Exploring the Role of BIM in Construction Safety in Developing Countries: Toward Automated Hazard Analysis

Abstract

:1. Introduction

2. Literature Review

2.1. BIM Implementation

2.2. BIM Application in Safety Management

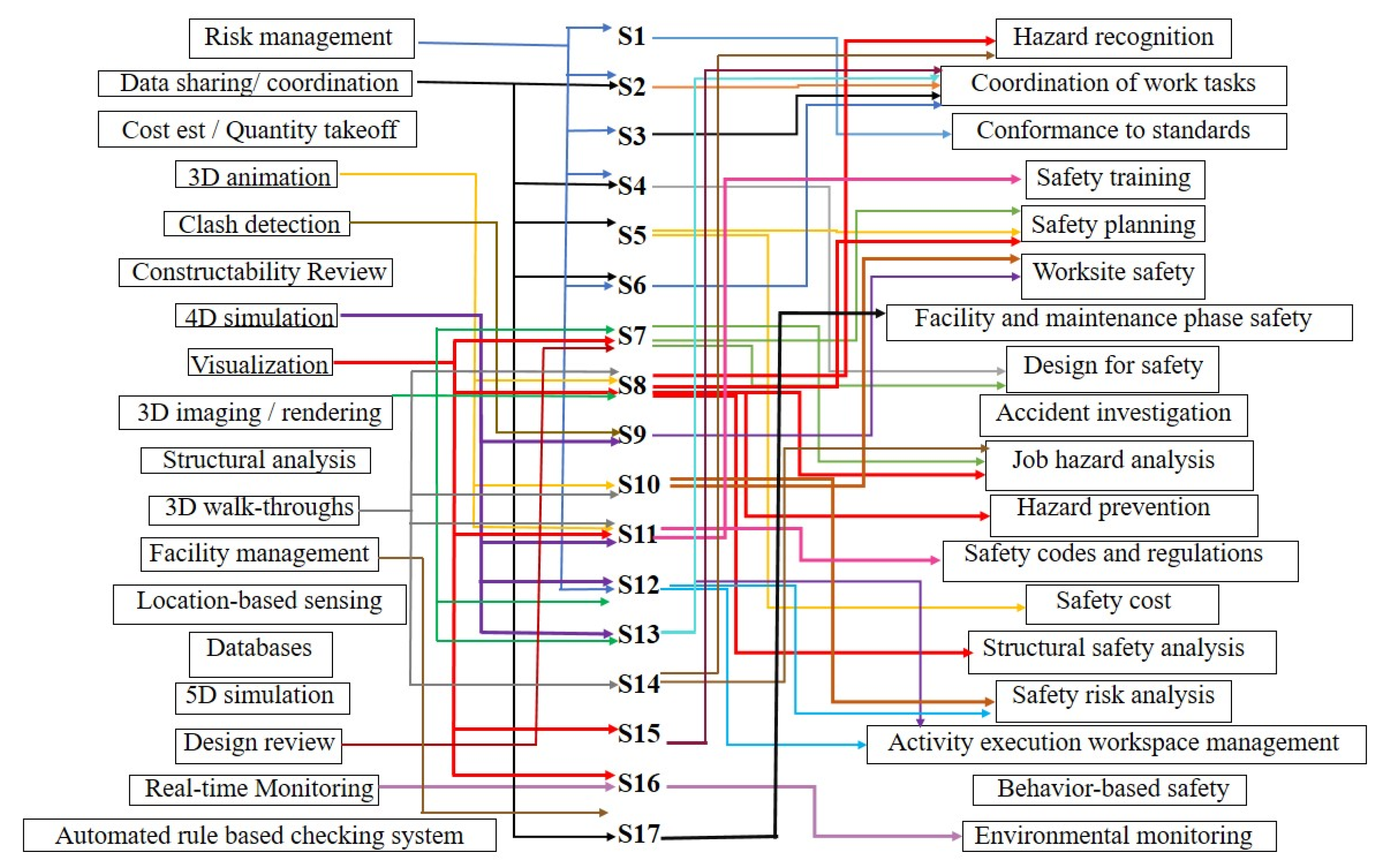

2.3. Synthesis of Safety Factors and BIM Features

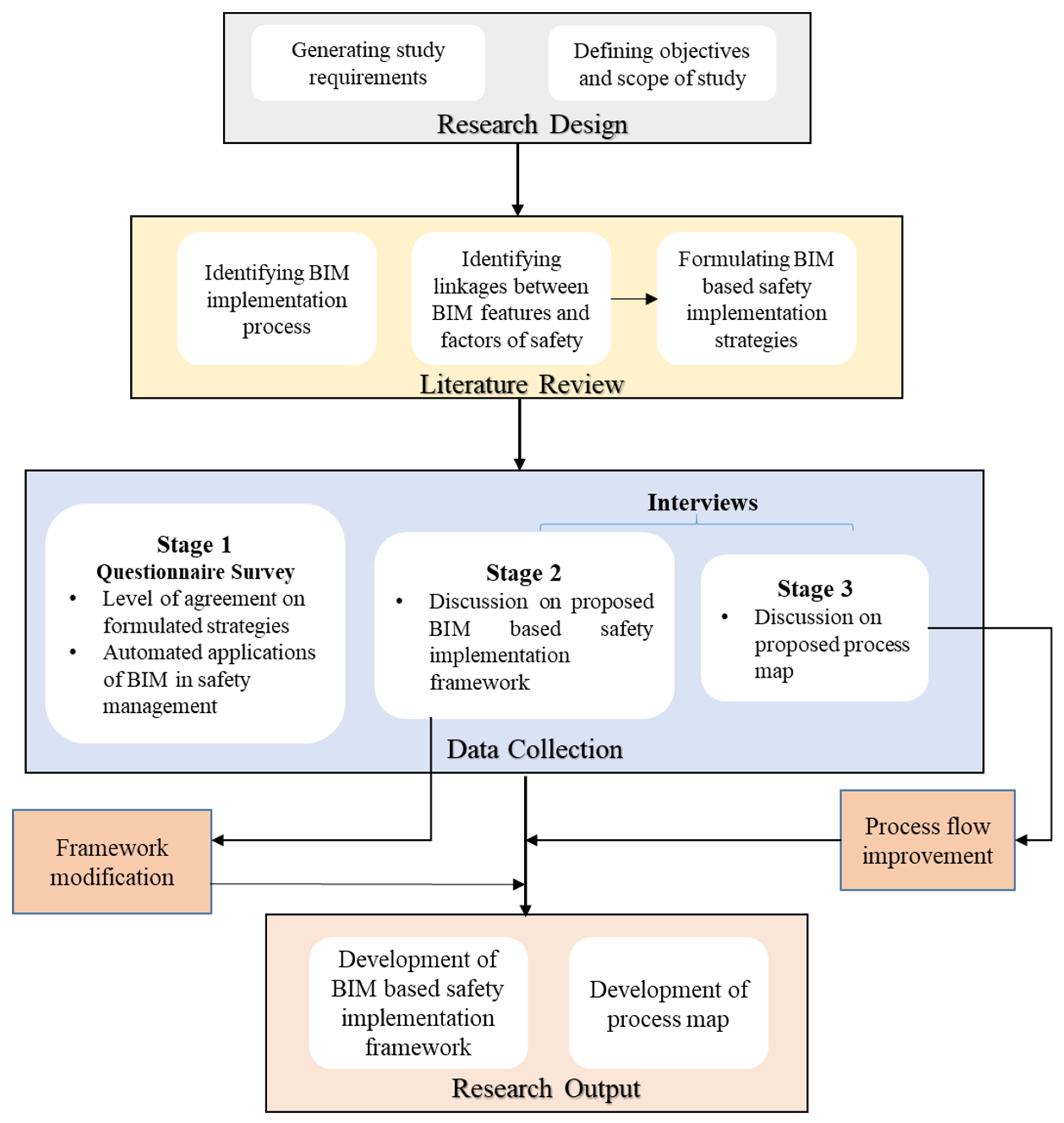

3. Methodology

3.1. Research Motivation and Design

3.2. Literature Review

3.3. Data Collection and Analysis

3.4. Research Output

4. Results and Discussion

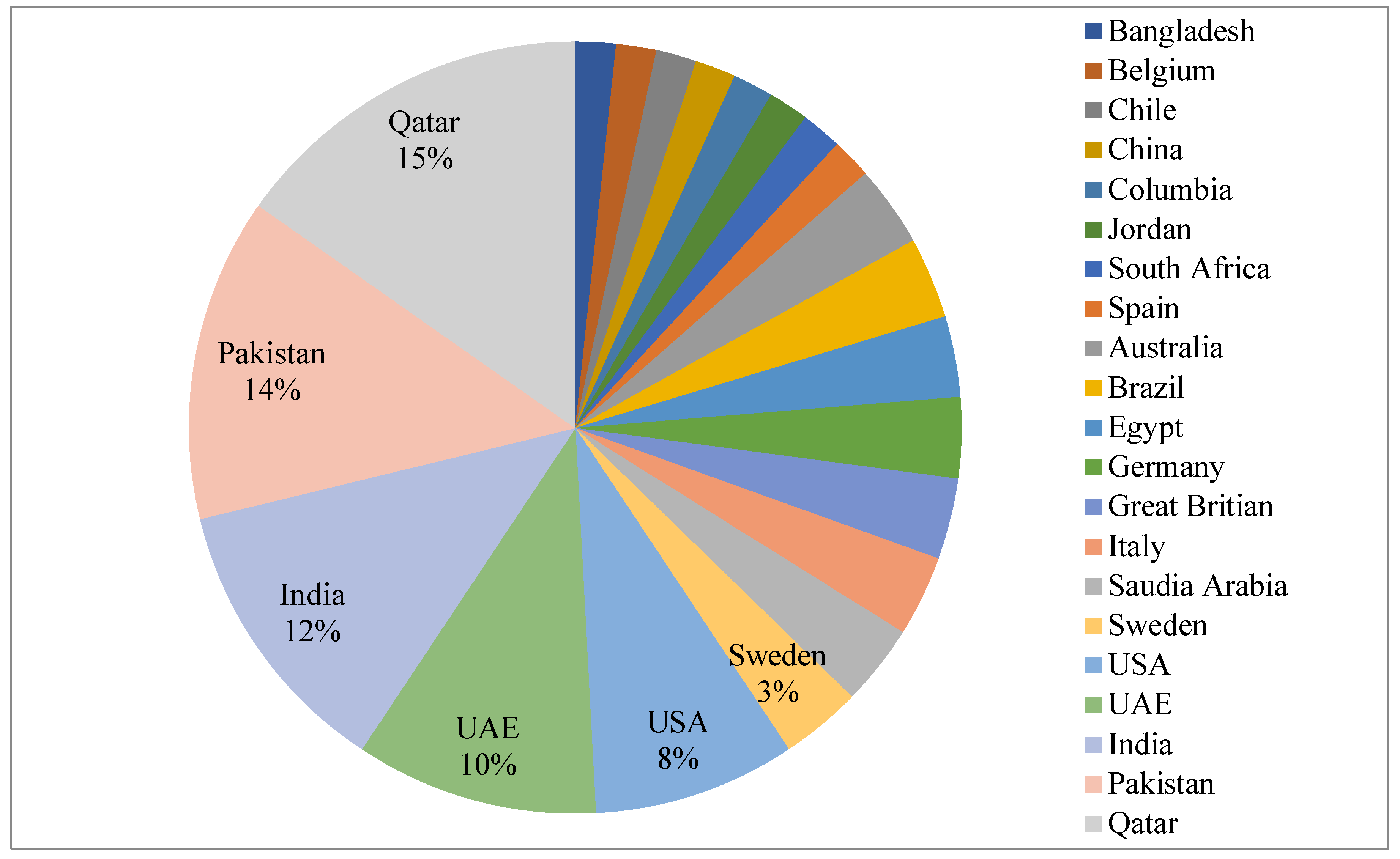

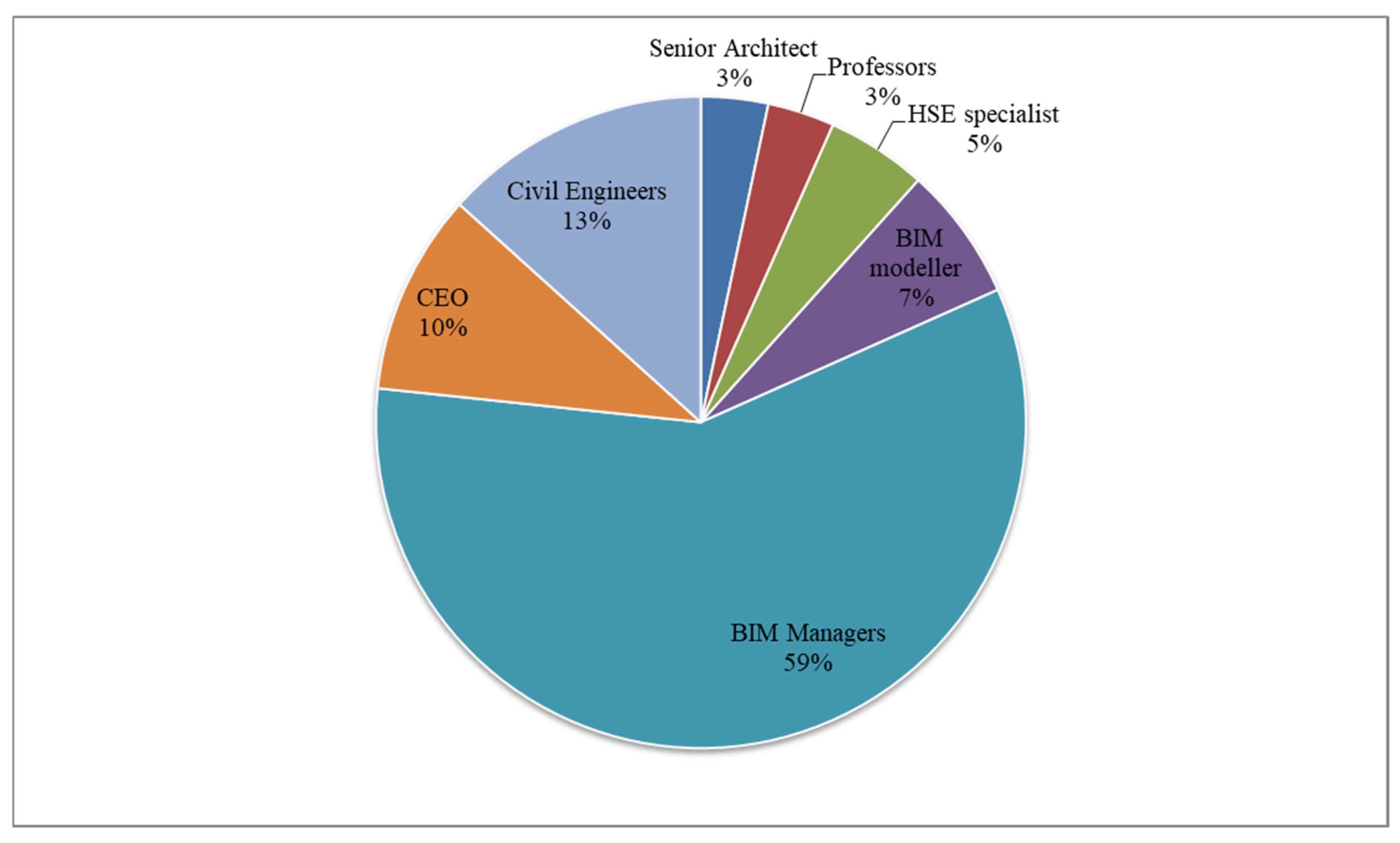

4.1. Demographic Information

