Circular Economy of Construction and Demolition Wood Waste—A Theoretical Framework Approach

Abstract

:1. Introduction

1.1. Amount of CDWW Generation

1.2. Types of Wood Waste

1.2.1. Untreated Wood Waste

1.2.2. Engineered Wood Waste (EWW)

1.2.3. Preservative-Treated or Painted Wood Waste

1.3. Physical Form of Wood Waste

1.4. Circular Economy (CE) and Wood Waste

2. Research Methodology

2.1. Literature Selection and Analysis Procedure

- The duplicate literature was excluded using the reference management software CiteSpace 5.7.R1. After the removal of duplicates, 52 remained.

- After reading and analysing the abstracts, keywords, and titles, only the studies related to wood waste management, LCA, and CE of wood waste were included. Consequently, 49 articles remained for further analysis and investigation.

2.2. Mapping the Content through CiteSpace Software

3. Result and Discussion

3.1. Keyword Co-Occurrence Network and Timeline View Analysis

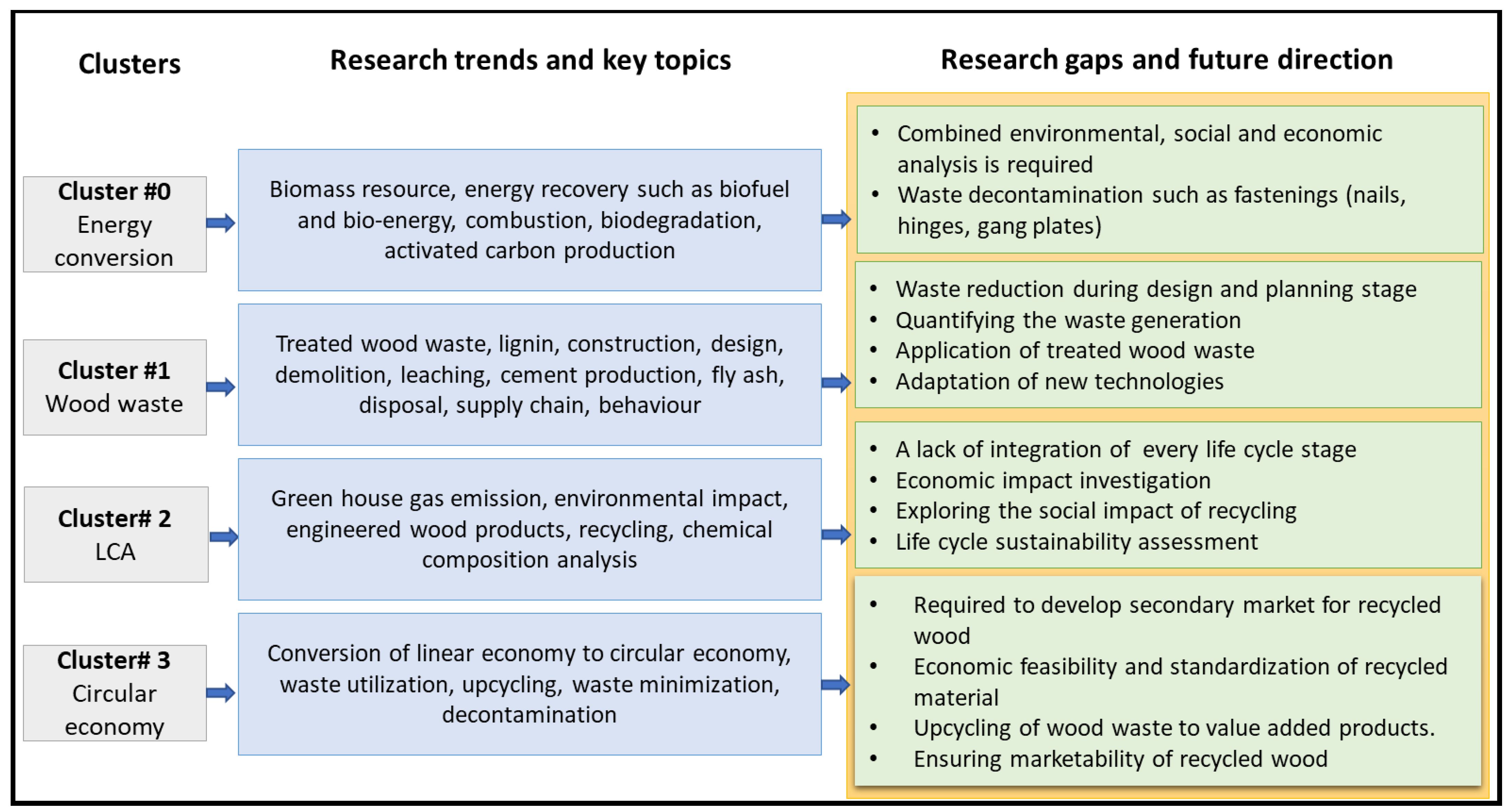

3.2. Cluster Analysis

4. Discussion

4.1. A Theoretical Framework for CDWW

4.1.1. Raw Material Extraction

4.1.2. Pre-Construction Phase

Application of BIM for Waste Prevention and Minimization

Application of Prefabricated Elements

4.1.3. Construction and Operation Phase

4.1.4. Renovation or Demolition Phase

4.1.5. Reuse Recycling or Energy Recovery

Reuse of Wood Waste

Recycling of Wood Waste

Energy Recovery

Dumping to Landfill

Transport of Waste Material

4.1.6. Marketability of Developed Material from CDWW

Recycled and Recovered Materials

Developed Products from CDWW Research and Innovation

4.2. CE Adaptation for Environmental, Economic, and Social Benefits

4.2.1. Reduction of GHG Emissions and Deforestation

4.2.2. Mitigating Climate Change

4.2.3. Economic Benefits

4.2.4. Social Benefits

5. Research Gaps and Future Directions

6. Conclusions and Recommendations

- While the planning for waste prevention and reduction can reduce wastage significantly, the application of BIM and prefabricated elements can reduce wastage further in the pre-construction stage.

- As demolition projects produce huge wood waste, pre-demolition audits for reusable materials, selective deconstruction, and source separation of treated and untreated wood waste can improve recovery and waste utilisation.

- The LCA studies are limited to environmental viewpoints while integrating economic and social perspectives can bring sustainable development and CE implementation.

- More studies are still required to integrate the management side (collection, sorting, separation) and end-of-life scenarios for CDWW.

- The construction industries and the government need to be proactive and evaluate the benefits of reuse, recycling, and recovery of wood waste materials to implement CE into actual practice.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yuan, H.; Shen, L. Trend of the research on construction and demolition waste management. Waste Manag. 2011, 31, 670–679. [Google Scholar] [CrossRef] [PubMed]

