Application of Smart Glasses for Field Workers Performing Soil Contamination Surveys with Portable Equipment

Abstract

:1. Introduction

2. Methods

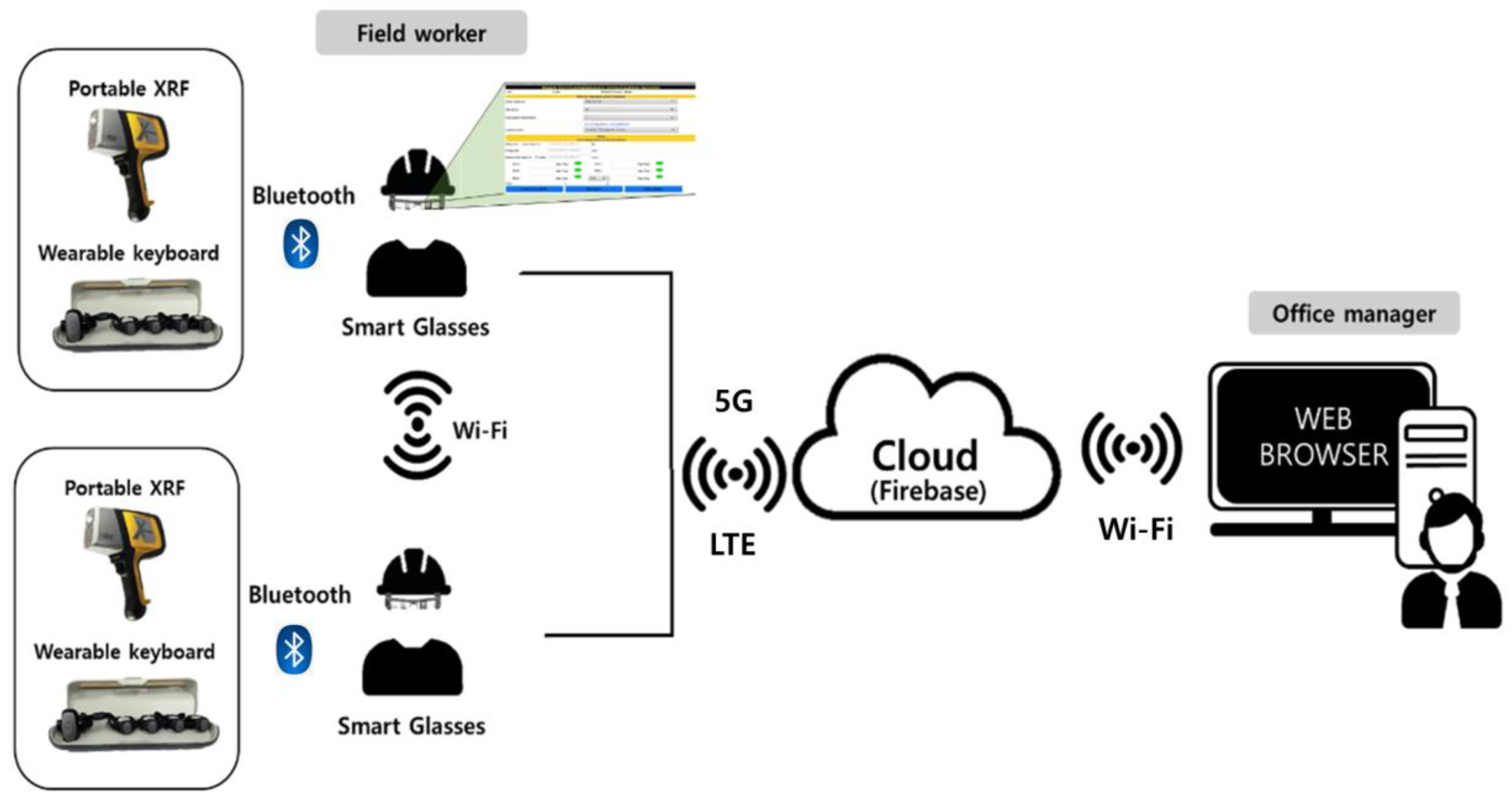

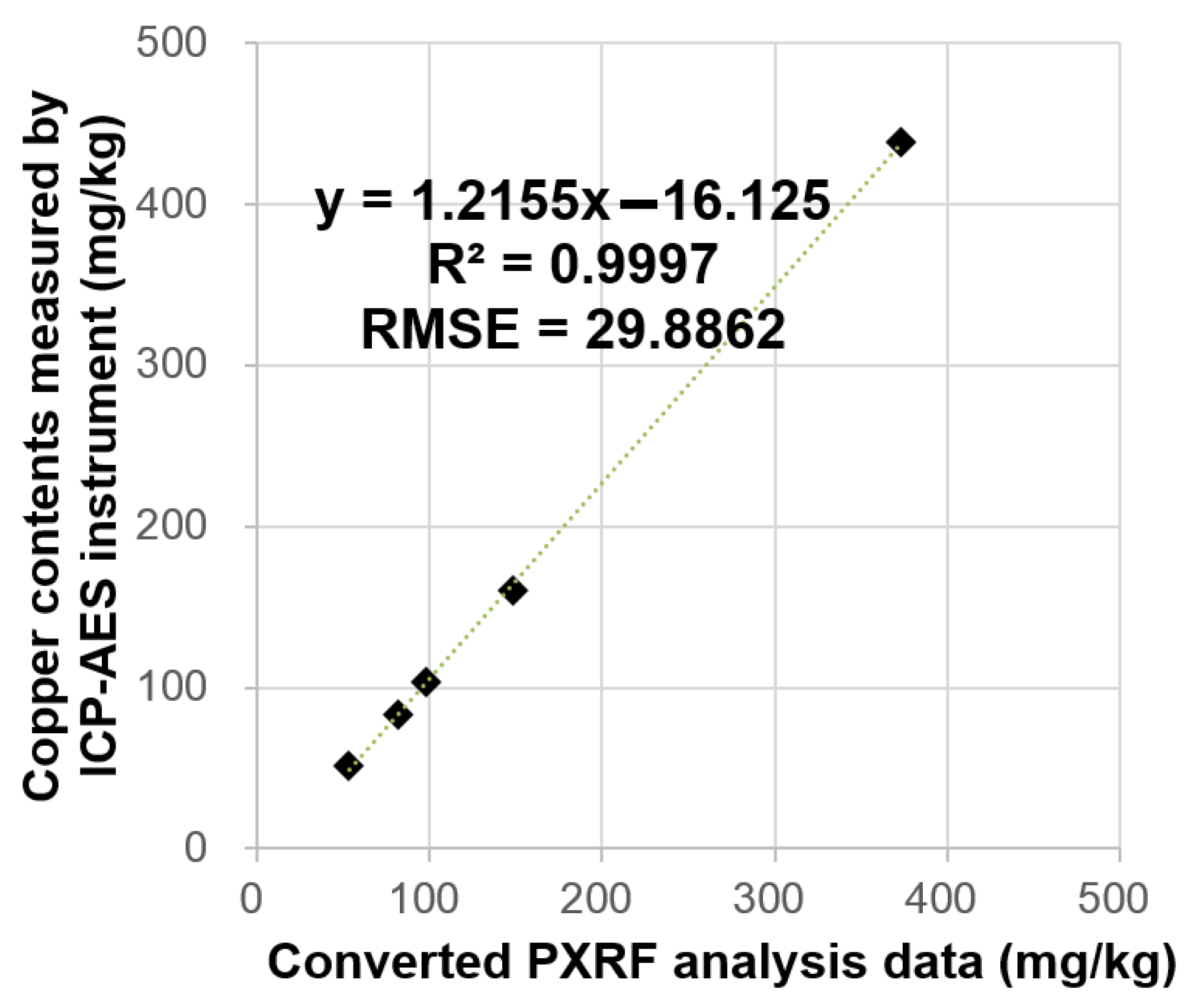

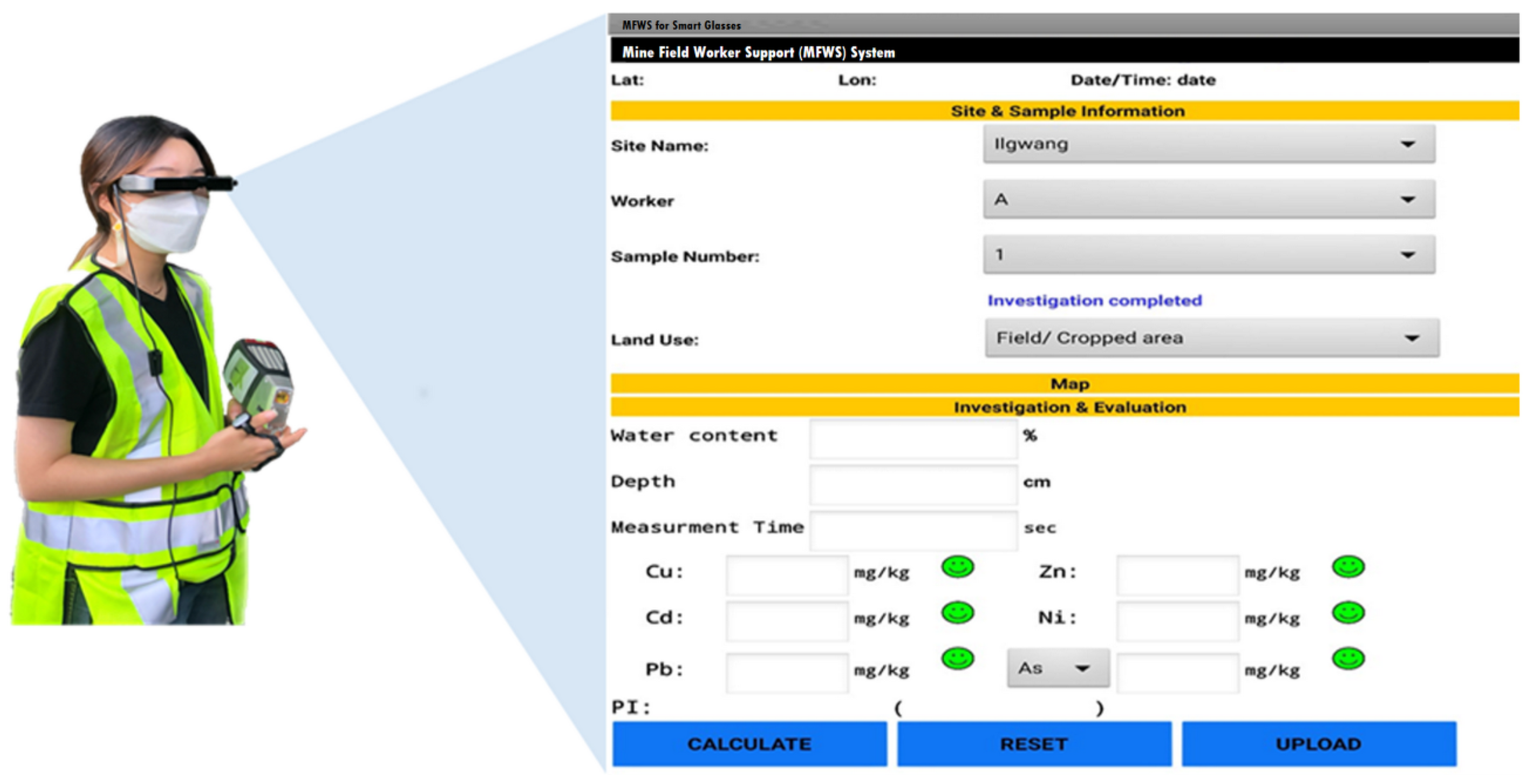

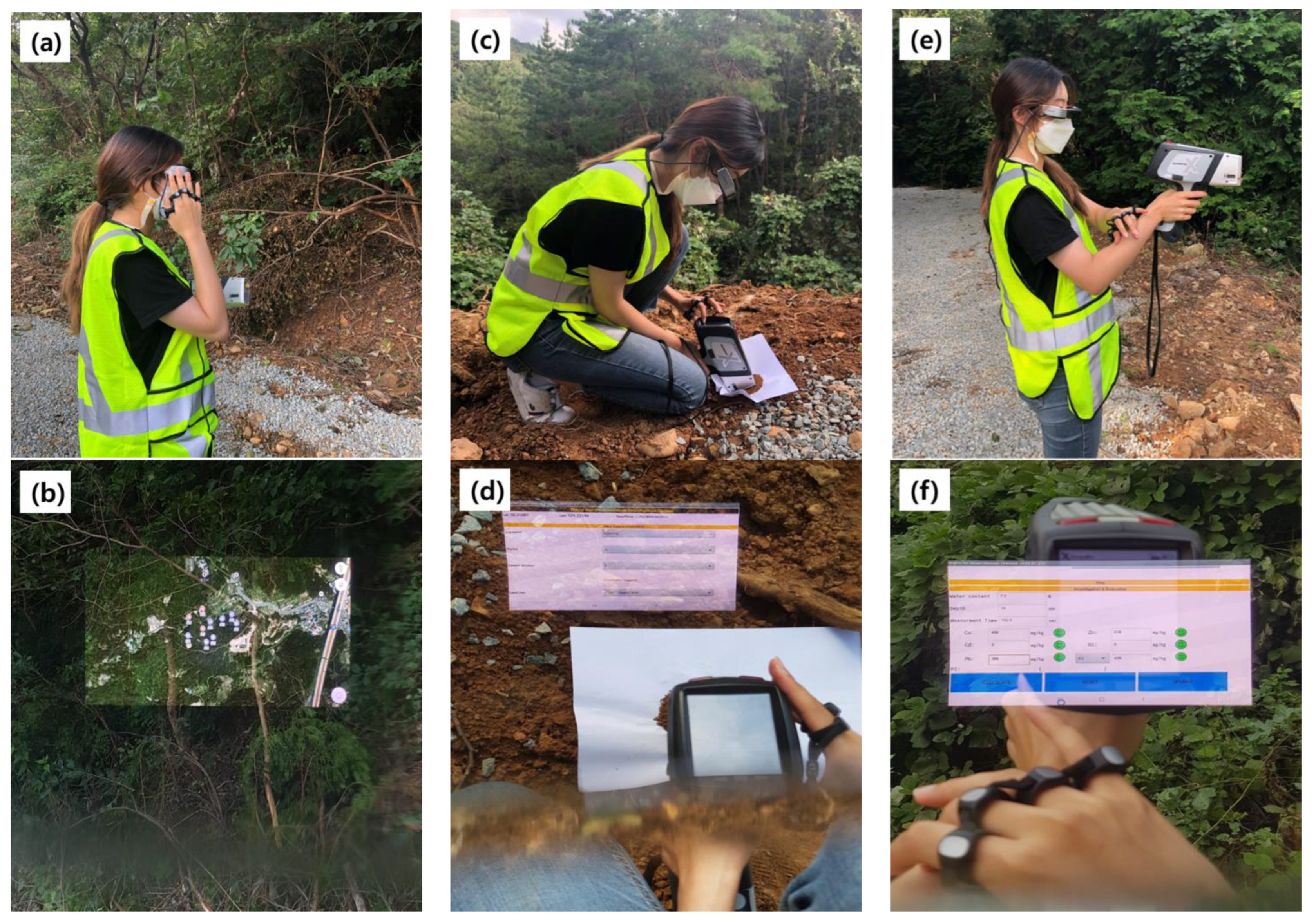

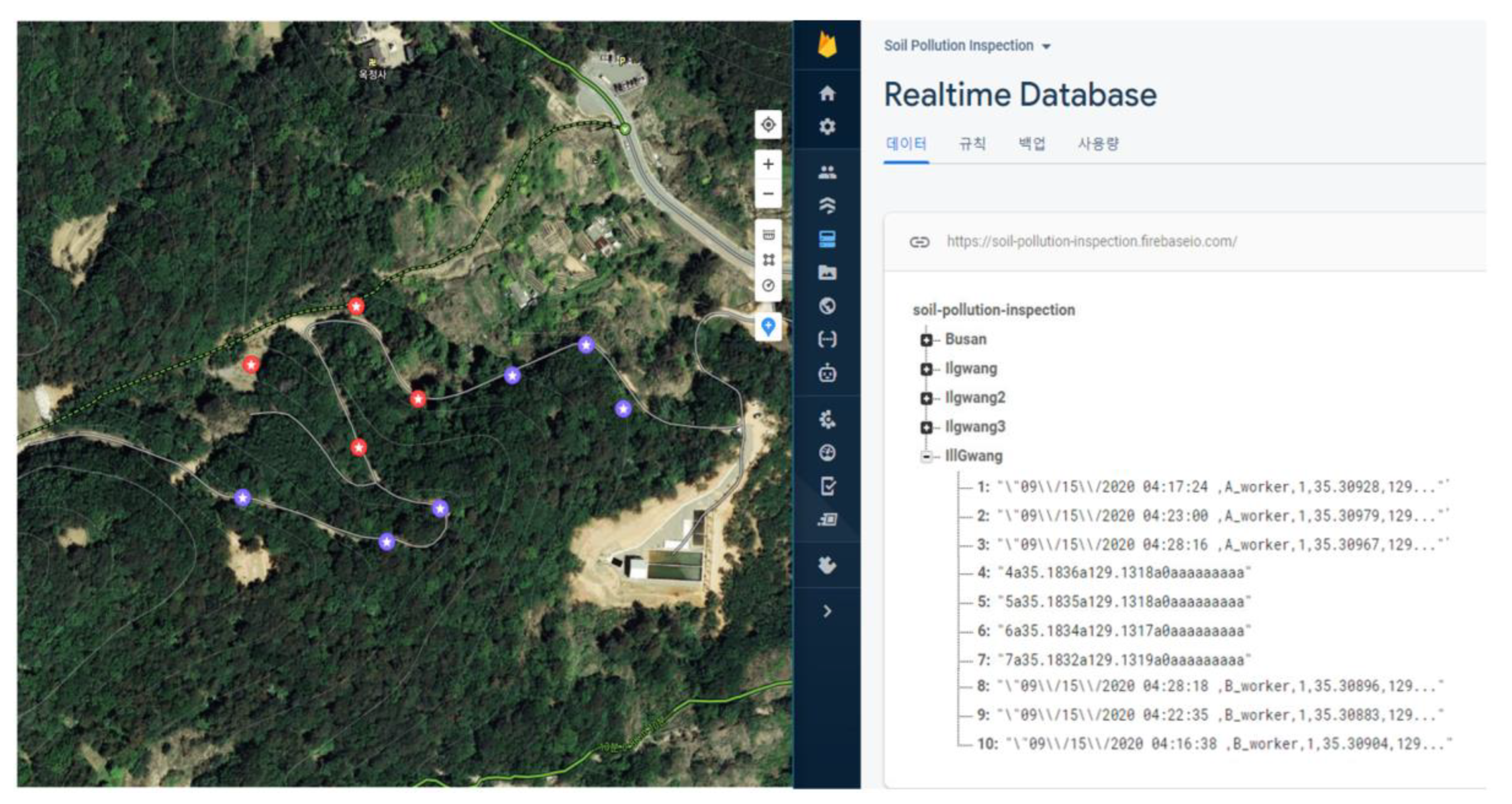

2.1. Development of Smart Glasses-Based Mine Field Worker Support (MFWS) System

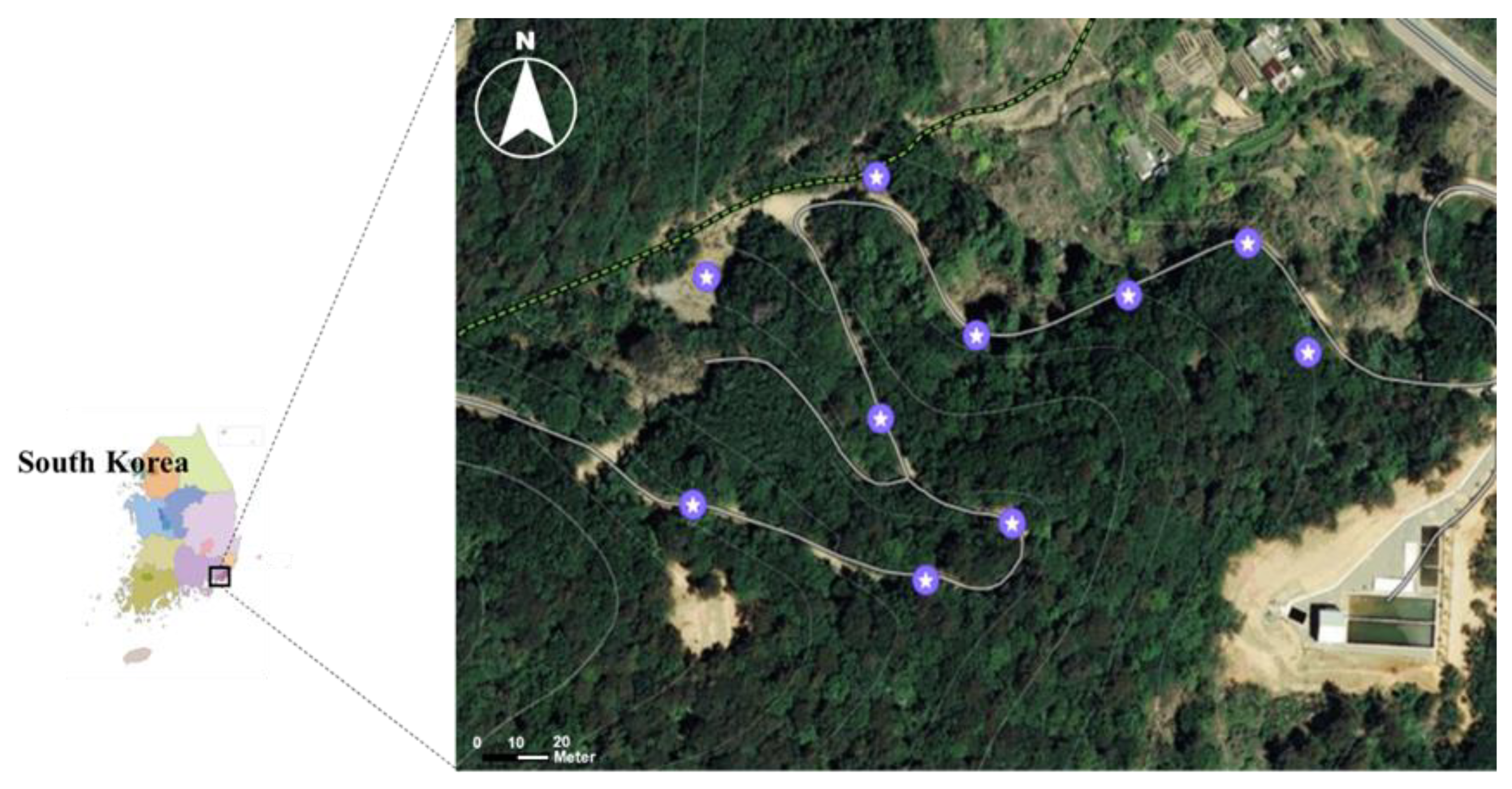

2.2. Field Experiment Method

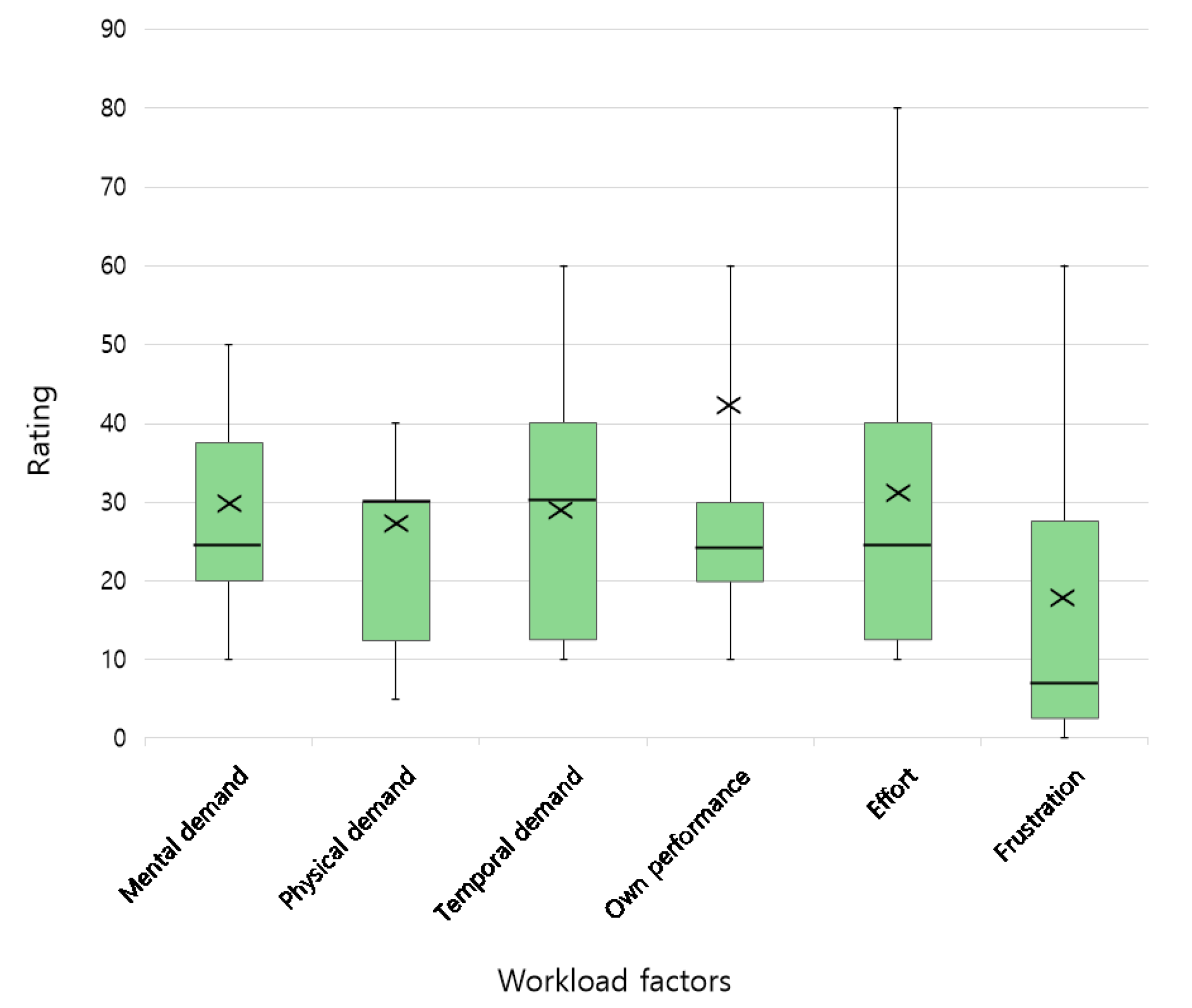

2.3. Subjective Workload Assessment Method

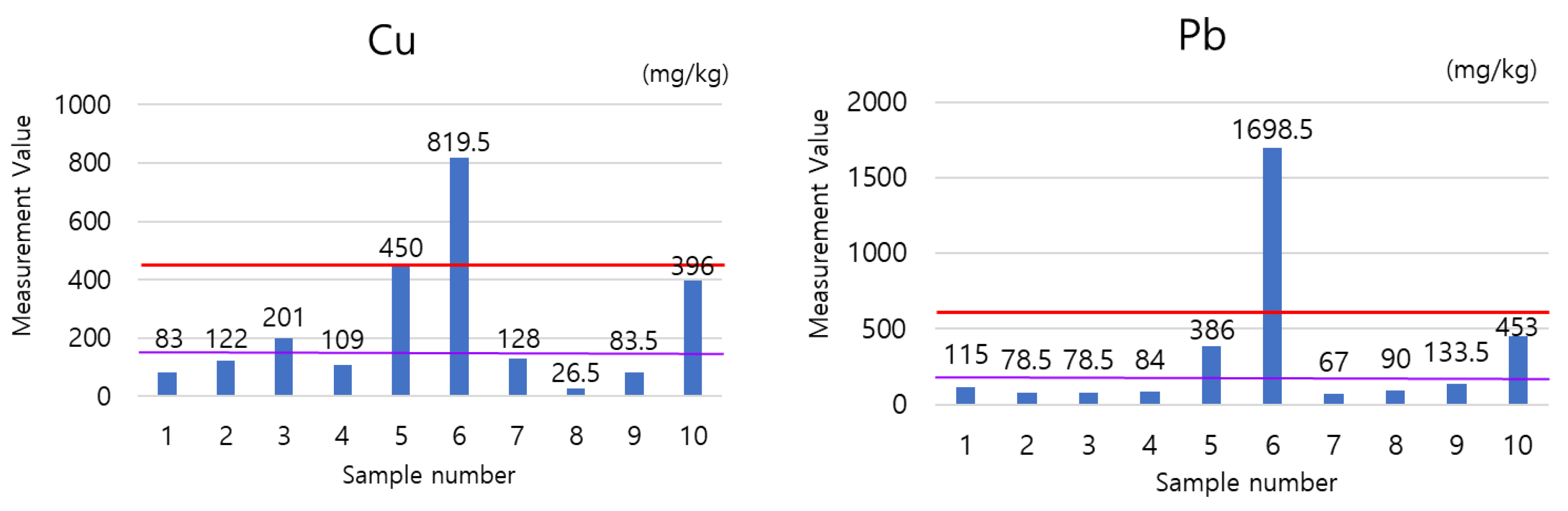

