Electric Kettles: An Assessment of Energy-Saving Potentials for Policy Making in the European Union

Abstract

1. Introduction

2. Definition of Representative Kettles for the EU-27 Market

2.1. Common Kettle Technologies

- A container filled with water where the actual heating and boiling takes place. It is usually equipped with a handle and a lid and offers additional room for sensors and the control system. The container can differ in construction design (single-wall, double-wall, insulated, and vacuum), material (plastic, steel, and glass), capacity, and included features (e.g., water-level indicator, filters, etc.);

- Cordless models are portable as they feature a base that is connected to the mains;

- A power cord with a plug;

- A heating element. This can be an immersed element in direct contact with the water or an underfloor element concealed in the bottom of the container. The types of elements are as follows:

- a.

- Common tubular heating element: This consists of a heating wire (as the original resistance heating element), often comprising a nickel-based, nichrome heating element (NiCr), magnesium oxide powder, and an outer casing;

- b.

- A thick film heating element, which generally consists of a metal core. The core is coated with a glass-ceramic lining, which ensures electrical insulation and carries conductive, screen-printed heater tracks. These elements can transfer a higher amount of energy/heat per surface. Additionally, such elements offer a lower thermal mass; therefore, heat losses to the surrounding material are lower. Currently, thick film heating elements are more expensive than conventional, tubular ones. Kettles with thick film heating element are very rare on the EU market.

- Sensors, control units, and mechanical or electrical switches that ensure the proper function of the kettle with features such as auto-switch-off, temperature selection, keep-warm, and boil-dry protection (i.e., precaution against empty operation). Temperature control is based on the following main technologies:

- Bi-metal switches: Steam from the boiling water is conducted to a mechanical bi-metallic disk in the base, handle, or lid. When the steam reaches a defined temperature, the bi-metallic disk snaps its position and cuts off the power. Bi-metal switches have tolerances of +/− 5 to 7 K.

- a.

- Thermistors: Electric elements that change their electrical resistance in response to a change in temperature. Kettles use Positive Temperature Coefficient (PTC) models typically chosen for several pre-set temperatures (step-approach) or Negative Temperature Coefficient (NTC) models with step or stepless temperature setting.

- b.

- Both NTCs and PTCs can provide features such as auto-switch-off, boil-dry (PTC), temperature selection, and keep-warm and are more accurate than bi-metal switches.