- Tam, V.W.; Tam, C.M. Evaluations of existing waste recycling methods: A Hong Kong study. Build. Environ. 2006, 41, 1649–1660. [Google Scholar] [CrossRef]

- Wu, H.; Zuo, J.; Yuan, H.; Zillante, G.; Wang, J. A review of performance assessment methods for construction and demolition waste management. Resour. Conserv. Recycl. 2019, 150, 104407. [Google Scholar] [CrossRef]

- Shen, L.Y.; Tam, V.W.Y.; Tam, C.M.; Drew, D. Mapping Approach for Examining Waste Management on Construction Sites. J. Constr. Eng. Manag. 2004, 130, 472–481. [Google Scholar] [CrossRef]

- Geng, S.; Wang, Y.; Zuo, J.; Zhou, Z.; Du, H.; Mao, G. Building life cycle assessment research: A review by bibliometric analysis. Renew. Sustain. Energy Rev. 2017, 76, 176–184. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ji, X.; Liu, G.; Ulgiati, S. Evaluating the transition towards cleaner production in the construction and demolition sector of China: A review. J. Clean. Prod. 2018, 195, 418–434. [Google Scholar] [CrossRef]

- Jin, R.; Yuan, H.; Chen, Q. Science mapping approach to assisting the review of construction and demolition waste management research published between 2009 and 2018. Resour. Conserv. Recycl. 2019, 140, 175–188. [Google Scholar] [CrossRef]

- Borzęcki, K.; Pudełko, R.; Kozak, M.; Borzęcka, M.; Faber, A. Spatial distribution of wood waste in Europe. Sylwan 2018, 162, 563–571. [Google Scholar]

- Bratkovich, S.T.; Howe, J.E.; Bowyer, J.; Pepke, E.; Frank, M.A.; Fernholz, K.A. Municipal Solid Waste (Msw) and Construction and Demolition (C&D) Wood Waste Generation and Recovery in the United States; Dovetail Partners, Inc.: Minneapolis, MN, USA, 2014; Available online: https://www.dovetailinc.org/upload/tmp/1580133530.pdf (accessed on 25 July 2022).

- Falk, R.H.; McKeever, D.B. Recovering wood for reuse and recycling: A United States perspective. In Proceedings of the European COST E31 Conference: Management of Recovered Wood Recycling Bioenergy and Other Options, Thessaloniki, Greece, 22–24 April 2004; University Studio Press: Thessaloniki, Greece, 2004; pp. 29–40. [Google Scholar]

- Weitz, A.P.K. Samantha Sifleet. In Wood Waste Inventory: Final Report; U.S.E.P. Agency: Research Triangle Park, NC, USA, 2018; p. 88. [Google Scholar]

- Recycling Wood in the UK. Available online: https://communitywoodrecycling.org.uk/what-we-do/recycling-wood-in-the-uk/ (accessed on 8 July 2022).

- Environmental Protection Department. Monitoring of Solid Waste in Hong Kong; Environmental Protection Department: Hong Kong, China, 2020; p. 6. [Google Scholar]

- Taylor, J.; Warnken, M. Wood Recovery and Recycling: A Source Book for Australia; Forest and Wood Products Australia: Melbourne VIC, Australia, 2008. [Google Scholar]

- Sustainability Victoria. Factsheet: Market Summary-Recycled Timber; Netbalance: Melbourne, VIC, Australia, 2015; pp. 1–5. Available online: https://docslib.org/market-summary-recycled-timber (accessed on 25 July 2022).

