1. Introduction

At the end of 2019, the European Commission (EC) announced the European Green Deal, an ambitious package of policy initiatives aimed at making the European Union (EU) carbon neutral by 2050 and decoupling economic growth from resource consumption [

1]. As calculations for the EU’s consumption footprint show, energy-using and energy-related products are responsible for large environmental impacts, especially in the impact category of mineral and metal resource use [

2]. In particular, raw material production is identified as a driver of the environmental impacts of household goods [

3].

To improve the environmental performance of appliances, the EU introduced product policies early on that focused on energy efficiency. The first date back to the 1970s oil crisis [

4], with requirements on the performance of space heating systems and the production of hot water in new or existing non–industrial buildings and on the insulation of heat and domestic hot-water distribution in new non-industrial buildings in Council Directive 1978/170/EEC [

5]. In 1997, the first labelling Directive (79/530/EEC) was published on the indication by labelling of the energy consumption of household appliances [

6]. In the same year, Council Directive 79/531/EEC regulated electric ovens [

7]. This was followed by Council Directive 1992/42/EEC of 21 May 1992 on efficiency requirements for new hot water boilers fired with liquid or gaseous fuels [

8]. In the same year, an energy labelling framework was established with Council Directive 1992/75/EEC of 22 September 1992 on the indication by labelling and standard product information of the consumption of energy and other resources by household appliances [

9]. The first directive on energy efficiency requirements for appliances was implemented in 1996 for household refrigerating appliances 96/57/EC [

10] and, in 2000, for ballasts for fluorescent lighting 2000/55/EC [

11]. In 2005, the EU moved from drafting independent product-specific legislations to the Directive 2005/32/EC (Ecodesign Directive) [

12], which established a framework for setting ecodesign requirements for energy-using products and amended Directives 92/42/EEC, 96/57/EC, and 2000/55/EC. The Ecodesign Directive was repealed 4 years later by Directive 2009/125/EC, which established a framework for setting ecodesign requirements for energy-related products in order to have a larger scope of application [

13]. Based on this directive and following the Methodology for Ecodesign of Energy-related Products (MEErP), individual product groups are assessed in preparatory studies where potential ecodesign requirements are elaborated. These requirements can then be formulated in so-called implementing measures, EU regulations that set ecodesign requirements for products placed on the market. At present, 27 product groups are regulated by such implementing measures, covering a wide range of product groups, including lighting, white goods such as refrigerators and washing machines, ICT products such as computers, a variety of heating and cooling products, and industrial appliances such as welding equipment. In addition to the ecodesign implementing measures, the supplementing Directive 2010/30/EU (repealed by Regulation (EU) 2017/1369 [

14]) establishes a framework for energy labelling energy-related products in order to pull the market towards more sustainable products [

15].

It was estimated that EU ecodesign and labelling measures saved 10% of the EU27’s primary energy consumption in 2020, and total financial savings in consumer spending were estimated at 60 billion euros [

16]. In 2020, the average EU household used 70 regulated products (of which 30 were light sources and 25 electronic products) [

16].

Whereas both generations of the Ecodesign Directive (2005 and 2009) focused on energy efficiency requirements—with particular emphasis on reducing energy consumption during the use stage—they also allowed legislators to address many other aspects, all aimed at reducing the environmental impact of the products, including aspects related to the circular economy. Indeed, both directives emphasise in Article 15 on “implementing measures” that the preparation of an implementing measure must take into account “the life cycle of the product and all its significant environmental impacts”. Furthermore, Annex I and II of the directives set out the method for setting generic and specific ecodesign requirements. From this perspective, the Ecodesign Directive takes a very holistic approach that goes far beyond energy efficiency alone.

Considering that it is not primarily technological but also cultural and market barriers that prevent industry actors from moving towards the circular economy, regulations can play a crucial role by pushing actors to overcome these barriers [

17]. Design standards and norms are considered an essential tool to promote this development [

18]. At the same time, the EU policy mix is still focused on waste management without promoting a circular economy holistically, and many product-related policies do not include resource efficiency aspects [

19].

However, EU policymakers have started to recognise this gap and the underlying potential, and in recent years there has been strong political advocacy for more consideration of circular economy aspects in product regulation. In its 2011 Roadmap to a Resource Efficient Europe, the EU proposed the goal of further improving the resource efficiency of products through the Ecodesign Directive [

20]. The first EU Action Plan for the Circular Economy [

21] announced that future product requirements developed under the Ecodesign Directive should include circular economy-relevant requirements. Then, in 2015, the EC issued the groundbreaking standardisation mandate M/543 for material efficiency aspects within the Ecodesign Directive, with the aim of extending product lifetime, increasing component reuse, and recycling materials [

22]. This mandate led to a series of standards that were published between 2019 and 2020 (

Table 1).

Whereas the standards were not published in time to be directly taken into account in the preparation of the implementing measures published in 2019, they do indicate a strong political will to increase the role of the circular economy within the Ecodesign Directive. The preparatory study and current proposal for the ecodesign implementing measure on mobile phones, cordless phones, and tablets proposed by the Commission in 2021 already covers many circular economy aspects and refers to the EN 4555X family of standards [

23]. This trend is also underlined in the EU’s latest Circular Economy Action Plan (CEAP) from 2020 [

24], which again refers directly to the Ecodesign Directive, but also announces the goal of going beyond energy-related products. This goal of expanding the product scope of the Ecodesign Directive is currently being developed in the Proposal for Ecodesign for Sustainable Products Regulation [

25].

2. Literature Review

Several academic articles and policy evaluation studies have examined the apparent shift of focus in the Ecodesign Directive from energy efficiency to resource efficiency. The following paragraphs describe seminal work in the area, whereas the focus of this literature analysis is on whether the respective texts analyse the presence of circular economy requirements in published ecodesign regulations. For the most part, other aspects of the reviewed papers will not be discussed in detail.

Of the studies and papers assessed, several elaborated a methodology for effectively regulating circular economy aspects or identifying the potential or weaknesses of the current policy-making process [

26,

27,

28,

29,

30,

31,

32,

33]. A high potential for regulating circular economy aspects via ecodesign implementing measures is identified [

34], but also the need to strengthen the role of resource efficiency aspects in preparatory studies [

28] and the lack of appropriate assessment methods and standards are highlighted, in particular, due to the product-specific character of circular economy aspects [

35].

Stakeholder views on the role of the circular economy in ecodesign implementing measures vary, ranging from regarding it as a necessary development and a particularly positive attitude towards product durability and recycling requirements [

36] to the view that the circular economy is a burdensome obstacle for original equipment manufacturers (OEMs), e.g., due to costly monitoring [

37].

To test a methodology or elaborate a framework for a single product group, several studies have conducted case studies on the regulation of circular economy aspects under the Ecodesign Directive or other policy frameworks. The product groups studied include washing machines [

26,

29], LCD-TVs [

26], electric motors [

38], vacuum cleaners [

28,

29], and enterprise servers [

35].

A number of studies define how to classify circular economy requirements, but with varying degrees of detail. Ardente and Mathieux [

26] provide an extensive circular economy typology, which divides circular economy ecodesign requirements into a declaration of indices (such as recycling rates or recycled content), thresholds of those indices, design for recycling (e.g., reduction in contaminants), design for disassembly, availability of spare parts, warranty, indices for durability, dematerialization (e.g., lightweight design), declaration of substances, threshold of substances, marking/labelling/tracing, and provision of information. Several studies provide only a limited number of examples of possible types of circular economy requirements [

35,

36].

