The Influence of Different Row Spacing and Weed Control Intervals on Weed Infestation and Yield-Related Traits of American (Gossypium hirsutum L.) and Desi (Gossypium arboreum) Cotton

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Details

2.2. Crop Husbandry

2.3. Data Recorded

2.3.1. Weeds Density

2.3.2. Allometric and Root Related Traits

2.3.3. Morphological and Yield Related Traits

2.4. Statistical Analysis

3. Results

3.1. Total and Individual Weed Density (m−2)

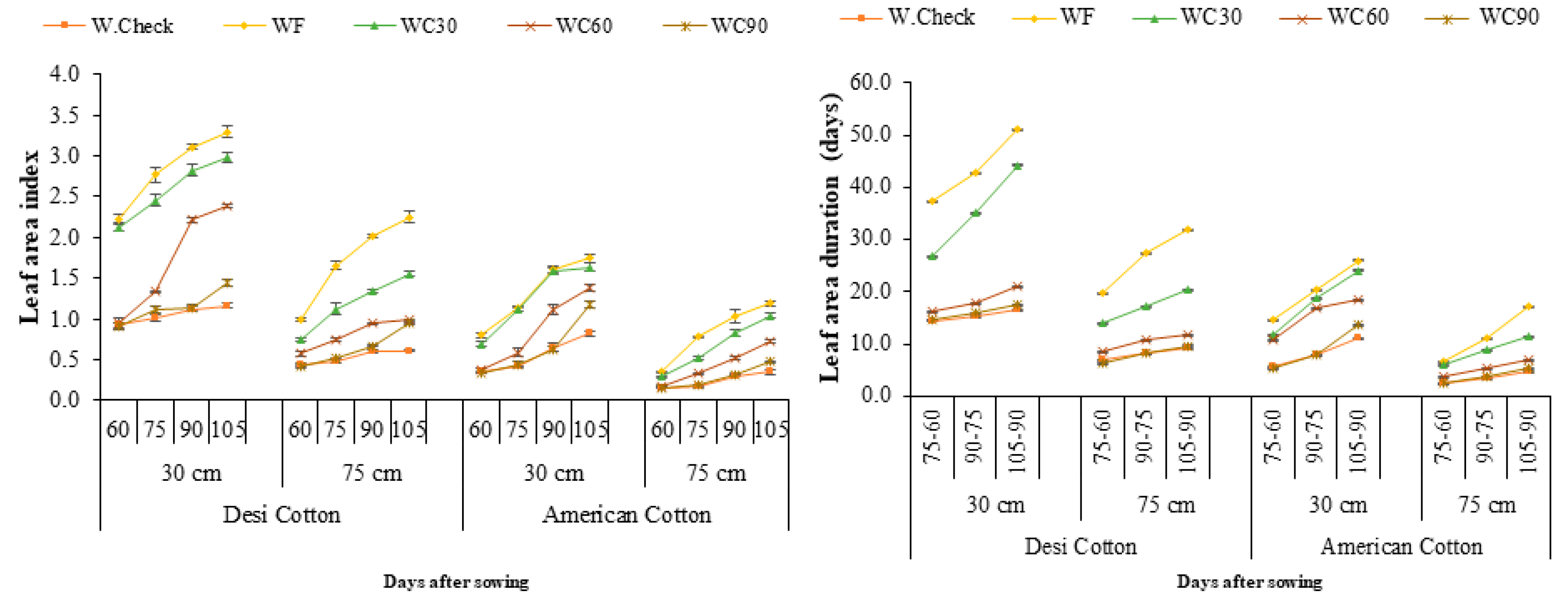

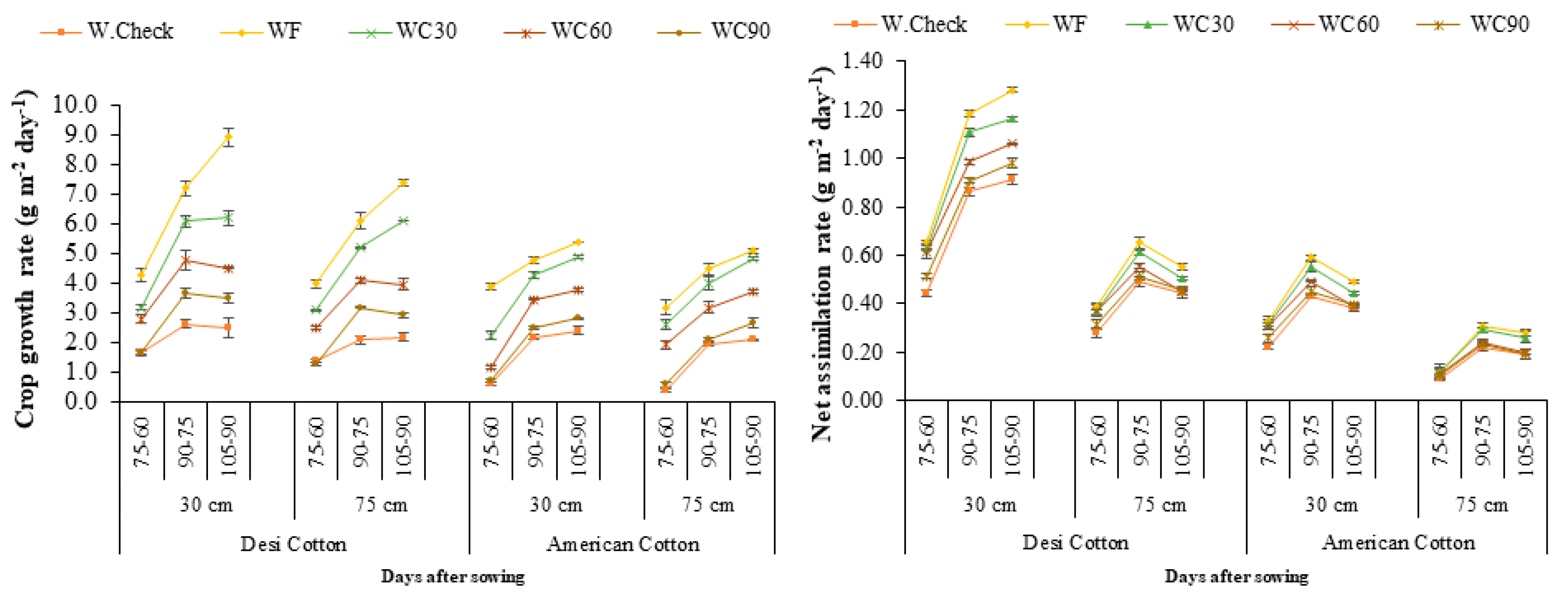

3.2. Allometric and Root Related Traits

3.3. Yield-Related Traits

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Karar, H.; Bashir, M.A.; Haider, M.; Haider, N.; Khan, K.A.; Ghramh, H.A.; Ansari, M.J.; Mutlu, Ç.; Alghanem, S.M. Pest Susceptibility, Yield and Fiber Traits of Transgenic Cotton Cultivars in Multan, Pakistan. PLoS ONE 2020, 15, e0236340. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, S.; Hasanuzzaman, M. (Eds.) Cotton Production and Uses; Springer Singapore: Singapore, 2020; ISBN 978-981-15-1471-5. [Google Scholar]

- Ali, H.; Sarwar, N.; Ahmad, S.; Farooq, O.; Nahar, K.; Hasanuzzaman, M. Cotton-Based Intercropping Systems. In Cotton Production and Uses; Springer: Singapore, 2020; pp. 321–340. [Google Scholar]

- Jabran, K.; Ul-Allah, S.; Chauhan, B.S.; Bakhsh, A. An Introduction to Global Production Trends and Uses, History and Evolution, and Genetic and Biotechnological Improvements in Cotton. In Cotton Production; Wiley: Hoboken, NJ, USA, 2019; pp. 1–22. [Google Scholar]

- GOP. Economic Survey of Pakistan; Economic Advisory Wing: Islamabad, Pakistan, 2021. [Google Scholar]

- FAO. Available online: www.faostat.fao.org (accessed on 12 December 2021).

