Does an Alternative Local Food Network Contribute to Improving Sustainable Food Security?

Abstract

:1. Introduction

2. Literature Review

2.1. Emerging Alternative Local Food Network to Enhance Food Security

2.2. Optimizing the Alternative Local Food Network

3. Materials and Methods

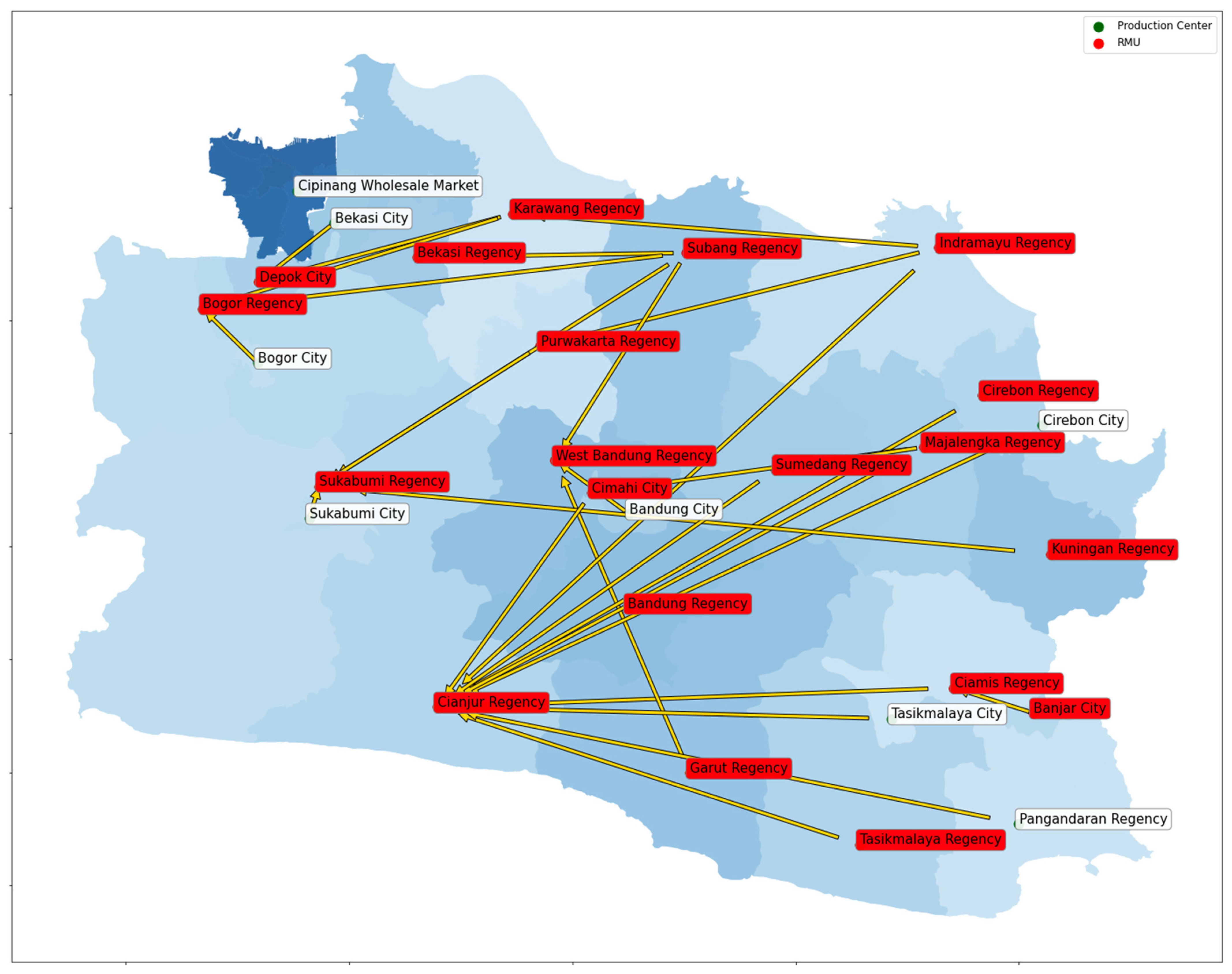

3.1. Materials

3.2. Linear Programming

- The objective function is in the form of minimization.

