1. Introduction

Most building structures are held up, in one way or another, on the ground. In this way, the geotechnical engineers need to know their physical and mechanical properties in order to guarantee the structural stability of the works to be built.

Geotechnical Engineering, based on the size of the particles, classifies soils into two large groups: coarse-grained soils (gravels and sands), and fine-grained soils (silts and clays); these being the clays that, in most cases, show the worst physical and mechanical properties in the presence of water within the soil mass [

1].

One of the problems that geotechnical engineers frequently encounter is the soils’ inability to withstand the structural loads they are subjected to; therefore, they are forced to find alternatives for the improvement of their physical and mechanical properties, mainly shearing strength and bearing capacity [

2].

There are some clay soils with marked expansive features, characterized by considerable changes in their volume when variations of water content occur, causing serious damage and deformations to structures cemented on them, particularly to buildings and light pavements [

3].

One of the methods to improve the mechanical behavior of soils is stabilization, which can be defined as the alteration or preservation of one or more soil properties to improve its characteristics. Stabilization, in a broad sense, incorporates the various methods used to modify the properties of a soil to improve its engineering performance [

4].

The most common method for improving the physical and mechanical properties of clay soils is stabilization with the use of binder materials such as cement and lime [

5,

6]. Although not a recent technique, a very practical soil improvement alternative is the addition of fibers.

With regard to the reinforcement of soils with fibers, it is clear that there are many possibilities when selecting the type of fiber to include in the reinforced soil. In general, synthetic materials characterized by high mechanical strength and high durability are sought. However, the high strengths obtained with these options may not always be required, and there is therefore a justification for looking for cheaper additives that can be used to improve soil properties.

In the past decade, the popularity of eco-friendly plant fibers has been considerably enhanced because of their favorable properties, including cheap and abundant availability, flexibility in handling and usage, low density, comparable mechanical characteristics, high strength-to-weight ratios, etc.

This work shows a review of the recent existing literature on some of the alternatives for the reinforcement of soils through the addition of natural fibers, since these are mainly residues of many agro-industrial processes that abound in developing countries. The objective is to get an approach of an essential principle of sustainable development, which are low-cost techniques, less polluting than those currently used and therefore more friendly to the environment, with a growing interest in recent decades by researchers in developing countries.

The review is carried out considering the problems observed by the researchers in their respective environment, the reasons that led them to carry out their study, as well as the methods used and a summary of the results obtained.

