Parametric Approach to Simplified Life Cycle Assessment of Social Housing Projects

Abstract

:1. Introduction

1.1. Bamboo Construction

1.2. Life Cycle Assessment (LCA)

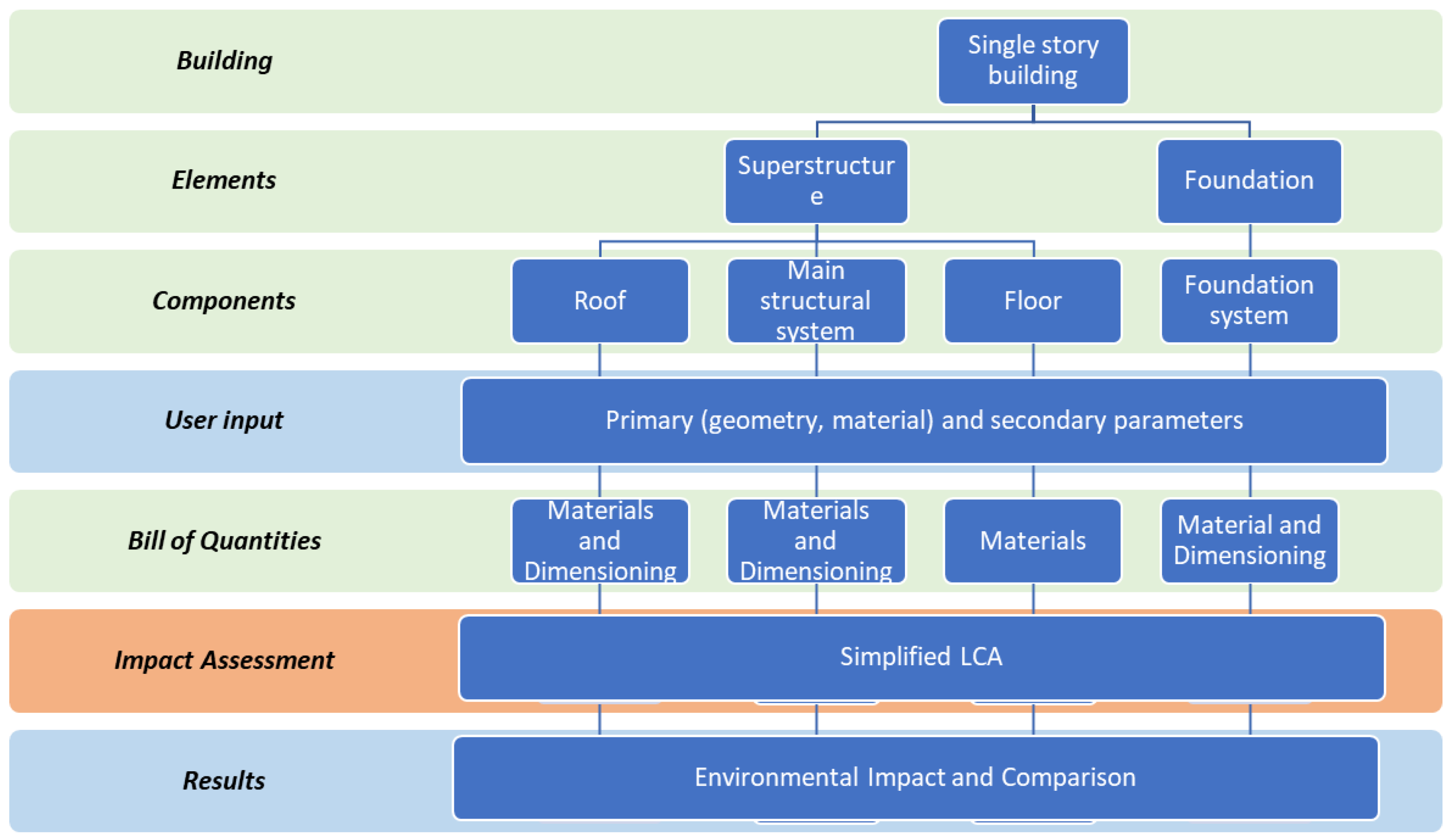

1.3. Parametric LCA

2. Materials and Methods

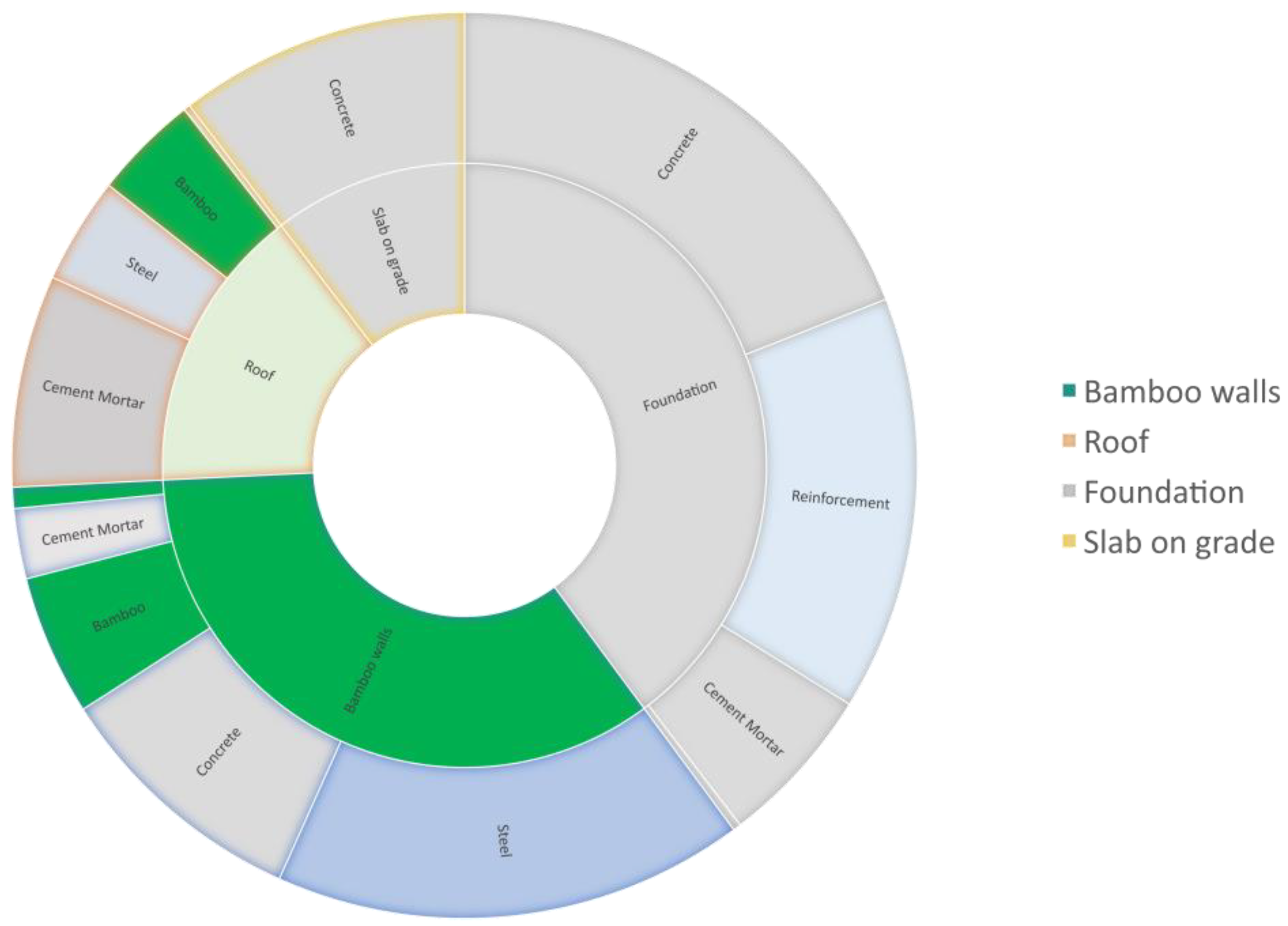

2.1. Construction Systems and Materials

2.2. Input Parameters

2.3. Load Calculation

2.4. Cement Bamboo Frame Building Structural Calculations

2.5. Concrete-Brick Building Structural Calculations

