1. Introduction

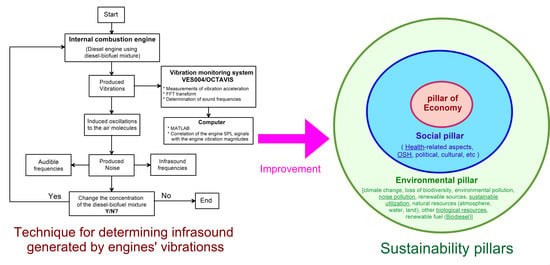

“Sustainability” constitutes a societal target that is analyzed in three pillars (or dimensions), the environmental, social, and economic ones. A similar concept is that of “sustainable development”, and thus, both terms are usually used synonymously. Moreover, there is a distinction between the two terms, wherein “sustainability” is repeatedly thought of as a long-term objective, while “sustainable development” is associated with many procedures and pathways to achieve it. The relationship among the three pillars of sustainability is indicated frequently by a diagram, emphasizing a hierarchy consisting of three concentric circles representing the three pillars, in which “economy” covers the internal circle, the “environment” covers the external one, and “society” covers the intermediate one (see

Figure 1).

It is easily comprehensible that the pillar of “economy” occupies the central position in the hierarchy and constitutes the common base and reference of the other two “sustainability” pillars. What is more, it is noticed that both “economy” and “society” are constrained by the limits of the “environment” pillar.

The most dominant issues associated with the environmental dimension of sustainability, since the year 2000, are climate change, loss of biodiversity, and environmental pollution (like noise pollution). In addition, the sustainable utilization (i.e., the proper management) of natural resources (such as atmosphere, water, land), renewable fuels (like biodiesel and other biofuels), and additional biological resources is vital for the benefit of the entire human community. However, the development of global science and technology has, as a consequence, recognized the environmental problems and energy crisis to be crucial issues. For instance, engine emissions, which directly or indirectly lead to these problems, have become the focus of significant parts of research [

1]. Thus, it is a very important and also inevitable task to improve the performance of diesel engines and reduce their emission of polluting gases, by the development and usage of alternative fuels (e.g., biofuels) [

2]. In other words, the main objective of “sustainable development” is to provide resources for the present generations without threatening the needs of the future ones.

In the frame of the environmental pillar of sustainability, “biofuel” is any fuel that is derived from biomass (e.g., plant, algae material, or animal waste), and furthermore, “biodiesel” is a renewable fuel that is produced from vegetable oils and fat tissues. Since such feedstock material can be replenished easily, “biofuel” constitutes a source of renewable energy, dissimilar to fossil fuels (e.g., petroleum, coal, and natural gas). When “biodiesel” is mixed with diesel fuel, it can be used in internal-combustion engines, while one considerable advantage is its lower pollution compared to diesel fuels.

Continuing this, “noise pollution”, also known as “sound pollution”, is the propagation of noise (i.e., of sound waves covering the infrasound, audible, and ultrasound spectra of frequencies) with ranging impacts on the activity of humans (e.g., of employees) or animals, with most of them being hurtful to a significant quantity. Noise pollution is normally determined as permanent exposure to high sound levels, which may lead to adverse effects in humans or other living organisms.

The source of outdoor noise worldwide is mainly caused by machines, vehicles, and transport systems. Bad urban planning can give rise to noise disintegration, while side-by-side industrial and residential buildings can result in noise pollution in the residential areas. Moreover, some of the foremost sources of noise in the occupational workplaces include vehicles, tractors, other internal-combustion engines, electrical generators, a variety of industrial machines and installations (e.g., cleaning baths, several productive machines, cutting machines, and low-speed machinery), et cetera.

Finally, as far as the social pillar of sustainability is concerned, an ordinary definition is that a “socially sustainable” society should ensure that people are not impeded by any type of obstacles in the areas of health, occupational safety, influence, and competence. “Social sustainability” substantially encompasses all human activities, and it is thought to lead to viable communities, which would be equitable and diverse, providing a high quality of life. Wide-based strategies for more sustainable social systems include, among other issues, high-quality education and high-level health-related aspects of sustainability. Occupational accidents have a key impact upon human probity, create high expenses for the social health/insurance system of any country, and deteriorate the sustainability of societies. In addition, occupational “health and safety” is one of the most vital issues in any organization because it assures its continual operation, productivity, and efficiency. It is known that any occupational accident or illness can affect both the employee and the business operation and, also, the overall sustainability performance of firms. Each organization is steadily more concerned with improving sustainability and OSH performance, and this is achieved by controlling sustainability and OSH risks, in accordance with their sustainability and OSH policy and in the context of strict legislation. There are plenty of organizations which apply sustainability and OHS reviews (or audits) to assess their sustainability and OHS performance.

