Research on Recycling Strategies for New Energy Vehicle Waste Power Batteries Based on Consumer Responsibility Awareness

Abstract

:1. Introduction

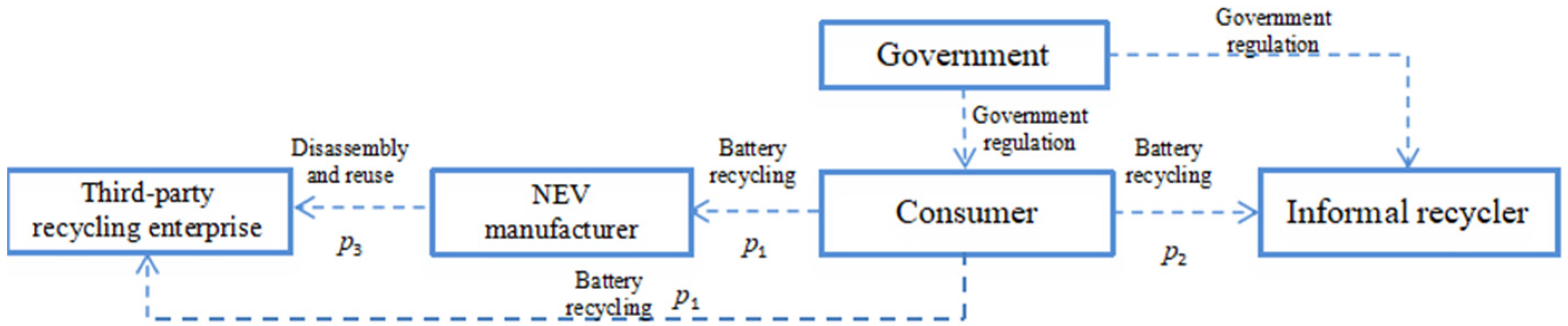

2. The Pricing Model of the Reverse Supply Chain of Waste Power Batteries

2.1. Problem Description

2.2. Model Assumptions

2.3. Single-Channel Recycling Decision Model for New Energy Manufacturers

2.3.1. Decentralized Decision Model

2.3.2. Centralized Decision-Making Model

2.4. Single-Channel Recycling Model for Third-Party Recycling Enterprises

2.4.1. Decentralized Decision-Making Model

2.4.2. Centralized Decision Model

3. Model Analysis

