Durability of Engineered Cementitious Composites Incorporating High-Volume Fly Ash and Limestone Powder

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials

2.2. Mixture Design and Sample Preparation

2.3. Test Methods

2.3.1. Mechanical Properties

2.3.2. Durability Properties

3. Results and Discussions

3.1. Compressive Strength and Flexural Tensile Strength

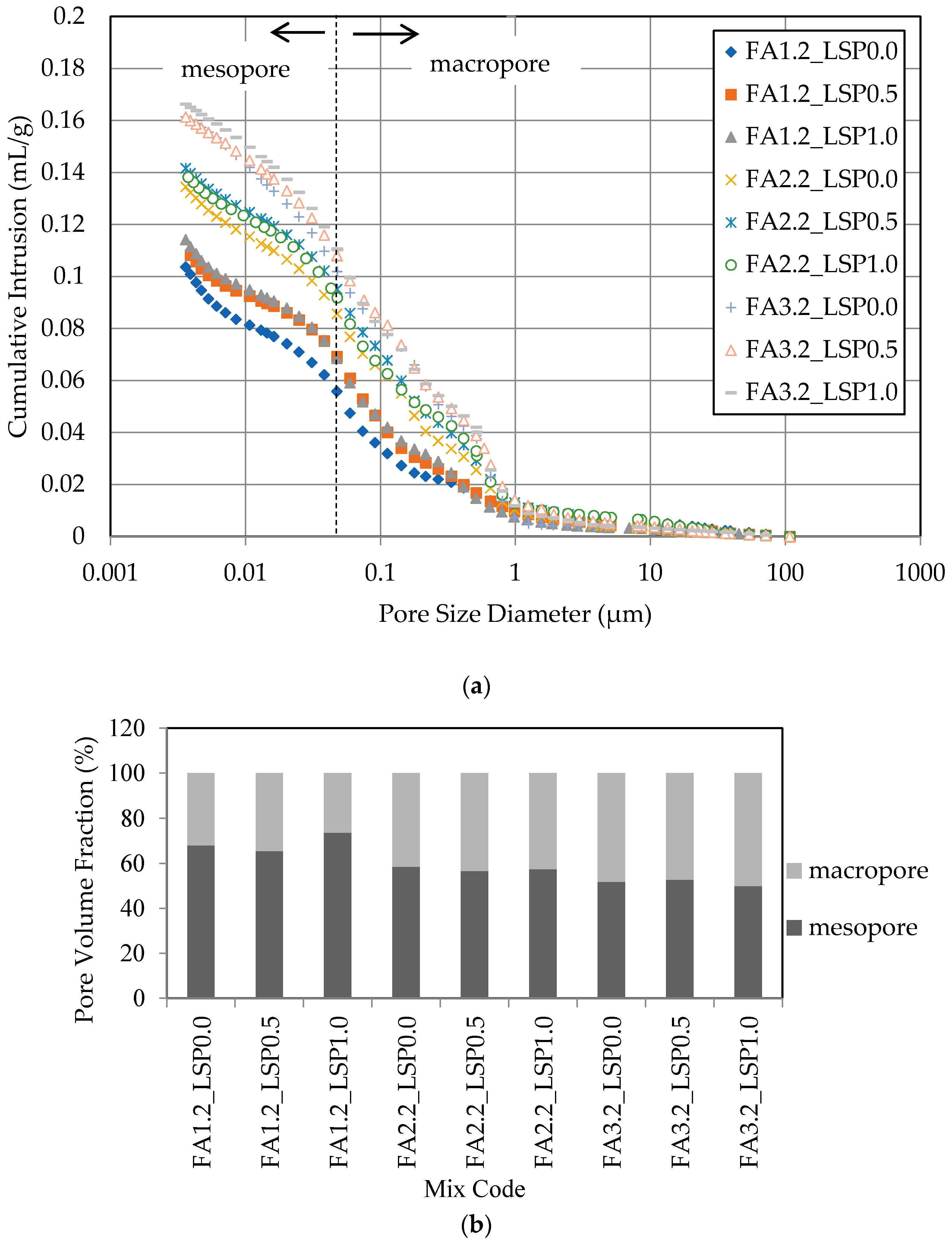

3.2. Mercury Intrusion Porosimetry

3.3. Freezing–Thawing Resistance

3.4. Rapid Chloride Ion Penetrability

3.5. The Relationship between MIP and Mechanical/Durability Properties

4. Conclusions

- The compressive and flexural strengths of ECC specimens decreased with increase in FA/PC ratio, regardless of LSP content, while the addition of LSP as aggregate enhanced the compressive strength in general. As for flexural strength of ECC specimens, the use of LSP instead of SS caused slight improvement for ECC specimens with 2.2 ratio of FA/PC, whilst the full replacement of LSP for SS had no clear effect for all FA/PC ratios.

- The MIP results showed that using higher ratio of FA/PC increased the total porosity of ECC specimens, resulting in higher volume fraction of macropores. On the other hand, in general, the partial replacement of LSP with SS caused a reduction in porosity and a refinement of pore distribution of ECC matrix. In particular, 100% replacement of LSP with SS for ECC specimens with FA/PC of 1.2 implied a positive influence on the formation of mesopores.

- The freezing–thawing resistance of ECC specimens decreased when FA/PC ratio increased, whilst for ECC specimens with a 3.2 ratio of FA/PC the full replacement of LSP with SS caused an increase in RDEM of ECC. On the other hand, for 1.2 and 2.2 ratio of FA/PC, the ECC specimens with LSP exhibited almost the same resistance with the ECC specimens with 100% SS.

- The charge passed increased as the ratio of FA/PC increased for ECC specimens, regardless of LSP content. However, the use of LSP induced a decrease in the chloride permeability of ECC specimens for all FA/PC ratios.