- Nalini, K.; Murhukrishnan, P.; Chinnusamy, C.; Vennila, C. Weeds of Cotton—A Review. Agric. Rev. 2015, 36, 140. [Google Scholar] [CrossRef]

- Clements, D.R.; DiTommaso, A.; Hyvönen, T. Ecology and Management of Weeds in a Changing Climate. In Recent Advances in Weed Management; Springer New York: New York, NY, USA, 2014; pp. 13–37. ISBN 9781493910199. [Google Scholar]

- Tursun, N.; Datta, A.; Budak, S.; Kantarci, Z.; Knezevic, S.Z. Row Spacing Impacts the Critical Period for Weed Control in Cotton (Gossypium hirsutum). Phytoparasitica 2016, 44, 139–149. [Google Scholar] [CrossRef]

- Blaise, D.; Kranthi, K.R.; Ravindran, C.D.; Thalal, K. High Plant Density Can Improve the Productivity of Rainfed Asiatic Cotton (Gossypium arboreum L.). Arch. Agron. Soil Sci. 2021, 67, 607–619. [Google Scholar] [CrossRef]

- Chauhan, B.S.; Florentine, S.K.; Ferguson, J.C.; Chechetto, R.G. Implications of Narrow Crop Row Spacing in Managing Weeds in Mungbean (Vigna radiata). Crop Prot. 2017, 95, 116–119. [Google Scholar] [CrossRef]

- Jabran, K.; Chauhan, B.S. Overview and Significance of Non-Chemical Weed Control. In Non-Chemical Weed Control; Elsevier: Amsterdam, The Netherlands, 2018; ISBN 9780128098813. [Google Scholar]

- Hussain, M.; Farooq, S.; Merfield, C.; Jabran, K. Mechanical Weed Control. In Non-Chemical Weed Control; Elsevier: Amsterdam, The Netherlands, 2018; pp. 133–155. [Google Scholar]

- Chauhan, B.S.; Johnson, D.E. Weedy Rice (Oryza sativa) I. Grain Characteristics and Growth Response to Competition of Weedy Rice Variants from Five Asian Countries. Weed Sci. 2010, 58, 374–380. [Google Scholar] [CrossRef]

- Nadeem, M.A.; Ali, A.; Tahir, M.; Naeem, M.; Chadhar, A.R.; Sagheer, A. Effect of Nitrogen Levels and Plant Spacing on Growth and Yield of Cotton. Pak. J. Life Soc. Sci. 2010, 8, 121–124. [Google Scholar]

- Rajakumar, D.; Gurumurthy, S.; Pandian, B.J.; Thiyagarajan, G. Population Dynamics and Nutrient Spray on the Yield and Economics of Direct Sown and Transplanted Hybrid Cotton TCHB 213. Indian J. Agric. Res. 2010, 44, 206–210. [Google Scholar]

- Brodrick, R.; Bange, M.P.; Milroy, S.P.; Hammer, G.L. Physiological Determinants of High Yielding Ultra-Narrow Row Cotton: Canopy Development and Radiation Use Efficiency. Field Crop. Res. 2013, 148, 86–94. [Google Scholar] [CrossRef]

- Reddy, K.R.; Hodges, H.F. Climate Change and Global Crop Productivity; CABI: Wallingford, UK, 2000; ISBN 0851997090. [Google Scholar]

- Siebert, J.D.; Stewart, A.M.; Leonard, B.R. Comparative Growth and Yield of Cotton Planted at Various Densities and Configurations. Agron. J. 2006, 98, 562–568. [Google Scholar] [CrossRef]

- Darawsheh, M.K.; Khah, E.M.; Aivalakis, G.; Chachalis, D.; Sallaku, F. Cotton Row Spacing and Plant Density Cropping Systems. I. Effects on Accumulation and Partitioning of Dry Mass and LAI. J. Food Agric. Environ. 2009, 7, 258–261. [Google Scholar]

- Singh, R. Weed Management in Major Kharif and Rabi Crops. Natl. Train. Adv. Weed Manag. 2014, 31–40. [Google Scholar]

- Watson, D.J. Comparative Physiological Studies on the Growth of Field Crops: I. Variation in Net Assimilation Rate and Leaf Area between Species and Varieties, and within and between Years. Ann. Bot. 1947, 11, 41–76. [Google Scholar] [CrossRef]

- Hunt, R. Plant Growth Analysis; Institute of Terrestrial Ecology: Suffolk, UK, 1982; Volume 4, ISBN 090428266X. [Google Scholar]

- Beadle, C.L. Plant Growth Analysis. In Techniques in Bioproductivity and Photosynthesis; Elsevier: Amsterdam, The Netherlands, 1985; pp. 20–25. [Google Scholar]

- Shapiro, S.S.; Wilk, M.B. An Analysis of Variance Test for Normality (Complete Samples). Biometrika 1965, 52, 591–611. [Google Scholar] [CrossRef]