- Pickin, J.; Jenkins-Jaiswal, T. National Waste Data and Reporting Cycle 2017–2019; The Blue Environment Pty Ltd.: Docklands, VIC, Australia, 2018; p. 863. [Google Scholar]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete—A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar]

- Cavalline, T.L.; Weggel, D.C. Recycled Brick Masonry Aggregate Concrete; Emerald Group Publishing Limited: Bingley, UK, 2013. [Google Scholar]

- Herrador, R.; Pérez, P.; Garach, L.; Ordóñez, J. Use of Recycled Construction and Demolition Waste Aggregate for Road Course Surfacing. J. Transp. Eng. 2012, 138, 182–190. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Wu, H.; Zuo, J.; Zillante, G.; Wang, J.; Yuan, H. Status quo and future directions of construction and demolition waste research: A critical review. J. Clean. Prod. 2019, 240, 118163. [Google Scholar] [CrossRef]

- Ximenes, F.; Björdal, C.; Cowie, A.; Barlaz, M. The decay of wood in landfills in contrasting climates in Australia. Waste Manag. 2015, 41, 101–110. [Google Scholar] [CrossRef]

- Shahidul, M.; Malcolm, M.L.; Hashmi, M.S.; Alhaji, M.H. Waste Resources Recycling in Achieving Economic and Environmental Sustainability: Review on Wood Waste Industry. In Reference Module in Materials Science and Materials Engineering; Digital Science & Research Solutions, Inc.: Cambridge, MA, USA, 2018; Volume 10, pp. 965–974. Available online: https://www.researchgate.net/publication/329284965_Waste_Resources_Recycling_in_Achieving_Economic_and_Environmental_Sustainability_Review_on_Wood_Waste_Industry (accessed on 25 July 2022).

- Shahiduzzaman, M.; Layton, A.; Alam, K. Decomposition of energy-related CO2 emissions in Australia: Challenges and policy implications. Econ. Anal. Policy 2015, 45, 100–111. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Fleminga, L.Y.P.; Densley-Tingleye, D.; Scherman, O.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Ximenes, F.A.; Cowie, A.L.; Barlaz, M.A. The decay of engineered wood products and paper excavated from landfills in Australia. Waste Manag. 2018, 74, 312–322. [Google Scholar] [CrossRef]

- Global Timber Outlook. Available online: https://greshamhouse.com/wp-content/uploads/2020/07/GHGTO2020FINAL.pdf (accessed on 15 August 2020).

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The Circular Economy–A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Elle MacArthur Fundation. Towards the Circular Economy, Economic and Business Rationale for an Accelerated Transition; Elle MacArthur Fundation: Cowes, UK, 2013; pp. 21–34. [Google Scholar]

- Araújo, C.K.D.C.; Salvador, R.; Piekarski, C.M.; Sokulski, C.C.; de Francisco, A.C.; Camargo, S.K.D.C.A. Circular Economy Practices on Wood Panels: A Bibliographic Analysis. Sustainability 2019, 11, 1057. [Google Scholar] [CrossRef]

- Kampelmann, S. Wood works: How local value chains based on urban forests contribute to place-based circular economy. Urban Geogr. 2020, 41, 911–914. [Google Scholar] [CrossRef]

- Diaz, M.A.H.; Scouse, A.; Kelley, S.S. Environmental full cost accounting of alternative materials used for railroad ties: Treated-wood and concrete case study. J. Clean. Prod. 2022, 364, 132536. [Google Scholar] [CrossRef]

- Rabbat, C.; Awad, S.; Villot, A.; Rollet, D.; Andrès, Y. Sustainability of biomass-based insulation materials in buildings: Current status in France, end-of-life projections and energy recovery potentials. Renew. Sustain. Energy Rev. 2022, 156, 111962. [Google Scholar] [CrossRef]

- Dias, S.; Almeida, J.; Santos, B.; Humbert, P.; Tadeu, A.; António, J.; Brito, J.; Pinhãoe, P. Lightweight cement composites containing end-of-life treated wood–Leaching, hydration and mechanical tests. Constr. Build. Mater. 2022, 317, 125931. [Google Scholar] [CrossRef]

- da Rosa Azambuja, R.; de Castro, V.G.; Trianoski, R.; Iwakiri, S. Recycling wood waste from construction and demolition to produce particleboards. Maderas. Cienc. Tecnol. 2018, 20, 681–690. [Google Scholar] [CrossRef]

- Choong, J.E.; Onn, C.C.; Yusoff, S.; Mohd, N.S. Life Cycle Assessment of Waste-to-Energy: Energy Recovery from Wood Waste in Malaysia. Pol. J. Environ. Stud. 2019, 28, 2593–2602. [Google Scholar] [CrossRef]

- Chen, C. Technology, CiteSpace II: Detecting and visualizing emerging trends and transient patterns in scientific literature. J. Am. Soc. Inf. Sci. Technol. 2006, 57, 359–377. [Google Scholar] [CrossRef]

- Janin, A.; Blais, J.-F.; Mercier, G.; Drogui, P. Optimization of a chemical leaching process for decontamination of CCA-treated wood. J. Hazard. Mater. 2009, 169, 136–145. [Google Scholar] [CrossRef]

