Key Enablers of Resilient and Sustainable Construction Supply Chains: A Systems Thinking Approach

Abstract

:1. Introduction

2. Literature Review

2.1. Sustainable Supply Chain Management (SSCM)

2.2. Resilient Supply Chain Management

2.3. Resilient Sustainable Supply Chain Management (RSSCM)

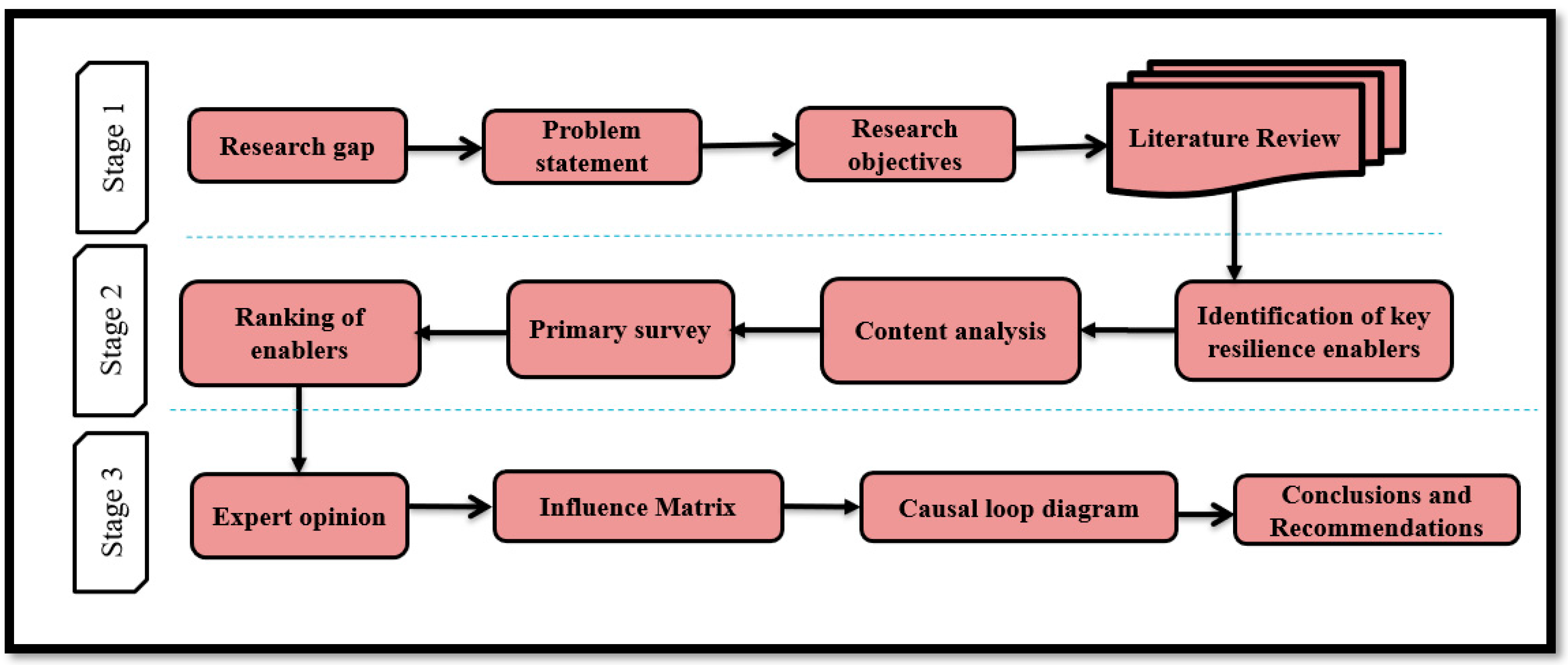

3. Research Methodology

3.1. Stage 1: Initial Study

3.2. Stage 2: Factors Shortlisting

3.3. Stage 3: Systems Thinking Approach

3.4. Data Collection and Analysis

Demographics of Primary Survey Respondents

4. Results and Discussions

4.1. Factors Shortlisting

4.2. Influence Matrix

4.3. Causal Loop Diagram (CLD)

4.3.1. Reinforcing Loop R1

4.3.2. Reinforcing Loop R2

4.3.3. Reinforcing Loop R3

4.3.4. Reinforcing Loop R4

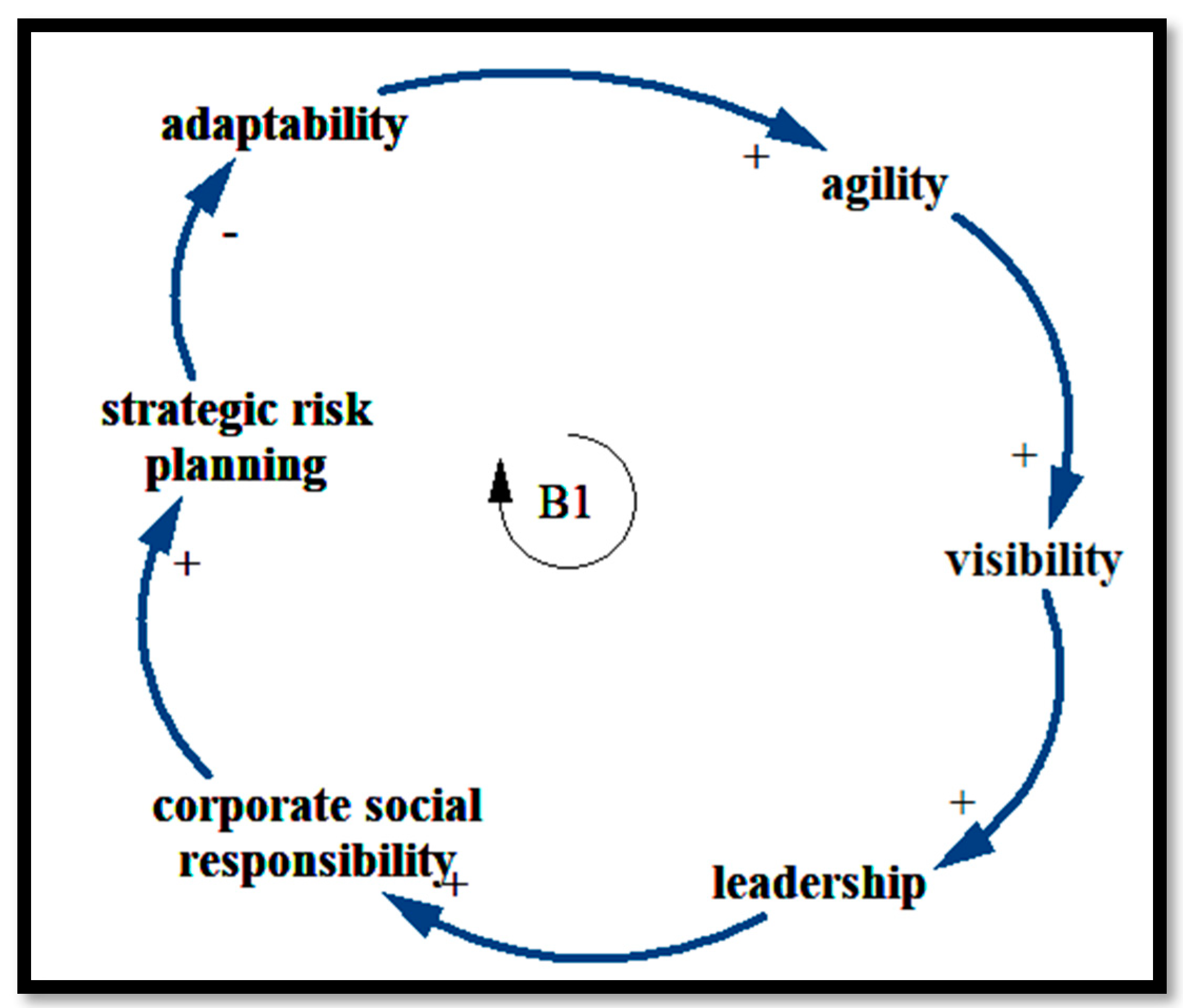

4.3.5. Balancing Loop B1

4.4. Loop Analysis

4.5. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Touboulic, A.; Walker, H. Theories in sustainable supply chain management: A structured literature review. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 16–42. [Google Scholar] [CrossRef]

