The Environmental Risk Assessment of Fire and Explosion in Storage Tanks of Petroleum Products

Abstract

:1. Introduction

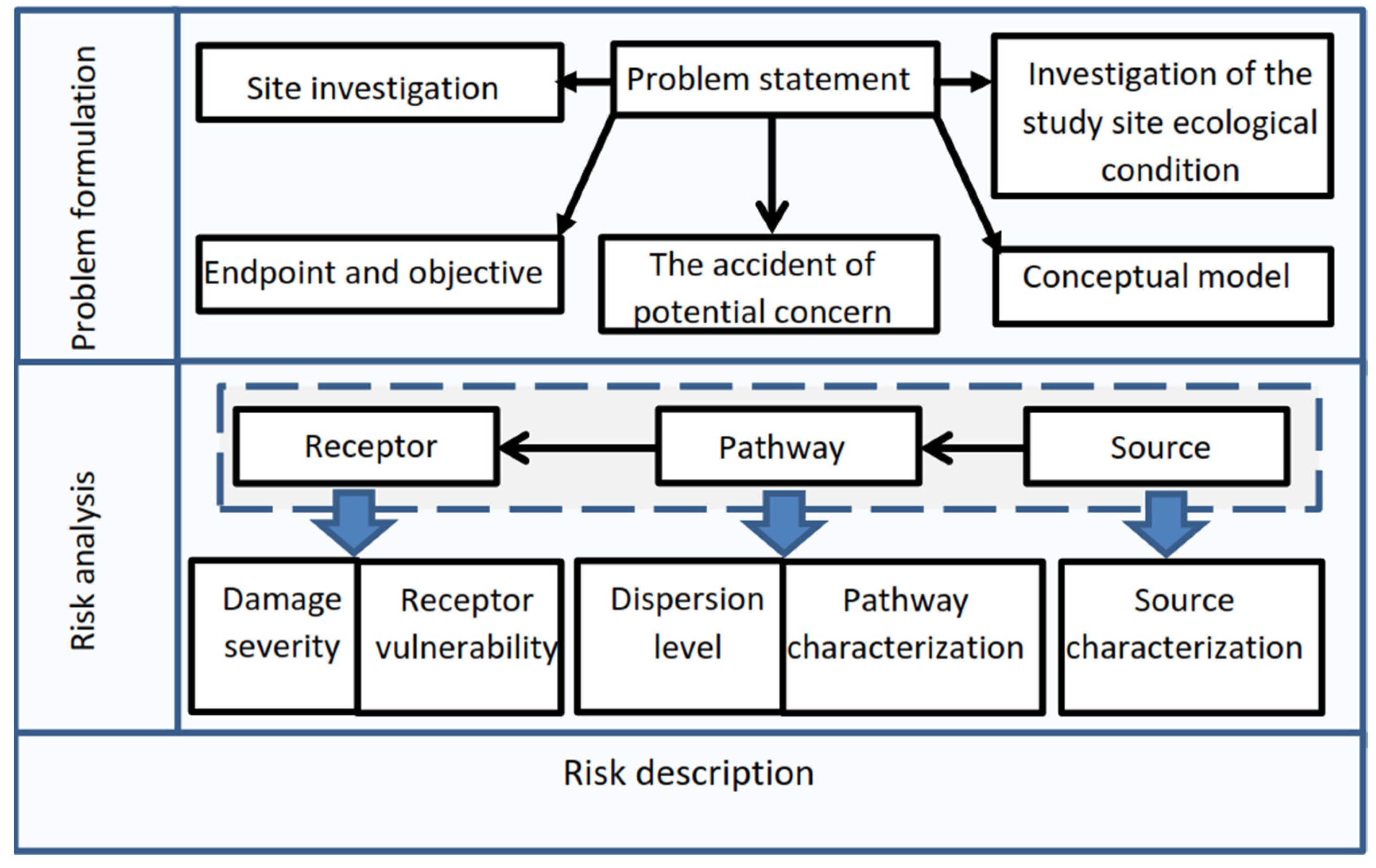

2. Materials and Methods

2.1. Problem Formulation

2.1.1. Problem Statement

2.1.2. Case Study

2.1.3. The Ecological Status of the Study Site

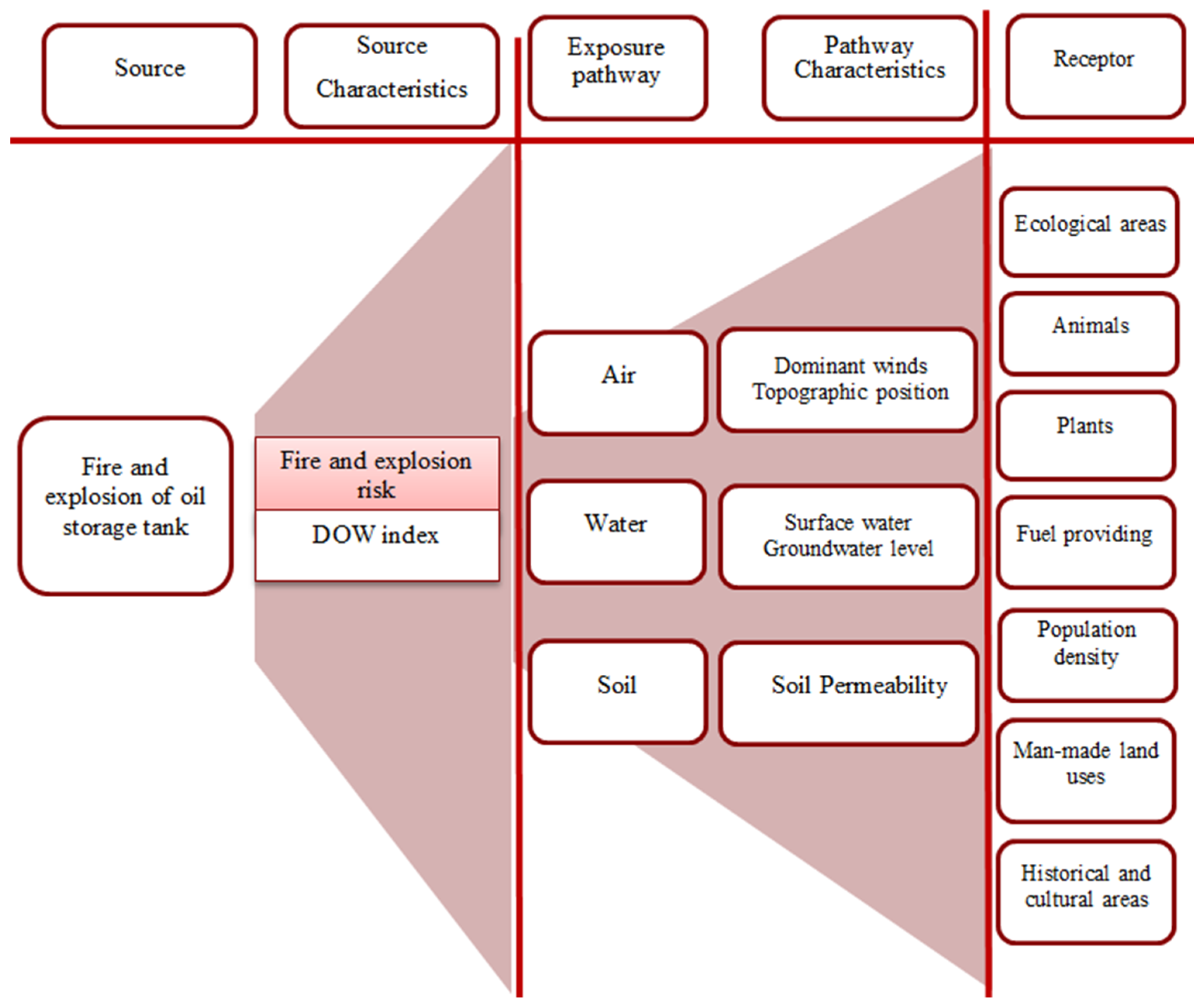

2.2. Risk Analysis

2.2.1. Source

2.2.2. Pathway

- Pathway characterization

- (1)

- Air: floating masses of pollutants are likely to be dispersed; henceforth, the local air pollution may expand and turn to regional air pollution. The prevailing winds [36] and the region’s topographic position (the presence of physical barriers) [37] have the highest impact on the distribution of air pollutants.

- (2)

- Water: water supplies may transfer contaminants [38] (e.g., stored fuel, firewater, and other extinguishing agents). The parameters overshadowing the exposure probability of water resources (surface water and groundwater level) were also identified.

- (3)

- Soil: permeability is the foremost factor affecting the distribution of soil contaminants. In this regard, the soil granularity, i.e., whether the soil is coarse- or fine-grain, may affect the permeability level.

