1. Introduction

Road obstacles are indispensable to land operations. These artificial structures are installed to disrupt, divert, restrict, and block the advance of mechanized enemy units. A large number of obstacles called “rock drops” remain at some border regions of South Korea, which are also near Seoul, the capital city. The obstacles were densely installed after the Korean War in order to hinder the mechanized units of North Korea from advancing into Seoul. During the Korean War, blocking the North Korean tanks advancing to the south was one of the most urgent tasks influencing victory or defeat. There were many cases, such as the battle in the Silryeong area (August to September 1950), in which anti-tank obstacles effectively repelled the enemy’s attacks. Thus, based on Forward Edge of Battle Area (FEBA), the South Korean Army has developed its own nested defense system around Seoul.

However, the basic concept of anti-tank obstacle operation in modern wars underwent a revolutionary change after the Gulf War. During the Gulf War, the Iraqi Army operated a complex four-fold obstacle system in which sand barricades were installed in the forefront, followed by tank traps, barbed-wire fences, and mine fields [

1]. Although the complex obstacle system was as deep as 0.8–3 km, the multinational force easily neutralized it through swift and clever maneuvers. The reason behind the failure was the qualitative gap in weapon systems between the United States and Iraq. Moreover, the U.S. Army and the multinational force implemented creative maneuver strategies and utilized excellent obstacle subjugation equipment and other effective engineering equipment suitable for the battlefield. Furthermore, the Iraqi Army also lost command of the air and was too outgunned to protect their obstacles. Consequently, Iraqi tanks and combat equipment placed at stationary positions were almost immobile, and the obstacles installed on the sand ground were easily overcome by the maneuvering equipment of the multinational force’s engineer corps. In other words, the creative maneuver schemes and excellent obstacle subjugation of the multinational force effectively incapacitated the anti-tank obstacles of the Iraqi Army, while the stationary obstacles deprived the Iraqi Army of flexibility in military operations, rendering it incapable of responding to the everchanging battlefield situations.

As an increasing number of areas are becoming urbanized and industrial complexes are being constructed around Seoul, traffic volumes continue to increase. Accordingly, the existing anti-tank obstacles are recognized as potential overheads and are blamed for traffic congestion and for causing hazards to roads and the urban landscape. The Republic of Korea Army (ROKA) is now facing civil complaints from local governments and residents, who demand the destruction or relocation of these obstacles. In fact, some obstacles are located at bottleneck spots for tactical purposes and cause at least one fatal road accident every year. Despite the urgent requests to local governments for a discussion about their relocation and destruction, no reasonable agreement has been arrived at owing to the following reasons: ① complicated decision-making process of the military, ② different guidelines of higher units for obstacle rearrangement and management, ③ local governments’ lack of understanding of the military purpose of rock drop obstacles, and ④ excessive budget for the replacement of obstacles.

Furthermore, the existing over-road obstacles were constructed at least 60 years ago and need to be dismantled or reconstructed. It is necessary to develop new types of obstacles that are sustainable and capable of replacing the existing ones, which has been one way to consider sustainable development in construction [

2,

3]. Such new sustainable types of obstacles should accord with eco-friendly urbanization projects and the sustainability policy of the army [

4]. In particular, the South Korean Army applies sustainability policies, including protective facilities that can ensure operational capability in various areas while realizing eco-friendly green growth [

5].

The aims of this study are to verify the effectiveness of the existing road obstacles (rock drops) and to contribute to the sustainability policy of the army through a sustainable replacement obstacle. This study analyzed the capability of the existing obstacles based on combat experiment results to achieve these aims. Due to time and cost constraints, the new obstacle was evaluated using a finite element analysis instead of a combat experiment. Thus, the new obstacle system was evaluated in terms of CO2 emission reduction.

2. Evaluation of Rock Drop Obstacle Effectiveness

Currently, the South Korean Army operates two types of rock drop obstacles. As shown in

Figure 1, the first obstacle is an overpass-type rock drop, and the second is a block-type rock drop made of cube-shaped concrete.