- Naslund, D.; Williamson, S. What is management in supply chain management?-a critical review of definitions, frameworks and terminology. J. Manag. Policy Pract. 2010, 11, 11–28. [Google Scholar]

- Reefke, H.; Sundaram, D. Key themes and research opportunities in sustainable supply chain management–identification and evaluation. Omega 2017, 66, 195–211. [Google Scholar] [CrossRef]

- Ghufran, M.; Khan, K.I.A.; Thaheem, M.J.; Nasir, A.R.; Ullah, F. Adoption of Sustainable Supply Chain Management for Performance Improvement in the Construction Industry: A System Dynamics Approach. Architecture 2021, 1, 161–182. [Google Scholar] [CrossRef]

- Cetinkaya, B.; Cuthbertson, R.; Ewer, G.; Klaas-Wissing, T.; Piotrowicz, W.; Tyssen, C. Sustainable Supply Chain Management: Practical Ideas for Moving towards Best Practice; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Janvier-James, A.M. A new introduction to supply chains and supply chain management: Definitions and theories perspective. Int. Bus. Res. 2012, 5, 194–207. [Google Scholar] [CrossRef]

- Sutrisna, M.; Kumaraswamy, M.M. Advanced ICT and smart systems for innovative “engineering, construction and architectural management”. Eng. Constr. Archit. Manag. 2015, 22, 5. [Google Scholar] [CrossRef]