- All constraint functions are in the form of equations.

- All decision variables have non-negative values.

3.3. Model Formulation

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Set | |

| Retailers (city level) | |

| J | Local wholesale markets |

| K | Nonlocal wholesale markets |

| L | Rice Milling Unit (RMU) (city level) |

| Q[l] | Some area adjacent to the l region |

| M | Local Production Center (city level) |

| N | Nonlocal Production Center (city level) |

| Parameters | |

| Number of retailers need in region i (tons/year) | |

| Rice production capacity from local production centers in region m (tons/year) | |

| Rice production capacity from nonlocal production centers in region n (tons/year) | |

| Rice inflows at non-local wholesale market (Cipinang) (tons/year); exclude local stock | |

| Maximum rice absorption by RMU in region i (tons/year) | |

| Maximum rice absorption by local wholesale market in region j (tons/year) | |

| Maximum rice absorption by non-local wholesale market in region k (tons/year) | |

| Distribution cost of rice from region i to j | |

| Selling price of rice in the local wholesale market region j (Rp/tons) | |

| Selling price of rice in the non-local wholesale market region k (Rp/tons) | |

| Decision Variables | |

| Amount of rice processed by rmu region | |

| Amount of rice flow in the local wholesale market region | |

| Amount of rice flow in the non-local wholesale market region | |

| Amount of rice distributed from local production centers to RMU region | |

| Amount of rice distributed from non-local production centers to RMU region | |

| Amount of rice distributed from RMU to local wholesale market | |

| Amount of rice distributed from RMU to non-local wholesale market | |

| Amount of rice distributed from non-local wholesale market to wholesale market | |

| Amount of rice distributed from non-local wholesale market to retailer region | |

| Amount of rice distributed from RMU to retailer region | |

| Amount of rice distributed from local wholesale market to retailer region | |

References

- Ville, A.S.; Po, J.Y.T.; Sen, A.; Bui, A.; Melgar-Quiñonez, H. Food security and the Food Insecurity Experience Scale (FIES): Ensuring progress by 2030. Food Secur. 2019, 11, 483–491. [Google Scholar] [CrossRef]

- el Bilali, H.; Callenius, C.; Strassner, C.; Probst, L. Food and Nutrition Security and Sustainability Transitions in Food Systems. Food Energy Secur. 2019, 8, e00154. [Google Scholar] [CrossRef]

- Niles, M.T.; Bertmann, F.; Belarmino, E.H.; Wentworth, T.; Biehl, E.; Neff, R. The early food insecurity impacts of COVID-19. Nutrients 2020, 12, 2096. [Google Scholar] [CrossRef] [PubMed]

- Tripathi, A.; Mishra, R.; Maurya, K.; Singh, R.; Wilson, D. Estimates for World Population and Global Food Availability for Global Health. In The Role of Functional Food Security in Global Health; Elsevier: Amsterdam, The Netherlands, 2019; pp. 3–24. [Google Scholar]

- Devereux, S.; Béné, C.; Hoddinott, J. Conceptualising COVID-19’s Impacts on Household Food Security. Food Secur. 2020, 12, 769–772. [Google Scholar] [CrossRef] [PubMed]

- Ericksen, P. Conceptualizing Food Systems for Global Environmental Change Research. Glob. Environ. Chang. 2008, 18, 234–245. [Google Scholar] [CrossRef]

- Firdaus, R.; Gunaratne, M.S.; Rahmat, S.; Kamsi, N. Does Climate Change Only Affect Food Availability? What Else Matters? Cogent Food Agric. 2019, 5, 1707607. [Google Scholar] [CrossRef]

- Carthy, U.M.; Uysal, I.; Badia-Melis, R.; Mercier, S.; O’Donnell, C.; Ktenioudaki, A. Global Food Security–Issues, Challenges and Technological Solutions. Trends Food Sci. Technol. 2018, 77, 11–20. [Google Scholar] [CrossRef]

- Martin-Shields, C.; Stojetz, W. Food Security and Conflict: Empirical Challenges and Future Opportunities for Research and Policy Making on Food Security and Conflict. World Dev. 2019, 119, 150–164. [Google Scholar] [CrossRef]

- Messer, E.; Cohen, M. Breaking the Links between Conflict and Hunger Redux. World Med. Health Policy 2015, 7, 211–233. [Google Scholar] [CrossRef]