- The correlation between the porosity and the test results was higher for freezing–thawing and chloride permeability tests with the R-square value of 0.9116 and 0.9747, respectively, compared to those of the compressive and flexure strengths.

- According to the test results, the replacement of LSP with silica sand can be advised for the development of sustainable ECC due to causing an improvement in pore size distribution and cumulative porosity of matrices resulting in an increase in the freezing–thawing resistance and chloride permeability as well as strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, V.C.; Kanda, T. Engineered Cementitious Composites for Structural Applications. J. Mater. Civ. Eng. 1998, 10, 66–69. [Google Scholar] [CrossRef]

- Zhou, Y.; Xi, B.; Yu, K.; Sui, L.; Xing, F. Mechanical properties of hybrid ultra-high performance engineered cementitous composites incorporating steel and polyethylene fibers. Materials 2018, 11, 1448. [Google Scholar] [CrossRef] [PubMed]

- Li, V.C.; Leung, C.K.Y. Steady-State and Multiple Cracking of Short Random Fiber Composites. J. Eng. Mech. 1992, 118, 2246–2264. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Q.; Gu, C.; Su, H.; Li, V.C. Influence of micro-cracking on the permeability of engineered cementitious composites. Cem. Concr. Compos. 2016, 72, 104–113. [Google Scholar] [CrossRef]

- Weimann, M.B.; Li, V.C. Hygral Behavior of Engineered Cementitious Composites (ECC). Int. J. Restor. Build. Monum. 2003, 9, 513–534. [Google Scholar]

- Şahmaran, M.; Li, V.C. Durability of mechanically loaded engineered cementitious composites under highly alkaline environments. Cem. Concr. Compos. 2008, 30, 72–81. [Google Scholar] [CrossRef]

- Ma, H.; Yi, C.; Wu, C. Review and outlook on durability of engineered cementitious composite (ECC). Constr. Build. Mater. 2021, 287, 122719. [Google Scholar] [CrossRef]

- Turk, K.; Nehdi, M.L. Coupled effects of limestone powder and high-volume fly ash on mechanical properties of ECC. Constr. Build. Mater. 2018, 164, 185–192. [Google Scholar] [CrossRef]

- Ranjith, S.; Venkatasubramani, R.; Sreevidya, V. Comparative Study on Durability Properties of Engineered Cementitious Composites with Polypropylene Fiber and Glass Fiber. Arch. Civ. Eng. 2017, 63, 83–101. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, G.; Guan, Z.; Ashour, A.; Ge, W.; Zhang, P.; Lu, W.; Cao, D. The effect of freeze–thaw cycles on flexural behaviour of FRP-reinforced ECC beams. Arch. Civ. Mech. Eng. 2021, 21, 101. [Google Scholar] [CrossRef]

- Zhang, W.; Yin, C.; Ma, F.; Huang, Z. Mechanical properties and carbonation durability of engineered cementitious composites reinforced by polypropylene and hydrophilic polyvinyl alcohol fibers. Materials 2018, 11, 1147. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Xia, K. Experimental study on the permeability of basalt fibre engineered cementitious composite (ECC). Mater. Struct. 2022, 55, 85. [Google Scholar] [CrossRef]

- Alnahhal, M.F.; Alengaram, U.J.; Jumaat, M.Z.; Alsubari, B.; Alqedra, M.A.; Mo, K.H. Effect of aggressive chemicals on durability and microstructure properties of concrete containing crushed new concrete aggregate and non-traditional supplementary cementitious materials. Constr. Build. Mater. 2018, 163, 482–495. [Google Scholar] [CrossRef]

- Hossain, M.M.; Karim, M.R.; Hasan, M.; Hossain, M.K.; Zain, M.F.M. Durability of mortar and concrete made up of pozzolans as a partial replacement of cement: A review. Constr. Build. Mater. 2016, 116, 128–140. [Google Scholar] [CrossRef]

- Lepech, M.D.; Li, V.C. Water permeability of engineered cementitious composites. Cem. Concr. Compos. 2009, 31, 744–753. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, Q.; Li, V.; Su, H.; Gu, C. Durability study on engineered cementitious composites (ECC) under sulfate and chloride environment. Constr. Build. Mater. 2017, 133, 171–181. [Google Scholar] [CrossRef]

- Yücel, H.E.; Öz, H.Ö.; Güneş, M.; Kaya, Y. Rheological properties, strength characteristics and flexural performances of engineered cementitious composites incorporating synthetic wollastonite microfibers with two different high aspect ratios. Constr. Build. Mater. 2021, 306, 124921. [Google Scholar] [CrossRef]

- Quan, X.; Wang, S.; Liu, K.; Zhao, N.; Xu, J.; Xu, F.; Zhou, J. The corrosion resistance of engineered cementitious composite (ECC) containing high-volume fly ash and low-volume bentonite against the combined action of sulfate attack and dry-wet cycles. Constr. Build. Mater. 2021, 303, 124599. [Google Scholar] [CrossRef]

- Mansoori, A.; Behfarnia, K. Evaluation of mechanical and durability properties of engineered cementitious composites exposed to sulfate attack and freeze–thaw cycle. Asian J. Civ. Eng. 2021, 22, 417–429. [Google Scholar] [CrossRef]

- Turk, K.; Kina, C. Freeze-thaw resistance and sorptivity of self-compacting mortar with ternary blends. Comput. Concr. 2018, 21, 149–156. [Google Scholar] [CrossRef]

- Benli, A.; Turk, K.; Kina, C. Influence of Silica Fume and Class F Fly Ash on Mechanical and Rheological Properties and Freeze-Thaw Durability of Self-Compacting Mortars. J. Cold Reg. Eng. 2018, 32, 04018009. [Google Scholar] [CrossRef]

- Yang, E.H.; Yang, Y.; Li, V.C. Use of high volumes of fly ash to improve ECC mechanical properties and material greenness. ACI Mater. J. 2007, 104, 620–628. [Google Scholar] [CrossRef]

