Application of Cement Paste in Mining Works, Environmental Protection, and the Sustainable Development Goals in the Mining Industry

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Characterization Methods

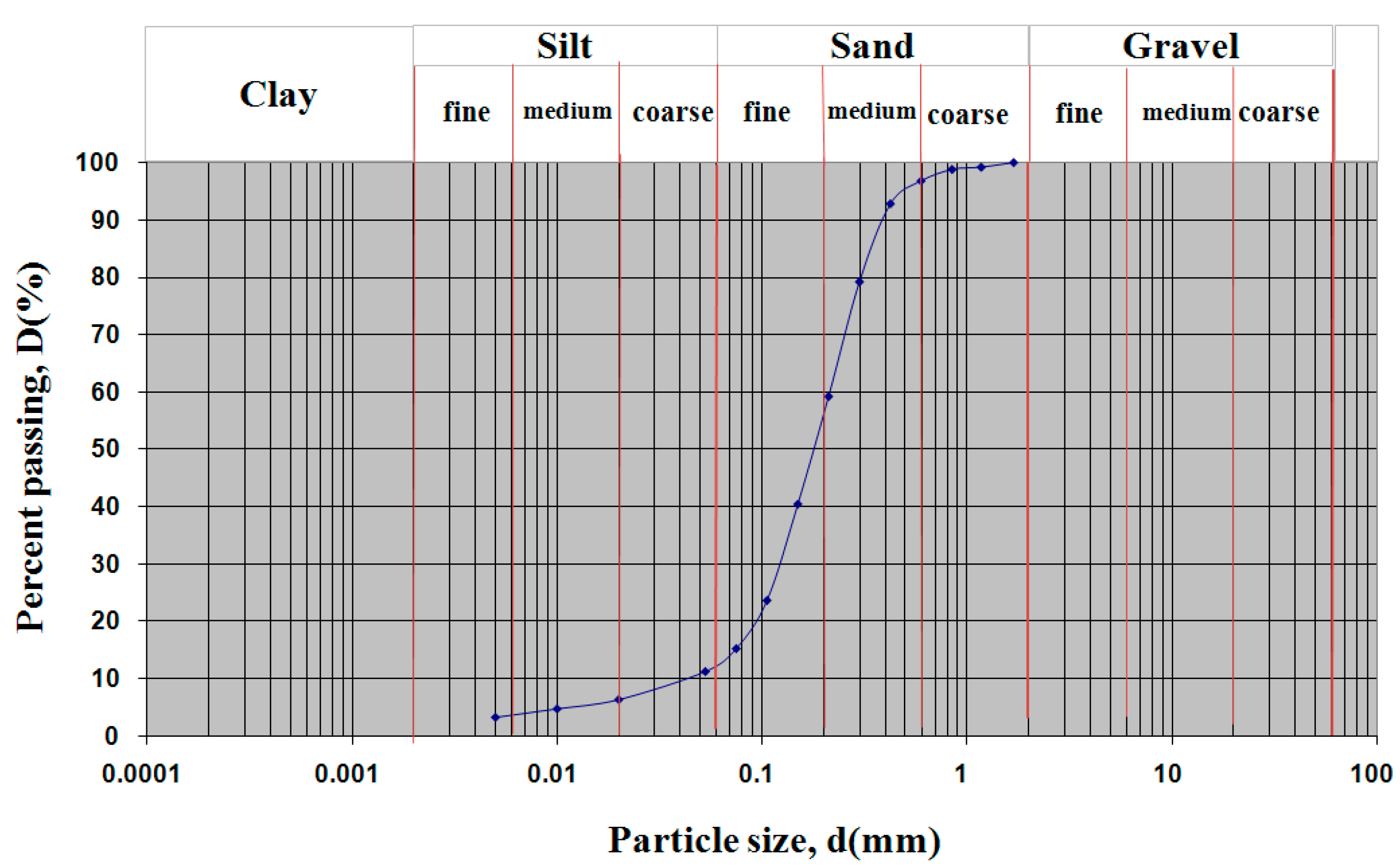

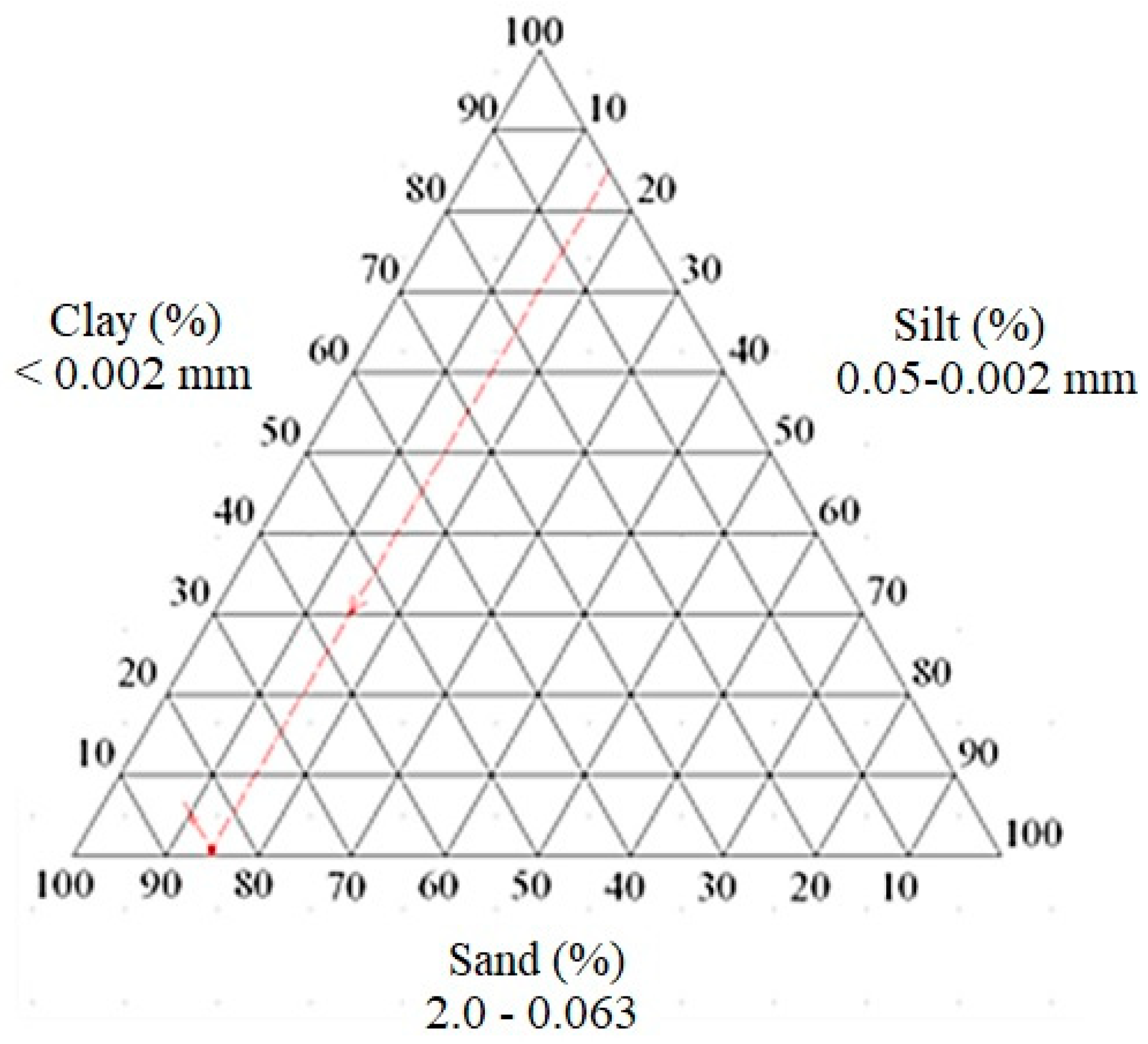

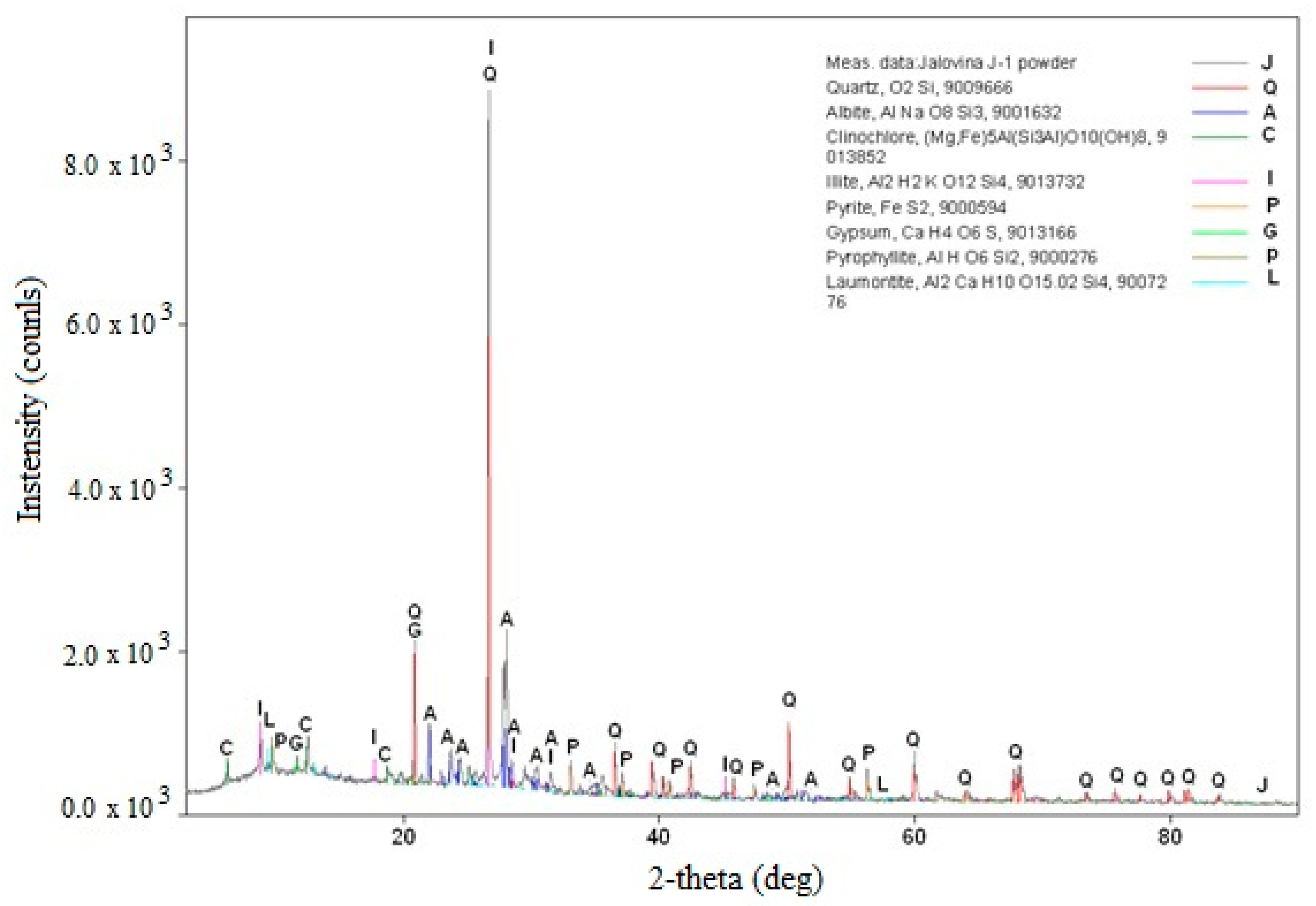

2.3. Flotation Tailing Characterization Results

3. Experimental Design

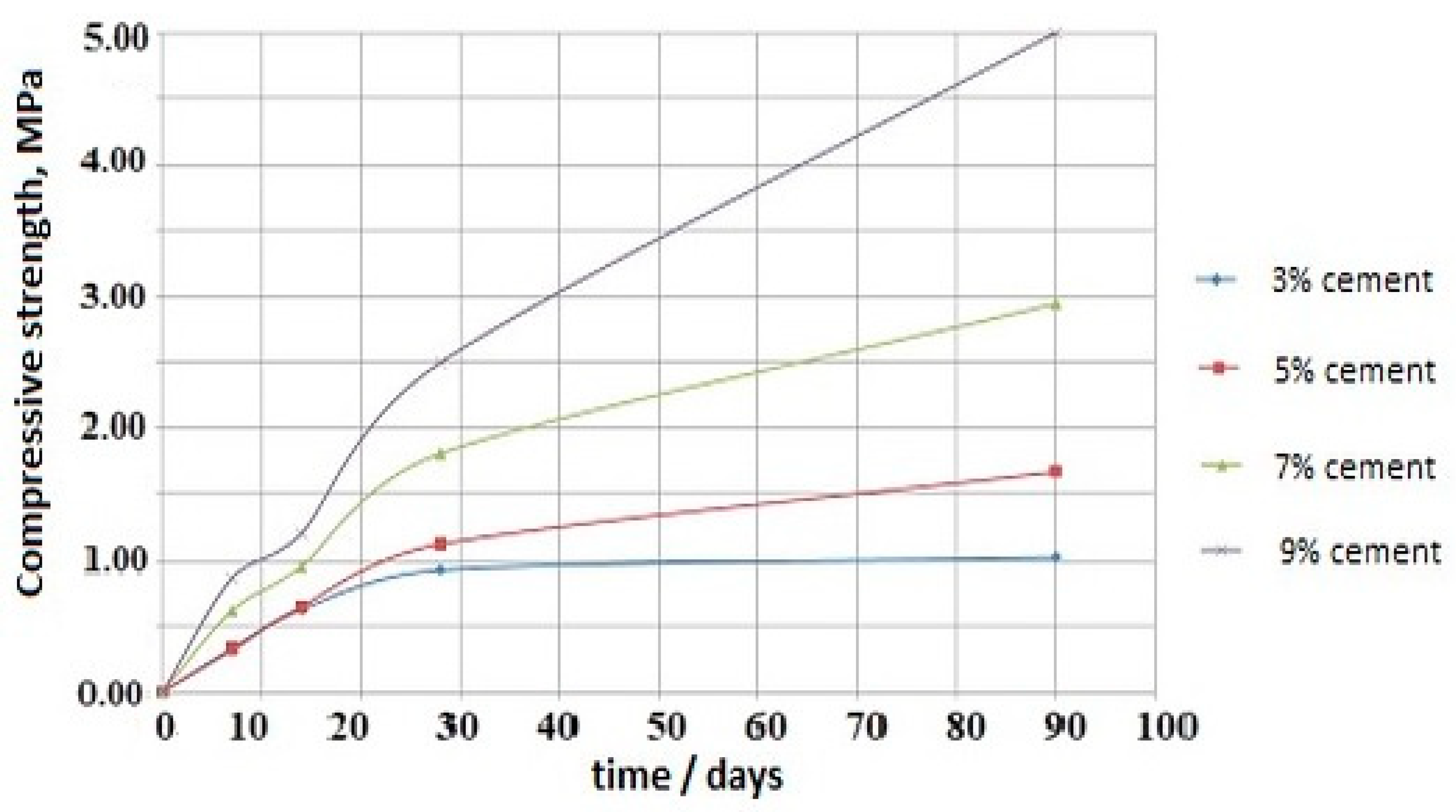

4. Results and Discussion

5. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Famiyeh, S.; Opoku, R.A.; Kwarteng, A.; Asante-Darko, D. Driving forces of sustainability in the mining industry: Evidence from a developing country. Resour. Policy 2021, 70, 101910. [Google Scholar] [CrossRef]