Bundgaard et al. [

28] define categories of resource efficiency aspects as reduction (e.g., use of resources during use), maintenance (e.g., maintenance instructions), reuse and redistribution (e.g., minimum lifespan), remanufacturing and refurbishment (e.g., easy to dismantle), and recyclability (e.g., information relevant for recycling). Polverini and Miretti [

30] propose a preliminary taxonomy of circular economy requirements as those aimed at increasing durability, repairability, and refurbishment capabilities, spare parts availability, recyclability via design for disassembly, information on material content and/or components marking, and promoting the reuse of secondary raw materials and/or components. Mathieux et al. [

32] identify the criteria for resource efficiency assessments in a product policy context as reusability/recyclability/recoverability, recycled content, content of hazardous substances, and durability (related to reliability and ability to be repaired, upgraded, remanufactured). Polverini [

33] adopts a preliminary taxonomy based on existing studies [

28,

30] and classifies circular economy aspects into the categories (1) durability, (2) repairability/refurbishment capacity/spare part availability, (3) recyclability, (4) reusability of components, (5) consumables, and (6) circular economy requirements, differentiated into information and performance requirements.

Although many of the assessed studies provide examples of circular economy requirements in ecodesign implementing measures, only a few papers systematically investigate whether resource or material efficiency requirements are regulated in the existing regulations.

In a 2013 EU study on material efficiency under ecodesign and MEErP, the authors took a closer look at the coverage of material efficiency under the Ecodesign Directive in all already published implementing measures and also in the existing draft regulations at that time [

27]. They found a high number of material-related requirements, but these were almost exclusively information-based requirements. The most detailed study on circular economy coverage in implementing measures was published in 2017 by Bundgaard et al. [

28]. In it, the authors evaluated a total of 23 adopted implementing measures and self-regulations developed under Article 17 of the Ecodesign Directive. They found 15 implementing measures that contained information requirements on resource efficiency, and only five that contained performance requirements. Based on the EU research programme REAPro, Mathieux et al. [

32] briefly described the circular economy coverage in seven selected implementing measures from ecodesign regulations published in 2019. In 2021, Polverini [

33] also focused on the 2019-generation of implementing measures but evaluated nine product groups and identified differences between the product families of business-to-consumer products (e.g., dishwasher), and business-to-business products (e.g., welding equipment), with clear commonalities in requirements identified for the former.

The following table (

Table 2) gives an overview of the different regulated product groups that have been assessed in the literature with regard to the coverage of circular economy aspects.

It should be noted that many of these studies do not assess systematically the shift towards more circular economy requirements within ecodesign, but rather how circular economy aspects can be integrated from a methodological point of view for specific product groups.

Our work differs from previous research in several aspects. First, our analysis extends the scope of previous work by systematically including all adopted ecodesign implementing measures, amendments, and repeals between 2008 and 2021 and showing what changes can be detected over time (excluding self-regulations developed under Article 17 of the Ecodesign Directive and energy labelling regulations). Second, the depth of analysis is increased by elaborating a clear classification of types and categories of circular economy requirements and delivering more nuanced results. Third, the differences between product families and generations of implementing measures are assessed and patterns are revealed.

By holistically assessing which circular economy requirements have been considered in ecodesign implementing measures and by analysing the differences between single product groups and product families (see

Section 3.2 for definition), we aim to improve the understanding of the current state of circular economy in EU product policy and provide guidance for future product legislation. By summarising the coverage of circular economy measures over more than 20 years of the EU Ecodesign Directive, we seek to synthesise lessons learned and provide an outlook as well as recommendations for future development of product regulations. To reduce conceptual ambiguity, we propose a circular economy taxonomy tailored to ecodesign implementing measures.

The following research questions are explored: What are the links between different ecodesign implementing measures and how have they evolved? Has there been a quantifiable increase in circular economy requirements in ecodesign implementing measures over the years? What types of circular economy requirements are the most prevalent in implementing measures? Which product group regulations impose the most and the most stringent circular economy requirements on OEMs? Are there differences in the type and quantity of circular economy requirements between product families?

Directed content analysis and quantitative keyword analysis of the legal texts are the methods used to answer these questions. The Materials and Methods section explains the methods used, defines a circular economy requirement, and describes the conceptual distinction between different types of circular economy requirements. It also explains the procedure used to conduct the content analysis and keyword analysis. The Results section presents the findings of the analysis and the Discussion section discusses the results, outlines the research limitations, identifies areas for further research, and draws conclusions.

3. Materials and Methods

This section starts by defining the circular economy and the different types and categories of circular economy requirements and then describes the method for conducting the content and quantitative keyword analysis based on these definitions.

3.1. Definition of Circular Economy in the Context of the Ecodesign Directive

As described in the Ecodesign Directive “an ecodesign requirement means any requirement in relation to a product, or the design of a product, intended to improve its environmental performance, or any requirement for the supply of information with regard to the environmental aspects of a product” [

13].

To assess whether there has been a shift towards circular economy requirements under the Ecodesign Directive, the concept of a circular economy needs to be defined. There is no harmonised understanding of what a circular economy is [

40], and many scholars try to circumvent this conceptual ambiguity by discussing material or resource efficiency instead. Material efficiency can be described as “the ratio between the performance output of a product, service or energy system and the input of materials required to provide such output” [

41]. The circular economy, however, describes a concept that has material efficiency at its core, but goes beyond this and aims to establish a more holistic and systemic economic system based on sustainable development.

Conceptually, a circular economy can be distinguished from a linear economy, a view of the economy that seems to represent reality, but only if the environmental dimension is ignored [

42]. However, the environmental dimension provides inputs (or resources) to the economy and functions as the repository of waste products (e.g., carbon dioxide emissions or solid waste in landfills). According to the first law of thermodynamics, there must be a balance between the energy and matter supplied to the economy (from the environment) and the outputs returned to the environmental system [

42]. Furthermore, according to the second law of thermodynamics, certain natural resources are irreversibly damaged (or degraded) and thus lost when used for economic activities [

43]. The environment has limited assimilative capacities to deal with this economic waste and therefore a circular economy aims to reduce the pressure on the environment to act as a sink for waste, either by reducing the amount of waste produced or by converting waste back into resources (recycling) [

42]. In line with this theoretical concept, the EC defines a circular economy as an economy, “where the value of products, materials and resources is maintained in the economy for as long as possible, and the generation of waste is minimised” [

21]. The benefits that such an economic system brings are potentially linked to all dimensions of sustainable development, with a particular focus on the environmental and economic dimensions [

40].

There are different frameworks defining how to achieve a circular economy. According to Article 2 of the Chinese Circular Economy Promotion Law [

44], “circular economy” is defined as a term for reducing, reusing, and recycling activities (3Rs). In the EU, Article 4 of the EU Waste Framework Directive defines a five-level waste hierarchy, from higher to lower priority with (1) prevention, (2) preparing for re-use, (3) recycling, (4) other recovery (e.g., energy recovery), to (5) disposal (4Rs) [

45]. The model of circular economy strategies can be extended to 9Rs, namely refuse (R0), rethink (R1), reduce (R2), re-use (R3), repair (R4), refurbish (R5), remanufacture (R6), repurpose (R7), recycle (R8), recover (R9) [

46].

