Modeling and Performance Analysis for High-Rise Building Using ArchiCAD: Initiatives towards Energy-Efficient Building

Abstract

:1. Introduction

2. Literature Review

2.1. Retrofit at a Glance

2.2. The Contributing Factors

2.3. Energy Performances Approaches

2.4. Building Information Modelling (BIM)

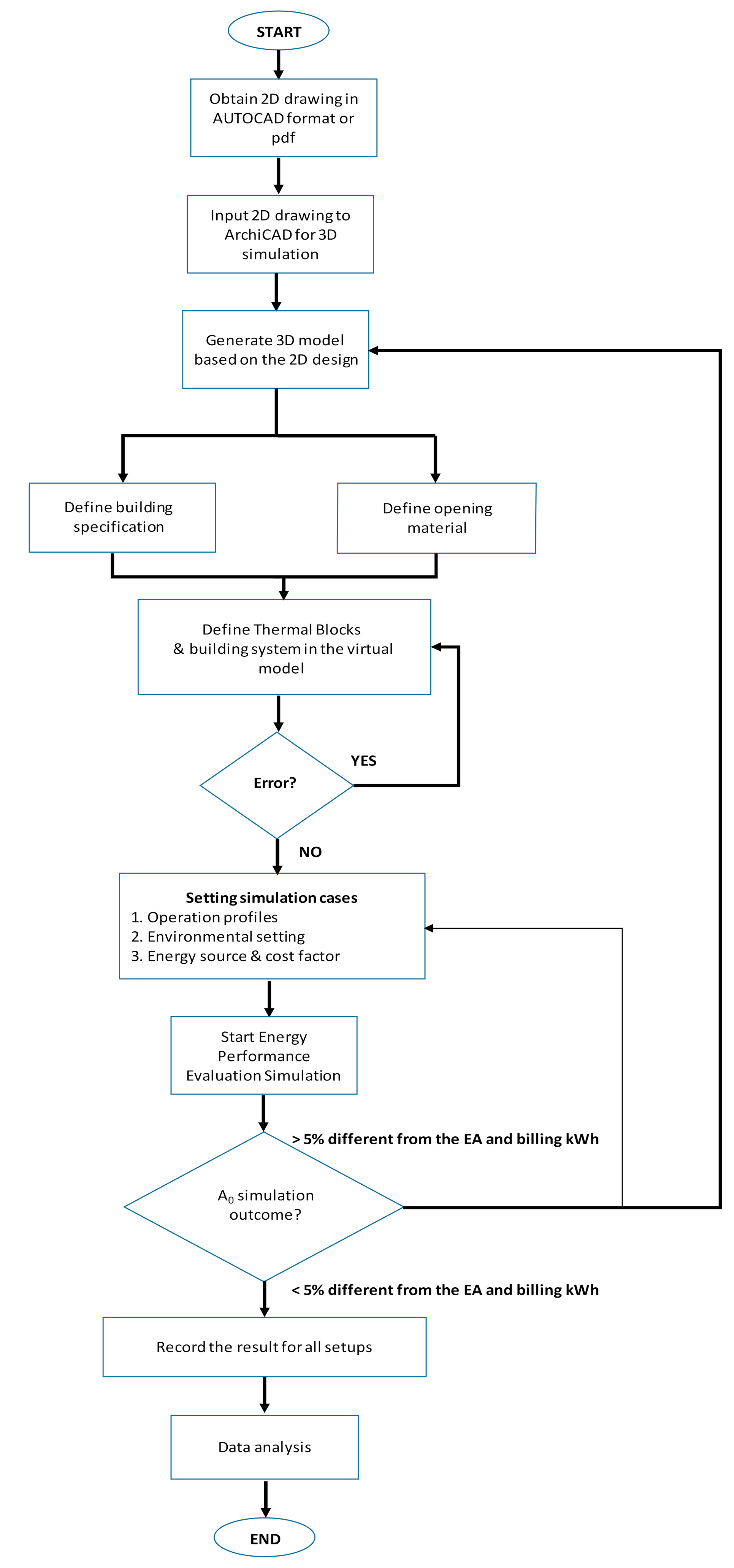

3. Data and Methods

3.1. Walk-Through Energy Audit

3.2. Modelling Phases

3.3. Simulation Setup—Energy Performance Evaluation

3.3.1. Operation Profile

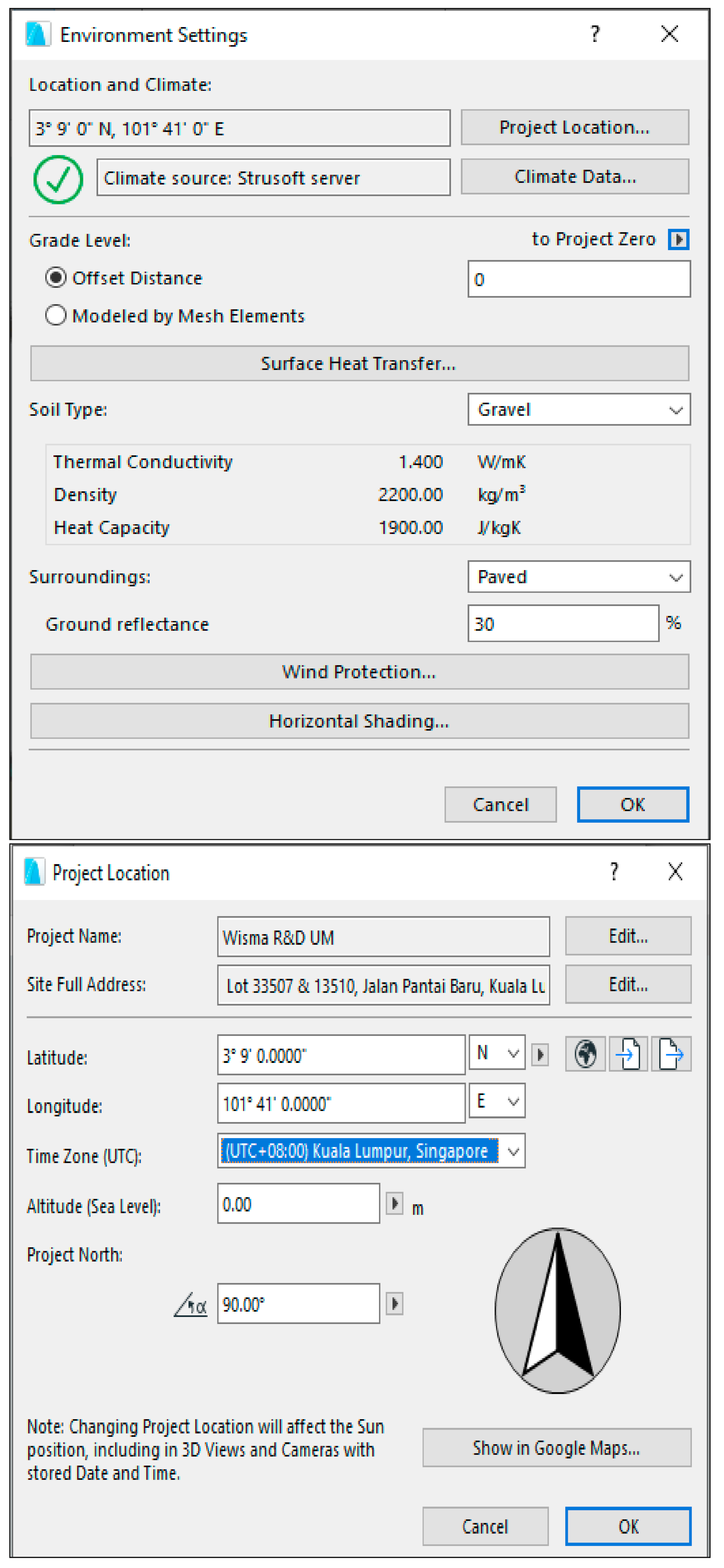

3.3.2. Environmental Settings

3.3.3. Energy Sources and Energy Cost Factor

4. Results and Discussion

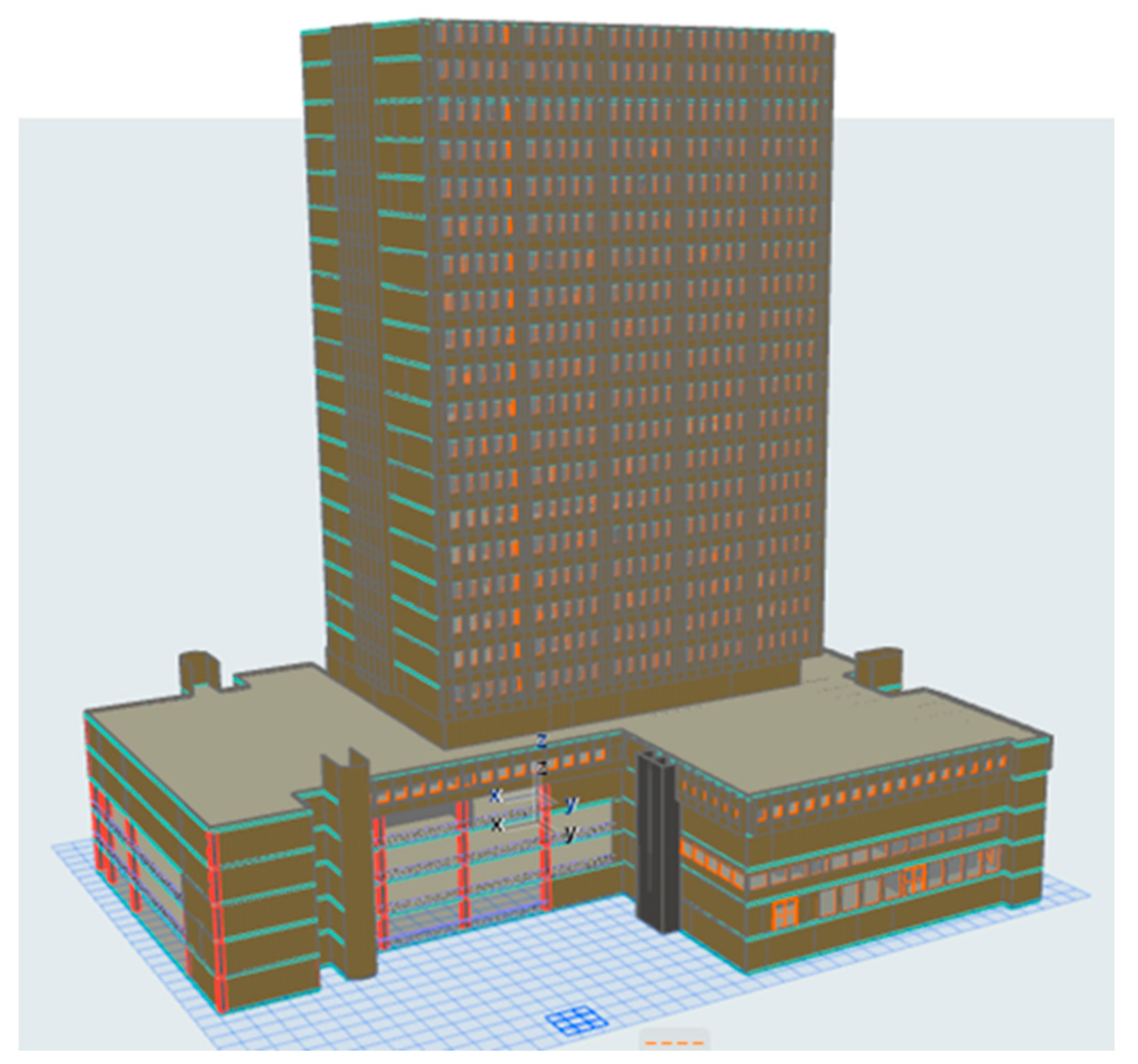

4.1. The Virtual Building Model

4.2. Energy Performance Evaluation for Existing Building Parameter (A0)

4.3. Infiltration (ACH) and Heat Transfer Coefficients (u-Value and R-Value)

4.4. Potential Energy Conservation Measure for Wisma R&D

4.5. Optimal Window Selection for Sustainable Building Operation

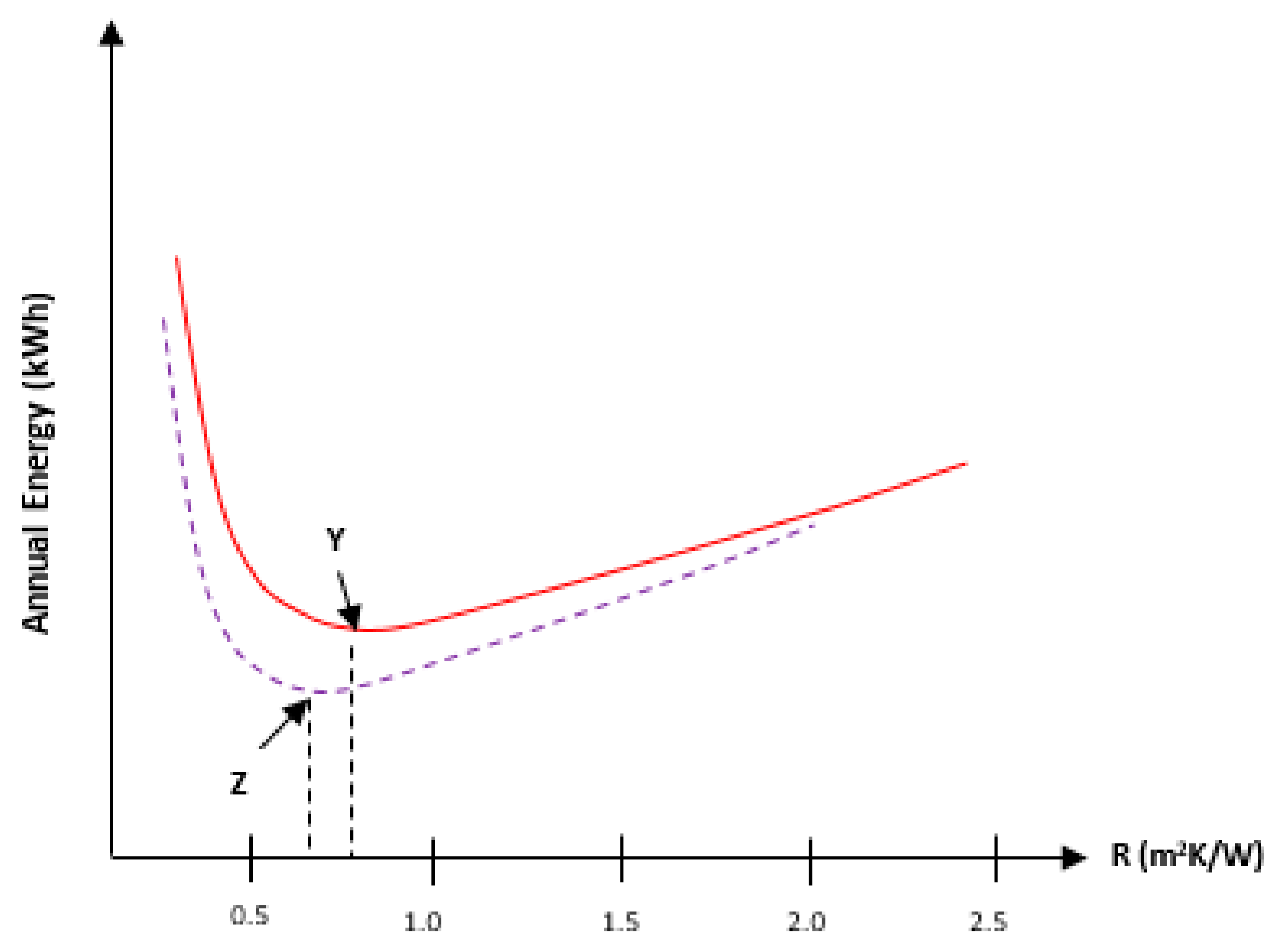

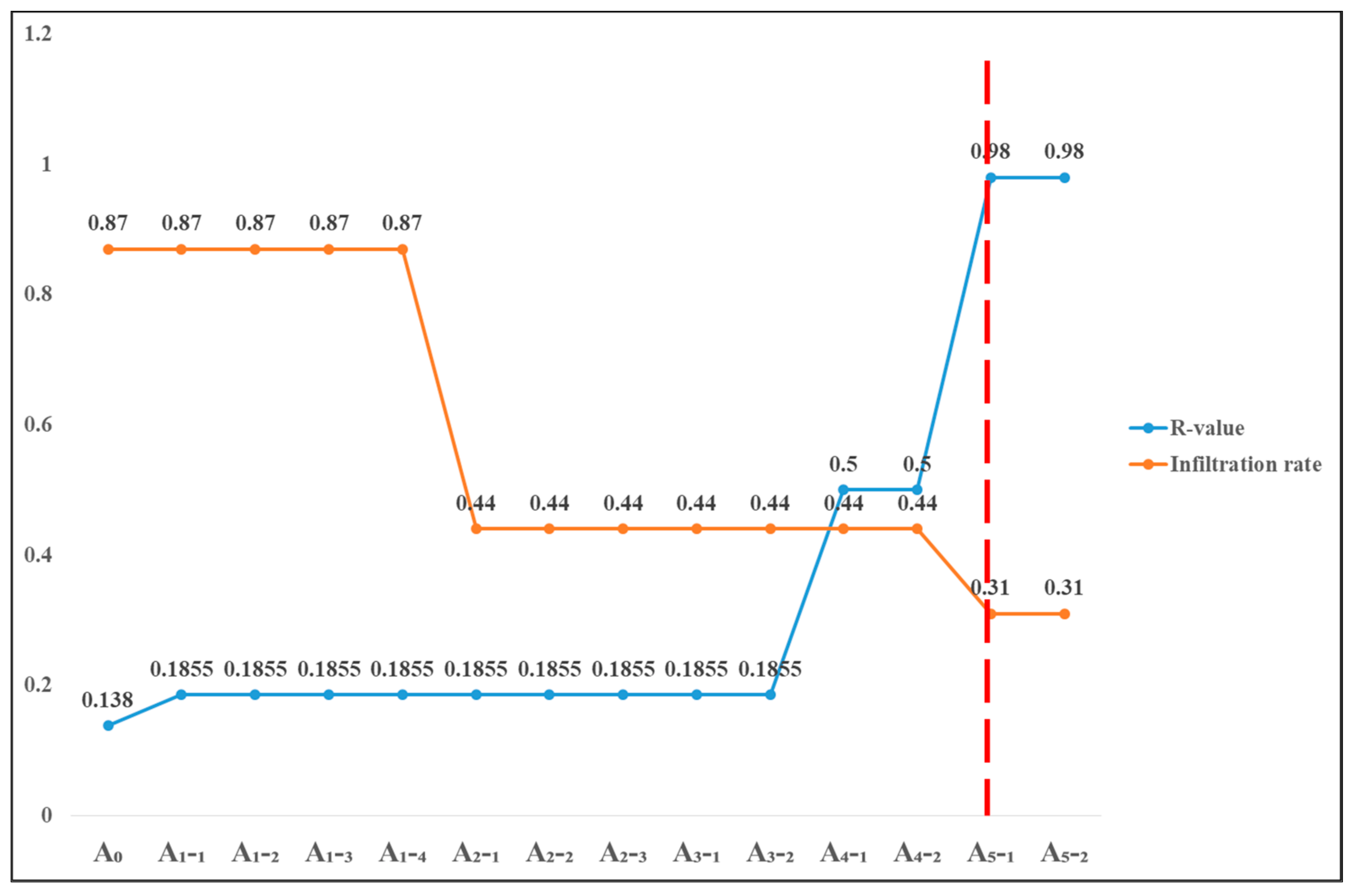

4.6. The Linkages between Heat Transfer Coefficient (R-Value) and Infiltration Rate on the Cooling Load Demand

4.7. Future Research and Recommendations

5. Conclusions

