Precision Ventilation for an Open-Plan Office: A Study of Variable Jet Interaction between Two Active Chilled Beams

Abstract

:1. Introduction

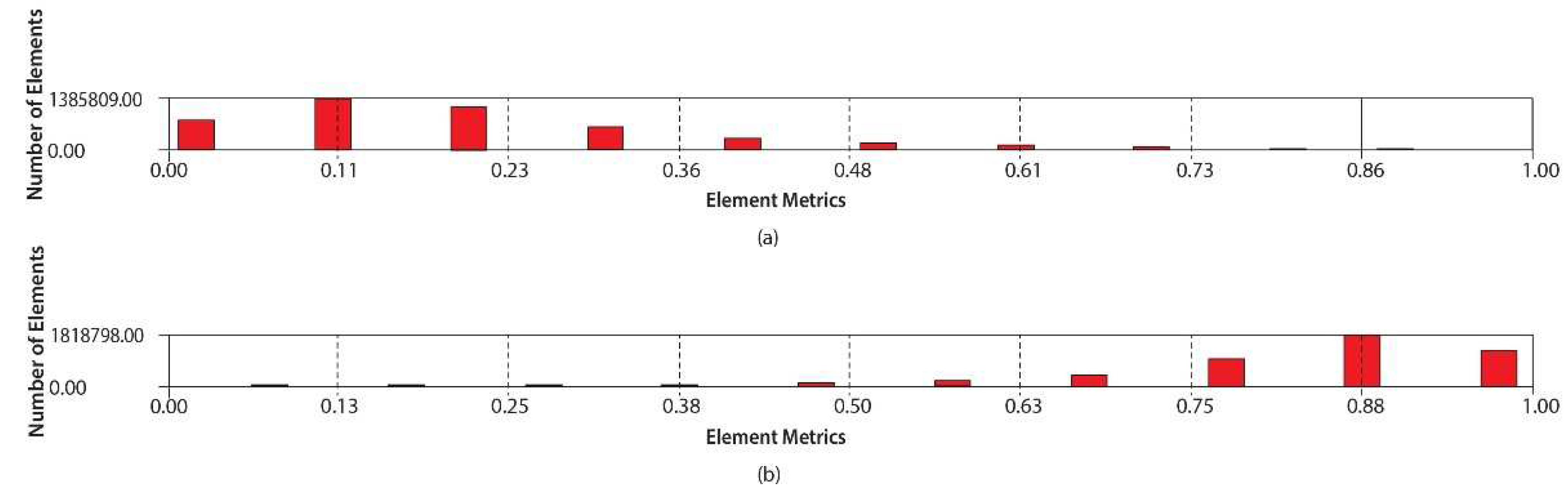

2. Methodology

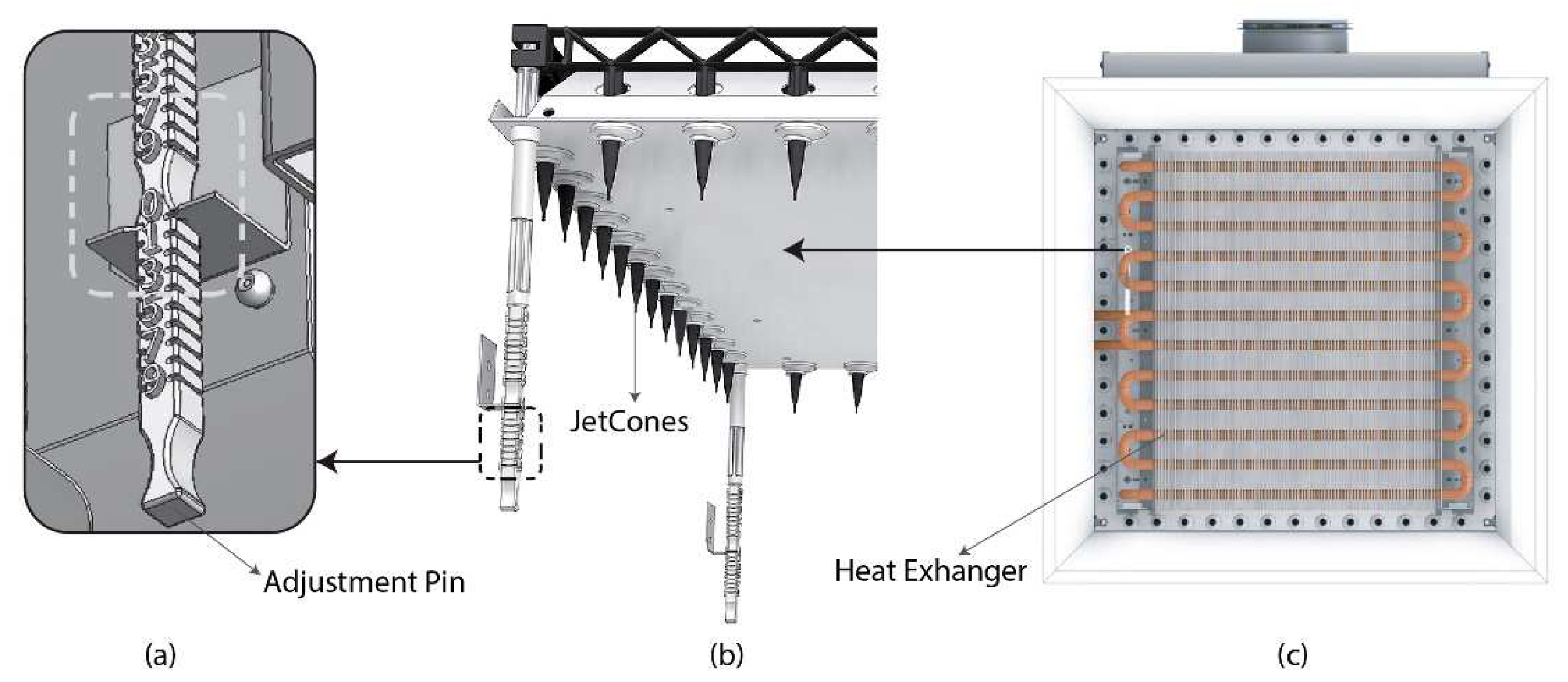

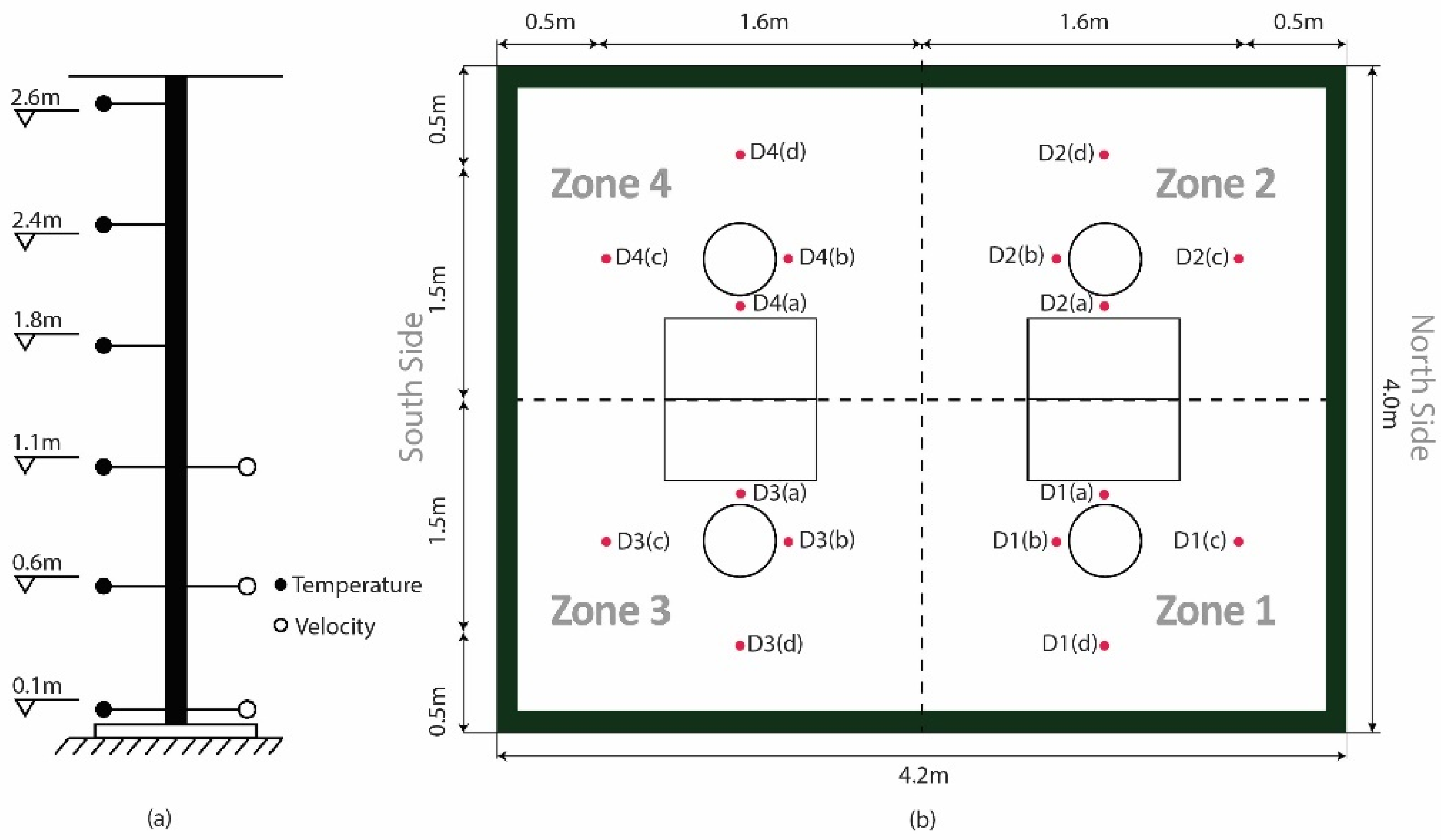