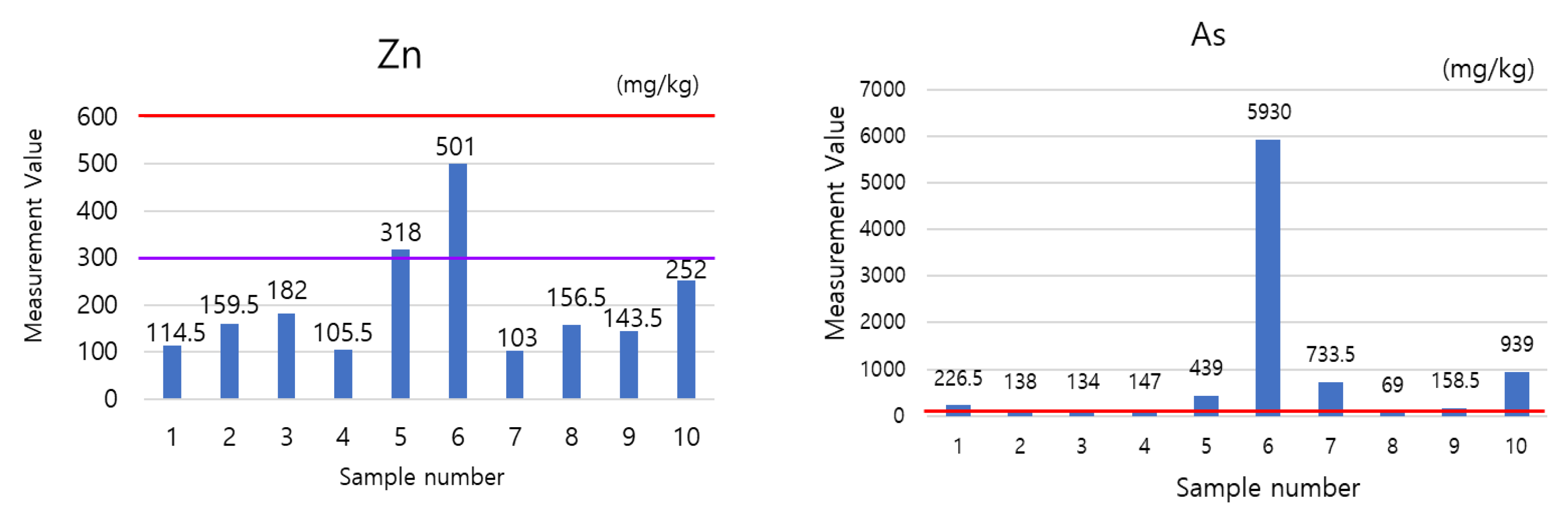

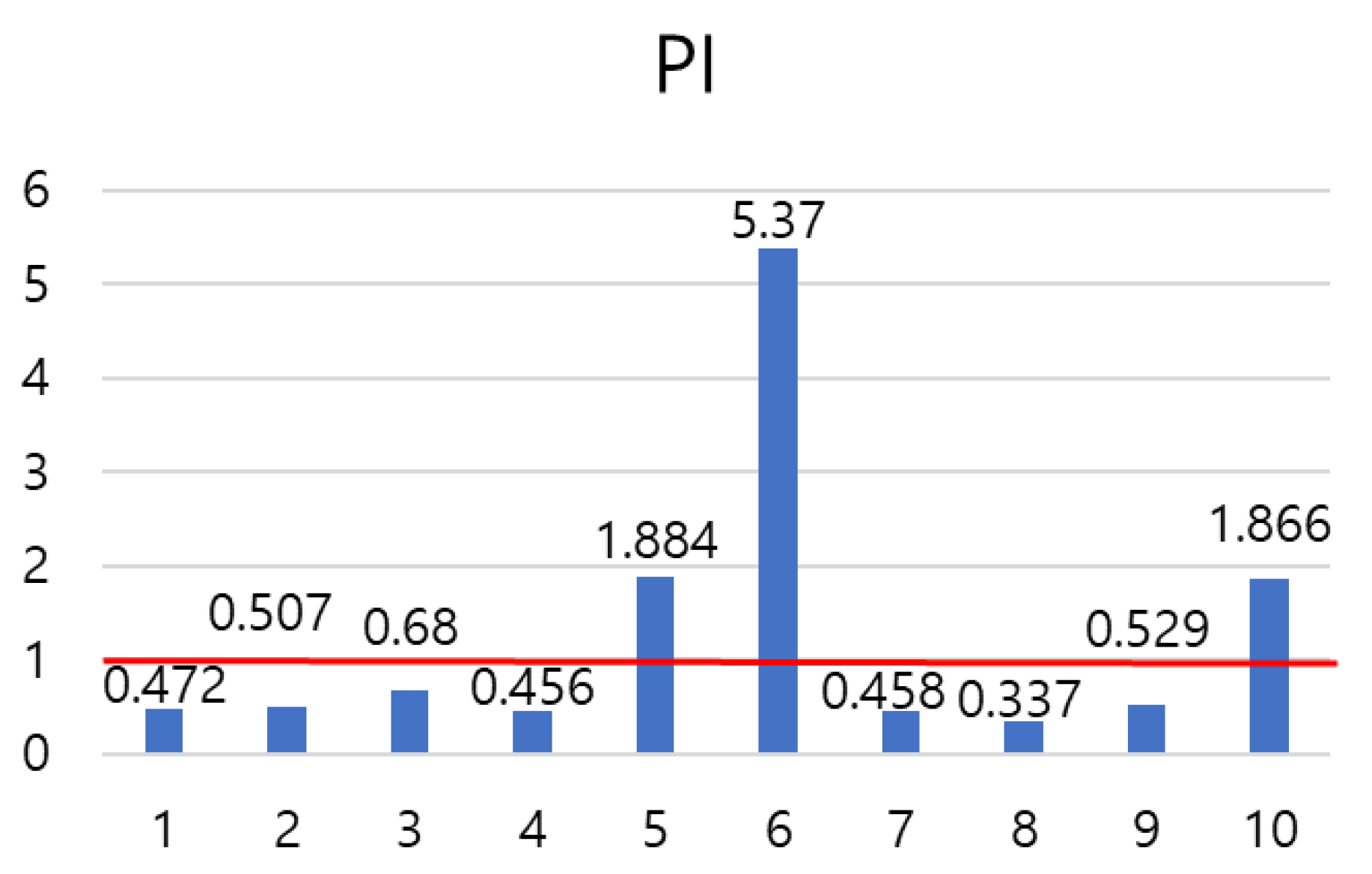

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Osher, L.J.; Leclerc, L.; Wiersma, G.B.; Hess, C.T.; Guiseppe, V.E. Heavy Metal Contamination from Historic Mining in Upland Soil and Estuarine Sediments of Egypt Bay, Maine, USA. Estuar. Coast. Shelf Sci. 2006, 70, 169–179. [Google Scholar] [CrossRef]

- Thornton, I. Sources and Pathways of Arsenic in South-West England: Health Implications. In Arsenic Exposure and Health; Chapell, W.R., Abernathy, C.O., Cothern, C.R., Eds.; Science and Technology Letters: London, UK, 1994; pp. 61–70. [Google Scholar]

