Determination of Energy Parameters and Their Variability between Varieties of Fodder and Turf Grasses

Abstract

:1. Introduction

2. Materials and Methods

2.1. Species and Varieties of Grasses

2.2. Experiment Field

2.3. Energy Properties Determination

- Moisture Content (MC) in Drying Chamber KBC-65 W (WAMED, Warsaw, Poland) using PN EN ISO 18134-2:2017-03E [31];

- Volatile Matter Content (VMC) in Muffle Furnace SNOL 8.2/1100 (RADWAG, Radom, Poland) using PN EN ISO 18123:2016-01 [32];

- Ash Content (AC) in Muffle Furnace SNOL 8.2/1100 (RADWAG, Radom, Poland) using PN EN ISO 18122:2015 [33];

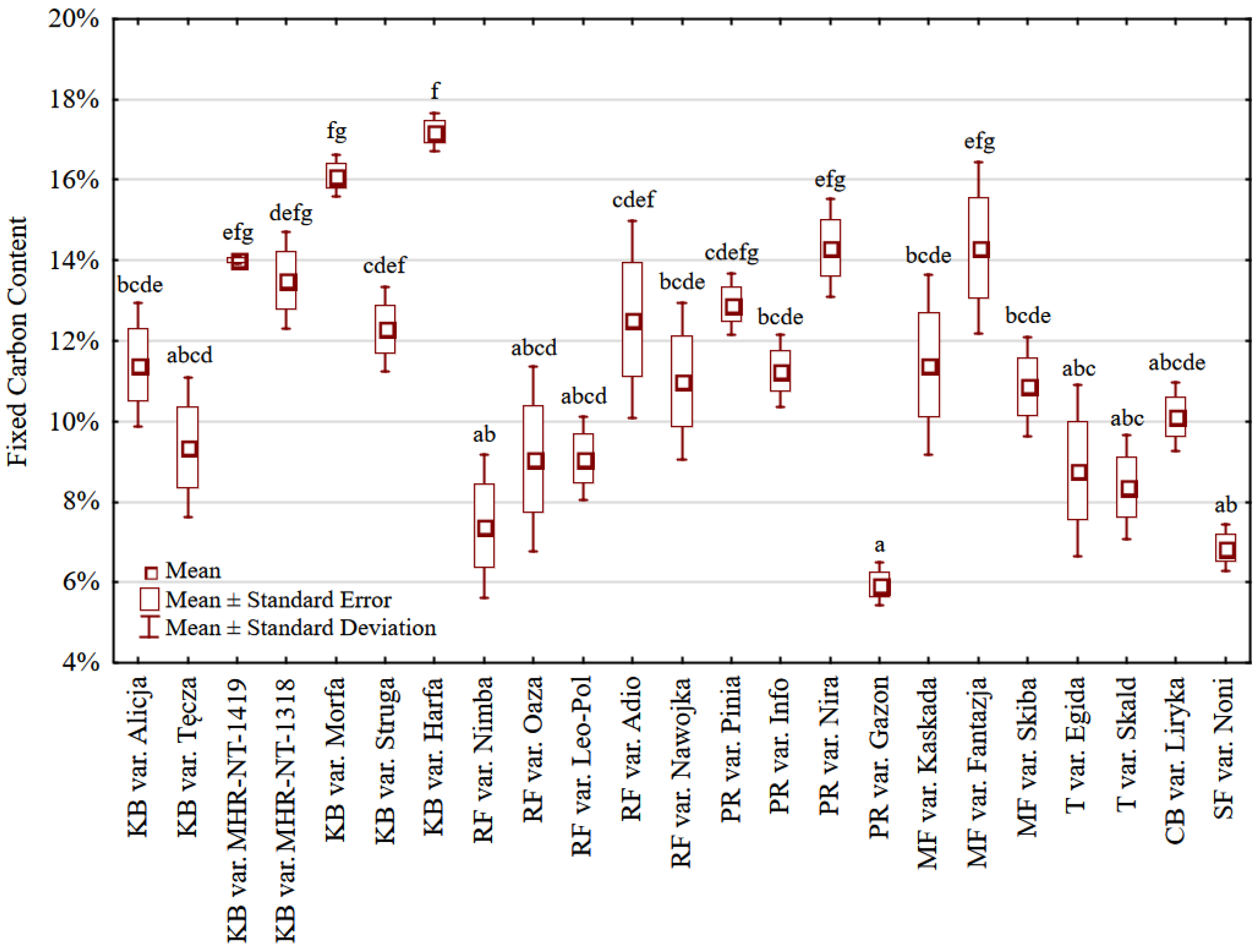

- Fixed Carbon Content (FCC) using appropriate formula according to ASTM-D-3172-73 [34];

- Higher Heating Value (HHV) in calorimetric bomb IKA C200 (IKA, Lucknow, India) according to PN-EN ISO 18125:2017-07 [35];

- Lower Heating Value (LHV) using the appropriate formula on the basis of the previously determined HHV and MC in the analytical dry state according to FAO [36].

2.4. Statistical Analysis

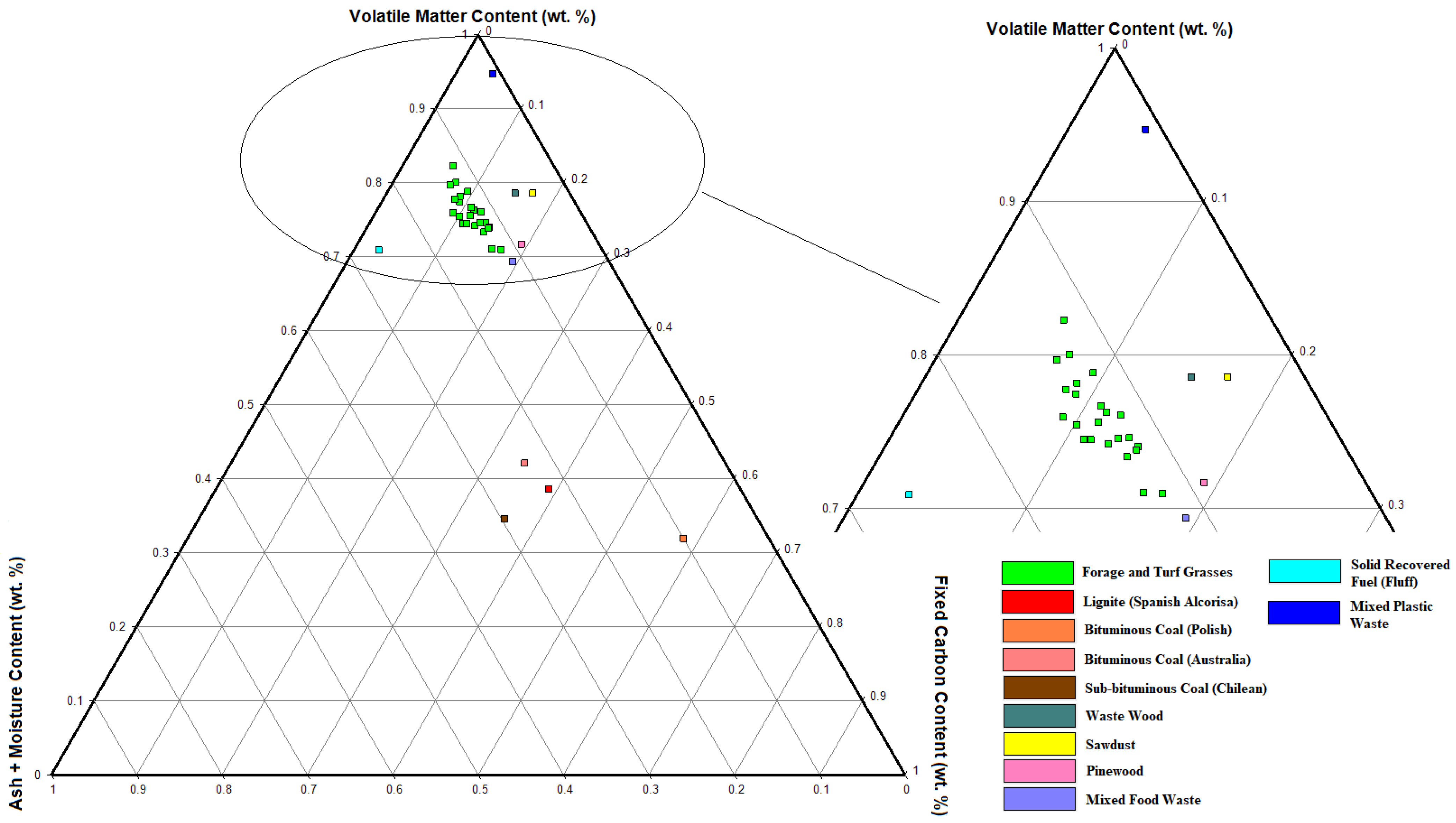

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Grass | {1} | {2} | {3} | {4} | {5} | {6} | {7} | {8} | {9} | {10} | {11} | {12} | {13} | {14} | {15} | {16} | {17} | {18} | {19} | {20} | {21} | {22} | {23} |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PR var. Pinia | 1.000000 | 0.996974 | 0.773455 | 1.000000 | 1.000000 | 0.763103 | 0.810083 | 0.933415 | 1.000000 | 0.943572 | 1.000000 | 0.999955 | 1.000000 | 1.000000 | 1.000000 | 1.000000 | 0.847683 | 1.000000 | 1.000000 | 0.999928 | 1.000000 | 0.999336 | |

| PR var. Info | 1.000000 | 0.999668 | 0.884507 | 1.000000 | 1.000000 | 0.877154 | 0.909395 | 0.978261 | 1.000000 | 0.865650 | 1.000000 | 0.999322 | 1.000000 | 1.000000 | 1.000000 | 1.000000 | 0.933024 | 1.000000 | 1.000000 | 0.999033 | 1.000000 | 0.994932 | |

| PR var. Nira | 0.996974 | 0.999668 | 1.000000 | 0.999999 | 0.994665 | 0.999999 | 1.000000 | 1.000000 | 0.984312 | 0.145525 | 0.999967 | 0.597720 | 0.999624 | 0.999999 | 1.000000 | 0.999950 | 1.000000 | 0.975557 | 0.997509 | 0.574153 | 0.914029 | 0.449881 | |