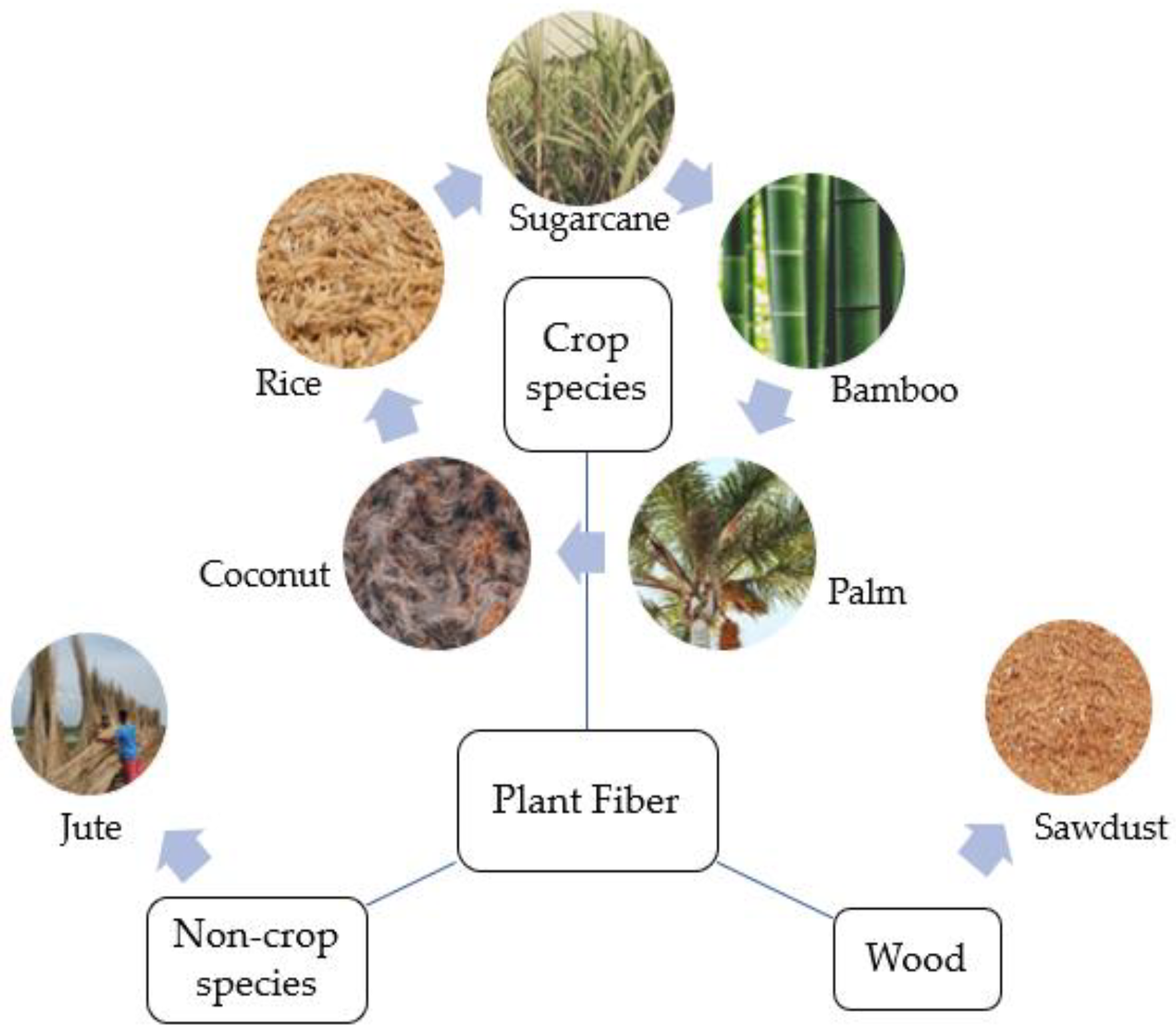

Figure 1 depicts a scheme of the classification of natural fibers on which this study mainly focuses, as well as which are investigated in the articles reviewed on their possible use in the improvement of the engineering properties of soils.

The structure of this review article consists of a section on materials and methods, which describes in a general way the criteria for the selection of articles used in this review, as well as the methodology for their search in the databases; then, a theoretical framework is provided to contextualize readers on the subject of soils, their classification and the characteristics of expansive soils. Following this, is the description of soil stabilization as a technique to improve the properties of expansive soils. Subsequently, a description of the contributions of various authors in the stabilization of soils with natural fibers is made, and mercerization is described as the most used technique for the chemical treatment of fibers prior to their use. Then, a review of the results contained in the reviewed articles is shown, organized by the different fibers investigated. Then, the analysis of the information obtained from the review is presented, indicating the trends that should be addressed by current and future works,. Finally, the conclusions are established by the authors.

2. Materials and Methods

2.1. Article Selection Criteria

Table 1 shows the selection criteria for the articles included in this review. Articles published in English with a main focus on the use of natural fibers for soil reinforcement worldwide were considered. On the contrary, documents published in languages other than English were excluded. The document considered the articles published between 2016 and 2021. The considered articles should have been published in peer-reviewed journals and those that addressed the issue of improving the engineering properties of soils by the addition of at least one of the 7 most abundant natural fibers were considered. The information contained in this document was drawn from the articles included in the revision. The main motivation was to present the readers with information on new trends in geotechnical engineering on the stabilization and/or reinforcement of soft soils with the use of more environmentally friendly natural materials.

2.2. Search Results

A total of 225 documents were retrieved from the following databases: Google Scholar (145), Science direct (35), and Springer (45) on the subject under investigation. The documents have an academic peer review, which guarantees the quality of the information collected. Of the total number of articles collected, 47 were duplicated and 106 were excluded on the basis of their documents and/or references, as they did not meet the inclusion criteria. The final revision included 30 articles on the use of the 7 most abundant natural fibers in improving the engineering properties of soils. In addition, 42 articles to critically observe global research trends on the uses of natural fibers in aspects of Geotechnical Engineering were included. At the beginning of the search, keywords were used at a first level such as: “soil reinforcement”, “expansive soil reinforcement”, “expansive soil treatment”; then, at a second level with more specific phrases such as “soil reinforcement natural fibers”, “soil reinforcement bamboo fibers”, “soil reinforcement jute fibers”, “soil reinforcement coir fibers”, “soil reinforcement palm fibers”, “soil reinforcement sugarcane fibers”, “soil reinforcement rice fibers”, and “soil reinforcement sawdust fibers”.

Figure 2 shows the worldwide distribution of the different selected articles on the subject of the study after the application of the eligibility criteria. In it can be seen that these correspond to research carried out in countries located in the continents of Asia, Oceania, and Africa. A significant number of them occur in the East Asian region, mainly in the countries of India (13), China (5), and Bangladesh (4).

Figure 3 shows the distribution, by country, of the 30 reviewed scientific articles that met all the eligibility criteria to be considered in this document. It is noted that more than a third (36%) of these correspond to material produced in the Republic of India, with the People’s Republic of China in second place at 17%. It should be noted that half of the work analyzed on natural fibers (plants) for soil reinforcement correspond to research carried out in the two most populous countries in the world.

On the other hand,

Figure 4 shows a distribution of the selected articles by continents that are considered for the analysis of the information corresponding to the technique of strengthening the soils with the use of natural fibers from plants. In this, it is observed that more than three-quarters of them (83%) are relevant to studies carried out in the Asian territory.

3. Soil

Soil is the most abundant construction material in civil works, and constitutes the support of structures such as buildings, roads, bridges, canals, towers, among others. It is also used as a material for road embankments, earth walls reinforced with geotextile, dikes, fillings for the adaptation of land in reliefs, and slopes for urban areas. hence, the need to study soils from the different perspectives and needs within the practices of civil engineering [

7] is relevant.

The study of soils is one of the most important aspects to consider when talking about the construction of any civil work, so it is of vital importance to know its physical, chemical, and mechanical properties, as well as its possible reactions when putting it in contact with other elements that are alien to its characteristics.