In our study, we adopt the EU definition of a circular economy with the aim of reducing waste and prolonging the effective use of materials and resources in order to contribute to sustainable development [

21]. In our taxonomy of circular economy requirements, we start from a 3R framework: reduce, reuse, and recycle (

Table 3). Based on these circular economy strategies, circular economy categories are defined to classify the circular economy requirements found in ecodesign implementing measures.

The categorisation of circular economy requirements results from the literature review, the CEAP [

24], the EN Standards on material efficiency, and a preliminary screening of ecodesign implementing measures.

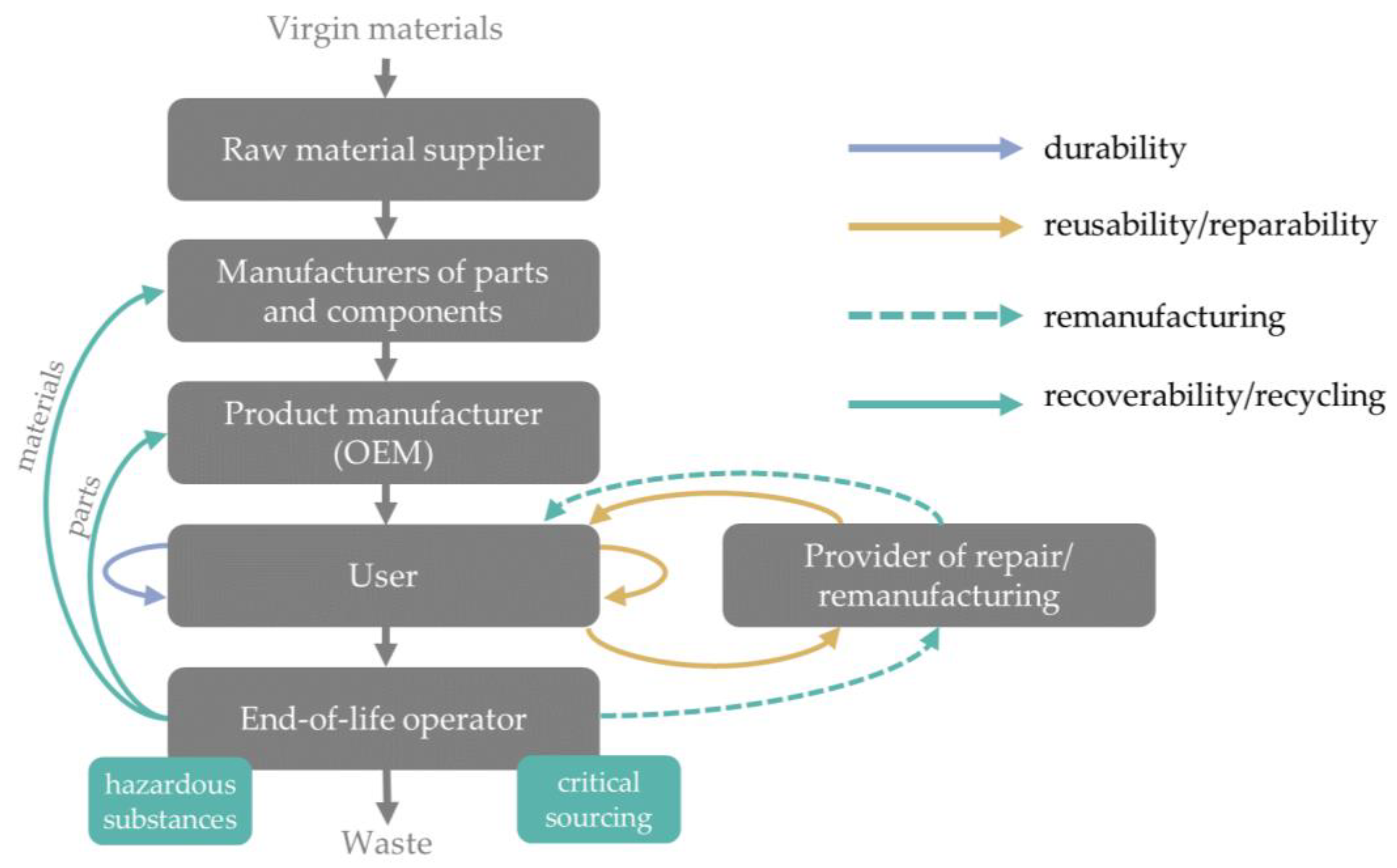

In the CEAP, the EU sets itself the goal of regulating (among other aspects) the durability, reusability, upgradability, repairability, the presence of hazardous chemicals, remanufacturing, and recycling of products. This corresponds to the circular economy categories found in the literature. Circular economy requirements can be classified into measures that increase the effective lifetime, either by improving the durability of the product or components (reduce) [

26,

32] or by increasing reusability/repairability and thus postponing disposal due to malfunction or technical failure (reuse) [

26,

28,

32]. Once products have reached their end-of-life (EOL), recycling recovers materials and/or components and uses them as input for the production of new products [

26,

28]. Accurate information about the presence of hazardous substances and also critical raw materials (critical sourcing) is essential for recyclers to develop efficient and safe processes [

26,

28].

There are some additional circular economy categories and types of requirements, but the first screening of ecodesign implementing measures revealed that they are not used in current ecodesign regulations. These include mandatory recycled contents, which is becoming increasingly important, as shown by its inclusion in the proposal for a Batteries Regulation in 2020 to replace the Directive 2006/66/EC on batteries [

47] (the legislation on batteries is not regulated under the ecodesign framework, even though the preparatory study for this regulation was carried out in line with the MEErP [

48]). The proposal also explicitly refers to the repurposing of batteries for a second life and introduces the so-called battery passport, a digital product passport (DPP) that could improve the traceability of batteries and thus increase recycling inflows. Relevant life cycle data such as charging cycles to facilitate repurposing can also be recorded in the DPP. The Batteries Directive from 2006 already included minimum collection and recycling rates to increase the number of recycled materials [

49]. Other new approaches can be found in the EU’s CEAP, which explicitly refers to measures against premature obsolescence, a ban on the destruction of unsold but durable goods, and the concept of “product-as-a-service” [

24]. In the future, some of these aspects may find their way into ecodesign implementing measures, so it may be necessary to include them in further analysis and to integrate other new circular economy approaches into the circular economy taxonomy for ecodesign implementing measures.

When assigning circular economy requirement types to the defined categories, the definitions of the EN standards on material efficiency are taken as a starting point. Therein,

Durability is defined as the ability to function as required, under defined conditions of use, maintenance and repair, until a limiting state is reached. The degree to which maintenance and repair are within the scope of durability varies between products

Repair is defined as the process of returning the product to serviceability

Reuse is defined as any operation by which products or components are used again for the same or another purpose for which they were conceived

Remanufacturing is defined as an industrial process that produces a product from used products or used parts where at least one change is made that influences the safety, original performance, purpose, or type of the product

Recycling is defined as a recovery operation of any kind by which waste materials are reprocessed into products, materials, or substances whether for the original or other purposes excluding energy recovery

Hazardous substance is defined as a substance that has, according to defined classification criteria, the potential for adversely impacting human health and/or the environment (not defined under standardisation mandate M/543 but in IEC Guide 109:2012 [

50])

A critical raw material (CRM) is defined as a material that, according to a defined classification methodology, is crucial due to its economic importance and its supply risk.