Keeping with this, infrasound (infrasonic) noise (i.e., sound waves with frequencies below the lower limit of ~20 Hz of human audibility) and audible (up to ~20 kHz) noise are very considerable threats in each day of human life, especially in occupational workplaces. According to the scientific literature, noise is one of the most significant hazard sources in workplaces and working environments in general, due to the generated dangers that offend human health [

3,

4,

5,

6]. Moreover, the ESAW’s taxonomy (i.e., the European Statistics on Accidents at Work, by EUROSTAT), as far as the sources of danger are concerned, considers the whole spectrum of noise as one of the noteworthy occupational sources of danger [

7].

Humans that are involved in various environments that include machines and relate to sustainable engineering projects, such as occupational environments with any kind of vehicle (of all types of transportation),vibration machines, industrial productive machines, and factories, as well as on wind turbine sites, are subject to multiple-sourced noise [

8]. The main feature is high alterability of exposure to noise at the occupational safety and health (OSH) workplace wherein a machine works, both indoors and outdoors.

As such, cars are the most commonly used vehicles in everyday life and one of the most distinguished origins of noise in urban areas. The hearable level of noise that the operators perceive has been decreased due to remarkable technical evolution in the last decades. Many scientists have found that the noise produced from engines of old car models considerably exceeds noise exposure limits and possibly procures great risk of noise-procured hearing damage [

9]. Much research has mentioned that the average daily exposure level to hearable noise in the operator’s position in all kinds of racing cars was between 89.6 and 96.6 dB-A [

10]. There are two methods of noise reduction in vehicle cabs, “active” (decrease of hearable noise produced by the car engine motor) and “passive” (a comfortable cabs framework provides limited exposure for the driver) [

8,

9,

11]. The level of noise is paradoxically lower inside the cab of operation than outside. The method of measurement was defined by the Authority of the European Union Directives (Directive, 2009).

The level of noise that is produced by engines significantly varies in vehicles and relies on many characteristics, comprising the kind and horse power of the engine, as well as the type of cab being investigated, due to a diversity in the noise level associated with a certain working load (rpm) in progress, which can be ascribed to the individual load of engines, vehicle speeds, and the driver’s skills [

12,

13]. The chassis’ vibrations can cause failure of the vestibulocochlear nerve. It can also take action in the cooperative interaction with noise for the possible development of noise-effect hearing loss [

12,

13].

Except from audible noise, vehicle engine motors are infrasound sources. Infrasound (sometimes mentioned as low-frequency noise) is constituted by sound waves or acoustic oscillations with frequencies below the lower limit of human audibility (about ~16 Hz or, more usually, ~20 Hz, according to the British-Standard BS4727-3:1995 and the IEC standard 60050-81:1994) [

14,

15]. According to the publication of G. Leventhall [

16], the popular theory that noise below ~20 Hz is inaudible is inaccurate, because the audibility threshold (or hearing threshold) has been measured (for some people) down to ~1.5 Hz.

The sense of hearing becomes slowly less sensitive as frequency reduces; therefore, in order for humans to apprehend the infrasound, the sound pressure should be considerably high. The ear is the main organ for feeling infrasound, but at a higher pressure, it is likely for a person to sense the vibrations from infrasound in many human body organs. The exposure to infrasound levels produced by a variety of vehicles has been examined in last decades but without providing any analysis regarding the exposure to infrasound risk [

17].

Until now, there have only been a few cases of research regarding infrasound noise affecting the vehicles and their drivers.

The research of Paschhold and Mayton [

12] revealed that vibrations, which are subjected the human body, demand the “dispatch” of energies in a frequency range between ~0.5 and ~80 Hz. The frequency range of ~20–~100 Hz is usually related with the definition of the conception of physical sources. Sometimes, many people, during the best weather conditions and specific intervals of day, are subjected to frequencies between ~20 Hz and ~40 Hz, related with the jet drift about 10 km overhead [

18].

The studies of Solecki in 1998 [

19] and Solecki and Leszek [

20,

21] showed that infrasonic frequencies can unfavorably affect the human body’s respiratory and cardiovascular systems. Furthermore, they found that the highest values of vibrations measured in the operator seats of agricultural vehicles remained mostly close to 15 Hz, equal to the resonance frequencies for different human body organs, such as the digestive system, chest, and diaphragm [

22,

23,

24,

25].