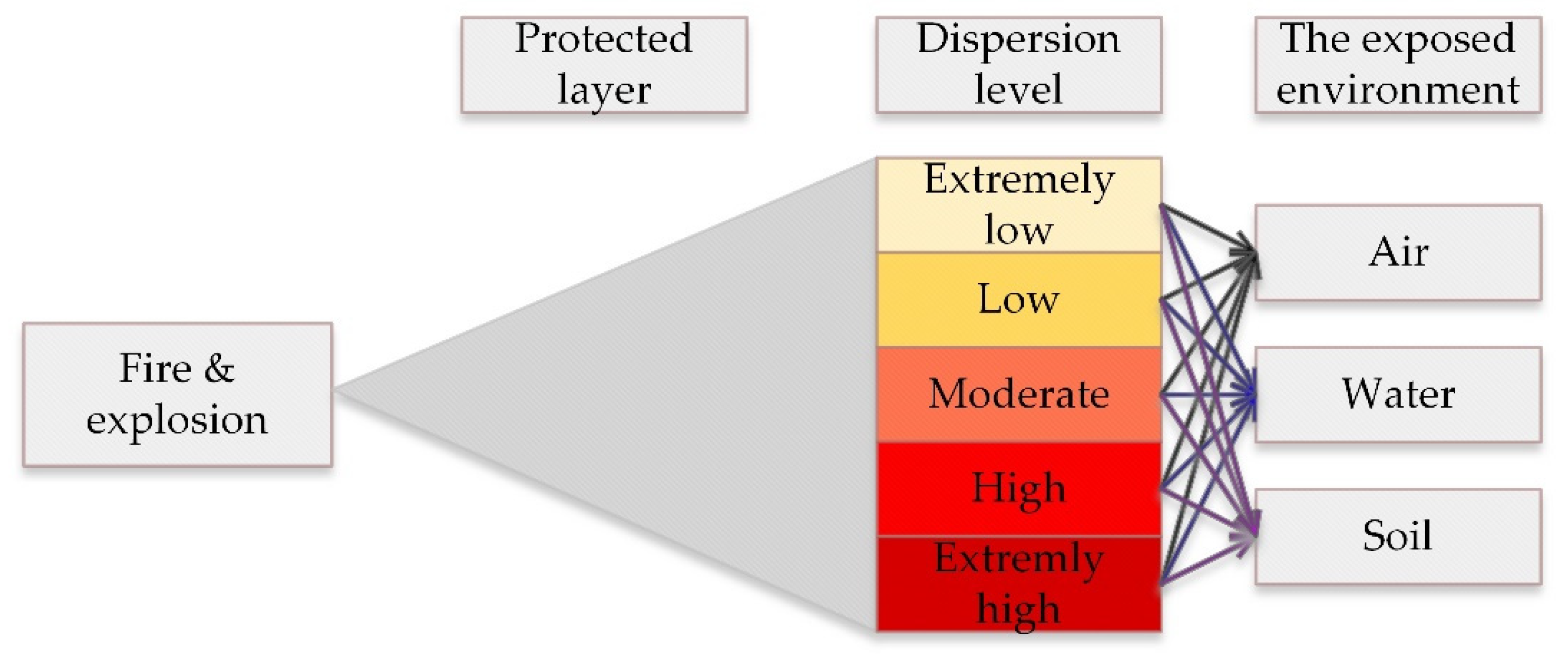

- Dispersion level

2.2.3. Receptor

- Receptor vulnerability

Biological Indicators

- Protected areas (of ecological value) [38].

Socio-Economic Indicators

- Socio-economic parameters include human-related indicators and provide the extent of damage to mankind as part of the environment. The most important indicators identified are as follows:

- Man-made land-use changes: the type of man-made changes that may endanger human life and exacerbate the condition in the case of being damaged [26,27]. In assessing the damage to land uses (industry, agriculture, tourism, housing, etc.), the activities and land uses of the region are of strategic importance.

- Disruption in fuel supply: it is of crucial importance owing to its prominent role in the economy, welfare, security, national image, and the occurrence of chaos.

- Historical and cultural areas: the registered sites, buildings, and places that are historically and culturally valuable [29].

- Severity of impact

2.3. Risk Description

3. Results

3.1. Problem Formulation

- Study site: an oil depot in the northwest of a city, specifically gasoline storage tanks.

- The site ecology: the site in question is located in the northwest region of a city (the site’s ecological characterization was presented in the previous section).

- The accident of foremost concern: fire and explosion.

- Conceptual model: risk analysis using the SPR model.

- Endpoint and objective: mitigating risk and preserving the environment.