- Hashim, H.T.; Miranda, A.V.; Babar, M.S.; Essar, M.Y.; Hussain, H.; Ahmad, S.; Basalilah, A.F.M. Yemen’s triple emergency: Food crisis amid a civil war and COVID-19 pandemic. Public Health Pract. 2021, 2, 100082. [Google Scholar] [CrossRef]

- Hassen, T.B.; el Bilali, H. Impacts of the Russia-Ukraine War on Global Food Security: Towards More Sustainable and Resilient Food Systems? Foods 2022, 11, 2301. [Google Scholar] [CrossRef] [PubMed]

- Tárik, M. The Russo-Ukrainian War Is A Threat To Food Security In The Arab World. Atlas J. 2022, 8, 2748–2755. [Google Scholar]

- Marnn, P.; Oo, T.T.; Zin, M.M.; Phyo, Z.M.; Claude, N.J. Performances of Myanmar Military in COVID-19 Pandemic Period and Disparities of Public Attitudes on Myanmar Military “Between Before COVID-19 And Present COVID-19 Period”. Tech. Soc. Sci. J. 2021, 16, 584–598. [Google Scholar] [CrossRef]

- Mohammed, N. The Russia-Ukraine War Crisis-It’s Impact on Indian Economy. Int. J. Res. Anal. Rev. 2022. Available online: https://ssrn.com/abstract=4080234 (accessed on 31 May 2022).

- George, J.; Adelaja, A.; Weatherspoon, D. Armed Conflicts and Food Insecurity: Evidence from Boko Haram’s Attacks. Am. J. Agric. Econ. 2020, 102, 114–131. [Google Scholar] [CrossRef]

- Mishra, K.; Rampal, J. The COVID-19 Pandemic and Food Insecurity: A Viewpoint on India. World Dev. 2020, 135, 105068. [Google Scholar] [CrossRef]

- Greenland, S.; Saleem, M.; Misra, R.; Mason, J. Sustainable Management Education and an Empirical Five-Pillar Model of Sustainability. Int. J. Manag. Educ. 2022, 20, 100658. [Google Scholar] [CrossRef]

- Prost, S.; Crivellaro, C.; Haddon, A.; Comber, R. Food Democracy in the Making: Designing with Local Food Networks. In Proceedings of the 2018 CHI Conference on Human Factors in Computing Systems, Montreal, QC, Canada, 21–26 April 2018; Volume 333, pp. 1–14. [Google Scholar]

- Béné, C. Resilience of Local Food Systems and Links to Food Security–A Review of Some Important Concepts in the Context of COVID-19 and Other Shocks. Food Secur. 2020, 12, 805–822. [Google Scholar] [CrossRef] [PubMed]

- Berti, G.; Mulligan, C. Competitiveness of Small Farms and Innovative Food Supply Chains: The Role of Food Hubs in Creating Sustainable Regional and Local Food Systems. Sustainability 2016, 8, 616. [Google Scholar] [CrossRef]

- Hermiatin, F.R.; Handayati, Y.; Perdana, T.; Wardhana, D. Creating Food Value Chain Transformations through Regional Food Hubs: A Review Article. Sustainability 2022, 14, 8196. [Google Scholar] [CrossRef]

- Paksoy, T.; Pehlivan, N.Y.; Kahraman, C. Organizational strategy development in distribution channel management using fuzzy AHP and hierarchical fuzzy TOPSIS. Expert Syst. Appl. 2012, 39, 2822–2841. [Google Scholar] [CrossRef]

- Kaviyani-Charati, M.; Ameli, M.; Souraki, F.H.; Jabbarzadeh, A. Sustainable network design for a non-profit food bank supply chain with a heterogeneous fleet under uncertainty. Comput. Ind. Eng. 2022, 171, 108442. [Google Scholar] [CrossRef]

- Mogale, D.G.; Kumar, M.; Kumar, S.K.; Tiwari, M.K. Grain silo location-allocation problem with dwell time for optimization of food grain supply chain network. Transp. Res. Part E Logist. Transp. Rev. 2018, 111, 40–69. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Dashtian, Z.; Weber, G.W.; Tomaskova, H.; Soltani, M.; Mousavi, N.S. An integrated decision-making approach for green supplier selection in an agri-food supply chain: Threshold of robustness worthiness. Mathematics 2021, 9, 1304. [Google Scholar] [CrossRef]