According to the publication of G. Leventhall [

16], low-frequency noise complaints’ inquiries oftentimes fail to measure any considerable noise. This has led some complainants to deduce that their awareness comes from non-acoustic waves (e.g., electromagnetic radiation). Besides, in the past 40 years, low-frequency sounds have attracted significant unfavorable publicity about their influence on health, relying primarily on media misunderstandings and overemphasis. Thus, one result coming from this exaggeration is that the public has a one-dimensional view of infrasound noise, associated only with its presence, whilst ignoring its low levels and dangers [

16].

Nowacki et al. [

17] focused on the infrasound waves and the symptoms that cause them during the driving procedure. More specifically, they investigated the reverberations that appeared in a plethora of vehicles in Poland’s urban areas, where they found that infrasound noise close to 5 Hz procured sleepiness, headaches, pressure ears, heart action disruptions, and respiratory system problems.

Bilski [

8] accomplished research on infrasound frequencies, which were produced during the operation of an agricultural tractor. The results showed that the highest noise levels were found at frequencies of ~250 Hz, ~1 kHz, and ~2 kHz. The study also concluded that the operator was considerably exposed to infrasound noise during the motion of the agricultural tractor.

Moreover, possible factors that can affect vibration, and thereafter generate infrasound noise, are the oxygen percentage in fuel compounds, together with the process of spraying and fuel injection [

26,

27,

28,

29,

30]. In the work of Taghizadeh-Alisaraei et al. [

31], there was a vibration analysis of a diesel engine using biodiesel and diesel fuel blends, wherein the results showed that the levels of the engine vibration varied considerably, in a way consistent with the composition of the fuel mixture.

On the other hand, there have been many studies, like the one in [

6], about the possible effects on health from ultrasound exposure. Ultrasound is transmitted into the air by a variety and different kinds of machines [

32,

33,

34]. Furthermore, several machines transmit ultrasound noise directly, and some others produce it as a by-product of primary operations [

34,

35].

In this study, the oscillation frequency of the sound source was examined, and conclusions could be drawn about the frequencies of the sound signals produced and their effects on human health and safety, concerning the people that are exposed to the corresponding produced sound waves. In this way, by measuring the frequency of the sound source and not its effects, such as the frequencies generated from the sound waves, the effect of the sound waves of the environment (i.e., the echo effect) was avoided, simplifying the presented approach. Thus, this work presents the investigation of possible infrasound originating from a diesel engine motor functioning with different proportions of biodiesel.

Taking into account that one of the significant objectives of sustainable engineering concentrates on the systems’ operation in a way that allows sustainable utilization of resources (like biofuels), the manner in which an engineering project achieves its sustainability aim is implemented by emphasizing, along with other issues, sustainable living, for example, the fulfillment of high-level health. In addition, the “Occupational Safety & Health Administration” (OSHA) accepts that measures to ensure OSH can be incorporated into sustainability actions and take advantage of the dynamics of sustainability to make every workplace healthier and safer.

Hence, this study tries to cover a “gap” in the scientific literature, which regards possible effects on OSH due to infrasound noise generated from a diesel engine (operating with various fuel blends and in diverse biodiesel proportions), under the view of the three “sustainability” dimensions. Its novelty is accomplished (i) through a suggested technique of estimating the infrasound consequences to employees’ health in the work environment and occupational safety, because of the vibrations of biodiesel engines (functioning with a variety of biofuel mixtures) and (ii) through the positive impact on the three “sustainability” pillars (economy, social, and environmental) in sustainable engineering projects and other enterprises.

The article’s composition is structured by the subsequent sections: (1) introduction, (2) technical overview of the experimental system and materials, (3) presentation of the experimental method and the new suggested technique, (4) measurements and results, (5) discussion of key topics, and (6) conclusions.

3. The Experimental Method

Analysis of measurements through FT, DFT, and FFT: Taking into account that there is a significant difficulty with measuring infrasound due to the lack of “appropriate measuring instruments”, this equipment deficiency can be overcome by the measurement of the engine’s oscillating behavior, using an efficient accelerometer (the VES004-OCTAVIS system), placed on the specific engine (i.e., on the sound source) that produces the infrasound. More particularly, the engine’s vibrations induce oscillations in the air molecules, and as a result, a noise is produced, which includes infrasound frequencies. Thus, by this way, the engine SPL (sound pressure level) signals can be correlated with the engine oscillation (or vibration) magnitudes, and also, the issue of the absence of an anechoic chamber can be overcome (in the case of intending to make acoustic intensity measurements by a sound meter).