4.2. Safety Management Strategies

4.3. Statistical Analysis

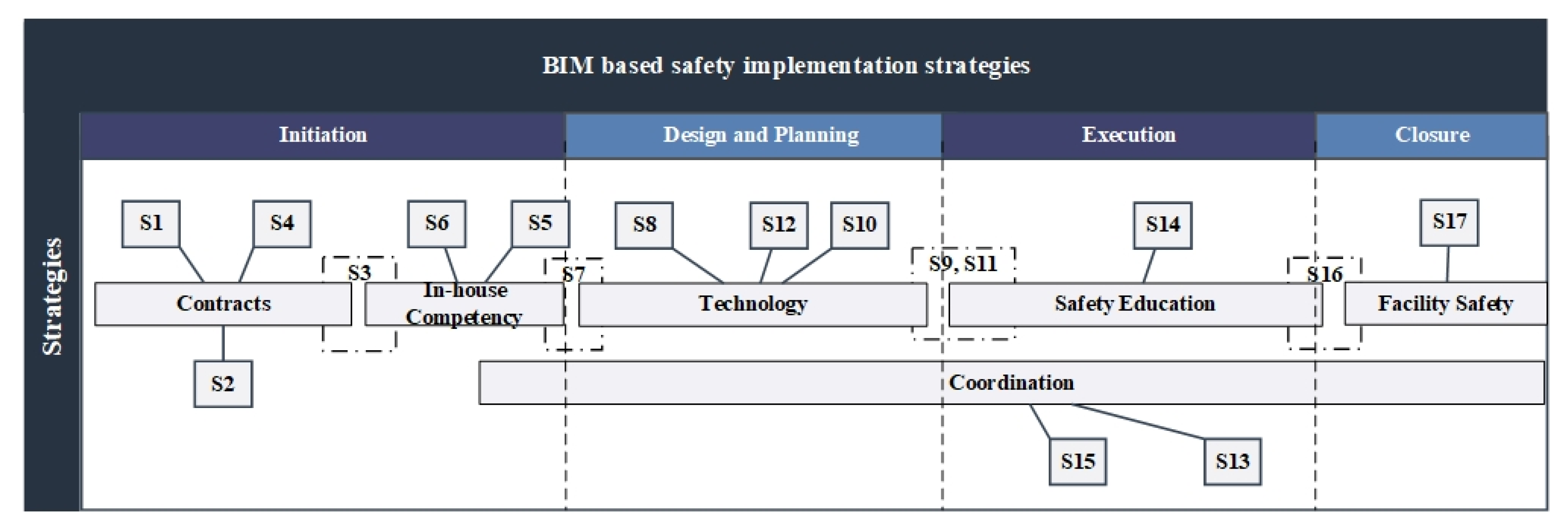

4.4. Safety Implementation Framework for Project Lifecycle

4.4.1. Project Initiation

4.4.2. Project Design and Planning

4.4.3. Project Execution

4.4.4. Project Closure

5. Realization of Hazard Identification Process

Automated Hazard Identification Process Map

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhou, Z.; Goh, Y.M.; Li, Q. Overview and analysis of safety management studies in the construction industry. Saf. Sci. 2015, 72, 337–350. [Google Scholar] [CrossRef]

