Smart and Sustainable Management of Shoe Machinery Companies in Taiwan during the COVID-19 Pandemic—Case Studies of the Tung Sheng Company and Strong Basic Enterprise Limited Company

Abstract

:1. Introduction

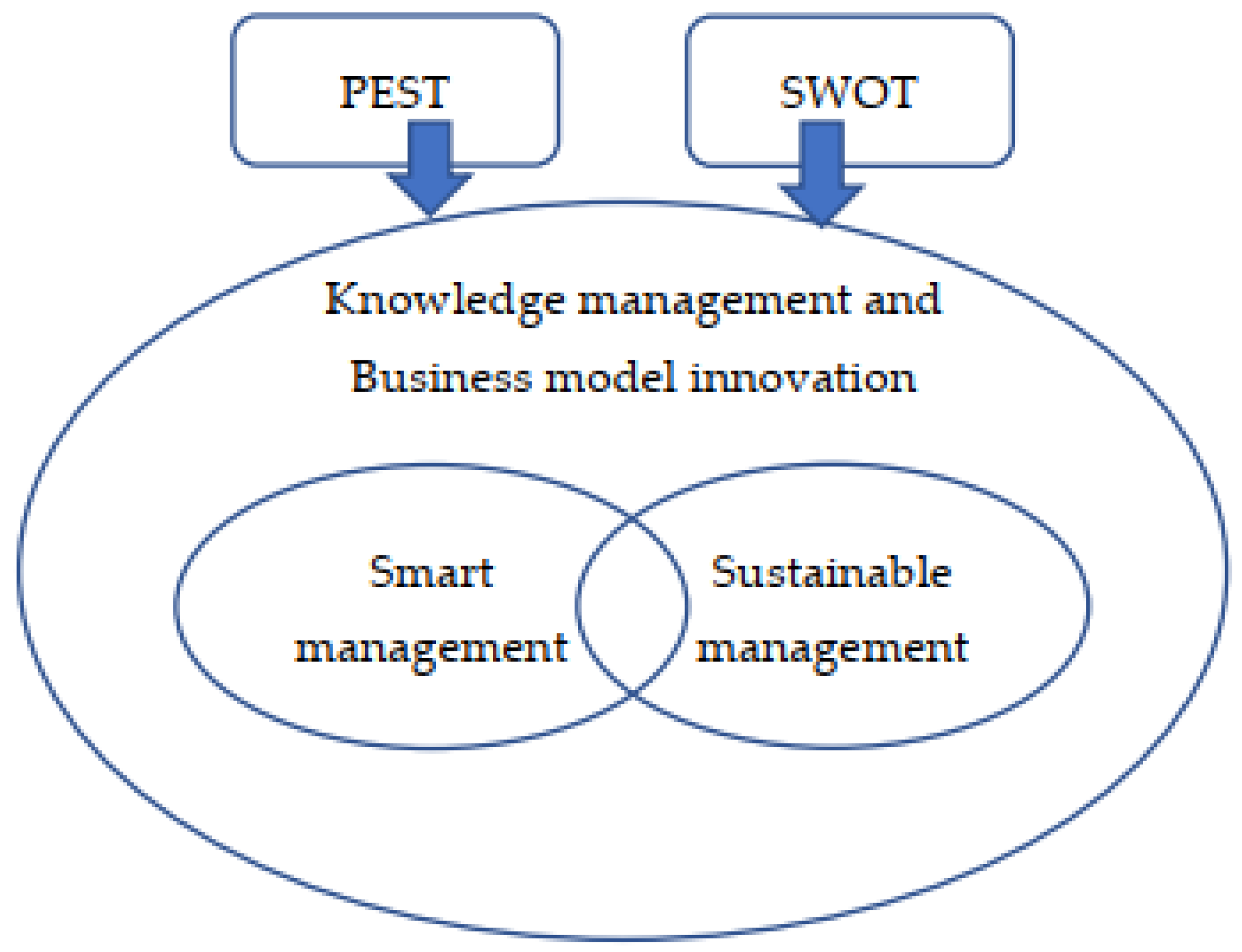

1.1. PEST and SWOT

1.2. Knowledge Management and Business Model Innovation

1.3. Smart Management

1.4. Sustainable Management

1.5. Smart Management and Sustainable Management

2. Practical Case Studies

2.1. Tung Sheng Company Limited

2.2. Strong Basic Enterprise Limited

3. Research Methods

3.1. Research Design

3.2. Data Collection

- How do you SWOT analyze the current PEST environment and adjust your business model?