- Kurakova, K.N.; Ponomarenko, T.V. Impact of mining industry growth on sustainable development indicators. In Proceedings of the E3S Web of Conferences, Agadir, Morocco, 22–24 July 2021; Volume 266, p. 06007. [Google Scholar]

- Huang, Y.; Raza, S.M.F.; Hanif, I.; Alharthi, M.; Abbas, Q.; Zain-ul-Abidin, S. The role of forest resources, mineral resources, and oil extraction in economic progress of developing Asian economies. Resour. Policy 2020, 69, 10187. [Google Scholar] [CrossRef]

- Jahanmiri, S.; Asadizadeh, M.; Alipour, A.; Nowak, S.; Sherizadeh, T. Predicting the Contribution of Mining Sector to the Gross Domestic Product (GDP) Index Utilizing Heuristic Approaches. Appl. Artif. Intell. 2021, 35, 1990–2012. [Google Scholar] [CrossRef]

- Jahanger, A.; Usman, M.; Murshed, M.; Mahmood, H.; Balsalobre-Lorente, D. The linkages between natural resources, human capital, globalization, economic growth, financial development, and ecological footprint: The moderating role of technological innovations. Resour. Policy 2022, 76, 102569. [Google Scholar] [CrossRef]

- Pons, A.; Vintrò, C.; Rius, J.; Vilaplana, J. Impact of Corporate Social Responsibility in mining industries. Resour. Policy 2021, 72, 102117. [Google Scholar] [CrossRef]

- Szabo, A.; Shriver, T.E.; Longo, S. Environmental threats and activism against extractive industries: The case of gold mining in Rosia Montană, Romania. J. Rural. Stud. 2022, 92, 26–34. [Google Scholar] [CrossRef]

- Fu, L.; Jiang, X.; He, L. How Natural Resource-Based Industry Affect Sustainable Development? An Evolutionary Study of China. Sustainability 2020, 12, 291. [Google Scholar] [CrossRef] [Green Version]

- Singhal, D.; Poonia, H. Sustainable Development and Mining Comparative Analysis with Reference of Environmental Law. Sustain. Dev. 2021, 14, 1–9. [Google Scholar]

- Carvalho, F.P. Mining industry and sustainable development: Time for change. Food Energy Secur. 2017, 62, 61–77. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, P.; Gojenko, B.; Yu, J.; Wei, L.; Luo, D.; Xiao, T. A review of water pollution arising from agriculture and mining activities in Central Asia: Facts, causes and effects. Environ. Pollut. 2021, 291, 118209. [Google Scholar] [CrossRef]