- Bolan, N.S.; Adriano, D.C.; Curtin, D. Soil Acidification and Liming Interactions with Nutrientand Heavy Metal Transformationand Bioavailability. In Advances in Agronomy; Elsevier: Amsterdam, The Netherlands, 2003; Volume 78, pp. 215–272. [Google Scholar] [CrossRef]

- Li, Z.; Ma, Z.; van der Kuijp, T.J.; Yuan, Z.; Huang, L. A Review of Soil Heavy Metal Pollution from Mines in China: Pollution and Health Risk Assessment. Sci. Total Environ. 2014, 468–469, 843–853. [Google Scholar] [CrossRef] [PubMed]

- Navarro, M.C.; Pérez-Sirvent, C.; Martínez-Sánchez, M.J.; Vidal, J.; Tovar, P.J.; Bech, J. Abandoned Mine Sites as a Source of Contamination by Heavy Metals: A Case Study in a Semi-Arid Zone. J. Geochem. Explor. 2008, 96, 183–193. [Google Scholar] [CrossRef]

- Bacchetta, G.; Boi, M.E.; Cappai, G.; De Giudici, G.; Piredda, M.; Porceddu, M. Metal Tolerance Capability of Helichrysum Microphyllum Cambess. Subsp. Tyrrhenicum Bacch., Brullo & Giusso: A Candidate for Phytostabilization in Abandoned Mine Sites. Bull. Environ. Contam. Toxicol. 2018, 101, 758–765. [Google Scholar]

- Luo, C.; Routh, J.; Dario, M.; Sarkar, S.; Wei, L.; Luo, D.; Liu, Y. Distribution and Mobilization of Heavy Metals at an Acid Mine Drainage Affected Region in South China, a Post-Remediation Study. Sci. Total Environ. 2020, 724, 138122. [Google Scholar] [CrossRef]