- Gattorna, J. Dynamic Supply Chain Alignment: A New Business Model for Peak Performance in Enterprise Supply Chains Across all Geographies; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Marley, K.A.; Ward, P.T.; Hill, J.A. Mitigating supply chain disruptions—A normal accident perspective. Supply Chain. Manag. Int. J. 2014, 19, 142–152. [Google Scholar] [CrossRef]

- Revilla, E.; Saenz, M.J. The impact of risk management on the frequency of supply chain disruptions: A configurational approach. Int. J. Oper. Prod. Manag. 2017, 37, 557–576. [Google Scholar] [CrossRef]

- Papadopoulos, T.; Gunasekaran, A.; Dubey, R.; Altay, N.; Childe, S.J.; Fosso-Wamba, S. The role of Big Data in explaining disaster resilience in supply chains for sustainability. J. Clean. Prod. 2017, 142, 1108–1118. [Google Scholar] [CrossRef]

- Lohmer, J.; Bugert, N.; Lasch, R. Analysis of resilience strategies and ripple effect in blockchain-coordinated supply chains: An agent-based simulation study. Int. J. Prod. Econ. 2020, 228, 107882. [Google Scholar] [CrossRef]

- Sawyerr, E.; Harrison, C. Developing resilient supply chains: Lessons from high-reliability organisations. Supply Chain. Manag. Int. J. 2019, 25, 77–100. [Google Scholar] [CrossRef] [Green Version]

- Katsaliaki, K.; Galetsi, P.; Kumar, S. Supply chain disruptions and resilience: A major review and future research agenda. Ann. Oper. Res. 2021, 1–38. [Google Scholar] [CrossRef] [PubMed]

- Petit-Boix, A.; Leipold, S. Circular economy in cities: Reviewing how environmental research aligns with local practices. J. Clean. Prod. 2018, 195, 1270–1281. [Google Scholar] [CrossRef]

- Ullah, F.; Thaheem, M.J. Concession period of public private partnership projects: Industry–academia gap analysis. Int. J. Constr. Manag. 2018, 18, 418–429. [Google Scholar] [CrossRef]

- Ullah, F.; Siddiqui, S. An investigation of real estate technology utilization in technologically advanced marketplace. In Proceedings of the 9th International Civil Engineering Congress (ICEC-2017),“Striving Towards Resilient Built Environment”, Karachi, Pakistan, 22–23 December 2017. [Google Scholar]

- Pettit, T.J.; Croxton, K.L.; Fiksel, J. The evolution of resilience in supply chain management: A retrospective on ensuring supply chain resilience. J. Bus. Logist. 2019, 40, 56–65. [Google Scholar] [CrossRef]

- Chowdhury, M.M.H.; Quaddus, M.; Agarwal, R. Supply chain resilience for performance: Role of relational practices and network complexities. Supply Chain. Manag. Int. J. 2019, 24, 5. [Google Scholar] [CrossRef]

- Nguyen, N.C.; Bosch, O.J. A systems thinking approach to identify leverage points for sustainability: A case study in the Cat Ba Biosphere Reserve, Vietnam. Syst. Res. Behav. Sci. 2013, 30, 104–115. [Google Scholar] [CrossRef]

- Sapiri, H.; Zulkepli, J.; Ahmad, N.; Abidin, N.Z.; Hawari, N.N. Introduction to System Dynamic Modelling and Vensim Software: UUM Press; UUM Press: Sintok Kedah, Malaysia, 2017. [Google Scholar]

- Ullah, F.; Sepasgozar, S.M. A study of information technology adoption for real-estate management: A system dynamic model. In Innovative Production And Construction: Transforming Construction Through Emerging Technologies; World Scientific: Perth, Australia, 2019; pp. 469–486. [Google Scholar]

- Cavone, G.; Dotoli, M.; Epicoco, N.; Morelli, D.; Seatzu, C. Design of modern supply chain networks using fuzzy bargaining game and data envelopment analysis. IEEE Trans. Autom. Sci. Eng. 2020, 17, 1221–1236. [Google Scholar] [CrossRef]

- Cavone, G.; Dotoli, M.; Epicoco, N.; Morelli, D.; Seatzu, C. A game-theoretical design technique for multi-stage supply chains under uncertainty. In Proceedings of the 2018 IEEE 14th International Conference on Automation Science and Engineering (CASE), Munich, Germany, 20–24 August 2018; pp. 528–533. [Google Scholar]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Stindt, D. A generic planning approach for sustainable supply chain management-How to integrate concepts and methods to address the issues of sustainability? J. Clean. Prod. 2017, 153, 146–163. [Google Scholar] [CrossRef]

