, NJ, USA, 2013. [Google Scholar]

- Yadav, Y.S.; Yadav, Y. Biomass Supply Chain Management: Perspectives and Challenges. In Proceedings of the First International Conference on Recent Advances in Bioenergy Research; Springer: New Delhi, India, 2016; pp. 267–281. [Google Scholar]

- Shahbazbegian, V.; Hosseini-Motlagh, S.-M.; Haeri, A. Integrated forward/reverse logistics thin-film photovoltaic power plant supply chain network design with uncertain data. Appl. Energy 2020, 277, 115538. [Google Scholar] [CrossRef]

- Manouchehrabadi, M.K.; Yaghoubi, S.; Tajik, J. Optimal scenarios for solar cell supply chain considering degradation in powerhouses. Renew. Energy 2020, 145, 1104–1125. [Google Scholar] [CrossRef]

- Dehghani, E.; Jabalameli, M.S.; Naderi, M.J.; Safari, A. An environmentally conscious photovoltaic supply chain network design under correlated uncertainty: A case study in Iran. J. Clean. Prod. 2020, 262, 121434. [Google Scholar] [CrossRef]

- Ishii, K.; Furuichi, T.; Fujiyama, A.; Watanabe, S. Logistics cost analysis of rice straw pellets for feasible production capacity and spatial scale in heat utilization systems: A case study in Nanporo town, Hokkaido, Japan. Biomass Bioenergy 2016, 94, 155–166. [Google Scholar] [CrossRef]

- Choo, Y.M.; Muhamad, H.; Hashim, Z.; Subramaniam, V.; Puah, C.W.; Tan, Y. Determination of GHG contributions by subsystems in the oil palm supply chain using the LCA approach. Int. J. Life Cycle Assess. 2011, 16, 669–681. [Google Scholar] [CrossRef]

- Hassan, M.N.A. Ghg Emissions and Costs of Developing Biomass Energy in Malaysia: Implications on Energy Security in the Transportation and Electricity Sector. Ph.D. Thesis, Carnegie Mellon University, Pittsburgh, PA, USA, 2012. [Google Scholar]

- Lam, H.L.; Ng, W.P.; Ng, R.T.; Ng, E.H.; Aziz, M.K.A.; Ng, D.K. Green strategy for sustainable waste-to-energy supply chain. Energy 2013, 57, 4–16. [Google Scholar] [CrossRef]

- Umar, M.S.; Jennings, P.; Urmee, T. Strengthening the palm oil biomass renewable energy industry in Malaysia. Renew. Energy 2013, 60, 107–115. [Google Scholar] [CrossRef] [Green Version]

- Bujang, B.; Safuan, A. Utilization of Durian Biomass for Biorenewable Applications. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2014. [Google Scholar]

- Shaharudin, M.S.; Fernando, Y. Low carbon footprint: The supply chain agenda in Malaysian manufacturing firms. In Promoting Sustainable Practices through Energy Engineering and Asset Management; IGI Global: Hershey, PA, USA, 2015; pp. 324–347. [Google Scholar]

- Amer, M. Extending Technology Roadmap through Fuzzy Cognitive Map-Based Scenarios: The Case of the Wind Energy Sector of Pakistan. 2013. Available online: https://pdxscholar.library.pdx.edu/open_access_etds/999/ (accessed on 29 March 2022).

- Mun, K.G. Designing Energy and Water Supply Chains for Prosperity; Rutgers The State University of New Jersey-New Brunswick: New Brunswick, NJ, USA, 2016. [Google Scholar]

- Seo, S.-K.; Yun, D.-Y.; Lee, C.-J. Design and optimization of a hydrogen supply chain using a centralized storage model. Appl. Energy 2020, 262, 114452. [Google Scholar] [CrossRef]

- Manakit, P. Optimal Utilization of Biomass Feedstocks: A Case Study Based on Rice and Sugar Mills in Thailand; University of Surrey: Guildford, UK, 2018. [Google Scholar]