- Dutta, M.; Islam, N.; Rabha, S.; Narzary, B.; Bordoloi, M.; Saikia, D.; Silva, L.F.O.; Saikia, B.K. Acid Mine Drainage in an Indian High-Sulfur Coal Mining Area: Cytotoxicity Assay and Remediation Study. J. Hazard. Mater. 2020, 389, 121851. [Google Scholar] [CrossRef]

- Estimation of Soil Erosion and Sediment Yield from Mine Tailing Dumps Using GIS: A Case Study at the Samgwang Mine, Korea. Available online: https://www.tandfonline.com/doi/full/10.1080/12269328.2012.674426 (accessed on 8 December 2020).

- Lee, H.-G.; Choi, Y.-S. A Study on the Soil Contamination (Maps) Using the Handheld XRF and GIS in Abandoned Mining Areas. J. Korean Assoc. Geogr. Inf. Stud. 2014, 17, 195–206. [Google Scholar] [CrossRef]

- Radu, T.; Diamond, D. Comparison of Soil Pollution Concentrations Determined Using AAS and Portable XRF Techniques. J. Hazard. Mater. 2009, 171, 1168–1171. [Google Scholar] [CrossRef]

- MOE. The Korean Standard Test (KST) Methods for Soils; Gwachun, Korea, 2009. Available online: http://me.go.kr/home/web/board/read.do;jsessionid=gwC0Cs0SjX8ND1XaKdjfp2OC.mehome1?pagerOffset=150&maxPageItems=10&maxIndexPages=10&searchKey=&searchValue=&menuId=&orgCd=&boardId=70036&boardMasterId=515&boardCategoryId=&decorator= (accessed on 8 September 2022). (In Korean).