2.1. Experimental and Simulation Setup

2.2. ACB Airflow Distribution

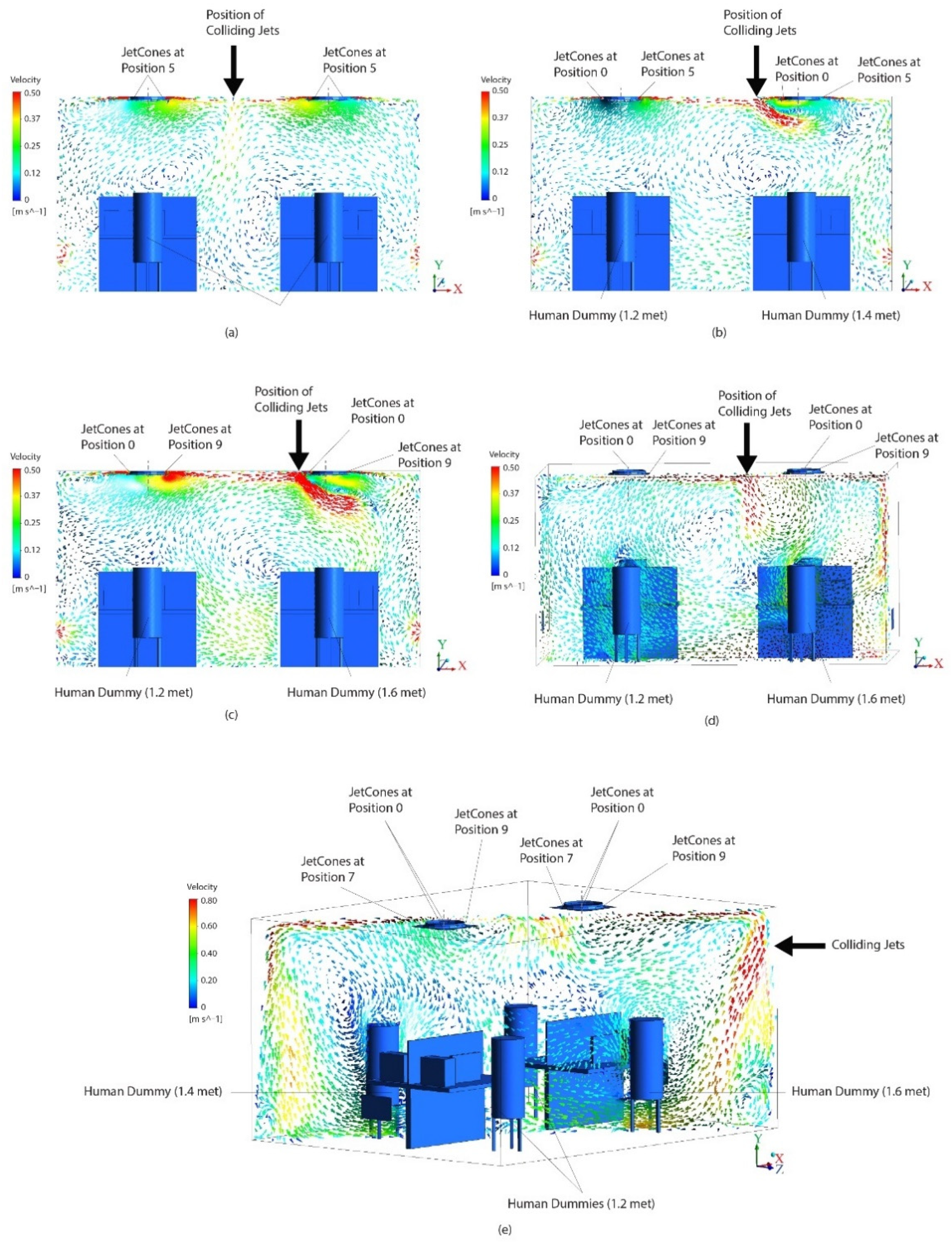

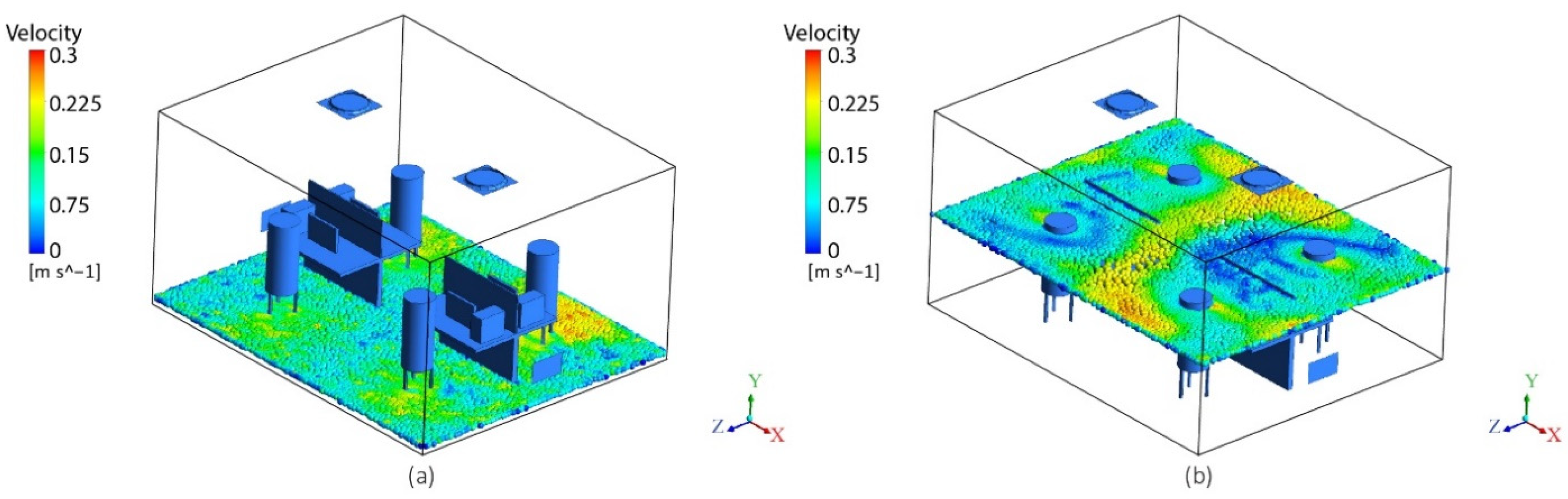

- In case 1, the metabolic rates in all zones were kept at 1.2 met. The adjustment pins of both the ACBs were kept at the same position (position 5) to achieve a uniform thermal environment for all four velocity zones.

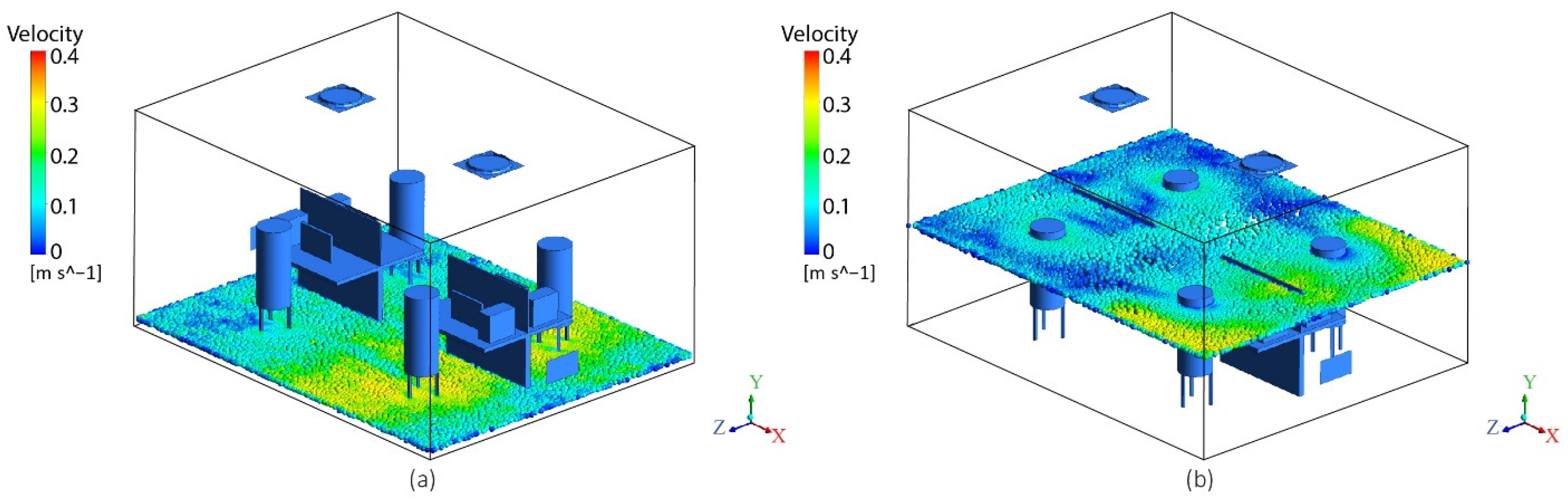

- In case 2, the metabolic rates of the two dummies in zones 1 and 2 were raised to 1.4 met. The pin positions were adjusted to push more airflow towards zones 1 and 2.