As the effectiveness of rock drop obstacles is closely related to the firepower and maneuver plan in a combat situation, it is impossible to quantify according to the size and scale of obstacles. For example, even if a rock drop obstacle is small in size and scale, the tactical commander’s operational goal can be achieved as long as the obstacle is protected by sufficient firepower and military forces. In contrast, however solidly an obstacle is installed, the enemy can subjugate it if there is no resistance. In other words, obstacles are not intended to perfectly disrupt the maneuver of the enemy but to delay it for a desired time or to attract the enemy to the desired place.

Figure 2 is a typical example of evaluating the effectiveness of an obstacle with respect to time and speed.

In this study, the obstacle effectiveness was determined based on the time required for trailblazing only by means of earthwork equipment and explosives (weapons) in a nontactical situation.

Table 1 presents the number of projectiles of ammunition required to destroy a rock drop. The types of ammunition were selected among anti-tank explosives for special purposes, such as the destruction of concrete structures. In the experiment, one or two projectiles destroyed each rock drop into pieces that could be handled by typical engineering equipment. As shown in the experimental results below, most rock drops, reinforced and unreinforced, were destroyed by one or two anti-tank projectiles. When the capability of standard commercial engineering equipment was considered, the maximum delay time for rock drop obstacles arranged in two columns and five rows was analyzed to be approximately 30 min.

Figure 3 shows the sizes and shapes of rock drops destroyed in the battle experiment.

In terms of how effective the overpass-type rock drop obstacles are in delaying the maneuver of the enemy, the battle experiment results reported by the existing studies were examined. Similar to the block-type rock drop, the subjugation of the overpass-type rock drop essentially depended on how fast and effectively it could be destroyed by ammunition and cleared off by engineering equipment. Accordingly, there was no significant difference except in the size of the concrete structure. It was evident that the overpass-type rock drop caused a delay of approximately 45 min.

In an interview with commanders of combat units, they shared the opinion that rock drop obstacles are not a tactical option for disrupting the maneuver of a tank or a mechanized unit nor for protecting Seoul from the enemy in modern warfare. As active and offensive measures have replaced the defensive and sequential responses conceived for warfare in the past, the stationary rock drop obstacles are much less important than before. Instead, it was suggested that, apart from the advancement in firepower and weapon systems, mobile obstacle systems should be developed for practical use. Moreover, as a growth in road networks accompanies urbanization, there are many ways around such stationary obstacles. Therefore, the interviewees considered it necessary to dismantle the existing obstacles or to replace them with a different type, especially in areas where traffic accidents or congestion are problematic.

3. Development of Sustainable Anti-Tank Obstacle

3.1. Selection of Alternative Obstacles

An interview was conducted with military experts on obstacles who proposed various alternatives to rock drop obstacles. Their common opinions can be summarized as follows:

Anti-tank trench applying Expanded Polystyrene (EPS) method;

Anti-tank trench using high expansion foam or other new materials;

Obstacle utilizing removable protective walls (Hesco/Pluq);

Obstacle applying the gabion method;

Obstacle using H-beam;

Anti-tank mines using prefabricated speed bumps;

Road crater with liquid explosive filled in PVC pipe.

However, these alternative obstacles were mostly suggested as ideas. An alternative obstacle to be installed on the road should allow automobile and even army tank traffic to flow freely during peacetime; this requirement is not satisfied by the above obstacles. Accordingly, the research team attempted to determine a satisfactory alternative by specifying the following three conditions through an interview with commanders of field units:

Preplanned obstacles ensure vehicle traffic, including tanks, during peacetime.

Engineer man-hours for installing the obstacle should be similar to or less than that of exploding a rock drop.

The obstacle effect should be similar to that of rock drops, i.e., approximately 30 min delay.

This study selected the anti-tank bollard as an alternative that satisfies the requirements. More specific requirements were derived, as in

Table 2.

The requirements in

Table 2 assume that the enemy tank does not run into the obstacle at high speed in order to subjugate it, but an explosive or a towing tank is used to cut or draw it out. If the enemy tank ran into the obstacle, the tank would be damaged, thereby increasing the time for clearing the obstacle.