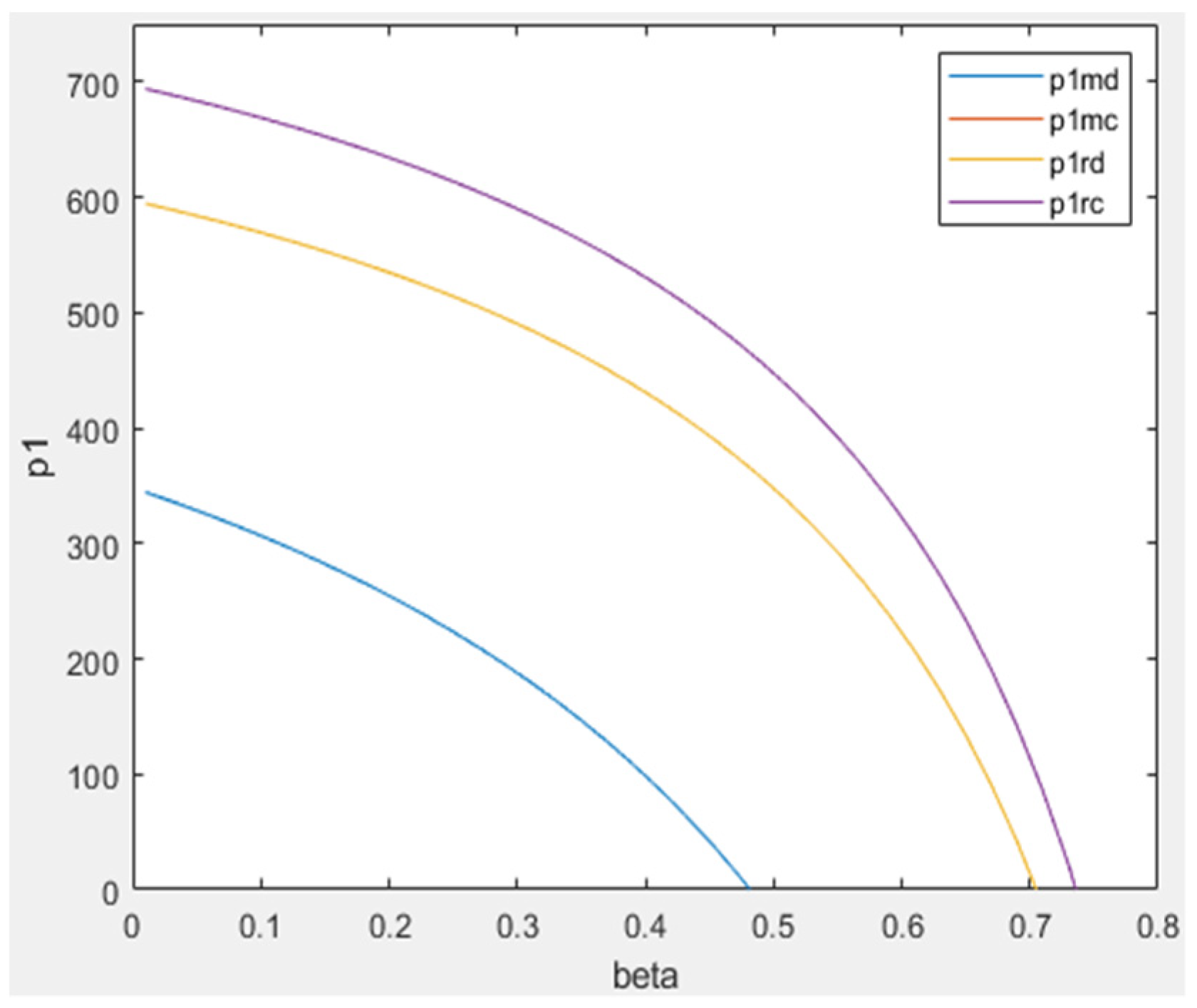

3.1. Analysis of Recycling Pricing,

3.2. Analysis of the Recycling Rate, r

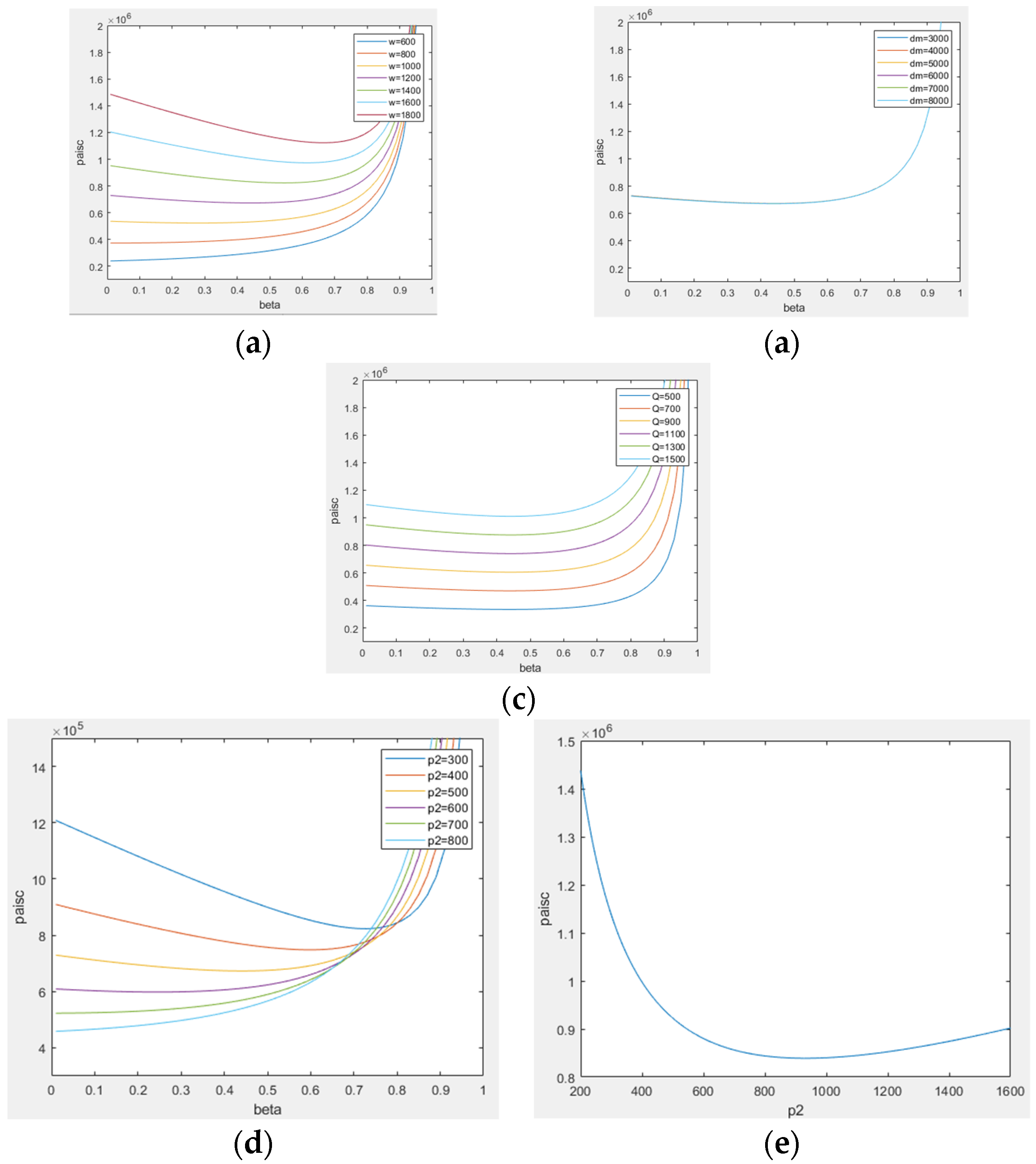

3.3. Analysis of Consumer Profits

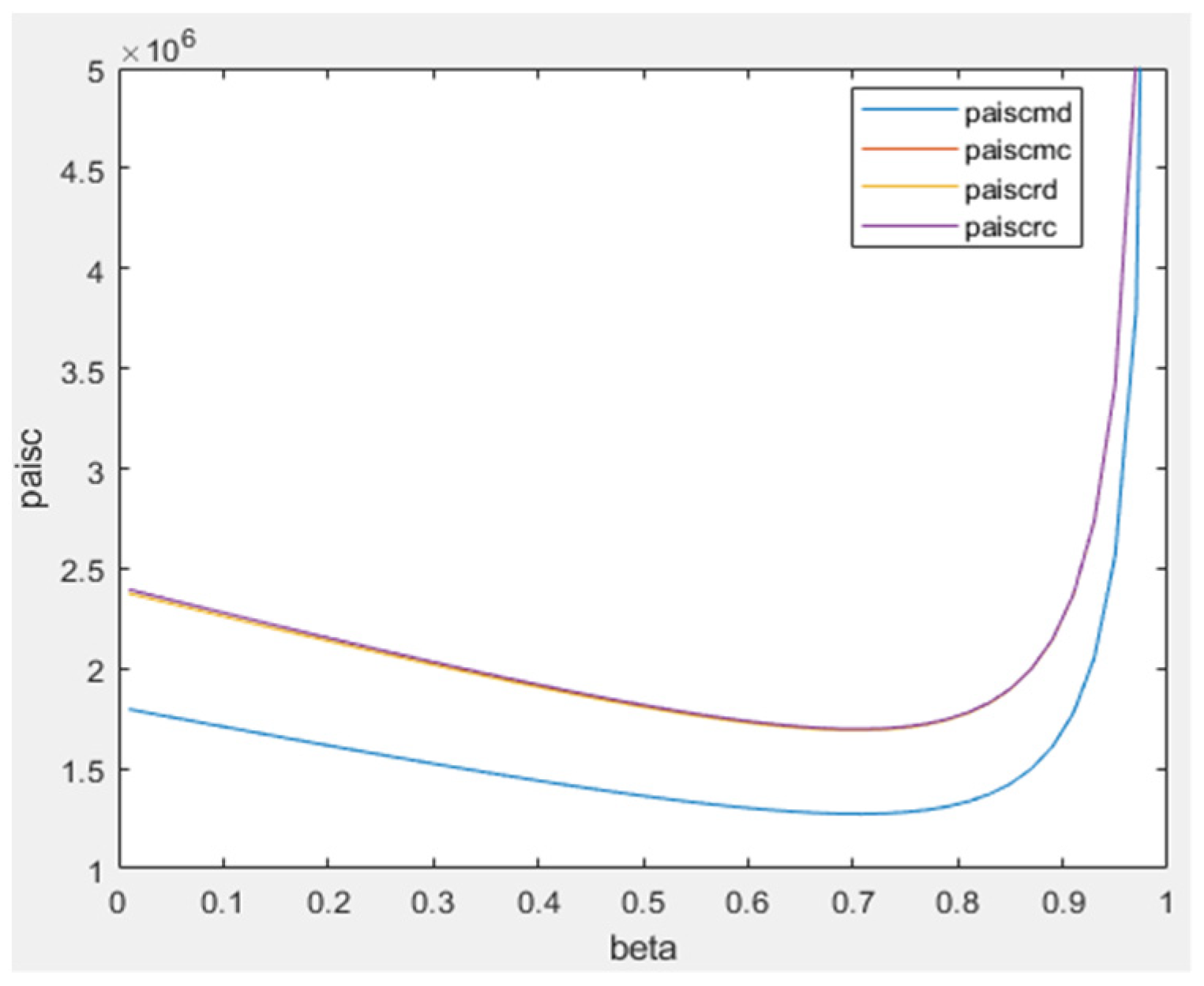

3.4. Analysis of Profit of the Supply Chain

3.5. Analysis of the Influencing Factors of Consumer Environmental Protection Responsibility Awareness,

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Li, Z. Why is 90% of the battery missing? How to break the cascade utilization of battery recycling? Resour. Recycl. 2020, 8, 33–36. [Google Scholar]