- Steel, R.G.D.; Torrie, J.H.; Dickey, D. Principles and Procedures of Statistics: A Biometrical Approach; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Mashingaidze, N.; Twomlow, S.J.; Hove, L. Crop and Weed Responses to Residue Retention and Method of Weeding in First Two Years of a Hoe-Based Minimum Tillage System in Semi-Arid Zimbabwe. J. SAT Agric. Res. 2009, 7, 1–11. [Google Scholar]

- Kulkarni, A.V.; Bahuguna, I.M.; Rathore, B.P. Application of Remote Sensing to Monitor Glaciers. NNRMS Bull. 2009, 79–82. [Google Scholar]

- Pettigrew, W.T.; Meredith, W.R., Jr. Genotypic Variation in Physiological Strategies for Attaining Cotton Lint Yield Production. J. Cotton Sci. 2012, 16, 179–189. [Google Scholar]

- Hamid, N.; Nabi, I.; Zafar, R. The Textiles and Garments Sector: Moving up the Value Chain. Lahore J. Econ. 2014, 19, 283. [Google Scholar] [CrossRef]

- Anjum, S.A.; Xie, X.Y.; Wang, L.C.; Saleem, M.F.; Man, C.; Lei, W. Morphological, Physiological and Biochemical Responses of Plants to Drought Stress. Afr. J. Agric. Res. 2011, 6, 2026–2032. [Google Scholar] [CrossRef]

- Khan, N.G.; Naveed, M.; Islam, N.U.; Iqbal, M.S. Assessment of New Upland Cotton Genotypes (Gossypium hirsutum L.) for Yield Stability and Adaptability. Asian J. Plant Sci. 2007, 6, 1012–1015. [Google Scholar] [CrossRef]

- Ali, H.; Afzal, M.N.; Muhammad, D. Effect of Sowing Dates and Plant Spacing on Growth and Dry Matter Partitioning in Cotton (Gossypium hirsutum L.). Pak. J. Bot. 2009, 41, 2145–2155. [Google Scholar]

- Adams, C.; Thapa, S.; Kimura, E. Determination of a Plant Population Density Threshold for Optimizing Cotton Lint Yield: A Synthesis. Field Crop. Res. 2019, 230, 11–16. [Google Scholar] [CrossRef]

- El Naim, A.M. Growth and Yield of Seed Cotton Response to Plant Spacing and Weeding Frequency under Flood Irrigation. J. Renew. Agric. 2013, 1, 27–32. [Google Scholar]

- Khanh, T.D.; Chung, M.I.; Xuan, T.D.; Tawata, S. The exploitation of crop allelopathy in sustainable agricultural production. J. Agron. Crop Sci. 2005, 191, 172–184. [Google Scholar] [CrossRef]

- Cheng, F.; Cheng, Z. Research progress on the use of plant allelopathy in agriculture and the physiological and ecological mechanisms of allelopathy. Front. Plant Sci. 2015, 6, 1020. [Google Scholar] [CrossRef]

- Naeem, M.; Farooq, M.; Farooq, S.; Ul-Allah, S.; Alfarraj, S.; Hussain, M. The impact of different crop sequences on weed infestation and productivity of barley (Hordeum vulgare L.) under different tillage systems. Crop Prot. 2021, 149, 105759. [Google Scholar] [CrossRef]

- Shahzad, M.; Hussain, M.; Jabran, K.; Farooq, M.; Farooq, S.; Gašparovič, K.; Aljuaid, B.S.; Shehawi, A.E.; Zuan, A.T.K. The impact of different crop rotations by weed management strategies’ interactions on weed infestation and productivity of wheat (Triticum aestivum L.). Agronomy 2021, 11, 2088. [Google Scholar] [CrossRef]

- Riaz Marral, M.W.; Khan, M.B.; Ahmad, F.; Farooq, S.; Hussain, M. The influence of transgenic (Bt) and non-transgenic (non-Bt) cotton mulches on weed dynamics, soil properties and productivity of different winter crops. PLoS ONE 2020, 15, e0238716. [Google Scholar] [CrossRef]

| Treatment | Trianthema portulacastrum | Cyperus rotundus | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Desi Cotton | American Cotton | Means WC | Desi Cotton | American Cotton | Means WC | |||||

| 30 cm | 75 cm | 30 cm | 75 cm | 30 cm | 75 cm | 30 cm | 75 cm | 30 cm | ||

| 45 DAS | ||||||||||

| WC | 10.67 e | 11.67 c–e | 16.33 ab | 11.67 c–e | 12.58 | 13.67 c | 16.00 a–c | 19.33 a | 14.67 c | 15.92 |