2.2. Overview of the Market in the EU-27

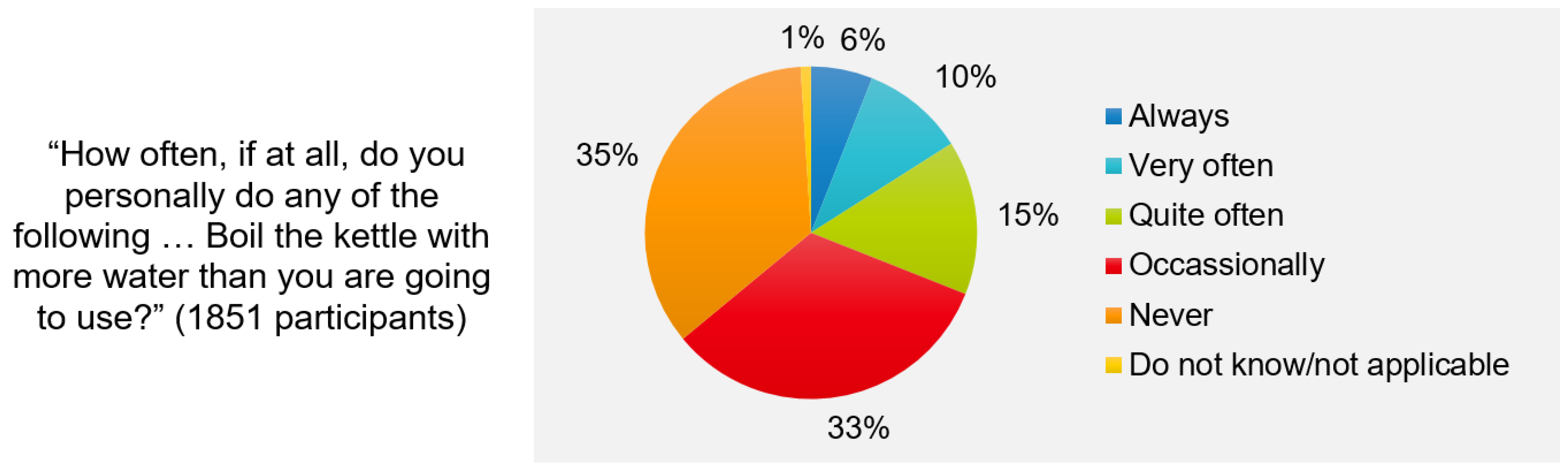

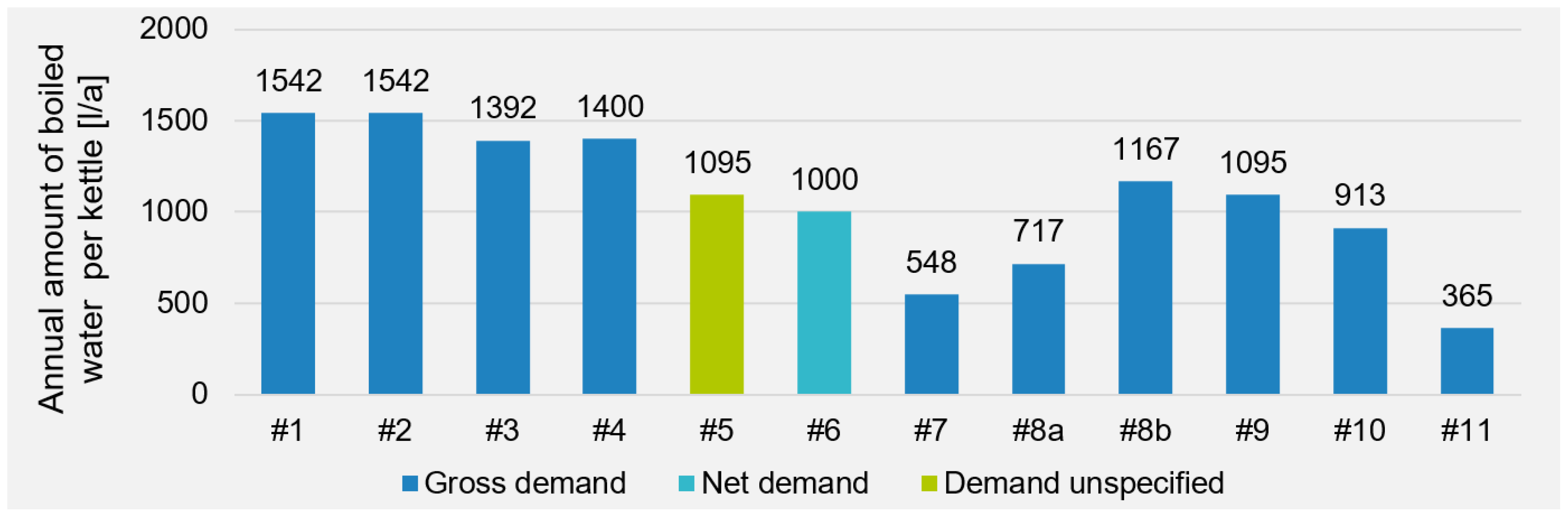

2.3. Utilisation of Kettles

2.4. Definition of Representative Kettles

3. Characterisation of the Base Cases

3.1. Existing Test Standards and Energy Efficiency Metrics

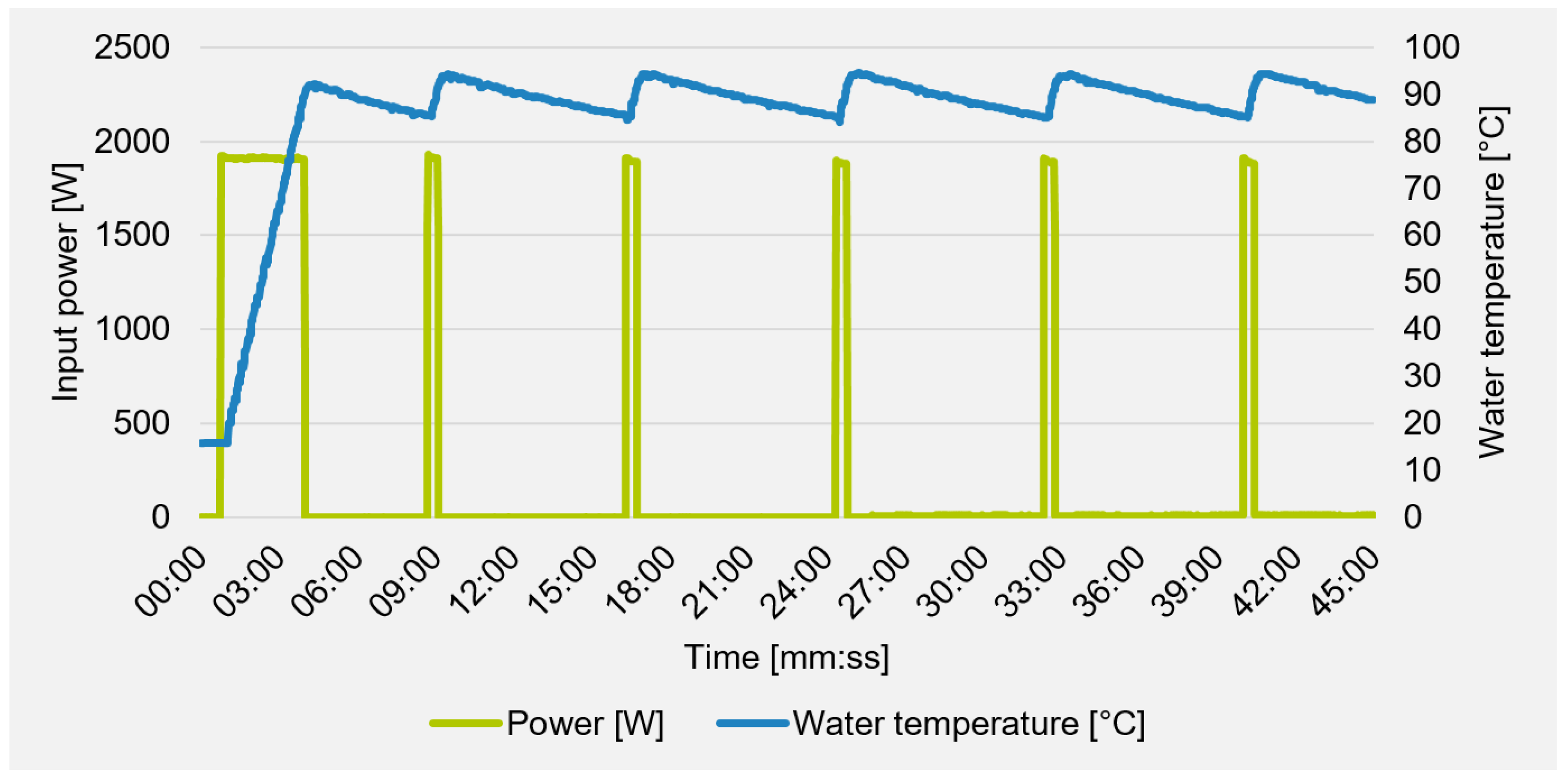

3.2. Measurement Method

- For kettles with pre-set temperature: energy consumption and time measurement for heating until shut-off at a pre-set temperature of 70 °C (or the nearest pre-set temperature above 70 °C) at minimum water capacity;

- For kettles with keep-warm feature: average input power, average water temperature, and maximum keep-warm time measurement for the keep-warm function at the maximum keep-warm temperature, and maximum time setting at a rated water capacity. In addition: temperature drop during a cool-down phase of 30 min after boiling at rated water capacity.

