IoT-Enabled Sustainable and Cost-Efficient Returnable Transport Management Strategies in Multimodal Transport Systems

Abstract

:1. Introduction

- (1)

- Through extensive field studies in collaborative logistics service providers in multimodal transport systems, this research summarized the operation process of RTIs into three typical schemes.

- (2)

- Based on three typical schemes, this work proposed decision models to help enterprises determine the conditions under which adopting IoT-RTIs management system is economical.

- (3)

- Based on decision models, this research studied the main factors affecting the application of IoT-RTIs management systems, based on which several managerial implications are presented.

2. Materials and Methods

2.1. Model Description

2.2. Assumptions

- 1

- All RTIs must be in perfect working condition before they can be used by the WC, which is why we assume some RTIs coming out from the IC still needs to undergo maintenance.After each operation cycle, some RTIs must be repaired to ensure their working conditions. Therefore, the return rate of RTIs should be considered when modeling.

- 2

- Even with IoT-RTIs management systems, the locations of RTIs can only be tracked at key nodes like the IC, IRC, WC, and DW, not throughout the entire production cycle. We assume IoT-RTIs management systems adoption can only increase the ratio of RTIs returned from the DW to the IC, not eliminate RTIs attrition. Therefore, even if IoT-enabled RTIs are used, the return rate of RTIs still needs to be considered when modeling, and the return rate should be larger than common RTIs and less than 1.

