Mechanical Behavior of Epoxy Reinforced by Hybrid Short Palm/Glass Fibers

Abstract

:1. Introduction

2. Experimental Work

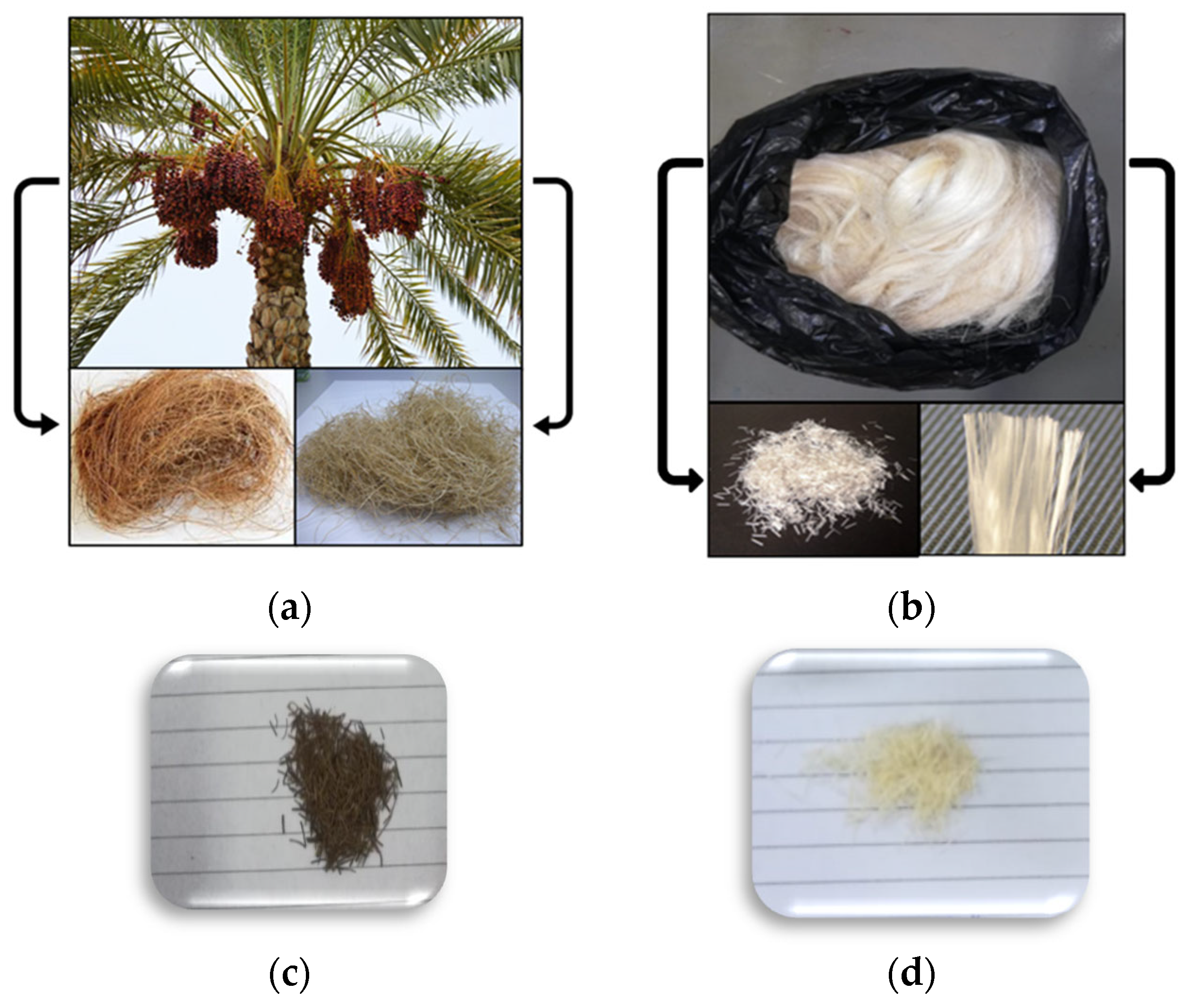

2.1. Raw Materials and Preparations

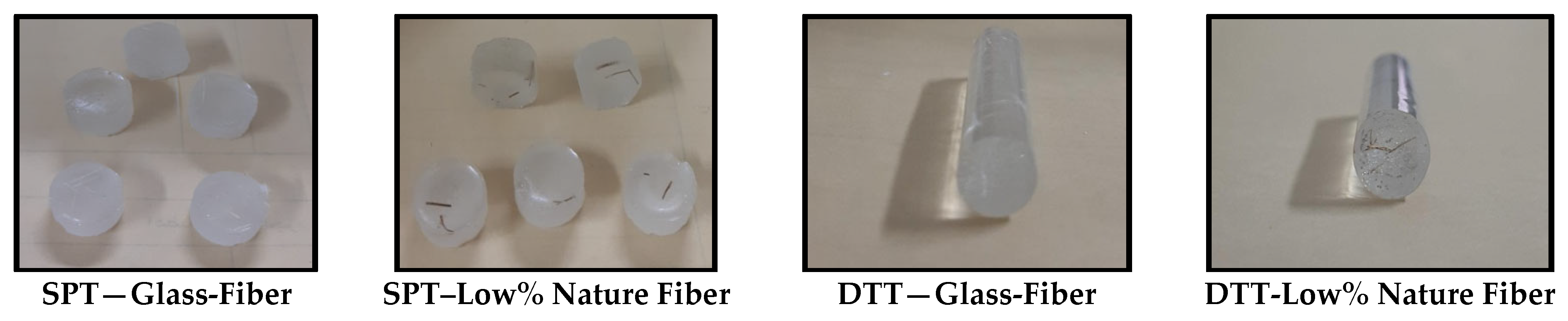

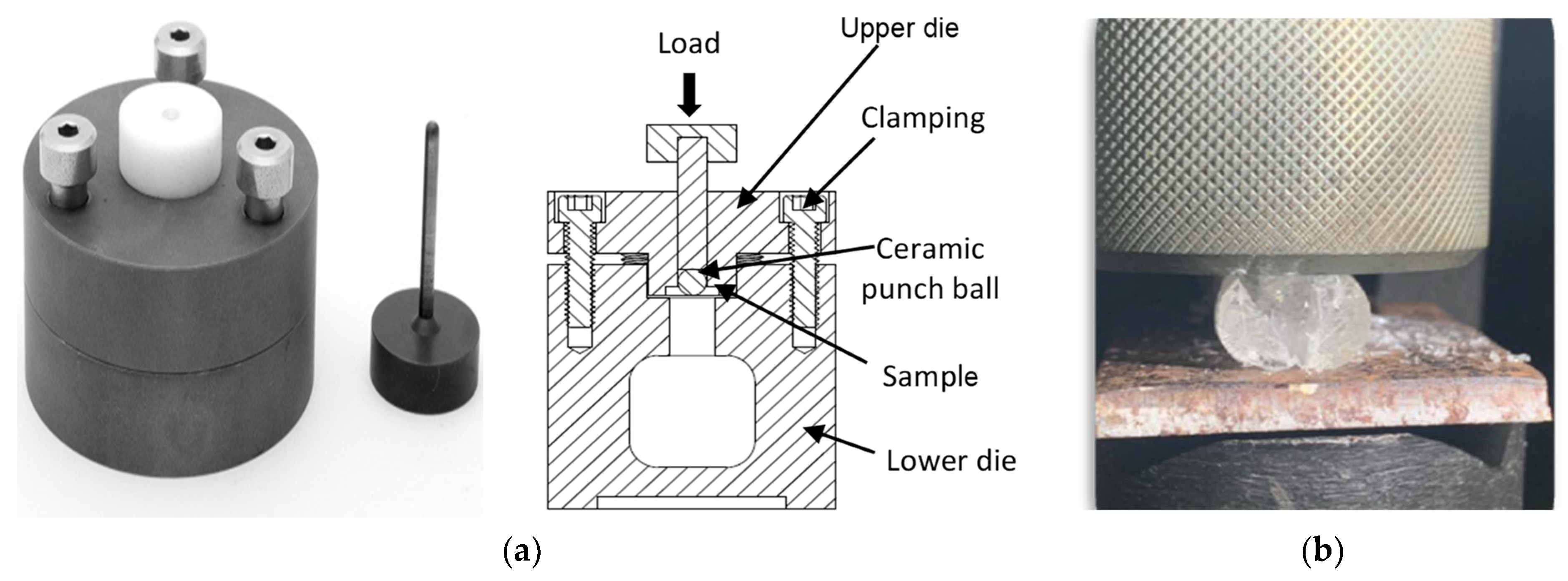

2.2. Small Punch and Diametral Tensile Tests

2.3. Microstructural Examination

3. Results and Discussion

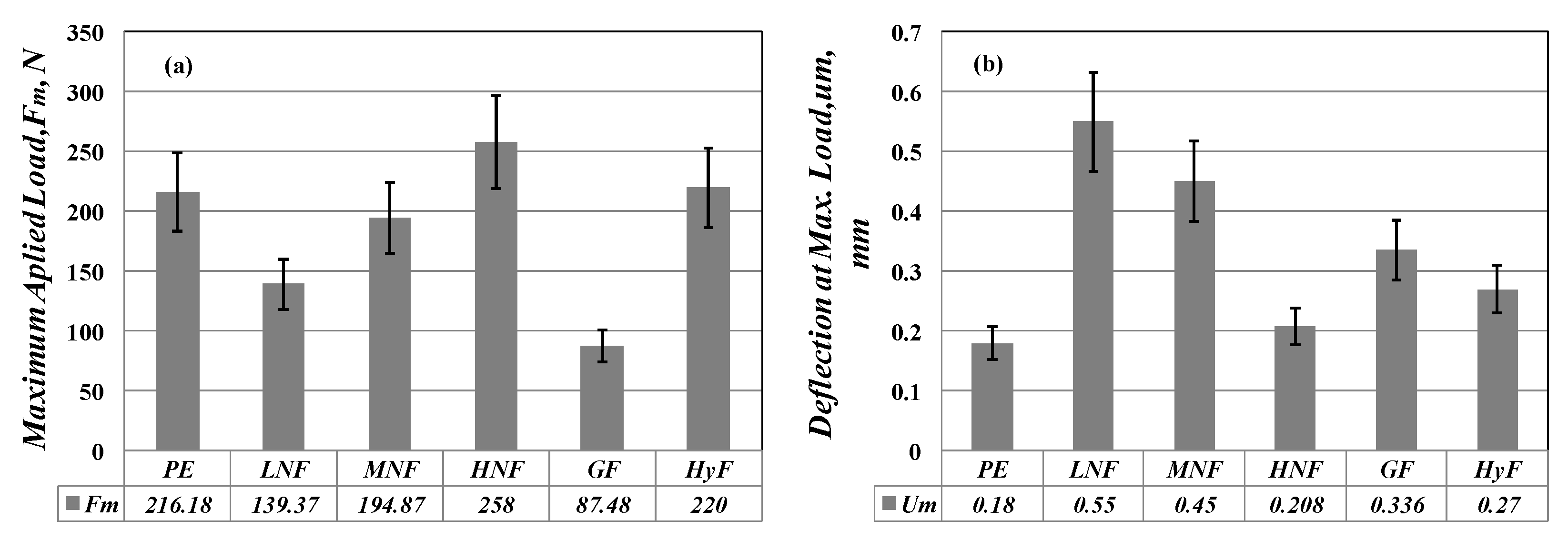

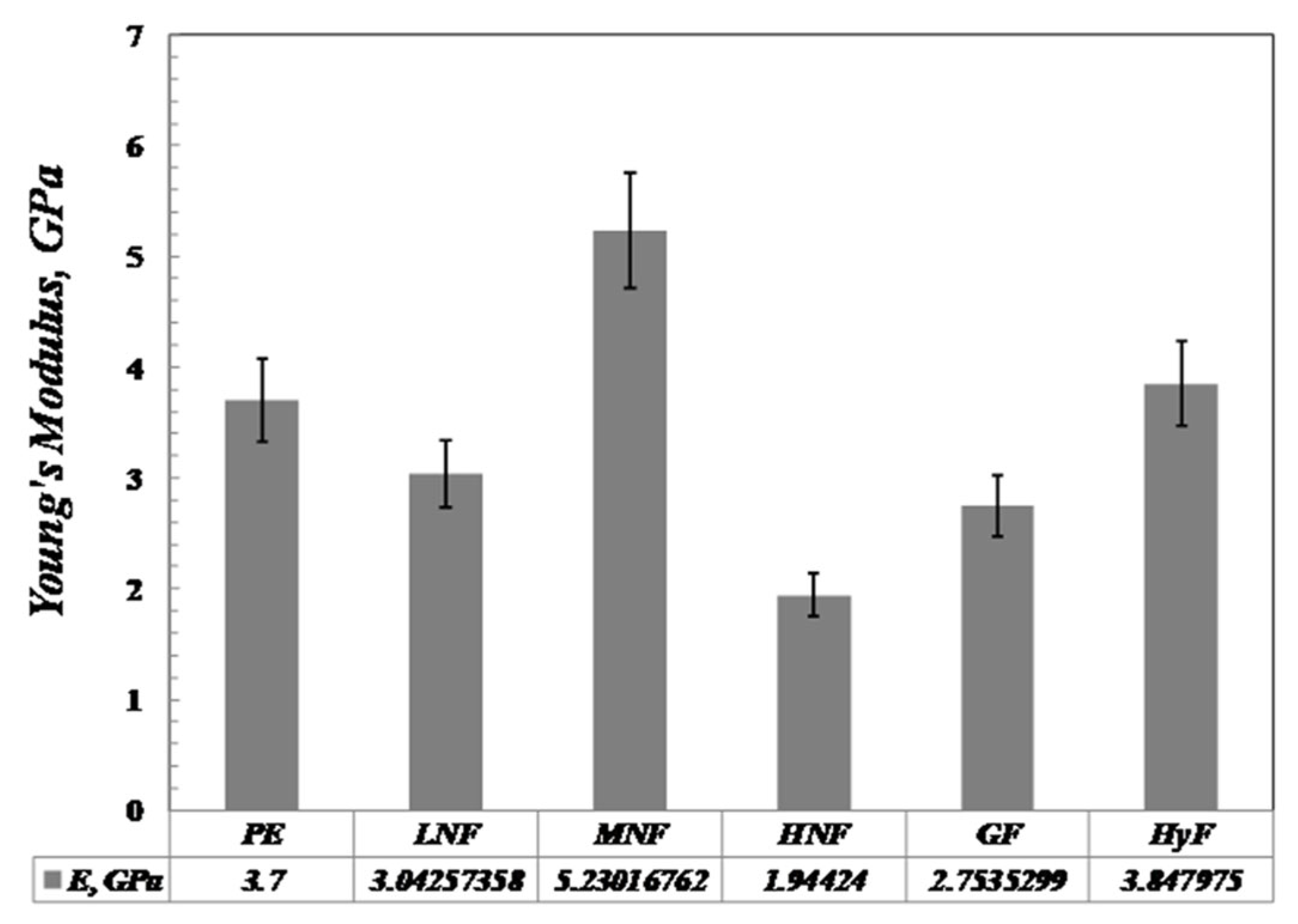

3.1. The DTT Results

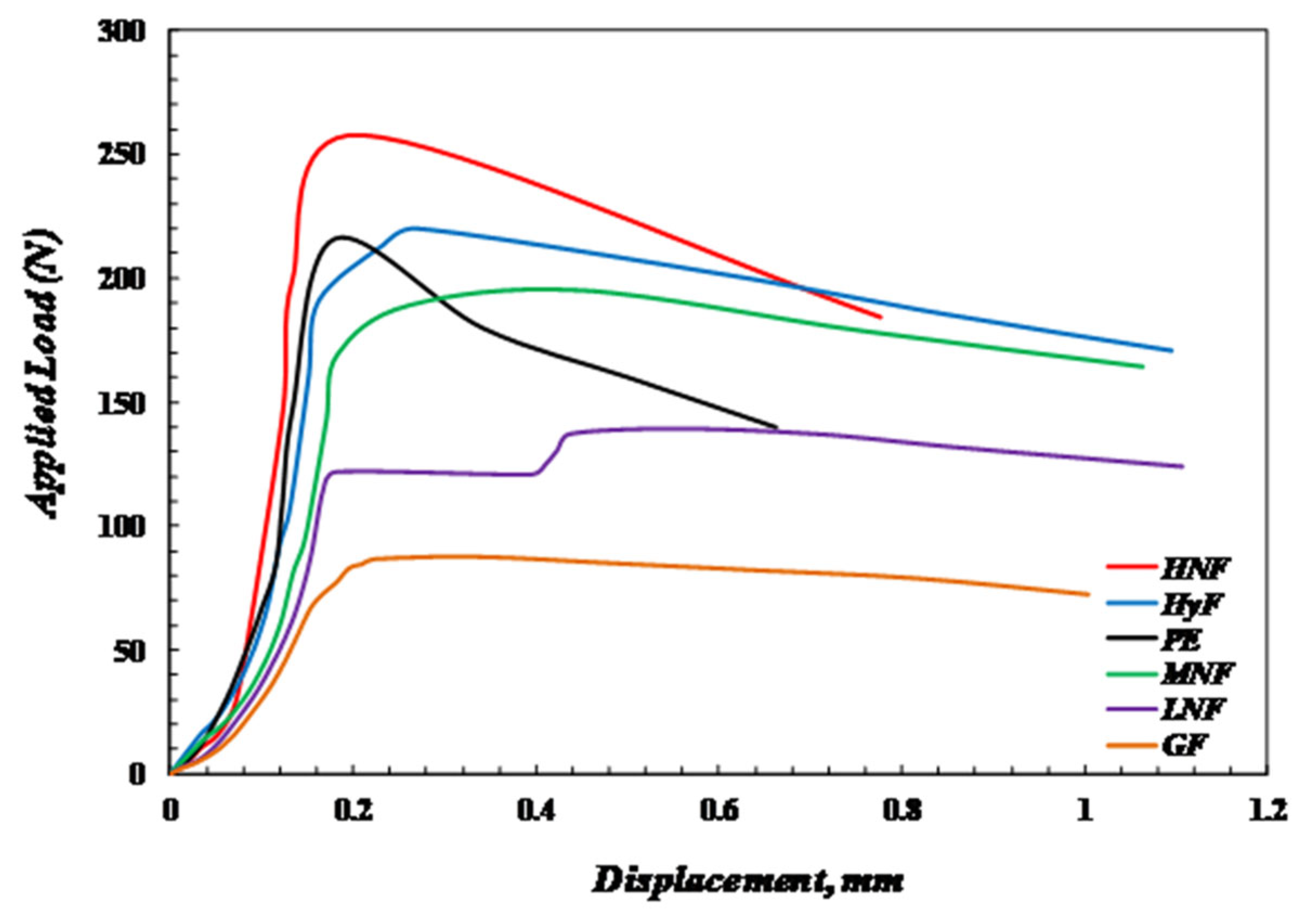

3.2. Small Punch Test Results

3.3. Morphological Analysis

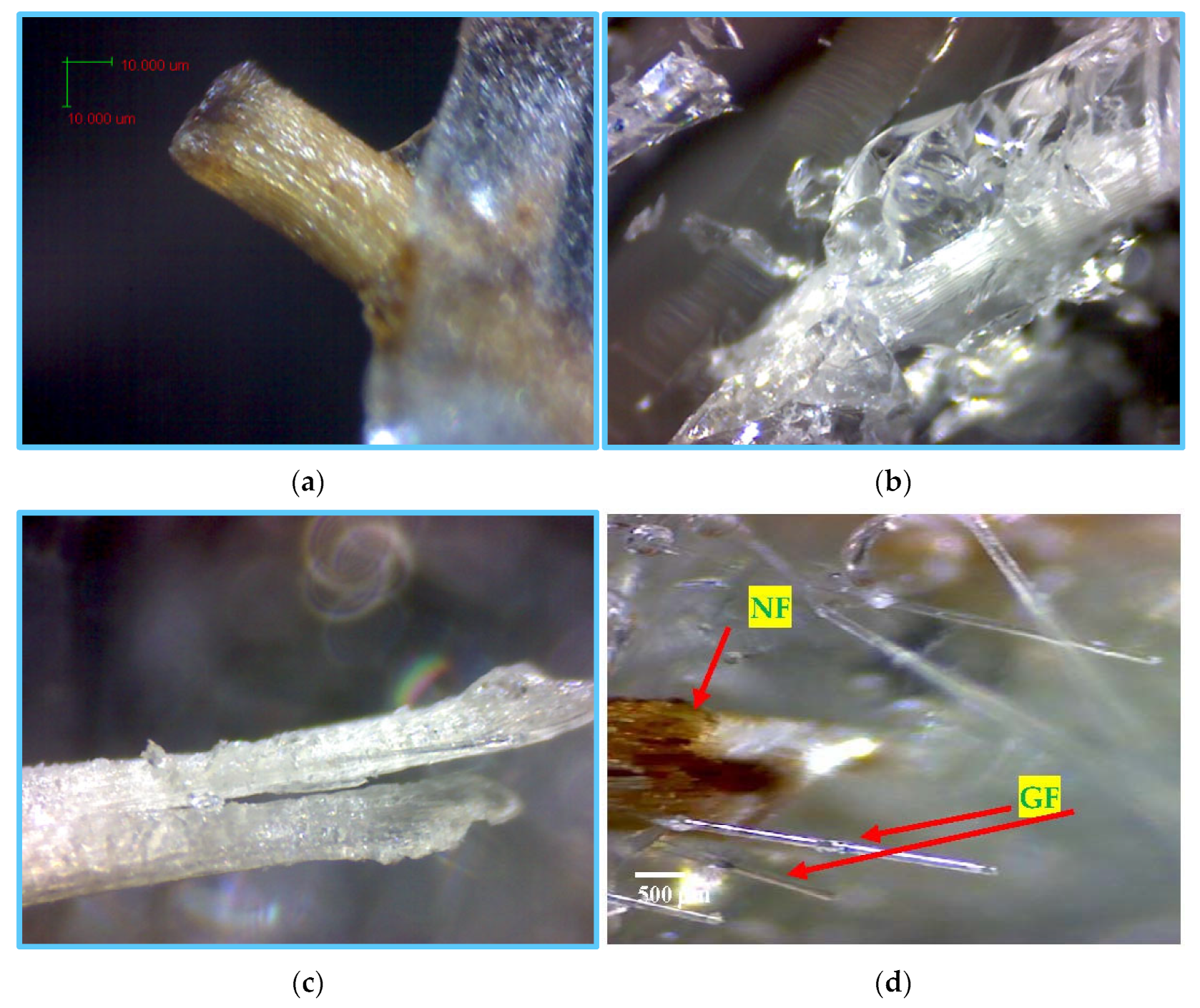

3.3.1. Optical Microscope

