Classification of Industrial Heat Source Objects Based on Active Fire Point Density Segmentation and Spatial Topological Correlation Analysis in the Beijing–Tianjin–Hebei Region

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Area

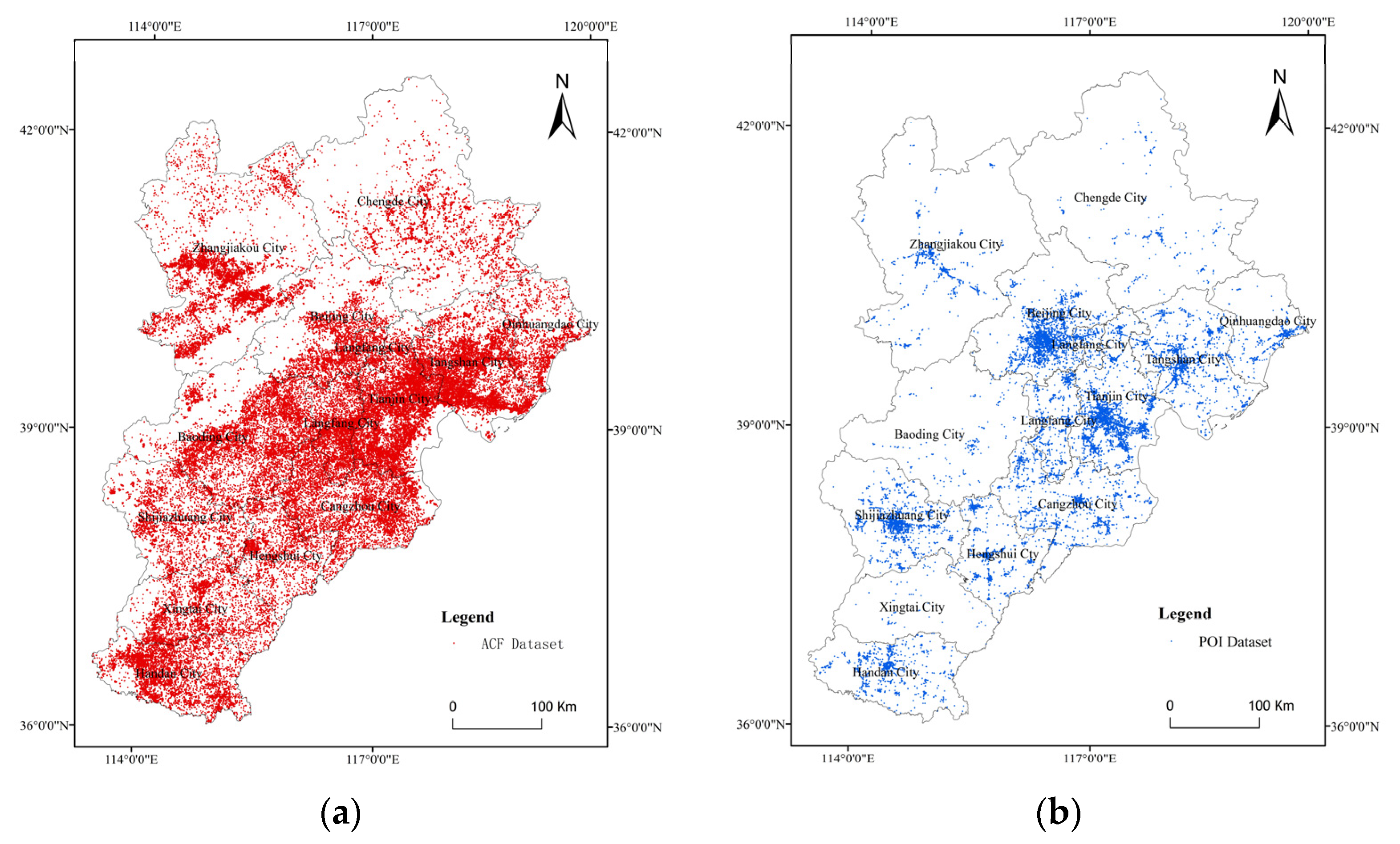

2.2. Data Sources

2.2.1. VIIRS Active Fire/Hotspot Data

2.2.2. Auxiliary Data

2.3. Identification and Classification of Industrial Heat Sources Based on Active Fire Point Density Segmentation

2.3.1. Data Preprocessing

2.3.2. Identification of Industrial Heat Source Objects in the BTH Region Based on an Improved Adaptive K-Means Algorithm

2.3.3. Classification of Industrial Heat Source Objects in the BTH Region Using Integrated Multi-Source Information

2.3.4. Validation of the Identified Industrial Heat Source Objects and the Classification Results

- (1)

- Objects belonging to the cement plant category are mostly found in mountainous areas and include long rotary kilns, dome-shaped raw material pre-homogenization pile units, and material delivery belts.