3.2. Risk Analysis

3.2.1. Source

Calculation of the Dow F&EI

Degree of Hazard

The F&EI Hazard Zone Measurement

3.2.2. Pathway

Pathway Characterization

Dispersion Level

3.2.3. Receptor

Receptor Vulnerability

Severity of Impact

3.3. Risk Description

4. Discussion

- If tank No. 3 has a fire accident, according to the Dow method calculations, the fire will affect a radius of 31 m, in which two storage tanks, including tank No. 1 containing diesel and tank No. 5 containing gasoline, are located, which can possibly influence it.

- If a fire or explosion occurs in Tank No. 5, subsequently, Tank No. 3 containing gasoline will also be in danger.

- If tank No. 5 has a fire accident, there is a tank within 31 m of it, including tank No. 3 containing gasoline, which is likely to be affected by the accident.

- If tank No. 11 has a fire incident, tank No. 3 containing gasoline and tank No. 8 containing kerosene will be affected.

- If a fire occurs in Tank No. 10, subsequently, Tank No. 11 and Tank No. 9 containing gasoline and diesel, respectively, will also be in the danger zone.

- 6.

- The control room, offices, and machinery station should be distanced at least 31 m from the fuel tanks.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Doregar Zavareh, R.; Dana, T.; Roayaei, E.; Monavari, S.M.; Jozi, S.A. Emission Risk Assessment of Toxic Gases of Floating Roof Tanks. Pollution 2022, 8, 875–888. [Google Scholar] [CrossRef]

- Zinke, R.; Köhler, F.; Klippel, A.; Krause, U.; Leitl, B. Emissions of volatile hydrocarbons from floating roof tanks and their local dispersion: Considerations for normal operation and in case of damage. J. Loss Prev. Process Ind. 2020, 66, 104179. [Google Scholar] [CrossRef]

- Bouafia, A.; Bougofa, M.; Rouainia, M.; Medjram, M.S. Safety Risk Analysis and Accidents Modeling of a Major Gasoline Release in Petrochemical Plant. J. Fail Anal. Prev. 2020, 20, 358–369. [Google Scholar] [CrossRef]

- Necci, A.; Argenti, F.; Landucci, G.; Cozzani, V. Accident scenarios triggered by lightning strike on atmospheric storage tanks. Reliab. Eng. Syst. Saf. 2014, 127, 30–46. [Google Scholar] [CrossRef]

- Qin, R.; Khakzad, N.; Zhu, J. An overview of the impact of Hurricane Harvey on chemical and process facilities in Texas. Int. J. Disaster Risk Reduct. 2020, 45, 101453. [Google Scholar] [CrossRef]

- Shi, L.; Shuai, J.; Xu, K. Fuzzy fault tree assessment based on improved AHP for fire and explosion accidents for steel oil storage tanks. J. Hazard. Mater. 2014, 278, 529–538. [Google Scholar] [CrossRef]

- Zinke, R.; Melnychuk, J.; Köhler, F.; Krause, U. Quantitative risk assessment of emissions from external floating roof tanks during normal operation and in case of damages using Bayesian Networks. Reliab. Eng. Syst. Saf. 2020, 197, 2–12. [Google Scholar] [CrossRef]

- Pouyakian, M.; Jafari, M.J.; Laal, F.; Nourai, F.; Zarei, E. A comprehensive approach to analyze the risk of floating roof storage tanks. Process Saf. Environ. Prot. 2021, 146, 811–836. [Google Scholar] [CrossRef]

- Kang, J.; Liang, W.; Zhang, L.; Lu, Z.; Liu, D.; Yin, W.; Zhang, G. A new risk evaluation method for oil storage tank zones based on the theory of two types of hazards. J. Loss Prev. Process Ind. 2014, 29, 267–276. [Google Scholar] [CrossRef]

- Lu, L.; Liang, W.; Zhang, L.; Zhang, H.; Lu, Z.; Shan, J. A comprehensive risk evaluation method for natural gas pipelines by combining a risk matrix with a bow-tie model. J. Nat. Gas Sci. Eng. 2015, 25, 124–133. [Google Scholar] [CrossRef]

- Chen, S.; Chen, B.; Fath, B.D. Ecological risk assessment on the system scale: A review of state-of-the-art models and future perspectives. Ecol. Model. 2013, 250, 25–33. [Google Scholar] [CrossRef]

- Vora, M.; Sanni, S.; Flage, R. An environmental risk assessment framework for enhanced oil recovery solutions from offshore oil and gas industry. Environ. Impact Assess. Rev. 2021, 88, 106512. [Google Scholar] [CrossRef]

- DEAT. Ecological Risk Assesment, Integrated Environmental Management Information Series 6; Department of Environmental Affairs and Tourism (DEAT): Pretoria, South Africa, 2005.