| PR var. Gazon | 0.773455 | 0.884507 | 1.000000 | 0.982023 | 0.731354 | 1.000000 | 1.000000 | 1.000000 | 0.630663 | 0.016994 | 0.943236 | 0.139016 | 0.879933 | 0.980032 | 0.995639 | 0.935850 | 1.000000 | 0.580394 | 0.786339 | 0.128878 | 0.406100 | 0.084343 | |

| KB var. MHR-NT-1318 | 1.000000 | 1.000000 | 0.999999 | 0.982023 | 1.000000 | 0.980012 | 0.988155 | 0.998976 | 1.000000 | 0.635898 | 1.000000 | 0.982935 | 1.000000 | 1.000000 | 1.000000 | 1.000000 | 0.992939 | 0.999999 | 1.000000 | 0.978980 | 0.999919 | 0.944818 | |

| KB var. Morfa | 1.000000 | 1.000000 | 0.994665 | 0.731354 | 1.000000 | 0.720323 | 0.770844 | 0.911271 | 1.000000 | 0.959549 | 1.000000 | 0.999984 | 1.000000 | 1.000000 | 0.999999 | 1.000000 | 0.812232 | 1.000000 | 1.000000 | 0.999973 | 1.000000 | 0.999692 | |

| KB var. Struga | 0.763103 | 0.877154 | 0.999999 | 1.000000 | 0.980012 | 0.720323 | 1.000000 | 1.000000 | 0.618758 | 0.016188 | 0.938575 | 0.133779 | 0.872422 | 0.977844 | 0.994985 | 0.930789 | 1.000000 | 0.568399 | 0.776236 | 0.123957 | 0.395220 | 0.080895 | |

| KB var. Harfa | 0.810083 | 0.909395 | 1.000000 | 1.000000 | 0.988155 | 0.770844 | 1.000000 | 1.000000 | 0.674281 | 0.020329 | 0.958368 | 0.159883 | 0.905453 | 0.986716 | 0.997476 | 0.952409 | 1.000000 | 0.624791 | 0.821940 | 0.148545 | 0.447582 | 0.098325 | |

| RF var. Nimba | 0.933415 | 0.978261 | 1.000000 | 1.000000 | 0.998976 | 0.911271 | 1.000000 | 1.000000 | 0.847286 | 0.044634 | 0.993226 | 0.285870 | 0.976825 | 0.998775 | 0.999898 | 0.991724 | 1.000000 | 0.809523 | 0.939638 | 0.268507 | 0.647492 | 0.187593 | |

| RF var. Oaza | 1.000000 | 1.000000 | 0.984312 | 0.630663 | 1.000000 | 1.000000 | 0.618758 | 0.674281 | 0.847286 | 0.982859 | 1.000000 | 0.999999 | 1.000000 | 1.000000 | 0.999989 | 1.000000 | 0.721906 | 1.000000 | 1.000000 | 0.999998 | 1.000000 | 0.999958 | |

| RF var. Leo-Pol | 0.943572 | 0.865650 | 0.145525 | 0.016994 | 0.635898 | 0.959549 | 0.016188 | 0.020329 | 0.044634 | 0.982859 | 0.774218 | 1.000000 | 0.870528 | 0.647607 | 0.499311 | 0.789957 | 0.024845 | 0.989397 | 0.937625 | 1.000000 | 0.998777 | 1.000000 | |

| RF var. Adio | 1.000000 | 1.000000 | 0.999967 | 0.943236 | 1.000000 | 1.000000 | 0.938575 | 0.958368 | 0.993226 | 1.000000 | 0.774218 | 0.996427 | 1.000000 | 1.000000 | 1.000000 | 1.000000 | 0.971689 | 1.000000 | 1.000000 | 0.995274 | 0.999997 | 0.982694 | |

| RF var. Nawojka | 0.999955 | 0.999322 | 0.597720 | 0.139016 | 0.982935 | 0.999984 | 0.133779 | 0.159883 | 0.285870 | 0.999999 | 1.000000 | 0.996427 | 0.999396 | 0.984705 | 0.949317 | 0.997164 | 0.186320 | 1.000000 | 0.999939 | 1.000000 | 1.000000 | 1.000000 | |

| KB var. MHR-NT-1419 | 1.000000 | 1.000000 | 0.999624 | 0.879933 | 1.000000 | 1.000000 | 0.872422 | 0.905453 | 0.976825 | 1.000000 | 0.870528 | 1.000000 | 0.999396 | 1.000000 | 1.000000 | 1.000000 | 0.929795 | 1.000000 | 1.000000 | 0.999134 | 1.000000 | 0.995360 | |

| KB var. Tęcza | 1.000000 | 1.000000 | 0.999999 | 0.980032 | 1.000000 | 1.000000 | 0.977844 | 0.986716 | 0.998775 | 1.000000 | 0.647607 | 1.000000 | 0.984705 | 1.000000 | 1.000000 | 1.000000 | 0.991986 | 0.999999 | 1.000000 | 0.981053 | 0.999936 | 0.949097 | |

| KB var. Alicja | 1.000000 | 1.000000 | 1.000000 | 0.995639 | 1.000000 | 0.999999 | 0.994985 | 0.997476 | 0.999898 | 0.999989 | 0.499311 | 1.000000 | 0.949317 | 1.000000 | 1.000000 | 1.000000 | 0.998723 | 0.999966 | 1.000000 | 0.940613 | 0.999144 | 0.876673 | |

| MF var. Kaskada | 1.000000 | 1.000000 | 0.999950 | 0.935850 | 1.000000 | 1.000000 | 0.930789 | 0.952409 | 0.991724 | 1.000000 | 0.789957 | 1.000000 | 0.997164 | 1.000000 | 1.000000 | 1.000000 | 0.967174 | 1.000000 | 1.000000 | 0.996212 | 0.999998 | 0.985440 | |

| MF var. Fantazja | 0.847683 | 0.933024 | 1.000000 | 1.000000 | 0.992939 | 0.812232 | 1.000000 | 1.000000 | 1.000000 | 0.721906 | 0.024845 | 0.971689 | 0.186320 | 0.929795 | 0.991986 | 0.998723 | 0.967174 | 0.674140 | 0.858227 | 0.173541 | 0.496342 | 0.116311 | |

| MFvar. Skiba | 1.000000 | 1.000000 | 0.975557 | 0.580394 | 0.999999 | 1.000000 | 0.568399 | 0.624791 | 0.809523 | 1.000000 | 0.989397 | 1.000000 | 1.000000 | 1.000000 | 0.999999 | 0.999966 | 1.000000 | 0.674140 | 1.000000 | 1.000000 | 1.000000 | 0.999986 | |

| T var. Egida | 1.000000 | 1.000000 | 0.997509 | 0.786339 | 1.000000 | 1.000000 | 0.776236 | 0.821940 | 0.939638 | 1.000000 | 0.937625 | 1.000000 | 0.999939 | 1.000000 | 1.000000 | 1.000000 | 1.000000 | 0.858227 | 1.000000 | 0.999903 | 1.000000 | 0.999162 | |

| T var. Skald | 0.999928 | 0.999033 | 0.574153 | 0.128878 | 0.978980 | 0.999973 | 0.123957 | 0.148545 | 0.268507 | 0.999998 | 1.000000 | 0.995274 | 1.000000 | 0.999134 | 0.981053 | 0.940613 | 0.996212 | 0.173541 | 1.000000 | 0.999903 | 1.000000 | 1.000000 | |

| CB var. Liryka | 1.000000 | 1.000000 | 0.914029 | 0.406100 | 0.999919 | 1.000000 | 0.395220 | 0.447582 | 0.647492 | 1.000000 | 0.998777 | 0.999997 | 1.000000 | 1.000000 | 0.999936 | 0.999144 | 0.999998 | 0.496342 | 1.000000 | 1.000000 | 1.000000 | 1.000000 | |

| SF var. Noni | 0.999336 | 0.994932 | 0.449881 | 0.084343 | 0.944818 | 0.999692 | 0.080895 | 0.098325 | 0.187593 | 0.999958 | 1.000000 | 0.982694 | 1.000000 | 0.995360 | 0.949097 | 0.876673 | 0.985440 | 0.116311 | 0.999986 | 0.999162 | 1.000000 | 1.000000 |

| Grass | {1} | {2} | {3} | {4} | {5} | {6} | {7} | {8} | {9} | {10} | {11} | {12} | {13} | {14} | {15} | {16} | {17} | {18} | {19} | {20} | {21} | {22} | {23} |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KB var. Alicja | 0.009998 | 0.999934 | 1.000000 | 0.119888 | 0.990772 | 0.107631 | 0.000369 | 0.302794 | 0.995790 | 1.000000 | 1.000000 | 1.000000 | 0.999880 | 1.000000 | 0.000185 | 0.966559 | 1.000000 | 0.812093 | 0.063724 | 0.165564 | 0.999993 | 0.000824 | |

| KB var. Tęcza | 0.009998 | 0.000437 | 0.015133 | 0.000185 | 0.440161 | 0.000185 | 0.999780 | 0.998641 | 0.375471 | 0.004599 | 0.010745 | 0.013033 | 0.201458 | 0.001384 | 0.111785 | 0.581692 | 0.002558 | 0.848731 | 1.000000 | 0.999968 | 0.133609 | 0.999999 | |

| KB var. MHR-NT-1419 | 0.999934 | 0.000437 | 0.999592 | 0.749870 | 0.481765 | 0.720249 | 0.000187 | 0.020786 | 0.551719 | 0.999999 | 0.999908 | 0.999780 | 0.776489 | 1.000000 | 0.000185 | 0.349599 | 1.000000 | 0.152020 | 0.002591 | 0.008674 | 0.875794 | 0.000195 | |

| KB var. MHR-NT-1318 | 1.000000 | 0.015133 | 0.999592 | 0.085399 | 0.997060 | 0.076211 | 0.000486 | 0.387043 | 0.998876 | 1.000000 | 1.000000 | 1.000000 | 0.999985 | 1.000000 | 0.000185 | 0.985833 | 1.000000 | 0.882284 | 0.090737 | 0.223021 | 1.000000 | 0.001219 | |

| KB var. Morfa | 0.119888 | 0.000185 | 0.749870 | 0.085399 | 0.001373 | 1.000000 | 0.000185 | 0.000191 | 0.001831 | 0.211715 | 0.113222 | 0.096791 | 0.004945 | 0.438309 | 0.000185 | 0.000779 | 0.308490 | 0.000323 | 0.000185 | 0.000187 | 0.008700 | 0.000185 | |