- Virtual building simulation is one of the sensible solutions in retrofitting initiatives. It is important to assist the building owner/management in analysing the potential saving from the retrofitting exercise and selecting the best building parameters to be retrofitted;

- Most of the available software has embedded the Energy Performance Evaluation feature. Hence, building professionals need to expose themselves to these important features and work hand-in-hand to optimise the utmost benefit, especially through retrofitting initiatives;

- For an optimal solution to enhance the building energy performance, it is important to analyse the heat transfer coefficients from the selected window’s glazing and opaque materials. In addition, the infiltration rate should receive equal attention. As it affects the window tightness, the opaque material selection proved to be the factor in enhancing the infiltration rate of a building;

- An improvement in the infiltration rate of one building could assist the management to consider a reduction in the cooling load which leads to a reduction in total energy consumption and energy cost, as well as carbon emission;

- The double-glazed window is proven to be better than the single glazed material. Triple-glazed is unnecessary as the double-glazed plus efficient frame material can meet the optimal window performances outlined in the ASHRAE’s guideline;

- BIM is an important process that all the building professionals should apply to ensure the performance of a new building/retrofitting initiative could be reviewed before it is approved;

- An annual energy saving of 0.8% could be achieved by Wisma R&D when the existing window is replaced with the double-glazed argon type with an ultimate aluminium frame. Without optimizing the window parameters combination, the estimated saving could not be achieved through retrofitting initiatives;

- Shading elements are not a practical and significant solution for Wisma R&D. The main reason was due to the small window area on the south-position façade of the building. Furthermore, the building is initially equipped with some extent of shading block, hence shading is not an effective approach for retrofitting the building;

- The linkage between the heat transfer coefficient and the infiltration rate is very important in the retrofitting decision-making. In this study, the decision on A3 versus A4 combination and A4 versus A5 makes a lot of difference to the final outcome, mainly on the cooling load consumption;