- Sikkema, R.; Junginger, M.; Pichler, W.; Hayes, S.; Faaij, A.P. The international logistics of wood pellets for heating and power production in Europe: Costs, energy-input and greenhouse gas balances of pellet consumption in Italy, Sweden and the Netherlands. Biofuels Bioprod. Biorefining 2010, 4, 132–153. [Google Scholar] [CrossRef]

- Marinelli, A.; Fagarazzi, C.; Tirinnanzi, A. Evaluation of the economic, environmental and territorial effects of some biomassenergy chain in Tuscany. Riv. Studi Sulla Sostenibilita 2012, 13–31. Available online: https://www.researchgate.net/publication/287601103_Evaluation_of_the_economic_environmental_and_territorial_effects_of_some_biomassenergy_chain_in_Tuscany (accessed on 29 March 2022).

- Monforti, F.; Bódis, K.; Scarlat, N.; Dallemand, J.-F. The possible contribution of agricultural crop residues to renewable energy targets in Europe: A spatially explicit study. Renew. Sustain. Energy Rev. 2013, 19, 666–677. [Google Scholar] [CrossRef]

- López, E.; Jirjis, R.; Anerud, E.; Kern, J.; Idler, C.; Sebastián, F.; Germer, S. Recommendations for management of large scale storage of wood prunings to avoid quality changes. In Proceedings of the 24th European Biomass Conference and Exhibition Proceedings, Amsterdam, The Netherlands, 6–9 June 2016; pp. 580–586. [Google Scholar]

- García-Galindo, D.; Gómez-Palmero, M.; López, E.; Sebastián, F.; Jirjis, R.; Gebresenbet, G.; Germer, S.; Pari, L.; Suardi, A.; Lapeña, A.; et al. Agricultural pruning harvesting demonstrations in Germany, France and Spain. Lessons learned and recommendations. In Proceedings of the European Biomass Conference and Exhibition Proceedings, Amsterdam, The Netherlands, 6–9 June 2016; pp. 1727–1733. [Google Scholar]

- Arranz-Piera, P.; Horta, F.; Kies, U.; Hagemann, H.; Reumerman, P.; Fallas, Y.; Obersteiner, G.; Velo, E. SME entrepreneurship in the solid biomass sector: First results of the “securechain” project (HORIZON2020). In Proceedings of the European Biomass Conference and Exhibition Proceedings, Amsterdam, The Netherlands, 6–9 June 2016; pp. 1666–1670. [Google Scholar]

- Pezdevšek Malovrh, Š.; Kumer, P.; Glavonjić, P.; Nonić, D.; Nedeljković, J.; Kisin, B.; Avdibegović, M. Different organizational models of private forest owners as a possibility to increase wood mobilization in Slovenia and Serbia. Croat. J. For. Eng. J. Theory Appl. For. Eng. 2017, 38, 127–140. [Google Scholar]

- Garcia, C.A.; Hora, G. State-of-the-art of waste wood supply chain in Germany and selected European countries. Waste Manag. 2017, 70, 189–197. [Google Scholar] [CrossRef]

- Korpinen, O.-J.; Aalto, M.; Virkkunen, M.; Raitila, J.; Ranta, T. Simulation-Based Assessment of the Properties and Performance of a Biomass Terminal. In Proceedings of the 25th European Biomass Conference and Exhibition, EUBCE 2017, Stockholm, Sweden, 12–15 June 2017; pp. 48–51. [Google Scholar]

- Kanzian, C.; Kühmaier, M. Regional energy wood logistics-optimal locations and catchment areas for storage. Austrian J. For. Sci. 2017, 134, 201–223. [Google Scholar]

- Koch, C.; Baluku, J.; Habakurama, I.I.; Mathern, A. The challenges of building inner sea offshore wind farms-the cases of Lillgrund and Anholt. In Proceedings of the 9th Nordic Conference on Construction Economics and Organization, Chalmers University of Technology, Göteborg, Sweden, 13–14 June 2017; p. 307. [Google Scholar]

