End-of-Life Textile Recognition in a Circular Economy Perspective: A Methodological Approach Based on Near Infrared Spectroscopy

Abstract

:1. Introduction

2. Materials and Methods

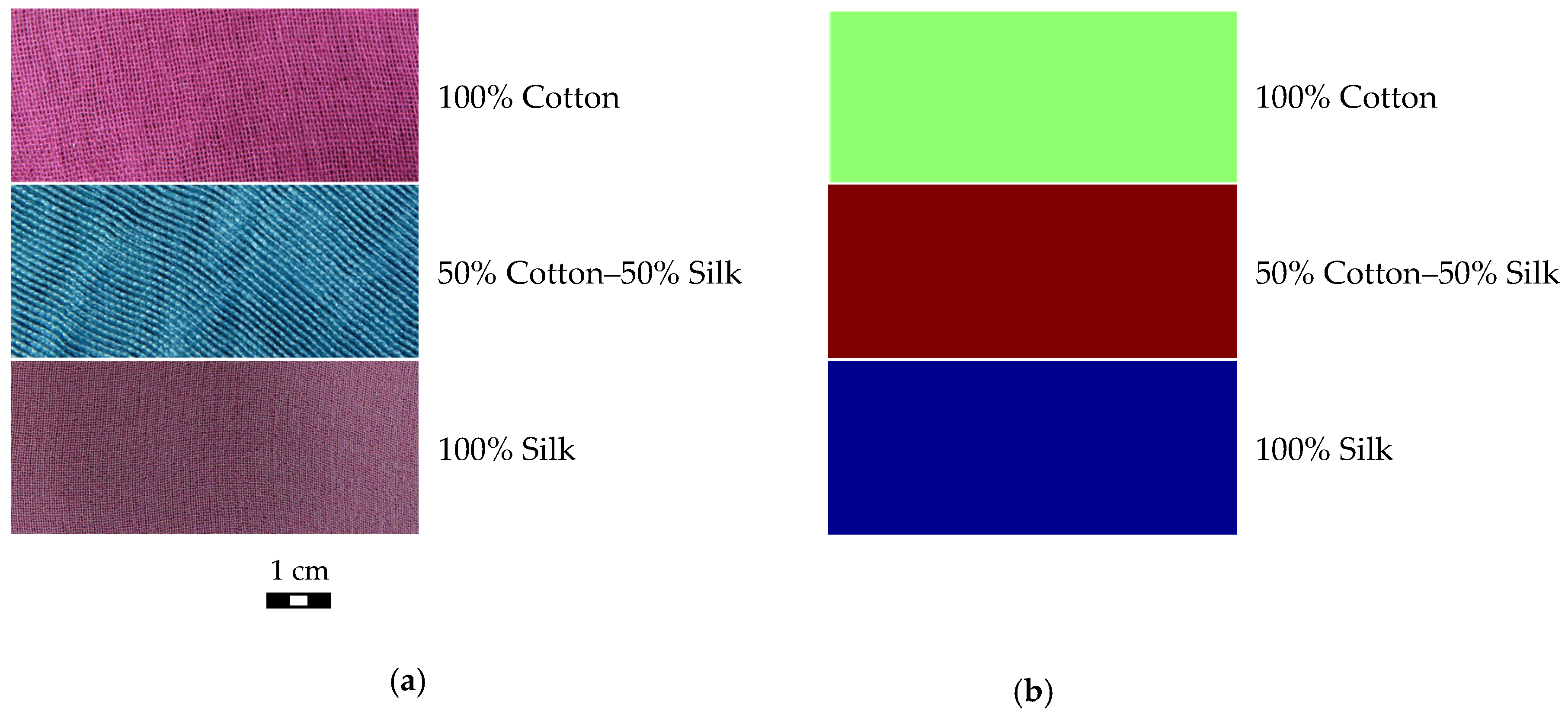