3.3. Measurement Results

3.3.1. Specific Consumption for Heating

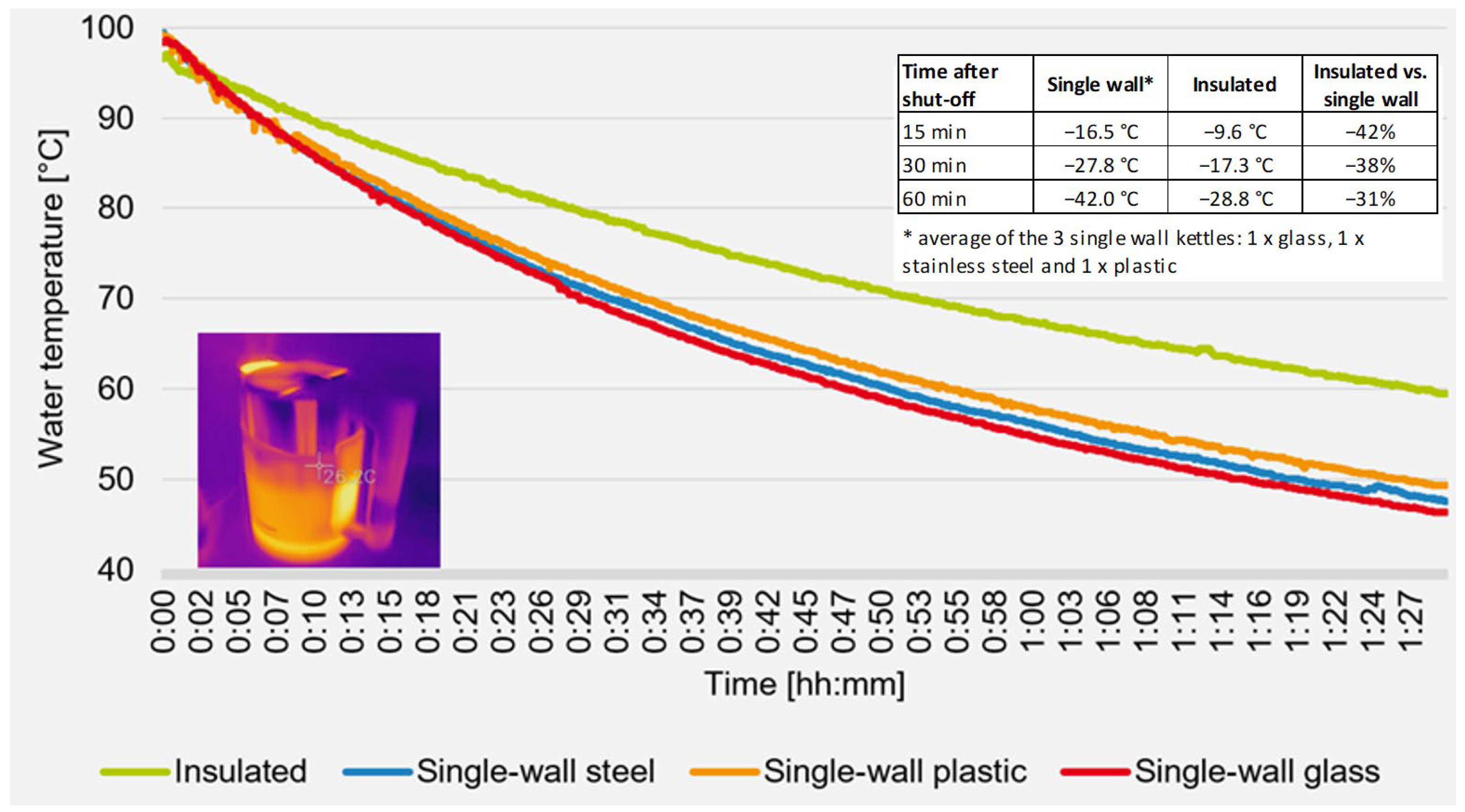

3.3.2. Keep-Warm and Cool-Down Measurements

3.4. Performance of the Representative Kettles

4. Energy-Saving Potentials

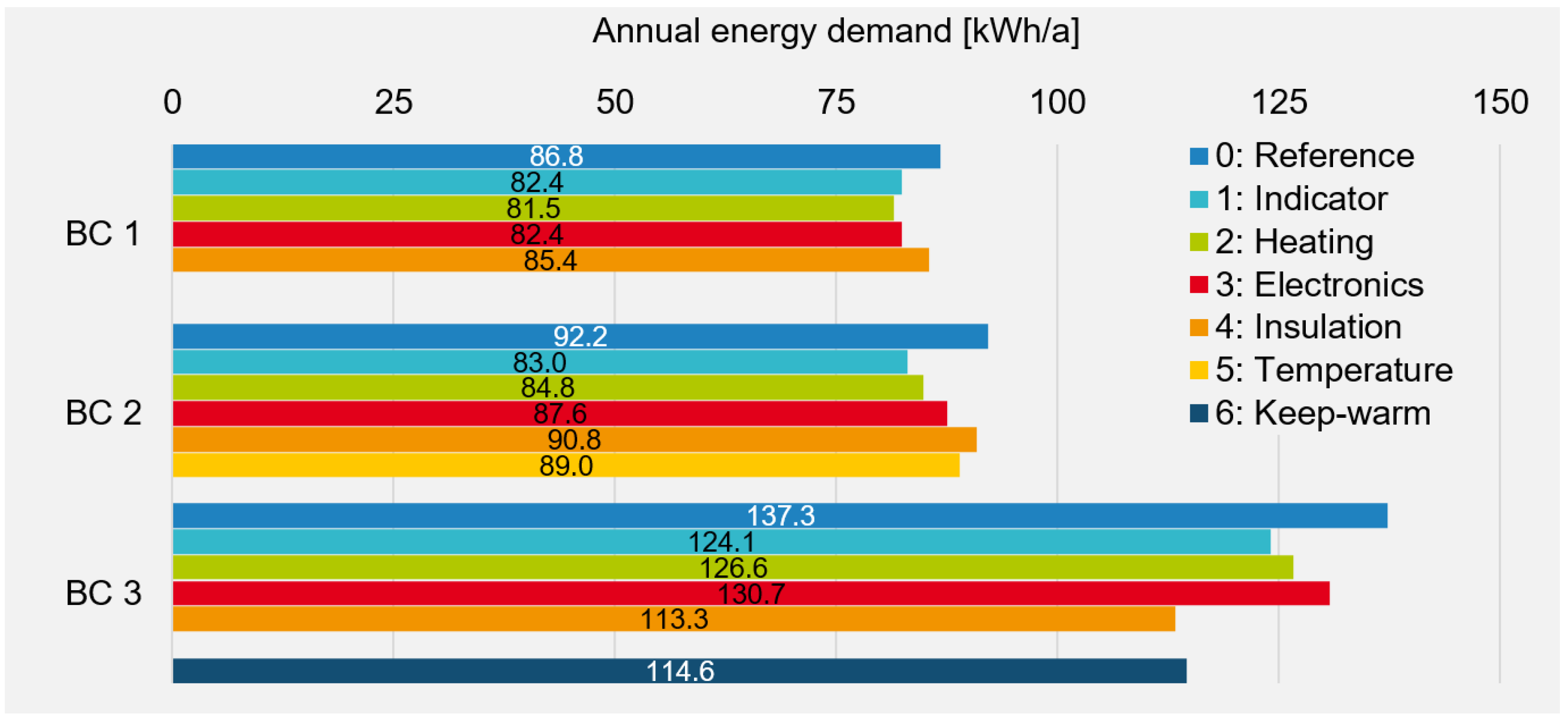

4.1. Overview of the Measures

- Indicator: This measures aims to reduce “overboiling”, which has a significant effect on energy consumption, by directly showing the user how much water is in the kettle. This is carried out using an enlarged water level indicator down to a low minimum volume (e.g., 0.25 l) and information on the filling level in both litres and cups.

- Heating: In this design option, conventional heating elements (immersed or concealed) are replaced by thick film heating elements. Thick film heating elements operate with higher efficiency due to their higher energy density and lower thermal losses, which has a particularly strong effect on performance in the case of low filling levels.

- Electronics: Measurements reveal an “overheating” of kettles, i.e., a situation where kettles exceed the boiling temperature beyond 95 °C as required by the current standard IEC 60530:1975 [17]. This measure seeks to reduce overheating by automatically shutting off the heating early by sensors and controllers with greater accuracy.

- Insulation: To minimise energy dissipation after boiling, this measure improves kettle insulation with a double-shell container. This has special relevance for keep-warm features but also reduces heat losses in general during the cooling phase, i.e., after boiling.

- Temperature: In some cases, e.g., preparing certain types of tea, temperatures of 95 °C or above are not required. This measure allows temperatures below 95 °C to be selected.

- Keep-warm: Currently, this measure is intended to limit the use of the keep-warm function when this is available. Excessive re-heating of boiled water is avoided by setting a maximum duration for keep-warm to 30 min.