- China Merchants Securities. In-Depth Report on Power Battery Recycling and Gradient Utilization Industry. Available online: http://chuneng.bjx.com.cn/news/20190801/996967.shtml (accessed on 12 March 2020).

- Lyu, X.; Xu, Y.; Sun, D. An Evolutionary Game Research on Cooperation Mode of the NEV Power Battery Recycling and Gradient Utilization Alliance in the Context of China’s NEV Power Battery Retired Tide. Sustainability 2021, 13, 4165. [Google Scholar] [CrossRef]

- Ma, X.M.; Ma, Y.; Zhou, J.P. The Recycling of Spent Power Battery: Economic Benefits and Policy Suggestions. IOP Conf. Ser. Earth Environ. Sci. 2018, 159, 012017. [Google Scholar] [CrossRef]

- Zhao, S.; Xu, N.; Qiao, Y.; Yang, B. Suggestions on speeding up recycling of power battery for new energy vehicles in China. Chin. J. Eng. Sci. 2018, 20, 144. [Google Scholar] [CrossRef]

- Power Battery Recycling in Europe and America Has Become a System. When Will China’s Recycling System Take Shape? Available online: https://www.chuandong.com/news/news209836.html (accessed on 29 July 2022).

- General Office of the State Council. Implementation Plan of Extended Producer Responsibility System (EB/OL). 25 December 2016. Available online: http://www.gov.cn/zhengce/content/2017-01/03/content_5156043.htm (accessed on 6 April 2022).