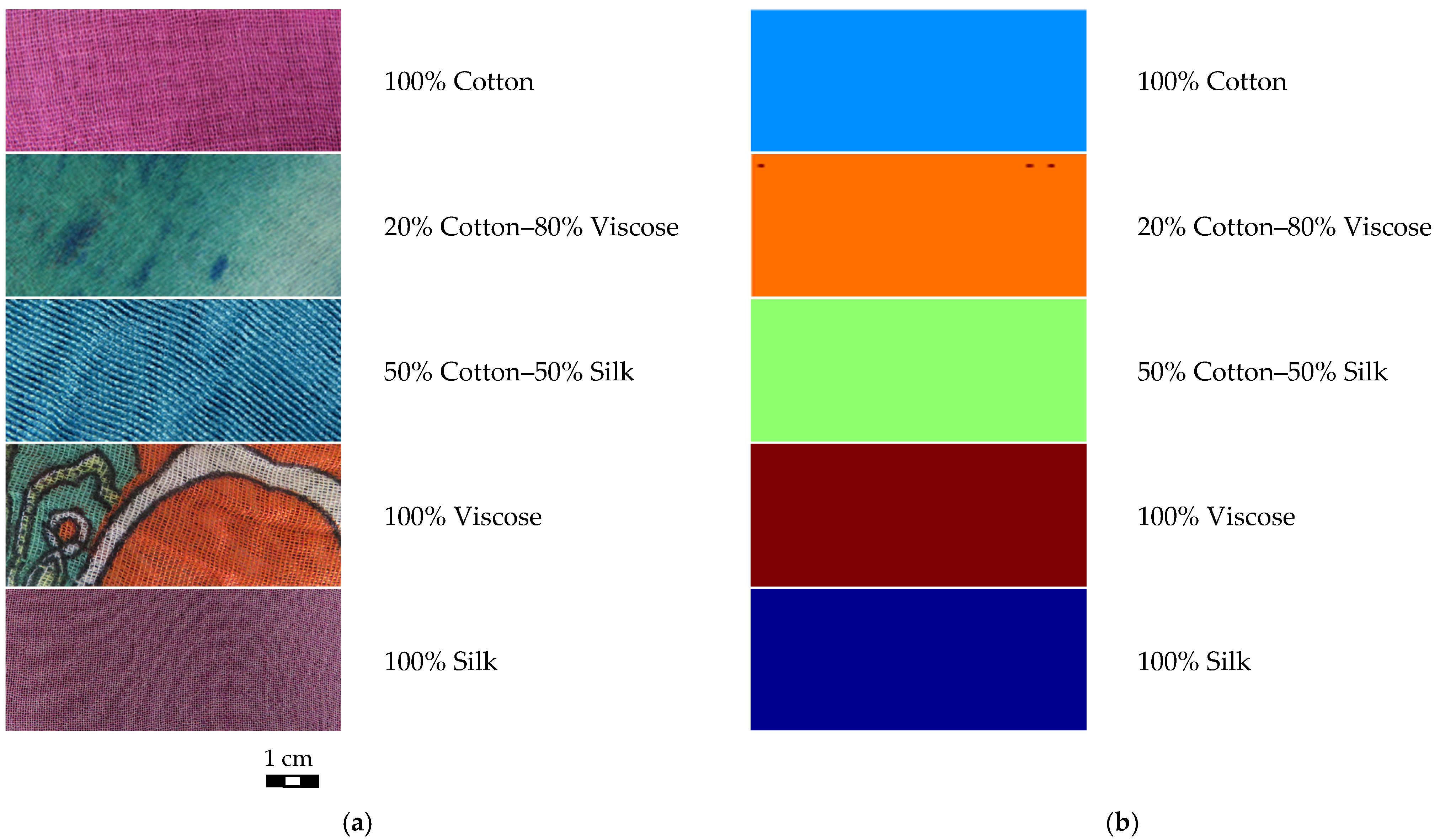

2.1. Analyzed Samples

- (a)

- 100% Cotton;

- (b)

- 100% Silk;

- (c)

- 100% Viscose;

- (d)

- 20% Cotton–80% Viscose;

- (e)

- 50% Cotton–50% Silk.