- By using the business model canvas and your knowledge management, how do you respond to the new generation of information and communication technologies as an opportunity to leverage your strengths and weaknesses for innovation in smart management?

- During the COVID-19 pandemic in Taiwan, how do you respond to this threat effectively?

- How do your responses to new smart information and communication technologies help you face the threat of the COVID-19 pandemic?

- During the COVID-19 pandemic, what are your vision and practices related to sustainability goals in potential combination with the application of smart technology?

4. Results and Discussion

4.1. Two-by-Two Matrix of SWOT Analysis in Combination with PEST

4.2. Analysis of Business Model Canvas and Innovation

- Customer segments include firms that produce shoes for sport brands and manufacturers that make rubber products for automobile industries.

- Value propositions are to keep being a pioneer as a total solution provider for the establishment of an entire plant, after-sales service, and follow-up maintenance.

- Channels include international exhibitions, participation in local shoe-making associations and trade organizations, and online platforms for instant communication. PEST and SWOT analysis suggests extending participation in African economic and trade networks and exhibitions, and to convert ICT applications into connection with customers and partners.

- Customer relationships are primarily based on customized machinery and service, as well as cross-investment to build up trust.

- Revenue streams are mostly from machinery product sales, the total solution for the establishment of a whole plant, commissions of introducing and transferring orders, and cross-shareholding investment.

- Key resources include capabilities in R&D, many granted patents for innovative machines, and development of diversified machinery products and an automatic rubber-recycling system.

- Key activities include participation in international exhibitions and exposure to governmental trade units, relevant associations and organizations, in order to reach more potential customers. It might be worthwhile to invite customers to visit the case study companies or to apply VR and 5G for virtual experiences in understanding the products.

- Key partnerships include upstream suppliers for materials and semi-finished products, strategic partners, outsourcing firms, and customers. For diversifying their business scope and partnerships, the case study companies invested in a department store in Hong Kong, cooperate with shoes brands in Japan, and keep looking for other potential investment opportunities.

- Cost structure consists of expenses from materials, production, logistics, R&D, and marketing, manufacturing overhead and administration costs, employee salaries, and equipment depreciation.

4.3. Smart Knowledge Management

4.4. Sustainable Management in Responsible Production

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aguilar, F.J. Scanning the Business Environment; Macmillan: New York, NY, USA, 1967. [Google Scholar]

- Emami Zeydi, A.; Ghazanfari, M.J.; Shaikhi Sanandaj, F.; Panahi, R.; Mortazavi, H.; Karimifar, K.; Karkhah, S.; Osuji, J. Coronavirus disease 2019 (COVID-19): A literature review from a nursing perspective. BioMedicine 2021, 11, 5–14. [Google Scholar] [CrossRef]

- The News Lens. Taiwan’s Level 3 COVID-19 Alert Expanded Nationwide. Available online: https://international.thenewslens.com/article/151210 (accessed on 19 May 2021).

