Effect of Sandy Soil Partial Replacement by Construction Waste on Mechanical Behavior and Microstructure of Cemented Mixtures

Abstract

:1. Introduction

2. Materials and Methods

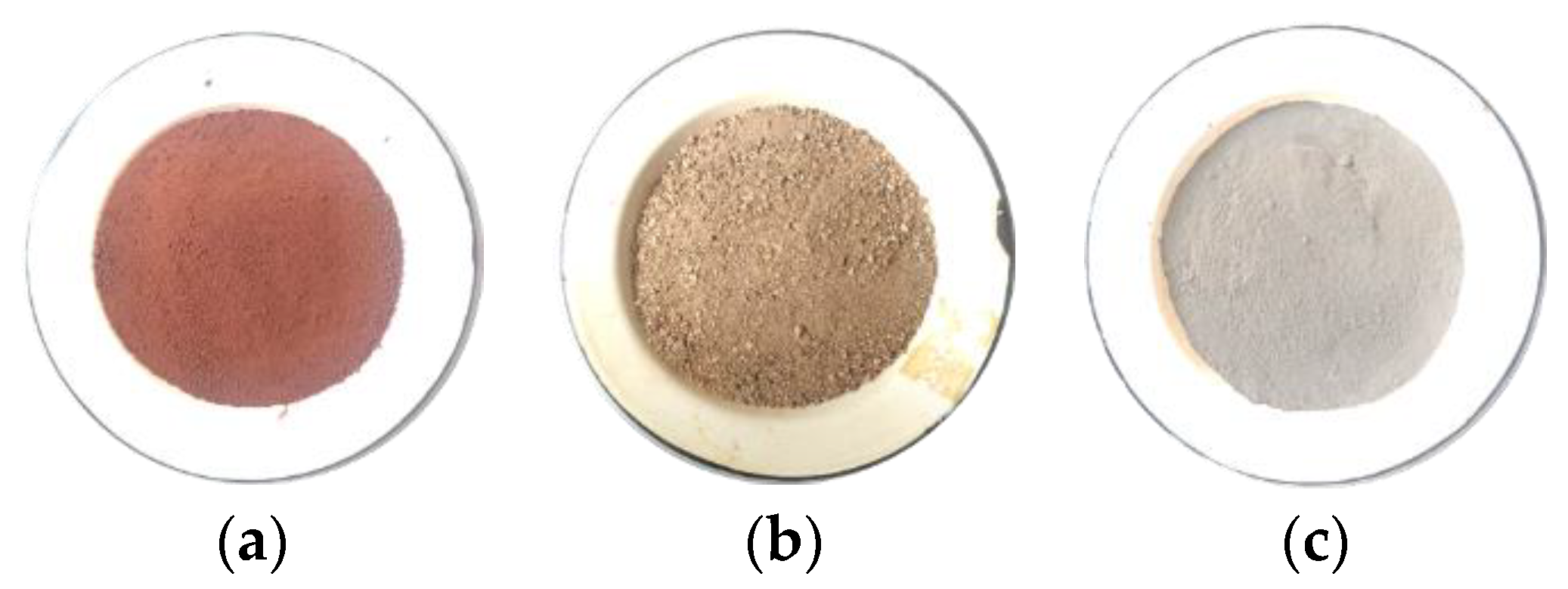

2.1. Materials

2.2. Specimen Preparation

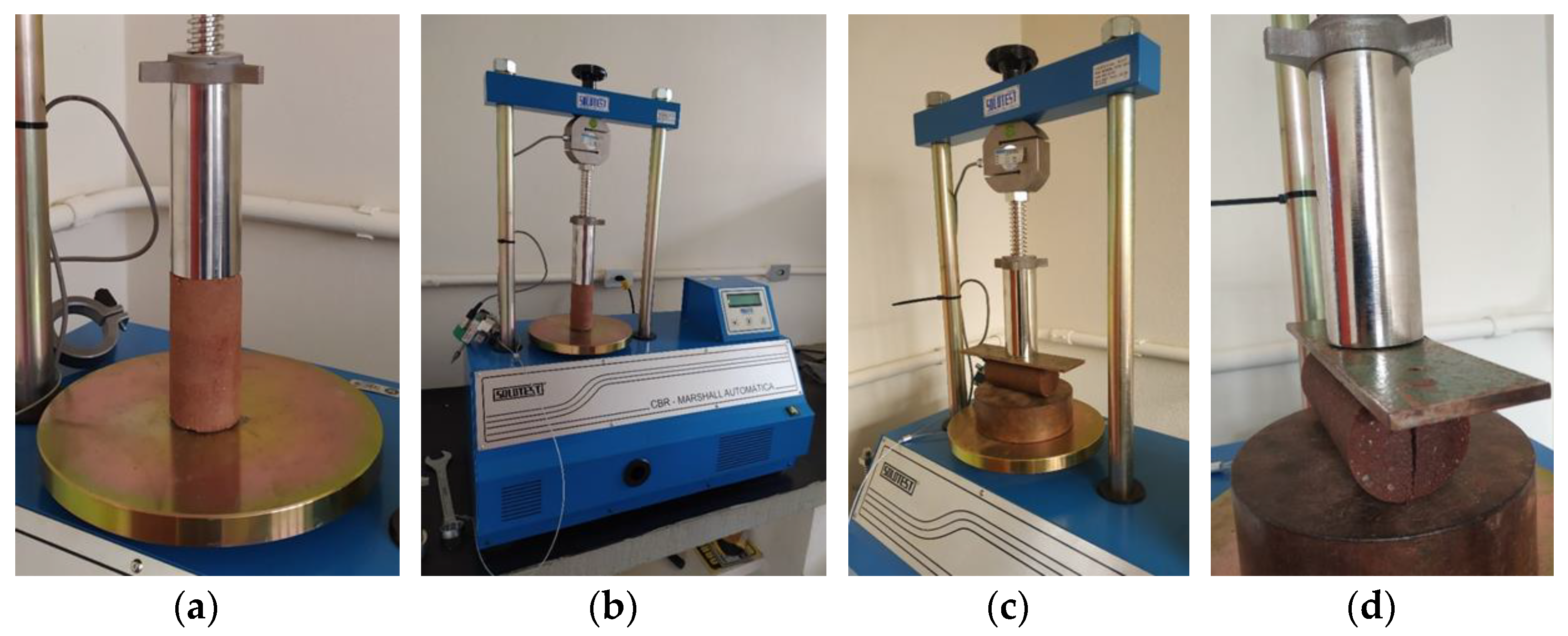

2.3. UCS and ITS

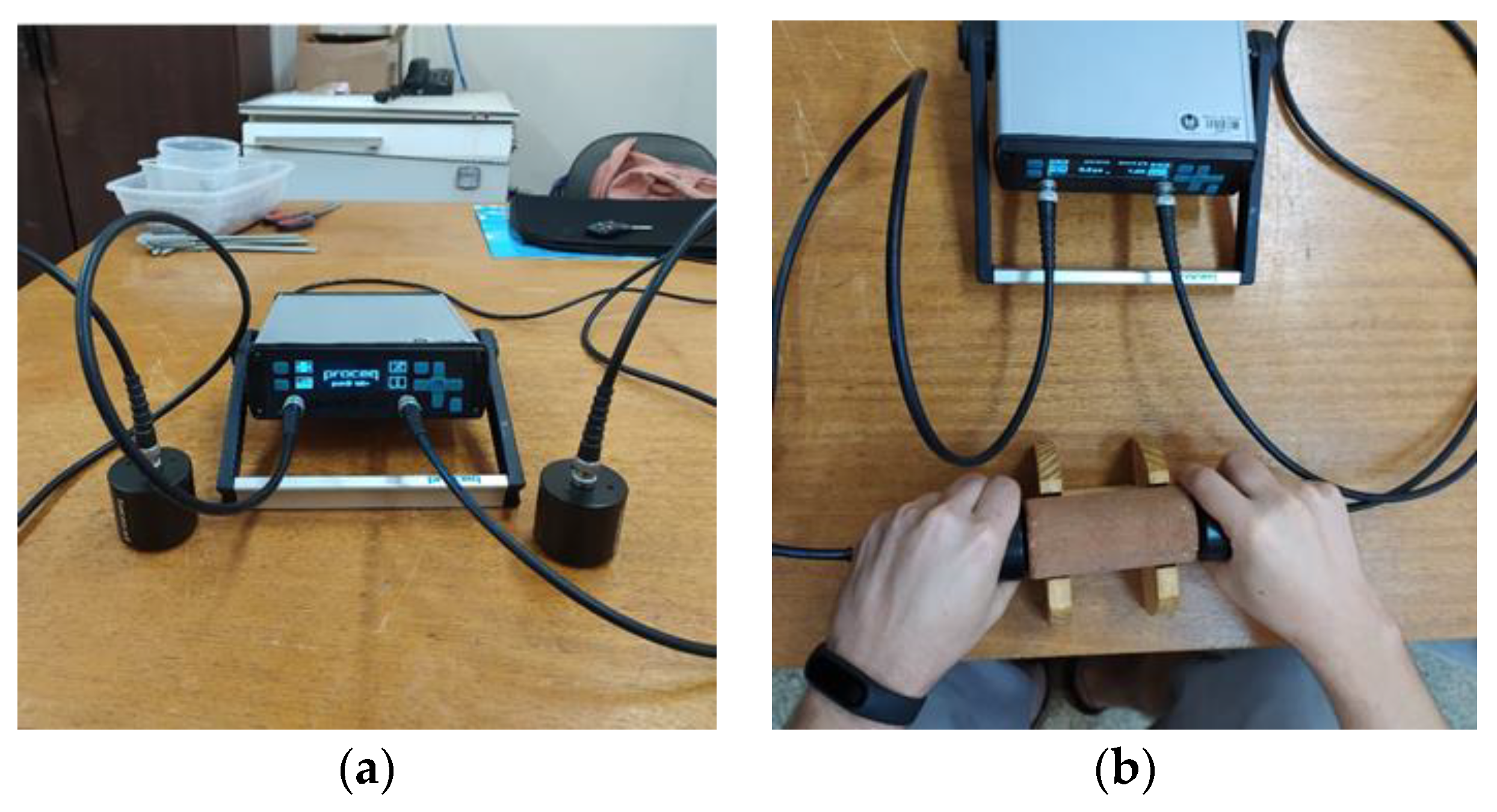

2.4. Ultrasonic Tests

2.5. Microstructural Tests