- Parsa, S.; Roper, I.; Muller-Camen, M.; Szigetvari, E. Have labour practices and human rights disclosures enhanced corporate accountability? The case of the GRI framework. Account. Forum 2018, 42, 47–64. [Google Scholar] [CrossRef]

- Sabri, Y.; Micheli, G.J.; Cagno, E. Supplier selection and supply chain configuration in the projects environment. Prod. Plan. Control. 2020, 33, 1–19. [Google Scholar] [CrossRef]

- Rajeev, A.; Pati, R.K.; Padhi, S.S.; Govindan, K. Evolution of sustainability in supply chain management: A literature review. J. Clean. Prod. 2017, 162, 299–314. [Google Scholar] [CrossRef]

- Daraei, A.; H Sherwani, A.F.; Faraj, R.H.; Kalhor, Q.; Zare, S.; Mahmoodzadeh, A. Optimization of the outlet portal of Heybat Sultan twin tunnels based on the value engineering methodology. SN Appl. Sci. 2019, 1, 270. [Google Scholar] [CrossRef]

- Rachwan, R.; Abotaleb, I.; Elgazouli, M. The influence of value engineering and sustainability considerations on the project value. Procedia Environ. Sci. 2016, 34, 431–438. [Google Scholar] [CrossRef]

- Seuring, S. Supply chain management for sustainable products–insights from research applying mixed methodologies. Bus. Strategy Environ. 2011, 20, 471–484. [Google Scholar] [CrossRef]

- Ashby, A.; Leat, M.; Hudson-Smith, M. Making connections: A review of supply chain management and sustainability literature. Supply Chain. Manag. Int. J. 2012, 17, 497–516. [Google Scholar] [CrossRef]

- Kshetri, N. 1 Blockchain’s roles in meeting key supply chain management objectives. Int. J. Inf. Manag. 2018, 39, 80–89. [Google Scholar] [CrossRef]

- Parmigiani, A.; Klassen, R.D.; Russo, M.V. Efficiency meets accountability: Performance implications of supply chain configuration, control, and capabilities. J. Oper. Manag. 2011, 29, 212–223. [Google Scholar] [CrossRef]

- Ribeiro, J.P.; Barbosa-Povoa, A. Supply Chain Resilience: Definitions and quantitative modelling approaches–A literature review. Comput. Ind. Eng. 2018, 115, 109–122. [Google Scholar] [CrossRef]

- Golan, M.S.; Jernegan, L.H.; Linkov, I. Trends and applications of resilience analytics in supply chain modeling: Systematic literature review in the context of the COVID-19 pandemic. Environ. Syst. Decis. 2020, 40, 222–243. [Google Scholar] [CrossRef] [PubMed]

- Waters, D. Supply Chain Risk Management: Vulnerability and Resilience in Logistics; Kogan Page Publishers: Philadelphia, PA, USA, 2011. [Google Scholar]

- Adobor, H.; McMullen, R.S. Supply chain resilience: A dynamic and multidimensional approach. Int. J. Logist. Manag. 2018, 29, 1451–1471. [Google Scholar] [CrossRef]

- Quinlan, A.E.; Berbés-Blázquez, M.; Haider, L.J.; Peterson, G.D. Measuring and assessing resilience: Broadening understanding through multiple disciplinary perspectives. J. Appl. Ecol. 2016, 53, 677–687. [Google Scholar] [CrossRef]

- Altay, N.; Gunasekaran, A.; Dubey, R.; Childe, S.J. Agility and resilience as antecedents of supply chain performance under moderating effects of organizational culture within the humanitarian setting: A dynamic capability view. Prod. Plan. Control. 2018, 29, 1158–1174. [Google Scholar] [CrossRef]

- Scholten, K.; Scott, P.S.; Fynes, B. Building routines for non-routine events: Supply chain resilience learning mechanisms and their antecedents. Supply Chain. Manag. Int. J. 2019, 24, 3. [Google Scholar] [CrossRef]

- Ruiz-Benítez, R.; López, C.; Real, J.C. The lean and resilient management of the supply chain and its impact on performance. Int. J. Prod. Econ. 2018, 203, 190–202. [Google Scholar] [CrossRef]

- McAllister, T.; McAllister, T. Developing Guidelines and Standards for Disaster Resilience of the Built Environment: A Research Needs Assessment; US Department of Commerce, National Institute of Standards and Technology: Gaithersburg, MD, USA, 2013.