2.3. Cost–Benefit Analysis

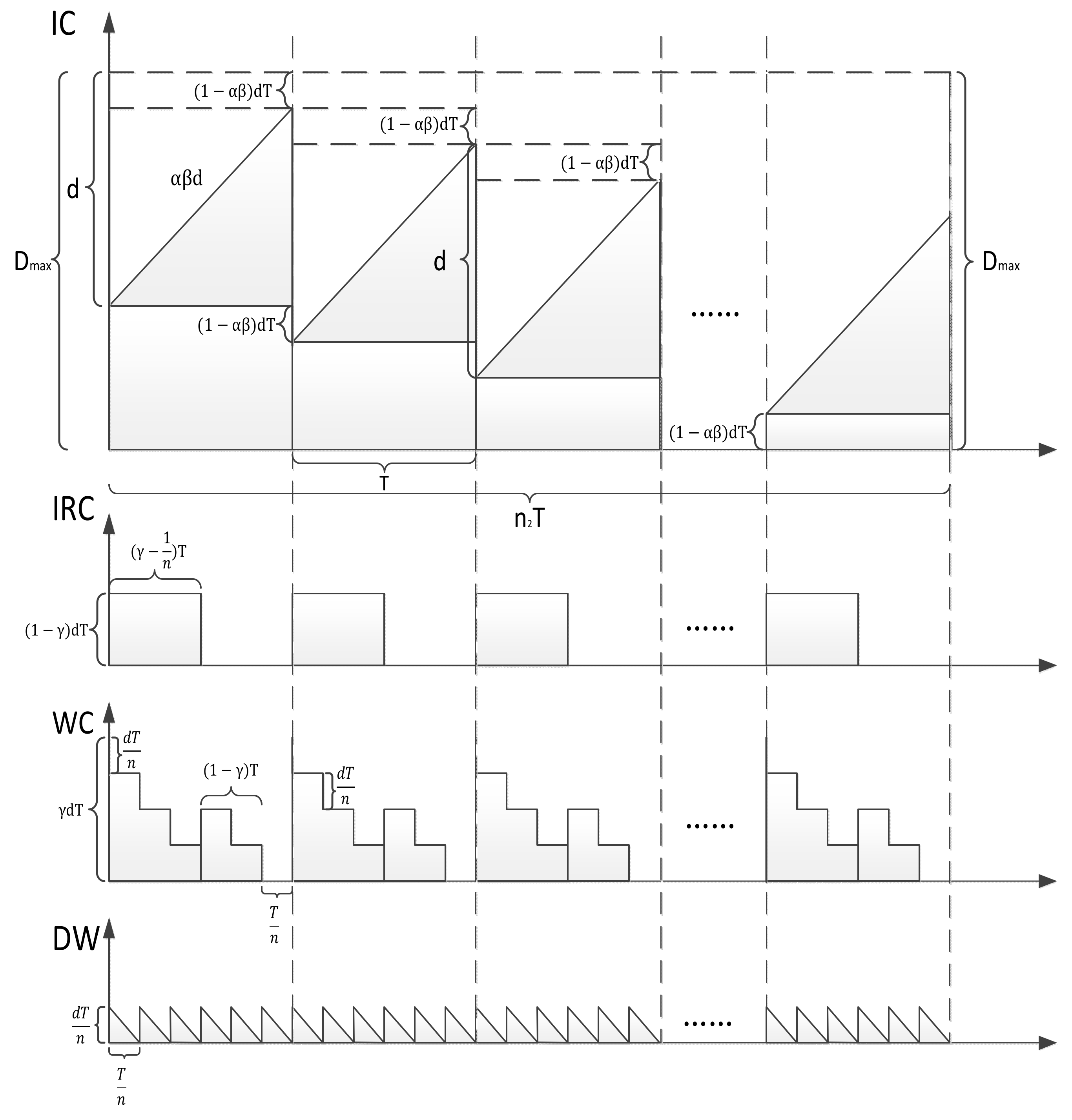

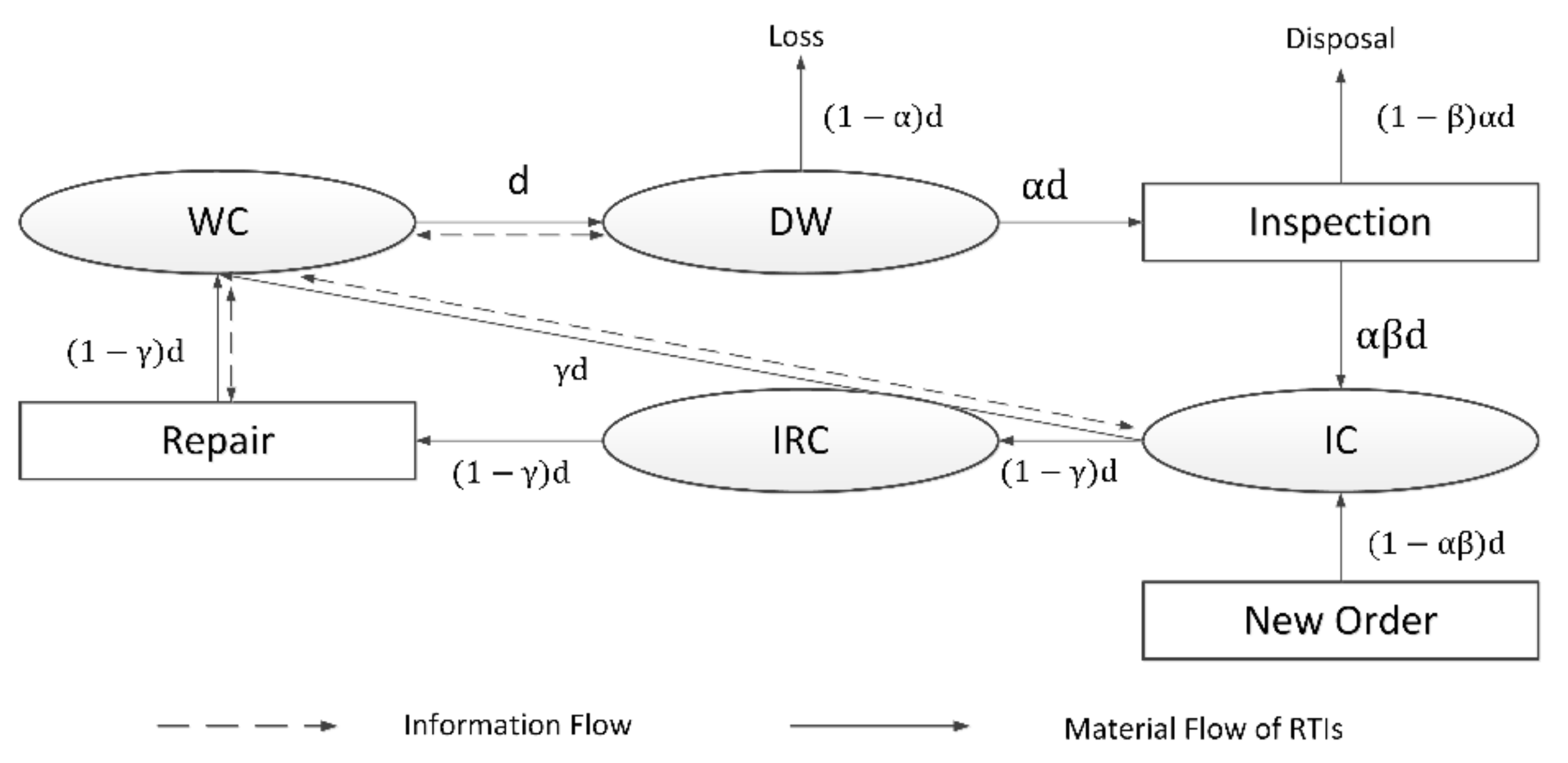

2.3.1. Scheme 1

2.3.2. Scheme 2

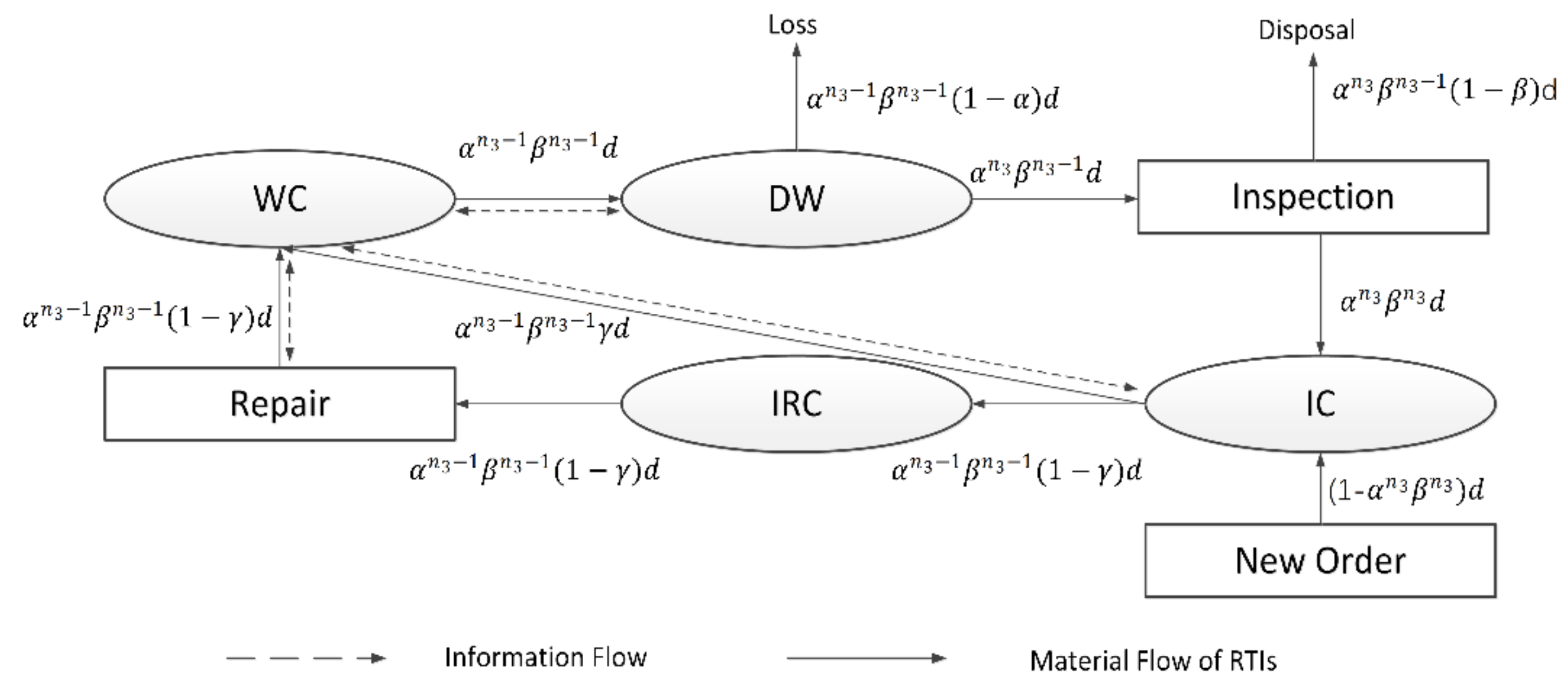

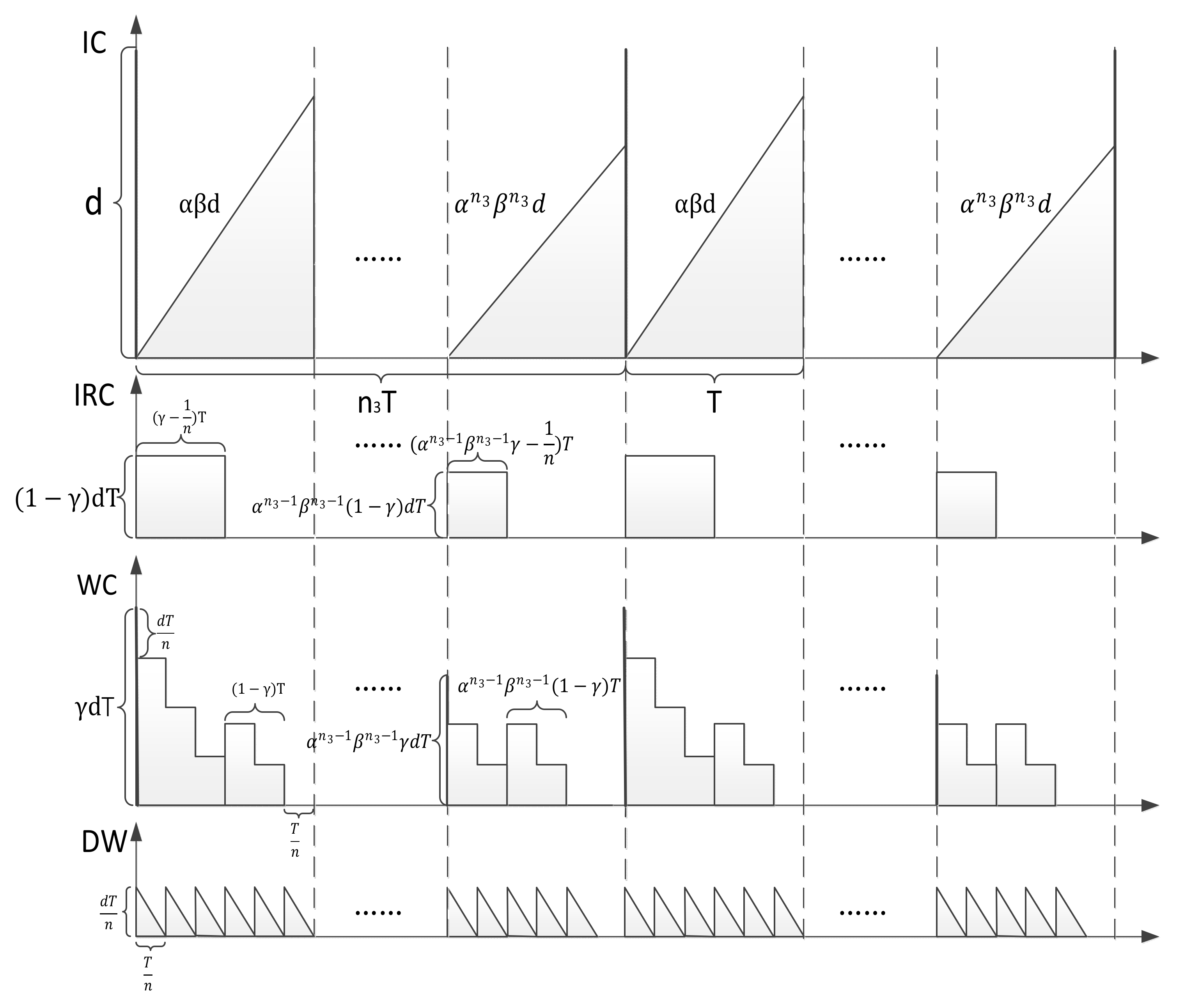

2.3.3. Scheme 3

3. Results

3.1. Parameters Setting

3.2. Results

| 0.55 | 424 | 5975 | 1022.5 | 7421.5 |

| 0.60 | 424 | 5600 | 1070 | 7094 |

| 0.65 | 424 | 5225 | 1117.5 | 6766.5 |

| 0.70 | 424 | 4850 | 1165 | 6439 |

| 0.75 | 424 | 4475 | 1212.5 | 6111.5 |

| 0.80 | 424 | 4100 | 1260 | 5784 |

| 0.85 | 424 | 3725 | 1307.5 | 5456.5 |

| 0.90 | 424 | 3350 | 1355 | 5129 |

| 0.95 | 424 | 2975 | 1402 | 4801 |

| 1.00 | 424 | 2600 | 1450 | 4474 |

| 0.55 | 2040 | 29,875 | 19,438 | 51,353 |

| 0.60 | 2040 | 28,000 | 18,250 | 48,290 |

| 0.65 | 2040 | 26,125 | 17,063 | 45,228 |

| 0.70 | 2040 | 24,250 | 15,875 | 42,165 |

| 0.75 | 2040 | 22,375 | 14,688 | 39,103 |

| 0.80 | 2040 | 20,500 | 13,500 | 36,040 |

| 0.85 | 2040 | 18,625 | 12,313 | 32,978 |

| 0.90 | 2040 | 16,750 | 11,125 | 29,915 |

| 0.95 | 2040 | 14,875 | 9938 | 26,853 |