- Yang, Y.K.; Zhang, B.; Liang, Y.L.; Lu, Q. Analysis on the current situation of waste power battery recycling policy and technology. Automob. Accessories 2021, 1, 50–51. [Google Scholar]

- National Development and Reform Commission. Development Plan of Circular Economy in the 14th Five Year Plan (EB/OL). 1 July 2021. Available online: https://www.ndrc.gov.cn/xxgk/zcfb/ghwb/202107/t20210707_1285527.html?code=&state=123 (accessed on 6 April 2022).

- Wang, F. “Internet + second-hand”, power battery recycling welcome good policy. 21st Century Economic Report, 23 July 2021. [Google Scholar]

- Hao, S.S.; Dong, Q.Y.; Li, J.H. Analysis and tendency on the recycling mode of used EV batteries based on cost accounting. Environ. Sci. China 2021, 41, 4745–4755. [Google Scholar]

- Shen, H.; Liu, J.; Zhao, X.G.; Liu, Q. Research on new energy vehicle battery recycling strategy in the post-subsidy era. J. Xi’an Technol. Univ. 2020, 40, 455–463. [Google Scholar]

- Xie, J.Y.; Le, W.; Guo, B.H. Pareto equilibrium of new energy vehicle power battery recycling based on extended producer responsibility. Manag. Sci. China 2022. [Google Scholar] [CrossRef]

- Mu, D.; Yang, J.; Li, X. The influence of enterprise cooperation within closed-loop supply chain on power battery recovery and recycling of new energy vehicles. Supply Chain Manag. 2021, 1, 54–67. [Google Scholar]

- Li, X.; Mu, D. Mu Recycling price decision and coordinated mechanism of electrical vehicle battery closed-loop supply chain. Soft Sci. 2018, 32, 124–129. [Google Scholar]

- Heydari, J.; Govindan, K.; Jafari, A. Reverse and Closed Loop Supply Chain Coordination by Considering Government Role. Transp. Res. Part D Transp. Environ. 2017, 52, 379–398. [Google Scholar] [CrossRef]

- Lu, C.; Zhao, M.Y.; Tao, J.; Liu, C.; Yu, J. Pricing strategy and coordination mechanism of power battery recycling under the dual risks from demand and quality. Oper. Res. Manag. Sci. 2020, 29, 195–203. [Google Scholar]

- Choi, Y.; Rhee, S.W. Current status and perspectives on recycling of end-of-life battery of electric vehicle in Korea (Republic of). Waste Manag. 2020, 106, 261–270. [Google Scholar] [CrossRef] [PubMed]

- Qiu, Z.G.; Zheng, Y.; Xu, Y.Q. Closed-loop supply chain recycling subsidy strategy of new energy vehicle power battery: An analysis based on evolutionary games. Bus. Res. 2020, 8, 28–36. [Google Scholar]

- Natkunarajah, N.; Scharf, M.; Scharf, P. Scenarios for the return of lithium-ion batteries out of electric cars for recycling. Procedia Cirp 2015, 29, 740–745. [Google Scholar] [CrossRef]

- Liu, K.; Wang, C. The impacts of subsidy policies and channel encroachment on the power battery recycling of new energy vehicles. Int. J. Low-Carbon Technol. 2021, 16, 770–789. [Google Scholar] [CrossRef]

- Xiong, Z.K.; Liang, X.P. Study on recycling mode of closed-loop supply chain considering consumer environmental awareness. Soft Sci. 2014, 28, 61–66. [Google Scholar]

- Jia, Y.L.; Li, C.B. Recycling Modes of Power Batteries of New Energy Vehicles Based on Principal Behavior; IEEE: Toronto, ON, Canada, 2018. [Google Scholar]

- Savaskan, R.C.; Bhattacharya, S.; Van Wassenhove, L.N. Closed-loop supply chain models with product manufacturing. Manag. Sci. 2004, 50, 239–252. [Google Scholar] [CrossRef]

- Savaskan, R.C.; Van Wassenhove, L.N. Reverse channel design: The case of competing retailers. Manag. Sci. 2006, 52, 1–14. [Google Scholar] [CrossRef]

- Sun, J.Y.; Teng, C.X.; Chen, Z.B. Channel selection model of remanufacturing closed-loop supply chain based on buy-back price and sale quantity. Syst. Eng. Theory Pract. 2013, 33, 3079–3086. [Google Scholar]