3.1. Soil Classification

Many of the current soil classification systems (ASTM, USCS, AASHTO) are based on the size of the particles that compose it. Based on this aspect, soils can be divided into two main groups: the first corresponds to coarse-grained soils (gravels and sands), which are composed primarily of particles with sizes smaller than the 3″ sieve (76.2 mm) and higher than the #200 sieve (75 μm), and the second corresponds to fine soils (silts and clays), composed of particles with sizes smaller than #200 sieve.

3.2. Expansive Soils

Expansive soils are those that show an appreciable volumetric change (swelling or contraction) when they experience variations in their moisture content, making the structures built on them unstable and susceptible to damage. In addition to being characterized by a large volume change, they also tend to have a high moisture retention capacity, low load capacity, low resistance, and low permeability.

When these soils are subjected to repeated cycles of drying and wetting, they usually experience cracks. The expansive nature of these types of soils is especially due to the presence of clay minerals, especially from the group of smectites. Many builders and geotechnical engineers try to avoid using expansive soils as building materials or building on them. However, the depletion of soils and suitable natural surfaces has sometimes made this inevitable [

8].

4. Soil Stabilization

Stabilization is a method of improving soil properties by mixing it with other materials or additives. In general terms, it is the process of improving the shearing strength parameters of the soil and, therefore, increasing its bearing capacity [

4,

9]. Nowadays, two methods often employed are mechanical and chemical stabilization [

10]. Each of the two methods may be used independently or simultaneously, in attempts to optimize the mechanical properties of the soil.

Currently, cement and lime are the most commonly used stabilizing agents for the treatment of soils with expansive characteristics. There have been several investigations carried out on the stabilization of expansive soils with the use of cement and lime [

11,

12,

13,

14,

15,

16,

17]. However, cement and lime treatments sometimes make soils fragile, being unfavorable in some dynamic load conditions, including traffic loads on pavement systems.

In recent years, numerous methods for the improvement of the mechanical properties of soils, as well as their compressive strength and tensile stresses through the addition of fibers and reinforcing materials [

18,

19], have been developed. The main purpose of soil reinforcement is to increase stability, increase carrying capacity, and reduce the settlements of the reinforced soil.

The option of reinforcing the soil with the use of fibers is highly preferred in the field of geotechnical and geoenvironmental engineering [

20,

21]. The concept of soil reinforcement using randomly distributed discrete fibers is inspired by the natural phenomenon that grass and/or plants growing on a slope can effectively stabilize it [

22,

23].

Compared to the traditional methods of reinforcement with geosynthetics, a soil reinforced with discrete short fibers is easier to prepare and can maintain isotropic strength without introducing possible weak planes [

24].

The concept of reinforcing soils with fibers was developed in ancient times, more than 5000 years ago, when civilizations used straw and hay to reinforce mud blocks. In the modern history of soil stabilization, the concept and principle of soil reinforcement was first developed by the French engineer Henri Vidal (1969), who showed that the introduction of reinforcing elements into a soil mass caused an increase in the shearing strength of the medium [

25]. Consequently, efforts to use fibrous materials began as an imitation of the past [

26].

Soil composites of natural and synthetic short fibers have recently attracted attention in the field of geotechnical engineering. The main purpose of reinforcing the soil mass is to improve its stability in order to increase its resistance to resist deformations and shear failures.

5. Stabilization of Clay Soils with Natural Fibers

Nowadays, there is a greater ecological awareness due to the observation that non-renewable natural resources are being depleted more frequently and that they will not last forever, while on the contrary, the landfills are full. Therefore, there is a need for the use of materials that are more respectful to the environment.

There are publications in which the use of fibers of organic origin has been proposed. Soil reinforcement using natural fibers is an ecologically friendly and very low-cost soil improvement technique [

27,

28]. The use of these fibers seems to be promising in underdeveloped countries where natural fibers are obtained from the remains of fruits and plants used in the food industry [

29].

The concept of reinforcing the soil with natural fibers originated in ancient times. However, natural and synthetic short fiber soil composites have recently attracted increasing attention in geotechnical engineering for the second time. Therefore, they remain a relatively new technique in geotechnical projects [

26].

Fiber-reinforced soil behaves like a composite material in which the fibers improve the strength of the soil. Shear stresses on the ground improve the tensile strength of the fibers, which in turn provides greater resistance to the soil [

30,

31]. The use of fibers in the soil is similar to the behavior of plant roots, contributing to soil stability by adding resistance to near-surface soils in which effective stress is low [

32,

33].

5.1. Natural Fibers as Soil Reinforcement

Currently, there is a need to use materials for soil reinforcement that are more environmentally friendly; therefore, lately there has been a lot of experimental research and a lot of interest around the world about the potential applications of natural fibers for soil reinforcement [

34].

The addition of natural fibers is more beneficial in terms of energy efficiency and health, as natural materials have a low energy consumption and less toxicity than artificial materials [

35]. They can be used in raw form and require less processing, so they cause less damage to the environment. In addition, when these natural stabilizing materials are used in the production of building materials, the resulting materials themselves become sustainable [

36].

Mainly, natural fibers can be divided in three groups from the point of view of their origin: (1) vegetable fibers (bamboo, jute, coir, hemp, etc.), (2) animal parts containing proteins (silk, hair, wool, etc.), and (3) minerals. However, based on the availability and applicability for large-scale geotechnical intentions, they have been projected towards plant fibers in terms of natural fibers [

37].