- Lončar, D.; Paunković, J.; Jovanović, V.; Krstić, V. Environmental and social responsibility of companies cross EU countries–Panel data analysis. Sci. Total Environ. 2019, 657, 287–296. [Google Scholar] [CrossRef] [PubMed]

- Doulati Ardejani, F.; Maghsoudy, S.; Shahhosseini, M.; Jodeiri Shokri, B.; Doulati Ardejani, S.; Shafaei, F.; Amirkhani Shiraz, F.; Rajaee, A. Developing a Conceptual Framework of Green Mining Strategy in Coal Mines: Integrating socio-economic, health and environmental factors. J. Min. Environ. 2022, 13, 101–115. [Google Scholar]

- Aron, A.S.; Molina, O. Green innovation in natural resource industries: The case of local suppliers in the Peruvian mining industry. Extr. Ind. Soc. 2020, 7, 353–365. [Google Scholar] [CrossRef] [Green Version]

- Gedam, V.V.; Raut, R.D.; de Sousa Jabbour, A.B.L.; Agrawal, N. Moving the circular economy forward in the mining industry: Challenges to closed-loop in an emerging economy. Resour. Policy 2021, 74, 102279. [Google Scholar] [CrossRef]

- Upadhyay, A.; Laing, T.; Kumar, V.; Dora, M. Exploring barriers and drivers to the implementation of circular economy practices in the mining industry. Resour. Policy 2021, 72, 102037. [Google Scholar] [CrossRef]

- Bull, A.J.; Fall, M. Curing temperature dependency of the release of arsenic from cemented paste backfill made with Portland cement. J. Environ. Manag. 2020, 269, 110772. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A. Cemented paste backfill for mineral tailings management: Review and future perspectives. Miner. Eng. 2019, 144, 106025. [Google Scholar] [CrossRef]

- Gardić, V.; Petrović, J.; Đurđevac-Ignjatovic, L.; Kolaković, S.; Vujović, S. Procena uticaja rudničkih drenažnih i komunalnih otpadnih voda na kvalitet površinskih voda u Boru i okolini. Chem. Ind. 2015, 69, 165–174. [Google Scholar]

- Ma, D.; Duan, H.; Liu, J.; Li, X.; Zhou, Z. The role of gangue on the mitigation of mining-induced hazards and environmental pollution: An experimental investigation. Sci. Total Environ. 2019, 664, 636–1448. [Google Scholar] [CrossRef]

- Xiu, Z.; Wang, S.; Ji, Y.; Wang, F.; Ren, F. Experimental study on the triaxial mechanical behaviors of the Cemented Paste Backfill: Effect of curing time, drainage conditions and curing temperature. J. Environ. Manag. 2022, 301, 113828. [Google Scholar] [CrossRef]

- Jiang, H.; Yi, H.; Yilmaz, E.; Liu, S.; Qiu, J. Ultrasonic evaluation of strength properties of cemented paste backfill: Effects of mineral admixture and curing temperature. Ultrasonics 2020, 100, 105983. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.; Chen, W.; Tian, M.; Guo, L. Effect of temperature on time-dependent rheological and compressive strength of fresh cemented paste backfill containing flocculants. Construct. Build. Mater. 2021, 267, 121038. [Google Scholar] [CrossRef]

- Fang, K.; Cui, L.; Fall, M. A coupled chemo-elastic cohesive zone model for backfill-rock interface. Comput. Geotech. 2020, 125, 103666. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, D.; Tian, Y.; Liu, X. Numerical simulation of stress-strain behaviour of cemented paste backfill in triaxial compression. Eng. Geol. 2017, 231, 165–175. [Google Scholar] [CrossRef]

- Fall, M.; Belem, T.; Samb, S.; Benzaazoua, M. Experimental characterization of the stress–strain behaviour of cemented paste backfill in compression. J. Mater. Sci. 2007, 42, 3914–3922. [Google Scholar] [CrossRef]

- Rybak, J.; Gorbatyuk, S.M.; Kongar-Syuryun, C.; Khayrutdinov, A.M.; Tyulyaeva, Y.; Makarov, P.S. Utilization of Mineral Waste: A Method for Expanding the Mineral Resource Base of a Mining and Smelting Company. Metallurgist 2021, 64, 851–861. [Google Scholar] [CrossRef]

- Kongar-Syuryun, C.; Ubysz, A.; Faradzhov, V. Models and algorithms of choice of development technology of deposits when selecting the composition of the backfilling mixture. IOP Conf. Ser. Earth Environ. Sci. 2021, 684, 012008. [Google Scholar] [CrossRef]