| 1.00 | 2040 | 13,000 | 8750 | 23,790 |

| 0.55 | 1232 | 10,549 | 1612 | 13,570 | 26,963 |

| 0.60 | 1232 | 10,422 | 1795 | 11,906 | 25,355 |

| 0.65 | 1232 | 10,244 | 1998 | 10,088 | 23,562 |

| 0.70 | 1232 | 10,009 | 2220 | 8083 | 21,544 |

| 0.75 | 1232 | 9713 | 2465 | 5943 | 19,353 |

| 0.80 | 1232 | 9351 | 2732 | 3911 | 17,226 |

| 0.85 | 1232 | 8916 | 3025 | 2303 | 15,476 |

| 0.90 | 1232 | 8405 | 3344 | 1250 | 14,231 |

| 0.95 | 1232 | 7812 | 3691 | 656 | 13,391 |

| 1.00 | 1232 | 3583 | 2025 | 181 | 7021 |

| 10 | 20 | 30 | 40 | 50 | |

|---|---|---|---|---|---|

| 200 | 31.5 | 75.6 | 119.7 | 163.8 | 207.9 |

| 400 | 29.4 | 73.5 | 117.6 | 161.7 | 205.8 |

| 600 | 27.4 | 71.5 | 115.6 | 159.7 | 203.8 |

| 800 | 25.3 | 69.4 | 113.5 | 157.6 | 201.7 |

| 1000 | 23.3 | 67.4 | 111.5 | 155.6 | 199.7 |

| 1200 | 21.2 | 65.3 | 109.4 | 153.5 | 197.6 |

| 1400 | 19.2 | 63.3 | 107.4 | 151.5 | 195.6 |

| 1600 | 17.1 | 61.2 | 105.3 | 149.4 | 193.5 |

| 1800 | 15.1 | 59.2 | 103.3 | 147.4 | 191.5 |

| 2000 | 13.0 | 57.1 | 101.2 | 145.3 | 189.4 |

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Notation | ||