| KB var. Struga | 0.990772 | 0.440161 | 0.481765 | 0.997060 | 0.001373 | 0.001208 | 0.030125 | 0.998155 | 1.000000 | 0.955028 | 0.992309 | 0.995442 | 1.000000 | 0.788723 | 0.000199 | 1.000000 | 0.893853 | 1.000000 | 0.869420 | 0.980728 | 1.000000 | 0.076873 | |

| KB var. Harfa | 0.107631 | 0.000185 | 0.720249 | 0.076211 | 1.000000 | 0.001208 | 0.000185 | 0.000190 | 0.001602 | 0.192455 | 0.101541 | 0.086497 | 0.004305 | 0.408021 | 0.000185 | 0.000690 | 0.283449 | 0.000297 | 0.000185 | 0.000186 | 0.007587 | 0.000185 | |

| RF var. Nimba | 0.000369 | 0.999780 | 0.000187 | 0.000486 | 0.000185 | 0.030125 | 0.000185 | 0.574798 | 0.022806 | 0.000254 | 0.000385 | 0.000437 | 0.008708 | 0.000199 | 0.786980 | 0.052005 | 0.000218 | 0.144989 | 0.949729 | 0.777278 | 0.004949 | 1.000000 | |

| RF var. Oaza | 0.302794 | 0.998641 | 0.020786 | 0.387043 | 0.000191 | 0.998155 | 0.000190 | 0.574798 | 0.995490 | 0.180974 | 0.316514 | 0.355332 | 0.959237 | 0.070202 | 0.002412 | 0.999805 | 0.117060 | 1.000000 | 1.000000 | 1.000000 | 0.903993 | 0.809521 | |

| RF var. Leo-Pol | 0.995790 | 0.375471 | 0.551719 | 0.998876 | 0.001831 | 1.000000 | 0.001602 | 0.022806 | 0.995490 | 0.973867 | 0.996582 | 0.998133 | 1.000000 | 0.843547 | 0.000194 | 1.000000 | 0.929578 | 1.000000 | 0.819150 | 0.965485 | 1.000000 | 0.059677 | |

| RF var. Adio | 1.000000 | 0.004599 | 0.999999 | 1.000000 | 0.211715 | 0.955028 | 0.192455 | 0.000254 | 0.180974 | 0.973867 | 1.000000 | 1.000000 | 0.997786 | 1.000000 | 0.000185 | 0.890468 | 1.000000 | 0.646272 | 0.032035 | 0.090911 | 0.999702 | 0.000443 | |

| RF var. Nawojka | 1.000000 | 0.010745 | 0.999908 | 1.000000 | 0.113222 | 0.992309 | 0.101541 | 0.000385 | 0.316514 | 0.996582 | 1.000000 | 1.000000 | 0.999914 | 1.000000 | 0.000185 | 0.970824 | 1.000000 | 0.825490 | 0.067828 | 0.174584 | 0.999996 | 0.000887 | |

| PR var. Pinia | 1.000000 | 0.013033 | 0.999780 | 1.000000 | 0.096791 | 0.995442 | 0.086497 | 0.000437 | 0.355332 | 0.998133 | 1.000000 | 1.000000 | 0.999967 | 1.000000 | 0.000185 | 0.980282 | 1.000000 | 0.858994 | 0.080015 | 0.200823 | 0.999999 | 0.001060 | |

| PR var. Info | 0.999880 | 0.201458 | 0.776489 | 0.999985 | 0.004945 | 1.000000 | 0.004305 | 0.008708 | 0.959237 | 1.000000 | 0.997786 | 0.999914 | 0.999967 | 0.960844 | 0.000187 | 1.000000 | 0.989168 | 0.999974 | 0.604262 | 0.855255 | 1.000000 | 0.024408 | |

| PR var. Nira | 1.000000 | 0.001384 | 1.000000 | 1.000000 | 0.438309 | 0.788723 | 0.408021 | 0.000199 | 0.070202 | 0.843547 | 1.000000 | 1.000000 | 1.000000 | 0.960844 | 0.000185 | 0.657004 | 1.000000 | 0.369069 | 0.010071 | 0.031759 | 0.987386 | 0.000242 | |

| PR var. Gazon | 0.000185 | 0.111785 | 0.000185 | 0.000185 | 0.000185 | 0.000199 | 0.000185 | 0.786980 | 0.002412 | 0.000194 | 0.000185 | 0.000185 | 0.000185 | 0.000187 | 0.000185 | 0.000216 | 0.000185 | 0.000343 | 0.019416 | 0.005959 | 0.000186 | 0.547047 | |

| MF var. Kaskada | 0.966559 | 0.581692 | 0.349599 | 0.985833 | 0.000779 | 1.000000 | 0.000690 | 0.052005 | 0.999805 | 1.000000 | 0.890468 | 0.970824 | 0.980282 | 1.000000 | 0.657004 | 0.000216 | 0.792824 | 1.000000 | 0.943062 | 0.995582 | 1.000000 | 0.125265 | |

| MF var. Fantazja | 1.000000 | 0.002558 | 1.000000 | 1.000000 | 0.308490 | 0.893853 | 0.283449 | 0.000218 | 0.117060 | 0.929578 | 1.000000 | 1.000000 | 1.000000 | 0.989168 | 1.000000 | 0.000185 | 0.792824 | 0.508818 | 0.018553 | 0.055684 | 0.997646 | 0.000316 | |

| MF var. Skiba | 0.812093 | 0.848731 | 0.152020 | 0.882284 | 0.000323 | 1.000000 | 0.000297 | 0.144989 | 1.000000 | 1.000000 | 0.646272 | 0.825490 | 0.858994 | 0.999974 | 0.369069 | 0.000343 | 1.000000 | 0.508818 | 0.996220 | 0.999963 | 0.999657 | 0.300256 | |

| T var. Egida | 0.063724 | 1.000000 | 0.002591 | 0.090737 | 0.000185 | 0.869420 | 0.000185 | 0.949729 | 1.000000 | 0.819150 | 0.032035 | 0.067828 | 0.080015 | 0.604262 | 0.010071 | 0.019416 | 0.943062 | 0.018553 | 0.996220 | 1.000000 | 0.472070 | 0.994793 | |

| T var. Skald | 0.165564 | 0.999968 | 0.008674 | 0.223021 | 0.000187 | 0.980728 | 0.000186 | 0.777278 | 1.000000 | 0.965485 | 0.090911 | 0.174584 | 0.200823 | 0.855255 | 0.031759 | 0.005959 | 0.995582 | 0.055684 | 0.999963 | 1.000000 | 0.749238 | 0.937573 | |

| CB var. Liryka | 0.999993 | 0.133609 | 0.875794 | 1.000000 | 0.008700 | 1.000000 | 0.007587 | 0.004949 | 0.903993 | 1.000000 | 0.999702 | 0.999996 | 0.999999 | 1.000000 | 0.987386 | 0.000186 | 1.000000 | 0.997646 | 0.999657 | 0.472070 | 0.749238 | 0.014251 | |

| SF var. Noni | 0.000824 | 0.999999 | 0.000195 | 0.001219 | 0.000185 | 0.076873 | 0.000185 | 1.000000 | 0.809521 | 0.059677 | 0.000443 | 0.000887 | 0.001060 | 0.024408 | 0.000242 | 0.547047 | 0.125265 | 0.000316 | 0.300256 | 0.994793 | 0.937573 | 0.014251 |

| Grass | {1} | {2} | {3} | {4} | {5} | {6} | {7} | {8} | {9} | {10} | {11} | {12} | {13} | {14} | {15} | {16} | {17} | {18} | {19} | {20} | {21} | {22} | {23} |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KB var. Alicja | 0.980680 | 0.843664 | 0.975708 | 0.038515 | 1.000000 | 0.002791 | 0.159848 | 0.934199 | 0.936268 | 0.999997 | 1.000000 | 0.999645 | 1.000000 | 0.695312 | 0.006538 | 1.000000 | 0.695908 | 1.000000 | 0.833792 | 0.622329 | 0.999968 | 0.053721 | |

| KB var. Tęcza | 0.980680 | 0.041634 | 0.118754 | 0.000357 | 0.673147 | 0.000190 | 0.989671 | 1.000000 | 1.000000 | 0.537820 | 0.998580 | 0.328390 | 0.991804 | 0.021034 | 0.418187 | 0.980426 | 0.021087 | 0.999626 | 1.000000 | 1.000000 | 1.000000 | 0.888345 | |

| KB var. MHR-NT-1419 | 0.843664 | 0.041634 | 1.000000 | 0.976919 | 0.997745 | 0.536407 | 0.000449 | 0.022126 | 0.022570 | 0.999710 | 0.639691 | 0.999998 | 0.773599 | 1.000000 | 0.000187 | 0.844722 | 1.000000 | 0.552883 | 0.010923 | 0.004025 | 0.191566 | 0.000234 | |

| KB var. MHR-NT-1318 | 0.975708 | 0.118754 | 1.000000 | 0.847979 | 0.999988 | 0.273428 | 0.001299 | 0.067871 | 0.069092 | 1.000000 | 0.885179 | 1.000000 | 0.951979 | 1.000000 | 0.000199 | 0.976008 | 1.000000 | 0.826061 | 0.035732 | 0.013940 | 0.414702 | 0.000419 | |

| KB var. Morfa | 0.038515 | 0.000357 | 0.976919 | 0.847979 | 0.222759 | 0.999998 | 0.000185 | 0.000256 | 0.000258 | 0.321388 | 0.015363 | 0.529242 | 0.027311 | 0.996095 | 0.000185 | 0.038733 | 0.996066 | 0.010732 | 0.000213 | 0.000192 | 0.001693 | 0.000185 | |

| KB var. Struga | 1.000000 | 0.673147 | 0.997745 | 0.999988 | 0.222759 | 0.024431 | 0.025001 | 0.511621 | 0.516558 | 1.000000 | 0.999971 | 1.000000 | 0.999999 | 0.984322 | 0.000765 | 1.000000 | 0.984413 | 0.999833 | 0.350688 | 0.184255 | 0.965022 | 0.006713 | |

| KB var. Harfa | 0.002791 | 0.000190 | 0.536407 | 0.273428 | 0.999998 | 0.024431 | 0.000185 | 0.000187 | 0.000187 | 0.041412 | 0.001082 | 0.093629 | 0.001923 | 0.708916 | 0.000185 | 0.002809 | 0.708327 | 0.000768 | 0.000185 | 0.000185 | 0.000247 | 0.000185 | |