- Hossain, M.U.; Leu, S.Y.; Poon, C.S. Sustainability analysis of pelletized bio-fuel derived from recycled wood product wastes in Hong Kong. J. Clean. Prod. 2016, 113, 400–410. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.; Cheng, J.C. Comparative LCA on using waste materials in the cement industry: A Hong Kong case study. Resour. Conserv. Recycl. 2017, 120, 199–208. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S. Poon, Comparative LCA of wood waste management strategies generated from building construction activities. J. Clean. Prod. 2018, 177, 387–397. [Google Scholar] [CrossRef]

- Hossain, M.U.; Wang, L.; Iris, K.M.; Tsang, D.C.; Poon, C.S. Environmental and technical feasibility study of upcycling wood waste into cement-bonded particleboard. Constr. Build. Mater. 2018, 173, 474–480. [Google Scholar] [CrossRef]

- Kim, M.H.; Jeong, I.T.; Park, S.B.; Kim, J.W. Analysis of environmental impact of activated carbon production from wood waste. Environ. Eng. Res. 2018, 24, 117–126. [Google Scholar] [CrossRef]

- Kim, M.H.; Song, H.B. Analysis of the global warming potential for wood waste recycling systems. J. Clean. Prod. 2014, 69, 199–207. [Google Scholar] [CrossRef]

- Heidari, A.; Khaki, E.; Younesi, H.; Lu, H.R. Evaluation of fast and slow pyrolysis methods for bio-oil and activated carbon production from eucalyptus wastes using a life cycle assessment approach. J. Clean. Prod. 2019, 241, 118394. [Google Scholar] [CrossRef]

- Silva, D.A.L.; Lahr, F.A.R.; Garcia, R.P.; Freire, F.M.C.S.; Ometto, A.R. Life cycle assessment of medium density particleboard (MDP) produced in Brazil. Int. J. Life Cycle Assess. 2013, 18, 1404–1411. [Google Scholar] [CrossRef]

- Corona, B.; Shen, L.; Sommersacher, P.; Junginger, M. Consequential Life Cycle Assessment of energy generation from waste wood and forest residues: The effect of resource-efficient additives. J. Clean. Prod. 2020, 259, 120948. [Google Scholar] [CrossRef]

- Risse, M.; Weber-Blaschke, G.; Richter, K. Richter, Eco-efficiency analysis of recycling recovered solid wood from construction into laminated timber products. Sci. Total Environ. 2019, 661, 107–119. [Google Scholar] [CrossRef]

- Faraca, G.; Tonini, D.; Astrup, T.F. Dynamic accounting of greenhouse gas emissions from cascading utilisation of wood waste. Sci. Total Environ. 2019, 651, 2689–2700. [Google Scholar] [CrossRef]

- Reed, D.; Bergman, R.; Kim, J.-W.; Taylor, A.; Harper, D.; Jones, D.; Knowles, C.; Puettmann, M.E. Cradle-to-Gate Life-Cycle Inventory and Impact Assessment of Wood Fuel Pellet Manufacturing from Hardwood Flooring Residues in the Southeastern United States. For. Prod. J. 2012, 62, 280–288. [Google Scholar] [CrossRef]

- Katers, J.F.; Snippen, A.J.; Puettmann, M.E. Life-Cycle Inventory of Wood Pellet Manufacturing and Utilization in Wisconsin. For. Prod. J. 2012, 62, 289–295. [Google Scholar] [CrossRef]

- Zhang, Y.; McKechnie, J.; Cormier, D.; Lyng, R.; Mabee, W.; Ogino, A.; MacLean, H.L. Life Cycle Emissions and Cost of Producing Electricity from Coal, Natural Gas, and Wood Pellets in Ontario, Canada. Environ. Sci. Technol. 2010, 44, 538–544. [Google Scholar] [CrossRef] [PubMed]

- Bais-Moleman, A.L.; Sikkema, R.; Vis, M.; Reumerman, P.; Theurl, M.C.; Erb, K.-H. Assessing wood use efficiency and greenhouse gas emissions of wood product cascading in the European Union. J. Clean. Prod. 2018, 172, 3942–3954. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, L.; Chang, Y.; Pang, M. Biomass direct-fired power generation system in China: An integrated energy, GHG emissions, and economic evaluation for Salix. Energy Policy 2015, 84, 155–165. [Google Scholar] [CrossRef]

- Nuss, P.; Gardner, K.H.; Jambeck, J.R. Comparative Life Cycle Assessment (LCA) of Construction and Demolition (C&D) Derived Biomass and U.S. Northeast Forest Residuals Gasification for Electricity Production. Environ. Sci. Technol. 2013, 47, 3463–3471. [Google Scholar] [PubMed]

- Perilhon, C.; Alkadee, D.; Descombes, G.; Lacour, S. Life Cycle Assessment Applied to Electricity Generation from Renewable Biomass. Energy Procedia 2012, 18, 165–176. [Google Scholar] [CrossRef]