In our definition, durability is defined as the useful life of the product without including repair measures, which are considered a separate category. Thus, requirements that are classified under durability include, for example, premature failure rate, survival factor, rated lifetime, minimum number of switching cycles for lamps, the minimum number of loading cycles for batteries, the minimum oscillations of the hose of vacuum cleaners, as well as mandatory warranty and updates on firmware, software, or safety. As maintenance is usually regulated together with measures related to repair—in the following we will use the term repairability—(e.g., “access to repair and maintenance information” in (EU) 2019/2019 on household refrigerating appliances), both are classified under repairability. Reusability is grouped together with repairability as both extend the time the product is used for the purpose for which it was designed. Requirements on reusability/repairability include, e.g., information on non-destructive disassembly, secure data deletion, warning about non-repairability, or requirements related to spare parts, such as availability, order procedure, maximum delivery time, or the replaceability of parts with commonly available tools. Requirements that promote recycling include, for example, design for recycling, marking of specific material fractions (e.g., plastic components), and information about how to return or dispose of the product or design for recycling. The requirements on design for recycling are normally combined with others as design for dismantling, recycling, and recovery, and thus also apply to the CE category repairability. In our analysis, we include requirements with reference to dismantling in the category of recycling to avoid double counting (exemption: non-destructive disassembly for maintenance purposes).

Information regarding hazardous materials as well as CRM content support the recycling process by indicating necessary safety measures or the presence of high-value materials. Requirements regarding hazardous materials and CRM include, for example, the provision of information on hazardous material content such as mercury, lead, cadmium or refrigerant gas, the ban of materials such as halogenated flame retardants, and the provision of information on CRM content such as cobalt.

Figure 1 gives an overview of the product value chain stakeholders in the linear or circular economy and the material flows that are influenced by the different circular economy categories.

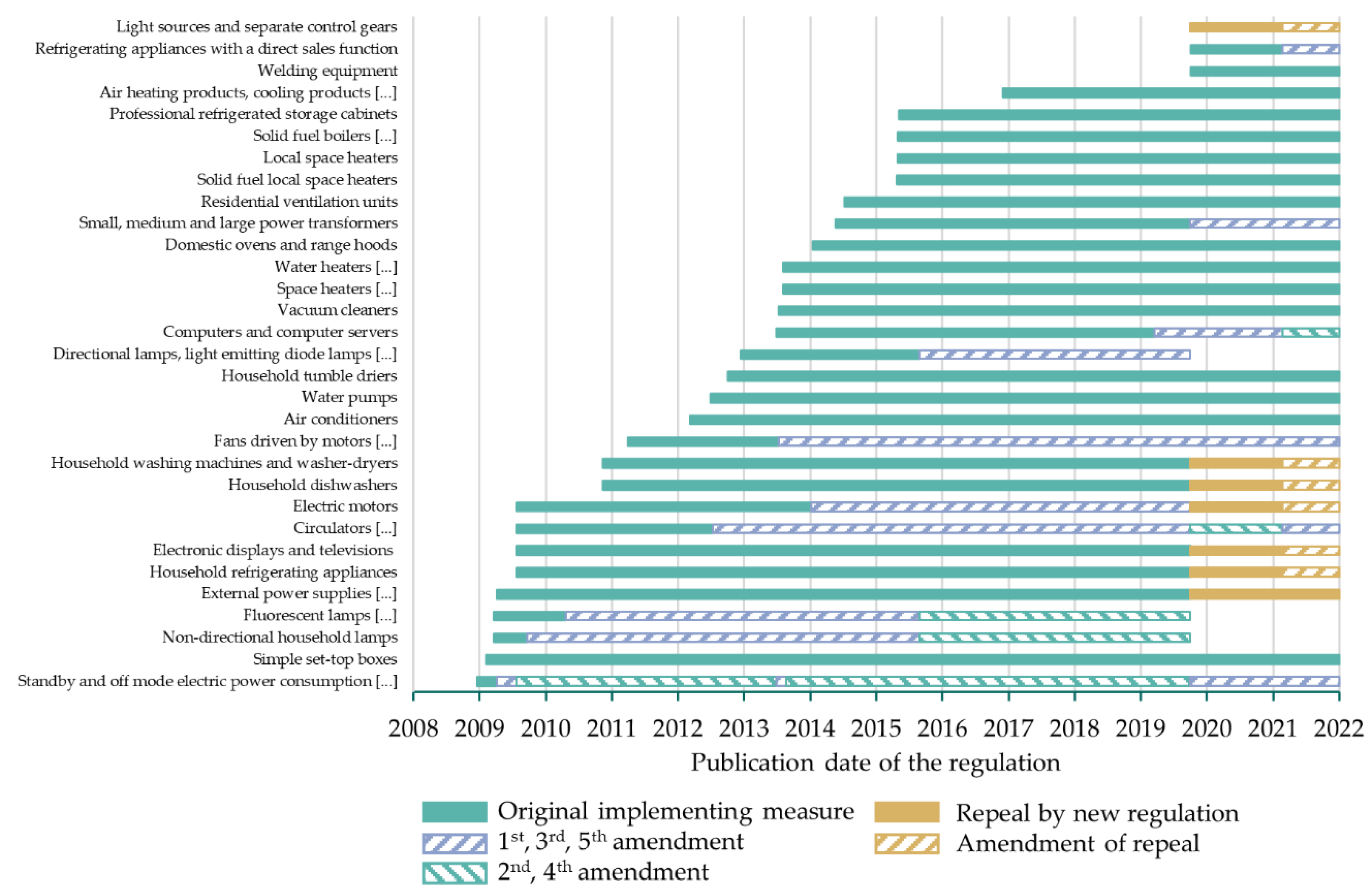

3.2. Type and Scope of Text Analysis

Our text analysis covers the 27 product groups regulated by ecodesign implementing measures from 2008 until 2021, including the legislative texts of 30 original implementing measures and 16 amendments or repeals. Three product groups (space heaters, electrical lamps, and luminaires) have subgroups that are regulated independently with separate implementing measures. Therefore, we considered them individually in our analysis, resulting in 30 product (sub)groups. On 1 October 2019, three separate implementing measures on different lighting sources were repealed by one implementing measure that covers all previous lighting sources. Thus, from 2019, we consider only 28 regulated product (sub)groups.

Voluntary agreements and energy labelling regulations were not part of the analysis.

First, a directed content analysis was carried out. The rationale for choosing this method is the different style of the regulatory texts, with changing sections and structures which require manual analysis. In addition, circular economy requirements are very product-specific, as also noted by Peiró et al. [

35], who pointed out that the “durability of lamps can be measured by lumen maintenance factor, whereas the durability of vacuum cleaners is assessed according to the fatigue life testing of motor and hose”. This individuality requires manual identification of requirements.

Changes to existing implementing measures take the form of amendments and repeals. Amendments are considered in the analysis when they introduce new circular economy requirements or when existent circular economy requirements are replaced or amended. Due to the nature of EU legislation, single amendments often affect several implementing measures at once, with a distinction between the individual implementing measures in the text. Repeals can also replace several implementing measures at once, as illustrated by the example of (EU) 2019/2020 on lamps, which replaced (EC) No. 244/2009, (EC) No. 245/2009, and (EU) No. 1194/2012 (all of which regulated different types of lamps). In order to provide a general overview of the development of ecodesign framework, each initial implementing measure, amendment, and repeal was marked with its official publication date. In contrast, each individual circular economy requirement was documented with its specific date of entry into force.