- Topuz, E.; Talinli, I.; Aydin, E. Integration of environmental and human health risk assessment for industries using hazardous materials: A quantitative multi criteria approach for environmental decision makers. Environ. Int. 2011, 37, 393–403. [Google Scholar] [CrossRef] [PubMed]

- Khan, F.; Rathnayaka, S.; Ahmed, S. Methods and Models in Process Safety and Risk Management: Past, Present and Future. Process Saf. Environ. Prot. 2015, 98, 116–147. [Google Scholar] [CrossRef]

- Khakzad, N.; Khan, F.; Amyotte, P. Quantitative risk analysis of offshore drilling operations: A Bayesian approach. Saf. Sci. 2013, 57, 108–117. [Google Scholar] [CrossRef]

- Xin, P.; Khan, F.; Ahmed, S. Dynamic Hazard Identification and Scenario Mapping Using Bayesian Network. Process Saf. Environ. Prot. 2016, 105, 143–155. [Google Scholar] [CrossRef]

- Nakayama, J.; Sakamoto, J.; Kasai, N.; Shibutani, T.; Miyake, A. Preliminary hazard identification for qualitative risk assessment on a hybrid gasoline-hydrogen fueling station with an on-site hydrogen production system using organic chemical hydride. Int. J. Hydrogen Energy 2016, 41, 7518–7525. [Google Scholar] [CrossRef]

- Xie, S.; Dong, S.; Chen, Y.; Peng, Y.; Li, X. A novel risk evaluation method for fire and explosion accidents in oil depots using bow-tie analysis and risk matrix analysis method based on cloud model theory. Reliab. Eng. Syst. Saf. 2021, 215, 107791. [Google Scholar] [CrossRef]

- Guo, X.; Ji, J.; Khan, F.; Ding, L. Fuzzy bayesian network based on an improved similarity aggregation method for risk assessment of storage tank accident. Process Saf. Environ. Pro.t 2020, 144, 242–252. [Google Scholar] [CrossRef]

- Luo, T.; Wu, C.; Duan, L. Fishbone diagram and risk matrix analysis method and its application in safety assessment of natural gas spherical tank. J. Clean Prod. 2018, 174, 296–304. [Google Scholar] [CrossRef]

- Zhao, J.; Li, W.; Bai, C. Risk Evaluation for Fire and Explosion Accidents in the Storage Tank Farm of the Refinery. Chem. Eng. Trans. 2017, 62, 1345–1350. [Google Scholar] [CrossRef]

- Fu, S.; Yan, X.; Zhang, D.; Li, C.; Zio, E. Framework for the quantitative assessment of the risk of leakage from LNG-fueled vessels by an event tree-CFD. J. Loss Prev. Process Ind. 2017, 43, 42–52. [Google Scholar] [CrossRef]

- Wang, J.; Song, W.H. Fire and Explosion Index calculation method incorporating classified safety measure credits. J. Loss Prev. Process Ind. 2013, 26, 1128–1133. [Google Scholar] [CrossRef]

- Wu, D.; Chen, Z. Quantitative risk assessment of fi re accidents of large-scale oil tanks triggered by lightning. EFA 2016, 63, 172–181. [Google Scholar] [CrossRef]

- Zeleňáková, M.; Zvijáková, L. Risk analysis within environmental impact assessment of proposed construction activity. Environ. Impact Assess. Rev. 2017, 62, 76–89. [Google Scholar] [CrossRef]

- Qinqin, C.; Jia, Q.; Yuan, Z.; Huang, L. Environmental risk source management system for the petrochemical industry. Process Saf. Environ. Prot. 2014, 92, 251–260. [Google Scholar] [CrossRef]

- Shahriar, A.; Sadiq, R.; Tesfamariam, S. Risk analysis for oil & gas pipelines: A sustainability assessment approach using fuzzy based bow-tie analysis. J. Loss Prev. Process Ind. 2012, 25, 505–523. [Google Scholar] [CrossRef]

- Bi, H.; Si, H. Dynamic risk assessment of oil spill scenario for Three Gorges Reservoir in China based on numerical simulation. Saf. Sci. 2012, 50, 1112–1118. [Google Scholar] [CrossRef]

- Yari, M.; Bagherpour, R.; Khoshouei, M.; Pedram, H. Investigating a comprehensive model for evaluating occupational and environmental risks of dimensional stone mining. Rud. Geološko-Naft. Zb. 2020, 35, 101–109. [Google Scholar] [CrossRef]

- Yari, M.; Monjezi, M.; Bagherpour, R.; Sayadi, A.R. Blasting Operation Management Using Mathematical Methods. Eng. Geol. Soc. Territ. 2015, 1, 483–493. [Google Scholar] [CrossRef]