- Ivanov, D.; Dolgui, A.; Sokolov, B. The impact of digital technology and Industry 4.0 on the ripple effect and supply chain risk analytics. Int. J. Prod. Res. 2019, 57, 829–846. [Google Scholar] [CrossRef]

- Kamalahmadi, M.; Parast, M.M. A review of the literature on the principles of enterprise and supply chain resilience: Major findings and directions for future research. Int. J. Prod. Econ. 2016, 171, 116–133. [Google Scholar] [CrossRef]

- Ullah, F.; Sepasgozar, S.M.; Shirowzhan, S.; Davis, S. Modelling users’ perception of the online real estate platforms in a digitally disruptive environment: An integrated KANO-SISQual approach. Telemat. Inform. 2021, 63, 101660. [Google Scholar] [CrossRef]

- Ullah, F.; Sepasgozar, S.M.; Thaheem, M.J.; Wang, C.C.; Imran, M. It’s all about perceptions: A DEMATEL approach to exploring user perceptions of real estate online platforms. Ain Shams Eng. J. 2021, 12, 4297–4317. [Google Scholar] [CrossRef]

- Karutz, R.; Riedner, L.; Vega, L.R.; Stumpf, L.; Damert, M. Compromise or complement? Exploring the interactions between sustainable and resilient supply chain management. Int. J. Supply Chain. Oper. Resil. 2018, 3, 117–142. [Google Scholar] [CrossRef]

- Mohamadi Zanjiran, D.; Hashemkhani Zolfani, S.; Prentkovskis, O. LARG supplier selection based on integrating house of quality, Taguchi loss function and MOPA. Econ. Res. Ekon. Istraživanja 2019, 32, 1944–1964. [Google Scholar] [CrossRef]

- Fritz, M.M.; Sustainable Supply Chain Management. Responsible Consumption and Production. Encyclopedia of the UN Sustainable Development Goals; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Kun, A. Social Dialogue and Corporate Social Responsibility (CSR) in the EU. In EU Collective Labour Law; Edward Elgar Publishing: Cheltenham, UK, 2021. [Google Scholar]

- Jabbarzadeh, A.; Fahimnia, B.; Sabouhi, F. Resilient and sustainable supply chain design: Sustainability analysis under disruption risks. Int. J. Prod. Res. 2018, 56, 5945–5968. [Google Scholar] [CrossRef]

- Fahimnia, B.; Jabbarzadeh, A. Marrying supply chain sustainability and resilience: A match made in heaven. Transp. Res. Part E Logist. Transp. Rev. 2016, 91, 306–324. [Google Scholar] [CrossRef]

- Ivanov, D. Simulation-based ripple effect modelling in the supply chain. Int. J. Prod. Res. 2017, 55, 2083–2101. [Google Scholar] [CrossRef]

- Ivanov, D. Revealing interfaces of supply chain resilience and sustainability: A simulation study. Int. J. Prod. Res. 2018, 56, 3507–3523. [Google Scholar] [CrossRef]

- Rojon, C.; McDowall, A.; Saunders, M.N. On the experience of conducting a systematic review in industrial, work, and organizational psychology: Yes, it is worthwhile. J. Pers. Psychol. 2011, 10, 133. [Google Scholar] [CrossRef]

- Jahan, S.; Khan, K.I.A.; Thaheem, M.J.; Ullah, F.; Alqurashi, M.; Alsulami, B.T. Modeling Profitability-Influencing Risk Factors for Construction Projects: A System Dynamics Approach. Buildings 2022, 12, 701. [Google Scholar] [CrossRef]

- Ullah, F. A beginner’s guide to developing review-based conceptual frameworks in the built environment. Architecture 2021, 1, 5–24. [Google Scholar] [CrossRef]

- Rasul, N.; Malik, M.S.A.; Bakhtawar, B.; Thaheem, M.J. Risk assessment of fast-track projects: A systems-based approach. Int. J. Constr. Manag. 2019, 21, 1099–1114. [Google Scholar] [CrossRef]

- Ullah, F.; Ayub, B.; Siddiqui, S.Q.; Thaheem, M.J. A review of public-private partnership: Critical factors of concession period. J. Financ. Manag. Prop. Constr. 2016, 21, 3. [Google Scholar] [CrossRef]

- Chowdhury, M.H.; Dewan, M.N.A.; Quaddus, M.A. Resilient Sustainable Supply Chain Management-A Conceptual Framework. In Proceedings of the International Conference on e-Business, Hangzhou, China, 9–11 September 2012; pp. 165–173. [Google Scholar]

- Ivanov, D. New drivers for supply chain structural dynamics and resilience: Sustainability, industry 4.0, self-adaptation. In Structural Dynamics and Resilience in Supply Chain Risk Management; Springer: Berlin/Heidelberg, Germany, 2018; pp. 293–313. [Google Scholar]

- Rosič, H.; Bauer, G.; Jammernegg, W. A framework for economic and environmental sustainability and resilience of supply chains. In Rapid Modelling for Increasing Competitiveness; Springer: Berlin/Heidelberg, Germany, 2009; pp. 91–104. [Google Scholar]

- Badurdeen, F.; Wijekoon, K.; Shuaib, M.; Goldsby, T.J.; Iyengar, D.; Jawahir, I.S. Integrated modeling to enhance resilience in sustainable supply chains. In Proceedings of the 2010 IEEE International Conference on Automation Science and Engineering, Toronto, ON, Canada, 21–24 August 2010; pp. 130–135. [Google Scholar]

- Brady, M. Realising supply chain resilience: An exploratory study of Irish firms’ priorities in the wake of Brexit. Contin. Resil. Rev. 2020, 3, 1. [Google Scholar] [CrossRef]

- Soni, U.; Jain, V.; Kumar, S. Measuring supply chain resilience using a deterministic modeling approach. Comput. Ind. Eng. 2014, 74, 11–25. [Google Scholar] [CrossRef]

- Mari, S.I.; Lee, Y.H.; Memon, M.S. Sustainable and resilient supply chain network design under disruption risks. Sustainability 2014, 6, 6666–6686. [Google Scholar] [CrossRef]

- Ralston, P.; Blackhurst, J. Industry 4.0 and resilience in the supply chain: A driver of capability enhancement or capability loss? Int. J. Prod. Res. 2020, 58, 5006–5019. [Google Scholar] [CrossRef]

- Jain, V.; Kumar, S.; Soni, U.; Chandra, C. Supply chain resilience: Model development and empirical analysis. Int. J. Prod. Res. 2017, 55, 6779–6800. [Google Scholar] [CrossRef]

- Zavala-Alcívar, A.; Verdecho, M.-J.; Alfaro-Saíz, J.-J. A conceptual framework to manage resilience and increase sustainability in the supply chain. Sustainability 2020, 12, 6300. [Google Scholar] [CrossRef]

- Mangla, S.K.; Kumar, P.; Barua, M.K. Flexible decision approach for analysing performance of sustainable supply chains under risks/uncertainty. Glob. J. Flex. Syst. Manag. 2014, 15, 113–130. [Google Scholar] [CrossRef]

- Govindan, K.; Azevedo, S.G.; Carvalho, H.; Cruz-Machado, V. Lean, green and resilient practices influence on supply chain performance: Interpretive structural modeling approach. Int. J. Environ. Sci. Technol. 2015, 12, 15–34. [Google Scholar] [CrossRef]

- Rha, J.S. Trends of Research on Supply Chain Resilience: A Systematic Review Using Network Analysis. Sustainability 2020, 12, 4343. [Google Scholar] [CrossRef]

- Cabral, I.; Espadinha-Cruz, P.; Grilo, A.; Puga-Leal, R.; Cruz-Machado, V. Decision-Making Models for Interoperable Lean, Agile, Resilient and Green Supply Chains. In Proceedings of the International Symposium on the Analytic Hierarchy Process, Sorrento, Italy, 15–18 June 2011; pp. 1–6. [Google Scholar]

- Ivanov, D.; Sokolov, B.; Dolgui, A. The Ripple effect in supply chains: Trade-off ‘efficiency-flexibility-resilience’in disruption management. Int. J. Prod. Res. 2014, 52, 2154–2172. [Google Scholar] [CrossRef]

- Christopher, M.; Rutherford, C. Creating supply chain resilience through agile six sigma. Crit. Eye 2004, 7, 24–28. [Google Scholar]

- Rajesh, R. On sustainability, resilience, and the sustainable–resilient supply networks. Sustain. Prod. Consum. 2018, 15, 74–88. [Google Scholar] [CrossRef]

- Parast, M.M.; Sabahi, S.; Kamalahmadi, M. The relationship between firm resilience to supply chain disruptions and firm innovation. In Revisiting Supply Chain Risk; Springer: Berlin/Heidelberg, Germany, 2019; pp. 279–298. [Google Scholar]

- Arnold, R.D.; Wade, J.P. A definition of systems thinking: A systems approach. Procedia Comput. Sci. 2015, 44, 669–678. [Google Scholar] [CrossRef]

- Mohammadi, A.; Abbasi, A.; Alimohammadlou, M.; Eghtesadifard, M.; Khalifeh, M. Optimal design of a multi-echelon supply chain in a system thinking framework: An integrated financial-operational approach. Comput. Ind. Eng. 2017, 114, 297–315. [Google Scholar] [CrossRef]

- Dhirasasna, N.; Sahin, O. A multi-methodology approach to creating a causal loop diagram. Systems 2019, 7, 42. [Google Scholar] [CrossRef]

- Giannakidou, A. Negative and positive polarity items: Variation, licensing, and compositionality. Semant. Int. Handb. Nat. Lang. Mean. 2011, 2, 1660–1712. [Google Scholar]

- Felli, F.; Liu, C.; Ullah, F.; Sepasgozar, S. Implementation of 360 videos and mobile laser measurement technologies for immersive visualisation of real estate & properties. In Proceedings of the 42nd AUBEA Conference, Singapore, 26–28 September 2018. [Google Scholar]