- Merrild, H.; Christensen, T.H. Recycling of wood for particle board production: Accounting of greenhouse gases and global warming contributions. Waste Manag. Res. 2009, 27, 781–788. [Google Scholar] [CrossRef]

- Rivela, B.; Moreira, M.T.; Muñoz, I.; Rieradevall, J.; Feijoo, G. Life cycle assessment of wood wastes: A case study of ephemeral architecture. Sci. Total Environ. 2006, 357, 1–11. [Google Scholar] [CrossRef]

- Wilson, J.B. Life-cycle inventory of particleboard in terms of resources, emissions, energy and carbon. Wood Fiber Sci. 2010, 42, 90–106. [Google Scholar]

- Azambuja, R.D.R.; de Castro, V.G.; Trianoski, R.; Iwakiri, S. Utilization of construction and demolition waste for particleboard production. J. Build. Eng. 2018, 20, 488–492. [Google Scholar] [CrossRef]

- Silva, D.A.L.; Lahr, F.A.R.; Varanda, L.D.; Christoforo, A.L.; Ometto, A.R. Environmental performance assessment of the melamine-urea-formaldehyde (MUF) resin manufacture: A case study in Brazil. J. Clean. Prod. 2015, 96, 299–307. [Google Scholar] [CrossRef]

- Jia, L.; Chu, J.; Ma, L.; Qi, X.; Kumar, A. Life Cycle Assessment of Plywood Manufacturing Process in China. Int. J. Environ. Res. Public Health 2019, 16, 2037. [Google Scholar] [CrossRef] [PubMed]

- Basalp, D.; Tihminlioglu, F.; Sofuoglu, S.C.; Inal, F.; Sofuoglu, A. Utilization of Municipal Plastic and Wood Waste in Industrial Manufacturing of Wood Plastic Composites. Waste Biomass-Valorization 2020, 11, 5419–5430. [Google Scholar] [CrossRef]

- Berger, F.; Gauvin, F.; Brouwers, H. The recycling potential of wood waste into wood-wool/cement composite. Constr. Build. Mater. 2020, 260, 119786. [Google Scholar] [CrossRef]

- Caldas, L.R.; Saraiva, A.B.; Lucena, A.F.; Da Gloria, M.Y.; Santos, A.S.; Filho, R.D.T. Building materials in a circular economy: The case of wood waste as CO2-sink in bio concrete. Resour. Conserv. Recycl. 2021, 166, 105346. [Google Scholar] [CrossRef]

- Augaitis, N.; Vaitkus, S.; Członka, S.; KAIRYTĖ, A. Research of Wood Waste as a Potential Filler for Loose-Fill Building Insulation: Appropriate Selection and Incorporation into Polyurethane Biocomposite Foams. Materials 2020, 13, 5336. [Google Scholar] [CrossRef]

- Souza, A.M.; Nascimento, M.F.; Almeida, D.H.; Silva, D.A.L.; Almeida, T.H.; Christoforo, A.L.; Lahr, F.A.R. Wood-based composite made of wood waste and epoxy based ink-waste as adhesive: A cleaner production alternative. J. Clean. Prod. 2018, 193, 549–562. [Google Scholar] [CrossRef]

- Sommerhuber, P.F.; Wang, T.; Krause, A. Wood–plastic composites as potential applications of recycled plastics of electronic waste and recycled particleboard. J. Clean. Prod. 2016, 121, 176–185. [Google Scholar] [CrossRef]

- Abreu, L.B.D.; Mendes, L.M.; Silva, J.R.M.D. Silva, Small objetcs manufactured with wood panel residues generated by rhe furniture industry. Rev. Árvore 2009, 33, 171–177. [Google Scholar] [CrossRef]

- Daian, G.; Ozarska, B. Wood waste management practices and strategies to increase sustainability standards in the Australian wooden furniture manufacturing sector. J. Clean. Prod. 2009, 17, 1594–1602. [Google Scholar] [CrossRef]

- Department, F.F. Global Forest Products Facts and Figures; FAO: Rome, Italy, 2017. [Google Scholar]

- Köhl, M.; Lasco, R.; Cifuentes, M.; Jonsson, Ö.; Korhonen, K.T.; Mundhenk, P.; de Jesus Navar, J.; Stinson, G. Changes in forest production, biomass and carbon: Results from the 2015 UN FAO Global Forest Resource Assessment. For. Ecol. Manag. 2015, 352, 21–34. [Google Scholar] [CrossRef]

- Sun, X.; Wang, L.; Gu, Z. A brief overview of China’s timber market system. Int. For. Rev. 2004, 6, 221–226. [Google Scholar] [CrossRef]

- Nag, O.S. World Leaders in Wood Product Exports. WorldAtlas. 2017. Available online: https://www.worldatlas.com/articles/world-leaders-in-wood-product-exports.html (accessed on 25 July 2022).