3.2. Evaluation of the Capability of the Alternative Obstacle

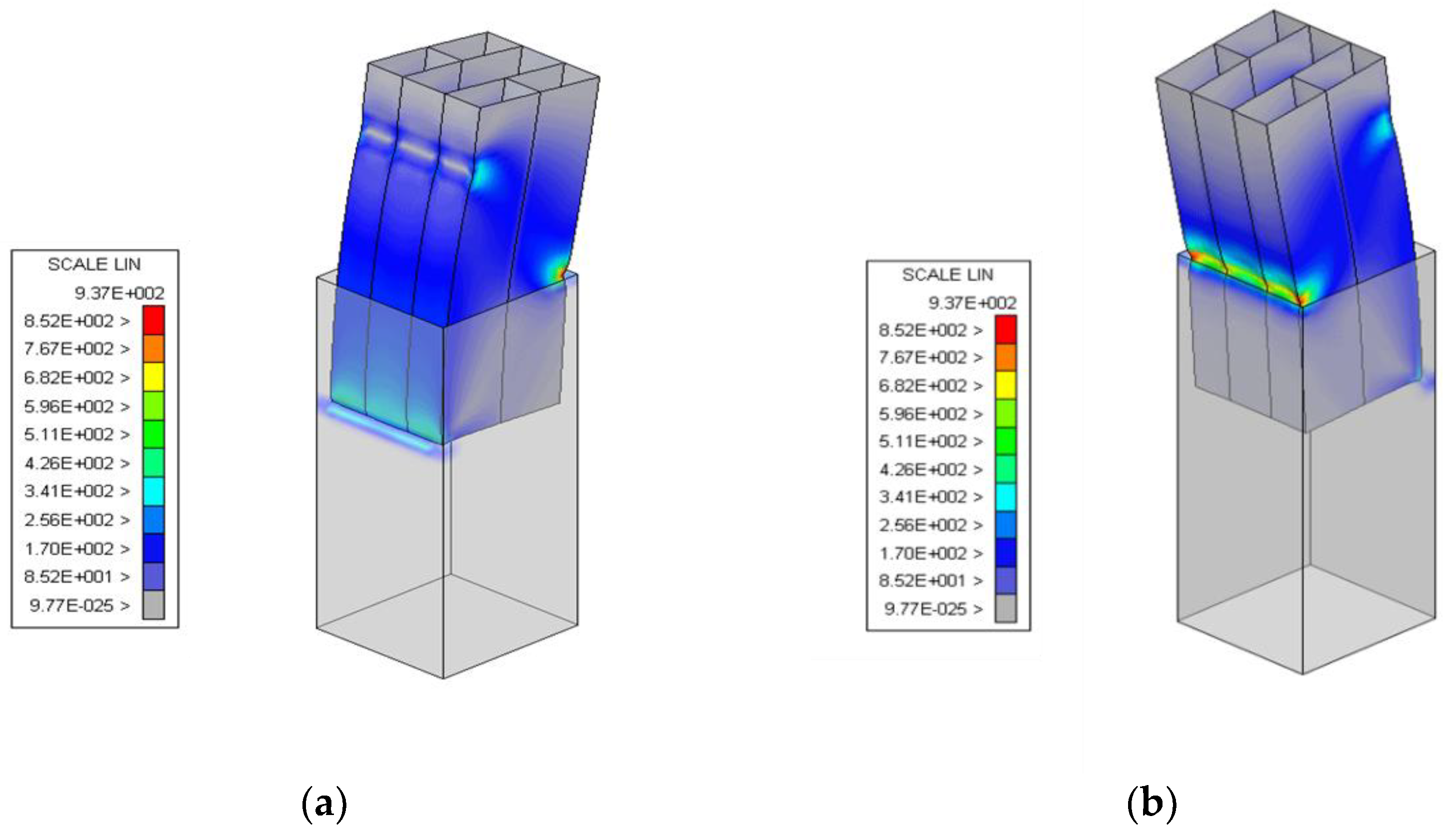

Finite element analysis was performed to evaluate the capability of the alternative obstacle. As illustrated in

Figure 4, the basic design was obtained by considering the requirements.

