Calculation and Assessment of CO2e Emissions in Road Freight Transportation: A Greek Case Study

Abstract

:1. Introduction

2. GHG Emissions from the Road Freight Transport Sector

3. GHG Emissions from the Road Freight Transport Sector

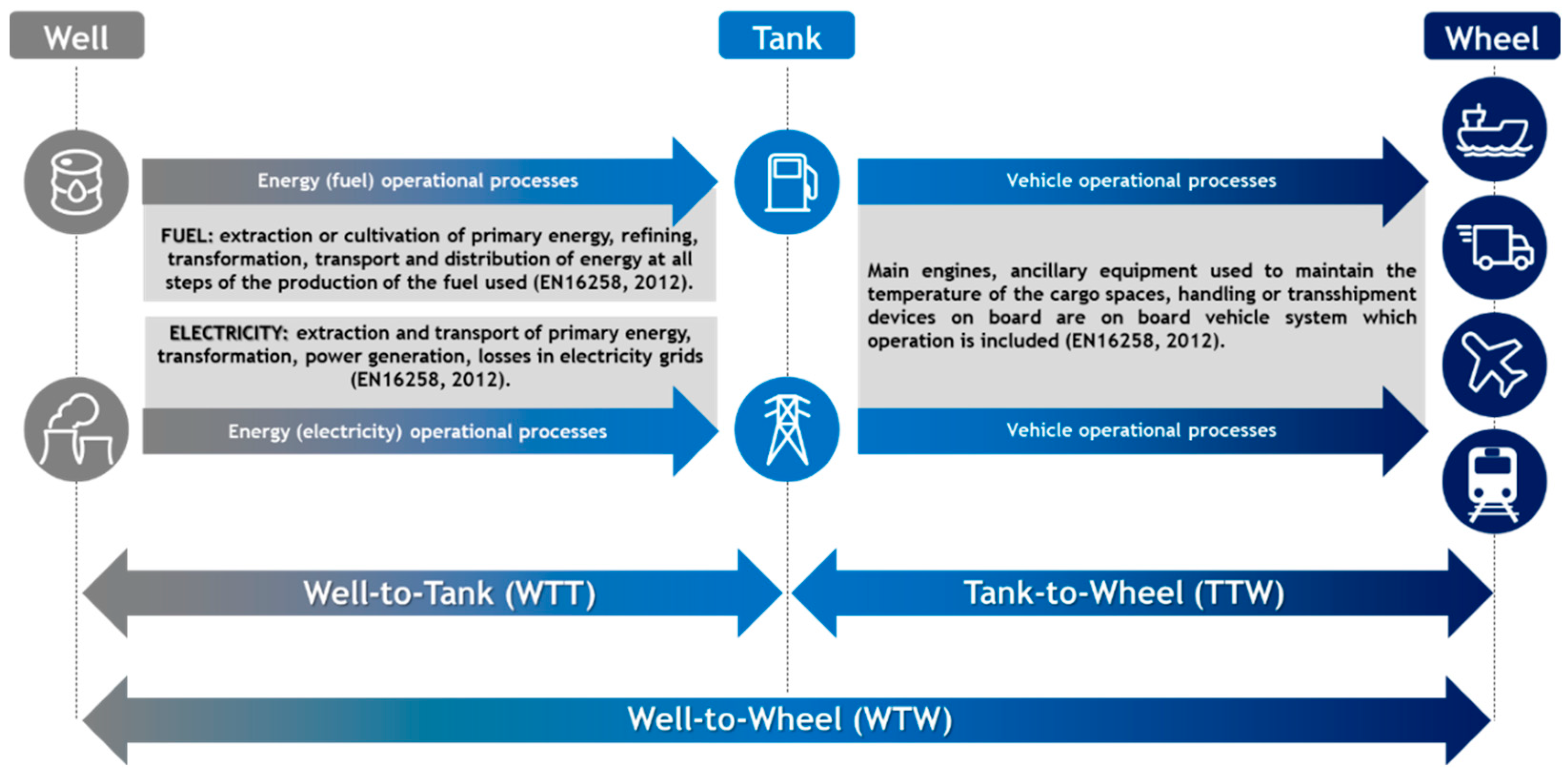

3.1. The EN 16258 Standard

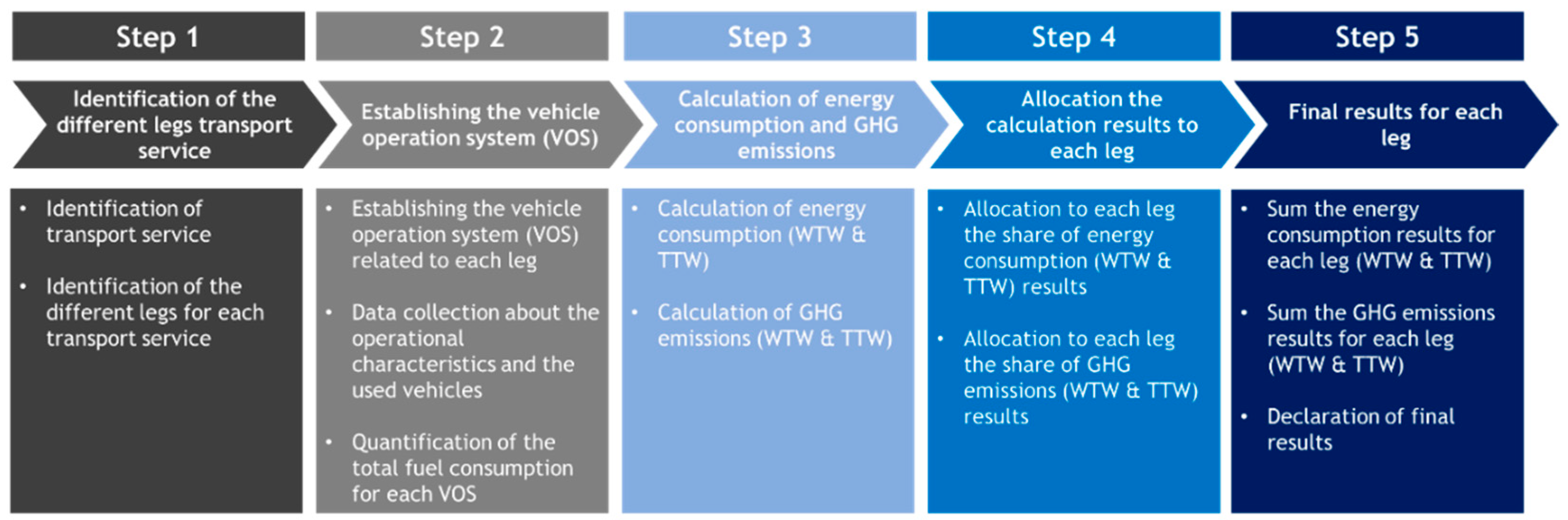

3.2. Carbon Footprint Calculation: Implementation Steps and Methodology

4. The Case of Papageorgiou Transport & Logistics (PTL) Company

4.1. Description of Papageorgiou Transport & Logistics (PTL) Company

4.2. Calculation and Allocation of Energy Consumption and GHG Emissions for PTL Company

4.3. Allocation of GHG Emissions for Each Route of Transport Operation

4.4. Allocation of GHG Emissions for the Total Transport Operation

5. Results of GHG Emissions and Energy Consumption for PTL Company

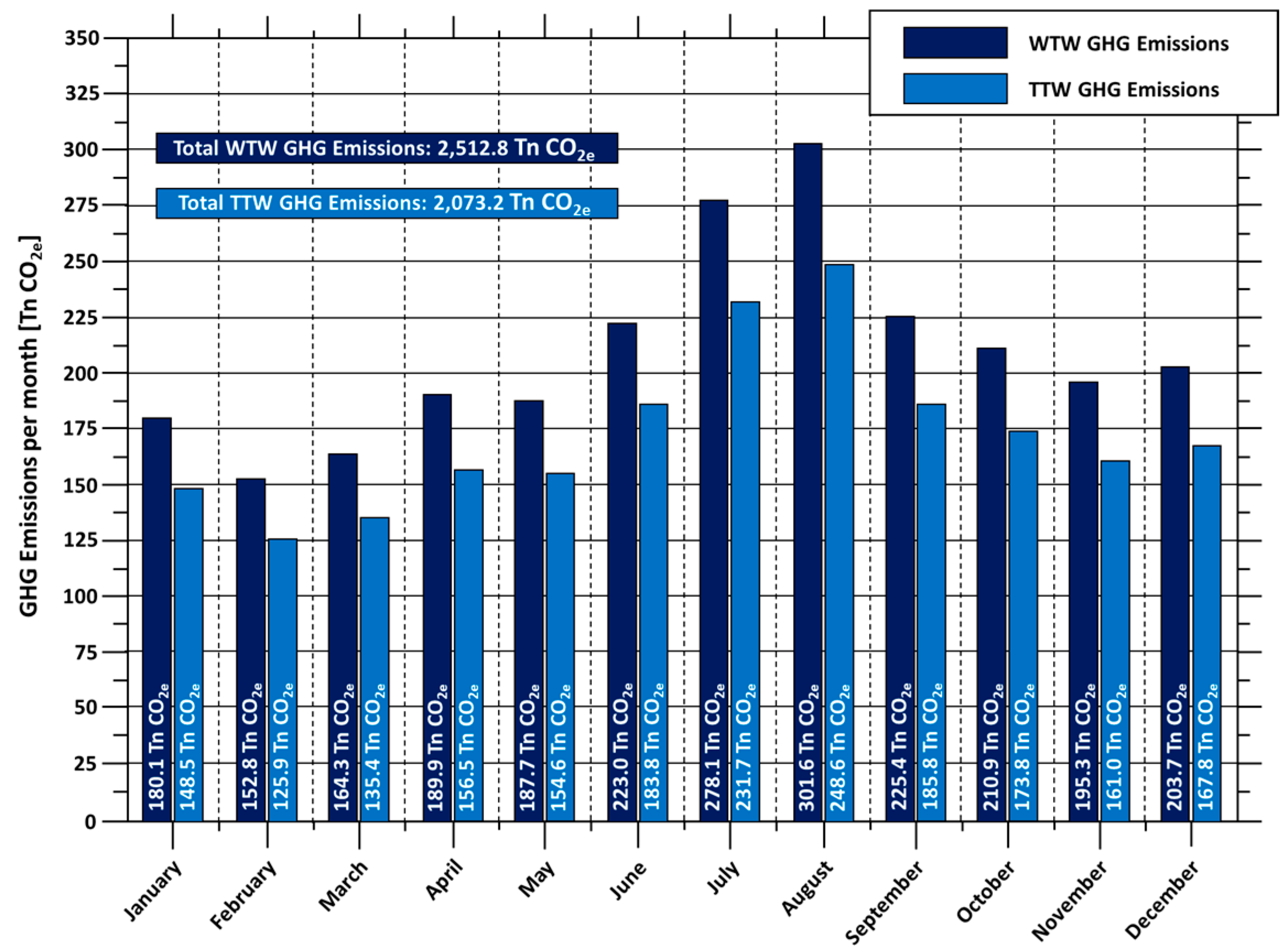

5.1. Total GHG Emissions and Energy Consumption

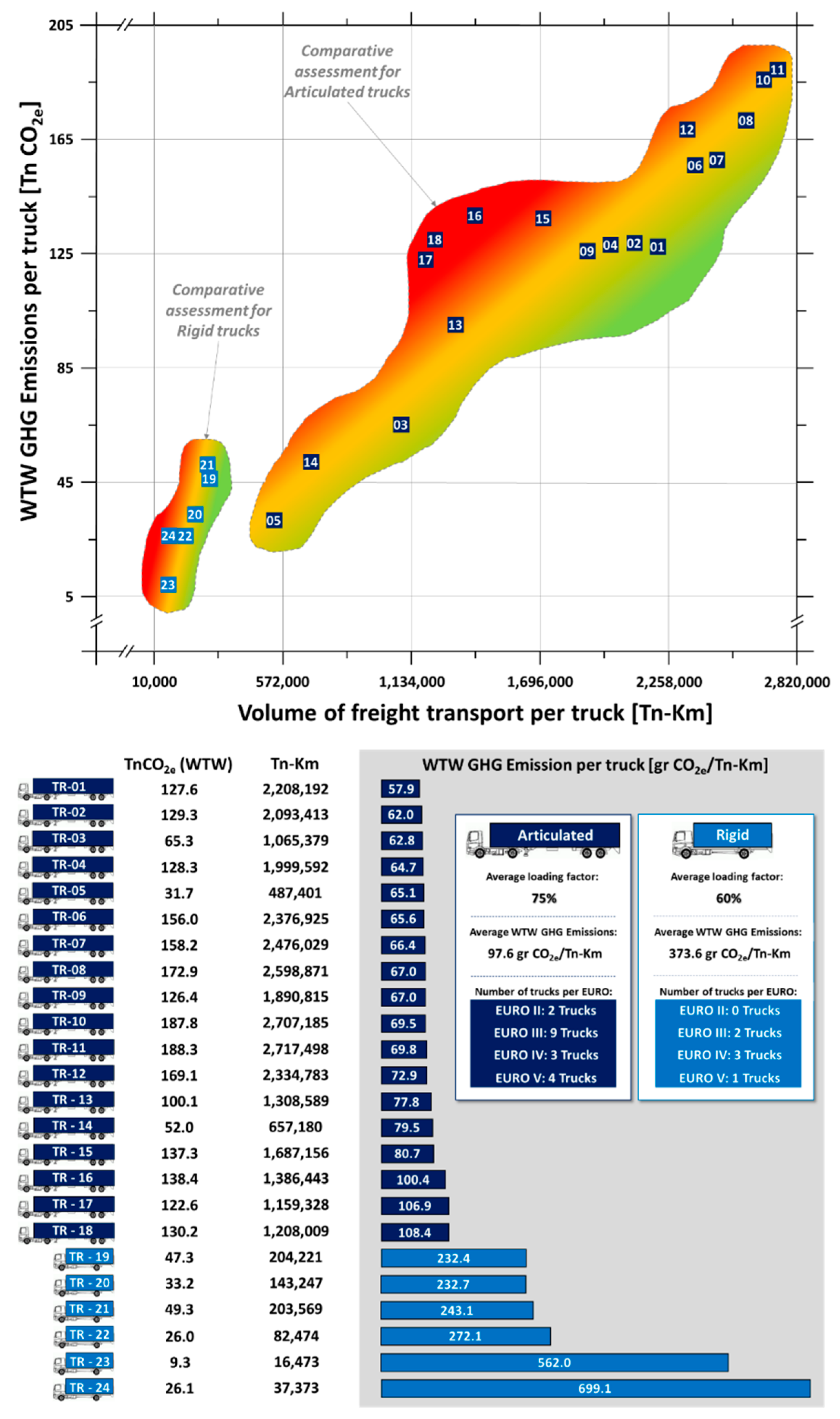

5.2. Allocated WTW GHG Emissions per Tn-Km

6. Using CNG as an Alternative Fuel for Reducing Emissions