To classify circular economy requirements, the Ecodesign Directive distinguishes between specific and generic ecodesign requirements (Article 2). A specific ecodesign requirement is defined as a “quantified and measurable ecodesign requirement relating to a particular environmental aspect of a product, such as energy consumption during use, calculated for a given unit of output performance”. A generic ecodesign requirement is defined as “any ecodesign requirement based on the ecological profile as a whole of a product without set limit values for particular environmental aspects”. In our analysis, we additionally classified generic requirements as hard or soft, depending on the level of ambition and detail. In addition, we distinguished functional (generic and specific) from informational requirements, which we subclassified as hard, medium, or soft (

Table 4). Hard informational requirements demand the provision of specific performance values for the product, whereas medium informational requirements demand specific actions from manufacturers, e.g., providing a list of spare parts on the company’s website. Finally, soft informational requirements are non-specific and allow OEMs greater leeway in meeting the requirements. An example of this is Regulation (EC) No 640/2009 on electric motors, which includes the very unspecific information requirement of providing “information relevant for disassembly, recycling or disposal at end-of-life” without further specifications. Changes to existing requirements through amendments that increase the level of ambition but do not change the type of requirement (specific functional, generic functional, informational) or the year of entry into force are not considered new requirements, as quantifying the “strength” of a circular economy requirement beyond our proposed classification is likely subjective.

Deciding what counts as a single requirement can be challenging, due to the aforementioned individuality of the legal texts and the specificity of product groups. When estimating the number of requirements per implementing measure, sub-items were grouped together as one requirement if they specify the same requirement for different operating states or product variations. For example, in Regulation (EC) No. 244/2009 on non-directional household lamps, the requirement in Annex II on the minimum number of switching cycles was counted as one requirement even though it sets two different conditions for different lamp types.

For some implementing measures, different implementation levels exist for the same requirement. In this case, each new implementation level (if the date of entry into force differs) was considered a replacement of the original requirement. For example, Regulation (EC) No. 244/2009 on non-directional household lamps introduced minimum lamp functionality requirements in 2009, but the requirements were increased in 2013. Therefore, when creating our database of circular economy requirements in ecodesign legislations, there are two entries, one for the first requirement, and (at the time of the amendment) one entry for the inclusion of the updated requirement which replaces the original requirement.

Within the implementing measures, there can be exemptions from the requirements for certain product types or variants (for example, in (EC) No. 245/2009 on fluorescent lamps in Annex I: “The following lamps shall be exempted from the provisions of this Regulation: [...]”). These exemptions from the requirements for certain product types were not considered in the analysis.

Each requirement was assessed to see if it addresses circular economy aspects and then assigned to a circular economy category (see

Table 3); allocation was not always straightforward. Two examples illustrate this process. The first one is Regulation (EC) No. 245/2009 on fluorescent lamps, where some requirements are clearly related to the circular economy, such as the lamp survival factor, which is defined as “the fraction of the total number of lamps which continue to operate at a given time under defined conditions and switching frequency” and related to durability. However, this is less clear for the lamp lumen maintenance factor. If we consider the functional unit of the lamp to be the amount of light (lumens) provided and assume that consumers will replace the lamp if the lumens emitted decrease over time, then this requirement does extend the lifetime of the product and accordingly, we consider it as a circular economy requirement. The second example is Regulation (EU) 2019/2020 on light sources, which states that “the energy consumption of the product and any of the other declared parameters shall not deteriorate after a software or firmware update”. The so-called “other declared parameters” technically include the parameter lifetime, but as the requirement relates mainly to energy consumption, it is not considered a circular economy requirement. Circular economy aspects that are mentioned in the “subject matter and scope” section of regulations were not considered in the content analysis. For example, Article 1 part 3 in Regulation (EU) 2019/1783 on transformers, which states that transformers with a replaced core or windings must be reassessed for conformity with the regulation, was not considered. However, it should be noted that the legal status of refurbished products is a necessity for a complete circular economy framework.

To differentiate between similar product groups, we defined the product families lighting, white goods, heaters/coolers, ICT, and other as follows:

Lighting combines the regulation of non-directional household lamps, fluorescent lamps, directional lamps, and the combined regulation of light sources and separate control gears.

White goods include the regulations on household refrigerating appliances, household dishwashers, household washing machines and washer-dryers, household tumble driers, domestic ovens and range hoods, professional refrigerated storage cabinets, and refrigerating appliances with a direct sales function.

Heaters/coolers include the regulations on fans driven by motors, air conditioners, space heaters, water heaters, ventilation units, solid fuel local space heaters, local space heaters, solid fuel boilers, and air heating products.

ICT includes the regulations on simple set-top boxes, external power supplies, electronic displays and televisions, and computers and computer servers.

All other product groups are classified as “other”.

Due to the chosen approach in the content analysis of defining what counts as an individual requirement on a qualitative case-by-case basis, the number of requirements identified should be treated with caution. Nevertheless, on an aggregated level, the results still reveal the main trends among ecodesign implementing measures. To reduce the ambiguity of the directed content analysis and create a more quantitative layer of analysis, a keyword analysis was also carried out. Based on an initial screening, appropriate keywords were defined and assigned to each circular economy category (according to our previously defined circular economy taxonomy) and the number of mentions of these keywords was counted. If necessary, the words were reduced to their word stem, such as “dismantl” for both “dismantle” and “dismantled”. The table with the results of the keyword analysis can be found in the

Supplementary Information (Table S1).

The word “replac*” was excluded from the analysis because, beyond its circular economy-related meaning, it is often used in amendments to refer to the replacement of articles from the original implementing measure. Although the keyword analysis provided more quantitative results, it has several limitations. Amendments and repeals often refer to several regulations and may combine amendments or repeals from different product groups. Therefore, differentiation between product groups and product families is not possible, and only the overall development across all ecodesign regulations can be presented.

The following chapter presents the results of the content and keyword analysis.

4. Results

In this section, we describe the chronological development of the implementing measures with their respective amendments and repeals and in more detail, the development of the types and categories of circular economy requirements based on the content analysis. Finally, we present the results of the keyword analysis.

4.1. Evolution of Ecodesign Regulations and Their Circular Economy Coverage

The first ecodesign implementing measure was published on 17 December 2009 for standby and off-mode electric power consumption, followed by eight other product groups (and several amendments) all based on the 2005 Ecodesign Directive on energy-using products. The first regulation referring to the 2009 Ecodesign Directive was published on 10 November 2010 on household dishwashers. New regulations were published frequently from 2008 to 2016, whereas no implementing measure, amendment, or repeal was added between 2016 and 2019, before a total of 13 regulations were published in 2019 (thereafter referred to as the “2019-generation”), 12 of which were published on 1 October 2019 (on 15 March 2019: computers and computer servers; on 1 October 2019: standby and off-mode electric power consumption, external power supplies, household refrigerating appliances, electronic displays and televisions, circulators, electric motors, household dishwashers, household washing machines, small, medium, and large power transformers, welding equipment, refrigerating appliances with a direct sales function, light sources, and separate control gears). The latest ecodesign regulation was published on 23 February 2021, amending several of the regulations from the 2019-generation.