| WF | - | - | - | - | - | - | - | - | - | - |

| WC30 | 10.33 e | 16.33 ab | 12.00 b–e | 11.67 c–e | 12.55 | 13.33 c | 19.33 a | 15.00 bc | 14.67 c | 15.58 |

| WC60 | 11.00 e | 16.00 a–c | 11.67 c–e | 12.33 a–e | 12.75 | 16.00 a–c | 19.00 a | 14.67 c | 17.00 a–c | 16.67 |

| WC90 | 10.67 e | 16.67 a | 11.33 de | 15.6 a–d | 13.58 | 13.67 c | 19.67 a | 14.43 c | 18.67 ab | 16.58 |

| Means S | 9.40 B | 11.20 A | 12.00 B | 13.90 A | ||||||

| Means CT | 10.33 | 10.27 | 13.07 | 12.83 | ||||||

| LSD value at 5% for S = 1.45, WC = 2.29, CT = 1.45, S × WC × CT = 4.59 | LSD value at 5% for S = 1.22, WC = 1.92, CT = 1.21, S × WC × CT = 3.85 | |||||||||

| 60 DAS | ||||||||||

| WC | 15.67 cd | 16.00 b–d | 17.6 a–d | 19.67 ab | 17.25 | 22.67 cd | 23.00 b–d | 24.67 a–d | 26.67 ab | 24.25 |

| WF | - | - | - | - | - | - | - | - | - | - |

| WC30 | - | - | - | - | - | - | - | - | - | - |

| WC60 | 14.67 d | 17.33 a–d | 17.6 a–d | 20.33 a | 17.50 | 21.67 cd | 24.43 a–d | 24.67 a–d | 27.33 a | 24.50 |

| WC90 | 15.67 cd | 18.67 a–c | 17.6 a–d | 20.67 a | 18.17 | 22.67 cd | 25.67 a–c | 24.67 a–d | 27.67 a | 25.17 |

| Means S | 9.90 | 11.27 A | 14.20 B | 15.47 A | ||||||

| Means CT | 9.80 B | 11.37 A | 14.00 B | 15.57 A | ||||||

| LSD value at 5% for S = 1.17, WC = 1.85, CT = 1.16, S × WC × CT = 3.69 | LSD value at 5% for S = 1.17, WC = 1.85, CT = 0.71, S × WC × CT = 3.69 | |||||||||

| 90 DAS | ||||||||||

| WC | 19.67 e | 23.67 bc | 22.33 cd | 25.67 a | 22.83 | 23.67 d | 24.00 cd | 25.67 b–d | 27.67 ab | 25.25 |

| WF | - | - | - | - | - | - | - | - | - | - |

| WC30 | - | - | - | - | - | - | - | - | - | - |

| WC60 | - | - | - | - | - | - | - | - | - | - |

| WC90 | 19.67 e | 26.00 a | 21.00 de | 24.67 ab | 21.83 | 23.67 d | 26.67 a–c | 25.67 b–d | 28.67 a | 26.17 |

| Means S | 8.27 B | 10.00 A | 9.86 | 10.70 | ||||||

| Means CT | 8.90 | 9.37 | 9.80 B | 10. 77 A | ||||||

| LSD value at 5% for S = 0.61, WC = 0.97, CT = 0.61, S × WC × CT = 1.94 | LSD value at 5% for S = 0.91, WC = 1.43, CT = 0.90, S × WC × CT = 2.86 | |||||||||

| Treatment | Cynodon dactylon | Echinochloa colona | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Desi Cotton | American Cotton | Means WC | Desi Cotton | American Cotton | Means WC | |||||

| 30 cm | 75 cm | 30 cm | 75 cm | 30 cm | 75 cm | 30 cm | 75 cm | 30 cm | ||

| 45 DAS | ||||||||||

| WC | 4.67 ef | 6.00 b–e | 5.00 ef | 7.0 bc | 5.67 | 0.67 b–d | 0.67 b–d | 0.33 cd | 1.00 a–c | 0.67 |

| WF | - | - | - | - | - | - | - | - | - | - |

| WC30 | 5.00 ef | 5.67 c–e | 4.00 f | 7.0 bc | 5.42 | 1.33 ab | 1.00 a–c | 1.00 a–c | 1.67 a | 1.25 |