2.6. Simplified Life Cycle Assessment

2.7. Case Study

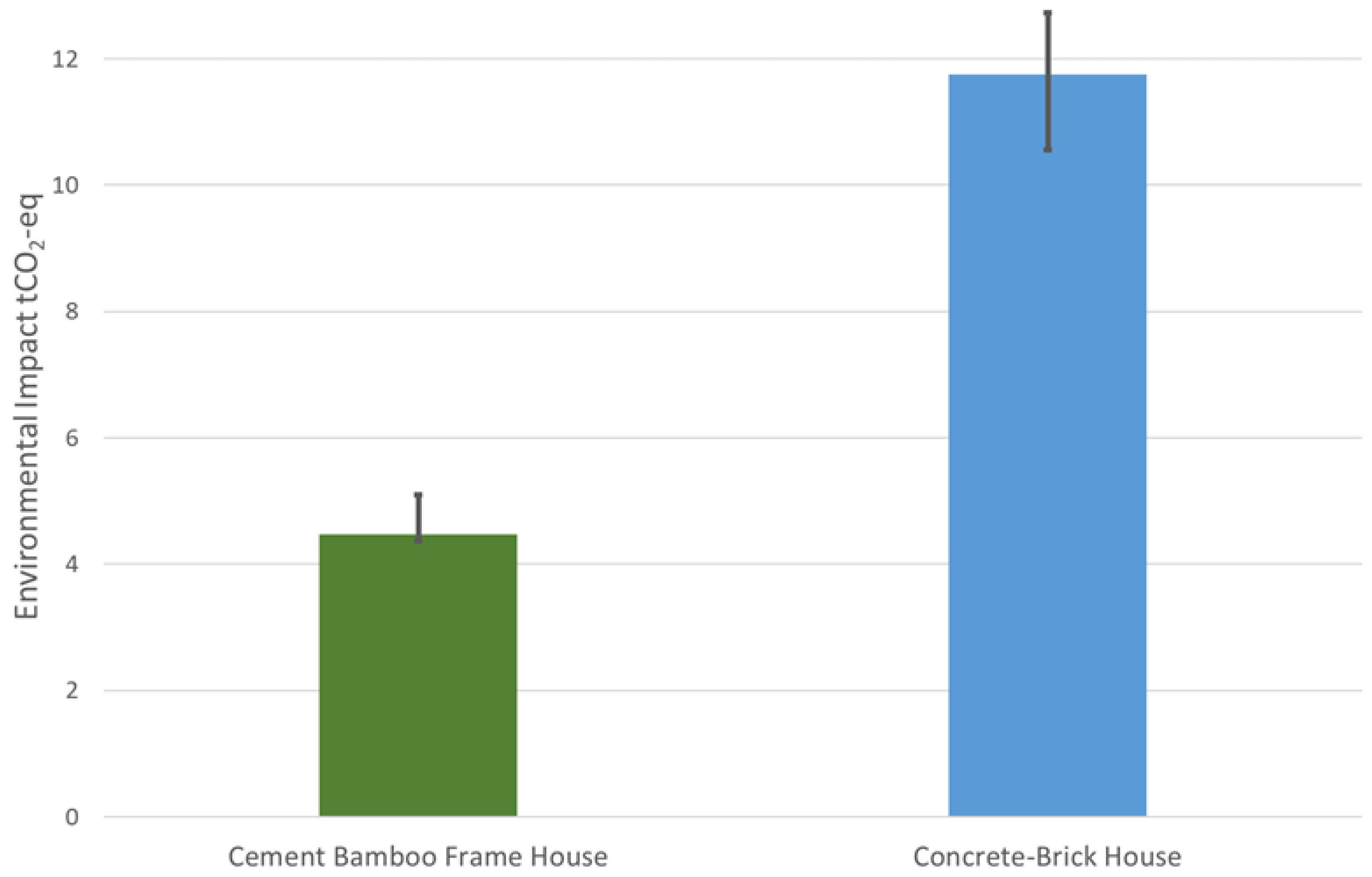

3. Results and Discussion

3.1. Basic Parameters

3.2. Advanced Parameters

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Desa, U. Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2016. [Google Scholar]

- Sachs, J.; Schmidt-Traub, G.; Kroll, C.; Lafortune, G.; Fuller, G.; Woelm, F. The Sustainable Development Goals and COVID-19. Sustainable Development Report 2020; Cambridge University Press: Cambridge, UK, 2020. [Google Scholar]

- Hollberg, A.; Ruth, J. LCA in architectural design—A parametric approach. Int. J. Life Cycle Assess. 2016, 21, 943–960. [Google Scholar] [CrossRef] [Green Version]

- Prinz, G.S.; Nussbaumer, A. On fast transition between shelters and housing after natural disasters in developing regions. In Technologies for Sustainable Development; Springer: Berlin, Germany, 2014; pp. 225–235. [Google Scholar]