- Available guidelines like ASHRAE and MS1525 should be used as references only. To optimize the result of retrofitting initiatives, the building owners need to conduct a thorough evaluation based on the multivariate model. As a consequence, the level of accuracy resulting from the Energy Performance Evaluation is found to be better.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References and Note

- IEA. Energy Technology Perspective 2017; IEA: Paris, France, 2018; p. 441. [Google Scholar]

- Abanda, F.H.; Byers, L. An investigation of the impact of building orientation on energy consumption in a domestic building using emerging BIM (Building Information Modelling). Energy 2016, 97, 517–527. [Google Scholar] [CrossRef]

- Jagarajan, R.; Asmoni, M.N.A.M.; Mohammed, A.H.; Jaafar, M.N.; Mei, J.L.Y.; Baba, M. Green retrofitting–A review of current status, implementations and challenges. Renew. Sustain. Energy Rev. 2017, 67, 1360–1368. [Google Scholar] [CrossRef]

- Gumbarević, S.; Dunović, I.B.; Milovanović, B.; Gaši, M. Method for Building Information Modeling Supported Project Control of Nearly Zero-Energy Building Delivery. Energies 2020, 13, 5519. [Google Scholar] [CrossRef]

- McCadden, L. USGBC Announces International Ranking of Top 10 Countries for LEED. 2016. Available online: https://www.usgbc.org/articles/usgbc-announces-international-ranking-top-10-countries-leed (accessed on 21 January 2019).