- Khairutdinov, A.; Ubysz, A.; Adigamov, A. The concept of geotechnology with a backfill is the path of integrated development of the subsoil. IOP Conf. Ser. Earth Environ. Sci. 2021, 684, 012007. [Google Scholar]

- Ponomarenko, T.; Nevskaya, M.; Jonek-Kowalska, I. Mineral Resource Depletion Assessment: Alternatives. Problems, Results. Sustainability 2021, 13, 862. [Google Scholar] [CrossRef]

- Resniova, E.; Ponomarenko, T. Sustainable Development of the Energy Sector in a Country Deficient in Mineral Resources: The Case of the Republic of Moldova. Sustainability 2021, 13, 3261. [Google Scholar] [CrossRef]

- Niemiec, D.; Duraj, M.; Cheng, X.; Marschalko, M.; Kubac, J. Selected black-coal mine waste dumps in the Ostrava Karvina region: An analysis of their potential use. IOP Conf. Ser. Earth Environ. Sci. 2017, 95, 042061. [Google Scholar] [CrossRef]

- Zglinicki, K.; Szamałek, K.; Wołkowicz, S. Critical Minerals from Post-Processing Tailing. A Case Study from Bangka Island, Indonesia. Minerals 2021, 11, 352. [Google Scholar] [CrossRef]

- Zglinicki, K.; Małek, R.; Szamałek, K.; Wołkowicz, S. Mining Waste as a Potential Additional Source of HREE and U for the European Green Deal: A Case Study of Bangka Island (Indonesia). Minerals 2022, 12, 44. [Google Scholar] [CrossRef]

- Han, G.; Zhang, J.; Sun, H.; Shen, D.; Wu, Z.; An, X.; Meye, S.M.; Huang, Y. Application of Iron Ore Tailings and Phosphogypsum to Create Artificial Rockfills Used in Rock-Filled Concrete. Buildings 2022, 12, 555. [Google Scholar] [CrossRef]

- Hefni, M.; Ahmed, H.A.M.; Omar, E.S.; Ali, M.A. The potential re-use of Saudi mine tailings in mine backfill: A path towards sustainable mining in Saudi Arabia. Sustainability 2021, 13, 6204. [Google Scholar] [CrossRef]

- Šajn, R.; Ristović, I.; Čeplak, B. Mining and Metallurgical Waste as Potential Secondary Sources of Metals—A Case Study for the West Balkan Region. Minerals 2022, 12, 547. [Google Scholar] [CrossRef]

- ISO 17892-4:16; Geotechnical Investigation and Testing—Laboratory Testing of Soil—Part 4: Determination of Particle Size Distribution. ISO: Geneva, Switzerland, 2016.

- Kolaković, S.; Trajković, S. Hidrotehničke Melioracije—Odvodnjavanje; FTN Novi Sad, GAF Niš: Novi Sad, Serbia, 2006; ISBN 86-7892-002-5. [Google Scholar]

- EN 12390-3:19; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. 2019. Available online: https://iss.rs/sr_Cyrl/project/show/iss:proj:62276 (accessed on 19 April 2022).

- Construction Standard CS3: 2013; Aggregates for Concrete. CEDD: Hong Kong, China, 2013.

- Đurđevac Ignjatović, L.; Ignjatović, D.; Ljubojev, M.; Zlatanović, D. Basic requirements of backfilling with flotation tailings in the Bor River underground mine. Min. Metall. Eng. Bor 2015, 3, 29–32. [Google Scholar] [CrossRef] [Green Version]

- Đurđevac Ignjatović, L.; Ignjatović, D.; Ljubojev, M.; Mitrović, M. Change the uniaxial compressive strength of paste backfill depending on change the parameters. Min. Metall. Eng. Bor 2016, 1, 17–24. [Google Scholar] [CrossRef]

- Mitchell, R.J. Stability of cemented tailings backfill. In Computer and Physical Modelling in Geotechnical Engineering; Balkema: Rotterdam, The Netherlands, 1989; pp. 501–507. [Google Scholar]

- Li, L.; Aubertin, M.; Simon, R.; Bussiere, B.; Belem, T. Modeling Arching Effects in Narrow Backfilled Stopes with FLAC. In Proceedings of the 3rd International FLAC Symposium, Sudbury, ON, Canada, 31 May 2003; Balkema: Rotterdam, The Netherlands, 2003; pp. 211–218. [Google Scholar]

- Belem, T.; Benzaazoua, M.; Bussiere, B. Mechanical Behaviour of Cemented Paste Backfill, Materials Science, Montreal. 2000. Corpus ID: 56076620. Available online: https://www.semanticscholar.org/paper/MECHANICAL-BEHAVIOUR-OF-CEMENTED-PASTE-BACKFILL-Belem-Benzaazoua/0618219d2edc0e8b73a96f8abd9d8b1369c0cf0d (accessed on 19 April 2022).