- Salzer, C.; Wallbaum, H.; Lopez, L.; Kouyoumji, J. Sustainability of Social Housing in Asia: A Holistic Multi-Perspective Development Process for Bamboo-Based Construction in the Philippines. Sustainability 2016, 8, 151. [Google Scholar] [CrossRef] [Green Version]

- Zabalza Bribián, I.; Valero Capilla, A.; Aranda Usón, A. Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Huang, B.; Xing, K.; Ness, D.; Liao, L.; Huang, K.; Xie, P.; Huang, J. Rethinking carbon–neutral built environment: Urban dynamics and scenario analysis. Energy Build. 2022, 255, 111672. [Google Scholar] [CrossRef]

- Gabel, M. Regenerative Development: Going Beyond Sustainability. 2015. Available online: http://www.kosmosjournal.org/article/regenerative-development-going-beyond-sustainability (accessed on 15 October 2021).

- Zea Escamilla, E.; Habert, G.; Correal Daza, J.; Archilla, H.; Echeverry Fernández, J.; Trujillo, D. Industrial or Traditional Bamboo Construction? Comparative Life Cycle Assessment (LCA) of Bamboo-Based Buildings. Sustainability 2018, 10, 3096. [Google Scholar] [CrossRef] [Green Version]

- Salzer, C.; Wallbaum, H.; Ostermeyer, Y.; Kono, J. Environmental performance of social housing in emerging economies: Life cycle assessment of conventional and alternative construction methods in the Philippines. Int. J. Life Cycle Assess. 2017, 22, 1785–1801. [Google Scholar] [CrossRef] [Green Version]

- Kaminski, S.; Lawrence, A.; Trujillo, D. Structural use of bamboo. Part 1: Introduction to bamboo. Struct. Eng. 2016, 94, 40–43. [Google Scholar]

- INBAR. Vernacular Bamboo Architecture: Tradition or Future? In Bamboo and Rattan Update (BRU); INBAR: Beijing, China, 2021. [Google Scholar]

- Zea Escamilla, E.; Habert, G. Environmental impacts of bamboo-based construction materials representing global production diversity. J. Clean. Prod. 2014, 69, 117–127. [Google Scholar] [CrossRef]

- Sharma, B.; Gatoo, A.; Bock, M.; Mulligan, H.; Ramage, M. Engineered bamboo: State of the art. Constr. Mater. 2015, 168, 57–67. [Google Scholar] [CrossRef] [Green Version]

- Lorenzo, R.; Godina, M.; Mimendi, L.; Li, H. Determination of the physical and mechanical properties of moso, guadua and oldhamii bamboo assisted by robotic fabrication. J. Wood Sci. 2020, 66, 1–11. [Google Scholar] [CrossRef]

- Mimendi, L.; Lorenzo, R.; Li, H. An innovative digital workflow to design, build and manage bamboo structures. Sustain. Struct. 2022, 2, 000011. [Google Scholar]

- Cardona, O.; López Muñoz, L.F.; Prieto, S.; Farbiarz, J.; Granada, C.; Gómez, C.M.; Rodríguez, J.D.; Cortés, G.; Castañeda, C. Assessment Manual for Rehabilitation and Reinforcement of Traditional Bahareque Houses Built before the Building Code 052 of 2002; Seismic Engeniering Colombian Association (AIS): Bogotá, Colombia, 2002. [Google Scholar]

- AIS. Colombian Code for Seismic Design and Construction, NSR-10; AIS: Bogotá, Colombia, 2004. [Google Scholar]

- ISO 22156:2021; Bamboo Structures—Bamboo Culms—Structural Design. ISO: London, UK, 2021.

- Amede, E.A.; Hailemariama, E.K.; Hailemariam, L.M.; Nuramo, D.A. A Review of Codes and Standards for Bamboo Structural Design. Adv. Mater. Sci. Eng. 2021, 2021, 4788381. [Google Scholar] [CrossRef]

- Hellweg, S.; Mila i Canals, L. Emerging approaches, challenges and opportunities in life cycle assessment. Science 2014, 344, 1109–1113. [Google Scholar] [CrossRef] [PubMed]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: London, UK, 2007.

- CSN EN 15978; Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method. SIST: Ljubljana, Slovenia, 2011.