- Tahmasebinia, F.; Jiang, R.; Sepasgozar, S.; Wei, J.; Ding, Y.; Ma, H. Implementation of BIM Energy Analysis and Monte Carlo Simulation for Estimating Building Energy Performance Based on Regression Approach: A Case Study. Buildings 2022, 12, 449. [Google Scholar] [CrossRef]

- Sadrzadehrafiei, S.; Sopian, K.; Mat, S.; Lim, C.; Hashim, H.S.; Zaharim, A. Potential Energy and Emission Reduction through Application of Triple Glazing. In Proceedings of the 6th International Conference on Energy and Development—Environment—Biomedicine (EDEB’12), Athens, Greece, 7 March 2012. [Google Scholar]

- Mun, T.L. The Development of GBI Malaysia (GBI). 2009.

- Hashim, S.Z.; Zakaria, I.B.; Ahzahar, N.; Yasin, F.; Aziz, A.H. Implementation of Green Building Incentives for Construction Key Players in Malaysia. Int. J. Eng. Technol. 2016, 8, 6. [Google Scholar]

- Solla, M.; Elmesh, A.; Memon, Z.A.; Ismail, L.H.; Kazee, M.F.A.; Latif, Q.B.A.I.; Yusoff, N.I.M.; Alosta, M.; Milad, A. Analysis of BIM-Based Digitising of Green Building Index (GBI): Assessment Method. Buildings 2022, 12, 429. [Google Scholar] [CrossRef]

- Love, P.; Bullen, P.A. Towards the sustainable adaptation of existing facilities. Facilities 2009, 27, 357–367. [Google Scholar] [CrossRef]

- Ma, Z.; Cooper, P.; Daly, D.; Ledo, L. Existing building retrofits: Methodology and state-of-the-art. Energy Build. 2012, 55, 889–902. [Google Scholar] [CrossRef]

- Noris, F.; Adamkiewicz, G.; Delp, W.W.; Hotchi, T.; Russell, M.; Singer, B.C.; Spears, M.; Vermeer, K.; Fisk, W.J. Indoor environmental quality benefits of apartment energy retrofits. Build. Environ. 2013, 68, 170–178. [Google Scholar] [CrossRef] [Green Version]

- Berardi, U. Aerogel-enhanced systems for building energy retrofits: Insights from a case study. Energy Build. 2018, 159, 370–381. [Google Scholar] [CrossRef]

- EPU. E.P.U. 11th Malaysia Plan; EPU: Kuala Lumpur, Malaysia, 2016. [Google Scholar]

- Walter, T.; Sohn, M.D. A regression-based approach to estimating retrofit savings using the Building Performance Database. Appl. Energy 2016, 179, 996–1005. [Google Scholar] [CrossRef] [Green Version]

- Yiing, C.F.; Yaacob, N.M.; Hussein, H. Achieving Sustainable Development: Accessibility of Green Buildings in Malaysia. Procedia-Soc. Behav. Sci. 2013, 101, 120–129. [Google Scholar] [CrossRef]

- Ali, S.B.M.; Hasanuzzaman, M.; Rahim, N.A. Investigation on the load factor performance at Wisma R&D universiti Malaya building. In Proceedings of the 5th IET International Conference on Clean Energy and Technology (CEAT2018), Kuala Lumpur, Malaysia, 5–6 September 2018. [Google Scholar]

- Ali, S.B.M.; Hasanuzzaman, M.; Rahim, N.A.; Mamun, M.A.A.; Obaidellah, U.H. Analysis of energy consumption and potential energy savings of an institutional building in Malaysia. Alex. Eng. J. 2021, 60, 805–820. [Google Scholar]

- Shaikh, P.H.; Nor, N.B.M.; Sahito, A.A.; Nallagownden, P.; Elamvazuthi, I.; Shaikh, M.S. Building energy for sustainable development in Malaysia: A review. Renew. Sustain. Energy Rev. 2017, 75, 1392–1403. [Google Scholar] [CrossRef]

- Magazzino, C.; Mele, M.; Schneider, N.; Shahzad, U. Does export product diversification spur energy demand in the APEC region? Application of a new neural networks experiment and a Decision Tree model. Energy Build. 2022, 258, 111820. [Google Scholar] [CrossRef]

- EC. National Energy Balance 2018; Energy Commission, Ed.; Energy Commission: Putrajaya, Malaysia, 2018; p. 86. [Google Scholar]

- Ghaffarianhoseini, A.; Tookey, J.; Ghaffarianhoseini, A.; Naismith, N.; Azhar, S.; Efimova, O.; Raahemifar, K. Building Information Modelling (BIM) uptake: Clear benefits, understanding its implementation, risks and challenges. Renew. Sustain. Energy Rev. 2017, 75, 1046–1053. [Google Scholar] [CrossRef]

- Bryde, D.; Broquetas, M.; Volm, J.M. The project benefits of Building Information Modelling (BIM). Int. J. Proj. Manag. 2013, 31, 971–980. [Google Scholar] [CrossRef] [Green Version]