On the other hand, based on the economic aspect, plant fibers used for soil reinforcement can be classified into three categories: (1) cultivated species, (2) uncultivated species, and (3) invasive species [

37].

Some aggregates or vegetable fibers have been used in several studies for soil reinforcement, among them: bamboo, jute, coco, palm, sugar cane bagasse, rise husk, and sawdust.

5.1.1. Bamboo Fiber (Bambusoideae)

Bamboo is a regenerated cellulose fiber and an abundant and viable natural resource, since there are more than 1250 species worldwide. Bamboo can grow naturally without using any pesticides and its fiber is rarely attacked by pests or infected by pathogens.

A study showed that a percentage combination of bamboo fiber with organic soil of the Khulna region, in Bangladesh, improved the mechanical properties in the use of embankments and subgrades. It has been shown that the addition of fiber improves ductility behavior and increases the California Bearing Ratio (CBR) value of the soil. It was observed from the test results that the CBR value of unswept and soaked soil increases with the increase in the length and diameter of the bamboo fiber. It was also found that increasing the percentage of bamboo fiber has a significant increase for the CBR value of the reinforced soil, with a fiber dose of 1.2% [

38].

On the other hand, in Kerala, a province of India, soils are weak and not suitable for any construction work, due to the marine clay with high contents of organic matter. The behavior of the compaction and strength of a marine clay reinforced with bamboo fiber has been described. The mean objective was focused to determine the reinforcing effect of discrete bamboo fibers distributed randomly on sea clay. The bamboo fiber used was crushed and added in five different percentages of fiber content, i.e., 0.25, 0.5, 0.75, 1, and 1.25% (by weight). Reinforced soil samples underwent unconfined compression tests and compaction tests [

39].

The behavior of the shear resistance of a floor reinforced with bamboo fiber is performed through tests of shearing on the reinforced and non-reinforced floor with different percentages of bamboo fiber. The study revealed that there is an increase in the parameters of the shearing strength of the soil with the increase of the percentage of fiber to an optimal amount. Two different fiber lengths were considered in the study and the shearing strength parameters also increase with increasing fiber length [

40].

The research focused on the reinforcement of sandy clay soils with bamboo fibers of 1.27 cm in width (1/2 inch) and 30 cm in length (12 inches), showing that reinforcement can increase bearing capacity and reduce the corresponding foundation settlement compared to unreinforced soil [

41].

The research on the reinforcement of clay soils with the use of bamboo fibers combined with flax has shown that values of cohesion and the angle of internal friction of soils are greater than those observed for pure clay, during the triaxial compression test at different confining pressures levels [

42].

5.1.2. Jute Fiber (Corchorus Capsularis)

Jute is one of the most widely grown natural fibers in the world, making it relatively inexpensive and commercially available in the required form. It is widely available in Asian countries as well as in Brazil. Several studies have been carried out on the uses of this material with geotechnical applications.

An experimental program of triaxial compression and shearing tests was carried out on reinforced and unreinforced soil specimens, observing how the content, length, and orientation of the jute fiber, dry density, and water content have an impact on the improvement of the parameters of the shearing strength. The study also shows a detailed discussion on the variation of the reinforcing effects and on the mechanisms that explain how fiber reinforcement effects are affected at the fiber and grain scale [

43].

The results of another recent study indicate that the inclusion of randomly distributed jute fibers significantly improves the value of the CBR (California Support Ratio) of the soil, for the soil studied (highly plastic clay designated as CH). The optimal value of the fiber content is 1.25%. A 226.92% improvement in the CBR value of reinforced soil compared to unreinforced soil with optimal jute fiber content has been observed [

44].

Similarly, evidence shows that the use of jute fiber improves the characteristics of subgrade soils. Clay material was used and it was observed that jute fiber reinforcement reduces the maximum dry unit weight and increases the optimal moisture content of the soil, while also increasing the CBR value of the soil when, for the same percentage of jute fiber, the ratio between the length and the diameter of the reinforcement fiber used decreases [

45].

On the other hand, the effects of jute fiber reinforcement on an expansive soil have been analyzed and it was observed that the most efficient results were achieved by adding a content of 0.6% fiber with a length of 6 mm to a soil optimized for proctor assay data. The cohesion of the reinforced samples increased with the increasing fiber content and length and then decreased with the further increase in fiber content and length [

46].

5.1.3. Coconut Fiber (Coir)

Coir is a versatile lignocellulosic fiber obtained from coconut trees [

47]. It is the material between the hard-inner shell and the outer layer of a coconut (Cocos nucifera), generally of a diameter that varies between 0.1 and 0.3 mm and of a length between 10 and 50 mm. The coconut is the most cultivated palm tree worldwide, hence its potential to be relatively inexpensive and have great availability in the form and quantities required. These fibers are biodegradable and eco-friendly, have the highest tear strength among all natural fibers and retain this property in wet conditions [

32]. Coir is biodegradable and takes approximately 20 years to decompose above ground.

Among the research carried out for the reinforcement of soils with coconut fiber, it can be mentioned that Proctor compaction tests developed for the different percentages of coir [

32]. In addition, with the optimal moisture content (OMC), shearing and unconfined compression tests were carried out for different coconut fiber fractions. Experimental results with and without coir reinforcement were compared to obtain the optimal amount of fiber reinforcement (% soil sample) needed to stabilize a weak soil along with inference on the effect on carrying capacity and shearing strength.

Coconut shell coir and lime for the treatment of an expansive clay soil is used with subgrade of a flexible pavement, obtaining the combined effect of the inclusion of lime and coir in the soil causing a significant increase in CBR between 1.04% and 9% [

48]. The increase in the content of coir marrow causes the reduction of density and the increase of optimal water content. The strength to unconfined compression of the modified soil (expansive soil + lime + coir marrow) is in the range of 300 KPa to 380 KPa after 3 days of curing, and after 7 days of curing it is in the range of 470 KPa to 570 KPa.

A study of the use of coconut fibers treated with alkali, coated with epoxy resin, and sprayed with stone powder for the improvement of a black cotton clay, indicated that the maximum dry unit weight decreases with the increase in the percentage of coir with and without optimal lime content. They also found that the alkaline treatment of the fiber causes a significant reduction in water absorption that leads to an appreciable improvement in the compaction and strength characteristics of the tested soil [

49].

An evaluation of the impact of coconut shell ash on the stabilization of sandy soils, mainly focused on increasing shearing strength, was carried out [

50]. When performing different tests with variable percentages of ash from the coconut shell, they observed that the addition between 0.4% and 0.8% caused an improvement in the maximum dry unit weight and optimal moisture content, as well as the internal friction angle and cohesion.

A study on the variation of the unlimited compressive strength (UCS) of a clay soil reinforced with coconut fiber concluded that the UCS of clay increases significantly with the addition of more coconut fiber. On the other hand, it was observed that the reinforced clay becomes stiffer than the initial soft clay, thus improving the stability of the soil being the coir a fiber with a higher tensile strength than others [

51].

5.1.4. Palm Fiber (Elaeis Guineensis)

The fiber obtained from the African oil palm is one of the materials that, in recent years, has begun to be studied as an alternative for soil reinforcement.

A very interesting study on the use of palm as a soil reinforcement mechanism was developed [

52], showing the incidence of four different variables (content, size, and orientation of strips of the palm sheath, as well as the normal strength applied in shearing tests) in the behavior and strength of the reinforced cohesive soil, with strips of palm sheath. The results of the tests showed that the use of strips of natural palm sheath improved the strength of the tested soil.

Another research focused on the use of natural fibers obtained from empty bunches of oil palm fruit to be added to a soft soil in percentages that varied from 5 to 8%. Compaction tests were carried out, as well as unconfined compression and CBR, observing that in the samples of compacted soil, more additions of palm fiber showed an increase in the parameters of shearing strength and bearing capacity [

53].

Research conducted on the use of dried and crushed palm fibers for improving the properties of a clay soil (shale) of high plasticity showed that the addition of randomly oriented fibers decreased the maximum dry unit weight of the soil and increased the values of the shearing strength, mainly in the cohesion parameter [

54].

A study showed the potential application of palm fiber located at the down riverside of Yangtze River, China, with the aim of exploring the mechanical behavior of a clay soil reinforced with palm fibers through unconfined compression tests on samples treated with palm fibers of different lengths and percentages, focusing on strength of soil reinforced with palm fiber [

55].

5.1.5. Sugarcane Bagasse Fiber

Bagasse fiber is a waste material of the sugarcane industry (Saccharum officinarum), left over from the extraction of sugarcane juice and existing as a rich resource for its high yield and annual production capacity. Sugarcane bagasse fiber has been identified as one of the potential materials for stabilizing expansive soils [

37].

An example of these investigations shows the influence of the addition of cane bagasse fibers, randomly distributed, in variable proportions (0.5% to 2%) on the engineering behavior of an expansive soil [

56]. A series of experimental tests were carried out on expansive soil samples with and without fibers, with the addition of certain percentages of hydrated lime. This paper presents linear shrinkage and unconfined compressive strength test results after several curing time periods of 3, 7, and 28 days.

Similarly, a study to evaluate the potential of bagasse fiber as a soil reinforcement material showed that these fibers mixed with bentonite in different contents (0.25%, 0.5%, 0.75%, and 1%) in relation to the dry unit weight of the soil increased the value of the unconfined compressive strength of soil samples [

57].

Research conducted on the degree of strength and stiffness response due to the variable sugarcane bagasse content, normal pressures, and soil conditions, found that the increase in fiber content up to 1.4% non-linearly increased the maximum shearing strength, and an increase in fiber content beyond 1.4% reduced the shearing strength of the soil [

58]. This study shows the potential usage of bagasse as reinforcement material in soils exposed to low loads.

On the other hand, the influence of hydrated lime and cane bagasse ash on the engineering properties of expansive soils has been analyzed, concluding that the additions of these two materials markedly improved the strength and carrying capacity of the stabilized expansive soil and significantly reduced the linear contraction of the treated expansive soil [

59].

