Dynamic Evaluation and Spatial Characteristics of Smart Manufacturing Capability in China

Abstract

:1. Introduction

2. Construction of Index System, Data Sources and Processing

2.1. Construction of Index System

2.1.1. Interpretation of the Indicator of Development Environment

2.1.2. Interpretation of the Indicator of Infrastructure Facilities

2.1.3. Interpretation of the Indicator of Industrial Development

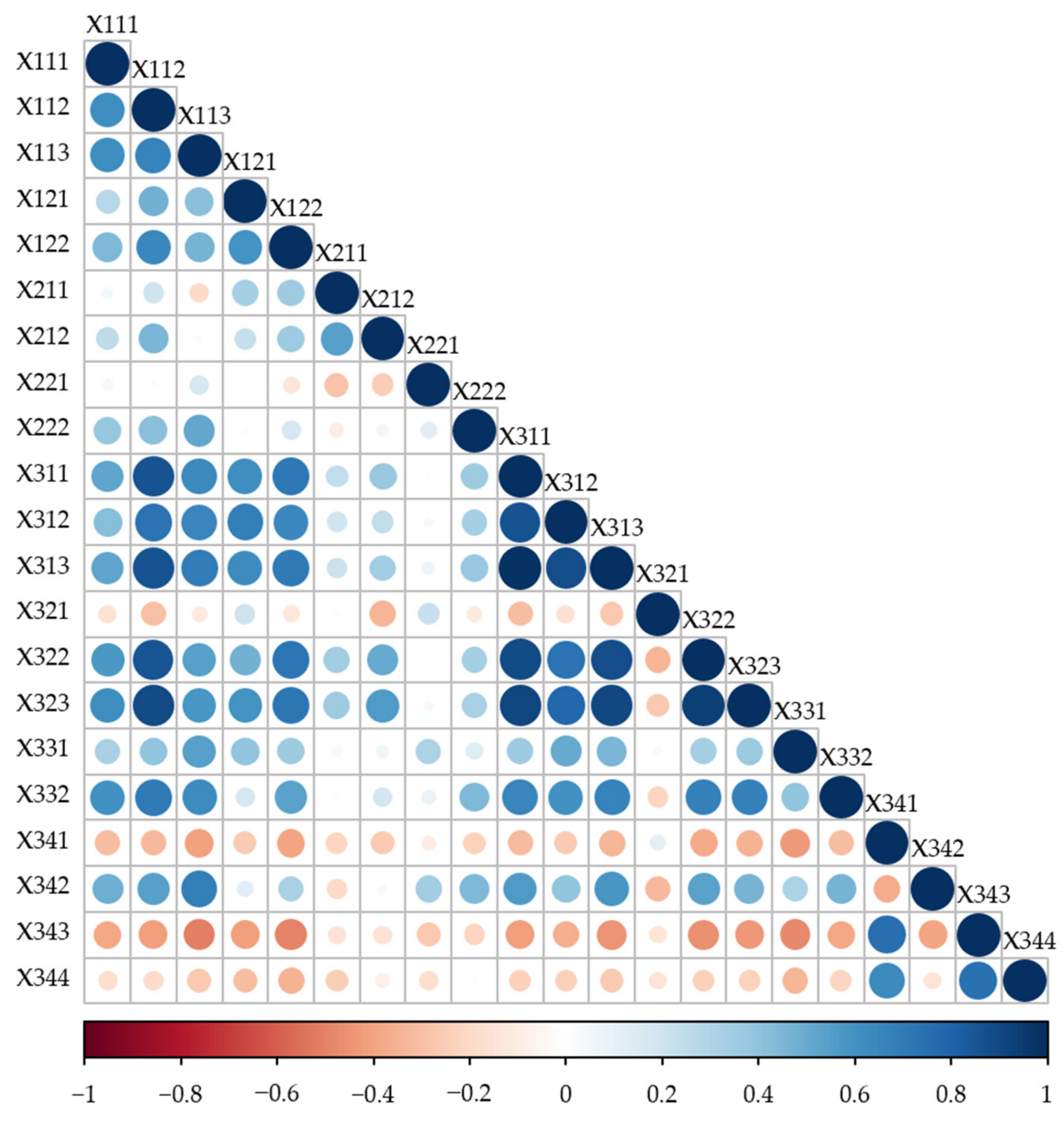

2.1.4. Correlation Analysis of Indicators

2.2. Data Sources and Processing

2.2.1. Data Sources

2.2.2. Data Processing

3. Research Methods

3.1. Comprehensive Evaluation Method

3.1.1. First Weighted Synthesis

3.1.2. Second Weighted Synthesis

3.2. Spatial Correlation Analysis Method

4. Results and Analysis

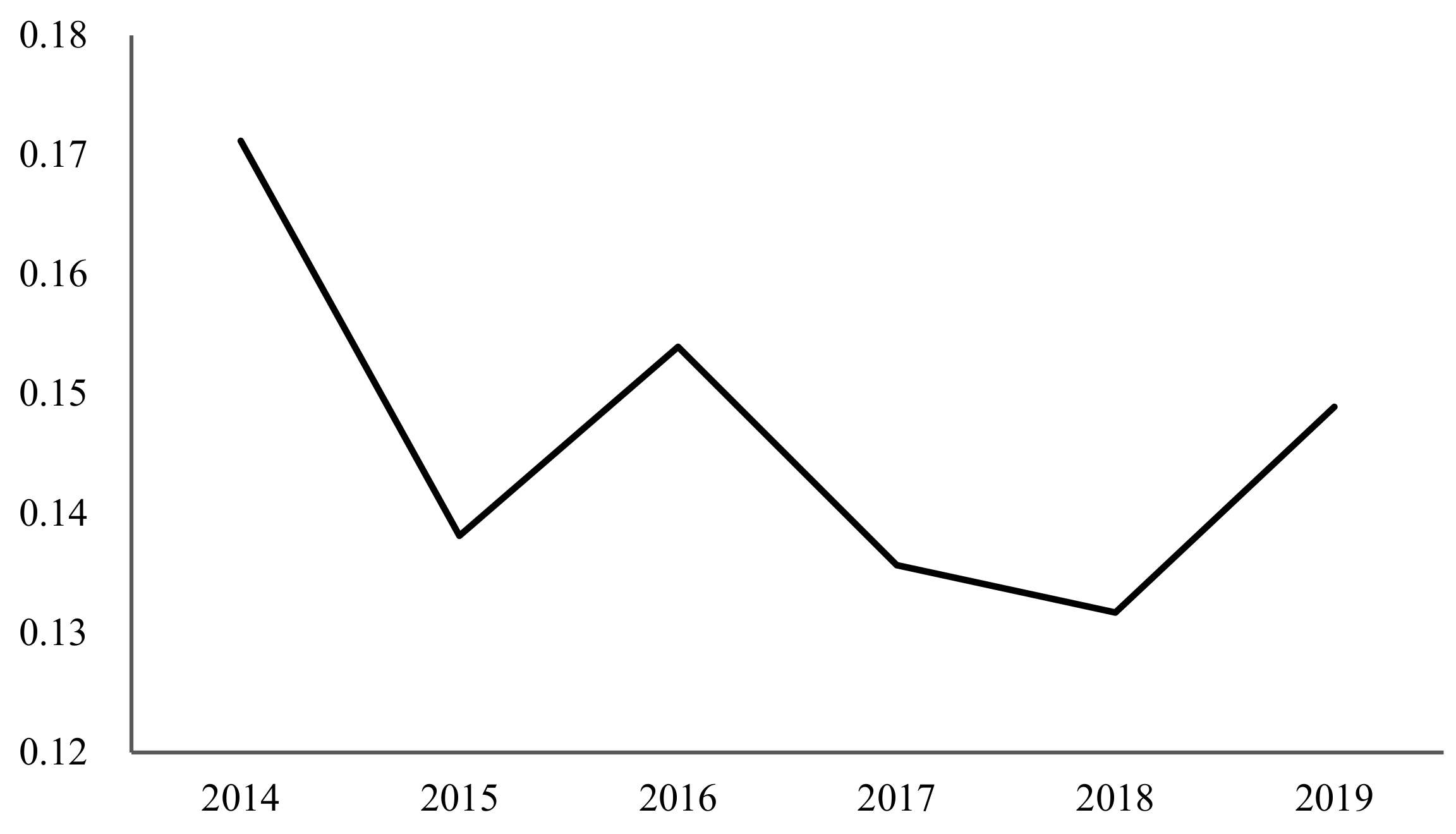