- Wilkinson, S. Analysing sustainable retrofit potential in premium office buildings. Struct. Surv. 2012, 30, 398–410. [Google Scholar] [CrossRef]

- Changsaar, C.; Abidin, N.I.; Khoso, A.R.; Luenhui, L.; Yaoli, X.; Hunchuen, G. Optimising energy performance of an Eco-Home using Building Information Modelling (BIM). Innov. Infrastruct. Solut. 2022, 7, 140. [Google Scholar] [CrossRef]

- Zhao, H.-X.; Magoulès, F. A review on the prediction of building energy consumption. Renew. Sustain. Energy Rev. 2012, 16, 3586–3592. [Google Scholar] [CrossRef]

- Alajmi, A. Energy audit of an educational building in a hot summer climate. Energy Build. 2012, 47, 122–130. [Google Scholar] [CrossRef]

- Sadrzadehrafiei, S.; Sopian, K.; Mat, S.; Lim, C. Energy consumption and energy saving in Malaysian office buildings. Models Methods Appl. Sci. 2011, 75, 1392–1403. [Google Scholar]

- Menezes, A.C.; Cripps, A.; Buswell, R.A.; Wright, J.; Bouchlaghem, D. Estimating the energy consumption and power demand of small power equipment in office buildings. Energy Build. 2014, 75, 199–209. [Google Scholar] [CrossRef] [Green Version]

- IEA. Air Conditioning Use Emerges as One of the Key Drivers of Global Electricity-Demand Growth; IEA: Paris, France, 2018. [Google Scholar]

- Yuan, L.; Ruan, Y.; Yang, G.; Feng, F.; Li, Z. Analysis of Factors Influencing the Energy Consumption of Government Office Buildings in Qingdao. Energy Procedia 2016, 104, 263–268. [Google Scholar] [CrossRef]

- Gasparella, A.; Pernigotto, G.; Cappelletti, F.; Romagnoni, P.; Baggio, P. Analysis and modelling of window and glazing systems energy performance for a well insulated residential building. Energy Build. 2011, 43, 1030–1037. [Google Scholar] [CrossRef]

- Hee, W.J.; Alghoul, M.A.; Bakhtyar, B.; Elayeb, O.; Shameri, M.A.; Alrubaih, M.S.; Sopian, K. The role of window glazing on daylighting and energy saving in buildings. Renew. Sustain. Energy Rev. 2015, 42, 323–343. [Google Scholar] [CrossRef]

- Han, G.; Srebric, J.; Enache-Pommer, E. Different modeling strategies of infiltration rates for an office building to improve accuracy of building energy simulations. Energy Build. 2015, 86, 288–295. [Google Scholar] [CrossRef]

- ASHRAE. The 2001 Ashrae Handbook; ASHRAE: Atlanta, GA, USA, 2001; p. 892. [Google Scholar]

- Ng, L.C.; Dols, W.S.; Emmerich, S.J. Evaluating potential benefits of air barriers in commercial buildings using NIST infiltration correlations in EnergyPlus. Build. Environ. 2021, 196, 107783. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, T.; Liu, X.; Li, L.; Jiang, Y. Energy saving potential for space heating in Chinese airport terminals: The impact of air infiltration. Energy 2021, 215, 119175. [Google Scholar] [CrossRef]

- Tahir, M.Z.; MNawi, N.M.; Rajemi, M.F. Building Energy Index: A Case Study of Three Government Office Buildings in Malaysia. Adv. Sci. Lett. 2015, 21, 1798–1801. [Google Scholar] [CrossRef]

- Moghimi, S.; Azizpour, F.; Mat, S.; Lim, C.H.; Salleh, E.; Sopian, K. Building energy index and end-use energy analysis in large-scale hospitals—case study in Malaysia. Energy Effic. 2014, 7, 243–256. [Google Scholar] [CrossRef]

- Huat, N.B.; Akasah, Z.A. An overview of Malaysia Green Technology Corporation Office Building: A showcase Energy-Efficient Building Project in Malaysia. J. Sustain. Dev. 2011, 4, 17. [Google Scholar]

- Noranai, Z.; Kammalluden, N. Study of Building Energy Index in Universiti Tun Hussein Onn Malaysia. Acad. J. Sci. 2012, 2, 429–433. [Google Scholar]

- Sadrzadehrafiei, S.; Sopian, K.; Mat, S.; Lim, C. Application of advanced glazing to mid-rise office buildings in Malaysia. Recent Res. Chem. Biol. Environ. Cult. 2011. Available online: https://docplayer.net/20482989-Application-of-advanced-glazing-to-mid-rise-office-buildings-in-malaysia.html (accessed on 16 June 2022).

- Jung, N.; Paiho, S.; Shemeikka, J.; Lahdelma, R.; Airaksinen, M. Energy performance analysis of an office building in three climate zones. Energy Build. 2018, 158, 1023–1035. [Google Scholar] [CrossRef]

- Al Qadi, S.; Sodagar, S.B.; Elnokaly, A. Estimating the heating energy consumption of the residential buildings in Hebron, Palestine. J. Clean. Prod. 2018, 196, 1292–1305. [Google Scholar] [CrossRef]

- Abanda, F.H.; Vidalakis, C.; Oti, A.H.; Tah, J.H.M. A critical analysis of Building Information Modelling systems used in construction projects. Adv. Eng. Softw. 2015, 90, 183–201. [Google Scholar] [CrossRef]

- Tam, W.Y.V.; Le, K.N.; Tran, C.N.N.; Wang, J.Y. A review on contemporary computational programs for Building’s life-cycle energy consumption and greenhouse-gas emissions assessment: An empirical study in Australia. J. Clean. Prod. 2018, 172, 4220–4230. [Google Scholar] [CrossRef]

- Liu, S.; Meng, X.; Tam, C. Building information modeling based building design optimization for sustainability. Energy Build. 2015, 105, 139–153. [Google Scholar] [CrossRef]

- Ahmad Farin, M.; Jasni, I.; Mazieana, C.A.; Rofizlan, A.; Mohammad Farid, A.H.; Sharifuddin, U.; Azra Fakhiera, S.; Siti Aisah, O.; Nurafizah, A. BIM Projects. In CIDB E-Construct; myBIM Centre: Kuala Lumpur, Malaysia, 2018. [Google Scholar]

- Naden, C. Better Building with New International Standards for BIM. 2019. Available online: https://www.iso.org/news/ref2364.html (accessed on 21 January 2019).