To develop the FE model, the authors, as consulted by military experts in the field, concluded that applying a static analysis within the current research scope was more suitable and sufficient. This is because it is expected that the mechanical behaviors and environments for the subjugation of obstacles are hardly involved with hard-impact or explosive effects. The enemy’s tanks would not utilize the explosive effect from their cannons to subjugate obstacles since the launch angle does not cover the low-height range where the obstacles are located. In addition, it is expected that the tanks would not rush into obstacles, risking self-damage. As the experts have advised, the subjugation will be cautiously tried by pulling over the obstructions with each tank’s maximum torque to push, which can be sufficiently expressed by the static analysis. For the finite element analysis, the main body used a shell element of 30 mm × 30 mm in size. The main body was modeled to be 50 mm in thickness and could move freely in the x, y, and z directions. The steel housing provided a space for the bollard body to rise and had flexural resistance against towing. The steel housing was modeled to use a steel plate with 40 mm thickness as a shell element and to be 30 mm × 30 mm in element size. As for the boundary condition of the steel housing, the x, y, and z directions were modeled as fixed conditions. That is, the steel housing was modeled to be firmly installed into the ground. The passive earth pressure caused by the towing of a tank was assumed to be sufficient to prevent deformation.

The modeling also assumed that the enemy tank had a towing force of 70 tons, and this power was generated at a contact point 1 m above the ground. The force corresponding to the maximum towing force of the enemy’s tanks was applied in the analysis, which was implemented as a static load. The towing force was converted into pressure units under the assumption that the contact surface of the tank was 300 mm × 10 mm. The force was applied to the bollard body in increments of 1 ton until plastic deformation.

Table 3 presents the material properties used in the finite element model.

The finite element analysis showed that the proposed anti-tank bollard started yielding a load of 169 tons and underwent tensile failure at a load of 307 tons. As verified by the finite element analysis, the proposed bollard had plastic deformation at a load more than twice the one under the initial assumption that it was pulled by the 70 tons-towing force of the enemy tank. Accordingly, even if the uncertainty of military operations is considered, the safety factor secured was more than doubled. Therefore, the proposed anti-tank bollards were evaluated to satisfactorily replace the existing rock drop obstacles. Moreover, the maximum stress at a load of 169 tons was 1.3 MPa.

Figure 5 shows the results of the finite element analysis.

Based on the finite element analysis, it was clear that the minimum pullout resistance against an enemy tank was satisfied by replacing rock drops with anti-tank bollards. However, unlike the existing rock drop, a single row of bollards has a limitation in securing a 30 min check in nontactical situations. Considering damage by explosion apart from the pullout, battle commanders stated that it is tactically necessary to apply at least five rows in order to achieve a minimum 30 min delay. Based on their opinion, this study suggests an anti-tank bollard system, as shown in

Figure 6.

4. Assessment of Sustainability Impact

The Organization for Economic Cooperation and Development (OECD) introduced the concept of sustainability with respect to project management [

7]. Sustainability includes sustainability assessment, especially in the decision-making stage of a project. Moreover, it is applicable to every field as sustainability encompasses not only policy-making but also the planning, scheduling, and implementation of a project [

8,

9]. As shown in

Figure 7, the sustainability assessment is based on the impacts on three main areas: economy, environment, and society [

10,

11].

Unfortunately, social and environmental impacts are very difficult to standardize [

12]. There is no analysis method for accurately evaluating the impact of military operations on sustainability. Nevertheless, this study attempted to optimize the use of energy, water, and other materials indispensable to military actions and to analyze the social and environmental cost of obstacles [

13,

14,

15]. In this regard, if an obstacle model could generate social, environmental, and economic benefits, it will be an exemplary model for future sustainable military operations [

16,

17,

18,

19].

For the sustainability impact assessment of the alternative obstacle, its environmental impact was first examined. The CO

2 emission was mainly considered to quantify and compare the original and the suggested obstacles [

20]. The existing rock drop is a huge concrete structure that uses a large amount of concrete. The reduction in concrete usage has a significant effect on sustainability awareness and green planning [

21]. According to the survey of the International Energy Agency and United Nations (UN) Environment Programme, the sector of building construction and operations accounted for 36% of the global energy use and 36% of carbon dioxide (CO

2) emissions from energy consumption in 2017 [

22]. The usage of concrete and reinforcement steel has such a great environmental impact that it occupies 65% of construction-related greenhouse gas (GHG) emissions. In the GHG emissions, approximately 40% of CO

2 emissions are attributable to the use of concrete [

23]. In addition, the mean embodied carbon dioxide (ECO2) from buildings is approximately 340 kg-CO

2/m

2, which accounts for approximately 60% of building structures [

24]. In other words, a decrease in the use of concrete for structures can result in a decrease in ECO2 and GHG emissions. This implies that the reduction in concrete materials and reinforcement steel in the construction planning and building stages has a significant impact on the carbon footprint, that is, sustainability [

25,

26,

27,

28,

29].