- Enshassi, A.; Ayyash, A.; Choudhry, R.M. BIM for construction safety improvement in Gaza strip: Awareness, applications and barriers. Int. J. Constr. Manag. 2016, 16, 249–265. [Google Scholar] [CrossRef]

- Safe Work Australia. Safe Work Australia. 2016. Available online: https://www.safeworkaustralia.gov.au/system/files/documents/1702/safe-work-australia-annual-report-2015-16.pdf (accessed on 4 May 2022).

- Bureau of Labor Statistics. United States Department of Labor. Available online: https://www.bls.gov/ (accessed on 5 May 2022).

- Awwad, R.; El Souki, O.; Jabbour, M. Construction safety practices and challenges in a Middle Eastern developing country. Saf. Sci. 2016, 83, 1–11. [Google Scholar] [CrossRef]

- Zahoor, H.; Chan, A.P.; Gao, R.; Utama, W.P. The factors contributing to construction accidents in Pakistan. Eng. Constr. Archit. Manag. 2017, 24, 463–485. [Google Scholar] [CrossRef]

- Malik, Q.; Nasir, A.R.; Muhammad, R.; Thaheem, M.J.; Ullah, F.; Khan, K.I.A.; Hassan, M.U. BIMp-Chart—A Global Decision Support System for Measuring BIM Implementation Level in Construction Organizations. Sustainability 2021, 13, 9270. [Google Scholar] [CrossRef]

- Eadie, R.; Browne, M.; Odeyinka, H.; McKeown, C.; McNiff, S. BIM implementation throughout the UK construction project lifecycle: An analysis. Autom. Constr. 2013, 36, 145–151. [Google Scholar] [CrossRef]

- Ahmad, Z.; Thaheem, M.J.; Maqsoom, A. Building information modeling as a risk transformer: An evolutionary insight into the project uncertainty. Autom. Constr. 2018, 92, 103–119. [Google Scholar] [CrossRef]

- Marefat, A.; Toosi, H.; Hasankhanlo, R.M. A BIM approach for construction safety: Applications, barriers and solutions. Eng. Constr. Archit. Manag. 2019, 26, 1855–1877. [Google Scholar] [CrossRef]

- Rodrigues, F.; Estrada, J.; Antunes, F.; Swuste, P. Safety through Design: A BIM-Based Framework; Springer: Cham, Switzerland, 2018; pp. 112–123. [Google Scholar]

- Akram, R.; Thaheem, M.J.; Nasir, A.R.; Ali, T.H.; Khan, S. