Environmental Assessment of Alternative Strategies for the Management of Construction and Demolition Waste: A Life Cycle Approach

Abstract

:1. Introduction

2. Materials and Methods

2.1. Methodology

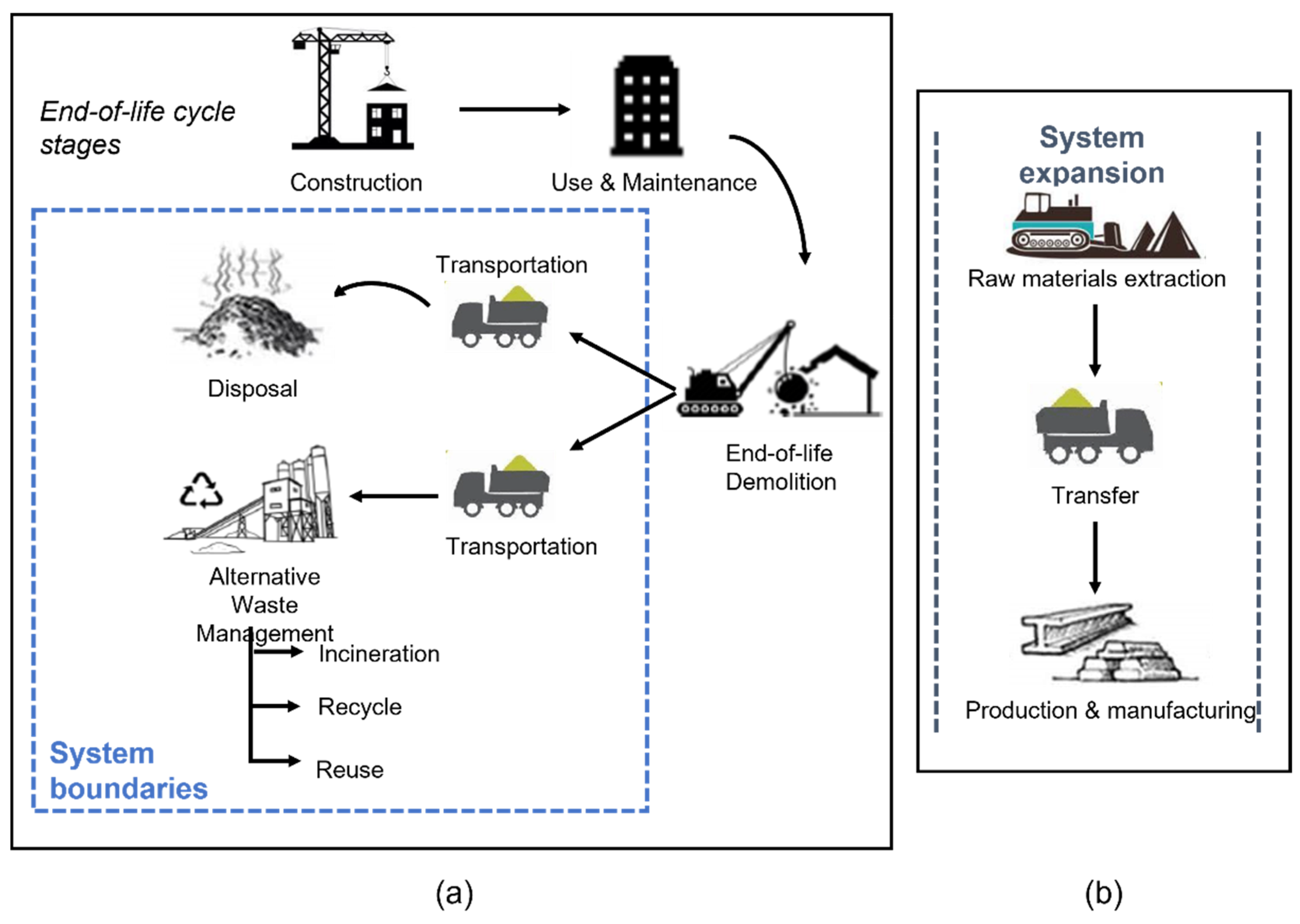

2.2. Functional Unit and System Boundaries and Expansion

2.3. Inventory Analysis

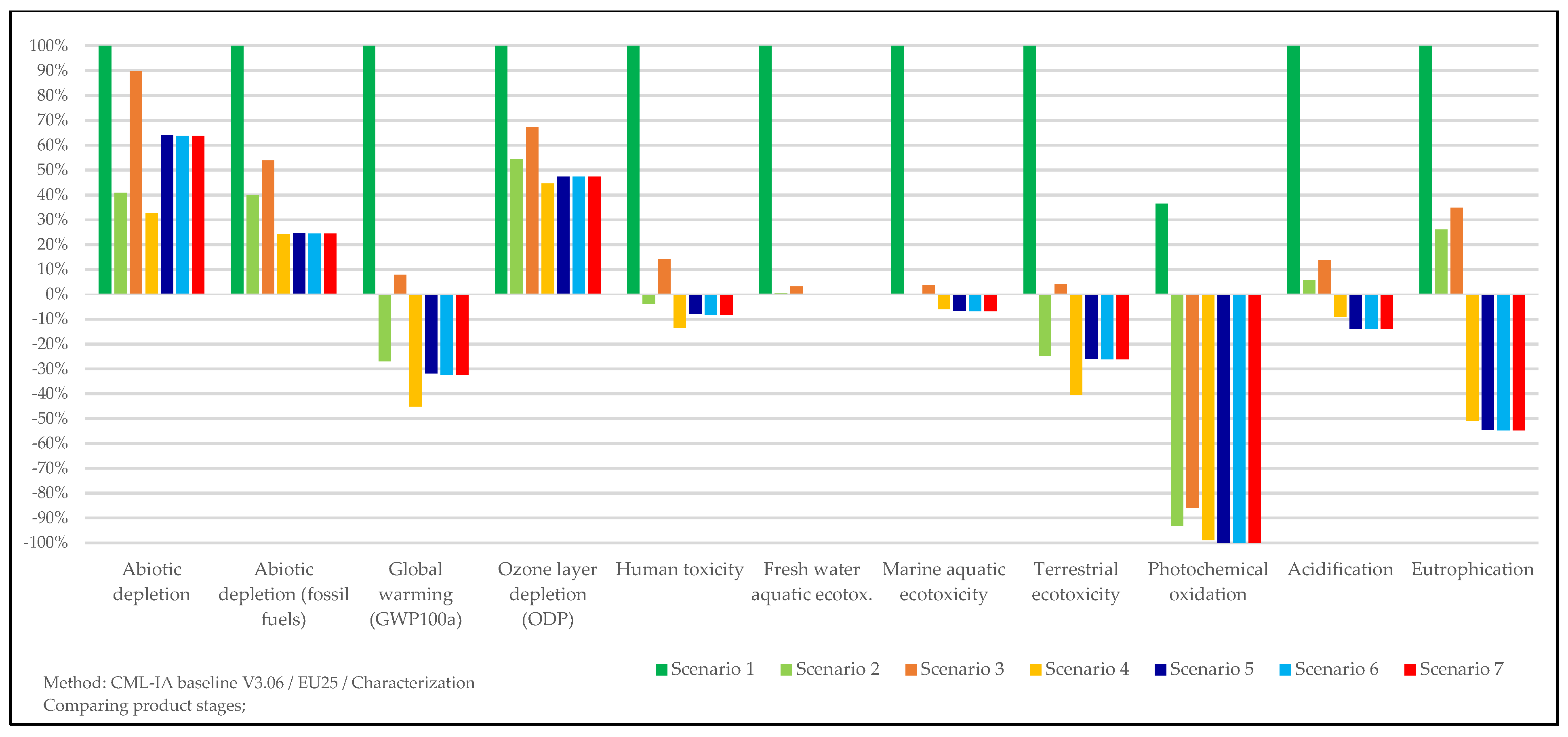

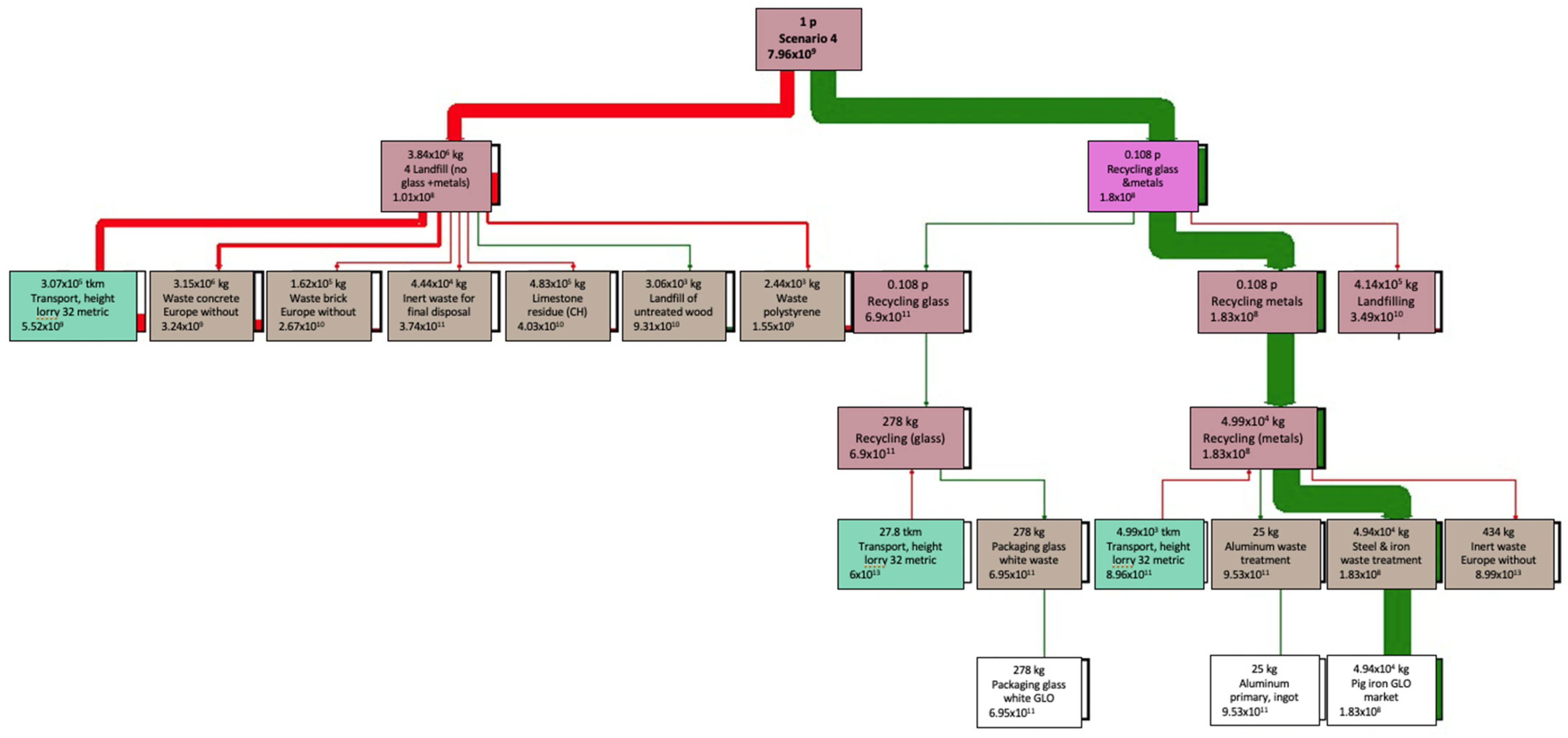

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Banias, G. Development of a System for the Optimal Construction and Demolition Waste Management; Aristotle University of Thessaloniki: Thessaloniki, Greece, 2009. [Google Scholar]

- Zhang, C.; Hu, M.; Di Maio, F.; Sprecher, B.; Yang, X.; Tukker, A. An overview of the waste hierarchy framework for analyzing the circularity in construction and demolition waste management in Europe. Sci. Total Environ. 2022, 803, 149892. [Google Scholar] [CrossRef]

- Turkyilmaz, A.; Guney, M.; Karaca, F.; Bagdatkyzy, Z.; Sandybayeva, A.; Sirenova, G. A comprehensive construction and demolition waste management model using PESTEL and 3R for construction companies operating in central Asia. Sustainability 2019, 11, 1593. [Google Scholar] [CrossRef] [Green Version]

- Singh, R.S.; Singh, T.; Hassan, M.; Larroche, C. Biofuels from inulin-rich feedstocks: A comprehensive review. Bioresour. Technol. 2022, 346, 126606. [Google Scholar] [CrossRef]

- Sharma, G.D.; Shah, M.I.; Shahzad, U.; Jain, M.; Chopra, R. Exploring the nexus between agriculture and greenhouse gas emissions in BIMSTEC region: The role of renewable energy and human capital as moderators. J. Environ. Manag. 2021, 297, 113316. [Google Scholar] [CrossRef]

- Adnan, M.; Xiao, B.; Xiao, P.; Zhao, P.; Bibi, S.; Venkateswarlu, K. Heavy Metal, Waste, COVID-19, and Rapid Industrialization in This Modern Era—Fit for Sustainable Future. Sustainability 2022, 19, 4746. [Google Scholar] [CrossRef]

- Venkateswarlu, K. Ashes from Organic Waste as Reagents in Synthetic Chemistry: A Review; Springer International Publishing: New York, NY, USA, 2021; Volume 19, ISBN 0123456789. [Google Scholar]

- Banias, G.; Achillas, C.; Vlachokostas, C.; Moussiopoulos, N.; Tarsenis, S. Assessing multiple criteria for the optimal location of a construction and demolition waste management facility. Build. Environ. 2010, 45, 2317–2326. [Google Scholar] [CrossRef]

- Mercante, I.T.; Bovea, M.D.; Ibáñez-Forés, V.; Arena, A.P. Life cycle assessment of construction and demolition waste management systems: A Spanish case study. Int. J. Life Cycle Assess. 2012, 17, 232–241. [Google Scholar] [CrossRef]

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of fine recycled concrete aggregates in concrete: A critical review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Solís-Guzmán, J.; Marrero, M.; Montes-Delgado, M.V.; Ramírez-de-Arellano, A. A Spanish model for quantification and management of construction waste. Waste Manag. 2009, 29, 2542–2548. [Google Scholar] [CrossRef]

- De Magalhães, R.F.; de Moura Ferreira Danilevicz, Â.; Saurin, T.A. Reducing construction waste: A study of urban infrastructure projects. Waste Manag. 2017, 67, 265–277. [Google Scholar] [CrossRef]

- European Commission. European Commission On Resource Efficient Opportunities in the Building Sector—COM(2014) 445 Final; European Commission: Bruxelles, Belgium, 2014; pp. 1–10.

- López Ruiz, L.A.; Roca Ramón, X.; Gassó Domingo, S. The circular economy in the construction and demolition waste sector—A review and an integrative model approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- Banias, G.; Achillas, C.; Vlachokostas, C.; Moussiopoulos, N.; Papaioannou, I. A web-based Decision Support System for the optimal management of construction and demolition waste. Waste Manag. 2011, 31, 2497–2502. [Google Scholar] [CrossRef]

- Menegaki, M.; Damigos, D. A review on current situation and challenges of construction and demolition waste management. Curr. Opin. Green Sustain. Chem. 2018, 13, 8–15. [Google Scholar] [CrossRef]

- European Parliament and Council. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives (Waste Framework); European Parliament and Council: Brussels, Belgium, 2008; Volume 9, pp. 3–30. [Google Scholar]

- European Commission. A New Circular Economy Action Plan For a Cleaner and More Competitive Europe, COM (2020) 98 Final; European Commission: Brussels, Belgium, 2020.

- Villoria Sáez, P.; Osmani, M. A diagnosis of construction and demolition waste generation and recovery practice in the European Union. J. Clean. Prod. 2019, 241, 118400. [Google Scholar] [CrossRef]

- Hoang, N.H.; Ishigaki, T.; Kubota, R.; Tong, T.K.; Nguyen, T.T.; Nguyen, H.G.; Yamada, M.; Kawamoto, K. Waste generation, composition, and handling in building-related construction and demolition in Hanoi, Vietnam. Waste Manag. 2020, 117, 32–41. [Google Scholar] [CrossRef]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Nadazdi, A.; Naunovic, Z.; Ivanisevic, N. Circular Economy in Construction and Demolition Waste Management in the Western Balkans: A Sustainability Assessment Framework. Sustainability 2022, 14, 871. [Google Scholar] [CrossRef]

- Zorpas, A.A. Sustainable waste management through end-of-waste criteria development. Environ. Sci. Pollut. Res. 2016, 23, 7376–7389. [Google Scholar] [CrossRef]

- Diotti, A.; Galvin, A.P.; Piccinali, A.; Plizzari, G.; Sorlini, S. Chemical and leaching behavior of construction and demolition wastes and recycled aggregates. Sustainability 2020, 12, 10326. [Google Scholar] [CrossRef]

- Weil, M.; Jeske, U.; Schebek, L. Closed-loop recycling of construction and demolition waste in Germany in view of stricter environmental threshold values. Waste Manag. Res. 2006, 24, 197–206. [Google Scholar] [CrossRef]

- Caldera, S.; Ryley, T.; Zatyko, N. Enablers and barriers for creating a marketplace for construction and demolition waste: A systematic literature review. Sustainability 2020, 12, 9931. [Google Scholar] [CrossRef]

- Iacovidou, E.; Purnell, P. Mining the physical infrastructure: Opportunities, barriers and interventions in promoting structural components reuse. Sci. Total Environ. 2016, 557–558, 791–807. [Google Scholar] [CrossRef] [Green Version]

- Ginga, C.P.; Ongpeng, J.M.C.; Daly, M.K.M. Circular economy on construction and demolition waste: A literature review on material recovery and production. Materials 2020, 13, 2970. [Google Scholar] [CrossRef]

- European Enviroment Agency Construction and Demolition Waste. Challenges and Opportunities in a Circular Economy; Brief. No. 14/2019; European Enviroment Agency Construction and Demolition Waste: Copenhagen, Denmark, 2020; Volume 8. [Google Scholar]

- Deloitte. Document Information Resource Efficient Use of Mixed Wastes; Deloitte: London, UK, 2017. [Google Scholar]

- European Commission Directorate. General EU Construction & Demolition Waste Management Protocol. Off. J. Eur. Union 2016, 1–22. [Google Scholar]

- Karachaliou, T.; Paralika, M. Progress and Challenges in C&D Waste Management in Greece. Int. J. Environ. Plan. Manag. 2019, 5, 32–41. [Google Scholar]

- Zygouras, M.; Karagiannidis, A.; Malamakis, A. Construction and demolition waste processing in Athens, Greece: A pilot demonstration. Int. J. Environ. Waste Manag. 2009, 3, 177–192. [Google Scholar] [CrossRef]

- Noll, D.; Wiedenhofer, D.; Miatto, A.; Singh, S.J. The expansion of the built environment, waste generation and EU recycling targets on Samothraki, Greece: An island’s dilemma. Resour. Conserv. Recycl. 2019, 150, 104405. [Google Scholar] [CrossRef]

- Ernst & Young. EY Study on the Circular Economy in Greece; Ernst & Young: Athens, Greece, 2016; pp. 1–48. [Google Scholar]

- Enviterra. Improved Management of Construction & Demolition Waste in Greece; Enviterra: Zutphen, The Netherlands, 2020; pp. 1–135. [Google Scholar]

- Bovea, M.D.; Powell, J.C. Developments in life cycle assessment applied to evaluate the environmental performance of construction and demolition wastes. Waste Manag. 2016, 50, 151–172. [Google Scholar] [CrossRef]

- Taboada, G.L.; Seruca, I.; Sousa, C.; Pereira, Á. Exploratory data analysis and data envelopment analysis of construction and demolitionwaste management in the European economic area. Sustainability 2020, 12, 4995. [Google Scholar] [CrossRef]

- Liu, W.; Chen, W.; Feng, Q.; Deo, R.C. Situations, challenges and strategies of urban water management in Beijing under rapid urbanization effect. Water Sci. Technol. Water Supply 2019, 19, 115–127. [Google Scholar] [CrossRef]

- Zorpas, A.A. Strategy development in the framework of waste management. Sci. Total Environ. 2020, 716, 137088. [Google Scholar] [CrossRef] [PubMed]

- Banti, D.C.; Tsangas, M.; Samaras, P.; Zorpas, A. LCA of a membrane bioreactor compared to activated sludge system for municipal wastewater treatment. Membranes 2020, 10, 421. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.U.; Wu, Z.; Poon, C.S. Comparative environmental evaluation of construction waste management through different waste sorting systems in Hong Kong. Waste Manag. 2017, 69, 325–335. [Google Scholar] [CrossRef] [PubMed]

- Rosado, L.P.; Vitale, P.; Penteado, C.S.G.; Arena, U. Life cycle assessment of construction and demolition waste management in a large area of São Paulo State, Brazil. Waste Manag. 2019, 85, 477–489. [Google Scholar] [CrossRef]

- Kucukvar, M.; Egilmez, G.; Tatari, O. Life cycle assessment and optimization-based decision analysis of construction waste recycling for a LEED-certified university building. Sustainability 2016, 8, 89. [Google Scholar] [CrossRef] [Green Version]

- Coelho, A.; De Brito, J. Influence of construction and demolition waste management on the environmental impact of buildings. Waste Manag. 2012, 32, 532–541. [Google Scholar] [CrossRef]

- Zambrana-Vasquez, D.; Zabalza-Bribián, I.; Jáñez, A.; Aranda-Usón, A. Analysis of the environmental performance of life-cycle building waste management strategies in tertiary buildings. J. Clean. Prod. 2016, 130, 143–154. [Google Scholar] [CrossRef] [Green Version]

- Vitale, P.; Arena, N.; Di Gregorio, F.; Arena, U. Life cycle assessment of the end-of-life phase of a residential building. Waste Manag. 2017, 60, 311–321. [Google Scholar] [CrossRef]

- Blengini, G.A. Life cycle of buildings, demolition and recycling potential: A case study in Turin, Italy. Build. Environ. 2009, 44, 319–330. [Google Scholar] [CrossRef]

- Lockrey, S.; Verghese, K.; Crossin, E.; Nguyen, H. Concrete recycling life cycle flows and performance from construction and demolition waste in Hanoi. J. Clean. Prod. 2018, 179, 593–604. [Google Scholar] [CrossRef]

- Ortiz, O.; Pasqualino, J.C.; Castells, F. Environmental performance of construction waste: Comparing three scenarios from a case study in Catalonia, Spain. Waste Manag. 2010, 30, 646–654. [Google Scholar] [CrossRef] [PubMed]

- Di Maria, F.; Micale, C. Life cycle analysis of management options for organic waste collected in an urban area. Environ. Sci. Pollut. Res. 2015, 22, 248–263. [Google Scholar] [CrossRef] [PubMed]

- Yazdanbakhsh, A. A bi-level environmental impact assessment framework for comparing construction and demolition waste management strategies. Waste Manag. 2018, 77, 401–412. [Google Scholar] [CrossRef] [PubMed]

- Penteado, C.S.G.; Rosado, L.P. Comparison of scenarios for the integrated management of construction and demolition waste by life cycle assessment: A case study in Brazil. Waste Manag. Res. 2016, 34, 1026–1035. [Google Scholar] [CrossRef] [PubMed]

- Dahlbo, H.; Bachér, J.; Lähtinen, K.; Jouttijärvi, T.; Suoheimo, P.; Mattila, T.; Sironen, S.; Myllymaa, T.; Saramäki, K. Construction and demolition waste management—A holistic evaluation of environmental performance. J. Clean. Prod. 2015, 107, 333–341. [Google Scholar] [CrossRef]

- Iodice, S.; Garbarino, E.; Cerreta, M.; Tonini, D. Sustainability assessment of Construction and Demolition Waste management applied to an Italian case. Waste Manag. 2021, 128, 83–98. [Google Scholar] [CrossRef]

- Yeheyis, M.; Hewage, K.; Alam, M.S.; Eskicioglu, C.; Sadiq, R. An overview of construction and demolition waste management in Canada: A lifecycle analysis approach to sustainability. Clean Technol. Environ. Policy 2013, 15, 81–91. [Google Scholar] [CrossRef]

- SimaPro, Version 9.1.1.7; Consultants Software. PRé: Amersfoort, The Netherlands, 2016; PRe SimaPro 2019.

- Dascalaki, E.G.; Sermpetzoglou, V.G. Energy performance and indoor environmental quality in Hellenic schools. Energy Build. 2011, 43, 718–727. [Google Scholar] [CrossRef]

- Butera, S.; Christensen, T.H.; Astrup, T.F. Life cycle assessment of construction and demolition waste management. Waste Manag. 2015, 44, 196–205. [Google Scholar] [CrossRef] [Green Version]

- Gaitani, N.; Cases, L.; Mastrapostoli, E.; Eliopoulou, E. Paving the way to nearly zero energy schools in Mediterranean region-ZEMedS project. Energy Procedia 2015, 78, 3348–3353. [Google Scholar] [CrossRef] [Green Version]

- Tsikra, P.; Andreou, E. Investigation of the Energy Saving Potential in Existing School Buildings in Greece. The role of Shading and Daylight Strategies in Visual Comfort and Energy Saving. Procedia Environ. Sci. 2017, 38, 204–211. [Google Scholar]

- Kuikka, S. LCA of the Demolition of a Building. Ph.D. Thesis, Division of Environmental System Analysis, Department of Energy and Environment, Chalmers University of Technology, Gothenburg, Sweden, 2012. [Google Scholar]

- Roussat, N.; Dujet, C.; Méhu, J. Choosing a sustainable demolition waste management strategy using multicriteria decision analysis. Waste Manag. 2009, 29, 12–20. [Google Scholar] [CrossRef] [PubMed]

| Indicators | Description |

|---|---|

| AD—Abiotic Depletion | Indicator of the use of nonrenewable sources for energy production |

| ADF—Abiotic Depletion (fossil fuels) | Indicator of fossil fuel extraction |

| GWP—Global Warming Potential | Indicator relevant to the GH effect according to IPCC |

| ODP—Ozone Depletion Potential | Indicator relevant to the stratospheric ozone depletion phenomenon |

| HT—Human Toxicity | Indicator of consequences of toxic substances |

| FWAE—Fresh Water Aquatic Ecotox | Indicator of products’ ecotoxic impacts on fresh water |

| MAE—Marine Aquatic Ecotoxicity | Indicator of toxic substances impact on the marine ecosystem |

| TE—Terrestrial Ecotoxicity | Indicator of toxic substances’ impacts on terrestrial ecosystems |

| PO—Photochemical Oxidation | Indicator of photo-smog creation |

| AP—Acidification Potential | Indicator relevant to the acid rain phenomenon |

| EP—Eutrophication Potential | Indicator relevant to surface water eutrophication |

| Material | EWC Code | Quantity | Material | EWC Code | Quantity |

|---|---|---|---|---|---|

| 1. Concrete | 17 01 01 | 1374.72 m3 | 11. Iron and steel (pipes) | 17 04 05 | 3.02 t |

| 2. Bricks | 17 01 02 | 181.90 t | 12. Reinforcing steel | 17 04 05 | 215.47 t |

| 3. Ceramic tiles | 17 01 03 | 14.82 t | 13. Insulation materials | 17 06 04 | 2.74 t |

| 4. Sanitary ware | 17 01 03 | 1.41 t | 14. Cables | 17 04 11 | 3381.00 m |

| 5. Marbles | 17 01 03 | 75.92 t | 15. Cement mortar | 17 01 07 | 3.80 t |

| 6. Wood | 17 02 01 | Other material | |||

| 7. Glass | 17 02 02 | 972.70 m2 | Windows frame | 17 04 02 | 48.30 m2 |

| 8. Plastic (pipes) | 17 02 03 | 0.43 t | Steel | 17 04 05 | 238.79 t |

| 9. Aluminum (cladding) | 17 04 02 | 660.00 m2 | Doors | 17 02 01 | 137.00 m2 |

| 10. Iron and steel (boiler) | 17 04 05 | 0.31 t | Cement plaster | 17 01 07 | 130.91 m3 |

| Impact Category | S1 | S2 | S3 | S4 | S5 | S6 | S7 |

|---|---|---|---|---|---|---|---|

| AD (kg Sb eq) | 1.17 | 0.479 | 1.05 | 0.382 | 0.749 | 0.747 | 0.747 |

| ADF (MJ) | 1.54 × 106 | 6.14 × 105 | 8.28 × 105 | 3.72 105 | 3.77 × 105 | 3.76 × 105 | 3.76 × 105 |

| GWP (kg CO2 eq) | 8.85 × 106 | 2.38 × 10−4 | 6.95 × 103 | 4 × 10−4 | 2.81 × 10−4 | 2.86 × 10−4 | 2.86 × 10−4 |