| WC60 | 5.67 c–e | 9.00 a | 6.0 b–e | 6.0 b–e | 6.58 | 0.67 b–d | 1.33 ab | 1.33 ab | 1.33 ab | 1.17 |

| WC90 | 4.00 f | 6.67 b–d | 5.33 d–f | 7.33 b | 5.83 | 0.67 b–d | 0.67 b–d | 1.67 a | 1.00 a–c | 1.00 |

| Means S | 3.93 B | 5.47 A | 0.77 | 0.87 | ||||||

| Means CT | 4.67 | 4.73 | 0.70 | 0.93 | ||||||

| LSD value at 5% for S = 0.46, WC = 0.73, CT = 0.46, S × WC × CT = 1.45 | LSD 5% for S = 0.30, WC = 0.48, CT = 0.71, S × WC × CT = 0.97 | |||||||||

| 60 DAS | ||||||||||

| WC | 9.33 d | 11.00 c | 11.00 c | 13.00 b | 11.08 | 2.33 bc | 2.11 d | 2.33 bc | 1.67 c | 2.17 |

| WF | - | - | - | - | - | - | - | - | - | - |

| WC30 | - | - | - | - | - | - | - | - | - | - |

| WC60 | 9.67 d | 12.00 bc | 12.00 bc | 14.67 a | 12.08 | 1.67 c | 3.67 a | 2.33 bc | 3.67 a | 2.83 |

| WC90 | 9.00 d | 13.00 b | 11.00 c | 15.00 a | 12.00 | 2.00 bc | 4.00 a | 2.67 b | 4.00 a | 3.17 |

| Means S | 6.20 B | 7.87 A | 1.33 B | 1.93 A | ||||||

| Means CT | 6.40 B | 7.67 A | 1.60 | 1.67 | ||||||

| LSD value at 5% for S = 0.38, WC = 0.60, CT = 0.37, S × WC × CT = 1.19 | LSD value at 5% for S = 0.29, WC = 0.46, C = 0.29, S × WC × CT = 0.92 | |||||||||

| 90 DAS | ||||||||||

| WC | 14.00 de | 15.67 bc | 14.6 c–e | 18.00 a | 15.58 | 2.67 e | 5.00 c | 4.00 d | 8.00 a | 4.92 |

| WF | - | - | - | - | - | - | - | - | - | - |

| WC30 | - | - | - | - | - | - | - | - | - | - |

| WC60 | - | - | - | - | - | - | - | - | - | - |

| WC90 | 13.67 e | 15.00 b–d | 16.00 b | 17.33 a | 15.50 | 3.00 e | 6.00 b | 5.67 bc | 6.33 b | 5.25 |

| RS means | 5.83 B | 6.60 A | 1.53 B | 2.53 A | ||||||

| CT means | 5.83 B | 6.60 A | 1.67 B | 2.40 A | ||||||

| LSD value at 5% for S = 0.19, WC = 0.62, CT = 0.39, S × WC × CT = 1.24 | LSD 5% for S= 0.29, WC= 0.46, CT = 0.29, S × WC × CT = 0.92 | |||||||||

| Treatment | Digera muricata | Total Weed Density | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Desi Cotton | American Cotton | Means WC | Desi Cotton | American Cotton | Means WC | |||||

| 30 cm | 75 cm | 30 cm | 75 cm | 30 cm | 75 cm | 30 cm | 75 cm | 30 cm | ||

| 45 DAS | ||||||||||

| WC | 2.67 ef | 4.00 a–e | 3.00 d–f | 5.00 ab | 3.67 | 32.33 d | 34.00 b–d | 44.00 a–c | 39.33 a–d | 38.17 |

| WF | - | - | - | - | - | - | - | - | - | - |

| WC30 | 3.00 d–f | 4.43 a–d | 2.00 f | 5.00 ab | 3.58 | 33.00 d | 43.67 ab | 34.00 cd | 40.00 a–d | 38.42 |

| WC60 | 3.33 c–f | 4.00 a–e | 4.00 a–e | 4.00 a–e | 3.75 | 34.67 cd | 45.33 a | 37.00 b–d | 39.00 a–d | 40.00 |

| WC90 | 2.00 f | 4.67 a–c | 3.33 c–f | 5.33 a | 3.83 | 31.00 d | 44.43 a | 36.00 b–d | 48.00 a | 40.83 |