Figure 2 shows the chronological evolution of ecodesign product regulations. As can be seen in the figure, lighting regulations were repealed in 2019 by a single regulation covering all lighting products. Note that several of the amendments and repeals address more than one regulation. A table listing the assessed legislations is included in the

Supplementary Information (Table S2). One product group that stands out is standby, off-mode electric power consumption of electrical and electronic household and office equipment, which can be interpreted as a horizontal regulation covering many product groups (compared to a vertical regulation covering one product group). This overarching character can explain the high number of amendments seen in

Figure 2, as the regulation has been amended each time that products falling within its scope were regulated with their own vertical regulations (and exempted from the horizontal regulation).

Figure 3 shows the regulations identified by the content analysis that include circular economy aspects according to our circular economy taxonomy. As can be seen in the figure, no circular economy requirements could be detected for only six product groups, namely standby power consumption (Regulation (EC) No. 1275/2008 and amendments), simple set-top boxes (Regulation (EC) No. 107/2009), external power supplies (Regulation (EC) No. 278/2009), air conditioners (Regulation (EU) No. 206/2012), household tumble driers (Regulation (EU) No. 932/2012), and power transformers (Regulation (EU) No. 548/2014 and amendment). Today, 21 out of 28 regulated product groups (75%) have active circular economy requirements.

Comparing our results to the literature, the findings are largely consistent with the assessments of [

27,

28,

32,

33]. Differences were found in three cases. Bundgaard et al. [

28] identified informational resource efficiency requirements in the 2010 regulation on domestic dishwashers and both specific and informational requirements in the 2010 regulation on household washing machines. The corresponding requirements are not specified, but most likely relate to water consumption during the use phase, which is specified in both regulations. In our analysis, the special case of water consumption during the use phase is not included in the circular economy taxonomy, and thus circular economy requirements are only identified in the 2019-generation of household dishwashers and washing machines (e.g., availability of spare parts). Similarly, Polverini [

33] identified one circular economy requirement in Regulation (EU) 2019/1783 on power transformers, which explicitly mentions transformers with “replaced core and one or more of the complete windings replaced”. However, as this definition is only mentioned in the “subject matter and scope” section of the regulation, which we did not assess, it was not included in our analysis.

It should be noted that

Figure 3 does not indicate the extent to which circular economy requirements are integrated into the regulation, and several product groups have only a very low circular economy coverage. For example, Regulation (EC) No. 640/2009 on electric motors only contains one non-specific informational requirement in Annex 2.2, stating that product information “relevant for disassembly, recycling or disposal at end-of-life” must be provided.

4.2. Types of Circular Economy Requirements

When assessing in more detail which kind of circular economy requirements are set in the regulations,

Figure 4 provides further insights. Here, it should be noted that the number of circular economy requirements (left axis) refers to the date of entry into force of the individual requirement, whereas the number of regulated product groups (right axis) refers to the publication date of the legal document. The chronological evolution shows a sharp increase in circular economy requirements caused by the three lighting regulations published in March 2009 and December 2012, and then only a moderate increase in mainly informational requirements (correlated with the increase in the number of regulated product groups) until the 2019-generation, which caused a second significant increase in specific and informational circular economy requirements and also set the first generic requirements. A line chart that was normalised to the number of regulated product groups can be found in the

Supplementary Information (Figure S1).

The results are in line with the findings of Bundgaard et al. [

28] who similarly identified that is was mostly the lighting regulations that included specific circular economy requirements in the early years of the Ecodesign Directive.

Figure 5 shows the types of circular economy requirements that were in force for each product group at the time of the latest amendment. It shows, that the product family lighting has the highest number of specific requirements per individual product regulation.

This is followed by white goods and ICT, although there are strong differences within these product families. There are almost no circular economy requirements for household tumble driers, domestic ovens and range hoods, and professional refrigerated storage cabinets, and this finding also applies to simple set-top boxes and external power supplies in the ICT product family. The product group of electronic displays and televisions has the highest number of circular economy requirements since its 2019 amendment. Before 2019, only hazardous substances were regulated (mercury or lead content), but in the 2019 amendment, several requirements were added: a ban on halogenated flame retardants, spare parts availability and maximum delivery time, availability of software updates, and several informational requirements.

Very few and weak circular economy requirements were found for heating and cooling products and other products such as industrial equipment. In the 2019-generation, mainly white goods (household refrigerating appliances, household dishwashers, household washing machines, and refrigerating appliances with a direct sales function), ICT (electronic displays and televisions, and computers and computer servers), the new combined lighting regulation, and the regulation on welding equipment (grouped into the product category “Other”) were responsible for almost all new circular economy requirements. Our results confirm the finding of other studies that the 2019-generation achieved a strong increase in circular economy requirements. However, not all product group regulations that are active today contain circular economy requirements: in the case of ICT regulations, simple set-top boxes were already regulated in 2009 and have not been amended or repealed since. In the preparatory study, environmental optimisation focuses mainly on energy consumption, and although improvements in recyclability can be detected in a reduction in flame retardants, this requirement does not find its way into the regulation [

51]. Examples of regulations from the 2019-generation that contain no or only a few circular economy requirements include those on external power supplies and electric motors. For motors, Dalhammer et al. [

38] identified several improvement options related to the use of rare earth elements (REEs), such as design for recycling to facilitate the extraction of REEs at the end-of-life, or the provision of information on key materials and their location. Despite these recommendations, none of them found their way into the 2019 update of the electric motor regulation. In the product family of white goods, an increasing number of circular economy requirements were integrated into the 2019-generation of regulations. No circular economy requirements are included in the regulation on household tumble driers (2012) and only a few in the regulations on domestic ovens and range hoods (2014) and in professional refrigerated storage cabinets (2015), all of which have not been amended since.

Whereas the findings shown in

Figure 4 and

Figure 5 illustrate the shift towards increasingly stringent circular economy requirements over time, the question remains as to which circular economy strategies from the 3Rs framework and which circular economy categories are most pronounced.

4.3. Categories of Circular Economy Requirements

Figure 6 shows the focus of the circular economy requirements within the ecodesign framework. There was a strong focus on durability (reduce) in the early ecodesign regulations, almost exclusively due to the three lighting regulations, whose requirements entered into force between 2009 and 2013. These included durability requirements such as lamp survival factor, lumen maintenance, rated and nominal lamp lifetime, the minimum number of switching cycles, and maximum premature failure rates. The lighting regulations also explain the decrease in the number of durability requirements and the slight decrease in requirements on hazardous chemicals in 2020, because the three existing lighting regulations were replaced by a single overarching lighting regulation. Despite this, the number of product groups remained constant in 2019, as two new product groups and one lighting regulation replaced the three former lighting regulations. The only other product groups subject to durability requirements before 2019 were the 2013 regulation on computers and computer servers, which includes informational requirements on the minimum number of loading cycles of the batteries, and the 2013 regulation on vacuum cleaners, which sets specific durability requirements for the minimum oscillations of the hose and for motor lifetime (requirements entered into force in 2017).

The findings correspond to those of Mudgal et al. [

27], who state that requirements on minimum lifetime or warranty have not been widely extended to other product groups after its introduction for lamps.

Over the years, recycling requirements have increased steadily, but this development is mainly due to often non-specific informational requirements (asking to provide “information relevant for [...] recycling, recovery and disposal at end-of-life”), e.g., in the regulations on vacuum cleaners, domestic ovens and range hoods, space heaters, water heaters, or ventilation units. The next real increase in specific requirements is in the 2019-generation, which mainly addressed aspects of repairability and recyclability. For example, Regulation (EU) 2019/2021 on electronic displays and televisions introduced design for recycling aspects (“[...] fastening or sealing techniques do not prevent the removal, using commonly available tools [...]”) and marking of components. The sharp increase in repairability requirements was caused by requirements related to spare parts, especially within the white goods product family, such as in the regulations on household refrigerating appliances, household dishwashers, and household washing machines, but also in non-white good requirements such as in the regulation on welding equipment.

Mathieux et al. [

32] noted that it is mainly recycling that is the focus of attention in the EU compared to reuse or remanufacturing. However, they do acknowledge that six of the Ecodesign regulations published in 2019 include requirements on reparability and lifetime extension, a number that corresponds with our findings.

When assessing differences between product groups,

Figure 7 shows a high share of durability aspects in the lighting regulations and a similarly high focus on reusability/repairability in the white goods product family. Requirements related to critical sourcing are a more recent and still rare aspect and were only found in Regulation (EU) 2019/1784 on welding equipment (information on the presence of critical raw materials and amounts) and in Regulation (EU) 2019/424 on computers and computer servers (weight range of cobalt in the batteries and neodymium in the hard disk drive), corresponding to the findings of other researchers [

32,

35].

4.4. Keyword Analysis

Finally,

Figure 8 shows the results of the keyword analysis. Unlike the content analysis, the keywords refer to the publication date of the regulation. Furthermore, keywords included in repealed regulation are not subtracted, which is why the increase in circular economy keywords is stronger and the curves do not drop in 2019. Taking these factors into account, the resulting graph mirrors the findings of the content analysis. There is an increase in circular economy keywords with the lighting regulations in 2009 and 2012 and a sharp increase due to the 2019-generation of ecodesign regulations. The increase in 2014 can be explained by the high frequency of the keyword “recover” in Regulation (EC) No. 1253/2014 on ventilation units, which here refers to the recovery of heat or moisture and can thus be recorded as an anomaly with no direct link to the circular economy.

Keywords with the highest frequency are “lifetime” with 47 mentions for durability aspects found in particular in the lighting regulations (e.g., Regulation (EC) No. 244/2009 and Regulation (EC) No. 1194/2012), “repair” with 168 mentions for reusability/repairability aspects and a high frequency in the 2019-generation (e.g., in Regulation (EU) 2019/1784, Regulation (EU) 2019/2019, Regulation (EU) 2019/2021, Regulation (EU) 2019/2022, Regulation (EU) 2019/2023, Regulation (EU) 2019/2024), “recycl*” with 65 mentions for recycling aspects (e.g., in Regulation (EU) 2019/2021 or Regulation (EU) 2016/2281), “mercury” with 82 mentions for hazardous chemicals, mainly in the lighting regulations (e.g., in Regulation (EC) 244/2009, Regulation (EC) No. 245/2009, and Regulation (EC) No. 1194/2012), and “critical raw materials” with 11 mentions for critical sourcing aspects (e.g., in Regulation (EU) 2019/424 and Regulation (EU) 2019/1784).

5. Discussion

In its 2005 version, the Ecodesign Directive already provided all the legal means needed to regulate circular economy aspects (see Article 15 4(a)).

Overall, our analysis showed a constant increase in the number of regulated product groups under the ecodesign framework, which only was interrupted between 2016 and 2019, and an overall increase in the number of circular economy-related requirements, but with significant variations between product groups.

The first lighting regulations (2009 and 2012) were already integrating a large number of circular economy requirements and focused especially on durability (reduce). However, the lighting regulations proved to be outliers and relatively few durability requirements were set for other product groups.

As discussed by Mudgal et al. [

27], the specific policy measure of minimum lifetime or warranty has high relevance to improving material efficiency but has not been widely extended to other product groups after its introduction for lamps. A prerequisite for its application is the availability of testing standards, which become more difficult (more time-consuming and costly) to implement as product complexity increases [

27,

52]. Since lamps are a comparably simple product, this can explain why it was possible to include durability requirements in the regulations ahead of other product groups. Compared to many other regulated product groups, lights have no moving parts and have unique usage patterns. Once installed, there is usually no direct contact with the user, who only switches the product on and off, so the risk of incorrect operation during the product’s lifetime is low. Accordingly, durability requirements were easier to set and more likely to be accepted by manufacturers for lighting products than for other product groups.

For more complex ecodesign products, the strategy was initially to regulate only individual components, such as the durability of the hose and minimum motor lifetime for vacuum cleaners in 2013. Further durability requirements of more complex products were implemented in the 2019-generation of ecodesign: for example, the availability of software and firmware updates for electronic displays, televisions, computers, and computer servers, or informational requirements on warranty (refrigerating appliances with a direct sales function) or the minimum number of battery loading cycles (computers and computer servers). The standard EN 45552:2020 on the assessment of the durability of energy-related products, despite its generic character, might lead to more (and more ambitious) functional durability requirements in the future.

The focus on durability for lighting can also be explained by the difficulty of repairing lighting products. In the three lighting regulations prior to 2019 we only found one requirement related to repairability (informational requirement on maintenance instructions for fluorescent lighting). Improvements in repairability are most likely not caused by missing spare parts, but instead by technical limitations or safety concerns. In 2009, the incandescent lamp faced competition from compact fluorescent lamps (CFL), which proved to be much more efficient and durable, but contained the toxic substance mercury [

53]. Accordingly, there were product-specific reasons why the ecodesign requirements should address durability, e.g., to avoid the release of toxic substances. In addition, the requirements guaranteed the cost-effectiveness of the CFL technology compared to cheaper incandescent lamps.

Whereas regulating repairability or recyclability at market entry is difficult for lighting products beyond informational requirements, requirements on recycling at the end of life are covered by the horizontal WEEE Directive. Therein, Annex V defines minimum recovery targets for lighting [

54].

If lighting regulations are regarded as an outlier, then the observed increase in circular economy requirements in the 2019-generation confirms the findings of other studies that a standardised approach to integrating circular economy aspects into the ecodesign policy-making process has only recently received greater attention [

30,

32,

33]. This trend can be seen for example in the policymaking process for the 2019 regulation on data servers with its strong focus on circular economy aspects [

35]. We found electronic displays and televisions since their 2019 amendment to be the single product group with the highest number of circular economy requirements. This strong emphasis on circular economy in the 2019 amendment goes in line with the methodological work of the REAPro Research programme by JRC, where a material efficiency assessment method was developed that was then applied to the policy formulation process of several product groups including that of electronic displays [

32]. The overall increase in circular economy requirements thus goes hand in hand with the improvement or development of methodological approaches on assessing material efficiency [

32], a process that is still ongoing [

33]. The revision of the MEErP is another important component for improving the circularity of products. In the revision, the systematic inclusion of material efficiency aspects in the modelling process was identified as one area for improvement [

55].