- Gürel, E.; Tat, M. SWOT analysis: A theoretical review. J. Int. Soc. Res. 2017, 10, 994–1006. [Google Scholar] [CrossRef]

- Parast, M.M. The impact of R&D investment on mitigating supply chain disruptions: Empirical evidence from U.S. firms. Int. J. Prod. Econ. 2020, 227, 107671. [Google Scholar] [CrossRef]

- Hock-Doepgen, M.; Clauss, T.; Kraus, S.; Cheng, C.F. Knowledge management capabilities and organizational risk-taking for business model innovation in SMEs. J. Bus. Res. 2021, 130, 683–697. [Google Scholar] [CrossRef]

- Osterwalder, A.; Pigneur, Y. Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers; Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Oliveira, M.A.Y.; Ferreira, J.J. Book Review: Business Model Generation—A Handbook for Visionaries, Game Changers and Challengers; OSF: Minato, Tokyo, 2010. [Google Scholar]

- Matt, D.T.; Modrak, V.; Zsifkovits, H. (Eds.) Industry 4.0 for SMEs: Challenges, Opportunities and Requirements; Palgrave Macmillan: Cham, Switzerland, 2020. [Google Scholar]

- Tao, F.; Qi, Q. New IT driven service-oriented smart manufacturing: Framework and characteristics. IEEE Trans. Syst. Man Cybern. Syst. 2019, 49, 81–91. [Google Scholar] [CrossRef]

- United Nations Development Programme. The SDGs in Action. Available online: https://www.undp.org/sustainable-development-goals (accessed on 25 June 2022).

- Peck, P. Introduction to the Circular Economy. Coursera Course: Circular Economy—Sustainable Materials Management. Available online: https://www.coursera.org/learn/circular-economy (accessed on 25 June 2022).

- International Institute for Sustainable Development. Business Strategy for Sustainable Development; Available online: https://www.iisd.org/publications/business-strategy-sustainable-development (accessed on 3 October 2001).

- Clark, C. Introduction to Setting SDG Strategy for Enterprises in 5 Steps. Coursera Course: Impact Measurement & Management for the SDGs. Available online: https://www.coursera.org/learn/impact-for-sdgs (accessed on 25 June 2022).

- Chang, N.J.; Fong, C.M. Green product quality, green corporate image, green customer satisfaction, and green customer loyalty. Afr. J. Bus. Manag. 2010, 4, 2836–2844. [Google Scholar]

- Balkyte, A.; Tvaronavičiene, M. Perception of competitiveness in the context of sustainable development: Facets of “sustainable competitiveness”. J. Bus. Econ. Manag. 2010, 11, 341–365. [Google Scholar] [CrossRef]

- Omer, A.M. Energy, environment and sustainable development. Renew. Sustain. Energy Rev. 2008, 12, 2265–2300. [Google Scholar] [CrossRef]

- Dincer, I. Renewable energy and sustainable development: A crucial review. Renew. Sustain. Energy Rev. 2000, 4, 157–175. [Google Scholar] [CrossRef]

- Utting, P. Business Responsibility for Sustainable Development (No. 2); Geneva 2000 Occasional Paper; United Nations Research Institute for Social Development (UNRISD): Geneva, Switzerland, 2000; Available online: https://www.econstor.eu/handle/10419/148835 (accessed on 25 June 2022).

- Aid, G. Ragn-Sells: From Waste to Resources. Coursera Course: Circular Economy—Sustainable Materials Management, Week 3. Available online: https://www.coursera.org/learn/circular-economy/lecture/PEmW4/ragn-sells-from-waste-to-resources (accessed on 25 June 2022).

- Bucea-Manea-Țoniş, R.; Prokop, V.; Ilic, D.; Gurgu, E.; Bucea-Manea-Țoniş, R.; Braicu, C.; Moanță, A. The Relationship between Eco-Innovation and Smart Working as Support for Sustainable Management. Sustainability 2021, 13, 1437. [Google Scholar] [CrossRef]

- United Nations Development Programme. Goal 12: Responsible Consumption and Production. Available online: https://www.undp.org/sustainable-development-goals#responsible-consumption-and-production (accessed on 25 June 2022).

- Tung Sheng Company Limited. Available online: https://www.tungsheng.com.tw (accessed on 25 June 2022).

- Tung Sheng Machinery, Tung Sheng/Strong Basic/Introduction. Available online: https://youtu.be/cNIF1GN0Pfk (accessed on 28 September 2021).

- Strong Basic Enterprise Limited, Trade 1111. Available online: http://trade.1111.com.cn/web/tungsheng (accessed on 25 June 2022).