- Baumann, H.; Tillman, A.-M. The Hitch Hiker’s Guide to LCA; Studentlitteratur AB: Lund, Sweden, 2004. [Google Scholar]

- Fnais, A.; Rezgui, Y.; Petri, I.; Beach, T.; Yeung, J.; Ghoroghi, A.; Kubicki, S. The application of life cycle assessment in buildings: Challenges, and directions for future research. Int. J. Life Cycle Assess. 2022, 27, 627–654. [Google Scholar] [CrossRef]

- Ciroth, A.; Recanati, F.; Arvidsson, R. Principles of Life Cycle Inventory Modeling: The Basic Model, Extensions, and Conventions. In Life Cycle Inventory Analysis; Springer: Berlin, Germany, 2021; pp. 15–51. [Google Scholar]

- Bueno, C.; Hauschild, M.Z.; Rossignolo, J.A.; Ometto, A.R.; Mendes, N.C. Sensitivity analysis of the use of Life Cycle Impact Assessment methods: A case study on building materials. J. Clean. Prod. 2016, 112, 2208–2220. [Google Scholar] [CrossRef] [Green Version]

- Zea Escamilla, E.; Habert, G. Method and application of characterisation of life cycle impact data of construction materials using geographic information systems. Int. J. Life Cycle Assess. 2016, 22, 1210–1219. [Google Scholar] [CrossRef] [Green Version]

- Basic, S.; Hollberg, A.; Galimshina, A.; Habert, G. A Design Integrated Parametric Tool for Real-Time Life Cycle Assessment–Bombyx Project. IOP Conf. Ser. Earth Environ. Sci. 2019, 323, 012112. [Google Scholar] [CrossRef]

- Hollberg, A.; Tschetwertak, J.; Schneider, S.; Habert, G. Design-Integrated LCA Using Early BIM. In Designing Sustainable Technologies, Products and Policies; Springer: Cham, Switzerland, 2018; pp. 269–279. [Google Scholar]

- Hollberg, A.; Kiss, B.; Röck, M.; Soust-Verdaguer, B.; Wiberg, A.H.; Lasvaux, S.; Galimshina, A.; Habert, G. Review of visualising LCA results in the design process of buildings. Build. Environ. 2021, 190, 107530. [Google Scholar] [CrossRef]

- Hollberg, A.; Ebert, M.; Schütz, S.; Cicek, B.; Gumpp, R.; Ruth, J. Application of a parametric LCA tool in students’ design projects. In Proceedings of the Sustainable Built Environment SBE16, Hamburg, Germany, 7–11 March 2016. [Google Scholar]

- Hollberg, A.; Kaushal, D.; Basic, S.; Galimshina, A.; Habert, G. A data-driven parametric tool for under-specified LCA in the design phase. IOP Conf. Ser. Earth Environ. Sci. 2020, 588, 052018. [Google Scholar] [CrossRef]

- Tam, V.W.; Zhou, Y.; Illankoon, C.; Le, K.N. A critical review on BIM and LCA integration using the ISO 14040 framework. Build. Environ. 2022, 213, 108865. [Google Scholar] [CrossRef]

- ASEP. National Structural Code of the Philippins 2015; ASEP: Quezon City, Philippines, 2015. [Google Scholar]

- EN 1995-1-1:2002; Eurocode 2: Design of Concrete Structures-Part 1-1: General Rules and Rules for Buildings. CEN: Brussels, Belgium, 2002.

- Ecoinvent. EcoInvent Database. Available online: http://www.ecoinvent.org (accessed on 15 October 2021).

- Edenhofer, O.; Pichs-Madruga, R.; Sokona, Y.; Farahani, E.; Kadner, S.; Seyboth, K. Climate Change 2014: Mitigation of Climate Change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

| Property | Symbol | Bamboo | Wood (50% Stress Grade) |

|---|---|---|---|

| Compression strength parallel to the grain | fc,o,adm | 8 | 6.54 |

| Bending strength | fm,adm | 7.7 | 10.3 |

| Shear strength | fv,adm | 8 | 1.69 |

| Tension strength parallel to the grain | ft,o,adm | 27 | - |

| Tension strength perpendicular to the grain | ft,90,adm | 0.09 | - |

| Modulus of elasticity—mean | Emean | 15,500 | - |

| Modulus of elasticity—5th percentile | Emin | 13,500 | 2910 |

| Material | ||

| Concrete strength | fc′ = 20 | MPa |

| Steel quality | Grade 40 | - |

| Roof | ||

| Roof type—choice 1 | Gable | |

| Roof angle | 30 | degrees |

| Foundation | ||

| f (length below the soil) | 0.6 | m |

| Soil permissible stresses | 50 | |

| Loads | ||

| Additional surcharge (concrete) | 1 | kPa |

| Additional surcharge (bamboo) | 0 | kPa |

| Roof live load | 0.6 | kPa |

| Input for Earthquake Force Calculations | ||

| Soil profile | SC—very dense soil and soft rock | - |

| Seismic zone | 4—rest | - |

| Seismic source type | A—7 ≤ M ≤ 8.4 | - |

| Input for Wind Force Calculations | ||

| Wind speed | 250 | kph |

| Exposure category | B | - |

| Structural Materials | Unit Weight | Unit |

| Concrete | 25 | kN/m3 |

| Cement Mortar | 1900 | kg/m3 |

| Steel | 7850 | kg/m3 |

| Fired Clay Bricks | 741 | kg/m3 |

| Wood | 5.4 | kN/m3 |

| Bamboo | 7 | kN/m3 |

| Non-Structural Materials | Unit Weight | Unit |

| G.I. Sheets | 0.0314 | kN/m2 |

| 100-mm CHBs | 3 | kN/m |

| Riblath (per 20 sheets) | 25 | kg |

| Primary Parameters | ||

| lx (parallel to building ridge––if existent) | 5.7 | m |

| ly (normal to building ridge––if existent) | 4.8 | m |

| Number of external doors (1 × 2.1) | 2 | - |

| Number of windows (0.9 × 1.2) | 5 | - |

| Minimum height (height of the walls) | 2.8 | m |

| Construction system | CBF/Concrete-Brick | |

| Interior separations | 5 | - |

| Secondary Parameters | ||

| Material | ||

| What is the concrete strength? | fc′ = 25 | MPa |

| What is the steel quality? | Grade 30 | - |

| Roof | ||

| Roof Type––Choice 1 | No slope | |

| Roof angle | 30 | ° |

| Foundation | ||

| f (length under soil) | 0.9 | m |

| Soil permissible stresses | 30 | |

| Loads | ||

| Additional surcharge (concrete) | 2 | kPa |

| Additional surcharge (bamboo) | 0 | kPa |

| Roof live load | 0.6 | kPa |

| Input for earthquake force calculation | ||

| Soil profile | SE-Soft Soil | - |

| Seismic zone | 4—rest | - |

| Seismic zource type | A—7 ≤ M ≤ 8.4 | - |

| Distance to seismic source (km) | 35.1 | km |

| Input for the wind’s force calculation | ||

| Wind speed (Wind. Map Figure 207A.5-1A, B or C) | 340 | kph |

| Exposure category | B |

| Parameter | Contribution to the Variability | Difference Variation |

|---|---|---|

| Geometry (lx, ly) | Very high | 90% |

| Concrete roof type | Very high | 95% for large geometries |

| Steel quality | High | 45% |

| Interior walls (rooms) | Moderate | 6–10% |

| Doors and windows | Moderate | 10% |

| Height | Moderate | 15% |

| Concrete quality | Moderate | 8% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eleftheriou, E.; Lopez Muñoz, L.F.; Habert, G.; Zea Escamilla, E. Parametric Approach to Simplified Life Cycle Assessment of Social Housing Projects. Sustainability 2022, 14, 7409. https://doi.org/10.3390/su14127409

Eleftheriou E, Lopez Muñoz LF, Habert G, Zea Escamilla E. Parametric Approach to Simplified Life Cycle Assessment of Social Housing Projects. Sustainability. 2022; 14(12):7409. https://doi.org/10.3390/su14127409

Chicago/Turabian StyleEleftheriou, Eleni, Luis Felipe Lopez Muñoz, Guillaume Habert, and Edwin Zea Escamilla. 2022. "Parametric Approach to Simplified Life Cycle Assessment of Social Housing Projects" Sustainability 14, no. 12: 7409. https://doi.org/10.3390/su14127409

APA StyleEleftheriou, E., Lopez Muñoz, L. F., Habert, G., & Zea Escamilla, E. (2022). Parametric Approach to Simplified Life Cycle Assessment of Social Housing Projects. Sustainability, 14(12), 7409. https://doi.org/10.3390/su14127409