| Means S | 2.30 B | 3.63 A | 28.20 B | 34.77 A | ||||||

| Means CT | 2.80 | 3.13 | 27.23 B | 31.23 A | ||||||

| LSD 5% for S = 0.49, WC = 1.12, CT = 0.49, S × WC × CT = 1.58 | LSD 5% for S = 3.39, WC = 2.64, CT = 3.39, S × WC × CT = 2.24 | |||||||||

| 60 DAS | ||||||||||

| WC | 9.00 d–f | 9.00 d–f | 11.6 a–c | 9.67 c–e | 9.83 | 59.0 e–g | 61.33 d–g | 67.33 b–d | 70.67 a–c | 64.58 |

| WF | - | - | - | - | - | - | - | - | - | - |

| WC30 | - | - | - | - | - | - | - | - | - | - |

| WC60 | 7.33 f | 12.00 ab | 9.00 d–f | 8.33 ef | 9.17 | 55.00 g | 69.33 b–d | 65.67 c–e | 74.43 ab | 66.08 |

| WC90 | 8.00 ef | 13.00 a | 8.33 ef | 10.6 b–d | 10.00 | 57.33 fg | 74.43 ab | 64.43 c–f | 78.00 a | 68.50 |

| Means S | 5.33 B | 6.27 A | 36.87 B | 42.80 A | ||||||

| Means CT | 5.83 | 5.77 | 37.63 B | 42.03 A | ||||||

| LSD 5% for S = 0.71, WC = 1.12, CT = 0.71, S × WC × CT = 2.24 | LSD 5% for S = 2.58, WC = 2.58, CT = 0.71, S × WC × CT = 3.24 | |||||||||

| 90 DAS | ||||||||||

| WC | 10. 67 de | 12.33 c | 12.67 bc | 14.43 a | 12.50 | 70.67 e | 84.43 c | 80 d | 95.67 a | 82.67 |

| WF | - | - | - | - | - | - | - | - | - | - |

| WC30 | - | - | - | - | - | - | - | - | - | - |

| WC60 | - | - | - | - | - | - | - | - | - | - |

| WC90 | 10.00 e | 14.00 ab | 12.00 cd | 15.33 a | 12.83 | 70 e | 91.00 b | 79.67 e | 92.33 ab | 83.25 |

| Means S | 4.53 B | 5.60 A | 30.03 B | 36.33 A | ||||||

| Means CT | 4.70 B | 5.43 A | 31.60 B | 34.77 A | ||||||

| LSD 5% for S = 0.51, WC = 0.80, CT = 0.71, S × WC × CT = 1.61 | LSD 5% for S = 1.36, WC = 2.16, CT = 1.37, S × WC × CT = 4.43 | |||||||||

| Treatments | Number of Monopodial Branches Plant−1 | Number of Sympodial Branches Plant−1 | Number of Flowers Plant−1 | ||||||||||||

| Desi Cotton | American Cotton | Means WC | Desi Cotton | American Cotton | Means WC | Desi Cotton | American Cotton | Means WC | |||||||

| 30 cm | 75 cm | 30 cm | 75 cm | 30 cm | 75 cm | 30 cm | 75 cm | 30 cm | 75 cm | 30 cm | 75 cm | ||||

| WC | 8.67 g–i | 10.67 fg | 5.67 l | 6.67 kl | 7.92 E | 28.67 g–i | 36.67 ef | 16.67 l | 20.67 kl | 25.67 E | 65.33 i | 72.0 h | 17.0 n | 18.33 mn | 43.17 E |

| WF | 15.00 c | 18.67 a | 8.33 h–j | 9.33 gh | 12.83 A | 54.00 c | 68.67 a | 27.33 h–j | 31.33 gh | 45.33 A | 197.0 b | 207.0 a | 27.0 k | 30.00 j | 115.25 A |

| WC30 | 13.67 d | 17.00 b | 7.33 jk | 8.33 h–j | 11.58 B | 48.67 d | 62.00 b | 23.33 jk | 27.33 h–j | 40.33 B | 185.0 d | 192.0 c | 25.0 kl | 27.33 k | 107.42 B |

| WC60 | 11.33 e | 15.33 c | 6.67 kl | 7.67 i–k | 10.25 C | 39.33 e | 55.33 c | 20.67 kl | 24.67 i–k | 35.00 C | 95.0 f | 133.0 e | 20.67 m | 23.33 l | 68.00 C |

