Textile and Product Development from End-of-Use Cotton Apparel: A Study to Reclaim Value from Waste

Abstract

:1. Introduction

2. Literature Review

2.1. Apparel and Textile Waste

2.2. Textile Waste Management

2.3. Textile Recycling

2.4. Products Made from Recycled Textiles

3. Materials and Methods

3.1. Research through Design Methodology

3.2. Collection, Sorting and Cutting End-of-Use Textile Products and Fabrics

3.3. Batting Development

3.4. Yarn Development

3.5. Fabric Development

3.5.1. Feltloom Nonwoven (Needle-Punched) Fabric Development

3.5.2. Woven Fabric Development

3.5.3. Quilted (Confetti Quilting) Fabric Development

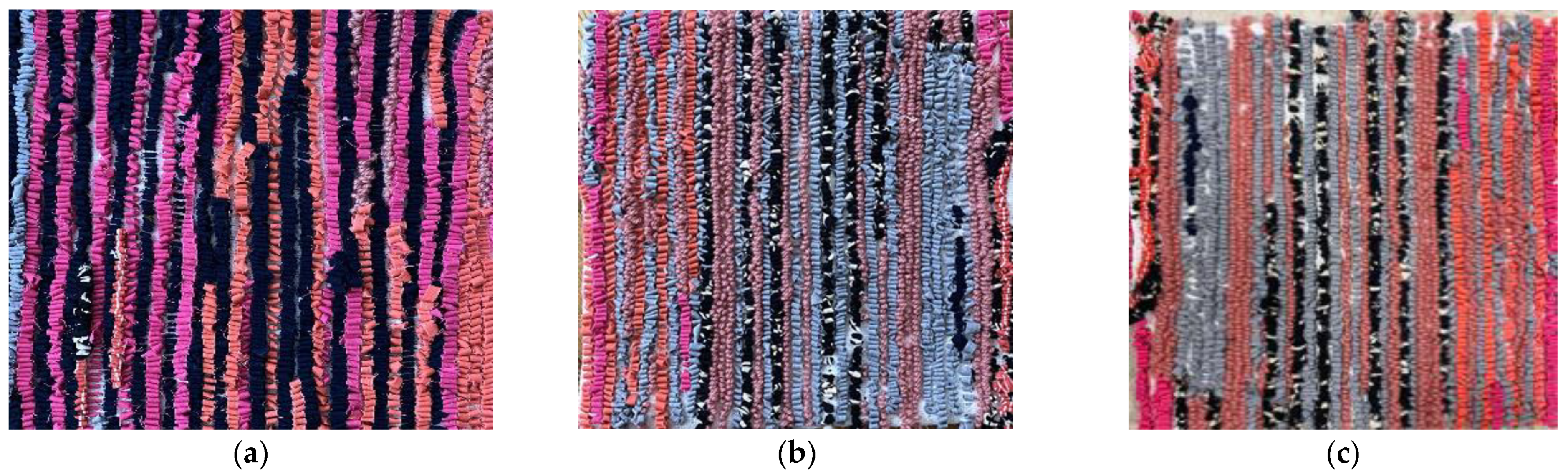

3.5.4. Loop Tufted Fabric Development

3.6. Textile Testing

3.6.1. Yarn Testing

3.6.2. Fabric Testing

3.7. Product Development

3.7.1. Cell Phone Cases and Glasses Case

3.7.2. Decorative Fabric

3.7.3. Bags: Handbag, Backpack, Makeup Bags, Tote Bag

3.7.4. Hat

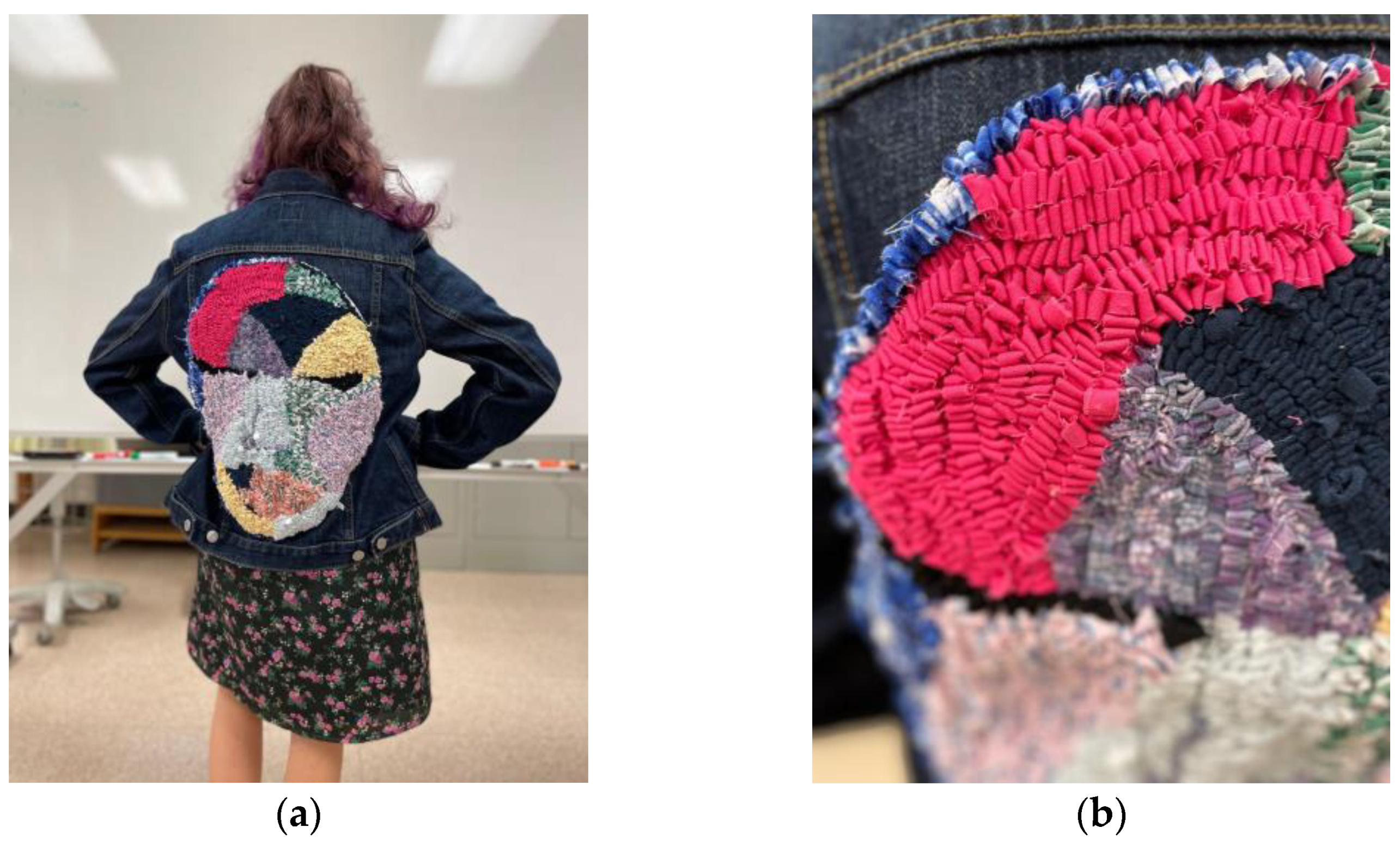

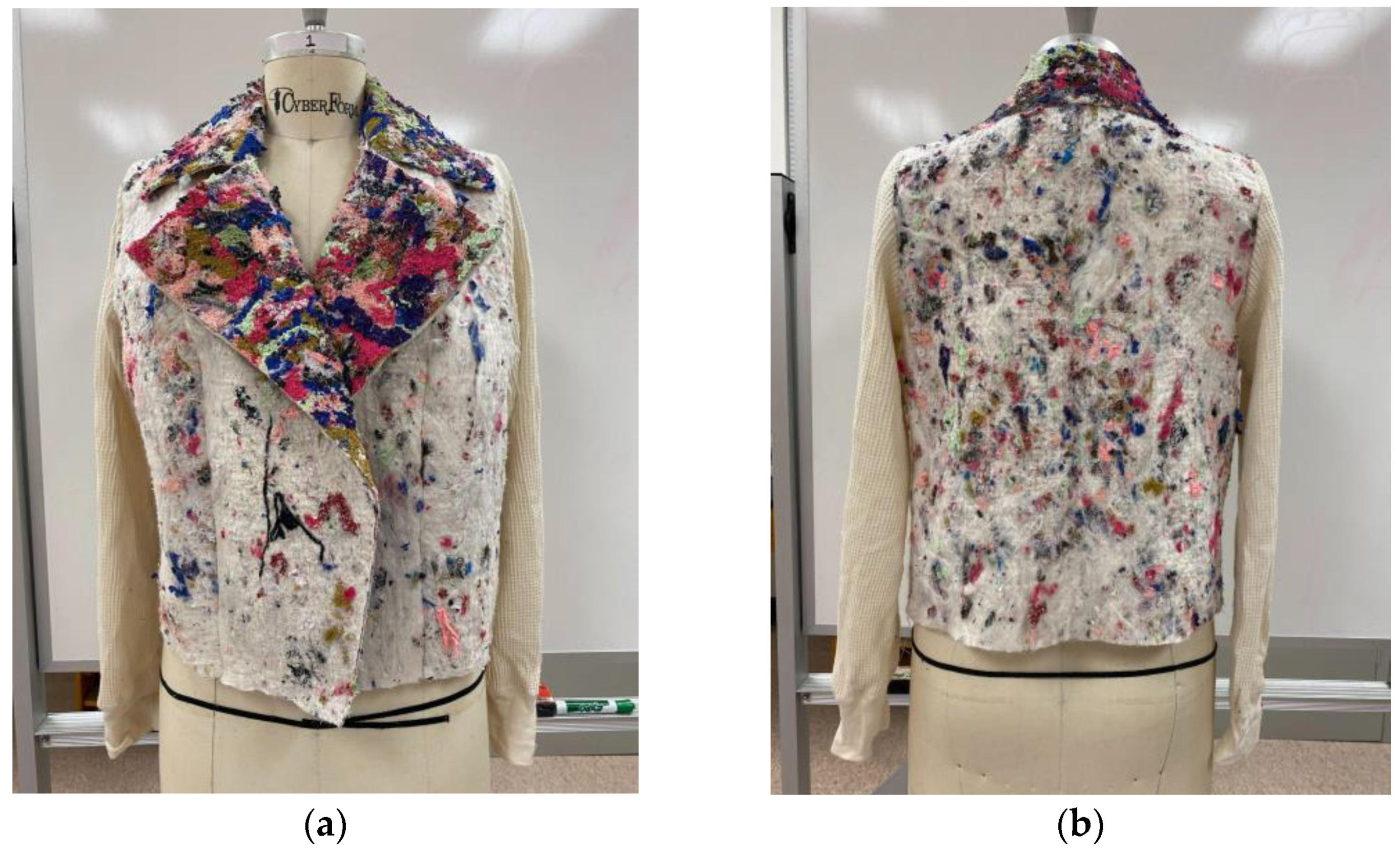

3.7.5. Garments

4. Results and Discussion

4.1. Textile (Batting, Yarn, Fabrics) Development

4.1.1. Batting Material

4.1.2. Yarn

4.1.3. Feltloom Nonwoven Fabric

4.1.4. Woven Textile

4.1.5. Quilt Fabric

4.1.6. Tufting

4.2. Textile Testing

4.2.1. Yarn Testing

4.2.2. Fabric Testing

4.3. Product Development

4.3.1. Cell Phone Cases and Glasses Case

4.3.2. Decorative Fabric

4.3.3. Bags: Handbag, Backpack, Makeup Bag, Tote Bag

4.3.4. Hat

4.3.5. Garments

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Textile Exchange. Preferred Fibers and Materials Market Report. 2021. Available online: https://textileexchange.org/wp-content/uploads/2021/08/Textile-Exchange_Preferred-Fiber-and-Materials-Market-Report_2021.pdf (accessed on 26 April 2022).

- American Apparel and Footwear Association. Apparelstats. 2021. Available online: https://www.aafaglobal.org (accessed on 26 April 2022).