- Norton, S.B.; Rodier, D.J.; van der Schalie, W.H.; Wood, W.P.; Slimak, M.W.; Gentile, J.H. A framework for ecological risk assessment at the EPA. Environ. Toxicol. Chem. 1992, 11, 1663–1672. [Google Scholar] [CrossRef]

- Waldschläger, K.; Lechthaler, S.; Stauch, G.; Schüttrumpf, H. The way of microplastic through the environment–Application of the source-pathway-receptor model (review). Sci. Total Environ. 2020, 713, 136584. [Google Scholar] [CrossRef] [PubMed]

- Holdgate, M.W. A Perspective of Environmental Pollution. Int. Relat. 1980, 6, 850–851. [Google Scholar] [CrossRef]

- AIChE. Dow’s Fire & Explosion Index Hazard Classification Guide, 7th ed.; Wiley: Hoboken, NJ, USA, 1994. [Google Scholar]

- Stevens, C.J.; Bell, J.N.B.; Brimblecombe, P.; Clark, C.M.; Dise, N.B.; Fowler, D.; Lovett, G.M.; Wolseley, P.A. The impact of air pollution on terrestrial managed and natural vegetation: Air pollution impacts on vegetation. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2020, 378, 20190317. [Google Scholar] [CrossRef] [PubMed]

- Goldemberg, J.; Lucon, O. Energy, Environment and Development, 2nd ed.; Earthscan: Oxford, UK, 2010. [Google Scholar] [CrossRef]

- Papadopoulou, M.P.; Antoniou, C. Environmental impact assessment methodological framework for liquefied natural gas terminal and transport network planning. Energy Policy 2014, 68, 306–319. [Google Scholar] [CrossRef]

- Ferdous, R.; Khan, F.; Sadiq, R.; Amyotte, P.; Veitch, B. Analyzing system safety and risks under uncertainty using a bow-tie diagram: An innovative approach. Process Saf. Environ. Prot. 2011, 91, 1–18. [Google Scholar] [CrossRef]

- Tenerelli, P.; Gallego, J.F.; Ehrlich, D. Population density modelling in support of disaster risk assessment. Int. J. Disaster Risk Reduct. 2015, 13, 334–341. [Google Scholar] [CrossRef]

- Kokangül, A.; Polat, U.; Dağsuyu, C. A new approximation for risk assessment using the AHP and Fine Kinney methodologies. Saf. Sci. 2017, 91, 24–32. [Google Scholar] [CrossRef]

- Kampa, M.; Castanas, E. Human health effects of air pollution. Environ. Pollut. 2008, 151, 362–367. [Google Scholar] [CrossRef]

| Parameter | Description |

|---|---|

| Geographical coordinates | Latitudes: between 35°46′55″ and 35°46′43″ N Longitude: between 51°17′43″ and 51°18′6″ E |

| Climate | Moderate: the average daily temperature is 17.4 °C |

| Distance to settlements | From the North: there is no settlement. From the South: the border of the oil depot near the restaurants located in District 5 of Tehran Municipality. From the East: 435 m from the Hesarak district From the West: 25 m from a residential complex with 12,000 square meters and 167 m from Kuhsar Forest Park. |

| Wind direction | West (W) |

| Surface water | Hesarak River flows along the eastern and southern boundary of the oil depot Kan River is located about 2.8 km from the western border of this oil depot |

| Groundwater level | Approximately equal or more than 130 m |

| Flooding risk | The oil depot under study located in the northwest of a city is subject to instability caused by flooding due to its proximity to the Kan River basin, the high relative share of constructions, relatively high density of population and housing, land-use changes, encroachment on the river bank and its bed, and improper exploitation of watercourse. |

| Geology | Upper red formation, conglomerate, and sandstone |

| Fault | The south of the site bordering a fault |

| Areas with environmental protection | The study site is located in none of the zones protected by the Environment Organization of Iran and international authorities; moreover, it lacks the characteristics of natural areas containing specific plant and animal species. |

| Socio-economic status | The study site is located on the northern edge of a city. The populations of the mentioned district and this city are 858,346 and 8,737,510 people, respectively. |

| Pathway | Description |

|---|---|

| Air | Air pollutionIncreased vibration and noise level |

| Water | Surface waters (Hesarak rivers)Groundwater |

| Soil | Surface soils and substrates |

| No. | Dispersion Level | Description | |

|---|---|---|---|

| Extent of Dispersion | Extent of Exposure | ||

| 1 | Extremely low | Air, water, and soil: slight pollutant dispersion in the study site | |