2.2. Methods

2.2.1. Hyperspectral Imaging System

2.2.2. Portable Spectrophotoradiometer

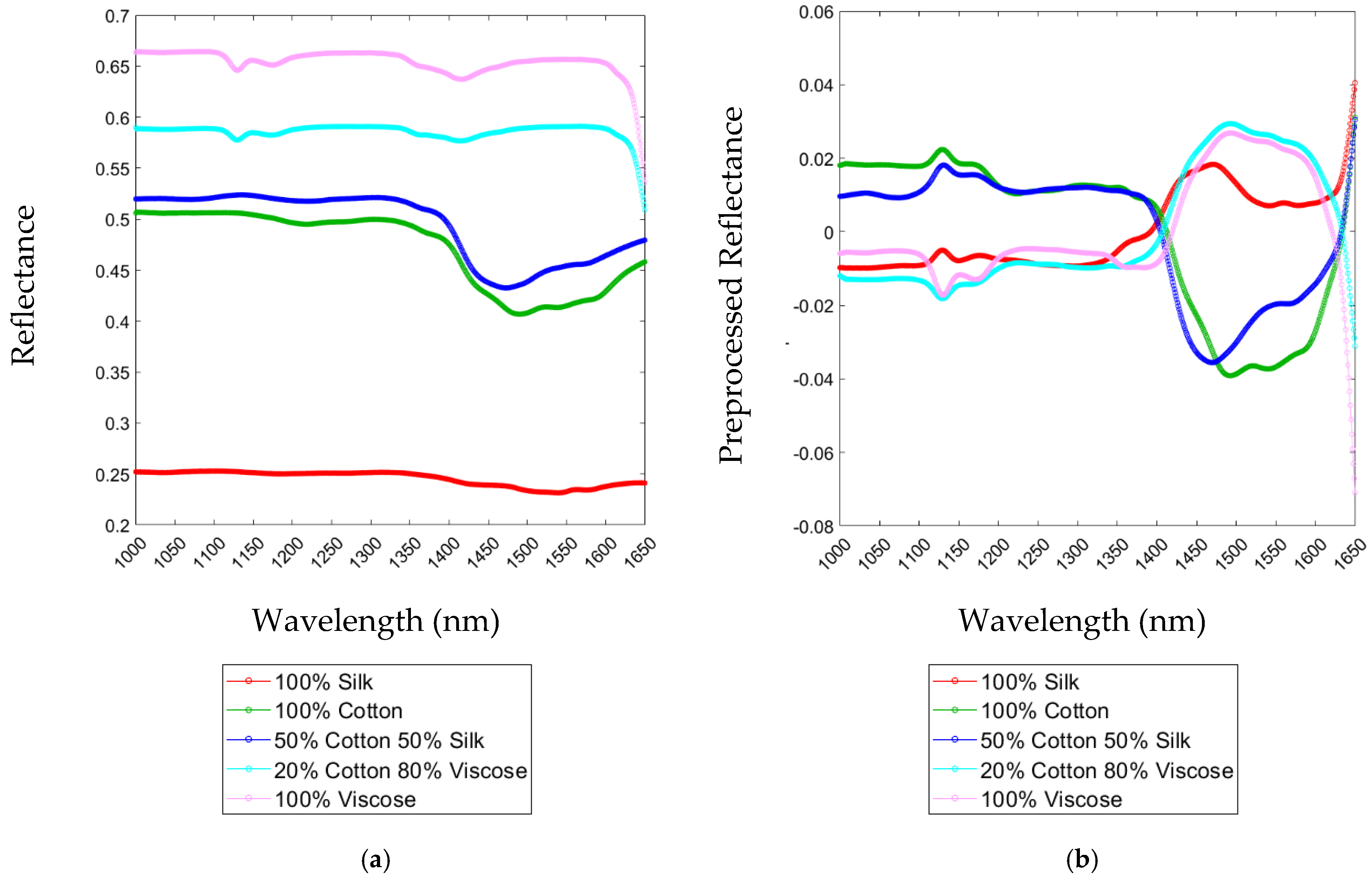

2.3. Spectral Data Collection, Processing and Analysis

2.3.1. Experimental Procedure

- 1st experimental setup. Identification of the following three classes of products: 100% cotton, 100% viscose and a blend of them (20% Cotton–80% viscose);

- 2nd experimental setup. Recognition of 100% cotton, 100% silk and a blend consisting in 50% cotton and 50% silk;