- Pirard, R.; Secco, L.D.; Warman, R. Do timber plantations contribute to forest conservation? Environ. Sci. Policy 2016, 57, 122–130. [Google Scholar] [CrossRef]

- Jiménez-Rivero, A.; de Guzmán-Báez, A.; García-Navarro, J. Enhanced on-site waste management of plasterboard in construction works: A case study in Spain. Sustainability 2017, 9, 450. [Google Scholar] [CrossRef]

- Gálvez-Martos, J.-L.; Styles, D.; Schoenberger, H.; Zeschmar-Lahl, B. Construction and demolition waste best management practice in Europe. Resour. Conserv. Recycl. 2018, 136, 166–178. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, L.O.; Akinade, O.O.; Ajayi, A.O.; Davila Delgado, M.; Bilal, M.; Bello, S.A. Salvaging building materials in a circular economy: A BIM-based whole-life performance estimator. Resour. Conserv. Recycl. 2018, 129, 175–186. [Google Scholar] [CrossRef]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and demolition waste management in China through the 3R principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Minunno, R.; O’Grady, T.; Morrison, G.M.; Gruner, R.L.; Colling, M. Strategies for Applying the Circular Economy to Prefabricated Buildings. Buildings 2018, 8, 125. [Google Scholar] [CrossRef]

- Yeheyis, M.; Hewage, K.; Alam, M.S.; Eskicioglu, C.; Sadiq, R. An overview of construction and demolition waste management in Canada: A lifecycle analysis approach to sustainability. Clean Technol. Environ. Policy 2013, 15, 81–91. [Google Scholar] [CrossRef]

- Hurmekoski, E.; Jonsson, R.; Nord, T. Context, drivers, and future potential for wood-frame multi-story construction in Europe. Technol. Forecast. Soc. Chang. 2015, 99, 181–196. [Google Scholar] [CrossRef]

- Sandberg, K.; Orskaug, T.; Andersson, A. Prefabricated Wood Elements for Sustainable Renovation of Residential Building Façades. Energy Procedia 2016, 96, 756–767. [Google Scholar] [CrossRef]

- Smith, R.E. History of prefabrication: A cultural survey. In Proceedings of the Third International Congress on Construction History, Cottbus, Germany, 20–24 May 2009. [Google Scholar]

- Jaillon, L.; Poon, C.S. Life cycle design and prefabrication in buildings: A review and case studies in Hong Kong. Autom. Constr. 2014, 39, 195–202. [Google Scholar] [CrossRef]

- Papargyropoulou, E.; Preece, C.; Padfield, R.; Abdullah, A. Sustainable Construction Waste Management in Malaysia: A Contractor’s Perspective. In Management and Innovation for a Sustainable Built Environment MISBE 2011; Citeseer: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Williams, I.; Turner, D. Waste Management Practices in the Small-Scale Construction Industry. 2011. Available online: https://eprints.soton.ac.uk/346322/1/003p_Williams.pdf (accessed on 25 July 2022).

- Esa, M.R.; Halog, A.; Rigamonti, L. Developing strategies for managing construction and demolition wastes in Malaysia based on the concept of circular economy. J. Mater. Cycles Waste Manag. 2017, 19, 1144–1154. [Google Scholar] [CrossRef]

- Diyamandoglu, V.; Fortuna, L.M. Deconstruction of wood-framed houses: Material recovery and environmental impact. Resour. Conserv. Recycl. 2015, 100, 21–30. [Google Scholar] [CrossRef]

- Duan, H.; Wang, J.; Huang, Q. Encouraging the environmentally sound management of C&D waste in China: An integrative review and research agenda. Renew. Sustain. Energy Rev. 2015, 43, 611–620. [Google Scholar]

- Mercer, T.; Frostick, L. Evaluating the potential for environmental pollution from chromated copper arsenate (CCA)-treated wood waste: A new mass balance approach. J. Hazard. Mater. 2014, 276, 10–18. [Google Scholar] [CrossRef]

- Chau, C.; Xu, J.; Leung, T.; Ng, W. Evaluation of the impacts of end-of-life management strategies for deconstruction of a high-rise concrete framed office building. Appl. Energy 2017, 185, 1595–1603. [Google Scholar] [CrossRef]

- Brambilla, G.; Lavagna, M.; Vasdravellis, G.; Castiglioni, C.A. Environmental benefits arising from demountable steel-concrete composite floor systems in buildings. Resour. Conserv. Recycl. 2019, 141, 133–142. [Google Scholar] [CrossRef]

- Nußholz, J.L.K.; Nygaard Rasmussen, F.N.; Milios, L. Circular building materials: Carbon saving potential and the role of business model innovation and public policy. Resour. Conserv. Recycl. 2019, 141, 308–316. [Google Scholar] [CrossRef]

- Farsi, M. composites, Wood-plastic composites: Influence of wood flour chemical modification on the mechanical performance. J. Reinf. Plast. Compos. 2010, 29, 3587–3592. [Google Scholar] [CrossRef]

- Ulubeyli, S.; Kazaz, A.; Arslan, V. Construction and Demolition Waste Recycling Plants Revisited: Management Issues. Procedia Eng. 2017, 172, 1190–1197. [Google Scholar] [CrossRef]

- Zheng, L.; Wu, H.; Zhang, H.; Duan, H.; Wang, J.; Jiang, W.; Dong, B.; Liu, G.; Zuo, J.; Song, Q. Characterizing the generation and flows of construction and demolition waste in China. Constr. Build. Mater. 2017, 136, 405–413. [Google Scholar] [CrossRef]