| WC90 | 9.67 fg | 13.00 d | 5.67 l | 6.67 kl | 8.75 D | 32.67 fg | 46.00 d | 16.67 l | 20.67 kl | 29.67 D | 74.0 h | 87.0 g | 17.67 n | 19.00 mn | 49.17 D |

| Means S | 9.20 B | 11.33 A | 30.80 B | 39.33 A | 72.4 B | 80.90 A | |||||||||

| Means CT | 13.30 A | 7.23 B | 47.20 A | 22.93 B | 130.77 A | 22.53 B | |||||||||

| LSD 5% S = 0.37, WC = 0.58, CT = 0.36, S × WC × CT = 1.16 | LSD 5% S = 1.47, WC = 2.33, CT = 2.33, S × WC × CT = 4.66 | LSD 5% for S = 0.84, WC =1.32, CT = 0.83, S × WC × CT = 2.64 | |||||||||||||

| Treatments | Number of Bolls Plant−1 | Seed Cotton Yield (kg ha−1) | ||||||||

| Desi Cotton | American Cotton | Means WC | Desi Cotton | American Cotton | Means WC | |||||

| 30 cm | 75 cm | 30 cm | 75 cm | 30 cm | 75 cm | 30 cm | 75 cm | |||

| WC | 69.00 h | 82.00 f | 38.00 o | 45.67 m | 58.67 E | 744.70 p | 717.20 q | 713.90 q | 579.40 s | 688.8 E |

| WF | 144.43 a | 130.00 b | 61.33 j | 66.33 i | 93.00 A | 1543.30 a | 1477.21 b | 1285.00 e | 1165.30 f | 1367.7 A |

| WC30 | 107.00 d | 119.33 c | 56.00 k | 56.00 k | 84.58 B | 1461.40 c | 1357.22 d | 1051.10 h | 983.30 j | 1213.3 B |

| WC60 | 83.00 f | 94.00 e | 44.67 m | 50.67 l | 68.08 C | 1111.11 g | 1026.10 i | 873.11 l | 755.00 o | 941.3 C |

| WC90 | 79.00 g | 83.33 f | 41.00 n | 46.67 m | 62.50 D | 958.67 k | 850.61 m | 791.91 n | 687.8 r | 822.2 D |

| Means S | 69.33 B | 77.40 A | 1053.4 A | 959.9 B | ||||||

| Means CT | 96.10 A | 50.63 B | 1124.8 A | 888.6 B | ||||||

| LSD 5% for S = 0.71, W = 1.12, C = 0.71, S × W × C = 2.24 | LSD value at 5% for S = 1.44, W = 2.28, C = 1.44, S × W × C = 4.56 | |||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, M.; Abbas, M.H.; Majeed, A.; Minhas, W.A.; Farooq, S.; Jabran, K. The Influence of Different Row Spacing and Weed Control Intervals on Weed Infestation and Yield-Related Traits of American (Gossypium hirsutum L.) and Desi (Gossypium arboreum) Cotton. Sustainability 2022, 14, 9867. https://doi.org/10.3390/su14169867

Hussain M, Abbas MH, Majeed A, Minhas WA, Farooq S, Jabran K. The Influence of Different Row Spacing and Weed Control Intervals on Weed Infestation and Yield-Related Traits of American (Gossypium hirsutum L.) and Desi (Gossypium arboreum) Cotton. Sustainability. 2022; 14(16):9867. https://doi.org/10.3390/su14169867

Chicago/Turabian StyleHussain, Mubshar, Muhammad Haider Abbas, Abdul Majeed, Waqas Ahmed Minhas, Shahid Farooq, and Khawar Jabran. 2022. "The Influence of Different Row Spacing and Weed Control Intervals on Weed Infestation and Yield-Related Traits of American (Gossypium hirsutum L.) and Desi (Gossypium arboreum) Cotton" Sustainability 14, no. 16: 9867. https://doi.org/10.3390/su14169867

APA StyleHussain, M., Abbas, M. H., Majeed, A., Minhas, W. A., Farooq, S., & Jabran, K. (2022). The Influence of Different Row Spacing and Weed Control Intervals on Weed Infestation and Yield-Related Traits of American (Gossypium hirsutum L.) and Desi (Gossypium arboreum) Cotton. Sustainability, 14(16), 9867. https://doi.org/10.3390/su14169867