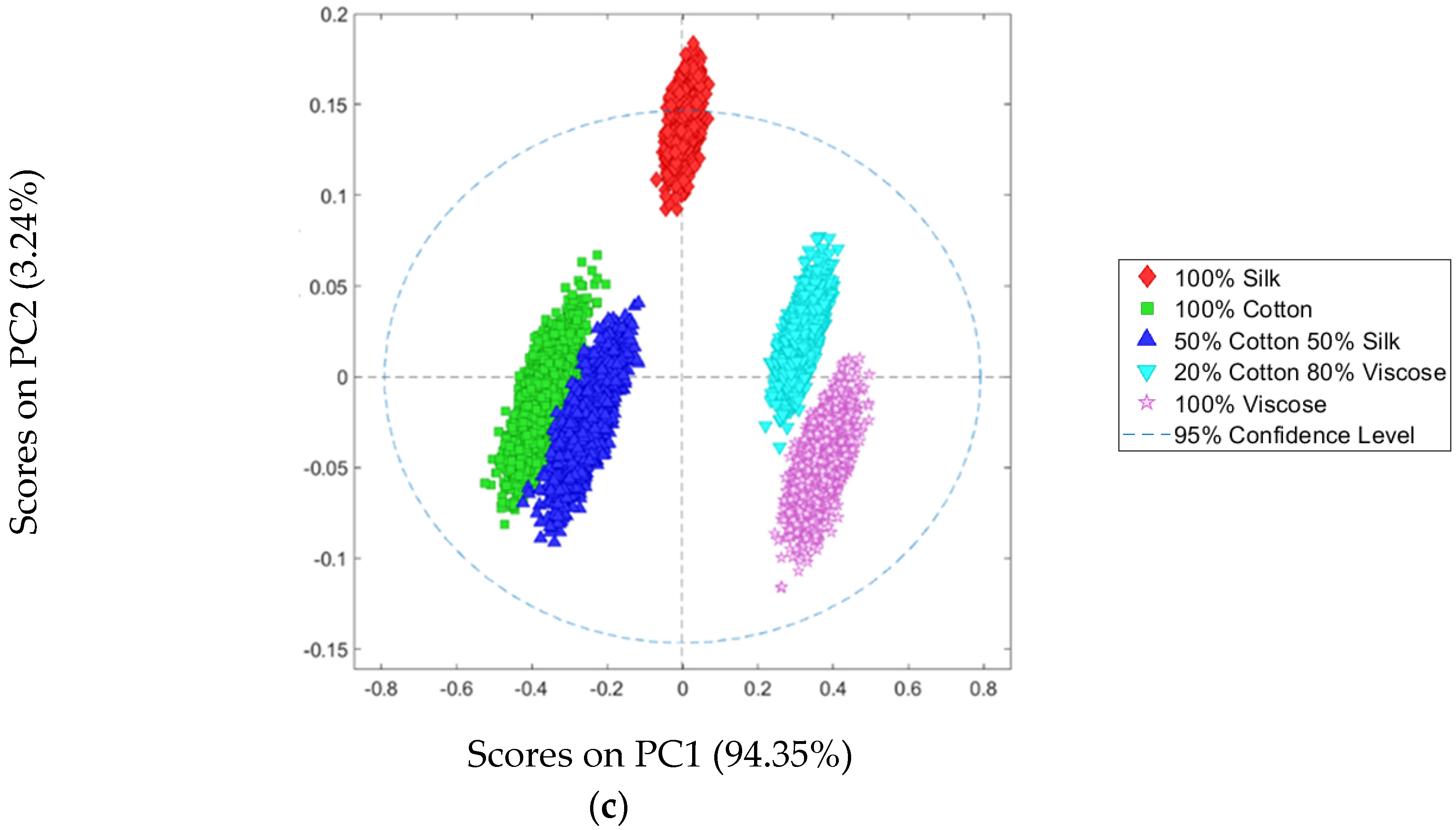

- 3rd experimental setup. Recognition of 100% cotton, 100% silk, 100% viscose and their blends (i.e., 20% Cotton–80% viscose and 50% Cotton–50% silk).

2.3.2. Data Handling and Explorative Analysis

2.3.3. Classification Procedure

3. Results and Discussion

3.1. Hyperspectral Imaging

3.2. Single-Spot Spectra

4. Conclusions and Future Perspectives

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Manshoven Saskia, C.M.; Vercalsteren, A.; Arnold, M.; Nicolau, M.; Lafond, E.; Fogh Mortensen, L.; Coscieme, L. Textiles and the Environment in a Circular Economy (Eionet Report—ETC/WMGE 2019/6). 2019, European Topic Centre on Waste and Materials. Available online: https://www.eea.europa.eu/publications/textiles-in-europes-circular-economy (accessed on 18 July 2022).