| RF var. Nimba | 0.159848 | 0.989671 | 0.000449 | 0.001299 | 0.000185 | 0.025001 | 0.000185 | 0.998513 | 0.998407 | 0.014433 | 0.309142 | 0.005601 | 0.208849 | 0.000291 | 0.999811 | 0.159114 | 0.000291 | 0.382374 | 0.999916 | 1.000000 | 0.798021 | 1.000000 | |

| RF var. Oaza | 0.934199 | 1.000000 | 0.022126 | 0.067871 | 0.000256 | 0.511621 | 0.000187 | 0.998513 | 1.000000 | 0.382636 | 0.990014 | 0.211672 | 0.964600 | 0.010827 | 0.576988 | 0.933576 | 0.010855 | 0.996194 | 1.000000 | 1.000000 | 0.999999 | 0.959715 | |

| RF var. Leo-Pol | 0.936268 | 1.000000 | 0.022570 | 0.069092 | 0.000258 | 0.516558 | 0.000187 | 0.998407 | 1.000000 | 0.387086 | 0.990508 | 0.214744 | 0.965931 | 0.011054 | 0.571989 | 0.935658 | 0.011082 | 0.996417 | 1.000000 | 1.000000 | 0.999999 | 0.958208 | |

| RF var. Adio | 0.999997 | 0.537820 | 0.999710 | 1.000000 | 0.321388 | 1.000000 | 0.041412 | 0.014433 | 0.382636 | 0.387086 | 0.999607 | 1.000000 | 0.999975 | 0.996311 | 0.000482 | 0.999997 | 0.996339 | 0.998519 | 0.246042 | 0.120067 | 0.913076 | 0.003757 | |

| RF var. Nawojka | 1.000000 | 0.998580 | 0.639691 | 0.885179 | 0.015363 | 0.999971 | 0.001082 | 0.309142 | 0.990014 | 0.990508 | 0.999607 | 0.991919 | 1.000000 | 0.465874 | 0.017171 | 1.000000 | 0.466479 | 1.000000 | 0.955962 | 0.830873 | 1.000000 | 0.120847 | |

| PR var. Pinia | 0.999645 | 0.328390 | 0.999998 | 1.000000 | 0.529242 | 1.000000 | 0.093629 | 0.005601 | 0.211672 | 0.214744 | 1.000000 | 0.991919 | 0.998606 | 0.999885 | 0.000277 | 0.999654 | 0.999886 | 0.981212 | 0.124120 | 0.054564 | 0.752965 | 0.001459 | |

| PR var. Info | 1.000000 | 0.991804 | 0.773599 | 0.951979 | 0.027311 | 0.999999 | 0.001923 | 0.208849 | 0.964600 | 0.965931 | 0.999975 | 1.000000 | 0.998606 | 0.608280 | 0.009506 | 1.000000 | 0.608905 | 1.000000 | 0.892361 | 0.708647 | 0.999996 | 0.074036 | |

| PR var. Nira | 0.695312 | 0.021034 | 1.000000 | 1.000000 | 0.996095 | 0.984322 | 0.708916 | 0.000291 | 0.010827 | 0.011054 | 0.996311 | 0.465874 | 0.999885 | 0.608280 | 0.000186 | 0.696723 | 1.000000 | 0.384951 | 0.005221 | 0.001920 | 0.110236 | 0.000204 | |

| PR var. Gazon | 0.006538 | 0.418187 | 0.000187 | 0.000199 | 0.000185 | 0.000765 | 0.000185 | 0.999811 | 0.576988 | 0.571989 | 0.000482 | 0.017171 | 0.000277 | 0.009506 | 0.000186 | 0.006497 | 0.000186 | 0.024345 | 0.744286 | 0.913290 | 0.120234 | 1.000000 | |

| MF var. Kaskada | 1.000000 | 0.980426 | 0.844722 | 0.976008 | 0.038733 | 1.000000 | 0.002809 | 0.159114 | 0.933576 | 0.935658 | 0.999997 | 1.000000 | 0.999654 | 1.000000 | 0.696723 | 0.006497 | 0.697318 | 1.000000 | 0.832694 | 0.620854 | 0.999966 | 0.053429 | |

| MF var. Fantazja | 0.695908 | 0.021087 | 1.000000 | 1.000000 | 0.996066 | 0.984413 | 0.708327 | 0.000291 | 0.010855 | 0.011082 | 0.996339 | 0.466479 | 0.999886 | 0.608905 | 1.000000 | 0.000186 | 0.697318 | 0.385510 | 0.005235 | 0.001925 | 0.110466 | 0.000204 | |

| MF var. Skiba | 1.000000 | 0.999626 | 0.552883 | 0.826061 | 0.010732 | 0.999833 | 0.000768 | 0.382374 | 0.996194 | 0.996417 | 0.998519 | 1.000000 | 0.981212 | 1.000000 | 0.384951 | 0.024345 | 1.000000 | 0.385510 | 0.977739 | 0.888980 | 1.000000 | 0.159502 | |

| T var. Egida | 0.833792 | 1.000000 | 0.010923 | 0.035732 | 0.000213 | 0.350688 | 0.000185 | 0.999916 | 1.000000 | 1.000000 | 0.246042 | 0.955962 | 0.124120 | 0.892361 | 0.005221 | 0.744286 | 0.832694 | 0.005235 | 0.977739 | 1.000000 | 0.999943 | 0.991194 | |

| T var. Skald | 0.622329 | 1.000000 | 0.004025 | 0.013940 | 0.000192 | 0.184255 | 0.000185 | 1.000000 | 1.000000 | 1.000000 | 0.120067 | 0.830873 | 0.054564 | 0.708647 | 0.001920 | 0.913290 | 0.620854 | 0.001925 | 0.888980 | 1.000000 | 0.997327 | 0.999619 | |

| CB var. Liryka | 0.999968 | 1.000000 | 0.191566 | 0.414702 | 0.001693 | 0.965022 | 0.000247 | 0.798021 | 0.999999 | 0.999999 | 0.913076 | 1.000000 | 0.752965 | 0.999996 | 0.110236 | 0.120234 | 0.999966 | 0.110466 | 1.000000 | 0.999943 | 0.997327 | 0.493102 | |

| SF var. Noni | 0.053721 | 0.888345 | 0.000234 | 0.000419 | 0.000185 | 0.006713 | 0.000185 | 1.000000 | 0.959715 | 0.958208 | 0.003757 | 0.120847 | 0.001459 | 0.074036 | 0.000204 | 1.000000 | 0.053429 | 0.000204 | 0.159502 | 0.991194 | 0.999619 | 0.493102 |

| Grass | {1} | {2} | {3} | {4} | {5} | {6} | {7} | {8} | {9} | {10} | {11} | {12} | {13} | {14} | {15} | {16} | {17} | {18} | {19} | {20} | {21} | {22} | {23} |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KB var. Alicja | 0.019657 | 1.000000 | 0.959694 | 0.000189 | 0.002649 | 0.000185 | 0.999958 | 0.966220 | 0.000420 | 0.000236 | 0.000185 | 0.434327 | 0.999808 | 1.000000 | 1.000000 | 0.000185 | 0.000606 | 0.203162 | 0.900860 | 0.613203 | 0.721009 | 0.000185 | |

| KB var. Tęcza | 0.019657 | 0.096556 | 0.000227 | 0.672831 | 1.000000 | 0.275834 | 0.000820 | 0.742414 | 0.998630 | 0.969170 | 0.367061 | 0.000186 | 0.000614 | 0.008528 | 0.002380 | 0.015759 | 0.999794 | 0.999997 | 0.000204 | 0.000187 | 0.000190 | 0.000185 | |

| KB var. MHR-NT-1419 | 1.000000 | 0.096556 | 0.676609 | 0.000226 | 0.015884 | 0.000188 | 0.982391 | 0.999808 | 0.002005 | 0.000639 | 0.000192 | 0.136780 | 0.966220 | 0.999999 | 0.999254 | 0.000185 | 0.003312 | 0.560481 | 0.537081 | 0.236268 | 0.317907 | 0.000185 | |

| KB var. MHR-NT-1318 | 0.959694 | 0.000227 | 0.676609 | 0.000185 | 0.000188 | 0.000185 | 1.000000 | 0.075630 | 0.000185 | 0.000185 | 0.000185 | 0.999996 | 1.000000 | 0.993607 | 0.999932 | 0.000185 | 0.000185 | 0.001378 | 1.000000 | 1.000000 | 1.000000 | 0.000186 | |

| KB var. Morfa | 0.000189 | 0.672831 | 0.000226 | 0.000185 | 0.972363 | 1.000000 | 0.000185 | 0.002949 | 0.999969 | 1.000000 | 1.000000 | 0.000185 | 0.000185 | 0.000186 | 0.000185 | 0.971026 | 0.999690 | 0.140233 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | |

| KB var. Struga | 0.002649 | 1.000000 | 0.015884 | 0.000188 | 0.972363 | 0.719199 | 0.000239 | 0.294904 | 1.000000 | 0.999944 | 0.816410 | 0.000185 | 0.000221 | 0.001155 | 0.000407 | 0.095858 | 1.000000 | 0.989738 | 0.000186 | 0.000185 | 0.000185 | 0.000185 | |

| KB var. Harfa | 0.000185 | 0.275834 | 0.000188 | 0.000185 | 1.000000 | 0.719199 | 0.000185 | 0.000546 | 0.983898 | 0.999571 | 1.000000 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.999875 | 0.957324 | 0.030309 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | |

| RF var. Nimba | 0.999958 | 0.000820 | 0.982391 | 1.000000 | 0.000185 | 0.000239 | 0.000185 | 0.367061 | 0.000188 | 0.000185 | 0.000185 | 0.981764 | 1.000000 | 1.000000 | 1.000000 | 0.000185 | 0.000192 | 0.012587 | 0.999996 | 0.997423 | 0.999482 | 0.000185 | |

| RF var. Oaza | 0.966220 | 0.742414 | 0.999808 | 0.075630 | 0.002949 | 0.294904 | 0.000546 | 0.367061 | 0.062652 | 0.020602 | 0.000820 | 0.005276 | 0.302454 | 0.878018 | 0.622921 | 0.000189 | 0.095222 | 0.998161 | 0.045347 | 0.011334 | 0.017887 | 0.000185 | |

| RF var. Leo-Pol | 0.000420 | 0.998630 | 0.002005 | 0.000185 | 0.999969 | 1.000000 | 0.983898 | 0.000188 | 0.062652 | 1.000000 | 0.994994 | 0.000185 | 0.000187 | 0.000266 | 0.000201 | 0.396508 | 1.000000 | 0.761478 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | |

| RF var. Adio | 0.000236 | 0.969170 | 0.000639 | 0.000185 | 1.000000 | 0.999944 | 0.999571 | 0.000185 | 0.020602 | 1.000000 | 0.999946 | 0.000185 | 0.000185 | 0.000202 | 0.000188 | 0.680377 | 1.000000 | 0.479364 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | |

| RF var. Nawojka | 0.000185 | 0.367061 | 0.000192 | 0.000185 | 1.000000 | 0.816410 | 1.000000 | 0.000185 | 0.000820 | 0.994994 | 0.999946 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.999161 | 0.983002 | 0.046690 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | |

| PR var. Pinia | 0.434327 | 0.000186 | 0.136780 | 0.999996 | 0.000185 | 0.000185 | 0.000185 | 0.981764 | 0.005276 | 0.000185 | 0.000185 | 0.000185 | 0.991431 | 0.634547 | 0.885180 | 0.000185 | 0.000185 | 0.000224 | 1.000000 | 1.000000 | 1.000000 | 0.000223 | |

| PR var. Info | 0.999808 | 0.000614 | 0.966220 | 1.000000 | 0.000185 | 0.000221 | 0.000185 | 1.000000 | 0.302454 | 0.000187 | 0.000185 | 0.000185 | 0.991431 | 0.999998 | 1.000000 | 0.000185 | 0.000189 | 0.009103 | 1.000000 | 0.999136 | 0.999866 | 0.000185 | |

| PR var. Nira | 1.000000 | 0.008528 | 0.999999 | 0.993607 | 0.000186 | 0.001155 | 0.000185 | 1.000000 | 0.878018 | 0.000266 | 0.000202 | 0.000185 | 0.634547 | 0.999998 | 1.000000 | 0.000185 | 0.000341 | 0.107285 | 0.975298 | 0.800936 | 0.880431 | 0.000185 | |

| PR var. Gazon | 1.000000 | 0.002380 | 0.999254 | 0.999932 | 0.000185 | 0.000407 | 0.000185 | 1.000000 | 0.622921 | 0.000201 | 0.000188 | 0.000185 | 0.885180 | 1.000000 | 1.000000 | 0.000185 | 0.000215 | 0.036333 | 0.999208 | 0.963598 | 0.985819 | 0.000185 | |

| MF var. Kaskada | 0.000185 | 0.015759 | 0.000185 | 0.000185 | 0.971026 | 0.095858 | 0.999875 | 0.000185 | 0.000189 | 0.396508 | 0.680377 | 0.999161 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.296404 | 0.001017 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | |

| MF var. Fantazja | 0.000606 | 0.999794 | 0.003312 | 0.000185 | 0.999690 | 1.000000 | 0.957324 | 0.000192 | 0.095222 | 1.000000 | 1.000000 | 0.983002 | 0.000185 | 0.000189 | 0.000341 | 0.000215 | 0.296404 | 0.855033 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | |

| MF var. Skiba | 0.203162 | 0.999997 | 0.560481 | 0.001378 | 0.140233 | 0.989738 | 0.030309 | 0.012587 | 0.998161 | 0.761478 | 0.479364 | 0.046690 | 0.000224 | 0.009103 | 0.107285 | 0.036333 | 0.001017 | 0.855033 | 0.000792 | 0.000288 | 0.000373 | 0.000185 | |

| T var. Egida | 0.900860 | 0.000204 | 0.537081 | 1.000000 | 0.000185 | 0.000186 | 0.000185 | 0.999996 | 0.045347 | 0.000185 | 0.000185 | 0.000185 | 1.000000 | 1.000000 | 0.975298 | 0.999208 | 0.000185 | 0.000185 | 0.000792 | 1.000000 | 1.000000 | 0.000187 | |

| T var. Skald | 0.613203 | 0.000187 | 0.236268 | 1.000000 | 0.000185 | 0.000185 | 0.000185 | 0.997423 | 0.011334 | 0.000185 | 0.000185 | 0.000185 | 1.000000 | 0.999136 | 0.800936 | 0.963598 | 0.000185 | 0.000185 | 0.000288 | 1.000000 | 1.000000 | 0.000199 | |

| CB var. Liryka | 0.721009 | 0.000190 | 0.317907 | 1.000000 | 0.000185 | 0.000185 | 0.000185 | 0.999482 | 0.017887 | 0.000185 | 0.000185 | 0.000185 | 1.000000 | 0.999866 | 0.880431 | 0.985819 | 0.000185 | 0.000185 | 0.000373 | 1.000000 | 1.000000 | 0.000192 | |

| SF var. Noni | 0.000185 | 0.000185 | 0.000185 | 0.000186 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.000223 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.000187 | 0.000199 | 0.000192 |

| Grass | {1} | {2} | {3} | {4} | {5} | {6} | {7} | {8} | {9} | {10} | {11} | {12} | {13} | {14} | {15} | {16} | {17} | {18} | {19} | {20} | {21} | {22} | {23} |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| KB var. Alicja | 1.000000 | 0.660479 | 0.000248 | 0.060298 | 0.734995 | 0.001712 | 0.705364 | 1.000000 | 0.011559 | 0.015134 | 0.000239 | 0.000196 | 0.129669 | 0.154592 | 0.255866 | 0.001264 | 0.442819 | 1.000000 | 0.005611 | 0.002163 | 0.287851 | 0.000185 | |

| KB var. Tęcza | 1.000000 | 0.415438 | 0.000201 | 0.141519 | 0.914831 | 0.004908 | 0.459447 | 1.000000 | 0.031555 | 0.040553 | 0.000389 | 0.000187 | 0.054587 | 0.066721 | 0.120412 | 0.003563 | 0.688803 | 0.999989 | 0.001950 | 0.000794 | 0.138818 | 0.000185 | |

| KB var. MHR-NT-1419 | 0.660479 | 0.415438 | 0.131005 | 0.000203 | 0.002700 | 0.000185 | 1.000000 | 0.798467 | 0.000186 | 0.000187 | 0.000185 | 0.041984 | 0.999996 | 0.999999 | 1.000000 | 0.000185 | 0.000809 | 0.964360 | 0.870514 | 0.685646 | 1.000000 | 0.000185 | |

| KB var. MHR-NT-1318 | 0.000248 | 0.000201 | 0.131005 | 0.000185 | 0.000185 | 0.000185 | 0.112434 | 0.000330 | 0.000185 | 0.000185 | 0.000185 | 1.000000 | 0.663574 | 0.608925 | 0.439645 | 0.000185 | 0.000185 | 0.000850 | 0.999362 | 0.999992 | 0.398943 | 0.000196 | |

| KB var. Morfa | 0.060298 | 0.141519 | 0.000203 | 0.000185 | 0.998584 | 0.999689 | 0.000209 | 0.034131 | 1.000000 | 1.000000 | 0.834106 | 0.000185 | 0.000185 | 0.000185 | 0.000186 | 0.998979 | 0.999995 | 0.009928 | 0.000185 | 0.000185 | 0.000187 | 0.000185 | |

| KB var. Struga | 0.734995 | 0.914831 | 0.002700 | 0.000185 | 0.998584 | 0.551895 | 0.003291 | 0.587577 | 0.922320 | 0.949027 | 0.091928 | 0.000185 | 0.000278 | 0.000315 | 0.000488 | 0.477478 | 1.000000 | 0.303786 | 0.000186 | 0.000185 | 0.000561 | 0.000185 | |

| KB var. Harfa | 0.001712 | 0.004908 | 0.000185 | 0.000185 | 0.999689 | 0.551895 | 0.000185 | 0.000942 | 1.000000 | 1.000000 | 0.999996 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 1.000000 | 0.828053 | 0.000350 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | |

| RF var. Nimba | 0.705364 | 0.459447 | 1.000000 | 0.112434 | 0.000209 | 0.003291 | 0.000185 | 0.834689 | 0.000187 | 0.000188 | 0.000185 | 0.035151 | 0.999986 | 0.999997 | 1.000000 | 0.000185 | 0.000974 | 0.975439 | 0.838459 | 0.640113 | 1.000000 | 0.000185 | |

| RF var. Oaza | 1.000000 | 1.000000 | 0.798467 | 0.000330 | 0.034131 | 0.587577 | 0.000942 | 0.834689 | 0.006102 | 0.008053 | 0.000209 | 0.000210 | 0.207190 | 0.242490 | 0.376775 | 0.000698 | 0.309614 | 1.000000 | 0.010655 | 0.004121 | 0.416483 | 0.000185 | |

| RF var. Leo-Pol | 0.011559 | 0.031555 | 0.000186 | 0.000185 | 1.000000 | 0.922320 | 1.000000 | 0.000187 | 0.006102 | 1.000000 | 0.991621 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 1.000000 | 0.993444 | 0.001673 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | |

| RF var. Adio | 0.015134 | 0.040553 | 0.000187 | 0.000185 | 1.000000 | 0.949027 | 1.000000 | 0.000188 | 0.008053 | 1.000000 | 0.984077 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 1.000000 | 0.996956 | 0.002193 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | |

| RF var. Nawojka | 0.000239 | 0.000389 | 0.000185 | 0.000185 | 0.834106 | 0.091928 | 0.999996 | 0.000185 | 0.000209 | 0.991621 | 0.984077 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 1.000000 | 0.234886 | 0.000189 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | |

| PR var. Pinia | 0.000196 | 0.000187 | 0.041984 | 1.000000 | 0.000185 | 0.000185 | 0.000185 | 0.035151 | 0.000210 | 0.000185 | 0.000185 | 0.000185 | 0.352760 | 0.307296 | 0.190880 | 0.000185 | 0.000185 | 0.000318 | 0.973471 | 0.997403 | 0.167138 | 0.000249 | |

| PR var. Info | 0.129669 | 0.054587 | 0.999996 | 0.663574 | 0.000185 | 0.000278 | 0.000185 | 0.999986 | 0.207190 | 0.000185 | 0.000185 | 0.000185 | 0.352760 | 1.000000 | 1.000000 | 0.000185 | 0.000204 | 0.449923 | 0.999892 | 0.996525 | 1.000000 | 0.000185 | |

| PR var. Nira | 0.154592 | 0.066721 | 0.999999 | 0.608925 | 0.000185 | 0.000315 | 0.000185 | 0.999997 | 0.242490 | 0.000185 | 0.000185 | 0.000185 | 0.307296 | 1.000000 | 1.000000 | 0.000185 | 0.000210 | 0.503729 | 0.999706 | 0.993395 | 1.000000 | 0.000185 | |