3. Results and Discussion

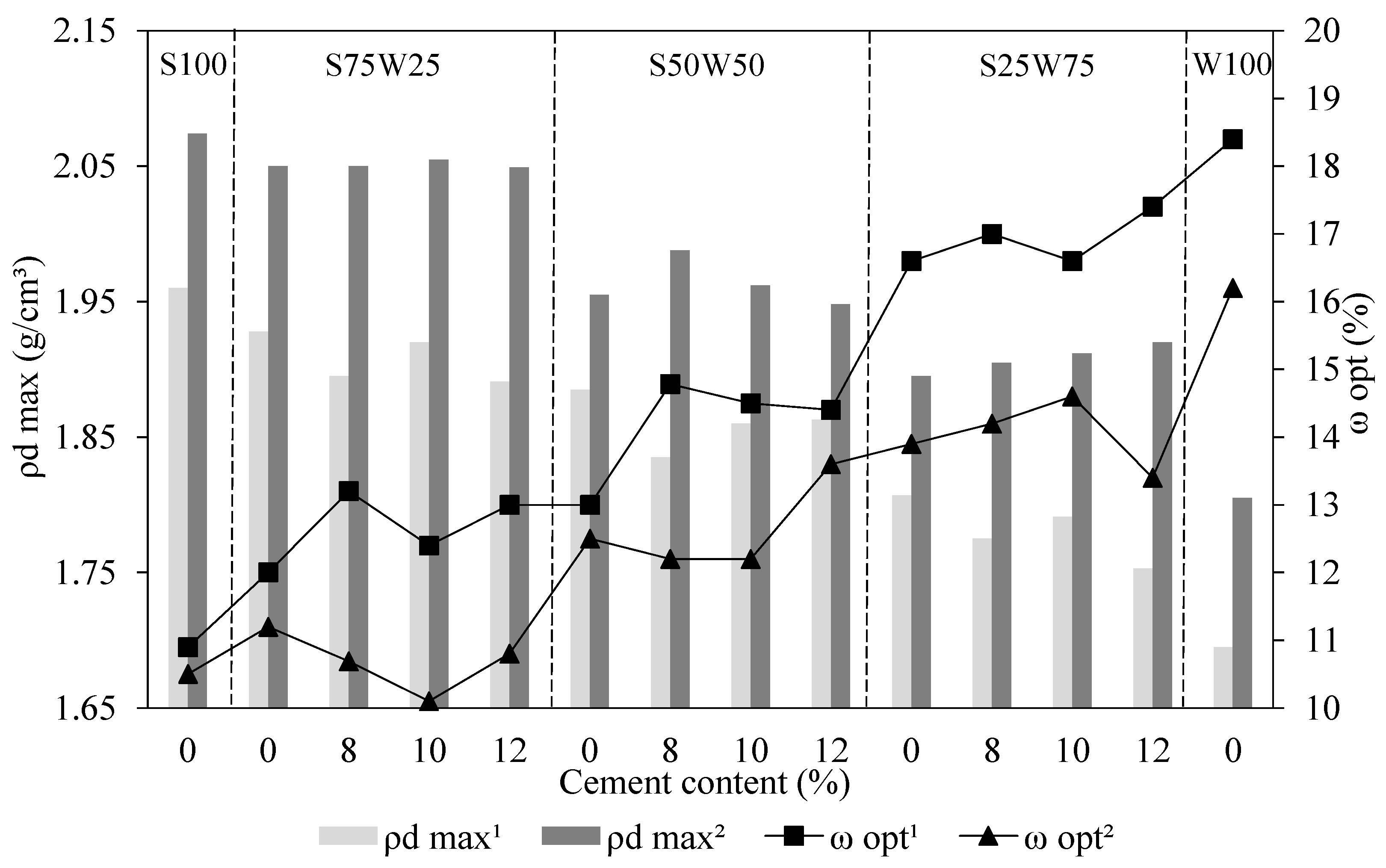

3.1. Compaction Parameters

3.2. UCS and ITS

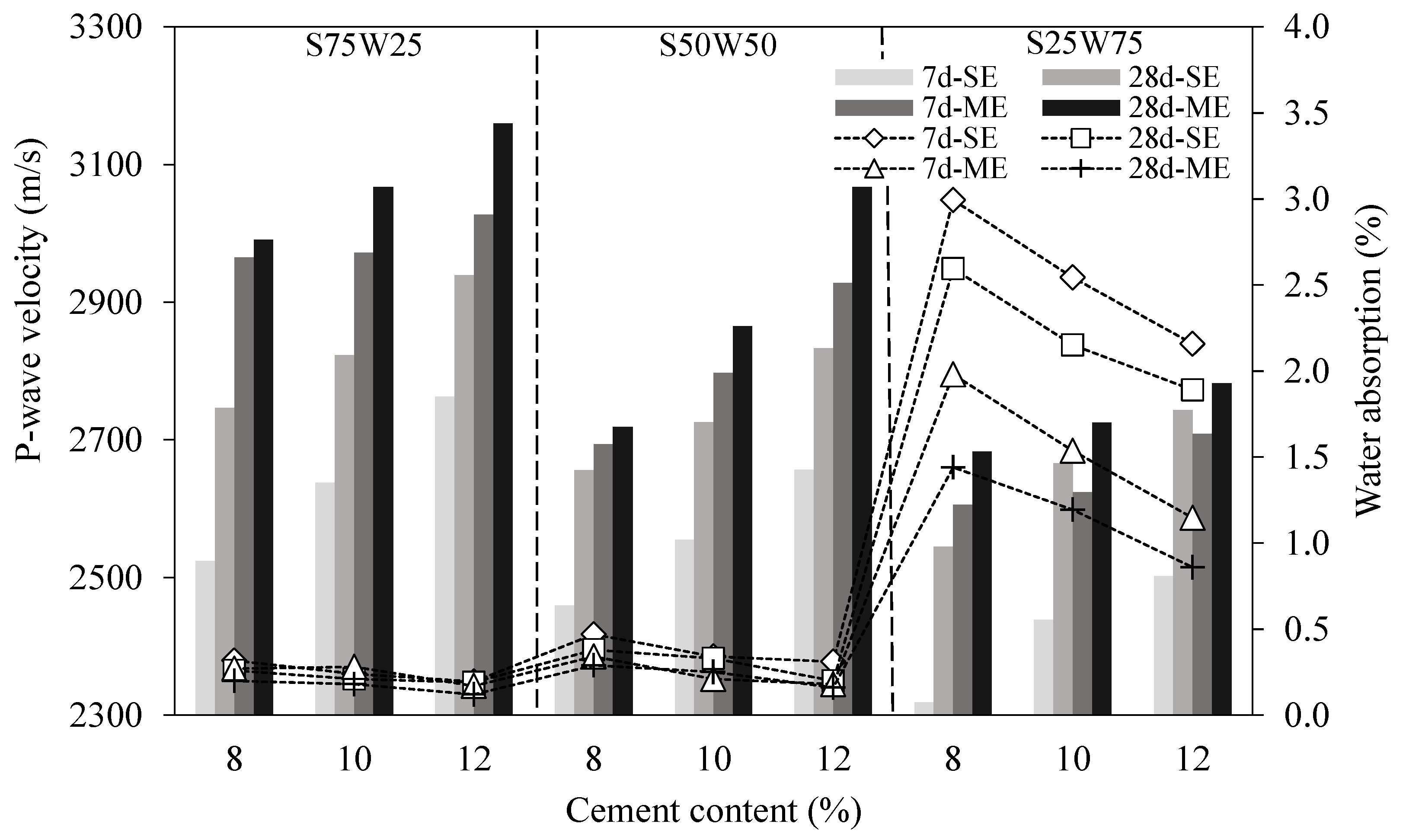

3.3. UPV and Water Absorption

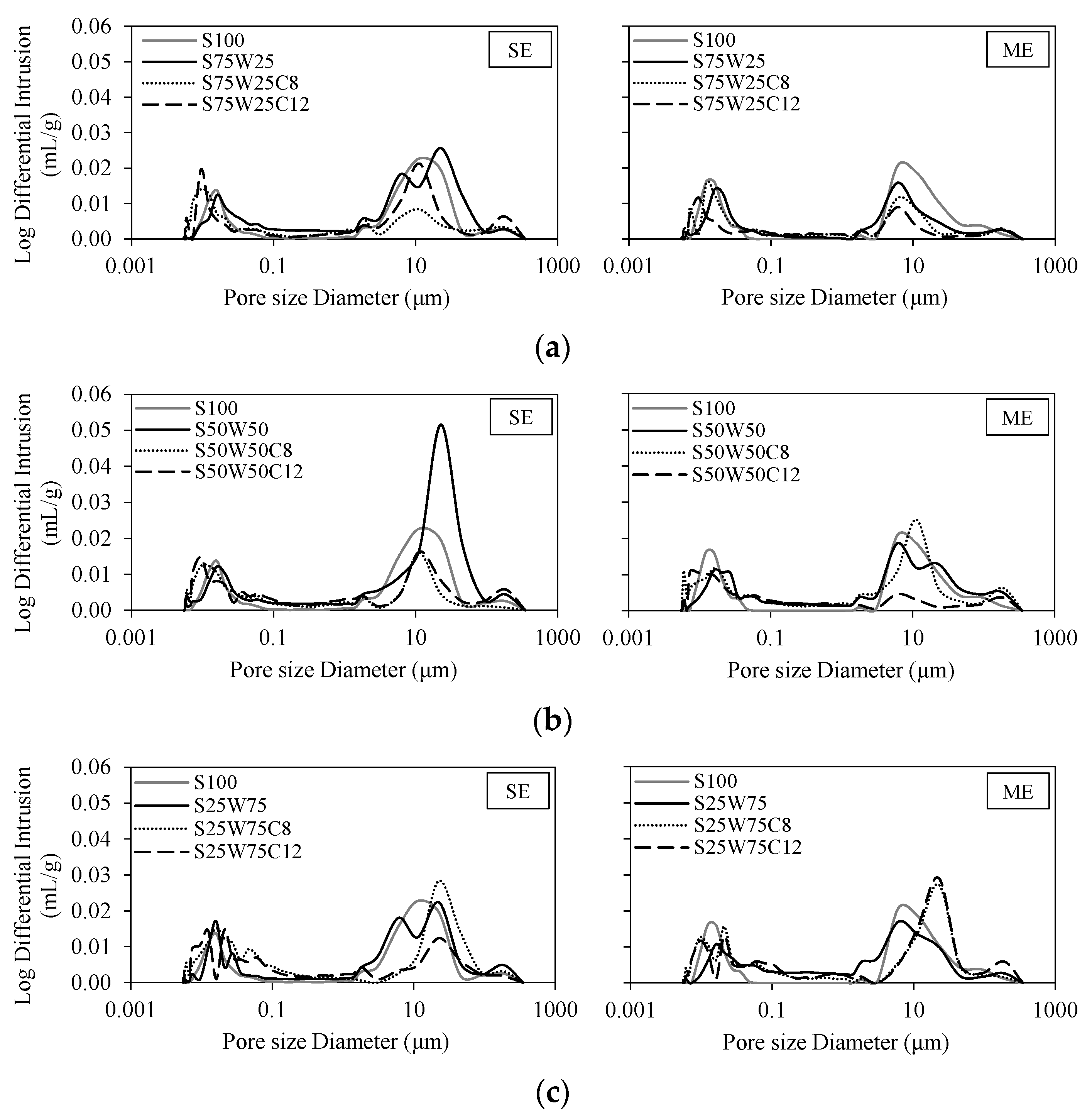

3.4. Pore Size Distribution

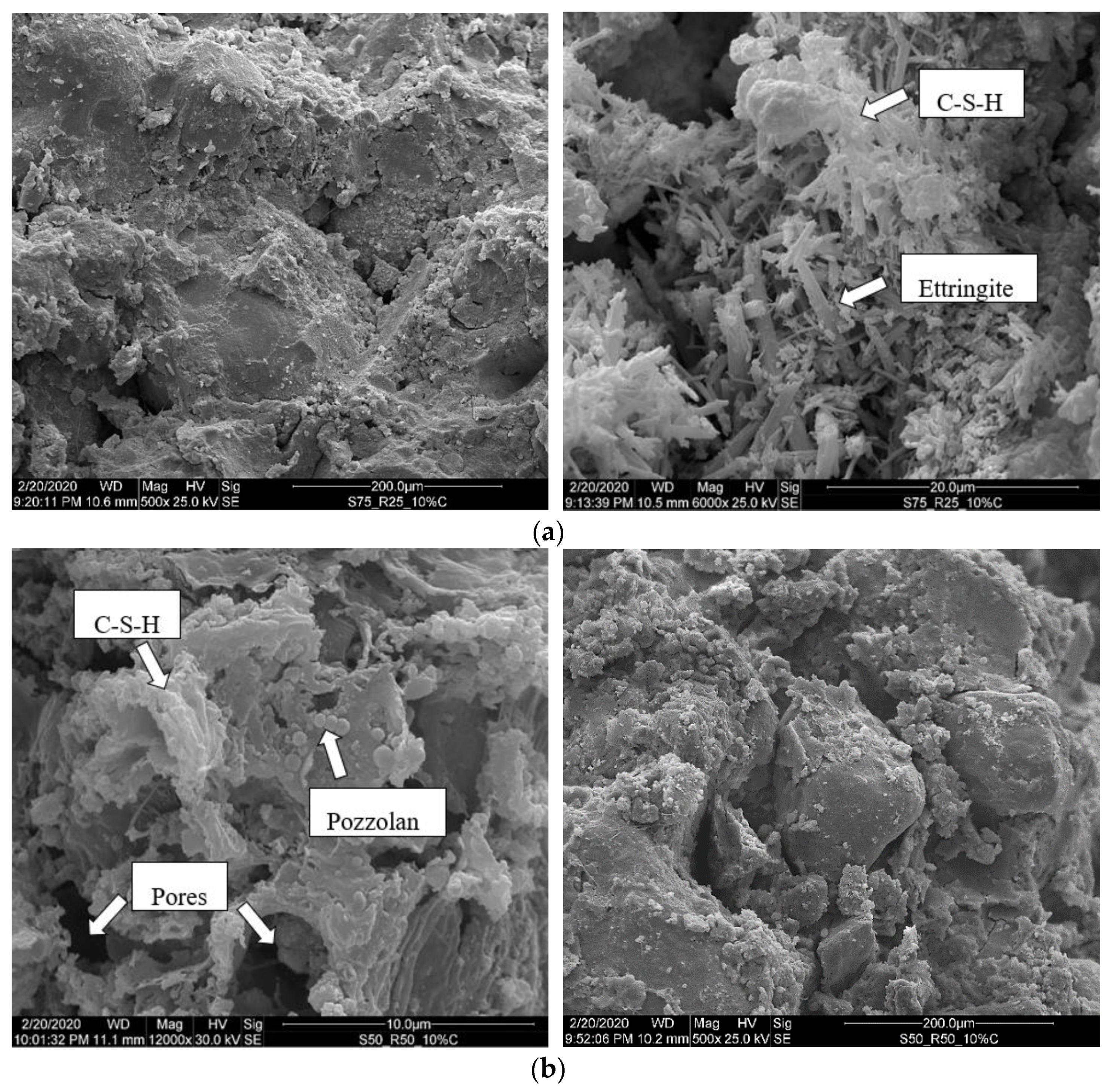

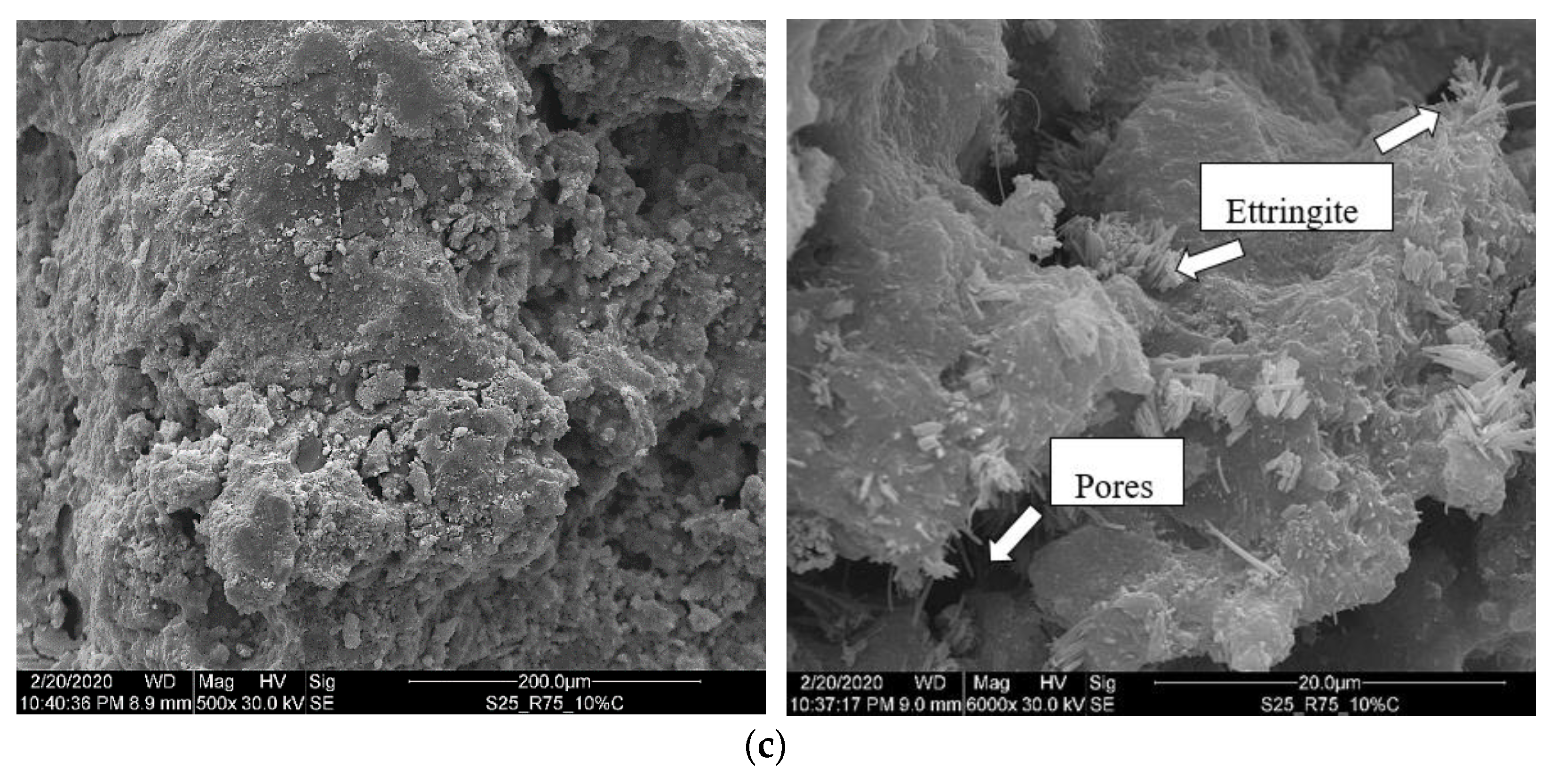

3.5. Microstructural Images by SEM

4. Conclusions

- The optimum moisture content of the mixtures was affected by both the presence and increase in the amounts of construction waste and cement, while only the CW content contributed to significant differences in maximum dry density.

- The improvement in mechanical behavior by cement is more evident in indirect tensile strength (30.8–140.9 times higher) than unconfined compressive strength (4.9–12.1 times higher). Thus, cemented soil-waste mixtures demonstrate viable applications, such as pavement layers.

- From 75% CW in the mixture, a limitation in the improvements is observed due to the reduction in cementation effects.

- UCS and ITS of S75W25- and S50W50-cemented mixtures proved to be statistically identical. Therefore, the mix with 50% of construction waste is most suitable, since it advances the use in civil applications.

- The results of p-wave velocity and ITS show satisfactory correlation, demonstrating the cemented mixtures with CW insertion follow the established trend of cemented soils.

- The natural soil, soil–CW, and soil–CW–cement mixtures presented a bimodal tendency in pore size distribution. Both increases in cement amount and compaction effort resulted in pore closure, reflecting in UCS and ITS gains.