- Xie, X.; Hong, Y.; Zeng, X.; Dai, X.; Wagner, M. A Systematic Literature Review for the Recycling and Reuse of Wasted Clothing. Sustainability 2021, 13, 13732. [Google Scholar] [CrossRef]

- Harmsen, P.; Scheffer, M.; Bos, H. Textiles for circular fashion: The logic behind recycling options. Sustainability 2021, 13, 9714. [Google Scholar] [CrossRef]

- Chen, X.; Memon, H.A.; Wang, Y.; Marriam, I.; Tebyetekerwa, M. Circular Economy and sustainability of the clothing and textile Industry. Mater. Circ. Econ. 2021, 3, 12. [Google Scholar] [CrossRef]

- Pandey, K. Fashion Industry May Use Quarter of World’s Carbon Budget by 2050. 2020. Available online: https://www.downtoearth.org.in/news/environment/fashion-industry-may-use-quarter-of-world-s-carbon-budget-by-2050-61183 (accessed on 18 July 2022).

- Ellen MacArthur Foundation. A New Textiles Economy: Redesigning Fashion’s Future; Ellen MacArthur Foundation: Cowes, UK, 2017. [Google Scholar]

- Beasley, J.; Georgeson, R.; Arditi, S.; Barczak, P. Advancing Resource Efficiency in Europe: Indicators and Waste Policy Scenarios to Deliver a Resource Efficient and Sustainable Europe; European Environmental Bureau (EEB): Brussels, Belgium, 2014. [Google Scholar]

- Saha, K.; Dey, P.K.; Papagiannaki, E. Implementing circular economy in the textile and clothing industry. Bus. Strategy Environ. 2021, 30, 1497–1530. [Google Scholar] [CrossRef]

- European Commission. Strategy for Textiles. Available online: https://ec.europa.eu/growth/industry/sustainability/strategy-textiles_en (accessed on 18 July 2022).

- Agency, E.P. Textiles: Material-Specific Data. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/textiles-material-specific-data (accessed on 18 July 2022).

- Hawley, J.M. Textile Recycling: A Systems Perspective. In Recycling in Textiles; Woodhead Publishing Limited: Sawston, UK, 2006. [Google Scholar]

- Cuc, S.; Vidovic, M. Environmental sustainability through clothing recycling. Oper. Supply Chain Manag. Int. J. 2014, 4, 108–115. [Google Scholar] [CrossRef]

- Blanch-Perez-del-Notario, C.; Saeys, W.; Lambrechts, A. Hyperspectral imaging for textile sorting in the visible–near infrared range. J. Spectr. Imaging 2019, 8, a17. [Google Scholar] [CrossRef]

- Mather, R.R.; Wardman, R.H. The Chemistry of Textile Fibres; Royal Society of Chemistry: London, UK, 2015. [Google Scholar]

- Zhou, J.; Yu, L.; Ding, Q.; Wang, R. Textile fiber identification using near-infrared spectroscopy and pattern recognition. Autex Res. J. 2019, 19, 201–209. [Google Scholar] [CrossRef]

- Du, W.; Zheng, J.; Li, W.; Liu, Z.; Wang, H.; Han, X. Efficient Recognition and Automatic Sorting Technology of Waste Textiles Based on Online Near infrared Spectroscopy and Convolutional Neural Network. Resour. Conserv. Recycl. 2022, 180, 106157. [Google Scholar] [CrossRef]

- Bonifazi, G.; Gasbarrone, R.; Palmieri, R.; Serranti, S. Near infrared hyperspectral imaging-based approach for end-of-life flat monitors recycling. Automatisierungstechnik 2020, 68, 265–276. [Google Scholar] [CrossRef]

- Bonifazi, G.; Palmieri, R.; Serranti, S. Concrete drill core characterization finalized to optimal dismantling and aggregates recovery. Waste Manag. 2017, 60, 301–310. [Google Scholar] [CrossRef]

- Bonifazi, G.; Fiore, L.; Gasbarrone, R.; Hennebert, P.; Serranti, S. Detection of Brominated Plastics from E-Waste by Short-Wave Infrared Spectroscopy. Recycling 2021, 6, 54. [Google Scholar] [CrossRef]

- Tekin, Y.; Kuang, B.; Mouazen, A.M. Potential of on-line visible and near infrared spectroscopy for measurement of pH for deriving variable rate lime recommendations. Sensors 2013, 13, 10177–10190. [Google Scholar] [CrossRef] [PubMed]

- Reich, G. Near-infrared spectroscopy and imaging: Basic principles and pharmaceutical applications. Adv. Drug Deliv. Rev. 2005, 57, 1109–1143. [Google Scholar] [CrossRef] [PubMed]

- Luypaert, J.; Massart, D.; Heyden, Y.V. Near-infrared spectroscopy applications in pharmaceutical analysis. Talanta 2007, 72, 865–883. [Google Scholar] [CrossRef] [PubMed]

- Bonifazi, G.; Capobianco, G.; Gasbarrone, R.; Serranti, S. Hazelnuts classification by hyperspectral imaging coupled with variable selection methods. In Sensing for Agriculture and Food Quality and Safety XIII; SPIE: Bellingham, WA, USA, 2021; Volume 11754. [Google Scholar]

- Choi, K.-H.; Lee, K.-J.; Kim, G. Nondestructive quality evaluation technology for fruits and vegetables using near-infrared spectroscopy. In Proceedings of the International Seminar on Enhancing Export Competitiveness of Asian Fruits, Bangkok, Thailand, 18–19 May 2006. [Google Scholar]

- Davies, A.; Grant, A. Near infra-red analysis of food. Int. J. Food Sci. Technol. 1987, 22, 191–207. [Google Scholar] [CrossRef]

- Bonifazi, G.; Capobianco, G.; Gasbarrone, R.; Serranti, S. Contaminant detection in pistachio nuts by different classification methods applied to short-wave infrared hyperspectral images. Food Control 2021, 130, 108202. [Google Scholar] [CrossRef]

- Currà, A.; Gasbarrone, R.; Cardillo, A.; Fattapposta, F.; Missori, P.; Marinelli, L.; Bonifazi, G.; Serranti, S.; Trompetto, C. In vivo non-invasive near-infrared spectroscopy distinguishes normal, post-stroke, and botulinum toxin treated human muscles. Sci. Rep. 2021, 11, 17631. [Google Scholar] [CrossRef]

- Heise, H.M. Medical applications of NIR spectroscopy. In Near-Infrared Spectroscopy; Springer: Berlin/Heidelberg, Germany, 2021; pp. 437–473. [Google Scholar]

- Ozaki, Y. Near-infrared spectroscopy—Its versatility in analytical chemistry. Anal. Sci. 2012, 28, 545–563. [Google Scholar] [CrossRef]

- Geladi, P.; Grahn, H.; Burger, J. Multivariate images, hyperspectral imaging: Background and equipment. In Techniques and Applications of Hyperspectral Image Analysis; John Wiley & Sons (Wiley): Hoboken, NJ, USA, 2007; pp. 1–15. [Google Scholar]

- Hyvarinen, T.; Herrala, E.; Dall’Ava, A. Direct Sight Imaging Spectrograph: Unique Add-On Component Brings Spectral Imaging to Industrial Applications; SPIE: Bellingham, WA, USA, 1998. [Google Scholar]

- ASD Inc. FieldSpec® 4 User Manual, ASD Document 600979; ASD Inc.: Boulder, CO, USA, 2015. [Google Scholar]

- ASD Inc. RS3™ User Manual, ASD Document 600545; ASD Inc.: Boulder, CO, USA, 2008. [Google Scholar]

- Wise, B.M.; Gallagher, N.B.; Bro, R.; Shaver, J.M.; Windig, W.; Koch, R.S. PLS_Toolbox Version 4.0 for use with MATLAB™; Eigenvector Research, Inc.: Wenatchee, WA, USA, 2006; p. 3905. [Google Scholar]

- Savitzky, A.; Golay, M.J. Smoothing and differentiation of data by simplified least squares procedures. Anal. Chem. 1964, 36, 1627–1639. [Google Scholar] [CrossRef]

- Tauler, R.; Peré-Trepat, E.; Lacorte, S.; Barceló, D. Chemometrics Modelling of Environmental Data; iEMSs: Brussels, Belgium, 2004. [Google Scholar]

- Wold, S.; Esbensen, K.; Geladi, P. Principal component analysis. Chemom. Intell. Lab. Syst. 1987, 2, 37–52. [Google Scholar] [CrossRef]

- Ballabio, D.; Consonni, V. Classification tools in chemistry. Part 1: Linear models. PLS-DA. Anal. Methods 2013, 5, 3790–3798. [Google Scholar] [CrossRef]

- Ballabio, D.; Grisoni, F.; Todeschini, R. Multivariate comparison of classification performance measures. Chemom. Intell. Lab. Syst. 2018, 174, 33–44. [Google Scholar] [CrossRef]