- Alves, T.; Machado, L.; de Souza, R.G.; de Wilde, P. Assessing the energy saving potential of an existing high-rise office building stock. Energy Build. 2018, 173, 547–561. [Google Scholar] [CrossRef]

- Mehdipoor, A. Level of Building Information Modelling (BIM) awareness and readiness among building professional in Malaysia. In Proceedings of the 11th ASEAN Postgraduate Seminar 2017, Kuala Lumpur, Malaysia, 15 November 2017. [Google Scholar]

- Graphisoft. Energy Evaluation Workflow: Overview. 2019. Available online: https://helpcenter.graphisoft.com/user-guide/77214/ (accessed on 20 October 2020).

- WBDG. Sun Control and Shading Devices 2018. Available online: https://www.wbdg.org/resources/sun-control-and-shading-devices (accessed on 20 October 2020).

- Evola, G.; Gullo, F.; Marletta, L. The role of shading devices to improve thermal and visual comfort in existing glazed buildings. Energy Procedia 2017, 134, 346–355. [Google Scholar] [CrossRef]

- Cuce, E. Accurate and reliable U-value assessment of argon-filled double glazed windows: A numerical and experimental investigation. Energy Build. 2018, 171, 100–106. [Google Scholar] [CrossRef]

- Yuan, J.; Farnham, C.; Emura, K. Optimal combination of thermal resistance of insulation materials and primary fuel sources for six climate zones of Japan. Energy Build. 2017, 153, 403–441. [Google Scholar] [CrossRef]

| Parameter | Detail Properties | u-Value (W/m2K) | Reference |

|---|---|---|---|

| External wall | Structure Brick Double PlasteredThickness: 125 mmSolar absorption: 85% | 2.74 | Drawing Layout |

| Internal wall | Stud partition | 1.18 | Drawing Layout & Energy Audit |

| Thickness: 100 mm | |||

| Concrete block | 1.74 | ||

| Thickness: 200 mm | |||

| Structure brick wall double plastered | 2.21 | ||

| Thickness: 125 mm | |||

| Slab | Structure Reinforced Concrete | N/A | Drawing Layout |

| Thickness: 310 m | |||

| Floor | IC: 03 Tile-Floor | N/A | Energy Audit |

| Colour: Light brown | |||

| Thickness: 10 mm | |||

| Roof | Flat roof Thickness: 380 mm | N/A | Energy Audit |

| Thermal Blocks | Operation Profile | Total Area (m2) | Supply Building System |

|---|---|---|---|

| Offices | General office | 11,333.42 | VRF |

| Circulation and Common Area | Unconditioned | 22,928.09 | VRF |

| Services & Facilities | Toilets and Sanitary Facilities | 7910.36 | Fresh air supply |

| Parameter | Window Details | ||

|---|---|---|---|

| Glazing Material | Opaque | Shading Element | |

| A0 | Single glazing | Frame metal [steel basic] | No shading |

| A1-1 | Double glazing [Basic-Air filled clear] | Frame metal [steel basic] | No shading |

| A1-2 | Double glazing [Basic-Air filled clear] | Frame metal [steel basic] | 80% shading sunscreen |

| A1-3 | Double glazing [Basic-Air filled clear] | Frame metal [steel basic] | External blind |

| A1-4 | Double glazing [Basic-Air filled clear] | Frame metal [steel basic] | External louver |

| A2-1 | Double glazing [Basic-Air filled clear] | Frame metal [Aluminum standard] | No shading |

| A2-2 | Double glazing [Basic-Air filled clear] | Frame metal [Aluminum standard] | 80% shading sunscreen |

| A2-3 | Double glazing [Basic-Air filled clear] | Frame metal [Aluminum standard] | External blind |

| A3-1 | Double glazing [Basic-Air filled dark] | Frame metal [Aluminum standard] | No shading |

| A3-2 | Double glazing [Basic-Air filled dark] | Frame metal [Aluminum standard] | 80% shading sunscreen |

| A4-1 | Double glazing [Standard-argon fill dark low E] | Frame metal [Aluminum standard] | No shading |

| A4-2 | Double glazing [Standard-argon fill dark low E] | Frame metal [Aluminum standard] | 80% shading sunscreen |

| A5-1 | Double glazing [Standard-argon fill dark low E] | Frame metal [Aluminum ultimate] | No shading |

| A5-2 | Double glazing [Standard-argon fill dark low E] | Frame metal [Aluminum ultimate] | 80% shading sunscreen |

| Parameters | Details |

|---|---|

| Internal temperature | Min = 16 °C; Max 23 °C |

| Occupancy data | Non-residential |

| Operating time | 8 a.m.–5 p.m. (9 h) |

| Occupancy count | total area/1000 persons |

| Human heat gain | 120 W/capita |

| Lighting type & heat gain Total equipment heat gain | Fluorescent lighting tube; 5 W/m2 Not included |