It is noted that the main noise emitted by diesel engines is related to the combustion process (in-cylinder pressure rise), and it was taken into account in the study, as well the effect of biodiesel/diesel blends on cylinder pressure rise, which is significant as well.

Figure 4 illustrates the experimental layout (or set-up) for obtaining the engine’s vibration measurements (panel ‘a’) and also captures the wires, electrodes, and the connectors on the diesel engine for the conducted experiment (panel ‘b’). Furthermore,

Figure 5 depicts the flow chart of the technique which was used to determine the infrasound and audible sound frequencies.

The engine was operated in 850, 1150, and 2000 rpm and without load. The expansion of this research is planned to be attained by an experimental device using an engine with specific loads, due to the fact that the combustion is very sensitive to the engine’s load.

It is clarified that the number of 850 rpm is very close to the minimum rpm of the used engine. On the other hand, at 2000 rpm, the engine presents its maximum torque, which constitutes its optimal operation for constant speed and, therefore, results in its most economical operation. More particularly, the torque itself expresses a characteristic of the engine but not of the performance of the vehicle. One such feature can be the intensity of combustion, and accordingly, near the maximum value of the torque, the optimal fuel economy is achieved. The selection of 1150 rpm ensured that the engine oscillation could cover (apart from the audible spectrum) the infrasound one (<20 Hz). For instance, an oscillated sound source with a frequency of 19 Hz (which corresponds to infrasound noise) produces pulsations with 19 × 60 = 1140 c/s (rpm). In this way, by measuring the frequency of the sound source and not of its sound effects (i.e., the frequencies of the generated sound waves), we avoided the sound waves’ effect of the environment and, consequently, simplified our study (echo effect).

Current measurements were made in two different states, on the diesel engine motor and inside the cabin. The results were related to measurements that were acquired on the different rotations per minute (rpms) as a time function. The usage of a Fourier Transform (F.T.) was necessary to transform the signal from the time domain to the frequency domain, in order to depict deductions regarding the relation frequency and the acceleration of the rolling relationship engine.

The F.T. is a mathematical transform that decomposes functions depending on space or time into functions depending on spatial frequency or temporal frequency [

37,

38]. Moreover, the F.T. of a function is a complex-valued function, representing the complex sinusoids that constitute the original function. For each frequency, the magnitude (absolute value) of the complex value represents the amplitude of a constituent complex sinusoid with that frequency, and the argument of the complex value represents that complex sinusoid’s phase offset. If a frequency is not present, the transform has a value of zero for that frequency. The F.T. is not limited to functions of time, but the domain of the original function is commonly referred to as the time domain. In addition, the F.T. is applied on a signal when it is not perfectly periodical and, mostly, when the period reaches to infinity. The fundamental equation that describes the Fourier transform of a random function

f(

t) is:

The Discrete Fourier (DFT) is an essential part in signal analysis and is one of the basic tools in digital signal processing. It is focused on the analysis of:

Discrete real-time functions of finite length.

Distinct real functions of fixed periodicity.

Distinct complex finite-length functions.

Distinct complex functions of specified periodicity.

In this research, a Fast Fourier Transform (FFT) was used to accelerate the calculations, and for this reason, the MATLAB software was the tool for converting the signals from the time domain to frequency spectrum [

37,

38].

4. Measurements and Results

The measurements which are displayed in the following figures constitute the outcomes of the FFT process of the signals, as they were measured in correlation to time and, after the FFT, to functions that differ in terms of frequency. It is essential to note that the results of the produced noise were gathered in order to survey the consequence of the user impact.

The outcomes of

Figure 6a comprise a Fourier transform into frequency and show in the variety of frequencies in the local magnitudes of the oscillation range. More significant peaks at the lower frequencies and also smaller peaks at the higher frequencies are obvious. Especially, this figure depicts that when the engine worked at 850 rpm but used fuel in a proportion of 20% biodiesel and 80% diesel oil (B20-D80), it produced a dominant frequency close to 28 Hz (see panel “b”). This occurred due to the fact that other diesel cycle processes occurred, followed by enormous motion of the engine parts (piston hit, etc.)

In

Figure 7a, the graph shows that when the fuel was proportional to B20-D80 (20% biodiesel and 80% of diesel oil)and the engine worked at 1150 rpm, a frequency with a magnitude of 38.5 Hz was produced(see panel “b”). This was normal, because diesel oil together with biodiesel were combusted correctly in every cycle process of the diesel engine.