- Rawat, Y.S.; Vishvakarma, S.C.; Todaria, N. Fuel wood consumption pattern of tribal communities in cold desert of the Lahaul valley, North-Western Himalaya, India. Biomass Bioenergy 2009, 33, 1547–1557. [Google Scholar] [CrossRef]

- Edo, M.; Skoglund, N.; Gao, Q.; Persson, P.-E.; Jansson, S. Fate of metals and emissions of organic pollutants from torrefaction of waste wood, MSW, and RDF. Waste Manag. 2017, 68, 646–652. [Google Scholar] [CrossRef]

- Shaw, J.P.; Moore, M.N. Introduction to the Department for Environment, Food and Rural Affairs (Defra) PREDICT 2 Tamar Estuary Research Workshop: Pathological risk evaluation using “health status-related” biomarkers. Mar. Environ. Res. 2011, 72, 1–2. [Google Scholar] [CrossRef] [PubMed]

- Palmiotto, M.; Fattore, E.; Paiano, V.; Celeste, G.; Colombo, A.; Davoli, E. Influence of a municipal solid waste landfill in the surrounding environment: Toxicological risk and odor nuisance effects. Environ. Int. 2014, 68, 16–24. [Google Scholar] [CrossRef] [PubMed]

- Hill, J. Circular Economy and the Policy Landscape in the UK. In Taking Stock of Industrial Ecology; Springer: Cham, Switzerland, 2016; pp. 265–274. [Google Scholar]

- Hislop, H.; Bégin, A. Waste 2010: The Role of Bans and Restrictions on Landfill in UK Waste Policy-A Green Alliance Project for Defra. 2010. Available online: https://www.agriculture.gov.au (accessed on 11 July 2022).

- Yargicoglu, E.N.; Sadasivam, B.Y.; Reddy, K.R.; Spokas, K. Physical and chemical characterization of waste wood derived biochars. Waste Manag. 2015, 36, 256–268. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Park, S.; Yi, H.; Feiock, R. Evaluating the employment impact of recycling performance in Florida. Waste Manag. 2020, 101, 283–290. [Google Scholar] [CrossRef]

- Liang, S.; Zhang, T.; Xu, Y. Comparisons of four categories of waste recycling in China’s paper industry based on physical input–output life-cycle assessment model. Waste Manag. 2012, 32, 603–612. [Google Scholar] [CrossRef]

- Sinha, A.; Miyamoto, B.T. Lateral load carrying capacity of laminated bamboo lumber and oriented strand board connections. J. Mater. Civ. Eng. 2014, 26, 741–747. [Google Scholar] [CrossRef]

- Thandavamoorthy, T.S. Wood waste as coarse aggregate in the production of concrete. Eur. J. Environ. Civ. Eng. 2016, 20, 125–141. [Google Scholar] [CrossRef]

- Khoshroo, M.; Javid, A.A.S.; Shalchiyan, M.; Nik, F. Evaluation of Mechanical and Durability Properties of Concrete Containing Natural Chekneh Pozzolan and Wood Chips. Iran. J. Sci. Technol. Trans. Civ. Eng. 2019, 44, 1159–1170. [Google Scholar] [CrossRef]

- Hyvärinen, M.; Ronkanen, M.; Kärki, T. The effect of the use of construction and demolition waste on the mechanical and moisture properties of a wood-plastic composite. Compos. Struct. 2019, 210, 321–326. [Google Scholar] [CrossRef]

- Thonemann, N.; Schumann, M. Environmental impacts of wood-based products under consideration of cascade utilization: A systematic literature review. J. Clean. Prod. 2018, 172, 4181–4188. [Google Scholar] [CrossRef]

- Yao, H. A Dynamic Approach for Evaluating the Sustainability Performance of Infrastructure Projects; The Hong Kong Polytechnic University: Hong Kong, China, 2009. [Google Scholar]

- Yuan, H. A model for evaluating the social performance of construction waste management. Waste Manag. 2012, 32, 1218–1228. [Google Scholar] [CrossRef] [PubMed]

- Kloepffer, W. Life cycle sustainability assessment of products. Int. J. Life Cycle Assess. 2008, 13, 89. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Ackermann, R.; Bach, V.; Berger, M.; Brankatschk, G.; Chang, Y.-J.; Grinberg, M.; Lehmann, A.; Martínez-Blanco, J.; Minkov, N.; et al. Challenges in Life Cycle Assessment: An Overview of Current Gaps and Research Needs. In LCA Compendium—The Complete World of Life Cycle Assessment; Springer Science and Business Media LLC: New York, NY, USA, 2014; pp. 207–258. [Google Scholar]

| County | CDWW | Year |

|---|---|---|

| The USA | 55.75 MT | 2020 |

| UK | 4.5 MT | 2020 |

| EU-28 countries | 50.2 MT | 2018 |

| Australia | 2,311,000 tons | 2018–19 |

| Victoria (Australia) | 511,000 tons | 2013–2014 |

| Germany | 11.9 MT | 2015 |

| Hong Kong | 20.72 MT | 2020 |

| Resource | Search Titles | No of Papers |

|---|---|---|

| Scopus | TITLE-ABS-KEY ((“circular economy” OR “industrial ecology” OR “industrial symbiosis”) AND (“wood waste”) OR (“timber waste”)) AND (“wood waste management”) AND (“Life cycle analysis”)) | 20 |