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kellner, F.; Schneiderbauer, M. Further Insights into the Allocation of Greenhouse Gas Emissions to Shipments in Road Freight Transportation: The Pollution Routing Game. Eur. J. Oper. Res. 2019, 278, 296–313. [Google Scholar] [CrossRef]

- McKinnon, A. Environmental Sustainability: A New Priority for Logistics Managers. In Green Logistics: Improving the Environmental Sustainability of Logistics; McKinnon, A., Browne, M., Whiteing, A., Piecyk, M., Eds.; Kogan Page: London, UK; Philadelphia, PA, USA; New Delhi, India, 2015; pp. 3–26. [Google Scholar]

- EEA Greenhouse Gas Emissions from Transport in Europe. Available online: https://www.eea.europa.eu/ims/greenhouse-gas-emissions-from-transport (accessed on 30 June 2022).

- IEA. Tracking Transport 2021; IEA: Paris, France, 2021.

- IEA. Global EV Outlook 2021; IEA: Paris, France, 2021.

- European Commission Reducing CO2 Emissions from Heavy-Duty Vehicles. Available online: https://ec.europa.eu/clima/eu-action/transport-emissions/road-transport-reducing-co2-emissions-vehicles/reducing-co2-emissions-heavy-duty-vehicles_en (accessed on 21 June 2022).