- Luján-Ornelas, C.; Güereca, L.P.; Franco-García, M.-L.; Heldeweg, M. A life cycle thinking approach to analyse sustainability in the textile industry: A literature review. Sustainability 2020, 12, 10193. [Google Scholar] [CrossRef]

- U.S. Environmental Protection Agency. Advancing Sustainable Materials Management: 2018 Fact Sheet. Available online: https://www.epa.gov/sites/default/files/2021-01/documents/2018_ff_fact_sheet_dec_2020_fnl_508.pdf (accessed on 26 April 2022).

- Sandin, G.; Peters, G.M. Environmental impact of textile reuse and recycling—A review. J. Clean. Prod. 2018, 184, 353–365. [Google Scholar] [CrossRef]

- Johnson, S.; Echeverria, D.; Venditti, R.; Jameel, H.; Yao, Y. Supply chain of waste cotton recycling and reuse: A review. AATCC J. Res. 2020, 7, 19–29. [Google Scholar] [CrossRef]

- Piribauer, B.; Bartl, A. Textile recycling processes, state of the art and current development: A mini review. Waste Manag. Res. 2019, 37, 112–119. [Google Scholar] [CrossRef]

- Kuusk, K.; Tajadura-Jiménez, A.; Väljamäe, A. A transdisciplinary collaborative journey leading to sensorial clothing. CoDesign 2020, 16, 311–327. [Google Scholar] [CrossRef]

- BBC. Why Clothes Are so Hard to Recycle. 2020. Available online: https://www.bbc.com/future/article/20200710-why-clothes-are-so-hard-to-recycle (accessed on 16 June 2022).

- Dhir, Y.J. Hazards of fashion and textile waste: Approaches for effective waste management. In Waste Management in the Fashion and Textile Industries; Nayak, R., Patnaik, A., Eds.; Woodhead Publishing: Duxford, UK, 2021; pp. 31–58. [Google Scholar]

- Ramkalaon, S.; Sayem, A.S.M. Zero-waste pattern cutting (ZWPC) to tackle over sixty billion square metres of fabric wastage during mass production of apparel. J. Text. Inst. 2021, 112, 809–819. [Google Scholar] [CrossRef]

- Xie, X.; Hong, Y.; Zeng, X.; Dai, X.; Wagner, M. A systematic literature review for the recycling and reuse of wasted clothing. Sustainability 2021, 13, 13732. [Google Scholar] [CrossRef]

- Rotimi, E.O.O.; Topple, C.; Hopkins, J. Towards a conceptual framework of sustainable practices of post-consumer textile waste at garment end of lifecycle: A systematic literature review approach. Sustainability 2021, 13, 2965. [Google Scholar] [CrossRef]

- DeVoy, J.E.; Congiusta, E.; Lundberg, D.J.; Findeisen, S.; Bhattacharya, S. Post-consumer textile waste and disposal: Differences by socioeconomic, demographic, and retail factors. Waste Manag. 2021, 136, 303–309. [Google Scholar] [CrossRef]

- Enes, E.; Kipöz, Ş. The role of fabric usage for minimization of cut-and-sew waste within the apparel production line: Case of a summer dress. J. Clean. Prod. 2020, 248, 119221. [Google Scholar] [CrossRef]

- Townsend, K.; Mills, F. Mastering zero: How the pursuit of less waste leads to more creative pattern cutting. Int. J. Fash. Des. Technol. Educ. 2013, 6, 104–111. [Google Scholar] [CrossRef]

- Morgan, L.R.; Birtwistle, G. An investigation of young fashion consumers’ disposal habits. Int. J. Consum. Stud. 2009, 33, 190–198. [Google Scholar] [CrossRef]

- Weber, S.; Lynes, J.; Young, S.B. Fashion interest as a driver for consumer textile waste management: Reuse, recycle, or disposal. Int. J. Consum. Stud. 2017, 41, 207–215. [Google Scholar] [CrossRef]

- Degenstein, L.M.; McQueen, R.H.; Krogman, N.T. ‘What goes where’? Characterizing Edmonton’s municipal clothing waste stream and consumer clothing disposal. J. Clean. Prod. 2021, 296, 126516. [Google Scholar] [CrossRef]