5.1.6. Rice Husk Fibers

Rice husk is an important agricultural by-product obtained from rice (Oryza sativa) at food crops. It is one of the most commonly available lignocellulosic materials worldwide. The composition of rice husk is more complex than that of other fibrous materials; silica is distributed 91.1% in rice husk and is presented as hydrated grains, which are biosynthesized by polymerization of silica acid by living organisms. Rice husk ash (RHA) is a pozzolanic material that could potentially be used in soil stabilization.

Based on the research conducted, the addition of certain amounts of RHA to a clay soil produced a significant increase in its Liquid (LL) and Plastic (PL) Limits and a decrease in its Plastic Index (PI); in addition, treatment with RHA resulted in a significant increase in uncoffin compressive strength [

60].

The potential of RHA as a soil stabilizer can be enhanced by mixing it with small amounts of cement or lime, mainly because the lime reacts with the silica present in the RHA and forms cementitious compounds and thus improves the geotechnical properties of expansive soils [

61]. RHA can also be used with a small amount of soil reinforcement materials, such as polypropylene and waste coconut fibers for good results.

A study of the use of RHA and cement in soil stabilization shows an increase in optimal moisture content, but a decrease in maximum dry density. Along with an increase in CBR, from the observations it can be seen that 10% of RHA and 6% of cement result in maximum improvement in desired soil properties [

62].

The addition of RHA and cement to a clay soil stabilizes it and improves its mechanical properties, specifically those corresponding to compaction, shearing strength characteristics, compressive strength, and CBR [

63].

5.1.7. Sawdust

Sawdust is a by-product of wood processing and is one of the most abundant sources of industrial waste in the world, generating major problems of environmental pollution due to its inadequate final disposal.

Due to the rough texture of its surface, sawdust can produce great friction that can improve the strength of the soil, generating the swelling potential and swelling pressure of the samples that are reduced with the increase in the addition of sawdust [

3]. The values of the shearing strength parameters (cohesion and friction angle) increase with the addition of sawdust before reaching an optimum; beyond the optimum, values begin to decrease.

The treatment of a clay with an increasing percentage of sawdust causes a reduction in its specific gravity, plasticity, maximum dry unit weight, and unconfined compressive strength, while causing an increase in its optimal moisture content and permeability; consequently, the workability of the clay is improved, but its strength is reduced. The modification of bentonite with sawdust resulted in a reduction in its specific gravity, maximum dry unit weight, and unconfined compressive strength, while increasing (slightly) its plasticity, optimal moisture content, and permeability [

8].

The stabilization of an expansive clay soil subgrade with the use of variable percentages of sawdust ash results in its optimization in compaction for a percentage of 16% in dry weight of material, to subsequently add variable percentages of calcium hydroxide [

64].

A study on the effects of pine sawdust on the volumetric compressibility of an expansive soil showed that the volumetric compressibility coefficient of the tested soil decreased significantly with the addition of a higher pine sawdust content; on the other hand, the consolidation coefficient of the tested soil increases [

65].

Figure 5 shows a representation of the worldwide locations of the research works mentioned above for seven of the natural fibers (plants) that are currently being analyzed for possible use in the improvement of the engineering properties of soils that present deficiencies in the support of the efforts due to possible constructions on them.

This information allows us to visualize the distribution of the current trend, as well as the importance given by some countries to research focused on the use of natural, environmentally friendly materials in the reinforcement and stabilization of soft soils in the world. Although there may be other research studies not considered in this review, it is very probable that the approaches to them are similar.

6. Mercerization of Fibers

The use of natural fibers presents drawbacks, such as the fact that this type of materials is characterized by a low chemical resistance and is susceptible to corrosion which, added to biodegradation, limits its use to temporary structures and low risk in the face of an eventual failure due to degradation [

29].

To mitigate this limitation, some researchers have proposed the use of natural fibers coated with synthetic materials, modifying their surface by physical and chemical methods reducing the hydrophilic nature of the fiber and decreasing its rate of biodegradation in natural environments [

47]. Among the substances used for the treatment and coating of natural fibers in order to reduce their biodegradability, we can mention: Boric Acid, Borax, Carbon Chloride (carbon tetrachloride), and Sodium Hydroxide (Soda Caustic) [

37].

NaOH was the main alkali agent for the alkaline treatment, whereas LiOH and KOH could also be used and compared specifically since lithium interacts more efficiently with hydroxyl groups of cellulose [

66]. In addition, scanning electron microscopy (SEM) is a common technique applied to visualize the effect of alkaline treatment on fibers [

67]; however, other visual techniques can be used to visualize the superficial effect of alkaline treatment on fibers.

Figure 6 shows a view of images with optical microscope 400× resolution of the mercerization effect on wood fibers surface using NaOH as an alkaline agent at different exposure times as a part of recent tests carried out by our research group in the laboratory.

Currently, alkaline treatment or mercerization is one of the chemical procedures of natural fibers most used in different applications [

68] which reduces the content of lignin, hemicellulose, waxes, and oils that cover the surface of the fibers, which also tends to increase the surface roughness of the fibers [

69]. Cellulose fibrillation increases the surface area available for the fiber-matrix interaction and potentially improves the properties of filler compounds.

The mercerization is a process that fibers interact with in a concentrated aqueous solution of a strong base to swell with resultant changes in the structure, dimension, morphology, and consequently, mechanical performance [

33].