- Nezhad, F.J.; Taghizadeh-Yazdi, M.; Dahooie, J.H.; Babgohari, A.Z.; Sajadi, S.M. Designing a new mathematical model for optimising a multi-product RFID-based closed-loop food supply chain with a green entrepreneurial orientation. Br. Food J. 2021, 124, 2114–2148. [Google Scholar] [CrossRef]

- Patidar, R.; Agrawal, S. A mathematical model formulation to design a traditional Indian agri-fresh food supply chain: A case study problem. Benchmarking Int. J. 2020, 27, 2341–2363. [Google Scholar] [CrossRef]

- Karan, E.; Asadi, S.; Mohtar, R.; Baawain, M. Towards the optimization of sustainable food-energy-water systems: A stochastic approach. J. Clean. Prod. 2018, 171, 662–674. [Google Scholar] [CrossRef]

- Teimoury, E.; Nedaei, H.; Ansari, S.; Sabbaghi, M. A multi-objective analysis for import quota policy making in a perishable fruit and vegetable supply chain: A system dynamics approach. Comput. Electron. Agric. 2013, 93, 37–45. [Google Scholar] [CrossRef]

- Borodina, O.; Borodina, E.; Ermolieva, T.; Ermoliev, Y.; Fischer, G.; Makowski, M.; Velthuizen, H.V. Sustainable agriculture, food security, and socio-economic risks in Ukraine. In Managing Safety of Heterogeneous Systems; Springer: Berlin/Heidelberg, Germany, 2012; pp. 169–185. [Google Scholar]

- Sonnino, R.; Faus, A.M.; Maggio, A. Sustainable food security: An emerging research and policy agenda. Int. J. Sociol. Agric. Food 2014, 21, 173–188. [Google Scholar]

- Rommel, M.; Posse, D.; Wittkamp, M.; Paech, N. Cooperate to Transform? Regional Cooperation in Community Supported Agriculture as a Driver of Resilient Local Food Systems. In Sustainable Agriculture and Food Security; Springer: Cham, Switzerland, 2022; pp. 381–399. [Google Scholar]

- Kang, H.; Roggio, A.M.; Luna-Reyes, L.F. Governance of local food systems: Current research and future directions. J. Clean. Prod. 2022, 338, 130626. [Google Scholar] [CrossRef]

- Barham, J.; Tropp, D.; Enterline, K.; Farbman, J.; Fisk, J.; Kiraly, S. Regional Food Hub Resource Guide; United States Department of Agriculture: Washington, DC, USA, 2012. [Google Scholar] [CrossRef]

- Hassan, A.; Shahzad, A.N.; Qureshi, M.K. Rice Production and Crop Improvement Through Breeding and Biotechnology. In Modern Techniques of Rice Crop Production; Springer: Singapore, 2022; pp. 605–627. [Google Scholar]

- Abbas, S.G.; Baig, M.B.; Straquadine, G.S. Impacts of Climate Change on Agricultural Labour Force and Food Security in Pakistan: The Importance of Climate-Smart Agriculture. In Food Security and Climate-Smart Food Systems; Springer: Berlin/Heidelberg, Germany, 2022; pp. 51–66. [Google Scholar]

- Setsoafia, E.D.; Ma, W.; Renwick, A. Effects of sustainable agricultural practices on farm income and food security in northern Ghana. Agric. Food Econ. 2022, 10, 1–15. [Google Scholar] [CrossRef]

- Amin-Chaudhry, A.; Young, S.; Afshari, L. Sustainability motivations and challenges in the Australian agribusiness. J. Clean. Prod. 2022, 361, 132229. [Google Scholar] [CrossRef]

- Rossi, T.; Pozzi, R.; Pirovano, G.; Cigolini, R.; Pero, M. A New Logistics Model for Increasing Economic Sustainability of Perishable Food Supply Chains through Intermodal Transportation. Int. J. Logist. Res. Appl. 2021, 24, 346–363. [Google Scholar] [CrossRef]