- (2)

- Objects belonging to the steel plant category include steel manufacturing and casting facilities that have obvious steel-frame structures, as well as blast furnaces and gas tanks.

- (3)

- The coal and chemical industry category includes coal kilns and coal stockpiles, with black areas corresponding to coal stockpiles or obvious signs of excavation.

- (4)

- Objects belonging to the oil and gas development category are generally located away from residential areas and include surface oil and gas platforms, oil wells, and oil and gas pipelines.

- (5)

- The objects belonging to the “other” category, include objects where the type of heat source object cannot be identified because of missing POI data or because the resolution of the remote sensing images is insufficient. This category also includes objects that do not belong to any of the above categories that are too small to be assigned to another category.

2.3.5. Evaluation of the Factors Influencing the Number of Industrial Heat Sources Based on OLS Regression Model

3. Results

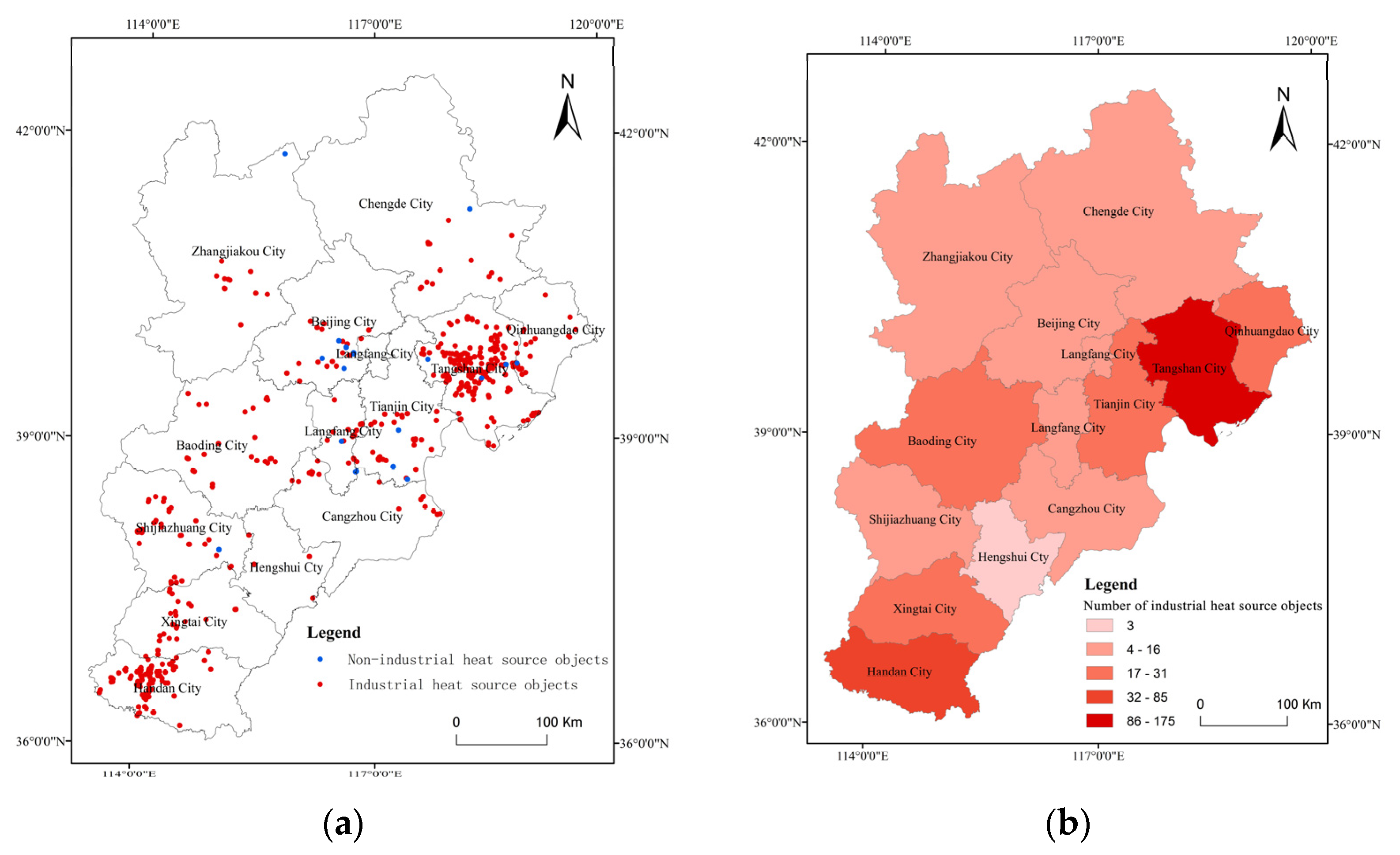

3.1. Analysis of the Results of the Industrial Heat Source Identification in the BTH Region

3.2. Analysis of the Results of the Industrial Heat Source Object Classification in the BTH Region

- (1)

- Of the 474 objects, 255 (53.80%) belong to the steel plant category; the biggest concentration of these is found in the cities of Tangshan and Handan.