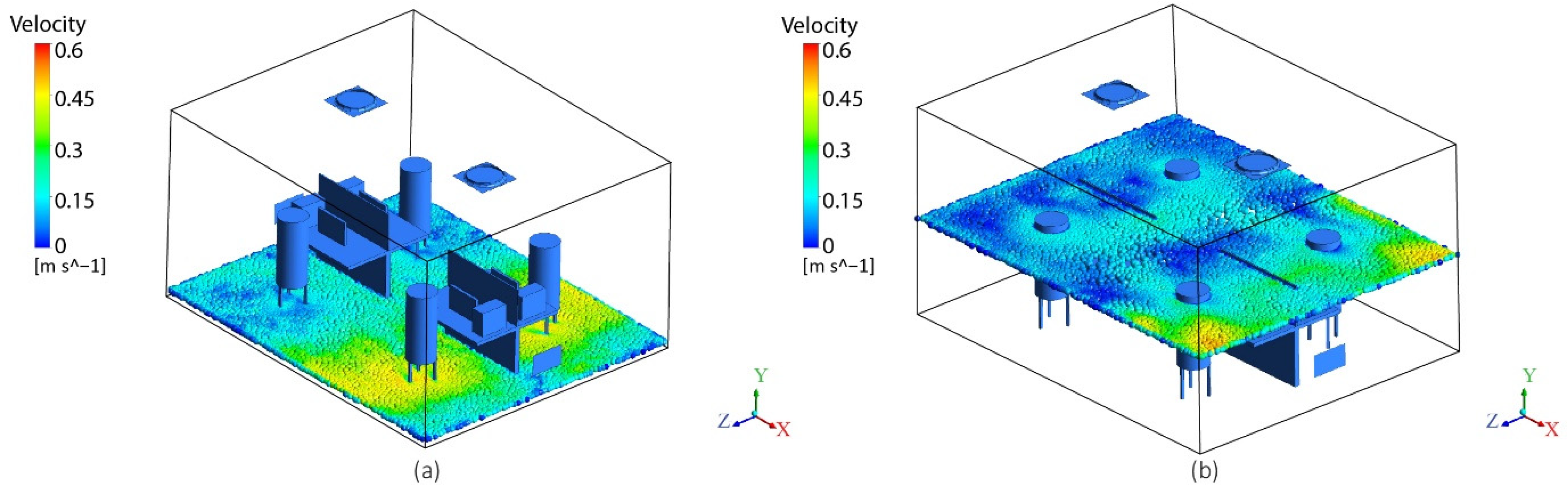

- In case 3, the metabolic rates of the two dummies in zones 1 and 2 were raised to 1.6 met. The pin positions were adjusted to push maximum airflow towards zones 1 and 2.

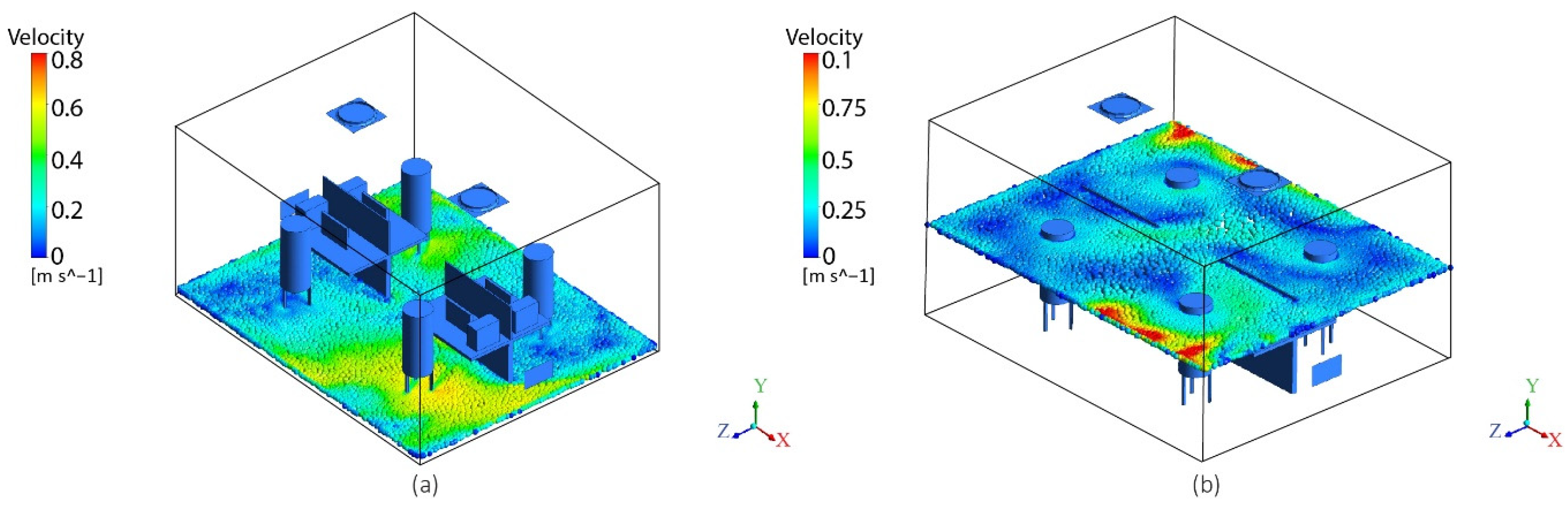

- In case 4, the metabolic rate of the dummy in zone 1 was raised to 1.6 met. The pin positions were adjusted to push maximum airflow towards zone 1 to achieve individual thermal comfort.

- In case 5, the metabolic rates of the two dummies in zones 1 and 4 were raised to 1.6 and 1.4 met, respectively. The pin positions were adjusted to push maximum airflow towards zone 1 and medium level airflow to zone 4.