- Huang, J.; Yu, C. Fiber Content Determination of Linen/Viscose Blends Using NIR Spectroscopy. BioResources 2020, 15, 3006–3016. [Google Scholar] [CrossRef]

- Quintero Balbas, D.; Lanterna, G.; Cirrincione, C.; Fontana, R.; Striova, J. Non-invasive identification of textile fibres using near-infrared fibre optics reflectance spectroscopy and multivariate classification techniques. Eur. Phys. J. Plus 2022, 137, 85. [Google Scholar] [CrossRef]

| Class | Sensitivity | Specificity | Err | P |

|---|---|---|---|---|

| Cotton 100% | 1.000 | 1.000 | 0.000 | 1.000 |

| Cotton 20%–Viscose 80% | 0.997 | 0.999 | 0.001 | 0.999 |

| Viscose 100% | 0.999 | 0.999 | 0.001 | 0.998 |

| Class | Sensitivity | Specificity | Err | P |

|---|---|---|---|---|

| 100% Cotton | 1.000 | 1.000 | 0.000 | 1.000 |

| 50% Cotton–50% Silk | 1.000 | 1.000 | 0.000 | 1.000 |

| 100% Silk | 1.000 | 1.000 | 0.000 | 1.000 |

| Class | Sensitivity | Specificity | Err | P |

|---|---|---|---|---|

| 100% Silk | 1.000 | 1.000 | 0.000 | 1.000 |

| 20% Cotton–80% Viscose | 0.990 | 0.992 | 0.008 | 0.992 |

| 50% Cotton–Silk 50% | 1.000 | 1.000 | 0.000 | 1.000 |

| 100% Viscose | 0.975 | 0.997 | 0.008 | 0.997 |

| 100% Cotton | 1.000 | 1.000 | 0.000 | 1.000 |

| Class | Sensitivity | Specificity | Err | P |

|---|---|---|---|---|

| 100% Cotton | 1.00 | 1.00 | 0.00 | 1.00 |

| 20% Cotton–80% Viscose | 1.00 | 1.00 | 0.00 | 1.00 |

| 100% Viscose | 1.00 | 1.00 | 0.00 | 1.00 |

| Class | Sensitivity | Specificity | Err | P |

|---|---|---|---|---|

| 100% Cotton | 1.00 | 1.00 | 0.00 | 1.00 |

| 50% Cotton–50% Silk | 1.00 | 1.00 | 0.00 | 1.00 |

| 100% Silk | 1.00 | 1.00 | 0.00 | 1.00 |

| Class | Sensitivity | Specificity | Err | P |

|---|---|---|---|---|

| 100% Silk | 1.00 | 1.00 | 0.00 | 1.00 |

| 20% Cotton–80% Viscose | 1.00 | 1.00 | 0.00 | 1.00 |

| 50% Cotton–50% Silk | 1.00 | 1.00 | 0.00 | 1.00 |

| 100% Viscose | 1.00 | 1.00 | 0.00 | 1.00 |

| 100% Cotton | 1.00 | 1.00 | 0.00 | 1.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bonifazi, G.; Gasbarrone, R.; Palmieri, R.; Serranti, S. End-of-Life Textile Recognition in a Circular Economy Perspective: A Methodological Approach Based on Near Infrared Spectroscopy. Sustainability 2022, 14, 10249. https://doi.org/10.3390/su141610249

Bonifazi G, Gasbarrone R, Palmieri R, Serranti S. End-of-Life Textile Recognition in a Circular Economy Perspective: A Methodological Approach Based on Near Infrared Spectroscopy. Sustainability. 2022; 14(16):10249. https://doi.org/10.3390/su141610249

Chicago/Turabian StyleBonifazi, Giuseppe, Riccardo Gasbarrone, Roberta Palmieri, and Silvia Serranti. 2022. "End-of-Life Textile Recognition in a Circular Economy Perspective: A Methodological Approach Based on Near Infrared Spectroscopy" Sustainability 14, no. 16: 10249. https://doi.org/10.3390/su141610249

APA StyleBonifazi, G., Gasbarrone, R., Palmieri, R., & Serranti, S. (2022). End-of-Life Textile Recognition in a Circular Economy Perspective: A Methodological Approach Based on Near Infrared Spectroscopy. Sustainability, 14(16), 10249. https://doi.org/10.3390/su141610249