- Samans, R.; Blanke, J.; Drzeniek, M.; Corrigan, G. The inclusive development index 2018 summary and data highlights. In Proceedings of the World Economic Forum, Geneva, Switzerland, 21 June 2018. [Google Scholar]

- Heiberger, R.; Robbins, N. Design of diverging stacked bar charts for Likert scales and other applications. J. Stat. Softw. 2014, 57, 1–32. [Google Scholar] [CrossRef]

- Hsueh, C.-F. Improving corporate social responsibility in a supply chain through a new revenue sharing contract. Int. J. Prod. Econ. 2014, 151, 214–222. [Google Scholar] [CrossRef]

- Bhushan, U.; Aserkar, R.; Kumar, K.N.; Seetharaman, A. Effectiveness of Just In Time Manufacturing Practices. Int. J. Bus. Manag. Econ. Res. (IJBMER) 2017, 8, 1109–1114. [Google Scholar]

- Lam, J.S.L.; Bai, X. A quality function deployment approach to improve maritime supply chain resilience. Transp. Res. Part E Logist. Transp. Rev. 2016, 92, 16–27. [Google Scholar] [CrossRef]

| Sr.# | Enablers | References | Category | NLS | Sr.# | Enablers | References | Category | NLS |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Top Management Support | [62,63,64,65,66] | S | 0.035 | 17 | Information Security | [43,62,63,65,67,68] | S | 0.025 |

| 2 | Adaptability | [11,18,62,67,69,70] | R, S | 0.042 | 18 | Strategic Risk Planning | [18,43,62,64,67,68,71,72] | S | 0.034 |

| 3 | Visibility | [11,18,43,62,66,67,69,70,71,72,73,74,75] | R, S | 0.106 | 19 | Corporate Social Responsibility | [43,67,72] | S | 0.035 |

| 4 | Health | [18,62] | S | 0.014 | 20 | Contingency Planning | [43,62,65,66,71,76] | S, R | 0.030 |

| 5 | Compatibility | [49,62,63,64,65,66,69] | S | 0.056 | 21 | Safety Stock | [62,69,73,76] | S, R | 0.035 |

| 6 | Quality Awareness | [77] | R | 0.007 | 22 | Flexible Transportation | [43,49,62,68,69,71,73] | S, R | 0.030 |

| 7 | Responsiveness | [76,77] | R | 0.014 | 23 | Resource Efficiency | [49,63,68,72] | S | 0.013 |

| 8 | Technological Capability | [70,77] | R | 0.021 | 24 | Transparency | [49,65,68,72] | S | 0.014 |

| 9 | Agility | [63,66,67,69,70,71,72,77,78] | S, R | 0.092 | 25 | Self-Regulation | [75,78] | S | 0.013 |

| 10 | Supply Chain Security | [64,69] | S | 0.021 | 26 | Market Sensitivity | [66,68,70,71] | R, S | 0.021 |

| 11 | Collaboration | [18,43,49,62,65,66,67,69,70,71,79] | R, S | 0.092 | 27 | Tenacity | [73] | R | 0.007 |

| 12 | Swift Trust | [11,64,66,67,70,71] | R, S | 0.030 | 28 | Leadership | [66,71,79] | S | 0.021 |

| 13 | Risk and Revenue Sharing | [67,70] | R, S | 0.014 | 29 | Just in Time | [73,76,77] | R, S | 0.035 |

| 14 | Information Sharing | [11,43,64,65,67,70,71,73,79] | R, S | 0.085 | 30 | Proper Scheduling | [64] | S | 0.001 |

| 15 | Flexible Structure | [62,63,67,69,70,71,73,76] | R, S | 0.034 | 31 | Composure | [71] | S | 0.007 |

| 16 | Risk Management Culture | [67,70] | R, S | 0.014 | 32 | Reasoning | [62,78] | S | 0.003 |

| Profile | Frequency | Percentage |

|---|---|---|

| Total responses = 106 | ||

| Job title | ||

| CEO | 4 | 4% |

| Construction Manager | 5 | 5% |

| Assistant Manager | 14 | 13% |

| Site Manager | 11 | 10% |

| Architect/Designer | 7 | 7% |

| Planning Engineer | 14 | 13% |

| Project Manager | 16 | 15% |

| Project Director | 10 | 9% |

| Academician | 12 | 12% |

| Others | 13 | 12% |

| Years of Professional Experience | ||

| 0–1 | 13 | 12% |

| 2–5 | 31 | 29% |

| 6–10 | 19 | 18% |

| 11–15 | 11 | 10% |

| 16–20 | 7 | 7% |

| >20 | 25 | 24% |

| Education | ||

| Diploma Holder | 6 | 6% |

| Graduation | 55 | 52% |

| Post-Graduation | 39 | 36% |

| PhD | 6 | 6% |

| Organization type | ||

| Government | 35 | 33% |

| Semi-Government | 15 | 14% |

| Private | 56 | 53% |

| Understanding of resilience and risk management in supply chains | ||

| No understanding at all | 8 | 8% |

| Slight | 10 | 9% |

| Moderate | 58 | 55% |

| High | 30 | 28% |

| Sr.No | Enablers | Normalized Literature Score (40%) | Normalized Field Score (60%) | Collective Score | Rank |