In

Figure 8a, the graph shows that although the fuel was proportional to B20-D80 (20% biodiesel and 80% of diesel oil), the engine produced a frequency very close to 20.8 Hz (see panel “b”) when it worked at 2000 rpm. This happened because mixed fuel was combusted faster in every cycle process of the diesel engine.

In

Figure 9a the graph depicts that when the fuel was proportional to B40-D60 (40% biodiesel and 60% of diesel oil) and the engine worked at 850 rpm, a frequency with a magnitude of 28.5 Hz (see panel “b”) was produced. This was caused because diesel oil together with biodiesel were combusted differently in every cycle process of the diesel engine.

In

Figure 10a, the graph provides information regarding the behavior of the engine when the fuel was proportional to B40-D60 (40% biodiesel and 60% of diesel oil) and functioned at 1150 rpm and produced frequencies close to 38.5 Hz (see panel “b”). This was caused because diesel oil together with biodiesel produced vibrations that derived from the combustion of mixed fuel diesel.

In

Figure 11a below, the graph shows that although the fuel was proportional to B40-D60 (40% biodiesel and 60% of diesel oil), the engine produced a frequency very close to 22.9 Hz (see panel “b”)when it functioned at 2000 rpm. This happened because mixed fuel was combusted faster and produced vibrations in every cycle process of the diesel engine.

In

Figure 12a, the graph depicts that when the fuel was proportional to B60-D40 (60% biodiesel and 40% of diesel oil) and the engine worked at 850 rpm, a magnitude of 28 Hz (see panel “b”) was produced. This was caused because diesel oil together with biodiesel were combusted differently in every cycle process of the diesel engine.

In

Figure 13a, the graph provides information regarding the behavior of the engine when the fuel was proportional to B60-D40 (60% biodiesel and 40% of diesel oil) and functioned at 1150 rpm and produced frequencies close to 38.2 Hz(see panel “b”). This was caused because diesel oil together with biodiesel produced vibrations that were derived from the combustion of mixed diesel fuel.

In the

Figure 14a, the graph shows that although the fuel was proportional to B60-D40 (60% biodiesel and 40% of diesel oil), the engine produced frequencies very close to 20.3 Hz (see panel “b”) when it functioned at 2000 rpm. This happened because the mixed fuel was combusted faster and, in addition, produced vibrations in every cycle process of the diesel engine.

Figure 15 adepicts that when the engine worked at 850 rpm but used fuel in a proportion of 80% biodiesel and 20% of diesel oil (B80-D20), it produced a frequency close to 28.2 Hz (see panel “b”).This happened because the diesel cycle processes took place and evolved along with intense movement of the mechanical parts.

In

Figure 16a, the graph shows that when the fuel was proportional to B80-D20(80% biodiesel and 20% of diesel oil) and the engine worked at 1150 rpm, a frequency with a magnitude of 38.2 Hz (see panel “b”)was produced. This result was normal, because diesel oil together with biodiesel combusted correctly in every cycle process of the diesel engine, which produced vibrations that were close to the frequency of 38 Hz.

In the

Figure 17a, the graph shows that although the fuel was proportional to B80-D20 (80% biodiesel and 20% of diesel oil), the engine produced a frequency very close to 19 Hz (see panel “b”) when it functioned at 2000 rpm. This happened because mixed fuel was combusted faster and produced vibrations in every cycle process of the diesel engine, producing infrasound.