| fraction of returned RTIs after usage | ||

| variable inspection cost per inspected RTI | ||

| cost of purchasing a new RTI | ||

| variable repair cost per repaired RTI | ||

| cost of purchasing a common RTI | ||

| cost of purchasing an IoT-RTI | ||

| d | demand rate in units per unit time | |

| cost of keeping an RTI in PF, per RTI per unit of time | ||

| cost of keeping a repairable RTI in inventory, per RTI per unit of time | ||

| cost of keeping a used RTI in inventory, per RTI per unit of time | ||

| cost of keeping an RTI in WC, per RTI per unit of time | ||

| delivery frequency of RTIs from WC to PF in each cycle | ||

| procurement cycle of RTIs in Scheme 2 | ||

| procurement cycle of RTIs in Scheme 3 | ||

| fixed inspection cost per cycle | ||

| fixed ordering cost per cycle | ||

| fixed repair cost per cycle | ||

| implementation cost of the IoT- RTIs management system per cycle | ||

| T | cycle time | |

| Abbreviation | ||

| expected total cost of Scheme 1 | ||

| expected total cost of Scheme 2 | ||

| expected total cost of Scheme 3 | ||

| fixed cost of Scheme 1 | ||

| fixed cost of Scheme 2 | ||

| fixed cost of Scheme 3 | ||

| inventory holding cost of Scheme 1 | ||

| inventory holding cost of Scheme 2 | ||

| inventory holding cost of Scheme 3 | ||

| IC | inventory center of RTIs | |

| IRC | inventory center of repairable RTIs | |

| PC | penalty cost | |

| DW | destination warehouse | |

| total cost of Scheme 1 | ||

| total cost of Scheme 2 | ||

| total cost of Scheme 3 | ||

| variable cost of Scheme 1 | ||

| variable cost of Scheme 2 | ||

| variable cost of Scheme 3 | ||

| WC | warehouse center | |

References

- Ilic, A.; Ng, J.W.P.; Bowman, P.; Staake, T. The value of RFID for RTI management. Electron. Mark. 2009, 19, 125–135. [Google Scholar] [CrossRef]

- Breen, L. Give me back my empties or else! A preliminary analysis of customer compliance in reverse logistics practices (UK). Manage Res. News 2006, 29, 532–551. [Google Scholar] [CrossRef]

- Li, Z.; Liu, G.; Liu, X.; Lai, X.; Xu, G. IoT-based Tracking and Tracing Platform for Prepackaged Food Supply Chain. Ind. Manage Data Syst. 2017, 117, 1–13. [Google Scholar] [CrossRef]