Whereas the EN 4555X series of standards on resource efficiency now exist, the standards are very generic and it remains to be seen how well they can be integrated into upcoming ecodesign regulations. The individuality of the product groups will most likely require the development of individual vertical product standards, as also pointed out by Polverini [

33]. Nevertheless, development is well underway also outside of the EU ecodesign context, as evidenced also by national legislation such as the French repairability index, which was implemented in 2021 [

56]. Our results also highlight the differences between product families, with a focus on durability for lighting regulations and a high share of reuse requirements for white goods. Although the low product complexity of lighting products might have facilitated the use of durability requirements, white goods would require more complex and time-consuming test standards [

57]. On the contrary, the repair of white goods is likely more attractive than lighting due to higher product costs, which has led to a greater role of requirements related to spare parts (reuse) in 2019. Those requirements can reduce the barrier to repair through lack of spare parts availability [

58].

Heating and cooling products were found to have very few circular economy requirements, which might be explained by their design; these products often have almost no moving parts and are of robust construction. Furthermore, heating and cooling products receive little attention in the academic publications regarding circular economy aspects, compared to other product groups that are assessed in dedicated case studies, like for example electric motors [

38], computers and computer servers [

35], or vacuum cleaners [

28,

29]. Another explanation for their low number of circular economy requirements is the fact that they were not among the products amended in 2019 and thus did not benefit from the advancements in material efficiency assessment methods [

32].

The hypothesis that the least preferable circular economy option in the 3R framework (recycle) is often the focus of research and policy efforts [

32] is not supported by our findings. Although it is true that the highest priority option of durability is almost exclusively addressed in the lighting regulations—which can be considered an exception within the ecodesign framework—both the content and the keyword analysis showed a stronger increase in reuse requirements compared to those related to recycling. In particular, the numerous requirements for spare parts in the 2019-generation indicate a strong political will to promote the reuse of products.

The circular economy requirements we have identified in this work are largely consistent with the literature [

27,

28,

32,

33] and based on our circular economy taxonomy we could furthermore differentiate between the strength and type of requirements. After having conducted the analysis, few adjustments to our initial taxonomy might be relevant: “consumables” could be added in the “reduce” strategy to account for the reduction in resource consumption during the use phase, for example, the use phase water consumption for domestic dishwashers and household washing machines. Furthermore, circular economy requirements can mainly regulate the product at the time of market entry, therefore repairability and recyclability can be regulated more easily than actual repair or recycling operations [

33]. Instead of “recycle”, the term “recyclability” will be more adequate in the taxonomy.

A common taxonomy with a clear classification of circular economy requirements is essential for advancing circular economy product regulations in the EU. Our proposed taxonomy can serve as a starting point. Similarly, further enhancement of standards and testing methods is needed to allow for the integration of more and stronger circular economy requirements in upcoming ecodesign legislation [

32]. Work is well underway [

32,

33] and is focussing on a variety of different approaches, including a scoring system for the repairability of products comparable to the French repairability index [

41,

59].

Many other possible circular economy requirements are not yet part of current ecodesign regulations. These include recycling and collection rates, for instance, which are already applied in other EU regulations such as the Batteries Directive [

49], or DPPs and recycled contents (see also [

33]), which have been introduced in the proposal for a new Batteries Regulation [

47]. Other novel concepts are product-as-a-service, bans of unsold goods, or measures against premature obsolescence, which are mentioned in both the CEAP 2020 [

24] as well as in the Impact Assessment for the Sustainable Products Initiative and the Proposal for Ecodesign for Sustainable Products Regulation [

25]. Critical sourcing requirements were only detected in two regulations, although this aspect may become increasingly important due to the high demand for critical raw materials needed for low-carbon technologies, such as cobalt and lithium. It is expected that all the above-mentioned aspects will play a greater role in future ecodesign regulations or in legislation based on the upcoming Ecodesign for Sustainable Products Regulation. Both the Ecodesign Working Plan 2016–2019 [

60] as well as its successor, the Ecodesign Working Plan 2022–2024 [

61] refer explicitly to the circular economy, indicating that ecodesign will continue to evolve from an energy efficiency focus towards a stronger emphasis on circular economy aspects [

62].

Although our results indicate that there has been an increase in the number and diversity of circular economy requirements, the actual impact of market-entry requirements on reuse and recycling rates can only be verified via ex-post evaluations, as also suggested by [

32]. Furthermore, many of the existing impact assessment studies do not consider material efficiency aspects, and if they do, they often do so only qualitatively or semi-quantitatively, as noted by [

33]. Thus, a stronger focus should be placed on assessing the impact of circular economy requirements, and in this respect, it will be very crucial to follow the impact of the 2019-generation ecodesign regulations on the market (e.g., does the number of repairs or spare part purchases increase significantly, and will the average lifetime of the products increase?).

In terms of the general development of the circular economy in the EU, the increasing inclusion of circular economy requirements in ecodesign can be seen as a positive indicator, helping to overcome cultural and market barriers and supporting the political advocacy to put more emphasis on resource efficiency.

Our analysis has several limitations: the robustness of our content analysis is limited due to its qualitative nature. In particular, the number of requirements should be treated with caution, not only because of the qualitative classification but also because of the different styles (wording) of the ecodesign regulations, which vary greatly in terms of the number and level of detail of the requirements per regulation. The keyword analysis added a layer of reliability and supported the trend identified by the content analysis.

We covered a wide range of legislative texts and identified overall trends within ecodesign. At the same time, this holistic approach and the focus of the legislative texts reduced the depth of the analysis for individual product groups and the policymaking process in general.

6. Conclusions

Our results show that the product groups covered by the Ecodesign Directive have expanded greatly over the years, with frequent amendments or repeals of existing legislation. Our taxonomy of circular economy requirements provided nuanced results, differentiating requirements by type and strength. We could show a clear increase in circular economy requirements over time, especially in the 2019-generation of implementing measures, where the number of specific and generic function requirements increased significantly. Prior to 2019, mainly informational requirements were implemented, with the exception of lighting regulations.

Lighting was identified as an outlier, with many requirements focussing on durability before implementing measures for other product groups including circular economy requirements. The focus on durability for lighting remains an exception also in the 2019-generation, where we did find a significant increase in measures, but mainly related to reusability/repairability and to a lesser extent recycling.

Electronic displays and televisions were found to be the product groups that include most circular economy requirements, in equal parts functional and informational requirements.

In terms of product families, lighting contains by far the highest and most stringent circular economy requirements, followed by white goods (with a high share of repairability requirements) and ICT (being the only product family that started to regulate critical sourcing). The product family Heaters and Coolers showed consistently very few circular economy requirements and mainly informational ones. For the remaining products (product family Other), it was only vacuum cleaners and welding equipment that include several circular economy requirements.

Although our results revealed the trend of product policies towards circular economy aspects, the drivers behind this development are yet to be identified. Which advocacy coalitions influence the product policy-making process, what are the advantages and disadvantages for the main stakeholders involved, and what role is played by macroeconomic considerations at the EU level? A robust method for integrating circular economy aspects into policy impact assessments and ex-post evaluations is needed to justify and steer the uptake of circular economy requirements in product policy regulations. The EN 4555X series of standards is already an important step in the right direction but needs to be extended by product group-specific (vertical) standards to improve the implementability of circular economy requirements. Another important building block is the revision of the MEErP with the aim of systematically including material efficiency aspects into the ecodesign impact assessment [

55]. Finally, the extension of ecodesign to non-energy-related products under the Proposal for Ecodesign for Sustainable Products Regulation [

25] offers the opportunity to integrate the circular economy into framework legislation from the outset and to increase the scope and environmental benefits of ecodesign. The large number of individual methodological advancements, standards, and initiatives show great inertia in the field of circular economy product policies and can be a great leap forward.