2.3. Measuring Points and Thermal Comfort Criteria

3. Results and Discussion

3.1. Air Velocity Distribution

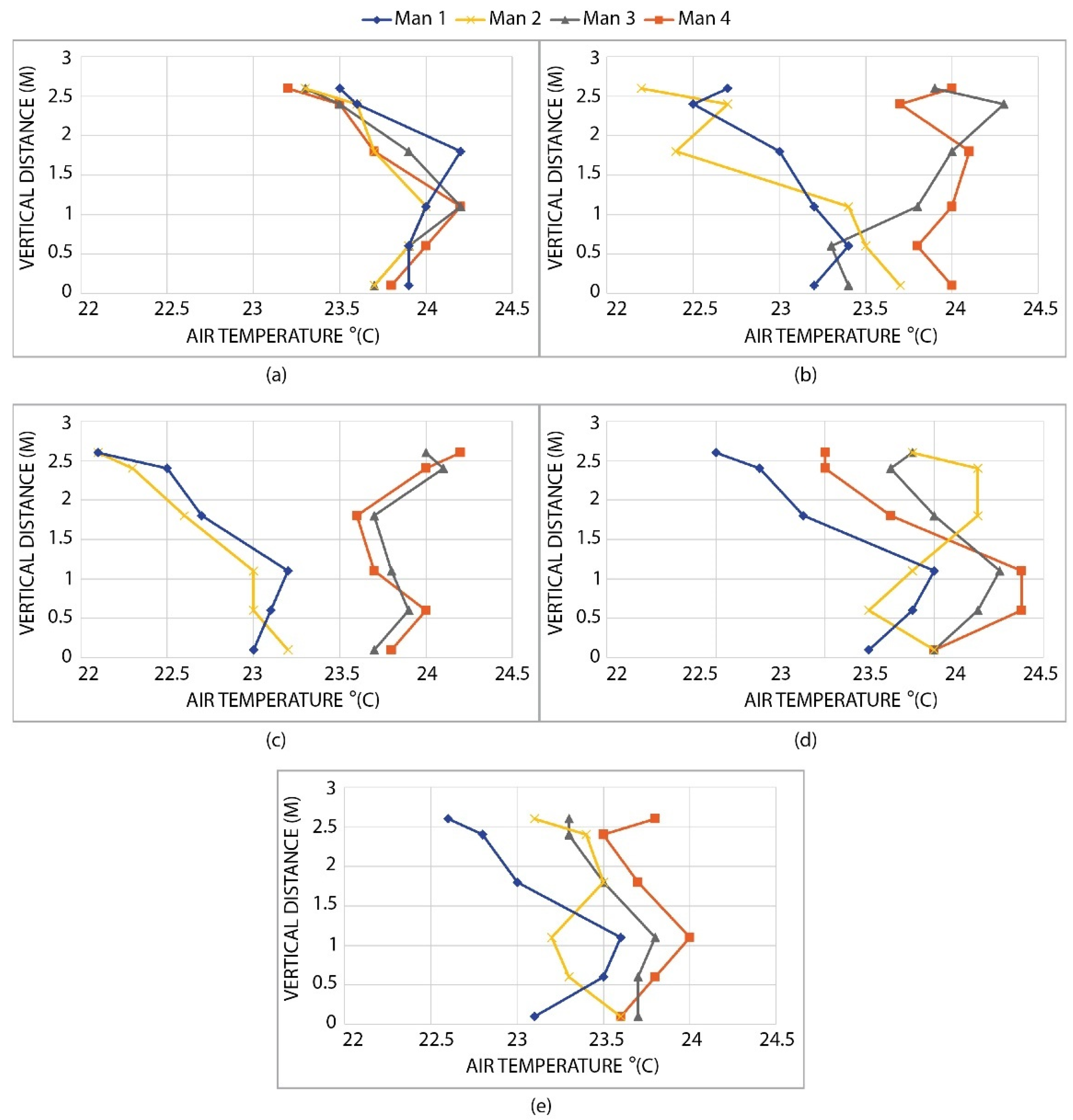

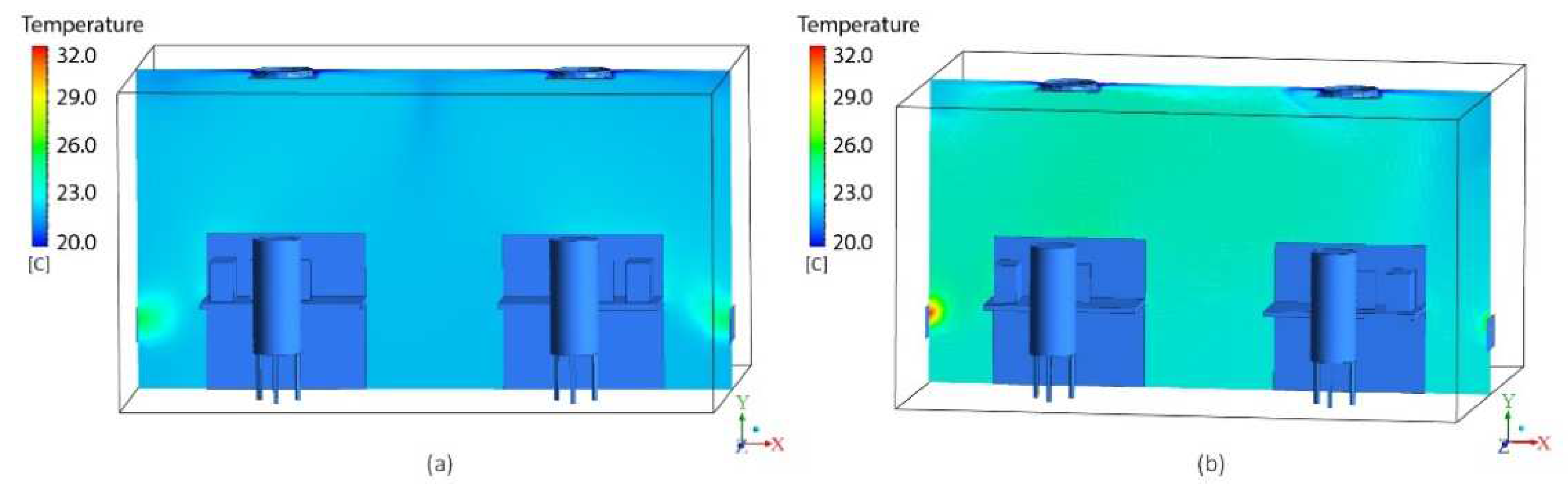

3.2. Air-Temperature Distribution

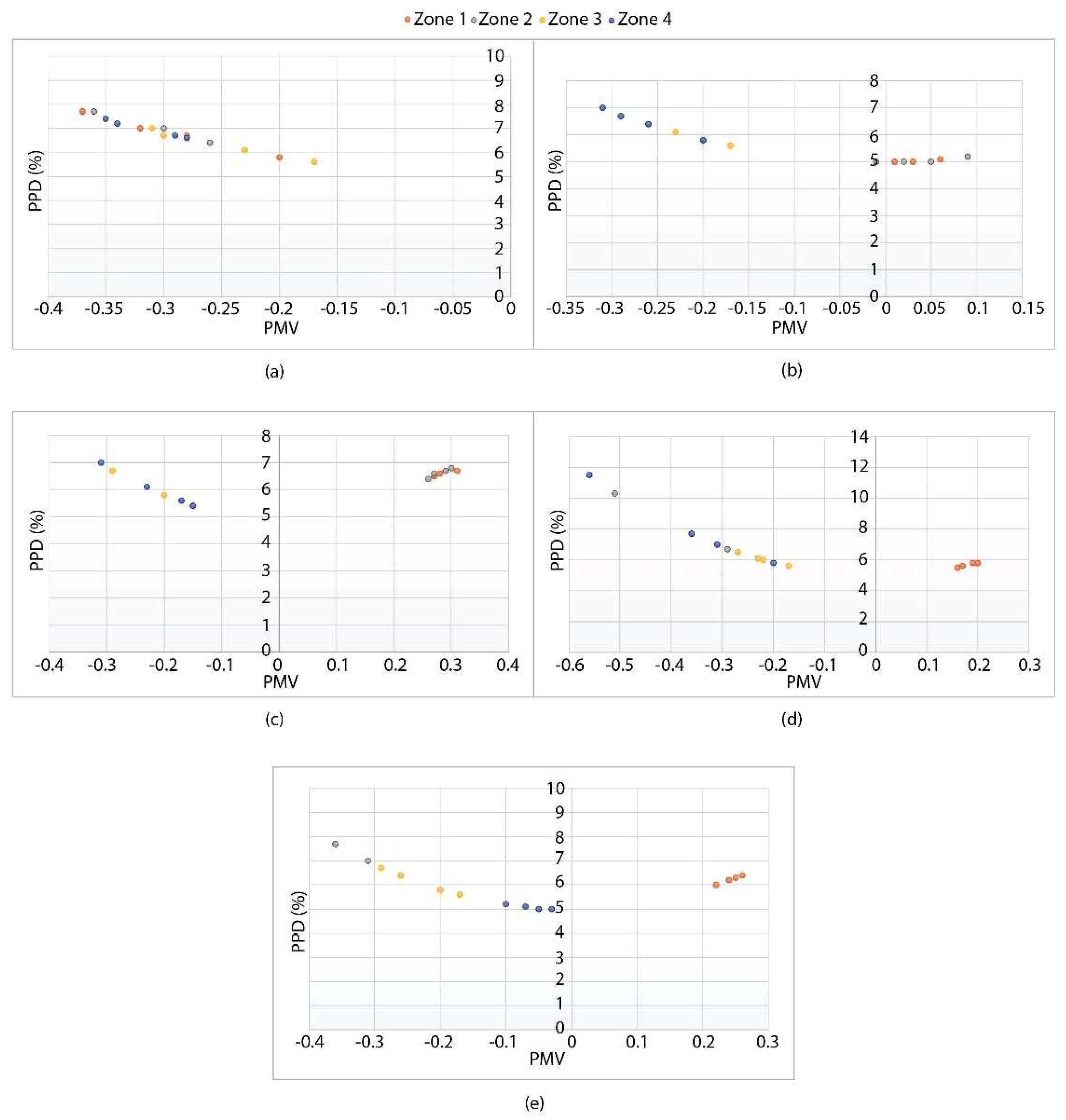

3.3. PMV-PPD Calculations

4. Conclusions

- -

- The change in momentum caused by ACB JetCone adjustments resulted in up to three variable air velocity zones in the same office space. The human dummies with low metabolic rates (1.2 met) could be exposed to air velocities as low as 0.1 m/s. Whereas dummies with metabolic rates of 1.4 and 1.6 met were able to become exposed to 0.45 and 0.55 m/s air velocities, respectively.

- -

- The acceptable PMV range for thermal comfort i.e., −0.5–0.5, could be maintained for the occupants with high metabolic rates using airflow adjustments. This also led to an overall PPD of less than 10% for all five cases.

- -

- Controlling the microclimate solely for a single velocity zone, i.e., case 4 with two ACBs in a large office space showed PMV and PPD values slightly above acceptable limits.

- -

- The local thermal discomfort through the vertical temperature difference was not found to be a problem while implementing precision ventilation. Both vertical and horizontal temperature distribution in all cases was maintained with a temperature difference in the occupied zone of less than 1.5 °C.

5. Limitations and Further Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Parameter | Description | Unit |

| ACB | Active chilled beams | - |

| AHU | Air handling unit | - |