- (2)

- One hundred and three (21.73%) of the objects were classified as cement plants; these are concentrated in the cities of Tangshan and Shijiazhuang.

- (3)

- There are 60 heat sources related to the coal and chemical industry (12.66% of the total), mainly in Tangshan, Shijiazhuang, and Handan; 37 heat sources (7.81%) classified as being related to oil and gas developments, mainly in Tangshan, Shijiazhuang, and Cangzhou; and 19 heat sources (4.01%) classified as “other”, mainly in Qinhuangdao and Handan.

3.3. Analysis of the Operation of Industrial Heat Sources in the BTH Region during the Period 2012–2021

- (1)

- Overall, the number of active industrial heat source objects in the BTH region first rises and then falls, with the number of objects reaching a peak in 2013.

- (2)

- The number of active industrial heat source objects was lowest in 2021 when there were only 238. This constitutes a decrease of 39.13% compared to the number in 2013 (391).

- (1)

- The largest number of objects belongs to the steel plant category, followed in order by the cement plants, coal and chemical industry, oil and gas developments, and “other” categories. The number of objects belonging to the cement plants, steel plants, and oil and gas development categories all tended to first increase and then decrease, reaching peaks in 2013, 2013, and 2017, respectively. The number of objects belonging to the chemical industry and “other” categories decreased throughout the study period. This is a result of constraints on coal mining and the effect of national environmental policies.

- (2)

- Of the categories shown, the greatest decline in the number of objects between 2013 and 2021 is for the steel plant category—a decline from 215 to 128, or 40.47% The next biggest decline is for the coal and chemical industry category (40.38%).

- (3)

- Overall, during the 2012–2021 period, the number of identified industrial heat source objects belonging to the cement plant, steel plant, coal and chemical industry, oil and gas development, and “other” categories decreased by 31.40%, 37.56%, 42.59%, 13.04%, and 100%, respectively, illustrating the effects of China’s supply-side reforms and the results achieved.

- (1)

- With the exception of Chengde and Hengshui, where there was a slight increase, the number of active industrial heat sources in the 13 prefecture-level cities in the BTH region during the period 2012–2021 showed a decreasing trend.

- (2)

- The most significant decline in the number of active industrial heat sources in 2021 compared with 2012 (76.92%) was in Beijing, followed by Langfang (66.67%); the number in Baoding and Xingtai also fell be more than 50%.

3.4. Analysis of the Factors Influencing the Number of Industrial Heat Sources in the BTH Region

- (1)

- The R2 of the OLS regression model was 0.976, which implied that EC, ER, OP, ES, and RD could explain 97.64% of the causes of variation in IH. The model passed the F-test (F = 173.942, p = 0.000 < 0.05), indicating that at least one of EC, ER, OP, ES, or RD affected the relationship of IH. The equation of the econometric regression model is shown as:

- (2)

- The regression coefficient value of EC was 295.272 and showed a 0.01 level of significance (t = 5.362, p = 0.000 < 0.01), implying that EC has a significant positive effect relationship with IH. The regression coefficient value of ER was −442.737, but it did not show significance (t = −0.154, p = 0.879 > 0.05), implying that ER does not have an effective relationship with IH. The regression coefficient value of OP was −124.946 and showed a 0.01 level of significance (t = −5.139, p = 0.000 < 0.01), implying that ER does not have an effective relationship with IH. The regression coefficient value of OP was −124.946 and showed a 0.01 level of significance (t = −5.139, p = 0.000 < 0.01), implying that OP has a significant negative effect on IH. The regression coefficient value of ES was 103.796 and showed a 0.01 level of significance (t = 3.435, p = 0.002 < 0.01), implying that ES has a significant positive effect relationship with IH. The regression coefficient value of RD was 4429.940 and showed a 0.01 level of significance (t = 5.691, p = 0.000 < 0.01), implying that RD has a significant positive effect relationship with IH.