- The peak reduction located in the macropores region on the PSD curves and/or translation of this region to the left of the horizontal axis indicates the occurrence of cement hydration products and pozzolanic reaction. On the other hand, its translation to the right reflects the performance of cement as a filler in general.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zheng, L.; Wu, H.; Zhang, H.; Duan, H.; Wang, J.; Jiang, W.; Dong, B.; Liu, G.; Zuo, J.; Song, Q. Characterizing the generation and flows of construction and demolition waste in China. Constr. Build. Mater. 2017, 136, 405–413. [Google Scholar] [CrossRef]

- Wu, H.; Zuo, J.; Zillante, G.; Wang, J.; Yuan, H. Status quo and future directions of construction and demolition waste research: A critical review. J. Clean. Prod. 2019, 240, 118163. [Google Scholar] [CrossRef]

- Chen, K.; Wang, J.; Yu, B.; Wu, H.; Zhang, J. Critical evaluation of construction and demolition waste and associated environmental impacts: A scientometric analysis. J. Clean. Prod. 2021, 287, 125071. [Google Scholar] [CrossRef]

- ABRELPE Panorama of Waste in Brazil 2020. Brazilian Assoc. Public Clean. Spec. Waste ABRELPE 2020. Available online: https://abrelpe.org.br/panorama-2020/ (accessed on 25 August 2022).

- Nunes, K.R.A.; Mahler, C.F. Comparison of construction and demolition waste management between Brazil, European Union and USA. Waste Manag. Res. 2020, 38, 415–422. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.; Tam, V.W.Y. Construction and demolition waste management contributing factors coupled with reduce, reuse, and recycle strategies for effective waste management: A review. J. Clean. Prod. 2020, 263, 121265. [Google Scholar] [CrossRef]

- Maués, L.M.F.; do Nascimento, B.D.M.O.; Lu, W.; Xue, F. Estimating construction waste generation in residential buildings: A fuzzy set theory approach in the Brazilian Amazon. J. Clean. Prod. 2020, 265, 121779. [Google Scholar] [CrossRef]

- Cristiano, S.; Ghisellini, P.; D’Ambrosio, G.; Xue, J.; Nesticò, A.; Gonella, F.; Ulgiati, S. Construction and demolition waste in the Metropolitan City of Naples, Italy: State of the art, circular design, and sustainable planning opportunities. J. Clean. Prod. 2021, 293, 125856. [Google Scholar] [CrossRef]

- Negash, Y.T.; Hassan, A.M.; Tseng, M.-L.; Wu, K.-J.; Ali, M.H. Sustainable Construction and Demolition Waste Management in Somaliland: Regulatory Barriers lead to Technical and Environmental Barriers. J. Clean. Prod. 2021, 297, 126717. [Google Scholar] [CrossRef]

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete—A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- Akanbi, L.A.; Oyedele, L.O.; Akinade, O.O.; Ajayi, A.O.; Davila Delgado, M.; Bilal, M.; Bello, S.A. Salvaging building materials in a circular economy: A BIM-based whole-life performance estimator. Resour. Conserv. Recycl. 2018, 129, 175–186. [Google Scholar] [CrossRef]

- dos Santos Ferreira, J.W.; Senez, P.C.; Casagrande, M.D.T. Pet Fiber Reinforced Sand Performance Under Triaxial and Plate Load Tests. Case Stud. Constr. Mater. 2021, 15, e00741. [Google Scholar] [CrossRef]

- dos Santos Ferreira, J.W.; Marroquin, J.F.R.; Felix, J.F.; Farias, M.M.; Casagrande, M.D.T. The feasibility of recycled micro polyethylene terephthalate (PET) replacing natural sand in hot-mix asphalt. Constr. Build. Mater. 2022, 330, 127276. [Google Scholar] [CrossRef]

- Sagoe-Crentsil, K.K.; Brown, T.; Taylor, A.H. Performance of concrete made with commercially produced coarse recycled concrete aggregate. Cem. Concr. Res. 2001, 31, 707–712. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A.; Alaejos, P.; Sánchez De Juan, M. Durability of recycled aggregate concrete. Constr. Build. Mater. 2013, 40, 1054–1065. [Google Scholar] [CrossRef]

- Moretti, J.P.; Sales, A.; Almeida, F.C.R.; Rezende, M.A.M.; Gromboni, P.P. Joint use of construction waste (CW) and sugarcane bagasse ash sand (SBAS) in concrete. Constr. Build. Mater. 2016, 113, 317–323. [Google Scholar] [CrossRef]

- Costa, F.N.; Ribeiro, D.V. Reduction in CO2 emissions during production of cement, with partial replacement of traditional raw materials by civil construction waste (CCW). J. Clean. Prod. 2020, 276, 123302. [Google Scholar] [CrossRef]

- Santos, E.C.G.; Palmeira, E.M.; Bathurst, R.J. Behaviour of a geogrid reinforced wall built with recycled construction and demolition waste backfill on a collapsible foundation. Geotext. Geomembranes 2013, 39, 9–19. [Google Scholar] [CrossRef]

- Rahman, M.A.; Imteaz, M.; Arulrajah, A.; Disfani, M.M. Suitability of recycled construction and demolition aggregates as alternative pipe backfilling materials. J. Clean. Prod. 2014, 66, 75–84. [Google Scholar] [CrossRef]

- Vieira, C.S.; Pereira, P.M.; Lopes, M.D.L. Recycled Construction and Demolition Wastes as filling material for geosynthetic reinforced structures. Interface properties. J. Clean. Prod. 2016, 124, 299–311. [Google Scholar] [CrossRef]

- Sangiorgi, C.; Lantieri, C.; Dondi, G. Construction and demolition waste recycling: An application for road construction. Int. J. Pavement Eng. 2014, 16, 530–537. [Google Scholar] [CrossRef]

- Cardoso, R.; Silva, R.V.; de Brito, J.; Dhir, R. Use of recycled aggregates from construction and demolition waste in geotechnical applications: A literature review. Waste Manag. 2015, 49, 131–145. [Google Scholar] [CrossRef] [PubMed]

- Sharma, R.K.; Hymavathi, J. Effect of fly ash, construction demolition waste and lime on geotechnical characteristics of a clayey soil: A comparative study. Environ. Earth Sci. 2016, 75, 377. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Zardikawi, O.A.A.; Abdulnafaa, M.D. Utilisation of construction and demolition materials with clay for road pavement subgrade. Road Mater. Pavement Des. 2017, 20, 702–714. [Google Scholar] [CrossRef]