| ASHRAE | American society of heating, refrigerating and air-conditioning engineers | - |

| ATD | Air terminal device | - |

| CFD | Computational fluid dynamics | - |

| HVAC | Heating ventilation and air conditioning | - |

| ISO | International organization for standardization | - |

| PMV | Predicted mean vote | - |

| PPD | Predicted percentage dissatisfied | - |

| RNG | Renormalization group | - |

| w | Total airflow in the room | L/s |

| Cp | Specific heat constant for air | J/(kg °C) |

| Δt | Temperature difference | K |

| q | Total heat load | W |

| fcl | Clothing surface area factor | - |

| hc | Convective heat transfer coefficient | W/(m2.K) |

| ta | Air temperature | °C |

| var | Relative air velocity | m/s |

| tcl | Clothing surface temperature | °C |

| pa | Partial water vapor pressure | Pa |

Appendix A

| Zones | Boundary Type |

|---|---|

| ACB Inlets | Velocity-inlet |

| Human Dummies | Wall |

| Tables and Equipment | Wall |

| Outlets | Pressure-outlet |

| Room Walls (Adiabatic) | Wall |

References

- Shahzad, S.; Brennan, J. Energy and comfort in contemporary open plan and traditional personal offices. Appl. Energy 2017, 185, 1542–1555. [Google Scholar] [CrossRef]

- Shafaghat, A.; Keyvanfar, A. Enhancing staff’s satisfaction with comfort toward productivity by sustainable Open Plan Office Design. Sustain. Cities Soc. 2015, 19, 151–164. [Google Scholar] [CrossRef]

- Mulville, M.; Callaghan, N.; Isaac, D. The impact of the ambient environment and building configuration on occupant productivity in open-plan commercial offices. J. Corp. Real Estate. 2016, 18, 180–193. [Google Scholar] [CrossRef]