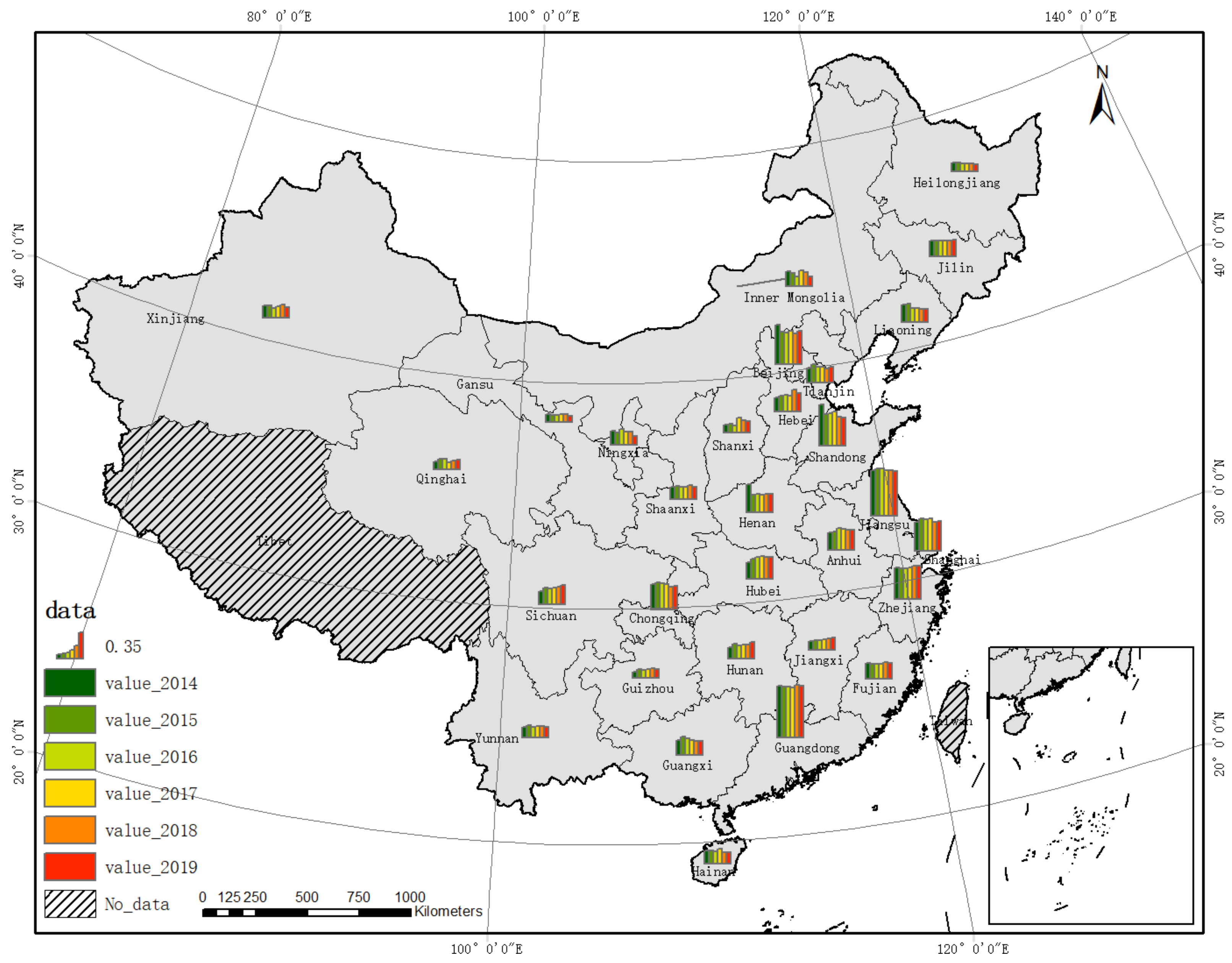

4.1. Analysis of Dynamic Evaluation Results

4.2. Spatial Correlation Analysis

5. Conclusions and Enlightenment

5.1. Conclusions

5.2. Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thoben, K.D.; Wiesner, S.; Wuest, T. “Industrie 4.0” and Smart Manufacturing—A Review of Research Issues and Application Examples. Int. J. Automot. Technol. 2017, 11, 4–19. [Google Scholar] [CrossRef]

- White House Office of the Press Secretary. President Obama Launches Advanced Manufacturing Partnership. Available online: https://obamawhitehouse.archives.gov/the-press-office/2011/06/24/president-obama-launches-advanced-manufacturing-partnership (accessed on 20 February 2022).

- Advanced Manufacturing National Program Office. Strategy for American Leadership in Advanced Manufacturing. Available online: https://www.manufacturing.gov/news/announcements/2018/10/strategy-american-leadership-advanced-manufacturing (accessed on 20 February 2022).

- China Academy of Industrie 4.0. National Industrial Strategy 2030: Strategic Guidelines for a German and European Industrial Policy. Available online: http://www.innobase.cn/?p=1949 (accessed on 22 February 2022).

- The Government Office for Science, London. The Future of Manufacturing: A New Era of Opportunity and Challenge for the UK Project Report. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/255922/13-809-future-manufacturing-project-report.pdf (accessed on 22 February 2022).

- Government of the French Republic. The New Face of Industry in France. Available online: https://www.economie.gouv.fr/files/nouvelle_france_industrielle_english.pdf (accessed on 22 February 2022).