4. Discussion

4.1. Analysis of the Spatial and Temporal Distribution of Industrial Heat Sources and Influencing Factors in the Beijing–Tianjin–Hebei Region

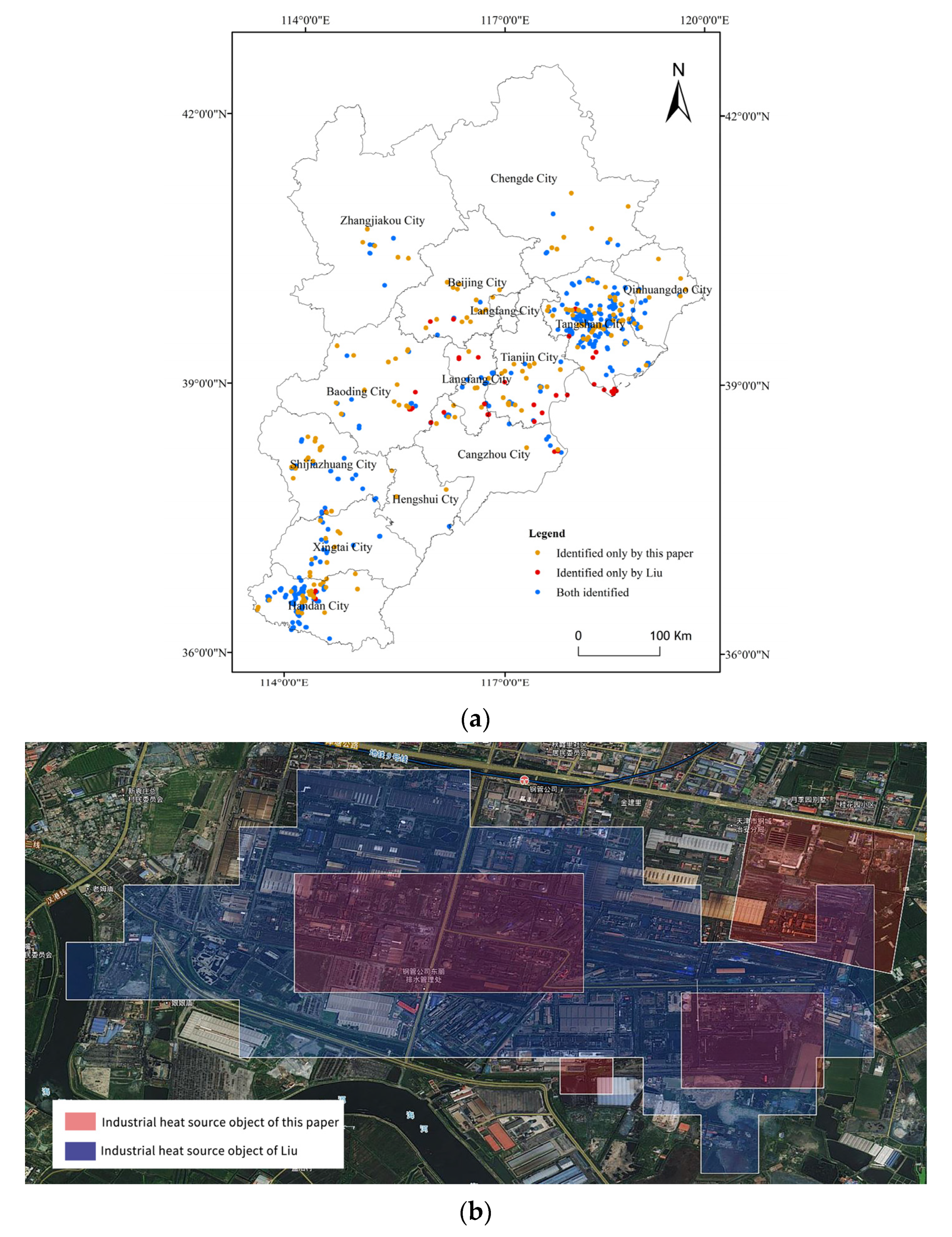

4.2. Comparative Analysis with Identification of Industrial Heat Source Objects Based on Nighttime Thermal Data

- (1)

- The number of industrial heat source objects identified using the method described in this paper is 73.86% greater than the number found using the nighttime thermal data.

- (2)

- In terms of spatial coverage, 84.09% (222) of the heat source objects identified using the thermal data overlap with the objects identified in this study; conversely, 63.18% (290) of the heat source objects identified in this study overlap with the objects identified using the thermal data, which means that the method described in this paper produces results with a higher spatial resolution.

- (3)

- After superimposing the identified heat sources on high-resolution remote sensing images, the industrial heat sources corresponding to plants and mines that were identified in this study have a finer minimum granularity. This greatly reduces the number of instances of “one industrial heat source object covering multiple industrial plants and mines” in the identification based on nighttime thermal data (Figure 8b).