- Xu, G.; Huang, G.Q.; Fang, J.; Chen, J. Cloud-based Smart Asset Management for Urban Flood Control. Enterp. Inf. Syst-UK 2017, 11, 719–737. [Google Scholar] [CrossRef]

- Xu, G.; Li, M.; Chen, C.H.; Wei, Y. Cloud asset-enabled integrated IoT platform for lean prefabricated construction. Automat. Constr. 2018, 93, 123–134. [Google Scholar] [CrossRef]

- Zhao, Z.H.; Lin, P.; Shen, L.D.; Zhang, M.D.; Huang, G.Q. IoT edge computing-enabled collaborative tracking system for manufacturing resources in industrial park. Adv. Eng. Inform. 2020, 43, 1–12. [Google Scholar] [CrossRef]

- Song, Y.X.; Yu, F.R.; Zhou, L.; Yang, X.; He, Z.F. Applications of the Internet of Things (IoT) in smart logistics: A comprehensive survey. IEEE Internet Things 2020, 8, 4250–4274. [Google Scholar] [CrossRef]

- Chen, Y.T.; Sun, E.W.; Chang, M.F.; Lin, Y.B. Pragmatic real-time logistics management with traffic IoT infrastructure: Big data predictive analytics of freight travel time for Logistics 4.0. Int. J. Prod. Econ. 2021, 238, 108157. [Google Scholar] [CrossRef]