|---|---|---|---|---|---|

| 1 | Top Management Support | 0.014 | 0.023 | 0.038 | 6 |

| 2 | Adaptability | 0.017 | 0.019 | 0.036 | 8 |

| 3 | Visibility | 0.042 | 0.019 | 0.061 | 1 |

| 4 | Health | 0.006 | 0.023 | 0.029 | 15 |

| 5 | Compatibility | 0.023 | 0.019 | 0.041 | 5 |

| 6 | Quality Awareness | 0.003 | 0.023 | 0.026 | 21 |

| 7 | Responsiveness | 0.006 | 0.023 | 0.029 | 17 |

| 8 | Technological Capability | 0.008 | 0.019 | 0.027 | 20 |

| 9 | Agility | 0.037 | 0.023 | 0.060 | 2 |

| 10 | Supply Chain Security | 0.008 | 0.019 | 0.027 | 19 |

| 11 | Collaboration | 0.037 | 0.019 | 0.055 | 3 |

| 12 | Swift Trust | 0.012 | 0.019 | 0.031 | 13 |

| 13 | Risk and Revenue Sharing | 0.006 | 0.019 | 0.024 | 22 |

| 14 | Information Sharing | 0.034 | 0.019 | 0.053 | 4 |

| 15 | Flexible Structure | 0.014 | 0.019 | 0.032 | 11 |

| 16 | Risk Management Culture | 0.006 | 0.019 | 0.024 | 23 |

| 17 | Information Security | 0.010 | 0.014 | 0.024 | 24 |

| 18 | Strategic Risk Planning | 0.014 | 0.019 | 0.032 | 10 |

| 19 | Corporate Social Responsibility | 0.014 | 0.019 | 0.033 | 9 |

| 20 | Contingency Planning | 0.012 | 0.019 | 0.031 | 15 |

| 21 | Safety Stock | 0.014 | 0.014 | 0.028 | 18 |

| 22 | Flexible Transportation | 0.012 | 0.019 | 0.031 | 14 |

| 23 | Resource Efficiency | 0.005 | 0.019 | 0.024 | 25 |

| 24 | Transparency | 0.006 | 0.019 | 0.024 | 26 |

| 25 | Self-Regulation | 0.005 | 0.019 | 0.024 | 27 |

| 26 | Market Sensitivity | 0.008 | 0.014 | 0.023 | 28 |

| 27 | Tenacity | 0.003 | 0.019 | 0.022 | 29 |

| 28 | Leadership | 0.008 | 0.023 | 0.032 | 12 |

| 29 | Just in Time | 0.014 | 0.023 | 0.038 | 7 |

| 30 | Proper Scheduling | 0.001 | 0.019 | 0.019 | 30 |

| 31 | Composure | 0.003 | 0.009 | 0.012 | 31 |

| 32 | Reasoning | 0.001 | 0.009 | 0.011 | 32 |

| Loop | Speed of Influence | Strength of Influence | Nature of Influence |

|---|---|---|---|

| R1 | Slow | Strong | Reinforcing |

| R2 | Slow | Strong | Reinforcing |

| R3 | Slow | Strong | Reinforcing |

| R4 | Slow | Strong | Reinforcing |

| B1 | Fast | Strong | Balancing |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghufran, M.; Khan, K.I.A.; Ullah, F.; Alaloul, W.S.; Musarat, M.A. Key Enablers of Resilient and Sustainable Construction Supply Chains: A Systems Thinking Approach. Sustainability 2022, 14, 11815. https://doi.org/10.3390/su141911815

Ghufran M, Khan KIA, Ullah F, Alaloul WS, Musarat MA. Key Enablers of Resilient and Sustainable Construction Supply Chains: A Systems Thinking Approach. Sustainability. 2022; 14(19):11815. https://doi.org/10.3390/su141911815

Chicago/Turabian StyleGhufran, Maria, Khurram Iqbal Ahmad Khan, Fahim Ullah, Wesam Salah Alaloul, and Muhammad Ali Musarat. 2022. "Key Enablers of Resilient and Sustainable Construction Supply Chains: A Systems Thinking Approach" Sustainability 14, no. 19: 11815. https://doi.org/10.3390/su141911815

APA StyleGhufran, M., Khan, K. I. A., Ullah, F., Alaloul, W. S., & Musarat, M. A. (2022). Key Enablers of Resilient and Sustainable Construction Supply Chains: A Systems Thinking Approach. Sustainability, 14(19), 11815. https://doi.org/10.3390/su141911815