- (4)

- Smaller-scale industrial heat sources were extracted using the method described in this paper. These results provide a finer description of industrial zones, better coverage, and better identification of industrial heat sources by category (Table 5).

- (1)

- The source thermal data were different. ACF (active fire data) was used in our study rather than nighttime thermal data. Compared with nighttime thermal data, ACF contained enough daytime and nighttime thermal data to improve temporal resolution. Furthermore, the spatial resolution (375 m) of ACF was higher than the nighttime thermal data (750 m).

- (2)

- The industrial heat source object detection models were different. The industrial heat source identification method using nighttime thermal data needs to rasterize those fire vector data. It makes it so that many different but spatially proximate objects cannot be distinguished (multiple industrial heat source entities in one industrial heat source object). In our study, a density segmentation method based on vector data was adopted to avoid the above problem.

5. Conclusions

- (1)

- In this study, out of 505,840 thermal anomalies found in the BTH region during the 2012–2021 period, 493 were extracted from the data as industrial heat source objects. The manual verification of these results confirmed that 474 of these objects did, in fact, correspond to industrial heat sources, an identification accuracy of 96.14%. A comparison between these results and results based on nighttime thermal showed that the number of industrial heat source objects identified using the method developed in this study was higher than the number identified using nighttime thermal data and that much smaller objects could be detected using the former method.

- (2)

- The verified industrial heat source objects were classified into five categories: cement plants, steel plants, coal and chemical industry, oil and gas, and other, which accounted for 21.73%, 53.80%, 12.66%, 7.81%, and 4.01% of the objects, respectively. The results of this categorization were found to be more accurate than one based on nighttime thermal data.

- (3)

- During the 2012–2021 period, the number of active industrial heat sources in the BTH region tended to first increase and then decrease, with the number of objects being highest in 2013 and then reducing in each subsequent year. In 2021, the number of active industrial heat sources was 153 lower than in 2013, a decrease of 39.13%. The number of objects in the cement plant, steel plant, coal and chemical industry, oil and gas development, and other categories fell by 31.40%, 37.56%, 42.59%, 13.04%, and 100% during the period 2013–2021.

- (4)

- From the regression analysis of the number of industrial heat sources using the five econometric data categories of EC, ER, OP, ES, and RD, it can be seen that EC, OP, ES, and RD all showed a 0.01 level of significance with the number of industrial heat sources.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ACF | NPP VIIRS 375-m active fire/hotspot data |

| BTH | Beijing-Tianjin-Hebei |

| POI | Point of Interest data |

| EC | Energy consumption level |

| ER | Environmental regulation |

| OP | Openness to the outside |

| IS | Industry scale |

| RD | R&D intensity |

References

- Deng, H.; Xu, B.; Zou, Y. The Economic Logic of China’s Industrialization: From Heavy Industry to Comparative Advantage. J. Econ. Res. 2018, 53, 17–31. [Google Scholar]

- Bin, X.; Lin, B. Investigating Spatial Variability of CO2 Emissions in Heavy Industry: Evidence from a Geographically Weighted Regression Model. J. Energy Policy 2012, 149, 112011. [Google Scholar]

- Chen, S. Energy Consumption, CO2 Emissions and the Sustainable Development of Chinese Industry. J. Econ. Res. 2009, 44, 41–55. [Google Scholar]

- Lei, R.; Sheng, Z.; Tpabc, D.; Xoabc, D. A Review of CO2 Emissions Reduction Technologies and Low-carbon Development in the Iron and Steel Industry Focusing on China. Renew. Sustain. Energy Rev. 2021, 143, 110846. [Google Scholar]

- Lin, B.; Tan, R. China’s CO2 Emissions of a Critical Sector: Evidence from Energy Intensive Industries. J. Clean. Prod. 2017, 142, 4270–4281. [Google Scholar] [CrossRef]

- IEA: Global Energy Review 2021. Available online: https://www.iea.org/reports/global-energy-review-2021 (accessed on 31 December 2021).