| PR var. Gazon | 0.255866 | 0.120412 | 1.000000 | 0.439645 | 0.000186 | 0.000488 | 0.000185 | 1.000000 | 0.376775 | 0.000185 | 0.000185 | 0.000185 | 0.190880 | 1.000000 | 1.000000 | 0.000185 | 0.000249 | 0.674102 | 0.996432 | 0.967507 | 1.000000 | 0.000185 | |

| MF var. Kaskada | 0.001264 | 0.003563 | 0.000185 | 0.000185 | 0.998979 | 0.477478 | 1.000000 | 0.000185 | 0.000698 | 1.000000 | 1.000000 | 1.000000 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.766913 | 0.000293 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | |

| MF var. Fantazja | 0.442819 | 0.688803 | 0.000809 | 0.000185 | 0.999995 | 1.000000 | 0.828053 | 0.000974 | 0.309614 | 0.993444 | 0.996956 | 0.234886 | 0.000185 | 0.000204 | 0.000210 | 0.000249 | 0.766913 | 0.126566 | 0.000185 | 0.000185 | 0.000266 | 0.000185 | |

| MF var. Skiba | 1.000000 | 0.999989 | 0.964360 | 0.000850 | 0.009928 | 0.303786 | 0.000350 | 0.975439 | 1.000000 | 0.001673 | 0.002193 | 0.000189 | 0.000318 | 0.449923 | 0.503729 | 0.674102 | 0.000293 | 0.126566 | 0.036429 | 0.014933 | 0.715904 | 0.000185 | |

| T var. Egida | 0.005611 | 0.001950 | 0.870514 | 0.999362 | 0.000185 | 0.000186 | 0.000185 | 0.838459 | 0.010655 | 0.000185 | 0.000185 | 0.000185 | 0.973471 | 0.999892 | 0.999706 | 0.996432 | 0.000185 | 0.000185 | 0.036429 | 1.000000 | 0.994036 | 0.000185 | |

| T var. Skald | 0.002163 | 0.000794 | 0.685646 | 0.999992 | 0.000185 | 0.000185 | 0.000185 | 0.640113 | 0.004121 | 0.000185 | 0.000185 | 0.000185 | 0.997403 | 0.996525 | 0.993395 | 0.967507 | 0.000185 | 0.000185 | 0.014933 | 1.000000 | 0.954894 | 0.000185 | |

| CB var. Liryka | 0.287851 | 0.138818 | 1.000000 | 0.398943 | 0.000187 | 0.000561 | 0.000185 | 1.000000 | 0.416483 | 0.000185 | 0.000185 | 0.000185 | 0.167138 | 1.000000 | 1.000000 | 1.000000 | 0.000185 | 0.000266 | 0.715904 | 0.994036 | 0.954894 | 0.000185 | |

| SF var. Noni | 0.000185 | 0.000185 | 0.000185 | 0.000196 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.000249 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.000185 | 0.000185 |

References

- Butlewski, K. Concept for Biomass and Organic Waste Refinery Plants Based on the Locally Available Organic Materials in Rural Areas of Poland. Energies 2022, 15, 3392. [Google Scholar] [CrossRef]

- Rather, R.A.; Wani, A.W.; Mumtaz, S.; Padder, S.A.; Khan, A.H.; Almohana, A.I.; Almojil, S.F.; Alam, S.S.; Baba, T.R. Bioenergy: A foundation to environmental sustainability in a changing global climate scenario. J. King Saud Univ.—Sci. 2022, 34, 101734. [Google Scholar] [CrossRef]

- Smith, M.; Kralli, A.; Lemoine, P. Analysis on Biomass in National Energy and Climate Plans; Trinomics, B.V.: Rotterdam, The Netherlands, 2021; pp. 11–17. [Google Scholar]

- Andersen, S.P.; Allen, B.; Domingo, G.C. Biomass in the EU Green Deal: Towards Consensus on the Use of Biomass for EU Bioenergy; Policy report; Institute for European Environmental Policy (IEEP): Brussels, Belgium, 2021; pp. 6–51. [Google Scholar]

- Titus, B.D.; Brown, K.; Helmisaari, H.-S.; Vanguelova, E.; Stupak, I.; Evans, A.; Clarke, N.; Guidi, C.; Bruckman, V.J.; Varnagiryte-Kabasinskiene, I.; et al. Sustainable forest biomass: A review of current residue harvesting guidelines. Energy Sustain. Soc. 2021, 11, 10. [Google Scholar] [CrossRef]

- Bransby, I.D.; Allen, D.J.; Gutterson, N.; Ikonen, G.; Richard, E.; Rooney, W.; Van Santen, E. Engineering Advantages, Challenges and Status of Grass Energy Crops. In Plant Biotechnology for Sustainable Production of Energy and Co-Products; Mascia, P., Scheffran, J., Widholm, J., Eds.; Biotechnology in Agriculture and Forestry, volume 66; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- Wicke, B.; Kluts, I.; Lesschen, J.P. Bioenergy Potential and Greenhouse Gas Emissions from Intensifying European Temporary Grasslands. Land 2020, 9, 457. [Google Scholar] [CrossRef]

- Elbersen, B.; Staritsky, I.; Hengeveld, G.; Jeurissen, L.; Lesschen, J.-P. Outlook of Spatial Biomass Value Chains in EU 28—Deliverable 2.3 of the Biomass Policies Project; Wageningen University and Research: Wageningen, The Netherlands, 2016. [Google Scholar]

- Cornell University. Benefits of Grass Biomass. Cornell University Cooperative Extension, Bioenergy Information Sheet #2, 2014; Cornell University, Department of Crop and Soil Sciences; pp 1–2. Available online: http://forages.org/files/bioenergy/Bioenergy_Info_Sheet_2.pdf (accessed on 1 August 2022).

- Bijarchiyan, M.; Sahebi, H.; Mirzamohammadi, S. A sustainable biomass network design model for bioenergy production by anaerobic digestion technology: Using agricultural residues and livestock manure. Energy Sustain. Soc. 2020, 10, 19. [Google Scholar] [CrossRef]

- Varnero, C.; Urrutia, M.; Ibaceta, S. Bioenergy from perennial grasses. In Advances in Biofuels and Bioenergy; Nageswara-Rao, M., Soneji, J.R., Eds.; InTechOpen: London, UK, 2018. [Google Scholar] [CrossRef]

- Gudka, B.; Jones, J.M.; Lea-Langton, A.R.; Williams, A.; Saddawi, A. A review of the mitigation of deposition and emission problems during biomass combustion through washing pre-treatment. J. Energy Inst. 2016, 89, 159–171. [Google Scholar] [CrossRef]

- Khalsa, J.H.A.; Döhling, F.; Berger, F. Foliage and Grass as Fuel Pellets–Small Scale Combustion of Washed and Mechanically Leached Biomass. Energies 2016, 9, 361. [Google Scholar] [CrossRef]

- Zeng, T.; Pollex, A.; Weller, N.; Lenz, V.; Nelles, M. Blended biomass pellets as fuel for small scale combustion appliances: Effect of blending on slag formation in the bottom ash and pre-evaluation options. Fuel 2018, 212, 108–116. [Google Scholar] [CrossRef]

- Näzelius, I.L.; Fagerström, J.; Boman, C.; Boström, D.; Öhman, M. Slagging in fixed-bed combustion of phosphorus-poor biomass: Critical ash-forming processes and compositions. Energy Fuels 2015, 29, 894–908. [Google Scholar] [CrossRef]

- Fournel, S.; Palacios, J.H.; Godbout, S.; Heitz, M. Effect of Additives and Fuel Blending on Emissions and Ash-Related Problems from Small-Scale Combustion of Reed Canary Grass. Agriculture 2015, 5, 561–576. [Google Scholar] [CrossRef]

- Lewandowski, I.; Scurlock, J.M.; Lindvall, E.; Christou, M. The development and current status of perennial rhizomatous grasses as energy crops in the US and Europe. Biomass Bioenergy 2003, 25, 335–361. [Google Scholar] [CrossRef]

- Nazli, R.I.; Tansi, V.; Öztürk, H.H.; Kusvuran, A. Miscanthus, switchgrass, giant reed, and bulbous canary grass as potential bioenergy crops in a semi-arid Mediterranean environment. Ind. Crops Prod. 2018, 125, 9–23. [Google Scholar] [CrossRef]

- Komor, A. Przestrzenne zróżnicowanie produkcji biomasy rolniczej pochodzenia roślinnego w państwach UE w kontekście rozwoju biogospodarki (Spatial Diversification of Agricultural Biomass Production of Plant Origin in EU Countries in the Context of Bioeconomy Development). Probl. Rol. Swiat. (Probl. World Agric.) 2018, 18, 100–110. [Google Scholar]

- Terlikowski, J. Biomasa z trwałych użytków zielonych jako źródło energii odnawialnej (Biomass from permament grassland as a source of renewable energy). Probl. Inżynierii Rol. (Probl. Agric. Eng.) 2012, 1, 43–49. [Google Scholar]

- Eurostat. Agricultural Production-Livestock and Meat. 2021. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Agricultural_production_-_livestock_and_meat (accessed on 1 August 2022).