- No 595/2009; CO2 Emission Performance Standards for New Heavy-Duty Vehicles and Amending Regulations (EC). European Parliament and of the Council: Brussels, Belgium, 2019. Available online: https://eur-lex.europa.eu/eli/reg/2019/1242/oj (accessed on 28 June 2022).

- Linton, C.; Grant-Muller, S.; Gale, W.F. Approaches and Techniques for Modelling CO2 Emissions from Road Transport. Transp. Rev. 2015, 35, 533–553. [Google Scholar] [CrossRef]

- Pandey, D.; Agrawal, M.; Pandey, J.S. Carbon Footprint: Current Methods of Estimation. Environ. Monit. Assess. 2011, 178, 135–160. [Google Scholar] [CrossRef] [PubMed]

- Wild, P. Recommendations for a Future Global CO2-Calculation Standard for Transport and Logistics. Transp. Res. Part D Transp. Environ. 2021, 100, 103024. [Google Scholar] [CrossRef]

- McKinnon, A.C.; Piecyk, M.I. Measurement of CO2 Emissions from Road Freight Transport: A Review of UK Experience. Energy Policy 2009, 37, 3733–3742. [Google Scholar] [CrossRef]

- McKinnon, A.C.; Piecyk, M.I. Measuring and Managing CO2 Emissions in European Chemical Transport; Heriot-Watt University: Edinburgh, UK, 2010. [Google Scholar]

- Duan, H.; Hu, M.; Zuo, J.; Zhu, J.; Mao, R.; Huang, Q. Assessing the Carbon Footprint of the Transport Sector in Mega Cities via Streamlined Life Cycle Assessment: A Case Study of Shenzhen, South China. Int. J. Life Cycle Assess. 2017, 22, 683–693. [Google Scholar] [CrossRef]

- Chang, C.-C.; Huang, P.-C. Carbon Footprint of Different Fuels Used in Public Transportation in Taiwan: A Life Cycle Assessment. Environ. Dev. Sustain. 2022, 24, 5811–5825. [Google Scholar] [CrossRef]

- Gustafsson, M.; Svensson, N.; Eklund, M.; Öberg, J.D.; Vehabovic, A. Well-to-Wheel Greenhouse Gas Emissions of Heavy-Duty Transports: Influence of Electricity Carbon Intensity. Transp. Res. Part D Transp. Environ. 2021, 93, 102757. [Google Scholar] [CrossRef]

- Santos, G. Road Transport and CO2 Emissions: What Are the Challenges? Transp. Policy 2017, 59, 71–74. [Google Scholar] [CrossRef]

- Ahmed, Z.; Ali, S.; Saud, S.; Shahzad, S.J.H. Transport CO2 Emissions, Drivers, and Mitigation: An Empirical Investigation in India. Air Qual. Atmos. Health 2020, 13, 1367–1374. [Google Scholar] [CrossRef]

- Yoon, Y.; Yang, M.; Kim, J. An Analysis of CO2 Emissions from International Transport and the Driving Forces of Emissions Change. Sustainability 2018, 10, 1677. [Google Scholar] [CrossRef]

- Greene, S.; Façanha, C. Carbon Offsets for Freight Transport Decarbonization. Nat. Sustain. 2019, 2, 994–996. [Google Scholar] [CrossRef]

- Liu, Y.; Feng, C. Decouple Transport CO2 Emissions from China’s Economic Expansion: A Temporal-Spatial Analysis. Transp. Res. Part D Transp. Environ. 2020, 79, 102225. [Google Scholar] [CrossRef]

- EN 16258; Methodology for Calculation and Declaration of Energy Consumption and GHG Emissions of Transport Services (Freight and Passengers). European Committee for Standardization: Brussels, Belgium, 2012.