- Rožman, M.; Peša, A.; Rajko, M.; Štrukelj, T. Building Organisational Sustainability during the COVID-19 Pandemic with an Inspiring Work Environment. Sustainability 2021, 13, 11747. [Google Scholar] [CrossRef]

- Gonzalez-Martin, J.; Kraakman, N.J.R. A state–of–the-art review on indoor air pollution and strategies for indoor air pollution control. Chemosphere 2021, 262, 128376. [Google Scholar] [CrossRef]

- Ageel, H.K.; Harrad, S. Occurrence, human exposure, and risk of microplastics in the indoor environment. Environ. Sci Process. Impacts 2022, 24, 17–31. [Google Scholar] [CrossRef]

- Nicol, J.F.; Roaf, S. Rethinking thermal comfort. Build. Res. Inf. 2017, 45, 711–716. [Google Scholar] [CrossRef]

- Brager, G.; Zhang, H. Evolving opportunities for providing thermal comfort. Build. Res. Inf. 2015, 43, 274–287. [Google Scholar] [CrossRef]

- Van Hoof, J. Forty years of Fanger’s model of thermal comfort: Comfort for all? Indoor Air 2008, 18, 182–201. [Google Scholar] [CrossRef]

- Sun, K.; Chen, X. Dynamic simulation of hydrogen-based off-grid zero energy buildings with hydrogen storage considering Fanger model thermal comfort. Int. J. Hydrog. Energy 2022, 47, 26435–26457. [Google Scholar] [CrossRef]

- Wang, Z.; de Dear, R. Individual difference in thermal comfort: A literature review. Build. Environ. 2018, 138, 181–193. [Google Scholar] [CrossRef]

- Ma, Z.; Zhao, D. Personal thermal management techniques for thermal comfort and building energy saving. Mater. Today Phys. 2021, 20, 100465. [Google Scholar] [CrossRef]

- Cao, G.; Awbi, H. A review of the performance of different ventilation and airflow distribution systems in buildings. Build. Environ. 2014, 73, 171–186. [Google Scholar] [CrossRef]

- Rhee, K.N.; Shin, M.S. Thermal uniformity in an open plan room with an active chilled beam system and conventional air distribution systems. Energy Build. 2015, 93, 236–248. [Google Scholar] [CrossRef]

- Latif, H.; Hultmark, G. Performance evaluation of active chilled beam systems for office buildings–A literature review. Sustain. Energy Technol. Assess. 2022, 52, 101999. [Google Scholar] [CrossRef]

- Yang, S.; Wan, M.P. Experimental study of a model predictive control system for active chilled beam (ACB) air-conditioning system. Energy Build. 2019, 203, 109451. [Google Scholar] [CrossRef]

- Dai, Y.; Qiu, J.; Tu. A review of the structure and application of active chilled beams (ACBs) for central air conditioning systems. Sci. Technol. Built Environ. 2022, 28, 350–367. [Google Scholar] [CrossRef]

- Hultmark, G. Supply Air Terminal Device L.; Lindab: Stockholm, Sweden, 2011; p. 15. [Google Scholar]

- Lindab Architect Plexus. In Lindab Plexus Active Chilled Beam, L.; Lindab A/S: Malmo, Sweden, 2021; p. 15.

- Veselý, M.; Zeiler, W. Personalized conditioning and its impact on thermal comfort and energy performance–A review. Renew. Sustain. Energy Rev. 2014, 34, 401–408. [Google Scholar] [CrossRef]

- Melikov, A.K.; Cermak, R. Personalized ventilation: Evaluation of different air terminal devices. Energy Build. 2002, 34, 829–836. [Google Scholar] [CrossRef]

- Al Assaad, D.; Ghali, K. Evaluation of different personalized ventilation air terminal devices: Inhalation vs. clothing-mediated exposures. Build. Environ. 2021, 192, 107637. [Google Scholar] [CrossRef]

- Latif, H.; Rahnama, S.; Hultmark, G.; Rupnik, K.; Afshari, A. Design strategies for decreasing cooling demand and increasing individual thermal comfort in open-plan offices: A review. In Proceedings of the 16th Conference of the International Society of Indoor Air Quality and Climate: Creative and Smart Solutions for Better Built Environments, Indoor Air 2020, online, 1 November 2020; International Society of Indoor Air Quality and Climate: Herndon, VA, USA, 2020. [Google Scholar]

- Saheb, H.; Mahdi, A.; Al-amir, Q.R. A numerical and experimental study of the effect of using personal ventilation systems on indoor air quality in office rooms. Front. Heat Mass Transf. 2021, 16. [Google Scholar] [CrossRef]

- Zhao, W.; Kilpeläinen, S. Thermal environment and ventilation efficiency in a simulated office room with personalized micro-environment and fully mixed ventilation systems. Build. Environ. 2021, 188, 107445. [Google Scholar] [CrossRef]

- Liu, J.; Dalgo, D.A. Performance analysis of a ductless personalized ventilation combined with radiant floor cooling system and displacement ventilation. Build. Simul. 2019, 12, 905–919. [Google Scholar] [CrossRef]

- Wu, B.; Cai, W. Experimental investigation on airflow pattern for active chilled beam system. Energy Build. 2018, 166, 438–449. [Google Scholar] [CrossRef]

- Saarinen, P.; Koskela, H.M. Asymmetric Collisions of Two Attached Plane Jets; Finnish Institute of Occupational Health: Helsinki, Finland, 2008. [Google Scholar]

- Koskela, H.; Häggblom, H. Air distribution in office environment with asymmetric workstation layout using chilled beams. Build. Environ. 2010, 45, 1923–1931. [Google Scholar] [CrossRef]

- Latif, H.; Rahnama, S. Precision Ventilation in an Open-Plan Office: A New Application of Active Chilled Beam (ACB) with a JetCone Feature. Sustainability 2022, 14, 4242. [Google Scholar] [CrossRef]

- Kristensen, M.H.; Jensen, J.S.; Jensen, R.L. Air Temperature Measurements Using Dantec Draught Probes. ANSYS Fluent. Available online: www.ansys.com/products/fluids/ansys-fluent (accessed on 22 February 2022).