- Sambra, A.; Sorensen, C.; Kristensen, E.F. Optimized harvest and logistics for biomass supply chain. In Proceedings of the 16th European Biomass Conference and Exhibition, Valencia, Spain, 2–6 June 2008. [Google Scholar]

- Karttunen, K.; Lättilä, L.; Korpinen, O.-J.; Ranta, T. Cost-efficiency of intermodal container supply chain for forest chips. Silva Fenn. 2013, 47, 24. [Google Scholar] [CrossRef] [Green Version]

- Tuominen, R.; Seppänen, T.; Soininen, H.; Karhu, H.; Tirkkonen, H.; Föhr, J.; Ranta, T. Demonstration tests on horse manure in order to strengthen the economic life of the south savo region. In Proceedings of the 26th European Biomass Conference and Exhibition Proceedings, Copenhagen, Denmark, 14–17 May 2018; pp. 339–341. [Google Scholar]

- Annevelink, E.; Staritsky, I.; Vanmeulebrouk, B.; Elbersen, B.; Gabrielle, B. LocaGIStics: Design & evaluation of regional biomass delivery chains. In Proceedings of the 24th European Biomass Conference and Exhibition, Amsterdam, The Netherland, 6–9 June 2016; pp. 174–175. [Google Scholar]

- Richter, A.; van der Laan, E.; Ketter, W.; Valogianni, L. Transitioning from the traditional to the smart grid: Lessons learned from closed-loop supply chains. In Proceedings of the 2012 International Conference on Smart Grid Technology, Economics and Policies (SG-TEP), Nuremberg, Germany, 3–4 December 2012. [Google Scholar]

- Reuß, M.; Grube, T.; Robinius, M.; Stolten, D. A hydrogen supply chain with spatial resolution: Comparative analysis of infrastructure technologies in Germany. Appl. Energy 2019, 247, 438–453. [Google Scholar] [CrossRef]

- Sosa, A.; Acuna, M.; McDonnell, K.; Devlin, G. Controlling moisture content and truck configurations to model and optimise biomass supply chain logistics in Ireland. Appl. Energy 2015, 137, 338–351. [Google Scholar] [CrossRef] [Green Version]

- Gnoni, M.; Elia, V.; Lettera, G. A strategic quantitative approach for sustainable energy production from biomass. Int. J. Sustain. Eng. 2011, 4, 127–135. [Google Scholar] [CrossRef]

- Dal-Mas, M.; Giarola, S.; Zamboni, A.; Bezzo, F. Strategic design and investment capacity planning of the ethanol supply chain under price uncertainty. Biomass Bioenergy 2011, 35, 2059–2071. [Google Scholar] [CrossRef]

- Pari, L.; Brambilla, M.; Civitarese, V.; Bisaglia, C. Preliminary evaluation of a short rotation forestry poplar biomass supply chain in Emilia Romagna Region. J. Agric. Eng. 2013, 44, 373–377. [Google Scholar] [CrossRef]

- Pantaleo, A.; De Gennaro, B.; Shah, N. Assessment of optimal size of anaerobic co-digestion plants: An application to cattle farms in the province of Bari (Italy). Renew. Sustain. Energy Rev. 2013, 20, 57–70. [Google Scholar] [CrossRef]

- Cannemi, M.; García-Melón, M.; Aragonés-Beltrán, P.; Gómez-Navarro, T. Modeling decision making as a support tool for policy making on renewable energy development. Energy Policy 2014, 67, 127–137. [Google Scholar] [CrossRef]

- Serrano, A.; Faulin, J.; Astiz, P.; Sánchez, M.; Belloso, J. Locating and designing a biorefinery supply chain under uncertainty in Navarre: A stochastic facility location problem case. Transp. Res. Procedia 2015, 10, 704–713. [Google Scholar] [CrossRef] [Green Version]