- Zhang, Y.X.; Li, G.C. A Summary of Japan’s Industrial and Technological Strategic System in the New Era. Contemp. Econ. Jpn. 2021, 40, 16. [Google Scholar]

- State Council of the People’s Republic of China. Made in China 2025. Available online: http://www.gov.cn/zhengce/content/2015-05/19/content_9784.htm (accessed on 24 February 2022).

- Zhou, J. Intelligent Manufacturing—Main Direction of “Made in China 2025”. China Mech. Eng. 2015, 26, 2273–2284. [Google Scholar]

- Cai, M.; Luo, J.W. Influence of COVID-19 on Manufacturing Industry and Corresponding Countermeasures from Supply Chain Perspective. Shanghai Jiaotong Univ. 2020, 25, 409–416. [Google Scholar] [CrossRef] [PubMed]

- The State Council of the PRC. On Accelerating the Cultivation and Development of Strategic Emerging Industries. Available online: http://www.gov.cn/zhengce/content/2010-10/18/content_1274.htm (accessed on 8 August 2022).

- Wu, W.Y.; Liu, J.Y. Mechanism and Optimization Path of Smart Manufacturing to Promote Industrial Transformation and Upgrading in China. J. Xi’an Univ. Financ. Econ. 2020, 33, 19–26. [Google Scholar]

- Chen, C. Smart Manufacturing Helps to Build a Community of Shared Future for Mankind. Forum Sci. Technol. China 2020, 4, 4–5. [Google Scholar]

- Wright, P.K.; Bourne, D.A. Manufacturing Intelligence; Addison Wesley: Boston, MA, USA, 1988; pp. 23–40. [Google Scholar]

- Smart Manufacturing Leadership Coalition (SMLC). Implementing 21st Century Smart Manufacturing Workshop Summary Report; SMLC: Washington, DC, USA, 2010. [Google Scholar]

- Davis, J.; Edgar, T.; Porter, J.; Bernaden, J.; Sarli, M. Smart manufacturing, manufacturing intelligence and demand-dynamic performance. Comput. Chem. Eng. 2012, 47, 145–156. [Google Scholar] [CrossRef]

- Kang, H.S.; Lee, J.Y.; Choi, S.S.; Kim, H.; Park, J.H.; Son, J.Y.; Kim, B.H.; Noh, S.D. Smart manufacturing: Past research, present findings, and future directions. Int. J. Pr. Eng. Man-GT. 2016, 3, 111–128. [Google Scholar] [CrossRef]

- Li, B.H.; Hou, B.C.; Yu, W.T.; Lu, X.B.; Yang, C.W. Applications of artificial intelligence in smart manufacturing: A review. Front. Inform. Tech. El. 2017, 18, 86–96. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A Survey on Technologies, Applications and Open Research Issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Abubakr, M.; Abbas, A.T.; Tomaz, I.; Soliman, M.S.; Luqman, M.; Hegab, H. Sustainable and Smart Manufacturing: An Integrated Approach. Sustainability 2020, 12, 2280. [Google Scholar] [CrossRef]

- Lee, Y.T.; Kumaraguru, S.; Jain, S.; Robinson, S.; Helu, M.; Hatim, Q.Y.; Rachuri, S.; Dornfeld, D.; Saldana, C.J.; Kumara, S. A Classification Scheme for Smart Manufacturing Systems’ Performance Metrics. Smart Sustain. Manuf. 2017, 1, 52–74. [Google Scholar] [CrossRef] [PubMed]

- European Commission. Energy-Efficient Buildings: Multi-Annual Roadmap for the Contractual PPP under Horizon 2020. Available online: https://op.europa.eu/en/publication-detail/-/publication/dc665bc5-f05b-4f13-b29c-ec1fdfb4cf87/language-en/format-PDF/source-search (accessed on 6 August 2022).

- Smart Process Manufacturing Engineering Virtual Organization Steering Committee. Smart Process Manufacturing: An Operations and Technology Roadmap. Available online: http://www.cameta.org.cn/uploadfile/2016/0109/20160109103304288.pdf (accessed on 6 August 2022).

- Kusiak, A. Smart Manufacturing. Int. J. Prod. Res. 2018, 56, 508–517. [Google Scholar] [CrossRef]

- Kusiak, A. Fundamentals of Smart Manufacturing: A Multi-Thread Perspective. Annu. Rev. Control 2019, 47, 214–220. [Google Scholar] [CrossRef]

- Qu, S.; Jian, R.; Chu, T.; Wang, J.; Tan, T. Computational Reasoning and Learning for Smart Manufacturing under Realistic Conditions. In Proceedings of the International Conference on Behavioral, Economic, and Socio-Cultural Computing, Shanghai, China, 30 October–1 November 2014. [Google Scholar]

- Jung, K.; Cho, H.; Leong, S.; Morris, K.; Lyons, K.W. Performance Challenges Identification Method for Smart Manufacturing Systems. Available online: https://nvlpubs.nist.gov/nistpubs/ir/2016/NIST.IR.8108.pdf (accessed on 3 August 2022).

- Marco, B.; Francesco, G.G.; Cristina, M. Reconfigurable Manufacturing Systems: Literature Review and Research Trend. J. Manuf. Syst. 2018, 49, 93–106. [Google Scholar]

- Zhen, B.X. Smart Manufacturing and National Innovation System—America’s Experiences in Developing the Advanced Manufacturing Industry. Frontiers 2015, 11, 27–39. [Google Scholar]

- Wu, C. Intelligent Manufacturing: A New Grasp of the Real Economy Innovation and Development. In Proceedings of the China’s Smart Manufacturing Forum, Shanghai, China, 25 September 2018. [Google Scholar]

- Meng, F.S.; Zhao, G. Research on the Factors Influencing the Development of Traditional Manufacturing to Smart Manufacturing. Sci. Tech. Prog. Policy 2018, 35, 66–72. [Google Scholar]

- Chen, G.; Xue, L.; Zhang, B. Evaluation of Smart Manufacturing Capability Based on Projection Pursuit Model of Genetic Algorithm—Data from 31 Provinces and Cities in China. Soc. Sci. Shenzhen 2020, 3, 41–49. [Google Scholar]

- China Industrial Research Institute of the 21st Century. China Intelligent Manufacturing Index (CIMI) Report 2019. Available online: https://www.sohu.com/a/373063703_120056153 (accessed on 15 May 2022).

- Zhou, J.M.; Cui, F.F.; Wang, W.L. The Spatial Effect of Financial Innovation on Intellectualized Transformational Upgrading of Manufacturing Industry: An Empirical Evidence from China. Sustainability 2022, 14, 7665. [Google Scholar] [CrossRef]

- Wu, M.J.; Xu, C.P.; Tang, L. The Research on Evaluation of Regional Smart Manufacturing Development Level in China. Reform Econ. Syst. 2020, 2, 60–65. [Google Scholar]

- Yi, W.M.; Dong, P.W.; Wang, J. Research on Evaluation Model of Enterprise Smart Manufacturing Capability Based on High Order Tensor Analysis. J. Ind. Technol. Econ. 2018, 37, 11–16. [Google Scholar]

- Wang, Y.M.; Zhang, X.W. Research on Smart Manufacturing Capability Maturity Index System of China’s Manufacturing Industry under Smart Economy. Sci. Decis. Mak. 2021, 28, 118–132. [Google Scholar]

- Wan, X.Y.; Zhao, H.; Zhang, Y. Construction and Measurement of Smart Development Evaluation Index System in China. Res. Econ. Manag. 2020, 17, 15. [Google Scholar]

- Han, M.C.; Feng, L.L. Research on the Impact of Industrial Robot Application on Labor Employment in China. J. Ind. Technol. Econ. 2020, 39, 117–122. [Google Scholar]

- Yager, R.R.; Filev, D.P. Induced Ordered Weighted Averaging Operators. IEEE T. Syst. Man. Cybern. 1999, 29, 141–150. [Google Scholar] [CrossRef]

- Xu, Z.S.; Da, Q.L. The Ordered Weighted Geometric Averaging Operators. Int. J. Intell. Syst. 2002, 17, 709–716. [Google Scholar] [CrossRef]

- Torra, V. OWA Operators in Data Modeling and Reidentification. IEEE T. Fuzzy Syst. 2004, 12, 652–660. [Google Scholar] [CrossRef]

- Xu, Z. Intuitionistic Fuzzy Aggregation Operators. IEEE T. Fuzzy Syst. 2007, 15, 1179–1187. [Google Scholar]

- Yi, P.T. Theory and Application of Multi-source Information Density Aggregation Operators; Science Press: Beijing, China, 2012. [Google Scholar]

- Zhang, F.M. Group Evaluation Methods and Applications under Model Expansion; Science Press: Beijing, China, 2015. [Google Scholar]

- Chen, L.; Wang, T.Z. Research on the TOPSIS Integrated Evaluation and Decision Method Based on Entropy Coefficient. Control Decis. 2003, 18, 4. [Google Scholar]

- Zhang, F.M. Dynamic Comprehensive Evaluation Method and Application; Science Press: Beijing, China, 2018; pp. 40–50. [Google Scholar]

- Guangdong’s Top 100 Private Enterprises Announced the List of Enterprises are Concentrated in Manufacturing. Available online: https://news.southcn.com/node_17a07e5926/0f1994eeed.shtml (accessed on 8 August 2022).

- Guangdong’s Progression of Smart Manufacturing: From “Machine Replacement” to “Data Replacement “. Available online: https://www.sohu.com/a/147629094_119689 (accessed on 8 August 2022).

- The Status of the Industrial Province Continues to Consolidate. Available online: http://www.sd.chinanews.com.cn/2/2020/1216/76571.html (accessed on 8 August 2022).

- Shan, Z.D. Smart Manufacturing and the Construction of a Strong Manufacturing Country. In Proceedings of the 2022 Yangtze River Delta Digital Economy Development Conference, Nanjing, China, 6 January 2022. [Google Scholar]

- Huang, Y.Q.; Xiao, H.W.; Zeng, W.X. Problems and Measures of Manufacturing Industry Development in Heilongjiang. Bus. Econ. 2020, 39, 24–25. [Google Scholar]

- Conceição, P.; Galbraith, J.K. Constructing Long and Dense Time-Series of Inequality Using the Theil Index. East. Econ. J. 2000, 26, 61–74. [Google Scholar]

- National Development and Reform Commission of the PRC. National Integrated Big Data Center Collaborative Innovation System Arithmetic Hub Implementation Plan. Available online: https://zfxxgk.ndrc.gov.cn/web/iteminfo.jsp?id=18126 (accessed on 9 August 2022).

| First-Level Indicator | Second-Level Indicator | Three-Level Indicator | Nature of the Indicators |

|---|---|---|---|

| Development environment | Government support | X111 Proportion of the internet integration demonstration projects (%) | P |

| X112 Proportion of pilot enterprises in the implementatio-n of the two-in-one integration management system (%) | P | ||

| X113 Proportion of local financial investment in science and technology (%) | P | ||

| Informatization level | X121 Total amount of the telecommunication service (100 million yuan) | P | |

| X122 Fixed assets investment in the information service industry (100 million yuan) | P | ||

| Infrastructure facilities | Circulation capability of product | X211 Length of the transportation route (km) | P |

| X212 Highway operation truck ownership (10,000 vehicle-s) | P | ||

| Digital foundation | X221 Coverage ratio of the cable (km/km2) | P | |

| X222 Number of websites per 100 enterprises (number) | P | ||

| Industrial development | Innovation capability | X311 Full-time equivalent of R&D personnel of industrial enterprises above the state-designated scale (man-year) | P |

| X312 Number of valid invention patents of industrial ent-erprises above the state-designated scale (number) | P | ||

| X313 Sales revenue of new products of industrial enterp-rises above the state-designated scale (10,000 yuan) | P | ||

| Production capability | X321 Industrial labor productivity (10,000 yuan/person) | P | |

| X322 Total profits of industrial enterprises above the stat- e-designated scale (100 million yuan) | P | ||

| X323 Total assets of industrial enterprises above the state-designated scale (100 million yuan) | P | ||

| Smart production | X331 Installation number of industrial robots (set) | P | |

| X332 Income of software business (10,000 yuan) | P | ||

| Green manufacturing | X341 Electricity consumption per unit of industrial added value (kw·h /10,000 yuan) | N | |

| X342 Emissions of exhaust gas per unit of industrial add-ed value (kg/10,000 yuan) | N | ||

| X343 Comprehensive utilization rate of general industrial solid waste (%) | P | ||

| X344 Completed investment in pollution control per unit of industrial added value (yuan/10,000 yuan) | P |

| Provinces | Value of Comprehensive Evaluation | Dynamic Comprehensive Value | |||||

|---|---|---|---|---|---|---|---|

| 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | ||

| Guangdong (GD) | 0.6823 | 0.6655 | 0.6708 | 0.6603 | 0.6930 | 0.6822 | 0.6803 |

| Jiangsu (JS) | 0.5999 | 0.6272 | 0.6224 | 0.6044 | 0.6018 | 0.5967 | 0.6023 |

| Zhejiang (ZJ) | 0.4220 | 0.4060 | 0.4136 | 0.4185 | 0.4424 | 0.4406 | 0.4344 |

| Beijing (BJ) | 0.5289 | 0.4367 | 0.4203 | 0.4427 | 0.4094 | 0.4379 | 0.4304 |

| Shanghai (SH) | 0.3786 | 0.4299 | 0.4162 | 0.4259 | 0.3841 | 0.3889 | 0.3966 |

| Shandong (SD) | 0.5410 | 0.4229 | 0.4294 | 0.4495 | 0.3844 | 0.3738 | 0.3936 |

| Chongqing (CQ) | 0.3442 | 0.3672 | 0.3505 | 0.3408 | 0.3099 | 0.3173 | 0.3234 |

| Hubei (HB) | 0.2280 | 0.2711 | 0.2957 | 0.3006 | 0.2977 | 0.2919 | 0.2938 |

| Anhui (AH) | 0.2326 | 0.2365 | 0.2828 | 0.2758 | 0.2684 | 0.2609 | 0.2655 |

| Hebei (HE) | 0.1866 | 0.2145 | 0.2209 | 0.2139 | 0.2897 | 0.2403 | 0.2460 |

| Henan (HA) | 0.3709 | 0.2345 | 0.2424 | 0.2319 | 0.2365 | 0.2416 | 0.2392 |

| Sichuan (SC) | 0.1807 | 0.2195 | 0.2081 | 0.2196 | 0.2378 | 0.2516 | 0.2389 |

| Jilin (JL) | 0.2111 | 0.2128 | 0.2160 | 0.2141 | 0.2074 | 0.2197 | 0.2153 |

| Fujian (FJ) | 0.2106 | 0.2056 | 0.1987 | 0.2004 | 0.2271 | 0.2154 | 0.2144 |

| Tianjin (TJ) | 0.1956 | 0.2425 | 0.2084 | 0.2076 | 0.1902 | 0.2051 | 0.2035 |

| Hunan (HN) | 0.1487 | 0.1994 | 0.1794 | 0.1894 | 0.1874 | 0.2198 | 0.2035 |

| Guangxi (GX) | 0.1942 | 0.2319 | 0.2133 | 0.1933 | 0.1777 | 0.1767 | 0.1843 |

| Shaanxi (SN) | 0.1605 | 0.1773 | 0.1668 | 0.1695 | 0.1906 | 0.1712 | 0.1756 |

| Liaoning (LN) | 0.2278 | 0.2411 | 0.1842 | 0.1802 | 0.1656 | 0.1688 | 0.1738 |

| Inner Mongolia (NM) | 0.1954 | 0.1777 | 0.1275 | 0.2108 | 0.1912 | 0.1329 | 0.1593 |

| Jiangxi (JX) | 0.1118 | 0.1254 | 0.1256 | 0.1406 | 0.1523 | 0.1652 | 0.1538 |

| Shanxi (SX) | 0.1008 | 0.1126 | 0.0949 | 0.1918 | 0.1683 | 0.1491 | 0.1538 |

| Hainan (HI) | 0.1662 | 0.1659 | 0.1553 | 0.1956 | 0.1462 | 0.1425 | 0.1527 |

| Xinjiang (XJ) | 0.1620 | 0.1651 | 0.1335 | 0.1547 | 0.1750 | 0.1433 | 0.1527 |

| Ningxia (NX) | 0.1801 | 0.1623 | 0.2006 | 0.1667 | 0.1658 | 0.1116 | 0.1417 |

| Yunnan (YN) | 0.1392 | 0.1627 | 0.1427 | 0.1455 | 0.1459 | 0.1346 | 0.1406 |

| Guizhou (GZ) | 0.0873 | 0.1155 | 0.1036 | 0.1212 | 0.1292 | 0.1219 | 0.1218 |

| Qinghai (QH) | 0.1083 | 0.1362 | 0.1437 | 0.0943 | 0.1153 | 0.1228 | 0.1192 |

| Heilongjiang (HL) | 0.1149 | 0.1173 | 0.1072 | 0.1067 | 0.1119 | 0.0974 | 0.1038 |

| Gansu (GS) | 0.1015 | 0.0887 | 0.0895 | 0.1078 | 0.1006 | 0.0826 | 0.0913 |

| Provinces | Comprehensive Ranking | Dynamic Comprehensive Ranking | |||||

|---|---|---|---|---|---|---|---|

| 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | ||

| Guangdong (GD) | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Jiangsu (JS) | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Zhejiang (ZJ) | 5 | 6 | 6 | 6 | 3 | 3 | 3 |