- Zhang, Z.; Zhang, W. Evaluation of various turbulence models in predicting airflow and turbulence in enclosed environments by CFD: Part 2—Comparison with experimental data from literature. HVAC R Res. 2007, 13, 871–886. [Google Scholar] [CrossRef]

- Hussain, S.; Oosthuizen, P.H. Evaluation of various turbulence models for the prediction of the airflow and temperature distributions in atria. Energy Build. 2012, 48, 18–28. [Google Scholar] [CrossRef]

- Blocken, B. LES over RANS in building simulation for outdoor and indoor applications: A foregone conclusion? Build. Simul. 2018, 11, 821–870. [Google Scholar] [CrossRef]

- Fang, Z.; Lin, Z. Investigation into sensitivities of factors in outdoor thermal comfort indices. Build. Environ. 2018, 128, 129–142. [Google Scholar] [CrossRef]

- Fabbri, K. The indices of feeling—predicted mean vote PMV and percentage people dissatisfied PPD. Indoor Therm. Comf. Percept. 2015, 75–125. [Google Scholar]

- Silva, A.S.; Ghisi, E. Performance evaluation of long-term thermal comfort indices in building simulation according to ASHRAE Standard 55. Build. Environ. 2016, 102, 95–115. [Google Scholar] [CrossRef]

- Lenzuni, P. Compliance with limits of acceptability for thermal comfort, and implications for long-term comfort. Build. Environ. 2021, 204, 108067. [Google Scholar] [CrossRef]

- Dawe, M.; Raftery, P. Comparison of mean radiant and air temperatures in mechanically conditioned commercial buildings from over 200,000 field and laboratory measurements. Energy Build. 2020, 206, 109582. [Google Scholar] [CrossRef]

- Wu, B.; Cai, W. Heat source effects on thermal comfort for active chilled beam systems. Build. Environ. 2018, 141, 91–102. [Google Scholar] [CrossRef]

- Turkowski, M.; Szufleński, P. New criteria for the experimental validation of CFD simulations. Flow Meas. Instrum. 2013, 34, 1–10. [Google Scholar] [CrossRef]

- Zhai, Y.; Zhang, H. Comfort under personally controlled air movement in warm and humid environments. Build. Environ. 2013, 65, 109–117. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, X. Experimental investigation into the effects of different metabolic rates of body movement on thermal comfort. Build. Environ. 2020, 168, 106489. [Google Scholar] [CrossRef]

- Gong, N.; Tham, K. The acceptable air velocity range for local air movement in the tropics. Hvac&r Res. 2006, 12, 1065–1076. [Google Scholar]

- Yamasawa, H.; Kobayashi, T. Experimental investigation of difference in indoor environment using impinging jet ventilation and displacement ventilation systems. Int. J. Vent. 2020, 1–18. [Google Scholar] [CrossRef]

- Liu, S.; Wang, Z. Schiavon, Predicted percentage dissatisfied with vertical temperature gradient. Energy Build. 2020, 220, 110085. [Google Scholar] [CrossRef]

- Melikov, A.K.; Nielsen, J.B. Local thermal discomfort due to draft and vertical temperature difference in rooms with displacement ventilation. ASHRAE Trans. 1989, 95, 1050–1057. [Google Scholar]

- Pinzon, J.A.; Vergara, P. Optimal management of energy consumption and comfort for smart buildings operating in a microgrid. IEEE Trans. Smart Grid. 2018, 10, 3236–3247. [Google Scholar] [CrossRef]

- Zhang, N.; Sun, Q. Event-triggered distributed hybrid control scheme for the integrated energy system. IEEE Trans. Industr Inform. 2021, 18, 835–846. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H. Event-triggered-based distributed cooperative energy management for multienergy systems. IEEE Trans. Industr. Inform. 2018, 15, 2008–2022. [Google Scholar] [CrossRef]

| Units | Values |

|---|---|

| ACB dimensions (L × W × H) | 0.6 × 0.6 × 0.2 m |

| ACB units | 2 |

| Functions | Cooling, heating, and ventilation |

| Operating system | Cooling 2-pipe system |

| Distribution profile | Radial |

| Capacity | 769 W each |

| Cases | Metabolic Rates (Met) | Adjustment Regulator Positions | ||||

|---|---|---|---|---|---|---|

| D1 | D2 | D3 | D4 | ACB 1 (adj. 1 + adj. 2…) | ACB 2 (adj. 1 + adj. 2…) | |

| Case 1 | 1.2 | 1.2 | 1.2 | 1.2 | 5 + 5 + 5 + 5 | 5 + 5 + 5 + 5 |

| Case 2 | 1.4 | 1.4 | 1.2 | 1.2 | 7 + 7 + 0 + 0 | 7 + 7 + 0 + 0 |

| Case 3 | 1.6 | 1.6 | 1.2 | 1.2 | 9 + 9 + 0 + 0 | 9 + 9 + 0 + 0 |

| Case 4 | 1.6 | 1.2 | 1.2 | 1.2 | 0 + 9 + 0 + 0 | 0 + 9 + 0 + 0 |

| Case 5 | 1.6 | 1.2 | 1.2 | 1.4 | 0 + 9 + 0 + 7 | 0 + 9 + 0 + 7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Latif, H.; Rahnama, S.; Maccarini, A.; Bradshaw, C.R.; Hultmark, G.; Nielsen, P.V.; Afshari, A. Precision Ventilation for an Open-Plan Office: A Study of Variable Jet Interaction between Two Active Chilled Beams. Sustainability 2022, 14, 11466. https://doi.org/10.3390/su141811466

Latif H, Rahnama S, Maccarini A, Bradshaw CR, Hultmark G, Nielsen PV, Afshari A. Precision Ventilation for an Open-Plan Office: A Study of Variable Jet Interaction between Two Active Chilled Beams. Sustainability. 2022; 14(18):11466. https://doi.org/10.3390/su141811466

Chicago/Turabian StyleLatif, Haider, Samira Rahnama, Alessandro Maccarini, Craig R. Bradshaw, Goran Hultmark, Peter V. Nielsen, and Alireza Afshari. 2022. "Precision Ventilation for an Open-Plan Office: A Study of Variable Jet Interaction between Two Active Chilled Beams" Sustainability 14, no. 18: 11466. https://doi.org/10.3390/su141811466

APA StyleLatif, H., Rahnama, S., Maccarini, A., Bradshaw, C. R., Hultmark, G., Nielsen, P. V., & Afshari, A. (2022). Precision Ventilation for an Open-Plan Office: A Study of Variable Jet Interaction between Two Active Chilled Beams. Sustainability, 14(18), 11466. https://doi.org/10.3390/su141811466