- Cao, H. End of life clothes and their management. In Waste Management in the Fashion and Textile Industries; Nayak, R., Patnaik, A., Eds.; Woodhead Publishing: Duxford, UK, 2021; pp. 157–172. [Google Scholar]

- Greenpeace. Poisoned Gifts—From Donation to the Dumpsite: Textile Waste Disguised as Second-Hand Clothes Exported to East Africa. Available online: https://www.greenpeace.org/static/planet4-international-stateless/2022/04/9f50d3de-greenpeace-germany-poisoned-fast-fashion-briefing-factsheet-april-2022.pdf (accessed on 16 June 2022).

- Ellen MacArthur Foundation. A New Textile Economy: Redesigning Fashion’s Future. 2017. Available online: https://ellenmacarthurfoundation.org/a-new-textiles-economy (accessed on 16 June 2022).

- Esteve-Turrillas, F.A.; de la Guardia, M. Environmental impact of Recover cotton in textile industry. Resour. Conserv. Recycl. 2017, 116, 107–115. [Google Scholar] [CrossRef]

- Wazna, M.E.; Gounni, A.; Bouari, A.E.; Alami, M.E.; Cherkaoui, O. Development, characterization and thermal performance of insulating nonwoven fabrics made from textile waste. J. Ind. Text. 2019, 48, 1167–1183. [Google Scholar] [CrossRef]

- Leonas, K.K. The use of recycled fibers in fashion and home products. In Textiles and Clothing Sustainability: Recycled and Upcycled Textiles and Fashion; Muthu, S.S., Ed.; Springer Nature: Singapore, 2017; pp. 55–77. [Google Scholar]

- Guo, Z.; Eriksson, M.; de la Motte, H.; Adolfsson, E. Circular recycling of polyester textile waste using a sustainable catalyst. J. Clean. Prod. 2021, 283, 124579. [Google Scholar] [CrossRef]

- Cheng, I. Why Asia matters: Circular economy in Japan, China and Taiwan. In Designing for the Circular Economy; Charter, M., Ed.; Routledge: Oxon, UK, 2018; pp. 54–69. [Google Scholar]

- Haule, L.V.; Carr, C.M.; Rigout, M. Preparation and physical properties of regenerated cellulose fibres from cotton waste garments. J. Clean. Prod. 2016, 112, 4445–4451. [Google Scholar] [CrossRef]

- Liu, W.; Liu, S.; Liu, T.; Zhang, J.; Liu, H. Eco-friendly post-consumer cotton waste recycling for regenerated cellulose fibers. Carbohydr. Polym. 2019, 206, 141–148. [Google Scholar] [CrossRef]

- Sherwood, J. Closed-loop recycling of polymers using solvents. Johns. Matthey Technol. Rev. 2020, 64, 4–15. [Google Scholar] [CrossRef]

- Innovation in Textiles. New Initiatives Promote Extended Recyclability of Garments. 2009. Available online: https://www.innovationintextiles.com/new-initiatives-promote-extended-recyclability-of-garments/ (accessed on 16 June 2022).

- Lindström, K.; Sjöblom, T.; Persson, A.; Kadi, N. Improving mechanical textile recycling by lubricant pre-treatment to mitigate length loss of fibers. Sustainability 2020, 12, 8706. [Google Scholar] [CrossRef]

- Zimmerman, J.; Stolterman, E.; Forlizzi, J. An analysis and critique of research through design: Towards a formalization of a research approach. In Proceedings of the DIS ’10: Proceedings of the 8th ACM Conference on Designing Interactive Systems, Online, 16 August 2010; pp. 310–319. [Google Scholar]

- Frayling, C.; Research in Art and Design. Royal College of Art Research Papers. 1993. Available online: https://researchonline.rca.ac.uk/384/3/frayling_research_in_art_and_design_1993.pdf (accessed on 6 June 2022).