| Parameter | Details |

|---|---|

| Project location | Kuala Lumpur |

| Project coordinate | 3°9′0″ N, 101°41′0″ E |

| Soil type | Gravel |

| Surrounding | Paved |

| Wind protection | Unprotected |

| Climate type | Moist |

| Annual average external temperature | 28 °C |

| Parameter | ArchiCAD Simulation | Energy Audit (EA) | Utility Bill (2018) |

|---|---|---|---|

| Gross Area (m2) | 42,171.87 | 41,331.6 | N/A |

| Envelope Area (m2) | 11,115.06 | N/A | N/A |

| Glazing ratio (%) | 21% | N/A | N/A |

| Infiltration at 50 Pa | 0.87 | N/A | N/A |

| Openings u-value (W/m2K) | 6.92–7.58 | N/A | N/A |

| Annual energy consumption (kWh) | 2,177,755.4 [51.64 kWh/m2a] | 2,646,418 | 2,100,323 |

| CO2 emission (kg/m2a) | 10.93 | N/A | N/A |

| Parameter | Window Details | Opening u-Value (W/m2K) | Opening R-Value (m2K/W) | Infiltration at 50 Pa (ACH) | ||

|---|---|---|---|---|---|---|

| Glazing Material | Opaque | Shading Element | ||||

| A0 | Single glazing | Frame metal [steel basic] | No shading | 6.92–7.58 | 0.132–0.144 | 0.87 |

| A1-1 | Double glazing [Basic-Air filled clear] | Frame metal [steel basic] | No shading | 4.18–7.09 | 0.141–0.23 | 0.87 |

| A1-2 | Double glazing [Basic-Air filled clear] | Frame metal [steel basic] | 80% shading sunscreen | 4.18–7.09 | 0.141–0.23 | 0.87 |

| A1-3 | Double glazing [Basic-Air filled clear] | Frame metal [steel basic] | External blind | 4.18–7.09 | 0.141–0.23 | 0.87 |

| A1-4 | Double glazing [Basic-Air filled clear] | Frame metal [steel basic] | External louver | 4.18–7.09 | 0.141–0.23 | 0.87 |

| A2-1 | Double glazing [Basic-Air filled clear] | Frame metal [Aluminium standard] | No shading | 3.06–7.09 | 0.141–0.32 | 0.44 |

| A2-2 | Double glazing [Basic-Air filled clear] | Frame metal [Aluminium standard] | 80% shading sunscreen | 3.06–7.09 | 0.141–0.32 | 0.44 |

| A2-3 | Double glazing [Basic-Air filled clear] | Frame metal [Aluminium standard] | External blind | 3.06–7.09 | 0.141–0.32 | 0.44 |

| A3-1 | Double glazing [Basic-Air filled dark] | Frame metal [Aluminium standard] | No shading | 3.06–7.09 | 0.141–0.32 | 0.44 |

| A3-2 | Double glazing [Basic-Air filled dark] | Frame metal [Aluminium standard] | 80% shading sunscreen | 3.06–7.09 | 0.141–0.32 | 0.44 |

| A4-1 | Double glazing [Standard-argon fill dark low E] | Frame metal [Aluminium standard] | No shading | 1.69–2.42 | 0.413–0.59 | 0.44 |

| A4-2 | Double glazing [Standard-argon fill dark low E] | Frame metal [Aluminium standard] | 80% shading sunscreen | 1.69–2.42 | 0.413–0.59 | 0.44 |

| A5-1 | Double glazing [Standard-argon fill dark low E] | Frame metal [Aluminium ultimate] | No shading | 0.78–1.49 | 0.67–1.28 | 0.31 |

| A5-2 | Double glazing [Standard-argon fill dark low E] | Frame metal [Aluminium ultimate] | 80% shading sunscreen | 0.78–1.49 | 0.67–1.28 | 0.31 |

| Indicator | Annual Energy Consumption (kWh) | Annual Energy Cost (RM) | Annual CO2 Emission (kg) |

|---|---|---|---|

| Existing parameter [A] | 2,177,755.4 | 794,880.72 | 460,938.54 |

| 3% cooling load reduction [B] | 2,159,621.5 | 788,261.84 | 459,673.38 |

| Saving (A-B) | 18,133.9 | 6618.88 | 1265.16 |

| Saving (A-B) in % | 0.833 | 0.833 | 0.274 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, S.B.M.; Mehdipoor, A.; Samsina Johari, N.; Hasanuzzaman, M.; Rahim, N.A. Modeling and Performance Analysis for High-Rise Building Using ArchiCAD: Initiatives towards Energy-Efficient Building. Sustainability 2022, 14, 9780. https://doi.org/10.3390/su14159780

Ali SBM, Mehdipoor A, Samsina Johari N, Hasanuzzaman M, Rahim NA. Modeling and Performance Analysis for High-Rise Building Using ArchiCAD: Initiatives towards Energy-Efficient Building. Sustainability. 2022; 14(15):9780. https://doi.org/10.3390/su14159780

Chicago/Turabian StyleAli, Siti Birkha Mohd, Amirhossein Mehdipoor, Noora Samsina Johari, Md. Hasanuzzaman, and Nasrudin Abd Rahim. 2022. "Modeling and Performance Analysis for High-Rise Building Using ArchiCAD: Initiatives towards Energy-Efficient Building" Sustainability 14, no. 15: 9780. https://doi.org/10.3390/su14159780

APA StyleAli, S. B. M., Mehdipoor, A., Samsina Johari, N., Hasanuzzaman, M., & Rahim, N. A. (2022). Modeling and Performance Analysis for High-Rise Building Using ArchiCAD: Initiatives towards Energy-Efficient Building. Sustainability, 14(15), 9780. https://doi.org/10.3390/su14159780