4.2. Data and Assumptions

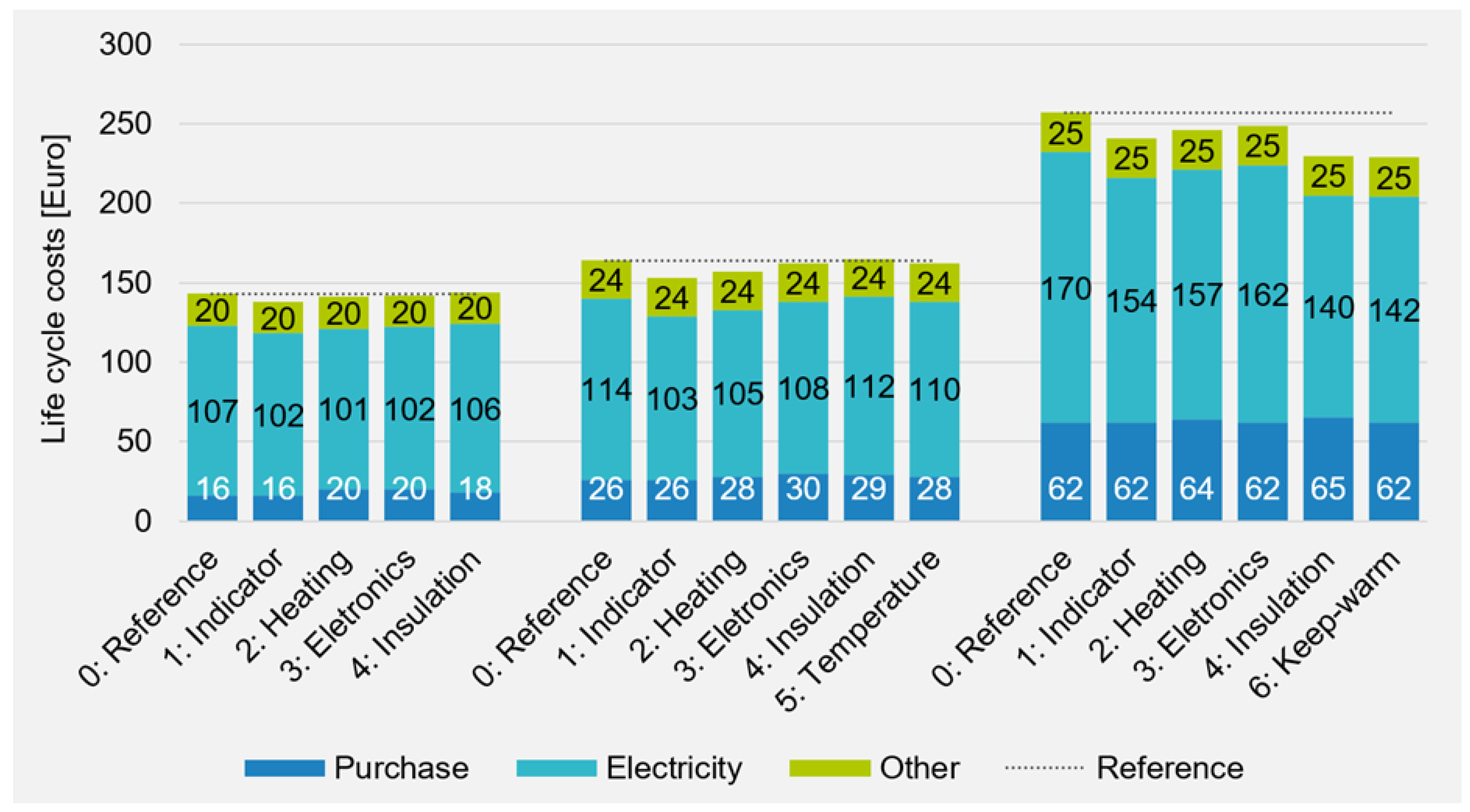

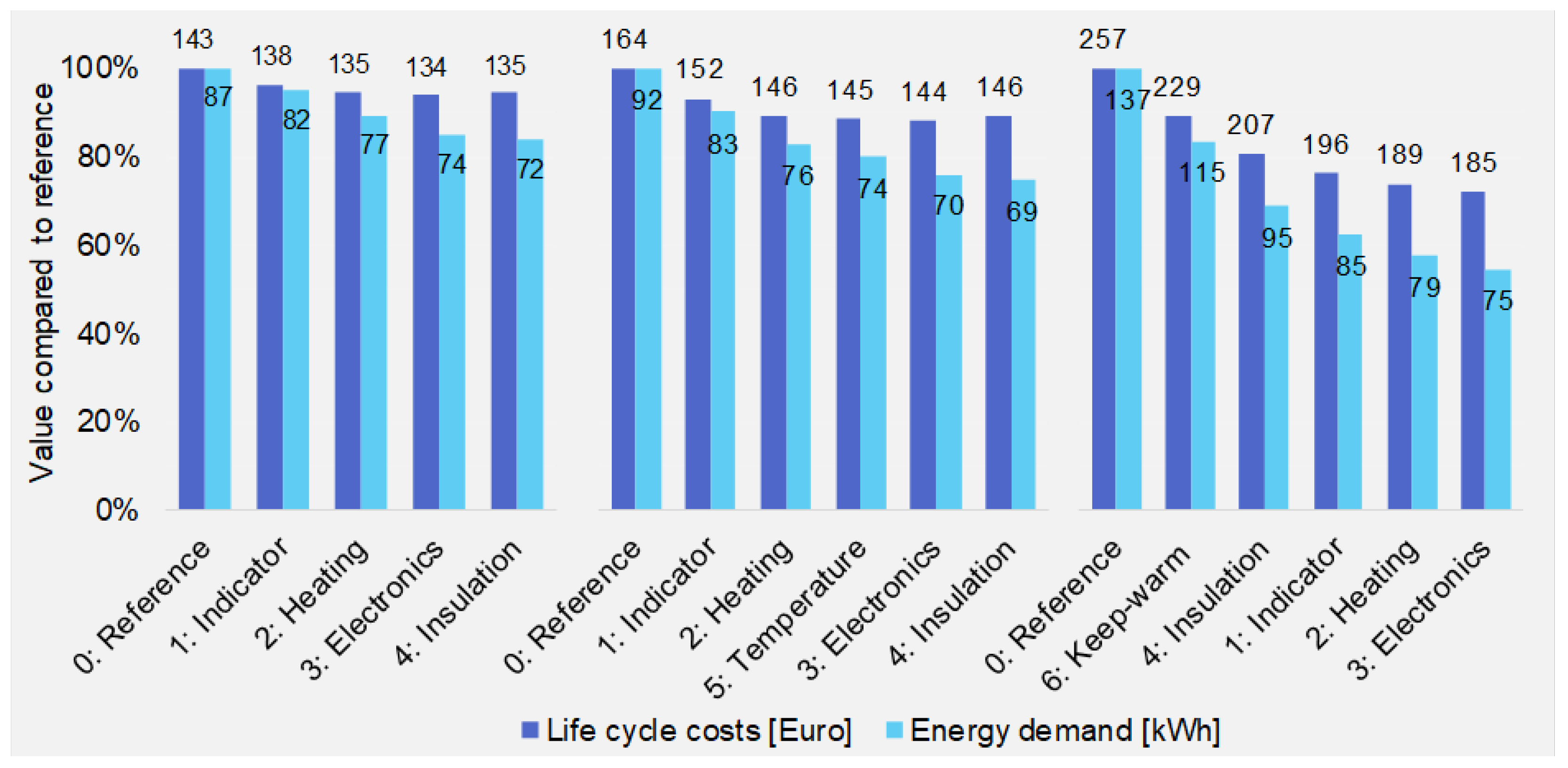

4.3. Analysis of Impact

4.4. Analysis of Packages

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stiftung Warentest, Wasserkocher. Einfach Schnell Heiß; Test 1/2013; Stiftung Warentest: Berlin, Germany, 2013; pp. 69–73. [Google Scholar]