| 2 | Low | Air: ≥1000 m | ≥500 m |

| Water: ≥2000 m | ≥1000 m | ||

| Soil: slight pollutant dispersion off-site | |||

| 3 | Moderate | Air: ≥3000 m | ≥1000 m |

| Water: ≥5000 m | ≥3000 m | ||

| Soil: ≥1500 m | ≥1000 m | ||

| 4 | High | Air: ≥6000 m | ≥1500 m |

| Water: ≥10,000 m | ≥8000 m | ||

| Soil: ≥2000 m | ≥1500 m | ||

| 5 | Extremely high | Air: ≥15,000 m | ≥2500 m |

| Water: ≥15,000 m | ≥10,000 m | ||

| Soil: ≥2500 m | ≥2000 m | ||

| No. | Degree | Description |

|---|---|---|

| 1 | Extremely low | No impact |

| 2 | Low | Biological: minor effects on the green space of the site |

| Human-related: reversible effects on personnel health | ||

| 3 | Moderate | Biological: minor off-site effects |

| Human-related: reversible effects on citizens’ health/severe injuries to the site personnel | ||

| 4 | High | Biological: acute off-site effects |

| Human-relate: acute effects on citizens’ health/death or severe injuries to several site personnel | ||

| 5 | Extremely high | Biological: acute and long-term effects off-site |

| Human-related: severe injuries to or death of several citizens |

| Material | MF | HC(BTU/LB) ×103 | NFPA CLASSIFICATION | Flash Point (Deg F) | Boiling Point (Deg F) | ||

|---|---|---|---|---|---|---|---|

| N(R) | N(F) | N(H) | |||||

| Gasoline | 16 | 18.8 | 1 | 3 | 0 | −45 | 100–400 |

| General process hazards factor (F1) | |||||||

| Base factors | Penalty factor range | Penalty factor used | |||||

| Base factor | 1 | 1 | |||||

| Material handling and transfer | 0.25–1.05 | 0.85 | |||||

| Access | 0.2–0.35 | 0 | |||||

| Drainage and spill control | 0.25–0.5 | 0.20 | |||||

| General process factor | 2.05 | ||||||

| Special process hazards factor (F2) | |||||||

| Base factors | Penalty factor range | Penalty factor used | |||||

| Base factor | 1 | 1 | |||||

| Toxic materials | 0.8–0.2 | 0.2 | |||||

| Sub-atmospheric pressure | 0.5 | 0 | |||||

| Operation near flammable materials | 0.8–0.3 | 0.5 | |||||

| Low temperature | 0.2–0.3 | 0 | |||||

| Quantity of flammable-unstable material | 1.57 | ||||||

| Corrosion and erosion | 0.1–0.75 | 0 | |||||

| Leakage from joins and packing | 0.1–1.5 | 0 | |||||

| Uses of fired equipment | 0 | ||||||

| Hot oil heat exchange system | 0.15–1.15 | 0 | |||||

| Rotating equipment | 0.5 | 0.5 | |||||

| Special process hazards factor | 3.77 | ||||||

| Parameter | Index Score | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Air | |||||

| Prevailing winds | Away from residential areas | Toward the margins of the city | Towards the promenade | Towards villages/low-density settlements/natural area | Toward the city/valuable ecological areas |

| Topographic position | Plain | Adjacent to Mahur hill | The foot of the mountain and the probability of air trapping | ||

| Water | |||||

| Groundwater level | Groundwater level more than 10 m/no well and spring at a distance of about 1500 m | Groundwater level more than 5 m/no well and spring at a distance of about 700 m | Groundwater level more than 5 m/wells and springs at a distance of approximately 300 m | Adjacent to wells, aqueducts, and springs/exploited groundwater level about 5 m or less | Adjacent to wells, springs, and aqueducts/exploited groundwater level less than 5 m |

| Surface water | Lack of permanent water resources at a distance of about 2000 m | Permanent bodies of surface water at a distance of about 1500 m | A permanent river at a distance of about 500 m | Adjacent to rivers, lakes, and other surface water sources | Adjacent to rivers, lakes, and other surface water resources of special ecological importance or overflow to areas of ecological value/habitat of special species |

| Soil | |||||

| Soil permeability | Fine-grained | Coarse-/fine-grained | Coarse-/fine-grained | Coarse-grained | |

| No. | Protective Layer | Score |

|---|---|---|

| 1 | Alarm systems warning to (1) people on the site and (2) service organizations such as the fire department | 4.846 |

| 2 | Cooling of adjacent equipment and structures with portable sprinklers (Deluge system) | 4.846 |