- Turk, K.; Demirhan, S. Effect of limestone powder on the rheological, mechanical and durability properties of ECC. Eur. J. Environ. Civ. Eng. 2017, 21, 1151–1170. [Google Scholar] [CrossRef]

- Marzouki, A.; Lecomte, A.; Beddey, A.; Diliberto, C.; Ben Ouezdou, M. The effects of grinding on the properties of Portland-limestone cement. Constr. Build. Mater. 2013, 48, 1145–1155. [Google Scholar] [CrossRef]

- Balayssac, J.P.; Détriché, C.H.; Grandet, J. Effects of curing upon carbonation of concrete. Constr. Build. Mater. 1995, 9, 91–95. [Google Scholar] [CrossRef]

- Parrott, L.J. Some effects of cement and curing upon carbonation and reinforcement corrosion in concrete. Mater. Struct./Mater. Constr. 1996, 29, 164–173. [Google Scholar] [CrossRef]

- Demirhan, S.; Turk, K.; Ulugerger, K. Fresh and hardened properties of self consolidating Portland limestone cement mortars: Effect of high volume limestone powder replaced by cement. Constr. Build. Mater. 2019, 196, 115–125. [Google Scholar] [CrossRef]

- ASTM C 150/C150M-12; Standard Specification for Portland Cement. ASTM Standards: West Conshohocken, PA, USA, 2019; pp. 1–9.

- ASTM C618-19; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM Standards: West Conshohocken, PA, USA, 2019.

- Li, V.C.; Wu, C.; Wang, S.; Ogawa, A.; Saito, T. Interface tailoring for strain-hardening polyvinyl alcohol-engineered cementitious composite (PVA-ECC). ACI Mater. J. 2002, 99, 463–472. [Google Scholar] [CrossRef]

- Şahmaran, M.; Lachemi, M.; Hossain, K.M.A.; Li, V.C. Internal curing of engineered cementitious composites for prevention of early age autogenous shrinkage cracking. Cem. Concr. Res. 2009, 39, 893–901. [Google Scholar] [CrossRef]

- Yang, E.H.; Sahmaran, M.; Yang, Y.; Li, V.C. Rheological control in production of engineered cementitious composites. ACI Mater. J. 2009, 106, 357–366. [Google Scholar] [CrossRef]

- Ahmaran, M.; Li, V.C. Influence of microcracking on water absorption and sorptivity of ECC. Mater. Struct./Mater. Constr. 2009, 42, 593–603. [Google Scholar] [CrossRef]

- ASTM C39/C39M-20; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM Standards: West Conshohocken, PA, USA, 2020.

- ASTM C78/C78M-18; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Third-Point Loading). ASTM Standards: West Conshohocken, PA, USA, 2018.

- ASTM D 4404; Standard Test Method for Determination of Pore Volume and Pore Volume Distribution of Soil and Rock by Mercury Intrusion Porosimetry. ASTM Standards: West Conshohocken, PA, USA, 2018.

- ASTM C666/C666M-03; Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing. ASTM Standards: West Conshohocken, PA, USA, 2008.

- Shi, C. Effect of mixing proportions of concrete on its electrical conductivity and the rapid chloride permeability test (ASTM C1202 or ASSHTO T277) results. Cem. Concr. Res. 2004, 34, 537–545. [Google Scholar] [CrossRef]

- ASTM C1202; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. ASTM Standards: West Conshohocken, PA, USA, 2012.