The advantage of the new alternative obstacle with respect to its effectiveness in sustainability in terms of CO

2 emissions was analyzed.

Table 4 presents the analysis result of CO

2 emissions, focusing on how advantageous the new obstacle is compared with the rock drop obstacle system. CO

2 emissions were analyzed under the assumption that one obstacle system consisting of eight rock drops was replaced by anti-tank bollards. For the analysis, the CO

2 emissions of ready-mixed concrete were converted to 3.152 ton-CO

2/ton and those of steel plates were converted to 3.466 ton-CO

2/ton [

30]. Consequently, approximately 3475.81 tons of CO

2 emissions could be reduced in each obstacle system. This corresponded to a 99.2% reduction in CO

2 emissions in each rock drop obstacle system. As the existing rock drop obstacles were constructed at least 60 years ago and its aging has accelerated, if 100 rock drop obstacle systems are replaced in the nearby regions of Seoul in which traffic volumes are ever increasing, then 347,581 tons of CO

2 emissions could be reduced. If the Korean carbon transaction price of USD 50/ton-CO

2 [

31] is applied, the reduction corresponds to total cost savings of USD 17,379,050.

As the existing rock drop obstacles are installed on major roads leading to Seoul, they frequently cause traffic congestion and accidents. Accordingly, the further contribution of obstacles with respect to economic and social aspects can be estimated. In particular, it is necessary to additionally consider the vehicle operation and time value costs incurred by rock drops with respect to traffic congestion cost. As the traffic congestion cost in Seoul is estimated to be approximately USD 5.4 million, the replacement of rock drop obstacles with alternatives will have a significant effect. A future study needs to address this matter.

5. Conclusions

As traffic volumes are ever-increasing and road networks continue to expand due to the continuous population growth and urbanization in cities near Seoul, an increasing number of civil complaints are being filed concerning rock drop obstacles that are installed to hinder the advance of tanks and mechanized enemy units. In particular, many of the rock drop obstacles have been constructed in bottleneck areas for military purposes. For this reason, local governments and residents complain that the obstacles cause traffic accidents and bottleneck situations and degrade the urban landscape. However, when local governments have discussions on the relocation and replacement of rock drop obstacles, they have difficulty determining the effectiveness of the obstacles as a military facility, and no firm criterion for such a discussion has been established. As a result, a local government and its counterpart handle each case according to different procedures and criteria.

Accordingly, this study surveyed the opinions of commanders in order to examine the effectiveness of rock drop obstacles. It became apparent that the rock drop obstacles were no longer an indispensable tactical option for interrupting the maneuver of tanks and mechanized enemy units and for protecting our country because of the advancement of weapon systems and new concepts of operations. Moreover, the commanders preferred mobile obstacles to rock drop-type stationary obstacles. They also demanded that such alternative obstacles should be eco-friendly and have minimal impact on road traffic.

This study designed an anti-tank bollard and examined its effectiveness as an obstacle through a finite element analysis while considering the above requirements. The proposed anti-tank bollard was resistant to 140 tons, which is twice the towing force of an enemy tank. When one obstacle system composed of eight rock drops was replaced by the new obstacle system, CO2 emissions could be reduced by 99.2% over the entire construction process. If 100 aged rock drop obstacle systems are replaced, then approximately 347,581 tons of CO2 emissions can be reduced. This result would correspond to total cost savings of USD 17,379,050 if the Korean carbon transaction price of USD 50/ton-CO2 is applied.