| 3 | Emergency response plan | 4.769 |

| 4 | Urgent medical measures | 4.154 |

| 5 | Evacuating staff from the site | 4.154 |

| 6 | Fixed foam system (foam injection from the top of the tank) | 4.077 |

| 7 | Portable foam system | 4.077 |

| 8 | Cooling adjacent equipment and structures with water spray using portable devices | 4 |

| 9 | Drawing material from the tank | 3.923 |

| 10 | Monitoring surrounding areas by observing or patrolling personnel | 3.923 |

| 11 | Gas detectors that constantly monitor the surrounding areas | 3.923 |

| 12 | Evacuating residents adjacent to the site | 3.923 |

| 13 | Equipping tanks with an automatic deluge system | 3.308 |

| 14 | Fixed foam system (foam injection from the bottom of the tank) | 3.154 |

| No. | Exposed Environment | Dispersion |

|---|---|---|

| 1 | Air | 4.46 |

| 2 | Water | 4.15 |

| 3 | Soil | 3.46 |

| Parameter | Index Score | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Biologic | |||||

| Ecological areas | Lack of protected area exposed to damage | Distance between 200 and 3000 m to areas under the protection of the Environment Organization or other national and international authorities and forest reserves | Distance between 1000 and 2000 m to areas under the protection of the Environment Organization or other national and international authorities and forest reserves | Distance less than 1000 m to areas under the protection of the Environment Organization or other national and international authorities and forest reserves | In or adjacent to areas of recorded ecological value |

| Animals | No/very few animals | Species without conservation value and non-endemic | Vulnerable species | One species of conservation value | A species of conservation value |

| Plants | No/very little vegetation | Urban green space (shrubs and bushes) | Hand-plant trees (non-fruitful) | Natural vegetation/fruitful trees/agriculture as well as hand-plant trees and green space | Natural vegetation (of conservation value) |

| Socioeconomic | |||||

| Population density | No population | 20 | 74 | 153 | 250 |

| Man-made land-uses | No residential, industrial, service, or commercial land use | Micro-scale commercial land use | Commercial land use | Industrial, service, and commercial land uses | Emergency response centers (fire department, medical centers)/residential land use/oil fields or similar areas |

| Fuel providing | Supporting site | Duty to fueling intercity gas stations | Storage of one type of fuel/tank with a capacity of fewer than 3 million liters | Contains more than one type of fuel in storage/tanks with a capacity of more than 3 million liters l | |

| Historical and cultural areas | No registered area of the historical and cultural area | Registered areas of regional value | Registered areas of national value | Registered areas of national and supra-regional value | Registered areas of international and national value |

| Exposed Aspect | Extent of Potential Impacts |

|---|---|

| Biologic | 2.4 |

| Socioeconomic | 4.7 |

| Source | Pathway | Receptor | ||||||

|---|---|---|---|---|---|---|---|---|

| Group | The characteristics of site and substances | Pathway characteristics | Pollutant dispersion (exposure) | Receptor vulnerability | Degree of impact | |||

| Method | Dow | Index | Questionnaire | Index | Questionnaire | |||

| Results | 3 of 5 | Results presented in Table 6 | Air | Water | Soil | Results presented in Table 9 | Biologic | Human-related |

| 4.4 | 4.1 | 3.4 | 4.2 | 4.7 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Doregar Zavareh, R.; Dana, T.; Roayaei, E.; Monavari, S.M.; Jozi, S.A. The Environmental Risk Assessment of Fire and Explosion in Storage Tanks of Petroleum Products. Sustainability 2022, 14, 10747. https://doi.org/10.3390/su141710747

Doregar Zavareh R, Dana T, Roayaei E, Monavari SM, Jozi SA. The Environmental Risk Assessment of Fire and Explosion in Storage Tanks of Petroleum Products. Sustainability. 2022; 14(17):10747. https://doi.org/10.3390/su141710747

Chicago/Turabian StyleDoregar Zavareh, Razieh, Tooraj Dana, Emad Roayaei, Seyed Massoud Monavari, and Seyed Ali Jozi. 2022. "The Environmental Risk Assessment of Fire and Explosion in Storage Tanks of Petroleum Products" Sustainability 14, no. 17: 10747. https://doi.org/10.3390/su141710747

APA StyleDoregar Zavareh, R., Dana, T., Roayaei, E., Monavari, S. M., & Jozi, S. A. (2022). The Environmental Risk Assessment of Fire and Explosion in Storage Tanks of Petroleum Products. Sustainability, 14(17), 10747. https://doi.org/10.3390/su141710747