- Zhang, Z.; Qian, S.; Ma, H. Investigating mechanical properties and self-healing behavior of micro-cracked ECC with different volume of fly ash. Constr. Build. Mater. 2014, 52, 17–23. [Google Scholar] [CrossRef]

- Long, W.J.; Li, H.D.; Mei, L.; Li, W.; Xing, F.; Khayat, K.H. Damping characteristics of PVA fiber-reinforced cementitious composite containing high-volume fly ash under frequency-temperature coupling effects. Cem. Concr. Compos. 2021, 118, 103911. [Google Scholar] [CrossRef]

- Şahmaran, M.; Yaman, I.Ö.; Tokyay, M. Transport and mechanical properties of self consolidating concrete with high volume fly ash. Cem. Concr. Compos. 2009, 31, 99–106. [Google Scholar] [CrossRef]

- Zhang, L.V.; Suleiman, A.R.; Nehdi, M.L. Self-healing in fiber-reinforced alkali-activated slag composites incorporating different additives. Constr. Build. Mater. 2020, 262, 120059. [Google Scholar] [CrossRef]

- Yuan, B.; Yu, Q.L.; Brouwers, H.J.H. Assessing the chemical involvement of limestone powder in sodium carbonate activated slag. Mater. Struct./Mater. Constr. 2017, 50, 136. [Google Scholar] [CrossRef]

- Aligizaki, K.K. Pore Structure of Cement-Based Materials: Testing Interpretation and Requirements (Modern Concrete Technology); Taylor & Francis: London, UK, 2005; 432p. [Google Scholar]

- Wu, K.; Shi, H.; Xu, L.; Gao, Y.; Ye, G. Effect of Mineral Admixture on Mechanical Properties of Concrete by Adjusting Interfacial Transition Zone Microstructure. Kuei Suan Jen Hsueh Pao/J. Chin. Ceram. Soc. 2017, 45, 623–630. [Google Scholar] [CrossRef]

- Liu, S.H.; Wang, J. Influence of limestone powder on pore structure of mortar. Jianzhu Cailiao Xuebao/J. Build. Mater. 2011, 14, 532–535. [Google Scholar] [CrossRef]

- Valcuende, M.; Parra, C.; Marco, E.; Garrido, A.; Martínez, E.; Cánoves, J. Influence of limestone filler and viscosity-modifying admixture on the porous structure of self-compacting concrete. Constr. Build. Mater. 2012, 28, 122–128. [Google Scholar] [CrossRef]

- Öznur Öz, H.; Erhan Yücel, H.; Güneş, M. Freeze-Thaw Resistance of Self Compacting Concrete Incorporating Basic Pumice. Int. J. Theor. Appl. Mech. 2016, 1, 285–291. [Google Scholar]

- Şahmaran, M.; Özbay, E.; Yücel, H.E.; Lachemi, M.; Li, V.C. Frost resistance and microstructure of Engineered Cementitious Composites: Influence of fly ash and micro poly-vinyl-alcohol fiber. Cem. Concr. Compos. 2012, 34, 156–165. [Google Scholar] [CrossRef]

- Kamada, E. Frost damage and pore structure of concrete. Proc. Jpn. Concr. Inst. 1988, 10, 51–60. [Google Scholar]

- Misra, S.; Yamamoto, A.; Tsutsumi, T.; Motohashi, K. Application of rapid chloride permeability test to quality control of concrete. Am. Concr. Inst. ACI Spec. Publ. 1994, SP-145, 487–502. [Google Scholar]

- Heikal, M.; El-Didamony, H.; Morsy, M.S. Limestone-filled pozzolanic cement. Cem. Concr. Res. 2000, 30, 1827–1834. [Google Scholar] [CrossRef]

- Liu, S.; Yan, P. Effect of limestone powder on microstructure of concrete. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2010, 25, 328–331. [Google Scholar] [CrossRef]

- Mohr, P.; Hansen, W.; Jensen, E.; Pane, I. Transport properties of concrete pavements with excellent long-term in-service performance. Cem. Concr. Res. 2000, 30, 1903–1910. [Google Scholar] [CrossRef]

- Armaghani, J.M.; Larsen, T.J.; Romano, D.C. Aspects of Concrete Strength and Durability. Transp. Res. Rec. 1992, 63–69. [Google Scholar]