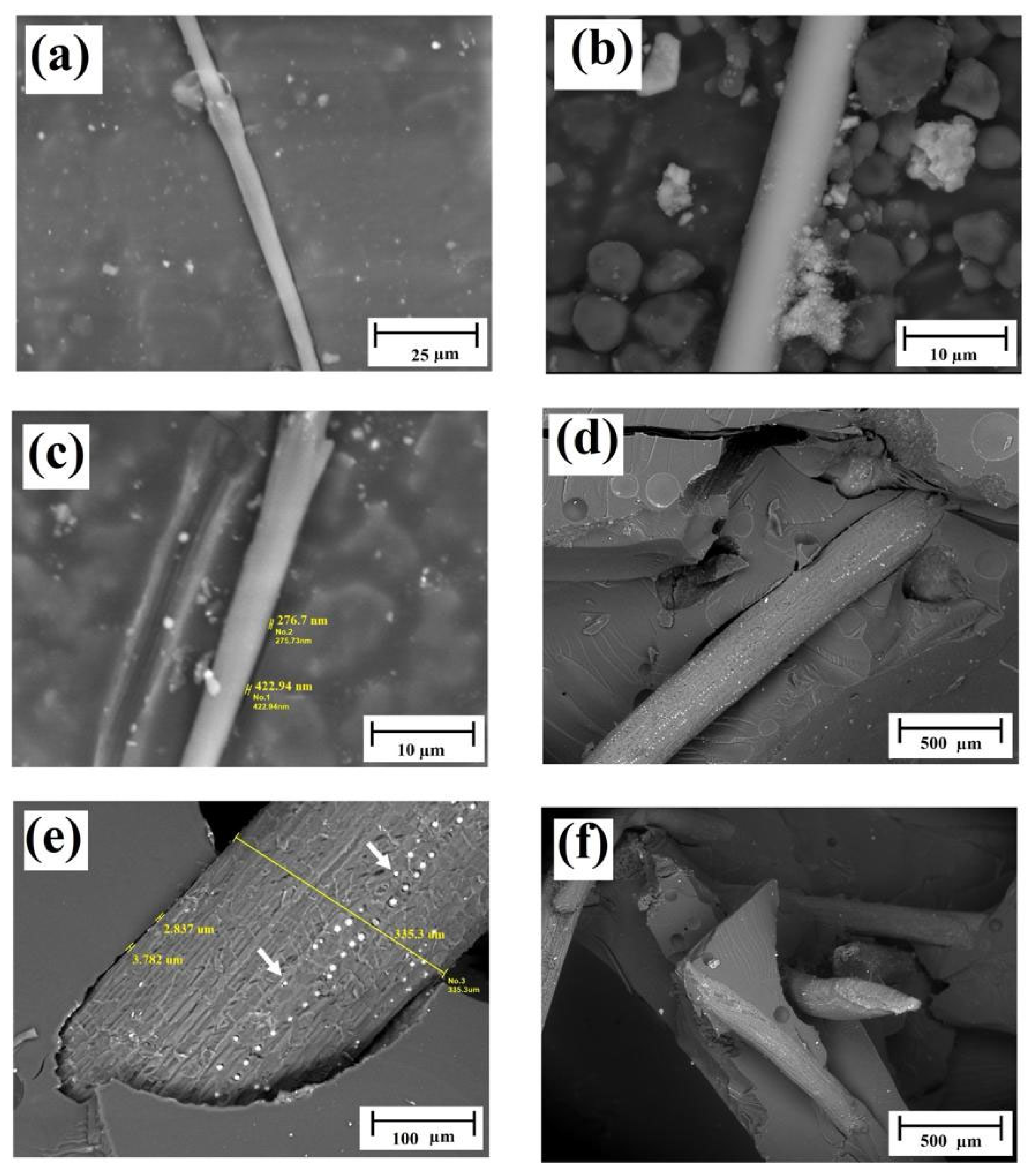

3.3.2. Scanning Electron Microscopy (SEM)

4. Conclusions

- Palm fibers can be used to improve the ductility of epoxy;

- The use of palm fibers in an epoxy-based composite may improve the strength of the epoxy according to the weight ratio of fiber used;

- For the same Wt.%, epoxy reinforced with short palm fibers has a higher DTS than epoxy reinforced with short glass fibers;

- The composite with high Wt.% of NF showed the highest DTS, 21.74 MPa, over other composites. The DTS of composites with medium and low Wt.% of NF was lower than that of the high Wt.% by 14% and 30%, respectively;

- The material-dependent empirical constants (βUTS) decreased from 0.43 to 0.06 by increasing the Wt.% of palm fibers from 6% to 41.6%;

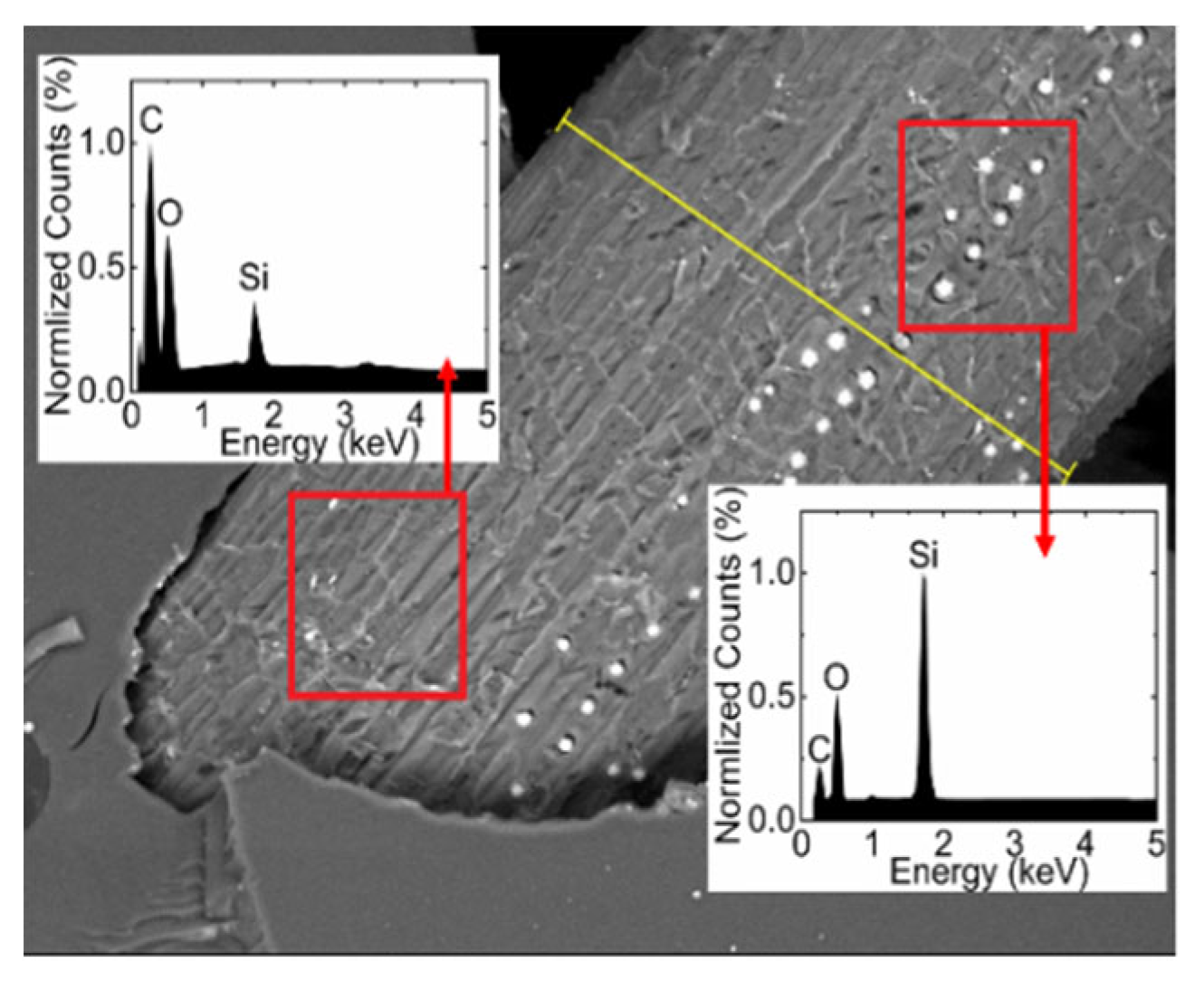

- SEM analysis showed that the natural fiber has a better adhesion bonding between the palm fiber/epoxy than in the glass fiber/epoxy case;

- The better adhesion bonding of the natural fiber is possibly attributed to silica bodies attached to the surfaces and the differences in the physicochemical interactions at the fiber/epoxy interfaces.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Asyraf, M.R.M.; Ishak, M.R.; Syamsir, A.; Nurazzi, N.M.; Sabaruddin, F.A.; Shazleen, S.S.; Norrrahim, M.N.F.; Rafidah, M.; Ilyas, R.A.; Rashid, M.Z.A.; et al. Mechanical properties of oil palm fibre-reinforced polymer composites: A review. J. Mater. Sci. Technol 2022, 17, 33–65. [Google Scholar] [CrossRef]