- BIO by Deloitte. Preparatory Study to Establish the Ecodesign Working Plan 2015–2017 Implementing Directive 2009/125/EC; Oeko-Institut and ERA Technology: Freiburg, Germany, 2015. [Google Scholar]

- Kemna, R. Methodology for Ecodesign of Energy-Related Products—MEErP 2011: Methodology Report. Part 1: Methods; COWI: Brussels, Belgium; Delft, The Netherlands, 2011. [Google Scholar]

- Murray, D.; Liao, J.; Stankovic, L.; Stankovic, V. Understanding usage patterns of electric kettle and energy saving potential. Appl. Energy 2016, 171, 231–242. [Google Scholar] [CrossRef]

- Gallego-Schmid, A.; Jeswani, H.K.; Mendoza, J.M.F.; Azapagic, A. Life cycle environmental evaluation of kettles: Recommendations for the development of eco-design regulations in the European Union. Sci. Total Environ. 2018, 625, 135–146. [Google Scholar] [CrossRef] [PubMed]

- Grzesik, K.; Guca, K. Screening Study of Life Cycle Assessment (LCA) of the Electric Kettle with SimaPro Software. Geomat. Environ. Eng. 2011, 5, 57–68. [Google Scholar]

- Fraunhofer ISI; VITO. Preparatory Study for Kettles Implementing the Ecodesign Working Plan 2016–2019. 2021. Available online: https://publica.fraunhofer.de/entities/publication/28f876ae-7649-4b50-9dbc-db72837c79a4/details (accessed on 12 September 2022).

- GfK. Kettles Market Data in the EU; GfK: Nuremberg, Germany, 2020. [Google Scholar]

- Department for Business, Energy & Industrial Strategy (BEIS). BEIS Public Attitudes Tracker (March 2020, Wave 33, UK); BEIS: London, UK, 7 May 2020.

- Schüler, D.; Grießhammer, R. PROSA—Wasserkocher: Kriterien für das Umweltzeichen für Klimarelevante Produkte und Dienstleistungen; Öko-Institut e.V.: Freiburg im Breisgau, Germany, 2009. [Google Scholar]

- Ayoub, A.; Irusta, C. Comparison between Electric Kettle and Stovetop Kettle: Life Cycle Assessment—Group LCA 2. Ghent University: Ghent, Belgium, 2014. [Google Scholar]

- Energimyndigheten. Vattenkokare. Available online: http://www.energimyndigheten.se/tester/tester-a-o/vattenkokare/ (accessed on 13 August 2020).

- Topten: Wasserkocher: Methodik von Topten. 12/2017 Bush. 2017. Available online: https://storage.topten.ch/source/files/Technische-Kriterien-Wasserkocher-2017.pdf (accessed on 10 October 2022).

- Bakker, C.; Wang, F.; Huisman, J.; den Hollander, M. Products that go round: Exploring product life extension through design. J. Clean. Prod. 2014, 69, 10–16. [Google Scholar] [CrossRef]

- Prakash, S.; Dehoust, G.; Gsell, M.; Schleicher, T.; Stamminger, R. Influence of the Service Life of Products in Terms of Their Environmental Impact: Establishing an Information Base and Developing Strategies against “Obsolescence”: Final Report; Texte 09/2020, Project No. (FKZ) UFOPLAN 3713 32 315, Report No. EF001182/ENG; Umweltbundesamt: Dessau-Roßlau, Germany, 2020. [Google Scholar]

- EN 50564:2011; Electrical and Electronic Household and Office Equipment—Measurement of Low Power Consumption. CEN-CENELEC: Brussels, Belgium, 2011.

- IEC 60530:1975; Methods for Measuring the Performance of Electric Kettles and Jugs for Household and Similar Use; No. 97.040.50. International Electrotechnical Commission: Geneva, Switzerland, 1975.

- Blue Angel. Electric Kettles for Household Use DE-UZ 133, RAL gGmbH, Bonn, Germany. 2013. Available online: https://produktinfo.blauer-engel.de/uploads/criteriafile/en/DE-UZ%20133-201309-en%20Criteria-2020-01-07.pdf (accessed on 1 September 2022).

- Ministry of Environment Korea. Electric Kettles and Electric Coffee Makers: EL408:2013. 2013. Available online: http://el.keiti.re.kr/enservice/enpage.do?mMenu=2&sMenu=1 (accessed on 25 January 2022).

- GB/T 22089:2008; Performance Requirements and Measuring Methods for Electric Kettles. Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- Environmental Protection Administration of Taiwan. Green Mark 126—Electric Kettles; Environmental Protection Administration of Taiwan: Taipei, Taiwan, 2013. [Google Scholar]

- Energy Efficiency Label Department Thailand. Manual Energy Saving Label No. 5 Project Electric Kettle. 2014. Available online: http://labelno5.egat.co.th/new58/wp-content/uploads/2016/form/mn/ele_kettle.pdf (accessed on 25 January 2022).

- ISIRI. Specification for Energy Consumption and Energy Labelling of Electrical Household Water Heaters. 2005; No. 7875. Available online: http://www.behsa.ir/index.php/booklibrary/standards/20-isiri-7875/file (accessed on 10 June 2020).

- Eurostat. Electricity prices by type of user [TEN00117]; Luxemburg, Luxemburg. 2022. Available online: https://ec.europa.eu/eurostat/databrowser/view/ten00117/default/table (accessed on 1 September 2022).

- European Commission. Directive 2012/19/EU of the European Parliament and of the Council of 4 July 2012 on waste electrical and electronic equipment (WEEE). Off. J. Eur. Union 2012, 34, 194–227. [Google Scholar]

- EN 45555:2019; General Methods for Assessing the Recyclability and Recoverability of Energy-Related Products. CEN-CENELEC: Brussels, Belgium, 2019.