| Web of Science | TITLE-ABS-KEY ((“circular economy” OR “industrial ecology” OR “industrial symbiosis”) AND (“wood waste”) OR (“timber waste”)) AND (“wood waste management”) AND (“Life cycle analysis”)) | 31 |

| Google Scholar | All in title: “Wood” OR “Timber” waste (“circular economy” OR “industrial ecology” OR “industrial symbiosis”) OR (“Life cycle analysis”) | 19 |

| Total literature | 70 | |

| After filtering the duplicates | 52 | |

| After full reading and analysis of the final portfolio | 49 | |

| Size | Silhouette | Top Keywords | |

|---|---|---|---|

| #0 Energy conversion | 10 | 0.7121 | Time-dependency; quality; resource cascading; combustion process; resource recovery; environmental impacts; wood waste-derived fuel; biomass |

| #1 Wood waste | 9 | 0.6361 | Recycling; reverse logistics; waste management; biomass; waste treatment |

| #2 Life cycle | 8 | 0.5033 | CO2 emission; waste treatment; life cycle assessment; dynamic life cycle assessment (LCA); global warming potential (GWP) |

| #3 Circular economy | 12 | 0.6193 | Cement production; particleboard; downcycling; techno-environmental feasibility; circular economy |

| References | Study Direction | Country | Application |

|---|---|---|---|

| [48] | LCA—environmental impacts | European countries | Waste wood combustion as boiler fuel. |

| [37] | LCA—environmental impacts | Malaysia | Waste-to-energy conversion as a sustainable approach and capacity to reduce GHG emissions. |

| [46] | Environmental impacts using LCA | Australia | Bio-oil and biochar production using a fast pyrolysis process. |

| [49] | LCA+LCC | Germany | Recovered wood waste from construction into glue-laminated timber (GLT) products. |

| [42] | Environmental impacts from LCA | Hong Kong | Construction wood waste is used to manufacture wood panels and power generation. |

| [54] | Environmental impacts | European Union | Recycling wood waste for biofuel production and developing the bio-economy sector to achieve climate change mitigation. |

| [44] | Environmental impacts using LCA | USA | Recycling wood residue to produce activated carbon and energy to reduce GHGs. |

| [62] | Environmental impacts using LCA | Brazil | MUF contributes less to photochemical oxidation and human toxicity impacts than UF. |

| References | Country | CE Practice |

|---|---|---|

| [66] | Brazil | Circular economy implementation for wood waste as CO2-sink in bio concrete. |

| [67] | Poland | Application of wood waste loose-fill building insulation. |

| [65] | Netherland | Wood–plastic composites from recycled plastics (electronic waste) and recycled particleboard. |

| [64] | European Union | Recycling plastic and wood wastes as wood–plastic composite contributes to CE through new product development. |

| [50] | Denmark | Cascading utilisation of post-consumer wood waste into particleboard. |

| [68] | Brazil | Recycling of wood waste and epoxy-based ink-waste as adhesive to produce particleboard. |

| [43] | Hong Kong | Upcycling of wood waste into cement-bonded particleboard. |

| [45] | USA | Recycling wood residue to produce particleboard and energy aims to reduce GHGs. |

| [69] | Norway | Upcycling of wood waste and plastics of electronic waste into wood–plastic composite to produce particleboard. |

| [70] | Brazil | Reuse OSB, MDF, and plywood residue mixture into small handmade objects. |

| [39] | Canada | Recycling of CCA-treated wood waste: extraction of arsenic, chromium, and copper, an opportunity to utilise treated wood waste. |

| [71] | Australia | Wood waste management generated from the wooden furniture manufacturing sector focusing waste management practices and strategies to increase sustainability. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jahan, I.; Zhang, G.; Bhuiyan, M.; Navaratnam, S. Circular Economy of Construction and Demolition Wood Waste—A Theoretical Framework Approach. Sustainability 2022, 14, 10478. https://doi.org/10.3390/su141710478

Jahan I, Zhang G, Bhuiyan M, Navaratnam S. Circular Economy of Construction and Demolition Wood Waste—A Theoretical Framework Approach. Sustainability. 2022; 14(17):10478. https://doi.org/10.3390/su141710478

Chicago/Turabian StyleJahan, Israt, Guomin Zhang, Muhammed Bhuiyan, and Satheeskumar Navaratnam. 2022. "Circular Economy of Construction and Demolition Wood Waste—A Theoretical Framework Approach" Sustainability 14, no. 17: 10478. https://doi.org/10.3390/su141710478

APA StyleJahan, I., Zhang, G., Bhuiyan, M., & Navaratnam, S. (2022). Circular Economy of Construction and Demolition Wood Waste—A Theoretical Framework Approach. Sustainability, 14(17), 10478. https://doi.org/10.3390/su141710478

_Zhang.png)