- Jeyapragash, R.; Srinivasan, V.; Sathiyamurthy, S. Mechanical properties of natural fiber/particulate reinforced epoxy composites—A review of the literature. Mater. Today Proc. 2020, 22, 1223–1227. [Google Scholar] [CrossRef]

- Kumar, R.; Anand, A. Tribological behavior of natural fiber reinforced epoxy-based composites: A review. Mater. Today Proc. 2019, 18, 3247–3251. [Google Scholar] [CrossRef]

- Dixit, S.; Goel, R.; Dubey, A.; Shivhare, P.R.; Bhalavi, T. Natural fibre reinforced polymer composite materials—A review. Polym. Renew. Resour. 2017, 8, 71–78. [Google Scholar] [CrossRef]

- Abdal-hay, A.; Suardana, N.P.G.; Jung, D.Y.; Choi, K.-S.; Lim, J.K. Effect of diameters and alkali treatment on the tensile properties of date palm fiber reinforced epoxy composites. Int. J. Precis. Eng. Manuf. 2012, 13, 1199–1206. [Google Scholar] [CrossRef]

- Helaili, S.; Chafra, M.; Chevalier, Y. Natural fiber alfa/epoxy randomly reinforced composite mechanical properties identification. Structures 2021, 34, 542–549. [Google Scholar] [CrossRef]

- Berthet, M.A.; Gontard, N.; Angellier-Coussy, H. Impact of fibre moisture content on the structure/mechanical properties relationships of PHBV/wheat straw fibres biocomposites. Compos. Sci. Technol. 2015, 117, 386–391. [Google Scholar] [CrossRef]

- Ramasamy, M.; Arul Daniel, A.; Nithya, M.; Sathees Kumar, S.; Pugazhenthi, R. Characterization of natural—Synthetic fiber reinforced epoxy based composite—Hybridization of kenaf fiber and kevlar fiber. Mater. Today Proc. 2021, 37, 1699–1705. [Google Scholar] [CrossRef]

- Ganesh, S.; Gunda, Y.; Mohan, S.R.J.; Raghunathan, V.; Dhilip, J.D.J. Influence of stacking sequence on the mechanical and water absorption characteristics of areca sheath-palm leaf sheath fibers reinforced epoxy composites. J. Nat. Fibers 2022, 19, 1670–1680. [Google Scholar] [CrossRef]

- Mylsamy, K.; Rajendran, I. Influence of Fibre length on the wear behaviour of chopped agave americana fibre reinforced epoxy composites. Tribol. Lett. 2011, 44, 75. [Google Scholar] [CrossRef]

- Nirmal, U.; Hashim, J.; Low, K.O. Adhesive wear and frictional performance of bamboo fibres reinforced epoxy composite. Tribol. Int. 2012, 47, 122–133. [Google Scholar] [CrossRef]

- Boopathi, L.; Sampath, P.S.; Mylsamy, K. Influence of fiber length in the wear behaviour of borassus fruit fiber reinforced epoxy composites. Int. J. Eng. Sci. Technol. 2012, 4, 4119–4129. [Google Scholar]

- Chaudhary, V.; Bajpai, P.K.; Maheshwari, S. An investigation on wear and dynamic mechanical behavior of jute/hemp/flax reinforced composites and its hybrids for tribological applications. Fibers Polym. 2018, 19, 403–415. [Google Scholar] [CrossRef]

- Sabeel Ahmed, K.; Khalid, S.S.; Mallinatha, V.; Amith Kumar, S.J. Dry sliding wear behavior of SiC/Al2O3 filled jute/epoxy composites. Mater. Des. 2012, 36, 306–315. [Google Scholar] [CrossRef]

- Nasir, R.M.; Montaha, M.R.A.; Radha, V.; Saad, A.Y.; Gitano-Briggs, H.W. Tribological performance of resin impregnated gunny (RIG) and resin reinforced honeycomb (RRH) material composites. Mater. Des. 2013, 48, 34–43. [Google Scholar] [CrossRef]

- Chin, C.W.; Yousif, B.F. Potential of kenaf fibres as reinforcement for tribological applications. Wear 2009, 267, 1550–1557. [Google Scholar] [CrossRef]

- Chin, C.W.; Yousif, B.F. Tribological behaviour of KFRE composite. Int. J. Mod. Phys. B 2010, 24, 5589–5599. [Google Scholar] [CrossRef]

- Yousif, B.F.; Chin, C.W. Epoxy composite based on kenaf fibers for tribological applications under wet contact condition. Surf. Rev. Lett. 2012, 19, 1250050. [Google Scholar] [CrossRef]

- Kumar, R.; Anand, A. Dry sliding friction and wear behavior of ramie fiber reinforced epoxy composites. Mater. Res. Express 2018, 6, 015309. [Google Scholar] [CrossRef]

- Nascimento, D.C.O.; Ferreira, A.S.; Monteiro, S.N.; Aquino, R.C.M.P.; Kestur, S.G. Studies on the characterization of piassava fibers and their epoxy composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 353–362. [Google Scholar] [CrossRef]

- Omrani, E.; Menezes, P.L.; Rohatgi, P.K. State of the art on tribological behavior of polymer matrix composites reinforced with natural fibers in the green materials world. Eng. Sci. Technol. Int. J. 2016, 19, 717–736. [Google Scholar] [CrossRef] [Green Version]