| ODP (kg CFC-11 eq) | 0.0207 | 0.0113 | 0.0139 | 0.0092 | 0.0098 | 0.0098 | 0.0098 |

| HT (kg 1,4-DB eq) | 1.01 × 105 | 3.9 × 10−3 | 1.43 × 104 | 1.37 × 10−4 | 7.95 × 10−3 | 8.28 × 10−3 | 8.28 × 103 |

| FWAE (kg 1,4-DB eq) | 2.05 × 106 | 9.73 × 103 | 6.49 × 104 | 1.96 × 10−3 | 2.77 × 10−3 | 7.05 × 10−3 | 7.05 × 10−3 |

| MAE (kg 1,4-DB eq) | 6.45 × 108 | 1.26 × 106 | 2.41 × 107 | 3.88 × 10−7 | 4.28 × 10−7 | 4.43 × 10−7 | 4.43 × 10−7 |

| TE (kg 1,4-DB eq) | 186 | −46.2 | 7.24 | −75.53 | −48.36 | −48.76 | −48.76 |

| PO (kg C2H4 eq) | 15.55 | −39.83 | −36.67 | −42.22 | −42.64 | −42.70 | −42.70 |

| AP (kg SO2 eq) | 491.82 | 28.42 | 67.00 | −44.92 | −67.77 | −68.41 | −68.41 |

| EP (kg PO4 eq) | 119.30 | 31.13 | 41.53 | −60.72 | −65.10 | −65.38 | −65.39 |

| Impact Categories | Best Performance Scenario | Worst Performance Scenario |

|---|---|---|

| Abiotic depletion | Scenario 4 | Scenario 1 |

| Abiotic depletion (fossil fuels) | Scenario 4 | Scenario 1 |

| Global warming (GWP100a) | Scenario 4 | Scenario 1 |

| Ozone layer depletion (ODP) | Scenario 4 | Scenario 1 |

| Human toxicity | Scenario 4 | Scenario 1 |

| Fresh water aquatic ecotoxicity | Scenario 7 | Scenario 1 |

| Marine aquatic ecotoxicity | Scenario 7 | Scenario 1 |

| Terrestrial ecotoxicity | Scenario 4 | Scenario 1 |

| Photochemical oxidation | Scenario 7 | Scenario 1 |

| Acidification | Scenario 7 | Scenario 1 |

| Eutrophication | Scenario 7 | Scenario 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banias, G.F.; Karkanias, C.; Batsioula, M.; Melas, L.D.; Malamakis, A.E.; Geroliolios, D.; Skoutida, S.; Spiliotis, X. Environmental Assessment of Alternative Strategies for the Management of Construction and Demolition Waste: A Life Cycle Approach. Sustainability 2022, 14, 9674. https://doi.org/10.3390/su14159674

Banias GF, Karkanias C, Batsioula M, Melas LD, Malamakis AE, Geroliolios D, Skoutida S, Spiliotis X. Environmental Assessment of Alternative Strategies for the Management of Construction and Demolition Waste: A Life Cycle Approach. Sustainability. 2022; 14(15):9674. https://doi.org/10.3390/su14159674

Chicago/Turabian StyleBanias, Georgios F., Christos Karkanias, Maria Batsioula, Lefteris D. Melas, Apostolos E. Malamakis, Dimitris Geroliolios, Stamatia Skoutida, and Xenofon Spiliotis. 2022. "Environmental Assessment of Alternative Strategies for the Management of Construction and Demolition Waste: A Life Cycle Approach" Sustainability 14, no. 15: 9674. https://doi.org/10.3390/su14159674

APA StyleBanias, G. F., Karkanias, C., Batsioula, M., Melas, L. D., Malamakis, A. E., Geroliolios, D., Skoutida, S., & Spiliotis, X. (2022). Environmental Assessment of Alternative Strategies for the Management of Construction and Demolition Waste: A Life Cycle Approach. Sustainability, 14(15), 9674. https://doi.org/10.3390/su14159674