- Ramey, H.H., Jr.; Lawson, R.; Worley, S., Jr. Relationship of cotton fiber properties to yarn tenacity. Text. Res. J. 1977, 47, 685–691. [Google Scholar] [CrossRef]

- Ki, C.-W.; Chong, S.M.; Ha-Brookshire, J.E. How fashion can achieve sustainable development through a circular economy and stakeholder engagement: A systematic literature review. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 2401–2424. [Google Scholar] [CrossRef]

| Tex | Breaking Force (kgf) Mean ± SD | Tenacity (gf/denier) Mean ± SD | Elongation (%) Mean ± SD | |

|---|---|---|---|---|

| Green yarn pulled from an end-of-use knitwear | 73 | 1.173 ± 0.060 | 1.785 ± 0.092 | 12.79 ± 0.33 |

| Grey yarn pulled from an end-of-use knitwear | 49 | 0.406 ± 0.029 | 0.921 ± 0.067 | 11.85 ± 1.63 |

| White yarn pulled from an end-of-use knitwear | 122 | 0.923 ± 0.106 | 0.840 ± 0.097 | 16.59 ± 1.50 |

| ¼ inch wide woven fabric strip | 1443 | 3.535 ± 0.730 | 0.272 ± 0.056 | 23.48 ± 0.94 |

| Sample | Thickness (Mean ± SD) (mm) | Rct (Mean ± SD) (°C·m2/W) | Stiffness (Mean ± SD) (g) | Air permeability (Mean ± SD) (mm/s) |

|---|---|---|---|---|

| Feltloom sample 1 | 3.04 ± 0.28 | 0.0797 ± 0.0025 | 122.45 ± 3.76 | 423.01 ± 30.71 |

| Feltloom sample 2 | 3.32 ± 0.44 | 0.1080 ± 0.0003 | 319.70 ± 20.15 | 333.98 ± 52.18 |

| Woven | 3.96 ± 0.51 | 0.0937 ± 0.0011 | 230.10 ± 3.54 | 694.99 ± 95.69 |

| Confetti quilt | 2.34 ± 0.19 | 0.0430 ± 0.0009 | 77.75 ± 8.58 | 409.79 ± 41.60 |

| Tufting | 8.58 ± 0.39 | 0.0892 ± 0.0034 | >1000 | 313.38 ± 61.29 |

| Stakeholders | Benefits |

|---|---|

| Fashion suppliers | Access more recycled materials for yarn and fabric production. May produce and sell high value yarns and fabrics made from recycled textiles. |

| Retailers | May offer more high-value product lines that are made from recycled textiles. |

| Clothing manufacturers | Access more high-value yarns and fabrics for manufacturing. Produce high-value apparel and other textile products from recycled textiles. |

| Consumers | Have more high-value product choices made from recycled textiles. If their clothing donations cannot be sold by charities, the end-of-use garments may be recycled and produced into high-value, second-life products. |

| Academic institutions | Following the research through design methodology used in this research, material researchers and product designers may work together to design and develop more high-value products from recycled materials. |

| Recycling agents | If donated clothing cannot be sold by charities, charities and textile recyclers can work together to recycle end-of-use apparel and produce high-value yarns and fabrics for product development. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, H.; Cobb, K.; Yatvitskiy, M.; Wolfe, M.; Shen, H. Textile and Product Development from End-of-Use Cotton Apparel: A Study to Reclaim Value from Waste. Sustainability 2022, 14, 8553. https://doi.org/10.3390/su14148553

Cao H, Cobb K, Yatvitskiy M, Wolfe M, Shen H. Textile and Product Development from End-of-Use Cotton Apparel: A Study to Reclaim Value from Waste. Sustainability. 2022; 14(14):8553. https://doi.org/10.3390/su14148553

Chicago/Turabian StyleCao, Huantian, Kelly Cobb, Michelle Yatvitskiy, Megan Wolfe, and Hongqing Shen. 2022. "Textile and Product Development from End-of-Use Cotton Apparel: A Study to Reclaim Value from Waste" Sustainability 14, no. 14: 8553. https://doi.org/10.3390/su14148553

APA StyleCao, H., Cobb, K., Yatvitskiy, M., Wolfe, M., & Shen, H. (2022). Textile and Product Development from End-of-Use Cotton Apparel: A Study to Reclaim Value from Waste. Sustainability, 14(14), 8553. https://doi.org/10.3390/su14148553