Alkaline treatment has two effects on the fiber: (1) it increases the roughness of the surface resulting in better mechanical interlocking; and (2) increases the amount of cellulose exposed on the surface of the fiber, thereby increasing the number of possible reaction sites. Consequently, alkaline treatment has a lasting effect on the mechanical behavior of the fibers, especially on the strength and stiffness of the fiber [

70].

In recent years, natural fibers reinforced composites are treated as the most promising material in different applications due to its attractive properties. Natural fibers are now dominant in the automotive, construction, and sporting industries due to its superior mechanical properties. These natural fibers include flax, hemp, jute, sisal, kenaf, coir, and many others [

71].

The various advantages of natural fibers is that they are low density, low cost, low energy inputs, and have comparable mechanical properties as well as better elasticity of polymer composites reinforced with natural fibers, extremely low shrinkage, good dimensional stability, high temperature resistance, good fatigue, and adherence to reinforcements [

72].

Based on

Table 2, alkaline treatment improved the mechanical properties in most cases, but some controversy results are also achieved, especially when a pre-load was combined with alkaline treatment which can be attributed to the removal of natural fibers’ main compositions.

7. Results and Discussions

Currently, in the field of geotechnical engineering, there are different alternatives for the improvement of the physical and mechanical properties of soils, specifically if they are not suitable to adequately withstand the stresses to which they are subjected by the structures built on them. However, in recent years, there has been a growing interest in alternatives that take into account a sustainable approach, focusing on the use of materials that are more respectful to the environment, such as organic fibers, which provide the soil with an improvement in its mechanical resistance, increasing its capacities to withstand the efforts exerted, and resulting in an ecologically friendly and very low-cost technique. In the research carried out in the field of geotechnical and geoenvironmental engineering, it has been observed that the soil reinforced with this type of fibers behaves as a composite and their random additions causes an increase in properties such as its shearing strength and bearing capacity, emulating the behavior of tree and wild plants roots on slopes.

The use of this type of natural materials is more beneficial than traditional methods, in terms of energy efficiency and environmental pollution, since these require lower energy consumption in their processing and application, in addition to not affecting the soil significantly due to the toxicity of inorganic and artificial materials that could be used for the stabilization of clay soils. An advantage of being able to be used in raw form is that it requires less processing, so they cause less damage to the environment.

The fibers presented in this work are agricultural by-products generated in high volume, in different regions of Asia, Africa, and Europe mainly, under environmental conditions of different temperature and humidity. This makes it possible to demonstrate the capacity of application of organic fibers from different regions for the improvement of mechanical properties of soils, based on specific criteria such as the identification of the type of predominant crop in a region and the type of process to which it is subjected for the generation of fiber as a usable by-product, as well as the knowledge of the characteristics of soils of the region that are candidates to stabilize with the application of organic fibers.

Next, an analysis of the information obtained from the different scientific articles reviewed is carried out. This analysis focuses on each of the natural fibers (plants) taken into account in this study, observing that the researchers considered fiber variables such as length, diameter, and percentage added by weight of dry soil, and response variables corresponding to soil characteristics such as behavior before compaction, the parameters of shearing strength, and bearing capacity, which also shows data on the optimal percentage of addition of the fibers to obtain the best values in the response variables analyzed.

7.1. Research on Bamboo Fibers

Table 3 shows five of the studies carried out in the last decade on the use of bamboo fibers for soil improvement. It can be seen that these are mainly concentrated in the south east of the Asian continent, which is linked to the fact that this type of grass plant grows naturally in the tropical areas of all continents, the most important areas being Southeast Asia and South America. The investigations expose values of optimal percentage of fibers between 1.0 and 4.0%. It is worth mentioning that in the research carried out by [

39], the fiber was crushed before being added to the soil, while in the investigations carried out by [

41,

42], the fibers were used in the form of strips or bands, in which two layers of reinforcement and four strips, respectively, were required as optimal values.

7.2. Research on Jute Fibers

The research reported with the use of jute fibers for soil reinforcement is shown in

Table 4. These correspond to countries located in Southeast Asia (India, Bangladesh, and China), ratifying the fact that these three nations contribute more than 90% of the world production of this type of fiber. The investigations expose values of optimal percentage of fibers between 0.6 and 1.25%. The investigations carried out by [

43,

46] additionally show a value of the optimal length of the fibers, which are 12 to 18 mm and 6 mm, respectively.

7.3. Research on Coconut Fibers

Table 5 shows five of the studies carried out with the use of coconut fibers in soil reinforcement. Considering that the global supply of coconut is led by Asian countries, highlighting that the three main producers are Indonesia, the Philippines, and India, it is not surprising that the sample of articles reviewed is from India and Indonesia, in which values of optimal percentage of fibers between 0.4 and 2.0% are exposed.

7.4. Research on Palm Fibers

Regarding the investigations with palm fibers, these are shown in

Table 6. All the investigations correspond to countries of Southeast Asia, highlighting Indonesia as one of the countries with the highest production worldwide. It is noted that in the investigations carried out by [

52] and [

55], the optimal values correspond to fiber lengths and percentages of 4 mm and 15 mm, and 0.5 and 0.4%, respectively.

7.5. Research on Cane Bagasse Fibers

With regard to the use of cane bagasse fibers,

Table 7 shows some of the research carried out in recent years, showing that these are more diversified than those of the previous fibers, since they are distributed in countries that correspond to the continents of Oceania, Asia, and Africa. Exhibiting an improvement in the properties of the soils with the increase in the percentage added to the soil was analyzed.