- Lipińska, H.; Kurzepa, K.; Kościk, S. Niewykorzystywane gospodarczo trwałe użytki zielone w powiecie chełmskim jako potencjał do produkcji biomasy na cele energetyczne (Economically unexploited permanent grassland in Chełm County as a potential source of biomass production for energy generation). Łąkarstwo W Polsce (Grassl. Sci. Pol.) 2017, 20, 107–119. [Google Scholar]

- Adamovics, A.; Platace, R.; Gulbe, I.; Ivanovs, S. The content of carbon and hydrogen in grass biomass and its influence on heating value. Eng. Rural Dev. 2018, 23, 1277–1281. [Google Scholar]

- Dradrach, A.; Gąbka, D.; Szlachta, J.; Wolski, K. Wartość energetyczna kilku gatunków traw uprawianych na glebie lekkiej (Energy value of several grass species cultivated on light soil). Łąkarstwo W Polsce (Grassl. Sci. Pol.) 2007, 10, 29–35. [Google Scholar]

- Danielewicz, D.; Surma-Ślusarska, B.; Żurek, G.; Martyniak, D. Selected Grass Plants as Biomass Fuels and Raw Materi-als for Papermaking. Part I. Calorific Value and Chemical Composition. BioResources 2015, 10, 8539–8551. [Google Scholar]

- Kornacki, A.; Maj, G. Wybrane właściwości peletów wytworzonych z trawy pozyskanej z trawnika przydomowego (Selected properties of pellets made of grass obtained from home lawn). Inżynieria Rol. (Agric. Eng.) 2011, 1, 103–108. [Google Scholar]

- Roy, R.; Ray, S. Development of a non-linear model for prediction of higher heating value from the proximate composition of lignocellulosic biomass. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–12. Available online: https://www.tandfonline.com/doi/full/10.1080/15567036.2020.1817191 (accessed on 10 July 2022). [CrossRef]

- Stolarski, M.J.; Śnieg, M.; Krzyżaniak, M.; Tworkowski, J.; Szczukowski, S. Short rotation coppices, grasses and other herbaceous crops: Productivity and yield energy value versus 26 genotypes. Biomass Bioenergy 2018, 119, 109–120. [Google Scholar] [CrossRef]

- Fijałkowska, D.; Styszko, L. Ciepło spalania biomasy wierzbowej (Calorific Value of Willow Biomass). Rocz. Ochr. Sr. (Annu. Set Environ. Prot.) 2011, 13, 875–890. [Google Scholar]

- Forage Variety Yield and Quality Differences. Project No.: 0008-016. Lakeland Agricultural Research Association. Available online: https://www.albertabeef.org/files/site-content/c5kij3Hn58pPQWChT4ucAZLNzrQDMeqOCKFiA7xM.pdf (accessed on 1 August 2022).

- PN-EN ISO 18134-2:2017-03E; Solid Biofuels. Determination of Moisture Content—Oven Dry Method—Part 2: Total Moisture—Simplified Method. European Committee for Standardization: Brussels, Belgium, 2017.

- PN-EN ISO 18123:2016-01; Solid Fuels. Determination of Volatile Content by Gravimetric Method. European Committee for Standardization: Brussels, Belgium, 2016.

- PN-EN ISO 18122:2015; Solid Biofuels. Determination of Ash Content. European Committee for Standardization: Brussels, Belgium, 2015.

- ASTM D 3172-73; Standard Method for Proximate Analysis of Coal and Coke. ASTM International: Conshohocken, PA, USA, 1984.

- PN-EN ISO 18125:2017-07; Solid Biofuels. Determination of Calorific Value. European Committee for Standardization: Brussels, Belgium, 2017.

- FAO. Wood Fuels Handbook; FAO: Rome, Italy, 2013. [Google Scholar] [CrossRef]

- Ogunsola, O.; Adeleke, O.; Aruna, A.T. Wood fuel analysis of some selected wood species within Ibadan. IOP Conf. Ser. Earth Environ. Sci. 2018, 173, 12–43. [Google Scholar] [CrossRef]

- Tanquilut, M.R.C.; Elauria, J.C.; Amongo, R.M.C.; Suministrado, D.C.; Yaptenco, K.F.; Elauria, M.M. Biomass Characterization of Pigeon Pea (Cajanus cajan) Wood for Thermochemical Conversion. Philipp. J. Agric. Biosyst. Eng. 2019, 15, 39–52. [Google Scholar]

- Shahabuddin, M.; Alam, T. Gasification of Solid Fuels (Coal, Biomass and MSW): Overview, Challenges and Mitigation Strategies. Energies 2022, 15, 4444. [Google Scholar] [CrossRef]

- Abad, A.; de las Obras-Loscertales, M.; García-Labiano, F.; de Diego, L.F.; Gayán, P.; Adánez, J. In situ gasification ChemicalLooping Combustion of coal using limestone as oxygen carrier precursor and sulphur sorbent. Chem. Eng. J. 2017, 310, 226–239. [Google Scholar] [CrossRef]

- Porada, S.; Czerski, G.; Grzywacz, P.; Makowska, D.; Dziok, T. Comparison of the gasification of coals and their chars with CO2 based on the formation kinetics of gaseous products. Thermochim. Acta 2017, 653, 97–105. [Google Scholar] [CrossRef]

- Dai, B.; Hoadley, A.; Zhang, L. Characteristics of high temperature C-CO2 gasification reactivity of Victorian brown coal char and its blends with high ash fusion temperature bituminous coal. Fuel 2017, 202, 352–365. [Google Scholar] [CrossRef]

- Park, S.-W.; Lee, J.-S.; Yang, W.-S.; Alam, M.T.; Seo, Y.-C.; Lee, S.-Y. Gasification characteristics of biomass for tar removal by secondary oxidant injection. J. Mater. Cycles Waste Manag. 2018, 20, 823–831. [Google Scholar] [CrossRef]

- Nanda, S.; Mohanty, P.; Pant, K.K.; Naik, S.; Kozinski, J.A.; Dalai, A.K. Characterisation of North American lignocellulosic biomass and biochars in terms of their candidacy for alternate renewable fuels. Bioenergy Res. 2013, 6, 663–677. [Google Scholar] [CrossRef]

- Liu, J.; Wang, D.; Yu, C.; Jiang, J.; Guo, M.; Hantoko, D.; Yan, M. A two-step process for energy-efficient conversion of food waste via supercritical water gasification: Process design, products analysis, and electricity evaluation. Sci. Total Environ. 2021, 752, 142331. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.Y.; Alam, M.T.; Han, G.H.; Choi, D.H.; Park, S.W. Gasification Applicability of Korean Municipal Waste Derived Solid Fuel: A Comparative Study. Processes 2020, 8, 1375. [Google Scholar] [CrossRef]

- Cho, M.-H.; Mun, T.-Y.; Choi, Y.-K.; Kim, J.-S. Two-stage air gasification of mixed plastic waste: Olivine as the bed material and effects of various additives and a nickel-plated distributor on the tar removal. Energy 2014, 70, 128–134. [Google Scholar] [CrossRef]

- Voća, N.; Bilandžija, N.; Jurišić, V.; Matin, A.; Krička, T.; Sedak, I. Proximate, ultimate, and energy values analysis of plum biomass by-products case study: Croatia’s potential. J. Agric. Sci. Technol. 2016, 18, 1655–1666. [Google Scholar]

- Ahmed, A.; Bakar, M.S.A.; Razzaq, A.; Hidayat, S.; Jamil, F.; Amin, M.N.; Sukri, R.S.; Shah, N.S.; Park, Y.-K. Characterization and Thermal Behavior Study of Biomass from Invasive Acacia mangium Species in Brunei Preceding Thermochemical Conversion. Sustainability 2021, 13, 5249. [Google Scholar] [CrossRef]

- Morais, R.F.D.; Souza, B.J.D.; Leite, J.M.; Soares, L.H.D.B.; Alves, B.J.R.; Boddey, R.M.; Urquiaga, S. Elephant grass genotypes for bioenergy production by direct biomass combustion. Pesqui. Agropecu. Bras. 2009, 44, 133–140. [Google Scholar] [CrossRef]

- Cornell University. Ash Content of Grasses for Biofuel. Cornell University Cooperative Extension, Bioenergy Information Sheet #5, 2006; Cornell University, Department of Crop and Soil Sciences; pp. 1–2. Available online: http://www.carborobot.hu/Download/Papers/Bioenergy_Info_Sheet_5.pdf (accessed on 1 August 2022).

- Bakker, R.R.; Elbersen, H.W. Managing ash content and quality in herbaceous biomass: An analysis from plant to product. In Proceedings of the 14th European Biomass Conference, Paris, France, 17–21 October 2005; WUR Bioenergy Papers and Project Reports. pp. 210–213. [Google Scholar]

- Undersander, D. Ash in forage. University of Wisconsin-Extension. Available online: https://fyi.extension.wisc.edu/forage/files/2016/04/ash_in_forage.pdf (accessed on 1 August 2022).

- Biedermann, F.; Obernberger, I. Ash Related Problems during Biomass Combustion and Possibilities for A Sustainable Ash Utilization. In Proceedings of the International Conference on World Renewable Energy Congress (WREC), Aberdeen, Scotland, UK, 22–27 May 2005; p. 8. [Google Scholar]

- Platače, R.; Adamovičs, A. The Evaluation of Ash Content in Grass Biomass Used for Energy Production. WIT Trans. Ecol. Environ. 2014, 190, 1057–1065. [Google Scholar]

- Duke, J.A. Lolium perenne L. Handbook of Energy Crops; Purdue University: West Lafayette, IN, USA, 1983. [Google Scholar]

- Falemara, B.C.; Joshua, V.I.; Aina, O.O.; Nuhu, R.D. Performance Evaluation of the Physical and Combustion Properties of Briquettes Produced from Agro-Wastes and Wood Residues. Recycling 2018, 3, 37. [Google Scholar] [CrossRef] [Green Version]

- Strandberg, A.; Thyrela, M.; Skoglund, N.; Lestander, T.A.; Broström, M.; Backman, R. Biomass pellet combustion: Cavities and ash formation characterized by synchrotron X-ray micro-tomography. Fuel Process. Technol. 2018, 176, 211–220. [Google Scholar] [CrossRef]

- Surup, G.R.; Trubetskaya, A.; Tangstad, M. Charcoal as an Alternative Reductant in Ferroalloy Production: A Review. Processes 2020, 8, 1432. [Google Scholar] [CrossRef]

- Wierzbowska, J.; Sienkiewicz, S.; Żarczyński, P.; Krzebietke, S. Environmental Application of Ash from Incinerated Biomass. Agronomy 2020, 10, 482. [Google Scholar] [CrossRef]

- Niedziolka, J.; Zuchniacz, A. Analiza energetyczna wybranych rodzajów biomasy pochodzenia roślinnego (An energetic analysis of selected plant biomass samples). Motrol Motoryz. I Energetyka Rol. 2006, 8A, 232–237. [Google Scholar]

- Wilk, B. Określenie Zależności Wartości Opałowej Od Wybranych Właściwości Fizykochemicznych Biomasy (Determination of the Dependence of the Calorific Value on the Selected Physicochemical Properties of Biomass); IChPW: Zabrze, Poland, 2006. [Google Scholar]

- Muthu Dinesh Kumar, R.; Arnand, R. Production of Biofuel from Biomass downdraft gasification and its applications. In Advanced Biofuels; Woodhead Publishing: Cambridgeshire, UK, 2019. [Google Scholar]

- Cavalaglio, G.; Cotana, F.; Nicolini, A.; Coccia, V.; Petrozzi, A.; Formica, A.; Bertini, A. Characterization of Various Biomass Feedstock Suitable for Small-Scale Energy Plants as Preliminary Activity of Biocheaper Project. Sustainability 2020, 12, 6678. [Google Scholar] [CrossRef]