- Pari, L.; Suardi, A.; Scarfone, A.; Acampora, A.; Frackowiak, P.; Adamczyk, F.; Santangelo, E. Harvesting of almond (Prunus dulcis, Mill.) pruning in Spain using a new chipper prototype. In Proceedings of the 24th European Biomass Conference and Exhibition, Amsterdam, The Netherlands, 6–9 June 2016; pp. 6–9. [Google Scholar]

- Annevelink, B.; Galindo, D.G.; Espatolero, S.; Staritsky, I.; Vanmeulebrouk, B. Logistical case study for the AragÓn region using the locagistics tool. Eur. Biomass Conf. Exhib. Proc. 2017, 2017, 41–47. [Google Scholar]

- Jeong, J.S.; Ramírez-Gómez, Á. Optimizing the location of a biomass plant with a fuzzy-DEcision-MAking Trial and Evaluation Laboratory (F-DEMATEL) and multi-criteria spatial decision assessment for renewable energy management and long-term sustainability. J. Clean. Prod. 2018, 182, 509–520. [Google Scholar] [CrossRef]

- Abad, A.V.; Cherrett, T.; Holdsworth, P. Waste-to-fuel opportunities for British quick service restaurants: A case study. Resour. Conserv. Recycl. 2015, 104, 239–253. [Google Scholar] [CrossRef]

- Yu, M. An Approach to Optimise Biofuel Supply Chain with Focus on the United Kingdom; University of Surrey: Guildford, UK, 2015. [Google Scholar]

- Khan, S.A.R.; Qianli, D. Does national scale economic and environmental indicators spur logistics performance? Evidence from UK. Environ. Sci. Pollut. Res. 2017, 24, 26692–26705. [Google Scholar] [CrossRef]

- Alam, M. Modeling the Woody Biomass Supply Chain for Energy Production in Northwestern Ontario. Ph.D. Thesis, Lakehead University, Thunder Bay, ON, Canada, 2014. [Google Scholar]

- Shabani, N.; Sowlati, T. A mixed integer non-linear programming model for tactical value chain optimization of a wood biomass power plant. Appl. Energy 2013, 104, 353–361. [Google Scholar] [CrossRef]

- Calvert, K. Geographies of Biomass and Solar Energy: Spatial Decision Support for Regional Energy Sustainability; Queen’s University: Kingston, ON, Canada, 2013. [Google Scholar]

- Chávez, H.; Castillo-Villar, K.K.; Webb, E. Simulation-based approach for the optimization of a biofuel supply chain. In Proceedings of the IIE Annual Conference Proceedings, Pittsburgh, PA, USA, 20–23 May 2017; 2017; pp. 271–276. [Google Scholar]

- Weldu, Y.W. Accounting for Human Health and Ecosystems Quality in Developing Sustainable Energy Products: The Implications of Wood Biomass-based Electricity Strategies to Climate Change Mitigation; University of Calgary: Calgary, AB, Canada, 2017. [Google Scholar]

- Dhanju, A. Four Essays on Offshore Wind Power Potential, Development, Regulatory Framework, and Integration; University of Delaware: New York, NY, USA, 2010. [Google Scholar]

- Brathwaite, N.H. A perfect Storm: How Biorenewables Scientists are Reading Kairos, Exercising Agency, and Locating a New Scientific Ethos that Supports Public Engagement; Iowa State University: Ames, IA, USA, 2010. [Google Scholar]

- Parker, N.; Fan, Y.; Ogden, J. From waste to hydrogen: An optimal design of energy production and distribution network. Transp. Res. Part E Logist. Transp. Rev. 2010, 46, 534–545. [Google Scholar] [CrossRef]

- Jessup, R.W. Development and status of dedicated energy crops in the United States. Vitr. Cell. Dev. Biol. -Plant 2009, 45, 282–290. [Google Scholar] [CrossRef]