Within the limitations that real battle experiments were not performed, the capability of the newly derived anti-tank obstacle has been explored using a finite element analysis, which finally showed its applicability. In future research, experiments using the current model will be implemented to verify its obtained adequacy. Nevertheless, the devised anti-tank obstacle of bollards must be adopted and continuously developed with the agreement that the old rock drops must be converted or reconstructed with the consideration of sustainability and civil-military cooperation.

Author Contributions

Conceptualization, S.P. and K.K.; methodology, K.K.; software, Y.J.; validation, S.P. and K.K.; formal analysis, K.K.; investigation, Y.J.; resources, Y.-J.P.; data curation, K.K.; writing—original draft preparation, Y.J.; writing—review and editing, Y.-J.P.; visualization, K.K.; supervision, Y.-J.P.; project administration, S.P. and Y.J.; funding acquisition, Y.-J.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by a grant (22SCIP-C146652-05) from the Korea Agency for Infrastructure Technology Advancement.

Acknowledgments

This work was supported by the research fund of the Korea Agency for Infrastructure Technology Advancement.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of this study; in the collection, analyses, or interpretation of the data; in writing the manuscript; or in the decision to publish the results.

References

- Freedman, L.; Karsh, E. How Kuwait Was Won: Strategy in the Gulf War. In The Iraqi Aggression Against Kuwait; Routledge: London, UK, 2019; pp. 67–104. [Google Scholar]

- Kanagarai, B.; Kiran, T.; Anand, N.; Al Jabri, K.; Justin, S. Development and strength assessment of eco-friendly geopolymer concrete made with natural and recycled aggregates. Constr. Innov. 2022. ahead of print. [Google Scholar] [CrossRef]

- Sev, A. How can the construction industry contribute to sustainable development? A conceptual framework. Sustain. Dev. 2009, 17, 161–173. [Google Scholar] [CrossRef]

- Spence, R.; Mulligan, H. Sustainable development and the construction industry. Habitat Int. 1995, 19, 279–292. [Google Scholar] [CrossRef]

- Kim, K.; Park, Y. Development of Design Considerations as a Sustainability Approach for Military Protective Structures: A Case Study of Artillery Fighting Position in South Korea. Sustainability 2020, 12, 6479. [Google Scholar] [CrossRef]

- Palasiewicz, T.; Kyjovsky, J. Criteria Determination for Obstacle Effectiveness Evaluation. In International Conference Knowledge-Based Organization; University of Defense: Brno, Czech Republic, 2017; Volume 13, p. 1. [Google Scholar]

- OECD. Principles for Evaluation of Development Assistance; Development Assistance Committee (DAC), OECD: Paris, France, 1991. [Google Scholar]

- Bond, A.; Morrison-Saunders, A.; Pope, J. Sustainability Assessment: The State of the Art; Impact Assess Project Appraisal; Taylor & Francis: Abingdon, UK, 2012; Volume 30, pp. 53–62. [Google Scholar]

- Morrison-Saunders, A.; Pope, J. Conceptualising and Managing Trade-Offs in Sustainability Assessment. Environ. Impact Assess. Rev. 2013, 38, 54–63. [Google Scholar] [CrossRef]

- Hofstetter, P. The value debate: Ecodesign in a global context—Are there differences in global values and do they matter? Int. J. Life Cycle Anal. 2002, 7, 62–63. [Google Scholar] [CrossRef]

- Schmidt, W.-P.; Sullivan, J. The value debate: Weighting of life cycle assessments in a global context: Global diversity exists and has to be valued. Int. J. Life Cycle Anal. 2002, 7, 250. [Google Scholar] [CrossRef]

- Heinzerling, L.; Ackerman, F. Pricing the Priceless—Cost Benefit Analysis of Environmental Protection; Georgetown Environmental Law and Policy Institute, Georgetown University Law Centre: Washington, DC, USA, 2002. [Google Scholar]

- Shapiro, J.M. Smart cities: Quality of life, productivity, and the growth effects of human capital. Rev. Econ. Stat. 2006, 88, 324–335. [Google Scholar] [CrossRef]

- Smart Cities: Governing, Modelling and Analyzing the Transition; Deakin, M., Ed.; Routledge: Abingdon, UK, 2013; pp. 1–236. [Google Scholar]