- Xue, Y.; Qu, S.; Yan, J.; Song, G.; Zhong, L. Beijing Cement Industry Air Pollutant Emission List and Pollution Characteristics. Int. J. Environ. Sci. Technol. 2014, 37, 201–204. [Google Scholar]

- Bo, X.; Zhao, C.; Wu, Y.; Su, Y.; Wang, L.; Tian, J.; Shi, Y.; Luo, M.; Li, S. A study of High Spatial and Temporal Resolution Emission Inventory Methods for the Iron and Steel Industry in Beijing, Tianjin and Hebei Regions. China Environ. Sci. 2015, 35, 2554–2560. [Google Scholar]

- Li, X.; Wang, X.; Liu, Z.; Wu, L.; Weng, Y.; Hu, J. Ningbo Human-caused VOC List and Contribution Analysis of Key Industrial Sectors. Environ. Sci. 2014, 35, 2497–2502. [Google Scholar] [CrossRef]

- Ma, C.; Yang, J.; Chen, F.; Rui, G. Assessing Heavy Industrial Heat Source Distribution in China Using Real-Time VIIRS Active Fire/Hotspot Data. Sustainability 2018, 10, 4419. [Google Scholar] [CrossRef]

- Ichoku, C.; Giglio, L.; Wooster, M.J.; Remer, L.A. Global Characterization of Biomass-burning Patterns Using Satellite Measurements of Fire Radiative Energy. Remote Sens. Environ. 2008, 112, 2950–2962. [Google Scholar] [CrossRef]

- Gao, H.; Zhao, C. Application of NOAA/AVHRR in Forest Fire Monitoring. J. Shandong For. Sci. Technol. 2007, 1, 33–35. [Google Scholar]

- Wei, Y.; Sang, H.; Zhang, T.; Cong, Y.; Gu, H. Straw Burning Fire Point Identification in Hebei Province Using Improved MODIS Fire Point Detection Algorithm. J. Glob. Position. Syst. 2019, 44, 125–130. [Google Scholar]

- Hafizur, R.M.; Nimish, S.; Seema, K.; Arindam, D. Potential Areas of Crop Residue Burning Contributing to Hazardous Air Pollution in Delhi during Post-monsoon Season. J. Environ. Qual. 2022, 51, 181–192. [Google Scholar]

- Sophia, P.; Maria, K.; Francesco, M.; Teodosio, L.; Filippos, V.; Valerio, T. Monitoring Temporal Variations in the Geothermal Activity of Miocene Lesvos Volcanic Field Using Remote Sensing Techniques and MODIS—LST Imagery. Int. J. Appl. Earth Obs. Geoinf. 2021, 95, 102251. [Google Scholar]

- Elvidge, C.D.; Zhizhin, M.; Baugh, K.; Hsu, F.-C.; Ghosh, T. Methods for Global Survey of Natural Gas Flaring from Visible Infrared Imaging Radiometer Suite Data. Energies 2015, 9, 14. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhao, F.; Wang, S.; Liu, W.; Wang, L. A Method for Monitoring Iron and Steel Factory Economic Activity Based on Satellites. Sustainability 2018, 10, 1935. [Google Scholar] [CrossRef]

- Hao, L.; Meng, Q.; Ge, X.; Zhang, Y.; Hu, D.; Zhang, L.; Tang, Z. A Method for Extraction of Industrial Thermal Contaminated Areas Based on Octant Method. Remote Sens. Technol. Appl. 2020, 35, 469–477. [Google Scholar]

- Ma, C.; Niu, Z.; Ma, Y.; Chen, F.; Yang, J.; Liu, J. Assessing the Distribution of Heavy Industrial Heat Sources in India between 2012 and 2018. ISPRS Int. J. Geo-Inf. 2019, 8, 568. [Google Scholar] [CrossRef]

- Lai, J. Study on Remote Sensing Identification and Spatial Distribution Pattern of Heat Source in Heavy Industry; Northwest Normal University: Lanzhou, China, 2020. [Google Scholar]

- Li, B.; Fan, J.; Han, L.; Sun, G.; Zhang, D.; Zhang, P. An Industrial Heat Source Extraction Method: BP Neural Network Using Temperature Feature Template. J. Geoinf. Sci. 2022, 24, 533–545. [Google Scholar]

- Xu, G.; Yue, J.; Dong, Y.; Lou, J.; Xiong, W.; Nie, Y. Deep Convolutional Network Satellite Image Cement Plant Target Detection. Chin. J. Image Graph. 2019, 24, 550–561. [Google Scholar]

- Lu, K.; Li, G.; Chen, Z.; Jiu, L.; Li, B.; Gao, J. Steel Plant Extraction Based on Negative Sample Multichannel Optimized SSD Network. J. Univ. Chin. Acad. Sci. 2020, 37, 352–359. [Google Scholar]

- Sun, J.; Liu, Y.; Dong, Y.; Xu, B.; Wei, X. Classification of Urban Industrial Heat Sources Based on Suomi-NPP VIIRS Nocturnal Thermal Anomaly Product—A Case Study of Beijing-Tianjin-Hebei Region. Geogr. Inf. Sci. 2018, 34, 13–19. [Google Scholar]

- Liu, Y.; Hu, C.; Zhan, W.; Sun, C.; Murch, B.; Ma, L. Identifying Industrial Heat Sources Using Time-series of the VIIRS Nightfire Product with an Object-oriented Approach. Remote Sens. Environ. 2018, 204, 347–365. [Google Scholar] [CrossRef]

- Ma, C.; Yang, J.; Xia, W.; Liu, J.; Zhang, Y.; Sui, X. A model for expressing industrial information based on object-oriented industrial heat sources detected using multi-source thermal anomaly data in China. Remote Sens. 2022, 14, 835. [Google Scholar] [CrossRef]

- Song, T.; Dong, G.; Tang, Z.; Chen, M.; Hu, Z.; Liang, X. Industrial Structure Optimization in Beijing-Tianjin-Hebei under the Triple Energy-Environment-Employment Constraint. Geogr. Res. 2017, 36, 2184–2196. [Google Scholar]

- Yang, H. Contribution of China’s Iron and Steel Industry to Air Pollution and Emission Reduction Measures; Beijing University: Beijing, China, 2019. [Google Scholar]

- Fang, C. Theoretical Basis and Regularity Analysis of Synergistic Development of Beijing-Tianjin-Hebei Urban Agglomeration. Adv. Geogr. Sci. 2017, 36, 15–24. [Google Scholar]

- VIIRS I-Band 375 m Active Fire Data. Available online: https://earthdata.nasa.gov/earth-observation-data/near-real-time/firms/viirs-i-band-active-fire-data (accessed on 31 December 2021).

- National POI Information Database. Available online: http://www.poilist.cn/ (accessed on 31 December 2021).

- Beijing Statistical Yearbook. Available online: https://data.cnki.net/yearbook/Single/N2021120006 (accessed on 15 July 2022).

- Tianjin Statistical Yearbook. Available online: https://data.cnki.net/yearbook/Single/N2022010263 (accessed on 15 July 2022).

- Hebei Statistical Yearbook. Available online: https://data.cnki.net/yearbook/Single/N2022060071 (accessed on 15 July 2022).

- Wang, C.; Zhang, Y.; Li, H. Research on the Relationship between Green Innovation Efficiency and Environmental Regulation in Beijing-Tianjin-Hebei Region-Take High-tech and Energy-intensive industries as Examples. J. Hebei Eng. Univ. (Nat. Sci. Ed.) 2020, 37, 107–112. [Google Scholar]

| Category | Keywords | |||

|---|---|---|---|---|

| Cement plants | Cement | Building Materials | Limestone | Concrete |

| Steel plants | Steel | Casting | Smelting | Machinery |

| Coal and chemical industry | Coal Chemistry | Coking | Mining | |

| Oil and gas developments | Oil | Natural Gas | Chemical | Energy |

| Other | Silicon Industry | Glass | Calcium Industry | |

| 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | Decline between 2012 and 2021 (%) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Beijing | 13 | 15 | 13 | 12 | 11 | 6 | 6 | 4 | 3 | 3 | 76.92% |

| Tianjin | 24 | 25 | 26 | 27 | 22 | 25 | 20 | 20 | 17 | 15 | 37.50% |

| Tangshan | 142 | 143 | 133 | 138 | 124 | 124 | 120 | 117 | 101 | 95 | 33.10% |

| Qinhuangdao | 20 | 20 | 14 | 13 | 13 | 16 | 16 | 13 | 11 | 11 | 45.00% |

| Chengde | 10 | 11 | 11 | 13 | 12 | 14 | 15 | 15 | 15 | 11 | −10.00% |

| Zhangjiakou | 6 | 8 | 8 | 7 | 7 | 8 | 7 | 5 | 5 | 4 | 33.33% |

| Baoding | 22 | 22 | 17 | 14 | 14 | 13 | 11 | 9 | 10 | 10 | 54.55% |

| Langfang | 12 | 12 | 11 | 12 | 11 | 9 | 10 | 3 | 5 | 4 | 66.67% |

| Cangzhou | 8 | 9 | 8 | 8 | 9 | 6 | 10 | 9 | 7 | 8 | 0.00% |

| Hengshui | 1 | 1 | 0 | 0 | 1 | 2 | 2 | 2 | 0 | 2 | −100.00% |

| Shijiazhuang | 31 | 30 | 30 | 24 | 25 | 27 | 27 | 25 | 25 | 20 | 35.48% |

| Xingtai | 20 | 22 | 21 | 18 | 16 | 14 | 14 | 15 | 11 | 10 | 50.00% |

| Handan | 73 | 73 | 72 | 67 | 65 | 63 | 58 | 52 | 47 | 45 | 38.36% |

| Total | 382 | 391 | 364 | 353 | 330 | 327 | 316 | 289 | 257 | 238 | 37.70% |

| 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | 2021 | Decline between 2012 and 2021 (%) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Cement plants | 86 | 90 | 80 | 71 | 67 | 70 | 65 | 64 | 62 | 59 | 31.40% |