- Tun-Hsiang, E.Y.; Larson, J.A.; English, B.C.; Gao, Y. Evaluating the Optimal Logistics System of Biomass Feedstocks for a Biorefinery with Alternative Harvest, Storage and Preprocessing Options: A Case Study of East Tennessee. In Proceedings of the American Society of Agricultural and Biological Engineers, Louisville, KY, USA, 7–10 August 2011; p. 1. [Google Scholar]

- An, H. Optimization and Simulation for Designing the Supply Chain of the Cellulosic Biofuel Industry; Texas A&M University: College Station, TX, USA, 2011. [Google Scholar]

- Han, S.-K. Managing Woody Biomass Transportation for Improved Biomass Economics; Oregon State University: Corvallis, OR, USA, 2011. [Google Scholar]

- Parker, N.C. Modeling Future Biofuel Supply Chains Using Spatially Explicit Infrastructure Optimization; University of California: Davis, CA, USA, 2011. [Google Scholar]

- Vimmerstedt, L.J.; Bush, B.; Peterson, S. Ethanol distribution, dispensing, and use: Analysis of a portion of the biomass-to-biofuels supply chain using system dynamics. PLoS ONE 2012, 7, e35082. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- de Bourgeois, W. Developing an Action Research Framework of Profit Sustainability in an Alternative Energy Economy Assessing the Business Models of Domestic and Global Energy Markets; D.B.A. Argosy University/Seattle: Ann Arbor, MI, USA, 2012. [Google Scholar]

- Okwo, A. Next-Generation Biofuels: The Supply Chain Approach to Estimating Potential Land-Use Change. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2012. [Google Scholar]

- Sharma, B. Scenario Optimization Approach for Designing Biomass Supply Chain; Oklahoma State University: Stillwater, OK, USA, 2012. [Google Scholar]

- Zhang, J.; Osmani, A.; Awudu, I.; Gonela, V. An integrated optimization model for switchgrass-based bioethanol supply chain. Appl. Energy 2013, 102, 1205–1217. [Google Scholar] [CrossRef]

- Leahy, J.; Lindenfeld, L. Linking knowledge with action: Applied social science considerations to improve woody bioenergy research and development effectiveness. In Wood-Based Energy in the Northern Forests; Springer: New York, NY, USA, 2013; pp. 219–227. [Google Scholar]

- Awudu, I.K. Modeling and Optimization of Biofuel Supply Chain Considering Uncertainties, Hedging Strategies, and Sustainability Concepts. Ph.D. Thesis, North Dakota State University, Fargo, ND, USA, 2013. [Google Scholar]

- Bai, Y. Integrated Supply Chain Design for Sustainable and Resilient Development of Biofuel Production; University of Illinois at Urbana-Champaign: Urbana, IL, USA, 2013. [Google Scholar]

- Emery, I.R. Direct and Indirect Greenhouse Gas Emissions from Biomass Storage: Implications for Life Cycle Assessment of Biofuels; Purdue University: West Lafayette, IN, USA, 2013. [Google Scholar]

- Lin, T. Systems Informatics and Analysis for Optimization of Biomass Feedstock Provision; University of Illinois at Urbana-Champaign: Champaign, IL, USA, 2014. [Google Scholar]

- Shah, A. Techno-Economic Analysis and Life Cycle Assessment of the Corn Stover Biomass Feedstock Supply Chain System for a Midwest-based First-Generation Cellulosic Biorefinery; Iowa State University: Ames, IA, USA, 2013. [Google Scholar]

- Argo, A.M.; Tan, E.C.; Inman, D.; Langholtz, M.H.; Eaton, L.M.; Jacobson, J.J.; Wright, C.T.; Muth, D.J., Jr.; Wu, M.M.; Chiu, Y.W. Investigation of biochemical biorefinery sizing and environmental sustainability impacts for conventional bale system and advanced uniform biomass logistics designs. Biofuels Bioprod. Biorefining 2013, 7, 282–302. [Google Scholar] [CrossRef] [Green Version]