- Tolner, M.; Vaszita, E.; Gruiz, K. On-Site Screening and Monitoring of Pollution by a Field-Portable X-ray Fluorescence Measuring Device. In Proceedings of the Consoil 2010 Conference, Salzburg, Austria, 22–24 September 2010; pp. 22–24. [Google Scholar]

- Rouillon, M.; Taylor, M.P. Can Field Portable X-ray Fluorescence (PXRF) Produce High Quality Data for Application in Environmental Contamination Research? Environ. Pollut. 2016, 214, 255–264. [Google Scholar] [CrossRef] [PubMed]

- Carr, R.; Zhang, C.; Moles, N.; Harder, M. Identification and Mapping of Heavy Metal Pollution in Soils of a Sports Ground in Galway City, Ireland, Using a Portable XRF Analyser and GIS. Environ. Geochem. Health 2008, 30, 45–52. [Google Scholar] [CrossRef]

- Kalnicky, D.J.; Singhvi, R. Field Portable XRF Analysis of Environmental Samples. J. Hazard. Mater. 2001, 83, 93–122. [Google Scholar] [CrossRef]

- Baykara, O.; Dogˇru, M. Measurements of Radon and Uranium Concentration in Water and Soil Samples from East Anatolian Active Fault Systems (Turkey). Radiat. Meas. 2006, 41, 362–367. [Google Scholar] [CrossRef]

- Clark, S.; Menrath, W.; Chen, M.; Roda, S.; Succop, P. Use of a Field Portable X-ray Fluorescence Analyzer to Determine the Concentration of Lead and Other Metals in Soil Samples. Ann. Agric. Environ. Med. 1999, 6, 27–32. [Google Scholar] [PubMed]

- Ene, A.; Bosneaga, A.; Georgescu, L. Determination of Heavy Metals in Soils Using XRF Technique. Rom. J. Phys. 2010, 55, 815–820. [Google Scholar]

- Parsons, C.; Grabulosa, E.M.; Pili, E.; Floor, G.H.; Roman-Ross, G.; Charlet, L. Quantification of Trace Arsenic in Soils by Field-Portable X-ray Fluorescence Spectrometry: Considerations for Sample Preparation and Measurement Conditions. J. Hazard. Mater. 2013, 262, 1213–1222. [Google Scholar] [CrossRef]

- McComb, J.Q.; Rogers, C.; Han, F.X.; Tchounwou, P.B. Rapid Screening of Heavy Metals and Trace Elements in Environmental Samples Using Portable X-ray Fluorescence Spectrometer, A Comparative Study. Water Air Soil Pollut. 2014, 225, 2169. [Google Scholar] [CrossRef]

- Weindorf, D.C.; Zhu, Y.; Chakraborty, S.; Bakr, N.; Huang, B. Use of Portable X-ray Fluorescence Spectrometry for Environmental Quality Assessment of Peri-Urban Agriculture. Environ. Monit. Assess. 2012, 184, 217–227. [Google Scholar] [CrossRef]

- Hu, W.; Huang, B.; Weindorf, D.C.; Chen, Y. Metals Analysis of Agricultural Soils via Portable X-ray Fluorescence Spectrometry. Bull. Environ. Contam. Toxicol. 2014, 92, 420–426. [Google Scholar] [CrossRef]

- McGladdery, C.; Weindorf, D.C.; Chakraborty, S.; Li, B.; Paulette, L.; Podar, D.; Pearson, D.; Kusi, N.Y.O.; Duda, B. Elemental Assessment of Vegetation via Portable X-ray Fluorescence (PXRF) Spectrometry. J. Environ. Manag. 2018, 210, 210–225. [Google Scholar] [CrossRef]

- Tighe, M.; Rogan, G.; Wilson, S.C.; Grave, P.; Kealhofer, L.; Yukongdi, P. The Potential for Portable X-ray Fluorescence Determination of Soil Copper at Ancient Metallurgy Sites, and Considerations beyond Measurements of Total Concentrations. J. Environ. Manag. 2018, 206, 373–382. [Google Scholar] [CrossRef]

- Lemiere, B. A Review of PXRF (Field Portable X-ray Fluorescence) Applications for Applied Geochemistry. J. Geochem. Explor. 2018, 188, 350–363. [Google Scholar] [CrossRef] [Green Version]

- Rawal, A.; Chakraborty, S.; Li, B.; Lewis, K.; Godoy, M.; Paulette, L.; Weindorf, D.C. Determination of Base Saturation Percentage in Agricultural Soils via Portable X-ray Fluorescence Spectrometer. Geoderma 2019, 338, 375–382. [Google Scholar] [CrossRef]

- Andrade, R.; Silva, S.H.G.; Weindorf, D.C.; Chakraborty, S.; Faria, W.M.; Mesquita, L.F.; Guilherme, L.R.G.; Curi, N. Assessing Models for Prediction of Some Soil Chemical Properties from Portable X-ray Fluorescence (PXRF) Spectrometry Data in Brazilian Coastal Plains. Geoderma 2020, 357, 113957. [Google Scholar] [CrossRef]

- Karimi, A.; Ahmadi, A.; Partabian, A. Potential Soil Pollution by Heavy Metals in Kurdistan Region, Western Iran: The Impact of Ultramafic Bedrock. Geopersia 2020, 10, 41–52. [Google Scholar]

- Suh, J.; Lee, H.; Choi, Y. A Rapid, Accurate, and Efficient Method to Map Heavy Metal-Contaminated Soils of Abandoned Mine Sites Using Converted Portable XRF Data and GIS. Int. J. Environ. Res. Public Health 2016, 13, 1191. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Choi, Y.; Suh, J.; Lee, S.-H. Mapping Copper and Lead Concentrations at Abandoned Mine Areas Using Element Analysis Data from ICP–AES and Portable XRF Instruments: A Comparative Study. Int. J. Environ. Res. Public Health 2016, 13, 384. [Google Scholar] [CrossRef]

- Kim, S.-M.; Choi, Y. Assessing Statistically Significant Heavy-Metal Concentrations in Abandoned Mine Areas via Hot Spot Analysis of Portable XRF Data. Int. J. Environ. Res. Public Health 2017, 14, 654. [Google Scholar] [CrossRef]

- Mitrasinovic, S.; Camacho, E.; Trivedi, N.; Logan, J.; Campbell, C.; Zilinyi, R.; Lieber, B.; Bruce, E.; Taylor, B.; Martineau, D. Clinical and Surgical Applications of Smart Glasses. Technol. Health Care 2015, 23, 381–401. [Google Scholar] [CrossRef]

- Syberfeldt, A.; Danielsson, O.; Gustavsson, P. Augmented Reality Smart Glasses in the Smart Factory: Product Evaluation Guidelines and Review of Available Products. IEEE Access 2017, 5, 9118–9130. [Google Scholar] [CrossRef]

- Kalantari, M.; Rauschnabel, P. Exploring the Early Adopters of Augmented Reality Smart Glasses: The Case of Microsoft HoloLens. In Augmented Reality and Virtual Reality; Springer: Berlin/Heidelberg, Germany, 2018; pp. 229–245. [Google Scholar]

- Danielsson, O.; Holm, M.; Syberfeldt, A. Augmented Reality Smart Glasses for Operators in Production: Survey of Relevant Categories for Supporting Operators. Procedia CIRP 2020, 93, 1298–1303. [Google Scholar] [CrossRef]