- Xu, G.; Li, M.; Luo, L.; Chen, C.H.; Huang, G.Q. Cloud-based Fleet Management for Prefabrication Transportation. Enterp. Inf. Syst. 2019, 13, 87–106. [Google Scholar] [CrossRef]

- Sounderpandian, J.; Boppana, R.V.; Chalasani, S.; Madni, A.M. Models for cost-benefit analysis of RFID implementations in retail stores. IEEE Syst. J. 2007, 1, 105–114. [Google Scholar] [CrossRef]

- Lee, I.; Lee, B.C. An investment evaluation of supply chain RFID technologies: A normative modeling approach. Int. J. Prod. Econ. 2010, 125, 313–323. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Li, Z.; Zhang, B.; Zhang, W. Barriers to promoting prefabricated construction in China: A cost–benefit analysis. J. Clean. Prod. 2018, 172, 649–660. [Google Scholar] [CrossRef]

- Goh, T.N.; Varaprasad, N. A statistical methodology for the analysis of the life-cycle of reusable containers. IIE Trans. 1986, 18, 42–47. [Google Scholar] [CrossRef]

- Kelle, P.; Silver, E.A. Forecasting the Returns of Reusable Containers. J. Oper. Manag. 1989, 8, 17–35. [Google Scholar] [CrossRef]

- Bojkow, E. Basic considerations on the calculation of the trippage number for returnable containers. Packag. Technol. Sci. 1991, 4, 315–331. [Google Scholar] [CrossRef]

- Kelle, P.; Silver, E.A. Purchasing Policy of New Containers Considering the Random Returns of Previously Issued Containers. IIE Trans. 1989, 21, 349–354. [Google Scholar] [CrossRef]

- Buchanan, D.J.; Abad, P.L. Optimal policy for a periodic review returnable inventory system. IIE Trans. 1998, 30, 1049–1055. [Google Scholar] [CrossRef]

- Chew, E.P.; Huang, H.C.; Horiana. Performance measures for returnable inventory: A case study. Prod. Plan. Control 2002, 13, 462–469. [Google Scholar] [CrossRef]

- Del Castillo, E.; Cochran, J.K. Optimal short horizon distribution operations in reusable container systems. J. Oper. Res. Soc. 1996, 47, 48–60. [Google Scholar] [CrossRef]

- Kim, T.; Glock, C.H.; Kwon, Y. A closed-loop supply chain for deteriorating products under stochastic container return times. Omega 2014, 43, 30–40. [Google Scholar] [CrossRef]

- Glock, C.H.; Kim, T. A joint economic lot size model with returnable transport items. Int. J. Integr. Supply Manag. 2015, 9, 202–224. [Google Scholar] [CrossRef]

- Glock, C.H.; Kim, T. Safety measures in the joint economic lot size model with returnable transport items. Int. J. Prod. Econ. 2016, 181, 24–33. [Google Scholar] [CrossRef]

- Cobb, B.R. Inventory control for returnable transport items in a closed-loop supply chain. Transp. Res. Part E Logist. Transp. Rev. 2016, 86, 53–68. [Google Scholar] [CrossRef]

- Achamrah, F.E.; Riane, F.; Sahin, E.; Limbourg, S. An Artificial-Immune-System-Based Algorithm Enhanced with Deep Reinforcement Learning for Solving Returnable Transport Item Problems. Sustainability 2022, 14, 5805. [Google Scholar] [CrossRef]

- Tornese, F.; Gnoni, M.G.; Thorn, B.K.; Carrano, A.L.; Pazour, J.A. Management and Logistics of Returnable Transport Items: A Review Analysis on the Pallet Supply Chain. Sustainability 2021, 13, 12747. [Google Scholar] [CrossRef]

- Liu, G.Q.; Li, L.; Chen, J.H.; Ma, F. Inventory sharing strategy and optimization for reusable transport items. Int. J. Prod. Econ. 2020, 228, 107742. [Google Scholar]