| Steel plants | 205 | 215 | 201 | 199 | 185 | 178 | 177 | 161 | 142 | 128 | 37.56% |

| Coal and chemical industry | 54 | 52 | 48 | 48 | 42 | 44 | 41 | 39 | 33 | 31 | 42.59% |

| Oil and gas developments | 23 | 22 | 25 | 27 | 30 | 32 | 26 | 23 | 18 | 20 | 13.04% |

| Other | 14 | 12 | 10 | 8 | 6 | 3 | 3 | 2 | 2 | 0 | 100.00% |

| Total | 382 | 391 | 364 | 353 | 330 | 327 | 316 | 289 | 257 | 238 | 37.70% |

| Coefficient | t | |

|---|---|---|

| C | −887.063 ** | −4.117 |

| Energy consumption level | 295.272 ** | 5.362 |

| Environmental regulation | −442.737 | −0.154 |

| Openness to the outside | −124.946 ** | −5.139 |

| Enterprise scale | 103.796 ** | 3.435 |

| R&D intensity | 4429.940 ** | 5.691 |

| Adj R2 | 0.971 | |

| F-statistic | 173.942 | |

| Cement Plants | Steel Plants | Coal and ChemicalIndustry | Oil and GasDevelopments | Other | Total | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Liu 2018 [24] | This Paper | Liu 2018 [24] | This Paper | Liu 2018 [24] | This Paper | Liu 2018 [24] | This Paper | This Paper | Liu 2018 [24] | This Paper | |

| Beijing | 1 | 4 | 1 | 9 | 2 | 0 | 1 | 2 | 1 | 5 | 16 |

| Tianjin | 0 | 6 | 7 | 18 | 2 | 1 | 4 | 5 | 0 | 13 | 30 |

| Tangshan | 10 | 23 | 72 | 108 | 21 | 26 | 9 | 9 | 1 | 112 | 167 |

| Qinhuangdao | 1 | 5 | 6 | 11 | 5 | 1 | 0 | 1 | 4 | 12 | 22 |

| Chengde | 0 | 9 | 4 | 5 | 0 | 0 | 0 | 0 | 1 | 4 | 15 |

| Zhangjiakou | 2 | 6 | 1 | 2 | 2 | 1 | 0 | 0 | 2 | 5 | 11 |

| Baoding | 3 | 11 | 5 | 8 | 7 | 1 | 0 | 2 | 3 | 15 | 25 |

| Langfang | 1 | 3 | 5 | 9 | 2 | 1 | 3 | 1 | 0 | 11 | 14 |

| Cangzhou | 0 | 1 | 3 | 7 | 3 | 0 | 5 | 5 | 0 | 11 | 13 |

| Hengshui | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 2 | 0 | 0 | 3 |

| Shijiazhuang | 4 | 14 | 4 | 10 | 7 | 6 | 1 | 5 | 1 | 16 | 36 |

| Xingtai | 2 | 10 | 4 | 10 | 7 | 2 | 0 | 2 | 0 | 13 | 24 |

| Handan | 1 | 10 | 27 | 45 | 18 | 19 | 1 | 3 | 6 | 47 | 83 |

| Total | 25 | 102 | 139 | 243 | 76 | 58 | 24 | 37 | 19 | 264 | 459 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, C.; Sui, X.; Zeng, Y.; Yang, J.; Xie, Y.; Li, T.; Zhang, P. Classification of Industrial Heat Source Objects Based on Active Fire Point Density Segmentation and Spatial Topological Correlation Analysis in the Beijing–Tianjin–Hebei Region. Sustainability 2022, 14, 11228. https://doi.org/10.3390/su141811228

Ma C, Sui X, Zeng Y, Yang J, Xie Y, Li T, Zhang P. Classification of Industrial Heat Source Objects Based on Active Fire Point Density Segmentation and Spatial Topological Correlation Analysis in the Beijing–Tianjin–Hebei Region. Sustainability. 2022; 14(18):11228. https://doi.org/10.3390/su141811228

Chicago/Turabian StyleMa, Caihong, Xin Sui, Yi Zeng, Jin Yang, Yanmei Xie, Tianzhu Li, and Pengyu Zhang. 2022. "Classification of Industrial Heat Source Objects Based on Active Fire Point Density Segmentation and Spatial Topological Correlation Analysis in the Beijing–Tianjin–Hebei Region" Sustainability 14, no. 18: 11228. https://doi.org/10.3390/su141811228