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions—A New Circular Economy Action Plan for a Cleaner and More Competitive Europe: COM (2020) 98; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- European Commission. Proposal for a Regulation of the European Parliament and of the Council: Establishing a Framework for Setting Ecodesign Requirements for Sustainable Products and Repealing Directive 2009/125/EC; European Commission: Brussels, Belgium, 2022. [Google Scholar]

| General | Description | Unit | BC 1 | BC 2 | BC 3 |

|---|---|---|---|---|---|

| Simple | Typical | Premium | |||

| Description | Concealed heating element | No | Yes | Yes | |

| Cordless | No | Yes | Yes | ||

| Container material | Plastic | Plastic | Plastic | ||

| Container capacity | [l] | 1.0 | 1.7 | 1.7 | |

| Real input power | [W] | 1000 | 2200 | 2200 | |

| Temperature selection | No | No | Yes | ||

| Keep-warm | No | No | Yes | ||

| Technical data | Lifetime | [a] | 6 | 6 | 6 |

| Water boiled | [l/a] | 800 | 800 | 800 | |

| Standby power | [W] | - | - | 0.250 | |

| Maximum volume (Vmax) | [l] | 1.0 | 1.7 | 1.7 | |

| Minimum volume (Vmin) | [l] | 0.50 | 0.50 | 0.50 | |

| Price | End-user price | [Euro] | 16 | 26 | 62 |

| Sales | Market share in 2020 | % | 15% | 79% | 6% |

| Name/Reference | Description | Country | Volume [l] | Start–End Water Temperature [°C] | Energy Efficiency Metric | Detail |

|---|---|---|---|---|---|---|

| IEC 60530:1975 [17] | Test standard | 1 | 15–95 | None (focus on boiling time) | ||

| Blue Angel/RAL-UZ 133 [18] | Eco label (voluntary endorsement label) | Germany | 1 | 20–100 (switch off) | Specific energy consumption [kWh/l] W20 = WM × 80/TM | WM: power consumption until automatic switch-off of the kettle Temperature difference compared to the boiling temperature of 100 °C |

| Topten [13] | Voluntary endorsement label (private initiative) | Switzerland | 1 | 15–100 (switch off) | Yearly energy consumption [kWh/a] Ekettle = Eboil + Ekeepwarm + Estand-by | Eboil = 365 × Econsumption to heat 1 l if T-setting feature is available: −10% Ekeep warm = Pkeep warm × 0.5 × (max time keep-warm) × 365 ll if no measurement possible: 15 W × 1 h × 365 Estand-by: Pstand-by × 8760 h |

| Eco-Label Standard (EL408:2013) [19] | Voluntary endorsement label | South Korea | 1 | 15–99 | Specific energy consumption [kWh/l] | |

| GB/T 22089-2008 [20] | Voluntary standard | China | Rated volume | 20 *–80 | η = C × M × (80−T1)/E × 100% | T1: start temperature |

| Greenmark N126 [21] | Voluntary endorsement label | Taiwan | 1 | 15–99 | Specific energy consumption [kWh/l] | |

| Energy Efficiency Label [22] | Voluntary comparative label | Thailand | 30–90 | η = ϱ × (90−30)/(0.24 P × t) × 100 | ||

| ISIRI 7875 [23] | MEPS and Energy Label | Iran | 1 | 20–90 | Specific energy consumption [kWh/l] | |

| Manufacturer (confidential) | Test method applied by a manufacturer | 20–98 | Efficiency: η = Q/Energy Consumption | With: Q = (98−20) × 4186 × Volume |

| Test | Type of Test | Quantity of Water | Measurement | Measured or Calculated Parameters |

|---|---|---|---|---|

| 1 | Heating 80 K | Rated water capacity | Until shut-off (at least +80 K) | E95°C,Vrated, t95°C,Vrated, EEI |

| 2 | Heating 80 K | Minimum water capacity | Until shut-off (at least +80 K) | E95°C,Vmin, t95°C,Vmin |

| 3 | Heating 80 K | 1 l * | Until shut-off (at least +80 K) | E95°C,1, t95°C,1 |

| 4 | Heating | Rated water capacity | Until shut-off, when 70 °C pre-set temperature (or the nearest pre-set temperature above 70 °C) is selected | E70°C,Vrated, t70°C,Vrated |

| 5 | Heating | Minimum water capacity | Until shut-off, when 70 °C pre-set temperature (or the nearest pre-set temperature above 70 °C) is selected | E70°C,Vmin, t70°C,Vmin |

| 6 | Keep-warm | Rated water capacity | Max keep-warm temperature selected Longest possible keep-warm time | tkwmax, Tkw, Pkw,Vrated, pkw,Vrated |

| 7 | Cool down | Rated water capacity | Tdrop | |

| 8 | Standby | 0 l | According to current harmonised standard | Pstandby |

| 9 | Durability | 1 l (or Vrated if Vrated > 1 l) | Until shut-off (at least +80 K) | Ncyc |

| Description | Unit | BC 1 | BC 2 | BC 3 | |

|---|---|---|---|---|---|

| Description | Capacity of the container [l] | 1.0 | 1.7 | 1.7 | |

| Real input power [W] | 1000 | 2200 | 2200 | ||

| Temperature setting | no | no | yes | ||

| Temperature holding | no | no | yes | ||

| Technical data Performance | Lifetime | [a] | 6 | 6 | 6 |

| Water boiled | [l/a] | 800 | 800 | 800 | |

| Standby power | [W] | - | - | 0.250 | |

| Maximum volume (Vmax) | [l] | 1.0 | 1.7 | 1.7 | |

| Minimum volume (Vmin) | [l] | 0.50 | 0.50 | 0.50 | |

| Heat 1 l from 15 °C to 98 °C (Tswitchoff) | time to heat [s] | 390 | 189 | 189 | |