- Esfahani, M.A. Evaluating the feasibility, usability, and strength of recycled construction and demolition waste in base and subbase courses. Road Mater. Pavement Des. 2018, 21, 156–178. [Google Scholar] [CrossRef]

- Panizza, M.; Natali, M.; Garbin, E.; Tamburini, S.; Secco, M. Assessment of geopolymers with Construction and Demolition Waste (CDW) aggregates as a building material. Constr. Build. Mater. 2018, 181, 119–133. [Google Scholar] [CrossRef]

- Sharma, A.; Sharma, R.K. Effect of addition of construction–demolition waste on strength characteristics of high plastic clays. Innov. Infrastruct. Solut. 2019, 4, 27. [Google Scholar] [CrossRef]

- Lukiantchuki, J.A.; de Oliveira, J.R.M.D.S.; de Almeida, M.D.S.S.; dos Reis, J.H.C.; Silva, T.B.; Guideli, L.C. Geotechnical Behavior of Construction Waste (CW) as a Partial Replacement of a Lateritic Soil in Fiber-Reinforced Cement Mixtures. Geotech. Geol. Eng. 2020, 39, 919–942. [Google Scholar] [CrossRef]

- Liu, L.; Li, Z.; Cai, G.; Liu, X.; Yan, S. Humidity field characteristics in road embankment constructed with recycled construction wastes. J. Clean. Prod. 2020, 259, 120977. [Google Scholar] [CrossRef]

- Leite, F.D.C.; Motta, R.D.S.; Vasconcelos, K.L.; Bernucci, L. Laboratory evaluation of recycled construction and demolition waste for pavements. Constr. Build. Mater. 2011, 25, 2972–2979. [Google Scholar] [CrossRef]

- Rodrigues, F.; Carvalho, M.T.; Evangelista, L.; De Brito, J. Physical-chemical and mineralogical characterization of fine aggregates from construction and demolition waste recycling plants. J. Clean. Prod. 2013, 52, 438–445. [Google Scholar] [CrossRef]

- Arulrajah, A.; Piratheepan, J.; Aatheesan, T.; Bo, M.W. Geotechnical Properties of Recycled Crushed Brick in Pavement Applications. J. Mater. Civ. Eng. 2011, 23, 1444–1452. [Google Scholar] [CrossRef]

- Arulrajah, A.; Piratheepan, J.; Disfani, M.M.; Bo, M.W. Geotechnical and Geoenvironmental Properties of Recycled Construction and Demolition Materials in Pavement Subbase Applications. J. Mater. Civ. Eng. 2013, 25, 1077–1088. [Google Scholar] [CrossRef]

- Arulrajah, A.; Ghorbani, B.; Narsilio, G.; Horpibulsuk, S.; Leong, M. Thermal performance of geothermal pavements constructed with demolition wastes. Geomech. Energy Environ. 2021, 28, 100253. [Google Scholar] [CrossRef]

- Arulrajah, A.; Yaghoubi, E.; Wong, Y.C.; Horpibulsuk, S. Recycled plastic granules and demolition wastes as construction materials: Resilient moduli and strength characteristics. Constr. Build. Mater. 2017, 147, 639–647. [Google Scholar] [CrossRef]

- Arulrajah, A.; Mohammadinia, A.; D’Amico, A.; Horpibulsuk, S. Cement kiln dust and fly ash blends as an alternative binder for the stabilization of demolition aggregates. Constr. Build. Mater. 2017, 145, 218–225. [Google Scholar] [CrossRef]

- Poltue, T.; Suddeepong, A.; Horpibulsuk, S.; Samingthong, W.; Arulrajah, A.; Rashid, A.S.A. Strength development of recycled concrete aggregate stabilized with fly ash-rice husk ash based geopolymer as pavement base material. Road Mater. Pavement Des. 2019, 21, 2344–2355. [Google Scholar] [CrossRef]

- Consoli, N.C.; Foppa, D.; Festugato, L.; Heineck, K.S. Key Parameters for Strength Control of Artificially Cemented Soils. J. Geotech. Geoenviron. Eng. 2007, 133, 197–205. [Google Scholar] [CrossRef]

- Consoli, N.C.; Cruz, R.C.; Floss, M.F.; Festugato, L. Parameters Controlling Tensile and Compressive Strength of Artificially Cemented Sand. J. Geotech. Geoenviron. Eng. 2010, 136, 759–763. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Chinkulkijniwat, A.; Raksachon, Y.; Suddeepong, A. Analysis of strength development in cement-stabilized silty clay from microstructural considerations. Constr. Build. Mater. 2010, 24, 2011–2021. [Google Scholar] [CrossRef]

- Lemaire, K.; Deneele, D.; Bonnet, S.; Legret, M. Effects of lime and cement treatment on the physicochemical, microstructural and mechanical characteristics of a plastic silt. Eng. Geol. 2013, 166, 255–261. [Google Scholar] [CrossRef]

- Tongwei, Z.; Xibing, Y.; Yongfeng, D.; Dingwen, Z.; Songyu, L. Mechanical behaviour and micro-structure of cement-stabilised marine clay with a metakaolin agent. Constr. Build. Mater. 2014, 73, 51–57. [Google Scholar] [CrossRef]

- Hasan, U.; Chegenizadeh, A.; Budihardjo, M.A.; Nikraz, H. Experimental Evaluation of Construction Waste and Ground Granulated Blast Furnace Slag as Alternative Soil Stabilisers. Geotech. Geol. Eng. 2016, 34, 1707–1722. [Google Scholar] [CrossRef]

- Oliveira, A.D.D.; Pelaquim, F.G.P.; Zanin, R.F.B.; Melo, T.R.D.; Tavares Filho, J.; Andrello, A.C.; Teixeira, R.S. The structure of tropical lateritic soils as an impacting factor in the shape of soil-water characteristic curves. Soils Rocks 2022, 45, 1–13. [Google Scholar] [CrossRef]

- Cancian, M.A.; Cancian, V.A.; Teixeira, R.S.; Fontenele, H.B.; Da costa Branco, C.J.M. Influência do teor de umidade, da porosidade e do intervalo de tempo até a aplicação da mistura solo-cimento em pavimento rodoviário. Transportes 2017, 25, 41–50. [Google Scholar] [CrossRef]

- ASTM D 854; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D 4318; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2017.