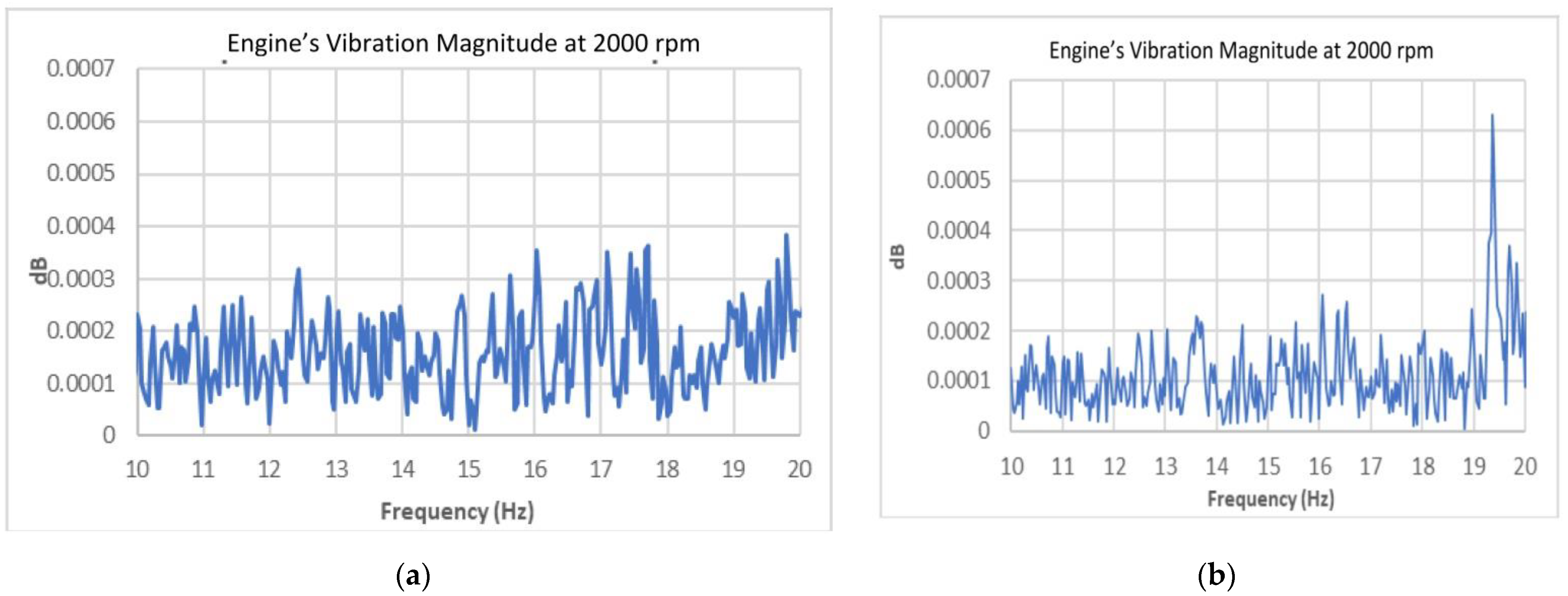

Figure 18 illustrates the signals produced by the FFT process, in a frequency range of 10–20 Hz and during the state of 2000 engine rpm, using (i) a biofuel mixture of B20-D80 (after zooming-in on the curve of

Figure 6b), and (ii) a biofuel mixture of B40-D60 (having zoomed-in on the curve of

Figure 9b), in order to unveil distinctly the existence of infrasound noise.

Taking into consideration that the dB range in the vertical axis of the above-referred figures was about 0–0.03 dB, and the fact that the typical averaged noise level (in dB) for diesel engines is around 100 dB, the reader could assume that there was a fault in the measurements and in their analyses. The explanation is that the curves of

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12,

Figure 13,

Figure 14,

Figure 15,

Figure 16,

Figure 17 and

Figure 18 do not illustrate the noise level (in dB) of the diesel-engine sound-source. On the contrary, the graphs illustrate the vibration magnitudes (in dB) that correspond to SPL (sound pressure level) signals of the engine sound source, recorded by the VES004-OCTAVIS system (and applying the FFT process), in the framework of using different engine rpms and various biofuel mixtures.

5. Discussion

In this section, the previous measurements/results and how they can be interpreted from the perspective of preceding studies and of the working hypotheses are discussed.

Sources of infrasound noise are included in the range from VLF (very low-frequency) atmospheric fluctuations up into the LF lower audio frequencies, and they comprise natural and environmental occurrences, signals from low-speed machinery and industrial installations, et cetera. This type of sound can produce a series of harmonic and sub-harmonic frequencies within the infrasound (and also, the audible range).

The ear of the human being is responsive to wave frequencies from ~20 Hz up to ~20 kHz, with a sound level magnitude from 0 dB up to 140 dB, and more specifically, it is more susceptible to mid-range frequencies and less receptive to high and low frequencies [

6]. It is ordinary to keep the frequency limits intended for audible sound amid ~20–~20,000 Hz, but on the other hand, these limits should be determined by the sensitivity of each individual [

6].

The numerous cellules from which a human body is comprised form a three-dimensional matrix, which depicts mechanical properties consisting of internal sound radiations and vibrations in a frequency spectrum between ~10 Hz and ~30 Hz [

39]. These cells display mechanical or acoustic pressures and forces, which are disseminated as signals across the ground or the air. Time alterations of mechanical forces are normally processed as sound signals, which excite the tympanum. Each time that the frequency tone decreases to below 100 Hz, it is encountered with less coherence until the frequency of 30 Hz, which is received periodically. The entry level frequency for tonal perception in the ear drum is ~20 Hz [

40]. As it has previously been referred to, the definition of “infrasound noise” focuses on the signals with frequencies below ~20 Hz, while “ultrasound” is defined as the sound with a frequency above ~20 kHz. From a biological point of view, the discrimination is not clear, but it can be varied from ~10 Hz to ~100 Hz. The energies which are included within audible signals are commonly not confined to a definition of a sinusoidal signal, but they are allocated across a frequency spectrum, because infrasound and low-frequency noises seem to provide a sequence on these two frequency domains [

24].