- Tung Sheng/Strong Basic, Company Profile. Available online: https://www.tungsheng.com.tw/about/company-profile (accessed on 25 June 2022).

- Tu, M.T. The Analysis of the Business Model of the Shoes Machinery Company in Taiwan: A Case Study of a Domestic Shoes Machinery Manufacturer. Master’s Thesis, Chaoyang University of Technology, Taichung, Taiwan, 2018. Available online: https://hdl.handle.net/11296/295cf2 (accessed on 25 June 2022). (In Chinese).

- Yin, R.K. Case Study Research Design and Methods, 2nd ed.; Sage: Thousand Oaks, CA, USA, 1994. [Google Scholar]

- Woodside, A.G. Case Study Research: Theory, Methods, Practice; Emerald: Bingley, UK, 2010. [Google Scholar]

- Patton, M.Q. Qualitative Evaluation and Research Methods, 3rd ed.; Sage: Newbury Park, CA, USA, 2000. [Google Scholar]

- Bansal, P.; Grewatsch, S.; Sharma, G. How COVID-19 informs business sustainability research: It’s time for a systems perspective. J. Manag. Stud. 2021, 58, 602–606. [Google Scholar] [CrossRef]

- Ranjbari, M.; Esfandabadi, Z.S.; Zanetti, M.C.; Scagnelli, S.D.; Siebers, P.-O.; Aghbashlo, M.; Peng, W.; Quatraro, F.; Tabatabaei, M. Three pillars of sustainability in the wake of COVID-19: A systematic review and future research agenda for sustainable development. J. Clean. Prod. 2021, 297, 126660. [Google Scholar] [CrossRef] [PubMed]

- Neumeyer, X.; Ashton, W.S.; Dentchev, N. Addressing resource and waste management challenges imposed by COVID-19: An entrepreneurship perspective. Resour. Conserv. Recycl. 2020, 162, 105058. [Google Scholar] [CrossRef] [PubMed]

- Industrial Technology Research Institute. Available online: https://www.itri.org.tw/english/index.aspx (accessed on 25 June 2022).

- Video of TS-508 Fully Automatic EVA Pulverizing Grinding System, Tung Sheng Machinery. Available online: https://youtu.be/GsTvGytou2A (accessed on 3 August 2021).

- TS-508 Fully Automatic Rubber Recycle Pulverizing System, Tung Sheng Machinery. Available online: https://youtu.be/iP55WIYscec (accessed on 17 August 2019).

- TS 508 403ACDM, Tung Sheng Machinery. Available online: https://youtu.be/L7JdEdxmqdg (accessed on 28 January 2021).

| Strength | Weakness | |

|---|---|---|

| O |

|

|

| T |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tu, M.-T.; Gau, L.-S.; Park, J.-H.; Huang, W.-S.; Duong, P.T.; Kim, J.-C. Smart and Sustainable Management of Shoe Machinery Companies in Taiwan during the COVID-19 Pandemic—Case Studies of the Tung Sheng Company and Strong Basic Enterprise Limited Company. Sustainability 2022, 14, 10274. https://doi.org/10.3390/su141610274

Tu M-T, Gau L-S, Park J-H, Huang W-S, Duong PT, Kim J-C. Smart and Sustainable Management of Shoe Machinery Companies in Taiwan during the COVID-19 Pandemic—Case Studies of the Tung Sheng Company and Strong Basic Enterprise Limited Company. Sustainability. 2022; 14(16):10274. https://doi.org/10.3390/su141610274

Chicago/Turabian StyleTu, Ming-Ta, Li-Shiue Gau, Ji-Hwan Park, Wen-Shin Huang, Pham Thuy Duong, and Jong-Chae Kim. 2022. "Smart and Sustainable Management of Shoe Machinery Companies in Taiwan during the COVID-19 Pandemic—Case Studies of the Tung Sheng Company and Strong Basic Enterprise Limited Company" Sustainability 14, no. 16: 10274. https://doi.org/10.3390/su141610274