- Sbiai, A.; Kaddami, H.; Fleury, E.; Maazouz, A.; Erchiqui, F.; Koubaa, A.; Soucy, J.; Dufresne, A. Effect of the Fiber Size on the Physicochemical and Mechanical Properties of Composites of Epoxy and Date Palm Tree Fibers Macromol. Mater. Eng. 2008, 293, 684–691. [Google Scholar] [CrossRef]

- ASTM E3205-20; Standard Test Method for Small Punch Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- Faiad, A.; Alsmari, M.; Ahmed, M.M.Z.; Bouazizi, M.L.; Alzahrani, B.; Alrobei, H. Date Palm Tree Waste Recycling: Treatment and Processing for Potential Engineering Applications. Sustainability 2022, 14, 1134. [Google Scholar] [CrossRef]

- Anusavice, K.J.; Shen, C.; Rawls, H.R. Phillips’ Science of Dental Materials; Elsevier Health Sciences: Alpharetta, GA, USA, 2012. [Google Scholar]

- Canay, Ş.; Hersek, N.; Çiftçi, Y.; Akça, K. Comparision of diametral tensile strength of microwave and oven-dried investment materials. J. Prosthet. Dent. 1999, 82, 286–290. [Google Scholar] [CrossRef]

- Mahmud, S.; Long, Y.; Abu Taher, M.; Xiong, Z.; Zhang, R.; Zhu, J. Toughening polylactide by direct blending of cellulose nanocrystals and epoxidized soybean oil. J. Appl. Polym. Sci. 2019, 136, 48221. [Google Scholar] [CrossRef]

- Delzendehrooy, F.; Ayatollahi, M.R.; Akhavan-Safar, A.; da Silva, L.F.M. Strength improvement of adhesively bonded single lap joints with date palm fibers: Effect of type, size, treatment method and density of fibers. Compos. Part B Eng. 2020, 188, 107874. [Google Scholar] [CrossRef]

- Kaddami, H.; Dufresne, A.; Khelifi, B.; Bendahou, A.; Taourirte, M.; Raihane, M.; Issartel, N.; Sautereau, H.; Gérard, J.-F.; Sami, N. Short palm tree fibers—Thermoset matrices composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1413–1422. [Google Scholar] [CrossRef]

- Shalwan, A.; Yousif, B.F. Investigation on interfacial adhesion of date palm/epoxy using fragmentation technique. Mater. Des. 2014, 53, 928–937. [Google Scholar] [CrossRef]

- d’Almeida, J.R.M.; Aquino, R.C.M.P.; Monteiro, S.N. Tensile mechanical properties, morphological aspects and chemical characterization of piassava (Attalea funifera) fibers. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1473–1479. [Google Scholar] [CrossRef]

- Elzubair, A.; Bonelli, C.M.C.; Suarez, J.C.M.; Mano, E.B. Morphological, Structural, Thermal and Mechanical Characterization of Piassava Fibers. J. Nat. Fibers 2007, 4, 13–31. [Google Scholar] [CrossRef]

| Material | Physical Properties | Value ** |

|---|---|---|

| Epoxy | Density | 1.11 ± 0.02 Kg/L |

| Temperature resistance | Humid 90 °C/dry 140 °C | |

| Modulus of elasticity, E, (GPa) | 3.7 | |

| Poisson’s ratio, ν | 0.36 | |

| E-glass fiber | Filament diameter | 13 µm |

| Linear density | 2400 tex | |

| Modulus of elasticity, E, (GPa) | 82 | |

| Poisson’s ratio, ν | 0.22 |

| Specimen, ID | Description | Short Palm Fiber, Wt.% | Short Glass Fiber, Wt.% |

|---|---|---|---|

| PE | Pure/Net Epoxy | 0 | 0 |

| LNF | Low percent Natural Fiber | 6 | 0 |

| MNF | Medium percent Natural Fiber | 15.8 | 0 |

| HNF | High percent Natural Fiber | 31.6 | 0 |

| GF | Glass Fiber | 0 | 15.8 |

| HyF | Hybrid Fiber | 15.8 | 15.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mousa, S.; Alomari, A.S.; Vantadori, S.; Alhazmi, W.H.; Abd-Elhady, A.A.; Sallam, H.E.-D.M. Mechanical Behavior of Epoxy Reinforced by Hybrid Short Palm/Glass Fibers. Sustainability 2022, 14, 9425. https://doi.org/10.3390/su14159425

Mousa S, Alomari AS, Vantadori S, Alhazmi WH, Abd-Elhady AA, Sallam HE-DM. Mechanical Behavior of Epoxy Reinforced by Hybrid Short Palm/Glass Fibers. Sustainability. 2022; 14(15):9425. https://doi.org/10.3390/su14159425

Chicago/Turabian StyleMousa, Saeed, Abdullah S. Alomari, Sabrina Vantadori, Waleed H. Alhazmi, Amr A. Abd-Elhady, and Hossam El-Din M. Sallam. 2022. "Mechanical Behavior of Epoxy Reinforced by Hybrid Short Palm/Glass Fibers" Sustainability 14, no. 15: 9425. https://doi.org/10.3390/su14159425

APA StyleMousa, S., Alomari, A. S., Vantadori, S., Alhazmi, W. H., Abd-Elhady, A. A., & Sallam, H. E.-D. M. (2022). Mechanical Behavior of Epoxy Reinforced by Hybrid Short Palm/Glass Fibers. Sustainability, 14(15), 9425. https://doi.org/10.3390/su14159425