- Iordanidis, A.; Asvesta, A.; Vasileiadou, A. Combustion behaviour of different types of solid wastes and their blends with lignite. Therm. Sci. 2018, 22, 1077–1088. [Google Scholar] [CrossRef]

- Corsaro, A.; Raclavská, H.; Hlavsová, A.; Frydrych, J.; Juchelková, D. Perennial grasses as prospective energy sources. Energy Sources Part A Recover. Util. Environ. Eff. 2016, 38, 1206–1211. [Google Scholar] [CrossRef]

- Kumar, S.; Ghosh, P. Sustainable bio-energy potential of perennial energy grass from reclaimed coalmine spoil (marginal sites) of India. Renew. Energy 2018, 123, 475–485. [Google Scholar] [CrossRef]

- Mohammed, I.Y.; Abakr, Y.A.; Kazi, F.K.; Yusup, S.; Alshareef, I.; Chin, S.A. Comprehensive Characterization of Napier Grass as a Feedstock for Thermochemical Conversion. Energies 2015, 8, 3403–3417. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- Baxter, L.L. Ash deposition during biomass and coal combustion: A mechanistic approach. Biomass Bioenergy 1993, 4, 85–102. [Google Scholar] [CrossRef]

- Lalak, J.; Martyniak, D.; Kasprzycka, A.; Żurek, G.; Moroń, W.; Chmielewska, M.; Wiącek, D.; Tyś, J. Comparison of selected parameters of biomass and coal. Int. Agrophys. 2016, 30, 475–482. [Google Scholar] [CrossRef]

- Demirbaş, A. Calculation of higher heating value of biomass fuels. Fuel 1997, 76, 431–434. [Google Scholar] [CrossRef]

- Greenhalf, C.E.; Nowakowski, D.J.; Bridgwater, A.V.; Titiloye, J.; Yates, N.; Riche, A.; Shield, I. Thermochemical characterisation of straws and high yielding perennial grasses. Ind. Crop. Prod. 2012, 36, 449–459. [Google Scholar] [CrossRef]

- Basu, P. Biomass Gasification and Pyrolysis: Practical Design and Theory; Academic Press: Cambridge, MA, USA, 2010. [Google Scholar]

- Guo, S.; Dong, X.; Liu, K.; Yu, H.; Zhu, C. Chemical, energetic, and structural characteristics of hydrothermal carbonization solid products for lawn grass. Bio. Resour. 2015, 10, 4613–4625. [Google Scholar] [CrossRef]

- Oginni, O.; Singh, K.; Zondlo, J.W. Pyrolysis of dedicated bioenergy crops grown on reclaimed mine land in West Virginia. J. Anal. Appl. Pyrolysis 2017, 123, 319–329. [Google Scholar] [CrossRef]

- Waliszewska, B.; Grzelak, M.; Gaweł, E.; Spek-Dźwigała, A.; Sieradzka, A.; Czekała, W. Chemical Characteristics of Selected Grass Species from Polish Meadows and Their Potential Utilization for Energy Generation Purposes. Energies 2021, 14, 1669. [Google Scholar] [CrossRef]

- Xing, J.; Luo, K.; Wang, H.; Gao, Z.; Fan, J. A comprehensive study on estimating higher heating value of biomass from proximate and ultimate analysis with machine learning approaches. Energy 2019, 188, 116077. [Google Scholar] [CrossRef]

- Khodaei, H.; Al-Abdeli, Y.M.; Guzzomi, F.; Yeoh, G.H. An overview of processes and considerations in the modelling of fixed-bed biomass combustion. Energy 2015, 88, 946–972. [Google Scholar] [CrossRef]

- Hosseinpour, S.; Aghbashlo, M.; Tabatabaei, M.; Mehrpooya, M. Estimation of biomass higher heating value (HHV) based on the proximate analysis by using iterative neural network-adapted partial least squares (INNPLS). Energy 2017, 138, 473–479. [Google Scholar] [CrossRef]

- Amaleviciute-Volunge, K.; Slepetiene, A.; Butkute, B. The suitability of perennial grasses for combustion as influenced by chemical composition and plant growth stage. Zemdirb.-Agric. 2020, 107, 317–322. [Google Scholar] [CrossRef]

- Alves, O.; Gonçalves, M.; Brito, P.; Monteiro, E. Modelling higher heating value of different separated fractions from municipal and construction and demolition wastes. In Proceedings of the Ecos 2018-The 31st International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems, Guimarães, Portugal, 17–22 June 2018. [Google Scholar]

- Murawski, M.; Grzelak, M.; Waliszewska, B.; Knioła, A.; Czekała, W. Wartość energetyczna i plonowanie łąk ekstensywnie użytkowanych (Energy value and yielding from extensively used meadows). Fragm. Agron. 2015, 32, 71–78. [Google Scholar]

| Species | Varieties |

|---|---|

| Kentucky Bluegrass (P. pratensis L.) | Tecza |

| Alicja | |

| MHR-NT-1419 | |

| Morfa | |

| MHR-NT-1318 | |

| Struga | |

| Harfa | |

| Red Fescue (F. rubra L.) | Nimba |

| Oaza | |

| Leo-pol | |

| Adio | |

| Nawojka | |

| Perennial Ryegrass (L. perenne L.) | Pinia |

| Info | |

| Nira | |

| Gazon | |

| Meadow Fescue (F. pratensis Huds.) | Kaskada |

| Fantazja | |

| Skiba | |

| Timothy (Ph. pratense L.) | Egida |

| Skald | |

| Common Bent (A. capillaris L.) | Liryka |

| Sheep Fescue (F. ovina L.) | Noni |

| Description | Nieznanice | Polanowice |

|---|---|---|

| Soil Type | brown | Degraded chernozem delivered from loess |

| Complex agricultural suitability | rye, good | wheat, very good |

| Class of soil valuation | IIIb | I |

| Soil pH in KCl | 6.0 | 7.2 |

| Species | Varieties | Moisture Content, % | Higher Heating Value, kJ∙kg−1 | Lower Heating Value, kJ∙kg−1 |

|---|---|---|---|---|

| Kentucky Bluegrass (P. pratensis L.) | Tecza | 5.17 ± 0.08 | 17,057 ± 219 bcde | 16,050 ± 200 bcd |

| Alicja | 7.34 ± 0.03 | 17,556 ± 57 fgh | 16,089 ± 59 bcd | |

| MHR-NT-1419 | 5.62 ± 0.12 | 17,484 ± 59 efgh | 16,365 ± 47 de | |

| Morfa | 5.68 ± 0.18 | 16,762 ± 105 abc | 15,672 ± 66 ab | |

| MHR-NT-1318 | 5.10 ± 0.02 | 17,778 ± 63 gh | 16,746 ± 55 ef | |

| Struga | 5.92 ± 0.05 | 16,975 ± 54 abcd | 15,826 ± 59 abc | |

| Harfa | 6.04 ± 0.01 | 16,689 ± 64 ab | 15,534 ± 58 a | |

| Red Fescue (F. rubra L.) | Nimba | 6.61 ± 0.03 | 17,688 ± 101 gh | 16,357 ± 91 de |

| Oaza | 6.20 ± 0.14 | 17,339 ± 133 defg | 16,113 ± 97 cd | |

| Leo-pol | 6.65 ± 0.17 | 16,891 ± 81 abcd | 15,605 ± 77 a | |

| Adio | 6.36 ± 0.06 | 16,842 ± 355 abc | 15,616 ± 321 a | |

| Nawojka | 6.69 ± 0.03 | 16,708 ± 266 ab | 15,428 ± 252 a | |

| Perennial Ryegrass (L. perenne L.) | Pinia | 5.39 ± 0.01 | 17,892 ± 318 h | 16,797 ± 299 f |

| Info | 6.11 ± 0.17 | 17,701 ± 32 gh | 16,471 ± 43 def | |

| Nira | 5.64 ± 0.05 | 17,591 ± 156 fgh | 16,462 ± 147 def | |

| Gazon | 6.01 ± 0.03 | 17,642 ± 115 gh | 16,435 ± 108 def | |

| Meadow Fescue (F. pratensis Huds.) | Kaskada | 5.41 ± 0.01 | 16,548 ± 18 a | 15,522 ± 16 a |

| Fantazja | 5.85 ± 0.15 | 16,912 ± 76 abcd | 15,779 ± 59 abc | |

| Skiba | 5.14 ± 0.13 | 17,170 ± 35 cdef | 16,162 ± 43 cd | |

| Timothy (Ph. pratense L.) | Egida | 5.94 ± 0.25 | 17,802 ± 172 h | 16,600 ± 178 ef |

| Skald | 6.04 ± 0.14 | 17,861 ± 34 h | 16,636 ± 40 ef | |

| Common Bent (A. capillaris L.) | Liryka | 6.97 ± 0.07 | 17,842 ± 40 h | 16,428 ± 47 def |

| Sheep Fescue (F. ovina L.) | Noni | 5.52 ± 0.15 | 18,616 ± 58 i | 17,453 ± 85 g |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sobol, Ł.; Wolski, K.; Radkowski, A.; Piwowarczyk, E.; Jurkowski, M.; Bujak, H.; Dyjakon, A. Determination of Energy Parameters and Their Variability between Varieties of Fodder and Turf Grasses. Sustainability 2022, 14, 11369. https://doi.org/10.3390/su141811369

Sobol Ł, Wolski K, Radkowski A, Piwowarczyk E, Jurkowski M, Bujak H, Dyjakon A. Determination of Energy Parameters and Their Variability between Varieties of Fodder and Turf Grasses. Sustainability. 2022; 14(18):11369. https://doi.org/10.3390/su141811369

Chicago/Turabian StyleSobol, Łukasz, Karol Wolski, Adam Radkowski, Elżbieta Piwowarczyk, Maciej Jurkowski, Henryk Bujak, and Arkadiusz Dyjakon. 2022. "Determination of Energy Parameters and Their Variability between Varieties of Fodder and Turf Grasses" Sustainability 14, no. 18: 11369. https://doi.org/10.3390/su141811369

APA StyleSobol, Ł., Wolski, K., Radkowski, A., Piwowarczyk, E., Jurkowski, M., Bujak, H., & Dyjakon, A. (2022). Determination of Energy Parameters and Their Variability between Varieties of Fodder and Turf Grasses. Sustainability, 14(18), 11369. https://doi.org/10.3390/su141811369