- Hong, X.; Xu, L.; Du, P.; Wang, W. Joint advertising, pricing and collection decisions in a closed-loop supply chain. Int. J. Prod. Econ. 2015, 167, 12–22. [Google Scholar] [CrossRef]

- Li, X.J.; Ai, X.Z.; Tang, X.W. Research on recycling channels of remanufactured products under competitive supply chain. J. Manag. Eng. 2016, 30, 90–98. [Google Scholar]

- Chen, J.; Tian, D.G. Selection of the Recycling Mode Based on Closed-loop Supply Chain Model. Chin. J. Manag. Sci. 2017, 25, 88–97. [Google Scholar]

- Zhou, X.; Xiong, H.; Chen, X. Reverse channel selection in closed-loop supply chain based on quality of recycled products. Control Decis. 2017, 32, 193–202. [Google Scholar]

- Zhang, C.; Lyu, R.; Li, Z.; MacMillen, S.J. Who should lead raw materials collection considering regulatory pressure and technological innovation? J. Clean. Prod. 2021, 298, 126762. [Google Scholar] [CrossRef]

- Chen, J.; Mei, J.; Cao, J. Decision making of hybrid recycling channels selection for closed-loop supply chain with dominant retailer. Comput. Integr. Manuf. Syst. 2021, 27, 954–964. [Google Scholar]

- Gong, B.; Gao, Y.; Liu, Z.; Cheng, Y.; Zheng, X. Selection of recycling channels in thepower battery closed-loop supply chain under government fund policy. Comput. Integr. Manuf. Syst. 2021. Available online: http://kns.cnki.net.ez.zust.edu.cn/kcms/detail/11.5946.tp.20210911.1259.004.html (accessed on 29 July 2022).

- Ding, X.; Ma, Y. Multiple attribute decision making problem in power battery recycling mode selection. Tongji Daxue Xuebao/J. Tongji Univ. 2018, 46, 1312–1318. [Google Scholar]

- Yao, Y.; Jiang, Q. Recovery mode analysis of vehicle spent power battery. Trends Overv. 2019, 12, 91–94. [Google Scholar]

- Ma, L.; Liu, Y.J.; Zhu, H. Design of dual-channel recycling contract for new energy vehicle batteries from the perspective of closed-loop supply chain. Sci. Technol. Manag. Res. 2021, 40, 184–192. [Google Scholar]

| Modes | |||||

|---|---|---|---|---|---|

| Manufacturer recycling (decentralized decision-making) | |||||

| Manufacturer recycling (centralized decision-making) | |||||

| Third-party recycling (decentralized decision-making) | |||||

| Third-party recycling (centralized decision-making) |

| Recycling Mode | |

|---|---|

| Manufacturer recycling (decentralized/centralized decision-making) | |

| Third-party recycling (decentralized decision-making) | |

| Third-party recycling (centralized decision-making) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, J.; Teng, H.; Wang, Y. Research on Recycling Strategies for New Energy Vehicle Waste Power Batteries Based on Consumer Responsibility Awareness. Sustainability 2022, 14, 10016. https://doi.org/10.3390/su141610016

Fan J, Teng H, Wang Y. Research on Recycling Strategies for New Energy Vehicle Waste Power Batteries Based on Consumer Responsibility Awareness. Sustainability. 2022; 14(16):10016. https://doi.org/10.3390/su141610016

Chicago/Turabian StyleFan, Jiajing, Hao Teng, and Yibo Wang. 2022. "Research on Recycling Strategies for New Energy Vehicle Waste Power Batteries Based on Consumer Responsibility Awareness" Sustainability 14, no. 16: 10016. https://doi.org/10.3390/su141610016

APA StyleFan, J., Teng, H., & Wang, Y. (2022). Research on Recycling Strategies for New Energy Vehicle Waste Power Batteries Based on Consumer Responsibility Awareness. Sustainability, 14(16), 10016. https://doi.org/10.3390/su141610016