| [kWh/l] | 0.108 | 0.115 | 0.115 | ||

| efficiency [%] | 89.0% | 83.8% | 83.8% | ||

| Heat Vmax from 15 °C to 98 °C (Tswitchoff) | time to heat [s] | 390 | 306 | 306 | |

| [kWh/l] | 0.108 | 0.110 | 0.110 | ||

| efficiency [%] | 89.0% | 87.7% | 87.7% | ||

| Heat Vmin from 15 °C to 98 °C (Tswitchoff) | time to heat [s] | 213 | 103 | 103 | |

| [kWh/l] | 0.119 | 0.125 | 0.125 | ||

| efficiency [%] | 81.4% | 77.0% | 77.0% | ||

| Heat 1 l from 15 °C to 80 °C | time to heat [s] | n.a. | n.a. | 148 | |

| [kWh/l] | n.a. | n.a. | 0.090 | ||

| efficiency [%] | 83.8% | ||||

| Vmax from 15 °C to 80 °C | time to heat [s] | n.a. | n.a. | 240 | |

| [kWh/l] | n.a. | n.a. | 0.086 | ||

| efficiency [%] | 87.7% | ||||

| Keep-warm: max time | [min] | n.a. | n.a. | 60.0 | |

| Keep-warm 1 l at 98 °C | [kW/l] | n.a. | n.a. | 0.127 | |

| Keep-warm 1 l at 90 °C | [kW/l] | n.a. | n.a. | 0.115 | |

| Keep warm 1 l at 80 °C | [kW/l] | n.a. | n.a. | 0.099 | |

| Yearly energy consumption | Heating (assuming 1 l at Tmax each time) – indicative | [kWh/a] | 86.75 | 92.19 | 92.19 |

| Heating (assuming 1 l filled in and 73% at 98 °C, 22% at 90 °C, and 5% at 80 °C) | [kWh/a] | 86.75 | 92.19 | 88.99 | |

| Keep-warm (assuming 1 l at 98 °C over 60 min every day) | [kWh/a] | - | - | 46.25 | |

| Standby | [kWh/a] | - | - | 2.09 | |

| Total energy consumption [kWh] | [kWh/a] | 86.75 | 92.19 | 137.33 |

| ID | Name | Details | Applies to | Changes Energy Demand During | Marginal Change in Price in Euro | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| BC 1 | BC 2 | BC 3 | ... Boiling by up to | ... Keep-Warm by up to | BC 1 | BC 2 | BC 3 | |||

| 1 | Indicator | Less overboiling through: Enlarged water level indicator, min volume, dual scale (in l and cup) | X | X | X | −10% | −10% | None | None | None |

| 2 | Heating | Thick film heating element | X | X | X | −8% | −8% | +3.50 | +2.00 | +2.00 |

| 3 | Electronics | More accurate T-sensor, 95 °C target temperature | X | X | X | −5% | −5% | +4.00 | +4.00 | None |

| 4 | Insulation | Double-shell container | X | X | X | −1.5% | −50% | +2.00 | +3.00 | +3.00 |

| 5 | Temperature | Allows temperatures below 95 °C to be selected | X | −3.5% | None | +2.00 | ||||

| 6 | Keep-warm | Max 30 min | X | None | −50% | None | ||||

| Scenario | BC | Design Options Implemented | Annual Energy Consumption [kWh/Year] | Purchase Cost [EUR] | Annual Maintenance Cost [EUR/Year] | Energy Consumption of the EU Stock in 2030 [TWh/Year] | Expenditure for the EU Stock in 2030 [Bn. EUR/Year] |

|---|---|---|---|---|---|---|---|

| BAU | 1 | No | 86.8 | 16.0 | 3.3 | 9.8 | 3.0 |

| 2 | No | 92.2 | 26.0 | 4.0 | |||

| 3 | No | 137.3 | 62.0 | 4.2 | |||

| LLCC | 1 | 1, 2, 3 | 73.6 | 23.5 | 3.3 | 7.4 (−24.7%) | 2.6 (−12.7%) |

| 2 | 1, 2, 3, 5 | 70.0 | 34.0 | 4.0 | |||

| 3 | All (1, 2, 3, 4, 6) | 75.0 | 67.0 | 4.2 | |||

| BAT | 1 | All (1, 2, 3, 4) | 72.5 | 25.5 | 3.3 | 7.2 (−25.8%) | 2.6 (−11.8%) |

| 2 | All (1, 2, 3, 4, 5) | 68.9 | 37.0 | 4.0 | |||

| 3 | All (1, 2, 3, 4, 6) | 75.0 | 67.0 | 4.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Durand, A.; Hirzel, S.; Rohde, C.; Gebele, M.; Lopes, C.; Olsson, E.; Barkhausen, R. Electric Kettles: An Assessment of Energy-Saving Potentials for Policy Making in the European Union. Sustainability 2022, 14, 12963. https://doi.org/10.3390/su142012963

Durand A, Hirzel S, Rohde C, Gebele M, Lopes C, Olsson E, Barkhausen R. Electric Kettles: An Assessment of Energy-Saving Potentials for Policy Making in the European Union. Sustainability. 2022; 14(20):12963. https://doi.org/10.3390/su142012963

Chicago/Turabian StyleDurand, Antoine, Simon Hirzel, Clemens Rohde, Marcel Gebele, Carlos Lopes, Emma Olsson, and Robin Barkhausen. 2022. "Electric Kettles: An Assessment of Energy-Saving Potentials for Policy Making in the European Union" Sustainability 14, no. 20: 12963. https://doi.org/10.3390/su142012963

APA StyleDurand, A., Hirzel, S., Rohde, C., Gebele, M., Lopes, C., Olsson, E., & Barkhausen, R. (2022). Electric Kettles: An Assessment of Energy-Saving Potentials for Policy Making in the European Union. Sustainability, 14(20), 12963. https://doi.org/10.3390/su142012963