- ASTM C 143:21; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2021.

- Magalhäes Gomes, A.; Costa, J.O.; Albertini, H.; Aguiar, J.E. Permeability of Concrete: A Study Intended for the “In Situ” Valuation Using Portable Instruments and Traditional Techniques. In Proceedings of the International Symposium (Non-Destructive Testing in Civil Engineering 2003), Berlin, Germany, 16–19 September 2003. [Google Scholar]

- Krstić, V. Chapter 12: Some Effective Methods for Treatment of Wastewater from Cu Production. In Water Pollution and Remediation: Heavy Metals. Environmental Chemistry for a Sustainable World; Inamuddin, Ahamed, M.I., Lichtfouse, E., Eds.; Springer: Cham, Switzerland, 2021; Volume 53, pp. 313–440. [Google Scholar]

- Krstić, V.; Pešovski, B. Novel multifunctional two layer catalytic activated titanium electrodes for various technological and environmental processes. Arab. J. Chem. 2021, 14, 103101. [Google Scholar] [CrossRef]

- Krstić, V.; Urošević, T.; Pešovski, B. A review on adsorbents for treatment of water and wastewaters containing copper ions. Chem. Eng. Sci. 2018, 192, 273–287. [Google Scholar] [CrossRef]

- Rybak, J.; Kongar-Syuryun, C.; Tyulyaeva, Y.; Khayrutdinov, A.M. Creation of Backfill Materials Based on Industrial Waste. Minerals 2021, 11, 739. [Google Scholar] [CrossRef]

- Yang, L.; Xu, W.; Yilmaz, E.; Wang, Q.; Qiu, J. A combined experimental and numerical study on the triaxial and dynamic compression behavior of cemented tailings backfill. Eng. Struct. 2020, 219, 110957. [Google Scholar] [CrossRef]

- Xu, W.; Liu, B.; Wu, W. Strength and deformation behaviors of cemented tailings backfill under triaxial compression. J. Cent. South Univ. 2020, 27, 3531–3543. [Google Scholar] [CrossRef]

- Wu, J.; Feng, M.; Chen, Z.; Mao, X.; Han, G.; Wang, Y. Particle size distribution effects on the strength characteristic of cemented paste backfill. Minerals 2018, 8, 322. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Jing, H.; Yin, Q.; Meng, B.; Han, G. Strength and ultrasonic properties of cemented waste rock backfill considering confining pressure, dosage and particle size effects. Construct. Build. Mater. 2020, 242, 118132. [Google Scholar] [CrossRef]

- Wang, J.; Fu, J.; Song, W. Mechanical properties and microstructure of layered cemented paste backfill under triaxial cyclic loading and unloading. Construct. Build. Mater. 2020, 257, 119540. [Google Scholar] [CrossRef]

- ASTM D4767-11; Standard Test Method for Consolidated Undrained Triaxial Compression Test for Cohesive Soils. ASTM International: West Conshohocken, PA, USA, 2011.

| D60 (mm) | D30 (mm) | D10 (mm) | Cu | Cc |

|---|---|---|---|---|

| 0.21500 | 0.12300 | 0.04200 | 5.12 | 1.68 |

| Gravel 60–2.0 (mm) | Sand 2.0–0.063 (mm) | Silt 0.063–0.002 (mm) | Clay < 0.002 (mm) |