- Zhang, M.H.; Li, H. Pore structure and chloride permeability of concrete containing nano-particles for pavement. Constr. Build. Mater. 2011, 25, 608–616. [Google Scholar] [CrossRef]

| Chemical Characteristics (Oxides and Phase) | |||||||||||

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | K2O + 0.66 Na2O | C3S | C2S | C3A | C4AF | |

| PC (%) | 61.5 | 19.6 | 4.8 | 3.3 | 3 | 3.5 | 0.7 | 55 | 15 | 7 | 10 |

| FA (%) | 14.92 | 41.76 | 22.91 | 9.23 | 2.95 | 1.6 | 2.05 | - | - | - | - |

| Physical Properties | |||||||||||

| Loss of Ignition | Insoluble Residue | SiO2 + Al2O3 + Fe2O3 | Autoclave Expansion, % | Specific gravity | Surface area (m2/kg) | Amount retained on 45 micron, % | |||||

| PC (%) | 1.9 | 0.44 | 27.7 | 0.09 | 3.15 | 371 | 3 | ||||

| FA (%) | 0.8 | - | 73.9 | 0 | 2.43 | 115 | 19 | ||||

| Fiber | Length (mm) | Diameter (µm) | Tensile Strength (MPa) | Modulus of Elasticity (GPa) | Density (kg/m3) | Max. Elongation (%) | Melting Temperature (°C) |

|---|---|---|---|---|---|---|---|

| PVA | 8 | 36 | 1600 | 40 | 1300 | 6.5 | 225 |

| Mixture ID | Unit Weight, (kg/m3) | Slump-Flow (cm) | ||||||

|---|---|---|---|---|---|---|---|---|

| PC | FA | Water | Sand | HRWR | PVA | |||

| SS | LSP | |||||||

| FA1.2_LSP0.0 | 570 | 684 | 332 | 432 | 0 | 9.0 | 26 | 27.1 |

| FA1.2_LSP0.5 | 570 | 684 | 332 | 218 | 218 | 10.1 | 26 | 27.6 |

| FA1.2_LSP1.0 | 570 | 684 | 332 | 0 | 440 | 10.3 | 26 | 27.5 |

| FA2.2_LSP0.0 | 392 | 862 | 331 | 402 | 0 | 6.5 | 26 | 27.0 |

| FA2.2_LSP0.5 | 392 | 862 | 331 | 202 | 202 | 7.2 | 26 | 27.2 |

| FA2.2_LSP1.0 | 392 | 862 | 331 | 0 | 408 | 7.3 | 26 | 27.1 |

| FA3.2_LSP0.0 | 299 | 955 | 329 | 386 | 0 | 6.5 | 26 | 27.2 |

| FA3.2_LSP0.5 | 299 | 955 | 329 | 194 | 194 | 6.6 | 26 | 27.9 |

| FA3.2_LSP1.0 | 299 | 955 | 329 | 0 | 392 | 6.7 | 26 | 27.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turk, K.; Kina, C.; Nehdi, M.L. Durability of Engineered Cementitious Composites Incorporating High-Volume Fly Ash and Limestone Powder. Sustainability 2022, 14, 10388. https://doi.org/10.3390/su141610388

Turk K, Kina C, Nehdi ML. Durability of Engineered Cementitious Composites Incorporating High-Volume Fly Ash and Limestone Powder. Sustainability. 2022; 14(16):10388. https://doi.org/10.3390/su141610388

Chicago/Turabian StyleTurk, Kazim, Ceren Kina, and Moncef L. Nehdi. 2022. "Durability of Engineered Cementitious Composites Incorporating High-Volume Fly Ash and Limestone Powder" Sustainability 14, no. 16: 10388. https://doi.org/10.3390/su141610388

APA StyleTurk, K., Kina, C., & Nehdi, M. L. (2022). Durability of Engineered Cementitious Composites Incorporating High-Volume Fly Ash and Limestone Powder. Sustainability, 14(16), 10388. https://doi.org/10.3390/su141610388