- Kellner, F. Allocating Greenhouse Gas Emissions to Shipments in Road Freight Transportation: Suggestions for a Global Carbon Accounting Standard. Energy Policy 2016, 98, 565–575. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K. Eco Friendly Biofuels for CI Engine Applications. In Advances in Eco-Fuels for a Sustainable Environment; Woodhead Publishing: Cambridge, UK, 2019. [Google Scholar]

- Speirs, J.; Balcombe, P.; Blomerus, P.; Stettler, M.; Brandon, N.; Hawkes, A. Can Natural Gas Reduce Emissions from Transport? Heavy Goods Vehicles and Shipping; Sustainable Gas Institute, Imperial College: London, UK, 2019. [Google Scholar]

| Data Collection for Each Truck | Data Collection for Each Leg |

|---|---|

|

|

| Symbol | Description |

|---|---|

| AGti | Allocated tank-to-wheels (TTW) GHG emissions for the route i, i = 1, 2, 3, …, n (in KgCO2e/Tn-km) |

| AGWi | Allocated well-to-wheels (WTW) GHG emissions for the route i, i = 1, 2, 3, …, n (in KgCO2e/Tn-km) |

| Di,j | Travel distance of the leg j of route i, i = 1, 2, 3, …, n and j = 1, 2, 3, …, k (in km) |

| DRi | Total travel distance of route i, i = 1, 2, 3, …, n (in km) |

| ECi,j | Energy consumption for the leg j of route i, i = 1, 2, 3, …, n and j = 1, 2, 3, …, k (in liters of Diesel) |

| EFt | Energy factor for the tank-to-wheels stage (35.9 MJ/L of Diesel) |

| Efw | Energy factor for the well-to-wheels stage (42.7 MJ/L of Diesel) |

| Eti | Tank-to-wheels (TTW) energy consumption for the route i, i = 1, 2, 3, …, n (in MJ) |

| EWi | Well-to-wheels (WTW) energy consumption for the route i, i = 1, 2, 3, …, n (in MJ) |

| GHGFt | GHG emission factor for the tank-to-wheels stage (2.67 KgCO2e/L of Diesel) |

| GHGFw | GHG emission factor for the well-to-wheels stage (3.24 KgCO2e/L of Diesel) |

| Gti | Tank-to-wheels (TTW) GHG emissions for the route i, i = 1, 2, 3, …, n (in KgCO2e) |

| GWi | Well-to-wheels (WTW) GHG emissions for the route i, i = 1, 2, 3, …, n (in KgCO2e) |

| LFi,j | Loading factor for the leg j of route i, i = 1, 2, 3, …, n and j = 1, 2, 3, …, k (in %) |

| PL | Payload of the truck which executes the route i, i = 1, 2, 3, …, n |

| TAGt | Allocated tank-to-wheels (TTW) GHG emissions for the total transport operation, (in KgCO2e/Tn-km) |

| TAGW | Allocated well-to-wheels (WTW) GHG emissions for the total transport operation, (in KgCO2e/Tn-km) |

| TD | Total distance of all routes which executed from the truck fleet of the company (in km) |

| Assessment of Retrofitting (Information and Primary Data) | |

|---|---|

| Type of truck: | Articulated-Heavy duty (40 t gross weight) |

| Type of road network: | 90% highway–10% rural |

| Average speed of truck: | 65 Km/h |

| Truck average loading factor: | 72% |

| Period of data collection: | 3 months |

| Fuel price (during the assessment period): | 1 €/Lt (diesel) and 0.76 €/Kg (CNG) |

| Distance traveled (for the assessment): | 12.525 Km |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gialos, A.; Zeimpekis, V.; Madas, M.; Papageorgiou, K. Calculation and Assessment of CO2e Emissions in Road Freight Transportation: A Greek Case Study. Sustainability 2022, 14, 10724. https://doi.org/10.3390/su141710724

Gialos A, Zeimpekis V, Madas M, Papageorgiou K. Calculation and Assessment of CO2e Emissions in Road Freight Transportation: A Greek Case Study. Sustainability. 2022; 14(17):10724. https://doi.org/10.3390/su141710724

Chicago/Turabian StyleGialos, Anastasios, Vasileios Zeimpekis, Michael Madas, and Konstantinos Papageorgiou. 2022. "Calculation and Assessment of CO2e Emissions in Road Freight Transportation: A Greek Case Study" Sustainability 14, no. 17: 10724. https://doi.org/10.3390/su141710724