|---|---|---|---|

| 0.00 | 84.80% | 15.20% | 0.00 |

| Filtration Coefficient (K) m/day (m/s) | Description | Orientation Texture |

|---|---|---|

| <0.01 (1.16 × 10−7) | Very few | Clay |

| 0.01–0.06 (1.16–7 × 10−7) | Quite a bit | |

| 0.06–0.15 (7 × 10−7–1.7 × 10−6) | Small | Clayey sand |

| 0.15–0.40 (1.7–4.6 × 10−6) | Medium | |

| 0.4–1.0 (4.6 × 10−6–1.2 × 10−5) | Large | |

| 1.0–2.5 (1.2–2.9 × 10−5) | Quite large | Sand |

| >2.5 (3 × 10−5) | The biggest |

| Elements | Flotation Tailing wt ± UM * | LoQ ** | Analysis Method |

|---|---|---|---|

| % Cu | 0.092 ± 5.84 | 0.00031 | AAS |

| % Cu-ox | 0.020 ± 10.00 | 0.00500 | AAS |

| % S | 2.060 ± 5.53 | 0.00500 | EA |

| % Al2O3 | 16.490 ± 3.47 | 0.00012 | ICP-AES |

| % SiO2 | 54.910 ± 2.75 | <1 | G |

| % Fe | 3.110 ± 5.35 | 0.00152 | AAS |

| (g/t) Hg | <0.1 ± 12.11 | 1.0 | AAS-Hg |

| ppm Cd | <1 ± 5.58 | 0.71 | ICP-AES |

| ppm Co | 13.00 ± 12.98 | 0.32 | AAS-Hg |

| ppm Ti | 0.16 ± 5.27 | 10.0 | ICP-AES |

| ppm Ni | 10.00 ± 8.84 | 1.0 | AAS |

| ppm Pb | <20 ± 13.56 | 0.63 | AAS |

| ppm Zn | 49.00 ± 24.12 | 3.4 | ICP-AES |

| ppm As | <30 ± 18.76 | 1.7 | AAS |

| % CaO | 5.540 ± 4.89 | 0.00500 | AAS |

| ppm Sb | <20 ± 12.99 | 2.5 | AAS |

| % Cl− | 0.010 ± 0.01 | 0.000050 | SF |

| % SO4−2 | 1.100 ± 0.11 | 0.000050 | NTU |

| No | Cement (%) | Flotation Tailings (%) |

|---|---|---|

| 1 | 3 | 73 |

| 2 | 5 | 71 |

| 3 | 7 | 69 |

| 4 | 9 | 67 |

| No. | Material Synthesis | Compressive Strength, σp (MPa) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| After 7 Days | After 14 Days | After 28 Days | After 90 Days | ||||||

| 1 | 3% cement 73% tailings | 0.323 | 0.316 | 0.631 | 0.622 | 0.935 | 0.925 | 0.998 | 1.021 |

| 0.308 | 0.612 | 0.912 | 1.046 | ||||||

| 0.317 | 0.623 | 0.928 | 1.019 | ||||||

| 2 | 5% cement 71% tailings | 0.345 | 0.331 | 0.664 | 0.645 | 1.131 | 1.123 | 1.685 | 1.671 |

| 0.333 | 0.638 | 1.118 | 1.667 | ||||||

| 0.315 | 0.633 | 1.120 | 1.661 | ||||||

| 3 | 7% cement 69% tailings | 0.627 | 0.617 | 0.966 | 0.950 | 1.788 | 1.809 | 2.961 | 2.945 |

| 0.611 | 0.953 | 1.818 | 2.937 | ||||||

| 0.613 | 0.931 | 1.821 | 2.937 | ||||||

| 4 | 9% cement 67% tailings | 0.881 | 0.862 | 1.199 | 1.203 | 2.511 | 2.497 | 5.086 | 4.998 |

| 0.854 | 1.212 | 2.478 | 4.979 | ||||||

| 0.851 | 1.198 | 2.502 | 4.929 | ||||||

| No | W1 (mg/L) | W2 (mg/L) |

|---|---|---|

| Cl− | 11.5 | 10.3 |

| SO4−2 | 89 | 122 |

| S2− | <0.005 | <0.005 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Đurđevac Ignjatović, L.; Krstić, V.; Radonjanin, V.; Jovanović, V.; Malešev, M.; Ignjatović, D.; Đurđevac, V. Application of Cement Paste in Mining Works, Environmental Protection, and the Sustainable Development Goals in the Mining Industry. Sustainability 2022, 14, 7902. https://doi.org/10.3390/su14137902

Đurđevac Ignjatović L, Krstić V, Radonjanin V, Jovanović V, Malešev M, Ignjatović D, Đurđevac V. Application of Cement Paste in Mining Works, Environmental Protection, and the Sustainable Development Goals in the Mining Industry. Sustainability. 2022; 14(13):7902. https://doi.org/10.3390/su14137902

Chicago/Turabian StyleĐurđevac Ignjatović, Lidija, Vesna Krstić, Vlastimir Radonjanin, Violeta Jovanović, Mirjana Malešev, Dragan Ignjatović, and Vanja Đurđevac. 2022. "Application of Cement Paste in Mining Works, Environmental Protection, and the Sustainable Development Goals in the Mining Industry" Sustainability 14, no. 13: 7902. https://doi.org/10.3390/su14137902

APA StyleĐurđevac Ignjatović, L., Krstić, V., Radonjanin, V., Jovanović, V., Malešev, M., Ignjatović, D., & Đurđevac, V. (2022). Application of Cement Paste in Mining Works, Environmental Protection, and the Sustainable Development Goals in the Mining Industry. Sustainability, 14(13), 7902. https://doi.org/10.3390/su14137902