7.6. Research on Rice Husk Fibers

The investigations with the use of the fiber of the rice husk are shown in

Table 8. We observe that all of them correspond to countries of Southeast Asia, which constitute the largest producers of this cereal worldwide. It should be noted that this type of fiber is usually used in an incinerated way (in the form of ash). The optimal values of this vary from 2.5 to 10%.

7.7. Research on Sawdust Fibers

Regarding the studies with the use of sawdust fibers, these are shown in

Table 9. They correspond to research work from countries in Africa and Asia. The related optimal values are between 7.5 and 8%. It should be noted that the research carried out by [

64] was carried out with the calcined sawdust fiber (ash) obtaining an optimal addition value of 16%.

7.8. Other Research Priorities

The main objectives of research on the use of material fibers in improving the engineering properties of soils with high clay contents include, but are not limited to:

- -

Use of materials of natural origin that are friendlier to the environment, contributing to the reduction of greenhouse gas emissions produced, in many cases, by the techniques currently used in soil reinforcement.

- -

Analysis of the sources of supply and achievement of the different fibers, considering that many of them can be obtained as waste from industrial and agro-industrial processes.

- -

Determination of the physical, chemical, and mechanical properties of the fibers to be used in the reinforcement of soils to correlate the chemical composition of the fibers with their physical and mechanical properties, as well as the nature of the soil in which their application is viable.

- -

Study of the biodegradability of fibers as a possible inconvenience for their use and the analysis of the different alternatives of chemical treatment prior to their addition to soils.

- -

Validation and standardization of the experimental results obtained from the mechanical properties of the soils with the addition of natural fibers, to establish the pretreatment processes and methodology of application of the fibers for the improvement of the engineering properties of clay soils.

- -

Improvement of the accuracy and technical basis of the environmental assessment of soil mixtures with the fibers studied.

8. Conclusions

Soil reinforcement with natural fibers has been applied since ancient times; however, the use of natural and synthetic short fibers has recently attracted increasing attention in geotechnical engineering.

This review article shows the reader the trend, in geotechnical engineering, towards the use of natural fibers for the reinforcement and improvement of the engineering and mechanical properties of soft clay soils, to be used in construction structures (i.e., pavements, slope stabilization, foundations for buildings). In some cases, this application of fibers includes the option of reincorporation into the productive chain of materials currently considered waste. The use of this type of materials has attracted the attention of researchers mainly for environmental reasons, requiring to know and understand in a better way concepts such as durability and soil-fiber interaction, in order to guarantee the effectiveness of its possible use in engineering works. Significant advances have been made in this regard in the last decade, but greater understanding is needed, particularly in aspects such as size, shape, percentage, form of distribution of fibers, biodegradability, mechanical properties, chemical composition, etc., requiring a multidisciplinary vision covering fields such as physics, chemistry, materials science, chemical engineering, and civil engineering providing valuable contributions from different points of view so that a deeper knowledge on the subject can be generated. This document has been intended to show the existence of low-cost and abundant materials in the world suitable to improve the engineering properties of some soils, with the great advantage of generating a reduced environmental impact compared to many of the techniques currently used.

As a result of the research carried out, knowledge about the characteristics of these materials arises, but there is still much to learn, and this provides opportunities and challenges for researchers and professionals to improve on mechanical characteristics in construction works, and meet needs in vulnerable sectors through the development of sustainable technologies in developing countries.

However, properties such as low durability, poor bonding, increased water absorption, and comparatively worse thermal and mechanical properties than man-made fibers still represent a major obstacle in the practical applications of plant fibers.

Although natural fibers, according to many authors, are divided into three large groups: plant fibers, mineral fibers, and animal fibers, based on their availability and quantity, the concept of natural fibers for fibers from plants is widely assumed.

It is important to note that in Latin America, research work on the use of natural fibers as soil reinforcement materials is scarce, predominating mainly in Asia, Europe and Africa. This opens an area of interest to work on the use of agricultural by-products of high availability in developing countries of America, for their identification and use as alternative materials for the reinforcement of expansive clay soils, and thus also minimize the amount of industrial and agro-industrial waste that is deposited in the environment and causes environmental pollution.

Considering the 30 scientific articles reviewed in this paper, approximately three-quarters (73%) correspond to research developed in four countries that are located in Southeast Asia (India, China, Bangladesh, and Pakistan), which are additionally part of the most populated nations in the world (1st China, 2nd India, 6th Pakistan, and 8th Bangladesh) with a group population of approximately 3,000,000,000 habitants. These countries must have a high production in their agricultural sector in order to be able to provide food to their habitants, which leads to a high production of waste, whose poor disposal generates great environmental inconveniences to their territories. In view of what has been mentioned above, these countries have seen the need to study alternatives with a focus on sustainability, promoting the use of this type of waste in the reinforcement and improvement of the engineering properties of the soils in the face of the shortage of land and optimal materials for the field of construction.

In the same way, the results of these investigations open the opportunity to carry out similar studies in other parts of the world, where natural fibers are available, such as waste materials from agro-industrial processes, which allow to expand knowledge about this new technique of improving the engineering properties of soils.