- ABNT NBR NM 30; Fine Aggregate—Determination of Water Absorption. Associação Brasileira de Normas Técnicas: São Paulo, Brazil, 2001.

- ASTM C 188; Standard Test Method for Density of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D 7928; Standard Test Method for Particle-Size Distribution (Gradation) of Fine-Grained Soils Using the Sedimentation (Hydrometer) Analysis. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D 6913; Standard Test Methods for Particle-Size Distribution (Gradation) of Soils Using Sieve Analysis. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D 698; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D 1557; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort. ASTM International: West Conshohocken, PA, USA, 2021.

- Pavan, M.A.; Bloch, M.F.; Zempulski, H.C.; Miyazawa, M.; Zocoler, D.C. Manual de Análise Química do Solo e Controle de Qualidade; IAPAR: Londrina, Brazil, 1992. [Google Scholar]

- de Carvalho, J.C.; de Rezende, L.R.; Cardoso, F.B.D.F.; de FL Lucena, L.C.; Guimarães, R.C.; Valencia, Y.G. Tropical soils for highway construction: Peculiarities and considerations. Transp. Geotech. 2015, 5, 3–19. [Google Scholar] [CrossRef]

- ASTM D 2166; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- ASTM D 3967; Standard Test Method for Splitting Tensile Strength of Intact Rock Core Specimens. ASTM International: West Conshohocken, PA, USA, 2016.

- dos Santos Ferreira, J.W.; Casagrande, M.D.T.; Teixeira, R.S. Sample dimension effect on equations controlling tensile and compressive strength of cement-stabilized sandy soil under optimal compaction conditions. Case Stud. Constr. Mater. 2021, 15, e00763. [Google Scholar] [CrossRef]

- Ferreira, J.; Casagrande, M.; Teixeira, R. Sample dimension effect on cement-stabilized sandy soil mechanical behavior. Soils Rocks 2022, 45, 1–10. [Google Scholar] [CrossRef]

- ASTM C 597; Standard Test Method for Pulse Velocity Through Concrete. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- ASTM D 4404; Standard Test Method for Determination of Pore Volume and Pore Volume Distribution of Soil and Rock by Mercury Intrusion Porosimetry. ASTM International: West Conshohocken, PA, USA, 2018. [CrossRef]

- Khan, Z.; Majid, A.; Cascante, G.; Hutchinson, D.J.; Pezeshkpour, P. Characterization of a cemented sand with the pulse-velocity method. Can. Geotech. J. 2006, 43, 294–309. [Google Scholar] [CrossRef]

- Toohey, N.M.; Mooney, M.A. Seismic modulus growth of lime-stabilised soil during curing. Geotechnique 2012, 62, 161–170. [Google Scholar] [CrossRef]

- Mandal, T.; Tinjum, J.M.; Edil, T.B. Non-destructive testing of cementitiously stabilized materials using ultrasonic pulse velocity test. Transp. Geotech. 2016, 6, 97–107. [Google Scholar] [CrossRef]

- Kutanaei, S.S.; Choobbasti, A.J. Effects of Nanosilica Particles and Randomly Distributed Fibers on the Ultrasonic Pulse Velocity and Mechanical Properties of Cemented Sand. J. Mater. Civ. Eng. 2017, 29, 04016230. [Google Scholar] [CrossRef]

| Material/Mixture | pH | Soil (%) | Waste (%) | Cement (%) |

|---|---|---|---|---|

| S100 | 5.27 | 100 | 0 | 0 |

| S75W25 | 8.85 | 75 | 25 | 0 |

| S50W50 | 10.29 | 50 | 50 | 0 |

| S25W75 | 11.05 | 25 | 75 | 0 |

| W100 | 11.23 | 0 | 100 | 0 |

| S75W25C8 | 11.98 | 75 | 25 | 8 |

| S75W25C10 | 12.24 | 75 | 25 | 10 |

| S75W25C12 | 12.31 | 75 | 25 | 12 |

| S50W50C8 | 12.40 | 50 | 50 | 8 |

| S50W50C10 | 12.52 | 50 | 50 | 10 |

| S50W50C12 | 12.65 | 50 | 50 | 12 |

| S25W75C8 | 12.50 | 25 | 75 | 8 |

| S25W75C10 | 12.59 | 25 | 75 | 10 |

| S25W75C12 | 12.73 | 25 | 75 | 12 |

| Compaction Effort | Curing Age (Days) | Factor | p-Value |

|---|---|---|---|

| SE | 7 | UCSS75W25C:UCSS50W50C | 0.7107 |

| 28 | 0.6393 | ||

| ME | 7 | 0.4551 | |

| 28 | 0.5268 | ||

| SE | 7 | ITSS75W25C:ITSS50W50C | 0.9544 |

| 28 | 0.2482 | ||

| ME | 7 | 0.7682 | |

| 28 | 0.3305 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Milani, D.M.; Ferreira, J.W.d.S.; Casagrande, M.D.T.; Andrello, A.C.; Teixeira, R.S. Effect of Sandy Soil Partial Replacement by Construction Waste on Mechanical Behavior and Microstructure of Cemented Mixtures. Sustainability 2022, 14, 12438. https://doi.org/10.3390/su141912438

Milani DM, Ferreira JWdS, Casagrande MDT, Andrello AC, Teixeira RS. Effect of Sandy Soil Partial Replacement by Construction Waste on Mechanical Behavior and Microstructure of Cemented Mixtures. Sustainability. 2022; 14(19):12438. https://doi.org/10.3390/su141912438

Chicago/Turabian StyleMilani, Diego Manchini, José Wilson dos Santos Ferreira, Michéle Dal Toé Casagrande, Avacir Casanova Andrello, and Raquel Souza Teixeira. 2022. "Effect of Sandy Soil Partial Replacement by Construction Waste on Mechanical Behavior and Microstructure of Cemented Mixtures" Sustainability 14, no. 19: 12438. https://doi.org/10.3390/su141912438

APA StyleMilani, D. M., Ferreira, J. W. d. S., Casagrande, M. D. T., Andrello, A. C., & Teixeira, R. S. (2022). Effect of Sandy Soil Partial Replacement by Construction Waste on Mechanical Behavior and Microstructure of Cemented Mixtures. Sustainability, 14(19), 12438. https://doi.org/10.3390/su141912438