- Meza-de-Luna, M.E.; Terven, J.R.; Raducanu, B.; Salas, J. A Social-Aware Assistant to Support Individuals with Visual Impairments during Social Interaction: A Systematic Requirements Analysis. Int. J. Hum.-Comput. Stud. 2019, 122, 50–60. [Google Scholar] [CrossRef]

- Machado, E.; Carrillo, I.; Saldana, D.; Chen, F.; Chen, L. An Assistive Augmented Reality-Based Smartglasses Solution for Individuals with Autism Spectrum Disorder. In Proceedings of the 2019 IEEE International Conference on Dependable, Autonomic and Secure Computing, International Conference on Pervasive Intelligence and Computing, International Conference on Cloud and Big Data Computing, Intl Conf on Cyber Science and Technology Congress (DASC/PiCom/CBDCom/CyberSciTech), Fukuoka, Japan, 5–8 August 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 245–249. [Google Scholar]

- Kirks, T.; Jost, J.; Uhlott, T.; Püth, J.; Jakobs, M. Evaluation of the Application of Smart Glasses for Decentralized Control Systems in Logistics. In Proceedings of the 2019 IEEE Intelligent Transportation Systems Conference (ITSC), Auckland, New Zealand, 27–30 October 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 4470–4476. [Google Scholar]

- Caria, M.; Todde, G.; Sara, G.; Piras, M.; Pazzona, A. Performance and Usability of Smartglasses for Augmented Reality in Precision Livestock Farming Operations. Appl. Sci. 2020, 10, 2318. [Google Scholar] [CrossRef] [Green Version]

- Spitzer, M.; Nanic, I.; Ebner, M. Distance Learning and Assistance Using Smart Glasses. Educ. Sci. 2018, 8, 21. [Google Scholar] [CrossRef]

- Han, D.-I.D.; Tom Dieck, M.C.; Jung, T. Augmented Reality Smart Glasses (ARSG) Visitor Adoption in Cultural Tourism. Leis. Stud. 2019, 38, 618–633. [Google Scholar] [CrossRef]

- Moghal, A.A.B.; Lateef, M.A.; Mohammed, S.A.S.; Lemboye, K.; Chittoori, B.C.S.; Almajed, A. Efficacy of Enzymatically Induced Calcium Carbonate Precipitation in the Retention of Heavy Metal Ions. Sustainability 2020, 12, 7019. [Google Scholar] [CrossRef]

- Moghal, A.A.B.; Lateef, M.A.; Abu Sayeed Mohammed, S.; Ahmad, M.; Usman, A.R.A.; Almajed, A. Heavy Metal Immobilization Studies and Enhancement in Geotechnical Properties of Cohesive Soils by EICP Technique. Appl. Sci. 2020, 10, 7568. [Google Scholar] [CrossRef]

- Abu Sayeed Mohammed, S.; Moghal, A.A.B.; Sanaulla, P.F.; Kotresha, K.; Reddy, H.P. Cadmium Fixation Studies on Contaminated Soils Using Nano Calcium Silicate—Treatment Strategy. Geotech. Front. 2017, 276. [Google Scholar] [CrossRef]

- NASA Task Load Index (TLX) v.1.0 Paper and Pencil Package. Available online: https://humansystems.arc.nasa.gov/groups/tlx/downloads/TLX_pappen_manual.pdf (accessed on 21 January 2020).

- Young, K.E.; Evans, C.A.; Hodges, K.V.; Bleacher, J.E.; Graff, T.G. A Review of the Handheld X-ray Fluorescence Spectrometer as a Tool for Field Geologic Investigations on Earth and in Planetary Surface Exploration. Appl. Geochem. 2016, 72, 77–87. [Google Scholar] [CrossRef]

- Epson Home Page. Available online: https://tech.moverio.epson.com/en/bt-350 (accessed on 14 August 2020).

- TAP Systems. Available online: https://www.tapwithus.com/how-tap-works (accessed on 18 August 2020).

- Choi, Y.; Kim, H.; Suh, J. Development of a Smartphone Application to Investigate Unsurfaced Road Conditions in Mines. Tunn. Undergr. Space 2018, 28, 555–568. [Google Scholar]

- MIT App Inventor. Available online: https://appinventor.mit.edu/ (accessed on 23 March 2020).

- Kloke, A. Contents of Arsenic, Cadmium, Chromium, Fluorine, Lead, Mercury and Nickel in Plants Grown on Contaminated Soil. In Proceedings of the UN-ECE Symposium, Genova, Switzerland, 13–15 November 1979. [Google Scholar]

- Gankhurel, B.; Fukushi, K.; Akehi, A.; Takahashi, Y.; Zhao, X.; Kawasaki, K. Comparison of Chemical Speciation of Lead, Arsenic, and Cadmium in Contaminated Soils from a Historical Mining Site: Implications for Different Mobilities of Heavy Metals. ACS Earth Space Chem. 2020, 4, 1064–1077. [Google Scholar] [CrossRef]

- Firebase. Available online: https://firebase.google.com/docs/database/security?hl=ko (accessed on 14 August 2020).

- Cain, B. A Review of the Mental Workload Literature; Defence Research and Development Toronto (Canada): Toronto, ON, Canada, 2007; pp. 1–35. [Google Scholar]

- Richer, G.; Gruber, H.; Friesenbichler, H.; Uscilowsk, A.; Jancurova, L.; Konova, D. Mental Workload: Identification and Evaluation of Hazards; Taking Measures. In Guide for Risk Assessment in Small and Medium Enterprises; The International Social Security Association (ISSA): Genova, Switzerland, 2008; pp. 1–25. [Google Scholar]

| Heavy metal | Cu | Cd | Pb | Zn | Ni | As | Cr |

| Permissible limit | 100 | 3 | 100 | 300 | 50 | 20 | 100 |

| Case | Total Measurement Time of Heavy Metal Content (Including Soil Sample Preparation, min) | Total Data Sharing Time (min) |

|---|---|---|

| Previous study without smart glasses-based application | 57.5 | 26.8 |

| This study with smart glasses-based application | 35.0 | 2.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.; Choi, Y. Application of Smart Glasses for Field Workers Performing Soil Contamination Surveys with Portable Equipment. Sustainability 2022, 14, 12370. https://doi.org/10.3390/su141912370

Kim D, Choi Y. Application of Smart Glasses for Field Workers Performing Soil Contamination Surveys with Portable Equipment. Sustainability. 2022; 14(19):12370. https://doi.org/10.3390/su141912370

Chicago/Turabian StyleKim, Dawon, and Yosoon Choi. 2022. "Application of Smart Glasses for Field Workers Performing Soil Contamination Surveys with Portable Equipment" Sustainability 14, no. 19: 12370. https://doi.org/10.3390/su141912370