| Beijing (BJ) | 4 | 3 | 4 | 4 | 4 | 4 | 4 |

| Shanghai (SH) | 6 | 4 | 5 | 5 | 6 | 5 | 5 |

| Shandong (SD) | 3 | 5 | 3 | 3 | 5 | 6 | 6 |

| Chongqing (CQ) | 8 | 7 | 7 | 7 | 7 | 7 | 7 |

| Hubei (HB) | 10 | 8 | 8 | 8 | 8 | 8 | 8 |

| Anhui (AH) | 9 | 11 | 9 | 9 | 10 | 9 | 9 |

| Hebei (HE) | 17 | 15 | 11 | 13 | 9 | 12 | 10 |

| Henan (HA) | 7 | 12 | 10 | 10 | 12 | 11 | 11 |

| Sichuan (SC) | 18 | 14 | 15 | 11 | 11 | 10 | 12 |

| Jilin (JL) | 12 | 16 | 12 | 12 | 14 | 14 | 13 |

| Fujian (FJ) | 13 | 17 | 17 | 16 | 13 | 15 | 14 |

| Tianjin (TJ) | 14 | 9 | 14 | 15 | 17 | 16 | 15 |

| Hunan (HN) | 23 | 18 | 19 | 20 | 18 | 13 | 16 |

| Guangxi (GX) | 16 | 13 | 13 | 18 | 19 | 17 | 17 |

| Shaanxi (SN) | 22 | 20 | 20 | 22 | 16 | 18 | 18 |

| Liaoning (LN) | 11 | 10 | 18 | 21 | 23 | 19 | 19 |

| Inner Mongolia (NM) | 15 | 19 | 25 | 14 | 15 | 25 | 20 |

| Jiangxi (JX) | 26 | 26 | 26 | 26 | 24 | 20 | 21 |

| Shanxi (SX) | 29 | 29 | 29 | 19 | 21 | 21 | 22 |

| Hainan (HI) | 20 | 21 | 21 | 17 | 25 | 23 | 23 |

| Xinjiang (XJ) | 21 | 22 | 24 | 24 | 20 | 22 | 24 |

| Ningxia (NX) | 19 | 24 | 16 | 23 | 22 | 28 | 25 |

| Yunnan (YN) | 24 | 23 | 23 | 25 | 26 | 24 | 26 |

| Guizhou (GZ) | 30 | 28 | 28 | 27 | 27 | 27 | 27 |

| Qinghai (QH) | 27 | 25 | 22 | 30 | 28 | 26 | 28 |

| Heilongjiang (HL) | 25 | 27 | 27 | 29 | 29 | 29 | 29 |

| Gansu (GS) | 28 | 30 | 30 | 28 | 30 | 30 | 30 |

| SMC | Eastern Regions | Central Regions | Western Regions |

|---|---|---|---|

| high | GD, JS, ZJ, BJ, SH, SD, HE | HB, AH | CQ |

| medium | FJ, TJ, GX, LN | HA, JL, HN, NM | SC, SN |

| low | HI | JX, SX, HL | XJ, NX, YN, GZ, QH, GS |

| Year | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|---|---|

| Moran’I | 0.1156 | 0.1183 | 0.1233 | 0.1499 | 0.1396 | 0.1478 |

| p-value | 0.0240 ** | 0.0120 ** | 0.0120 ** | 0.0090 *** | 0.0100 *** | 0.0090 *** |

| Type of Aggregation | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 |

|---|---|---|---|---|---|---|

| H-H | JS, ZJ, SH, SD, HA | JS, ZJ, SH, SD, HB | JS, ZJ, SH, SD, HB, AH | JS, ZJ, SH, SD, HB, AH | JS, ZJ, BJ, SH, SD, HB, AH, HE | JS, ZJ, SH, SD, HB, AH |

| L-H | HB, AH, HE, JL, FJ, TJ, HN, LN, NM, JX, SX, HI | AH, HE, HA, FJ, TJ, HN, LN, NM, JX, SX, HI | HE, HA, FJ, TJ, HN, LN, JX, SX, HI | HE, HA, FJ, TJ, HN, LN, NM, JX, SX, HI | HA, FJ, TJ, HN, LN, NM, JX, SX, HI | HE, HA, FJ, TJ, HN, LN, JX, SX, HI |

| L-L | SC, GX, SN, XJ, NX, YN, GZ, QH, HL, GS | SC, JL, GX, SN, XJ, NX, YN, GZ, QH, HL, GS | SC, JL, GX, SN, NM, XJ, NX, YN, GZ, QH, HL, GS | SC, JL, GX, SN, XJ, NX, YN, GZ, QH, HL, GS | SC, JL, GX, SN, XJ, NX, YN, GZ, QH, HL, GS | SC, JL, GX, SN, NM, XJ, NX, YN, GZ, QH, HL, GS |

| H-L | GD, BJ, CQ | GD, BJ, CQ | GD, BJ, CQ | GD, BJ, CQ | GD, CQ | GD, BJ, CQ |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, J.; Li, Z.; Wang, X.; Ji, Y. Dynamic Evaluation and Spatial Characteristics of Smart Manufacturing Capability in China. Sustainability 2022, 14, 10733. https://doi.org/10.3390/su141710733

Xue J, Li Z, Wang X, Ji Y. Dynamic Evaluation and Spatial Characteristics of Smart Manufacturing Capability in China. Sustainability. 2022; 14(17):10733. https://doi.org/10.3390/su141710733

Chicago/Turabian StyleXue, Jie, Zhenyan Li, Xian Wang, and Yanli Ji. 2022. "Dynamic Evaluation and Spatial Characteristics of Smart Manufacturing Capability in China" Sustainability 14, no. 17: 10733. https://doi.org/10.3390/su141710733