In frequency signals lower than ~100 Hz, the experiential results from vibration simulations in the ears and within the whole body seem to be akin. The sound, which is transferred through the air with adequate intensity, is absorbed from the human body by stimulating non-acoustic tissue (or an organ), which generates issues basically comparable to vibrations that cover the whole-body [

14]. The difference, which connects the human body’s mechanical vibration and the sound absorption, gets less significant as the frequency is decreased.

The noise generates negative counter actions on the nervous system, which are associated with abilities such as reading efficiency, awareness, problem solving, and memory. Moreover, noise seems to present a negative impact on children at school, mostly because it is difficult to adjust. Sometimes, it may also lead to increased levels of stress hormones and blood pressure at rest, as well as poor school performance of children. Previous studies found that most people cannot manage the noise exposure result, and some of them run a higher risk of bearing its noxious effects. According to the studies of Solecki in 1998 [

19] and Solecki and Leszek [

20,

21], infrasonic noise can adversely affect the human organization, and the high vibration values measured on the operator seats of agricultural vehicles remain mostly close to 15 Hz, equal to the resonance frequencies for different human body organs [

22,

23,

24,

25].

Taking into account the guidelines of NTP 205 “Ultrasound: Occupational Exposure” report by INSHT [

6,

41], the sources of ultrasound generation can be categorized in accordance with their frequencies, as (i) low frequency (LF: 10,000–100,000 Hz), for industrial applications; (ii) medium frequency (MF: (0.1–1.0 MHz), for therapeutic purposes; and (iii) high frequency (HF: 1.0–10 MHz), mostly used for medical applications and non-destructive control devices. Certainly, the sources with very low frequencies (VLF), lower than 20 Hz, constitute the infrasound spectrum of noise.

A plethora of workers, due to their jobs and occupations, are exposed daily (apart from audible sound waves) to the above-referred non-audible sound waves. Ultrasound exposure is normally used in the medical sector to get images (by ultrasound echography) and also in medical treatments. On the other hand, it would be very significant to investigate and specify (i) the possible effects of infrasound exposure on people (especially in the workplaces) and (ii) what limits humans can tolerate, before infrasound grows to become dangerous and harmful to their health. The research and the common practices in the work environment, and also in the field of occupational safety, constitute important issues in the scientific investigation for environmental health in workplaces, which is impacted by a variety of factors involving the effect of infrasound.

The main noise emitted by diesel engines is related to the combustion process (in-cylinder pressure rise), and it was taken into account in this study, and also, the effect of biodiesel/diesel blends on cylinder pressure rise have been studied in the literature. On the other hand, for first time in comparison with the scientific literature, the potential effects on human health in the Occupational Safety of sustainable engineering projects were examined through this study (by measuring the infrasound noise with the new proposed technique), in the framework of the usage of specific engine rpms (850, 1150, and 2000) and different biofuel mixtures (B20-D80, B40-D60, B60-D40, and B80-D20).

The theoretical background that was taken into account in the technique’s implementation was outlined as follows: Solid objects, which are oscillating around their equilibrium position and in direct contact with the ambient air, produce sound waves propagated in all directions. These waves cause small movements of the air molecules around the equilibrium position, and the frequency of this movement is the same in comparison with the frequency of the sound source. The oscillation direction of the molecules is the same as the propagation direction of the sound wave, so the acoustic waves are longitudinal waves. Therefore, by studying the oscillation frequency of the sound source, we could draw conclusions about the frequencies of the generated sound signals and their effects on the H_S&H of the people who are exposed to the corresponding sound waves that are produced.