- Pereira, Â.G.; Quintana, S.C. From technocratic to participatory decision support systems: Responding to the new governance initiatives. J. Geogr. Inf. Decis. Anal. 2002, 6, 95–107. [Google Scholar]

- Komninos, N. Intelligent Cities: Innovation, Knowledge Systems and Digital Spaces; Routledge: Abingdon, UK, 2013; pp. 1–320. [Google Scholar]

- Dalkey, N.C. The Delphi Method; An Experimental Study of Group Opinion; RM-5888-PR.; The Rand Corp.: Santa Monica, CA, USA, 1969. [Google Scholar]

- Thompson, B. Exploratory and Confirmatory Factor Analysis: Understanding Concepts and Applications; American Psychological Association: Washington, DC, USA, 2004. [Google Scholar]

- Cattell, R.B. The Screen Test for the Number of Factors. Multivar. Behav. Res. 2010, 1, 245–276. [Google Scholar] [CrossRef] [PubMed]

- Fernández, Y.F.; López, M.A.F.; Blanco, B.O. Innovation for sustainability: The impact of R&D spending on CO2 emissions. J. Clean. Prod. 2018, 172, 3459–3467. [Google Scholar] [CrossRef]

- Kim, J.J.; Goodwin, C.W.; Kim, S.K. Communication Turns green construction planning into reality. J. Green Build. 2017, 12, 168–186. [Google Scholar] [CrossRef]

- International Energy Agency and the United Nations Environment Programme. 2018 Global Status Report: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction sector. 2018, p. 9. Available online: https://www.worldgbc.org/sites/default/files/2018%20GlobalABC%20Global%20Status%20Report.pdf (accessed on 27 January 2021).

- Pacheco-Torgal, F.; Cabeza, L.; Labrincha, J.; De Magalhaes, A. Eco Efficient Construction and Building Materials: Life Cycle Assessment (LCA), Eco-Labelling and Case Studies; Elsevier: Cambridge, UK, 2014; pp. 624–630. [Google Scholar]

- Clark, D.; Bradley, D. Information Paper—31: Embodied Carbon of Steel Versus Concrete Buildings; Cundall Johnston and Partners LLP: Newcastle, UK, 2013; p. 4. [Google Scholar]

- Lee, I.J.; Yu, H.; Chan, S.L. Carbon Footprint of Steel-Composite and Reinforced Concrete Buildings, Standing Committee on Concrete Technology Annual Concrete Seminar 2016, Hong Kong, 20 April 2016. Construction Industry Council. Available online: https://www.devb.gov.hk/filemanager/en/content_971/7_Carbon_Footprint_for_Steel_Composite_and_Reinforced_Concrete_Buildings.pdf (accessed on 27 January 2021).

- Kim, S.K.; Kim, M.H. A Study on the development of the optimization algorithm to minimize the loss of reinforcement bars. J. Archit. Inst. Korea 1991, 7, 385–390. [Google Scholar]

- Lee, D.H.; Lee, S.G.; Kim, S.K. Composite phase-change material mold for cost-effective production of free-from concrete panels. J. Constr. Eng. Manag. 2017, 143, 04017012. [Google Scholar] [CrossRef]

- Kim, S.K.; Hong, W.K.; Joo, J.K. Algorithms for reducing the waste rate of reinforcement bars. J. Asian Archit. Build. 2004, 3, 17–23. [Google Scholar] [CrossRef]

- Hwang, J.W.; Park, C.J.; Wang, S.K.; Choi, C.H.; Lee, J.H.; Park, H.W. A Case Study on the Cost Reduction of the Rebar Work through the Bar Loss Minimization. In Proceedings of the KIBIM Annual Conference 2012, Seoul, Korea, 19 May 2012. [Google Scholar]

- Korea Institute of Construction Technology (KICT). The Environmental Load Unit Composition and Program Development for LCA of Building, The Second Annual Report of the Construction Technology R&D Program. 2004. Available online: http://www.ndsl.kr/ndsl/search/detail/report/reportSearchResultDetail.do?cn=TRKO201000018952 (accessed on 27 January 2021).

- CDP Worldwide. Carbon Pricing Connect. Available online: https://www.cdp.net/en/climate/carbon-pricing/carbon-pricing-connect (accessed on 30 August 2020).

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).