- Fan, X.X.; Gong, Y.M.; Xu, X.H.; Zou, B.P. Optimal decisions in reducing loss rate of returnable transport items. J. Clean Prod. 2019, 214, 1050–1060. [Google Scholar]

- Zhang, Y.P.; Che, A.D.; Chu, F. Improved model and efficient method for bi-objective closed-loop food supply chain problem with returnable transport items. Int. J. Prod. Res. 2022, 60, 1051–1068. [Google Scholar]

- Tsiliyannis, C.A. Parametric analysis of environmental performance of reused/recycled packaging. Environ. Sci. Technol. 2005, 39, 9770–9777. [Google Scholar]

- Atamer, B.; Bakal, I.S.; Bayindir, Z.P. Optimal pricing and production decisions in utilizing reusable containers. Int. J. Prod. Econ. 2013, 143, 222–232. [Google Scholar]

- Goudenege, G.; Chu, C.; Jemai, Z. Reusable containers management: From a generic model to an industrial case study. Supply Chain. Forum. 2013, 14, 26–38. [Google Scholar] [CrossRef]

- Bottani, E.; Montanari, R.; Rinaldi, M.; Vignali, G. Modeling and multi-objective optimization of closed loop supply chains: A case study. Comput. Ind. Eng. 2015, 87, 328–342. [Google Scholar] [CrossRef]

- Santos, L.P.; Proenca, J.F. Development return supply chain: A research on the automotive supply chain. Sustainability 2022, 14, 6587. [Google Scholar] [CrossRef]

- Mensendiek, A. Scheduling with returnable containers. J. Sched. 2015, 18, 593–605. [Google Scholar] [CrossRef]

- Ni, L.; He, Y.; Zhou, L.; Deng, L. Robust control optimization of triple-echelon closed-loop pallet pool system in multi-uncertain environment. J. Inform. Comput. Sci. 2015, 12, 2635–2645. [Google Scholar] [CrossRef]

- Hariga, M.A.; Glock, C.H.; Kim, T. Integrated product and container inventory model for a single-vendor single-buyer supply chain with owned and rented returnable transport items. Int. J. Prod. Res. 2016, 54, 1964–1979. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Chu, F.; Che, A.D.; Yu, Y.G.; Feng, X. Novel model and kernel search heuristic for multi-period closed-loop food supply chain planning with returnable transport items. Int. J. Prod. Res. 2019, 57, 7439–7456. [Google Scholar] [CrossRef]

- Na, B.; Sim, M.K.; Lee, W.J. An optimal purchase decision of reusable packaging in the automotive industry. Sustainability 2019, 11, 6579. [Google Scholar] [CrossRef]

- Kim, T.; Glock, C.H. On the use of RFID in management of reusable containers in closed-loop supply chains under stochastic container return quantities. Transp. Res. Part E Logist. Transp. Rev. 2014, 64, 12–27. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Kou, X.; Liu, H.; Zhang, S.; Qie, L. IoT-Enabled Sustainable and Cost-Efficient Returnable Transport Management Strategies in Multimodal Transport Systems. Sustainability 2022, 14, 11668. https://doi.org/10.3390/su141811668

Zhang Y, Kou X, Liu H, Zhang S, Qie L. IoT-Enabled Sustainable and Cost-Efficient Returnable Transport Management Strategies in Multimodal Transport Systems. Sustainability. 2022; 14(18):11668. https://doi.org/10.3390/su141811668

Chicago/Turabian StyleZhang, Yanqi, Xiaofei Kou, Haibin Liu, Shiqing Zhang, and Liangliang Qie. 2022. "IoT-Enabled Sustainable and Cost-Efficient Returnable Transport Management Strategies in Multimodal Transport Systems" Sustainability 14, no. 18: 11668. https://doi.org/10.3390/su141811668

APA StyleZhang, Y., Kou, X., Liu, H., Zhang, S., & Qie, L. (2022). IoT-Enabled Sustainable and Cost-Efficient Returnable Transport Management Strategies in Multimodal Transport Systems. Sustainability, 14(18), 11668. https://doi.org/10.3390/su141811668