The previously presented measurements showed that the usage of a significant percentage of biodiesel in the fuel mixture caused vibrations due to alterations in the engine’s bearing. Thus, the fuel blend meaningfully affected the generated noise frequencies. In other words, the experiments, and, consequently, the resulted measurements, showed that mixed fuels can produce frequencies that are close to infrasound (see

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12,

Figure 13,

Figure 14,

Figure 15,

Figure 16,

Figure 17 and

Figure 18, panels a,b). Besides, potential factors that can affect vibration, and, subsequently, generate infrasound frequencies, are the oxygen percentage in fuel compounds, together with the process of spraying and fuel injection [

26,

27,

28,

29,

30]. As specified by the graphs, whenever the biofuel proportion was increased, it caused infrasound production, with frequencies below 20 Hz (for instance, see

Figure 17b and

Figure 18a,b). According to the work of Chaitidis et al. [

26], increasing the biofuel content of the mixture leads to a reduced vibration energy. Furthermore, when the engine rpm rosed (

reduced), the energy of vibrations were decreased (

increased), and consequently, the generated infrasound phenomenon was lessened (

enhanced), as it could be inferred by the comparison between (i) the curves of the

Figure 6a,

Figure 7a and

Figure 8a; (ii) the graphs of the

Figure 9a,

Figure 10a and

Figure 11a; and (ii) the curves of the

Figure 12a,

Figure 13a and

Figure 14a. Hence, it was revealed that the greater the percentage of the biodiesel fuel amount and lower the engine’s rpm, the more frequent was the infrasound phenomenon.

Taghizadeh-Alisaraei et al. [

31] attained a vibration analysis of a diesel engine using biodiesel and diesel fuel blends, with their main result having been that the engine’s vibrations (e.g., the oscillation intensity) were dependent on the composition of the fuel mixture.

In the current study, the resultant measurements showed, for first time, that mixed fuels (diesel-biofuel) can produce noise frequencies that are close to the infrasound and audible areas. More explicitly, the fuel blend meaningfully affects the generated noise frequencies, due to the fact that the usage of a significant percentage of biodiesel in the fuel mixture causes vibrations, owing to alterations in the engine bearing. Moreover, these noise frequencies (and, particularly, the infrasound ones) present high interest, especially from the view point of sustainability, due to the potential effects on human safety and health in the field of OSH sustainable engineering projects. Besides, the sound’s effects on health are strongly dependent on the energies involved and on the substantial exposure of any employee.

Until now, the range of subsonic sound (infrasound) has not been measured and has not been considered by the OSH responsible (or officers). The insidious way that the infrasound appears during the engine operation but without being sensed by the drivers/operators/employees could cause them serious health problems. Although in the last decade, there has been an explicit technical improvement in the abatement of noise that vehicle drivers subjected to at the workplace, there have been no regulations regarding the infrasound produced, maybe due to a variety of fuels that can be combusted by a vehicle (Biodiesel, LPG, CNG).

The OSH visualization of the occupational workplaces (by examining the infrasound and audible noise frequencies generated by diesel engines and other industrial machines) could certainly help safety officers to (i) lessen (or eliminate) critical risk factors within the OSH field and (ii) more efficiently protect the employees, by taking the most essential safety measures. This probably will contribute to achieving an improved allotment of the limited financial resources and shrinking mortgage costs and support, allowing financial managers to have more available budget for implementing other risk-reduction projects. This corollary is valid in general, and so far, there is not a specified safety level (or threshold) regarding the infrasound effect, which could be considered as a safe threshold in the OSH field. However, infrasound detection measurements should be incorporated into OSH Sustainability Management Systems and occupational risk assessment protocols.

The novelty of this article is fulfilled (i) through the suggested technique of estimating the infrasound consequences to employees at workplaces and (ii) due to its positive impact on the “sustainability” pillars of sustainable engineering projects. This means that by evaluating the machine’s oscillating behavior through the usage of accelerometers (due to the lack of “appropriate measuring instruments”) on the engine (i.e., the source of the generated infrasound and audible noise), it is possible for the directors to upgrade the OSH and also to validate the sustainable operation (in its three dimensions of economy, society, and environment) of industrial and technical engineering projects, as well. Hence, the proposed technique contributes significantly to improve the total pillars of sustainability.

Some directions for future research are highlighted as follows:

A variety of machines and installations in industry transmit infrasound noise directly (for instance, cleaning baths, several productive machines, cutting machines, low-speed machinery, wind turbines, etc.), and many others generate it as a by-product of basic operations (for example, pressurized and air high-speed drills). Thus, a study that relies, on the one hand, on the scientific literature review and, on the other hand, on research by the usage of experimental measurements and results, in order to determine the effects on human safety health due to dangerous infrasound noises coming from such machines (e.g., industrial and productive machines/devices), could be very interesting.

The extension of this research is planned to be achieved by an experimental device using an engine with specific loads, due to the fact that the combustion is very sensitive to the engine’s load.

It is proposed that infrasound detection measurements and also the obligation (or requirement) of using specific signaling at workplaces concerning infrasound effects on H_S&H should be included in OSH Sustainability Management Systems [

42], such as OHSAS18001, ISO45001, etc, and in occupational risk assessment protocols.