- Jouzdani, J.; Fathian, M.; Makui, A.; Heydari, M. Robust Design and Planning for a Multi-Mode Multi-Product Supply Network: A Dairy Industry Case Study. Oper. Res. 2020, 20, 1811–1840. [Google Scholar] [CrossRef]

- Sanjaya, S.; Perdana, T. Logistics System Model Development on Supply Chain Management of Tomato Commodities for Structured Market. Procedia Manuf. 2015, 4, 513–520. [Google Scholar] [CrossRef]

- Bashiri, M.; Tjahjono, B.; Lazell, J.; Ferreira, J.; Perdana, T. The Dynamics of Sustainability Risks in the Global Coffee Supply Chain: A Case of Indonesia–UK. Sustainability 2021, 13, 589. [Google Scholar] [CrossRef]

- Abbasian, M.; Sazvar, Z.; Mohammadisiahroudi, M. A hybrid optimization method to design a sustainable resilient supply chain in a perishable food industry. Environ. Sci. Pollut. Res. 2022, 2022, 1–24. [Google Scholar] [CrossRef]

- De, A.; Gorton, M.; Hubbard, C.; Aditjandra, P. Optimization model for sustainable food supply chains: An application to Norwegian salmon. Transp. Res. Part E Logist. Transp. Rev. 2022, 161, 102723. [Google Scholar] [CrossRef]

- Krishnan, R.; Arshinder, K.; Agarwal, R. Robust optimization of sustainable food supply chain network considering food waste valorization and supply uncertainty. Comput. Ind. Eng. 2022, 171, 108499. [Google Scholar] [CrossRef]

- Esteso, A.; Alemany, M.M.E.; Ortiz, A.; Liu, S. Optimization model to support sustainable crop planning for reducing unfairness among farmers. Cent. Eur. J. Oper. Res. 2022, 30, 1101–1127. [Google Scholar] [CrossRef]

- Hoehn, D.; Margallo, M.; Laso, J.; Fernández-Ríos, A.; Ruiz-Salmón, I.; Aldaco, R. Energy Systems in the Food Supply Chain and in the Food Loss and Waste Valorization Processes: A Systematic Review. Energies 2022, 15, 2234. [Google Scholar] [CrossRef]

- Perdana, T.; Tjahjono, B.; Kusnandar, K.; Sanjaya, S.; Wardhana, D.; Hermiatin, F.R. Fresh agricultural product logistics network governance: Insights from small-holder farms in a developing country. Int. J. Logist. Res. Appl. 2022, 1–24. [Google Scholar] [CrossRef]

- Perdana, T.; Chaerani, D.; Achmad, A.L.H. Supporting data for the integrated Agent-Based Modelling and Robust Optimization on food supply network design in COVID-19 pandemic. Data Brief 2022, 40, 107809. [Google Scholar] [CrossRef]

- Prajapati, D.; Zhou, F.; Dwivedi, A.; Singh, T.; Lakshay, L.; Pratap, S. Sustainable agro-food supply chain in e-commerce: Towards the circular economy. Sustainability 2022, 14, 8698. [Google Scholar] [CrossRef]

- Marlyono, S. Peranan Literasi Informasi Bencana Terhadap Kesiapsiagaan Bencana Masyarakat Jawa Barat. J. Geogr. Gea 2016, 16, 116–123. [Google Scholar]

- Komatsuzaki, M.; Syuaib, M. Comparison of the Farming System and Carbon Sequestration between Conventional and Organic Rice Production in West Java, Indonesia. Sustainability 2010, 2, 833–843. [Google Scholar] [CrossRef]

- Statistics of Jawa Barat. Statistics Indonesia, December 2021. Available online: https://jabar.bps.go.id/ (accessed on 9 February 2022).

- Pasar Induk Beras Cipinang. PT. Food Station Tjipinang Jaya, February 2022. Available online: http://pibc.foodstation.co.id/ (accessed on 9 February 2022).

- Rao, S. Engineering Optimization: Theory and Practice; John Wiley & Sons: Orlando, FL, USA, 2019; ISBN 1-119-45471-9. [Google Scholar]

- Kharisma, A.; Perdana, T. Linear Programming Model for Vegetable Crop Rotation Planning: A Case Study. Int. J. Agric. Resour. Gov. Ecol. 2019, 15, 358–371. [Google Scholar] [CrossRef]

- Utami, H.N.; Sadeli, A.H.; Perdana, T. Customer Value Creation of Fresh Tomatoes through Branding and Packaging as Customer Perceived Quality. J. ISSAAS 2016, 22, 123–136. [Google Scholar]

- Abokyi, E.; Folmer, H.; Asiedu, K.F. Public buffer stocks as agricultural output price stabilization policy in Ghana. Agric. Food Secur. 2018, 7, 69. [Google Scholar] [CrossRef]

- Kumaran, G.M.M.; Gautam, G.; Rao, B.V.C. A Transformational, Effective, and Smart Public Distribution System: An Innovative Journey. In Citizen Empowerment through Digital Transformation in Government; Chapman and Hall/CRC: Boca Raton, FL, USA, 2021; pp. 125–139. [Google Scholar]

- Harris, F.; Amarnath, G.; Joy, E.J.; Dangour, A.D.; Green, R.F. Climate-related hazards and Indian food supply: Assessing the risk using recent historical data. Glob. Food Secur. 2022, 33, 100625. [Google Scholar] [CrossRef]

- Lin, Y.; Marjerison, R.K.; Choi, J.; Chae, C. Supply Chain Sustainability during COVID-19: Last Mile Food Delivery in China. Sustainability 2022, 14, 1484. [Google Scholar] [CrossRef]

- Eashwar, S.; Chawla, P. Evolution of Agritech Business 4.0–Architecture and Future Research Directions. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Atlanta, GA, USA, 2022; Volume 775, p. 012011. [Google Scholar]

- Sivakumar, E.; Ganesan, G. Harnessing I4. 0 Technologies for Climate Smart Agriculture and Food Security. In Proceedings of the 5th International Conference on Future Networks and Distributed Systems, Dubai, United Arab Emirates, 15–16 December 2021; pp. 504–510. [Google Scholar]

- Bortolini, M.; Faccio, M.; Ferrari, E.; Gamberi, M.; Pilati, F. Fresh food sustainable distribution: Cost, delivery time and carbon footprint three-objective optimization. J. Food Eng. 2016, 174, 56–67. [Google Scholar] [CrossRef]

| Consumer Area | Supply from Local Wholesale Market (tons) | Supply from Nonlocal Wholesale Market (tons) | Supply from RMU | Total Supply | Total Demand | Percentage of Demand Fulfillment |

|---|---|---|---|---|---|---|

| Ciamis Regency | 0 | 0 | 107,747 | 107,747 | 107,747 | 100% |

| Garut Regency | 0 | 0 | 233,393 | 233,393 | 233,393 | 100% |

| Tasikmalaya Regency | 0 | 0 | 156,637 | 156,637 | 156,637 | 100% |

| Tasikmalaya City | 59,135 | 0 | 0 | 59,135 | 59,135 | 100% |

| Cirebon Regency | 0 | 0 | 197,002 | 197,002 | 197,002 | 100% |

| Cirebon City | 28,748 | 0 | 0 | 28,748 | 28,748 | 100% |

| Indramayu Regency | 0 | 0 | 155,353 | 155,353 | 155,353 | 100% |

| Majalengka Regency | 108,231 | 0 | 0 | 108,231 | 108,231 | 100% |

| Kuningan Regency | 0 | 0 | 97,041 | 97,041 | 97,041 | 100% |

| Sukabumi Regency | 219,507 | 0 | 0 | 219,507 | 219,507 | 100% |

| Sukabumi City | 29,421 | 0 | 0 | 29,421 | 29,421 | 100% |

| Bogor City | 0 | 0 | 100,317 | 100,317 | 100,317 | 100% |

| Depok City | 220,541 | 0 | 0 | 220,541 | 220,541 | 100% |

| Bekasi Regency | 0 | 0 | 344,402 | 344,402 | 344,402 | 100% |

| Bekasi City | 273,739 | 0 | 0 | 273,739 | 273,739 | 100% |

| Bogor Regency | 392,651 | 146,000 | 0 | 538,651 | 538,651 | 100% |

| Cianjur Regency | 0 | 0 | 201,059 | 201,059 | 201,059 | 100% |

| Bandung Regency | 309,363 | 0 | 30,023 | 339,386 | 339,386 | 100% |

| Bandung City | 224,220 | 0 | 0 | 224,220 | 224,220 | 100% |

| Cimahi City | 55,222 | 0 | 0 | 55,222 | 55,222 | 100% |

| Sumedang Regency | 59,894 | 0 | 43,411 | 103,306 | 103,306 | 100% |

| West Bandung Regency | 0 | 0 | 152,222 | 152,222 | 152,222 | 100% |

| Subang Regency | 27,337 | 0 | 116,955 | 144,292 | 144,292 | 100% |

| Purwakarta Regency | 0 | 0 | 86,250 | 86,250 | 86,250 | 100% |

| Karawang Regency | 0 | 0 | 210,907 | 210,907 | 210,907 | 100% |

| Banjar City | 0 | 0 | 16,379 | 16,379 | 16,379 | 100% |

| Pangandaran Regency | 35,992 | 0 | 0 | 35,992 | 35,992 | 100% |

| Total | 2,044,000 | 146,000 | 2,249,097 | 4,439,097 | 4,439,097 | 100% |

| Farmer (by Region) | Rice Production (tons/year) | Rice Distributed to Local RMU (tons/year) | Percentage |

|---|---|---|---|

| Local (West Java) | 5,257,909 | 5,184,135 | 99% |

| Ciamis Regency | 170,666 | 170,666 | 100% |

| Garut Regency | 254,636 | 254,636 | 100% |

| Tasikmalaya Regency | 264,921 | 264,921 | 100% |

| Tasikmalaya City | 23,937 | 23,937 | 100% |

| Cirebon Regency | 282,344 | 282,344 | 100% |

| Cirebon City | 635 | 635 | 100% |

| Indramayu Regency | 786,395 | 786,395 | 100% |

| Majalengka Regency | 320,832 | 320,832 | 100% |

| Kuningan Regency | 149,159 | 149,159 | 100% |

| Sukabumi Regency | 288,388 | 288,388 | 100% |

| Sukabumi City | 8583 | 8583 | 100% |

| Bogor City | 120 | 120 | 100% |

| Depok City | 175 | 175 | 100% |

| Bekasi Regency | 316,891 | 316,891 | 100% |

| Bekasi City | 1593 | 1593 | 100% |

| Bogor Regency | 173,901 | 173,901 | 100% |

| Cianjur Regency | 358,639 | 358,639 | 100% |

| Bandung Regency | 176,101 | 176,101 | 100% |

| Bandung City | 4096 | 4096 | 100% |

| Cimahi City | 245 | 245 | 100% |

| Sumedang Regency | 167,608 | 167,608 | 100% |

| West Bandung Regency | 91,361 | 91,361 | 100% |

| Subang Regency | 555,981 | 555,981 | 100% |

| Purwakarta Regency | 91,048 | 91,048 | 100% |

| Karawang Regency | 661,712 | 661,712 | 100% |

| Banjar City | 17,606 | 17,606 | 100% |

| Pangandaran Regency | 90,339 | 16,565 | 18% |

| Non-Local (Outside West Java) | 1,810,499 | - | 0% |

| Banten (Outside West Java) | 898,117 | - | 0% |

| Kudus Regency (Outside West Java) | 107,204 | - | 0% |

| Demak Regency (Outside West Java) | 378,181 | - | 0% |

| Cilacap Regency (Outside West Java) | 426,996 | - | 0% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perdana, T.; Chaerani, D.; Hermiatin, F.R.; Achmad, A.L.H.; Fridayana, A. Does an Alternative Local Food Network Contribute to Improving Sustainable Food Security? Sustainability 2022, 14, 11533. https://doi.org/10.3390/su141811533

Perdana T, Chaerani D, Hermiatin FR, Achmad ALH, Fridayana A. Does an Alternative Local Food Network Contribute to Improving Sustainable Food Security? Sustainability. 2022; 14(18):11533. https://doi.org/10.3390/su141811533

Chicago/Turabian StylePerdana, Tomy, Diah Chaerani, Fernianda Rahayu Hermiatin, Audi Luqmanul Hakim Achmad, and Ananda Fridayana. 2022. "Does an Alternative Local Food Network Contribute to Improving Sustainable Food Security?" Sustainability 14, no. 18: 11533. https://doi.org/10.3390/su141811533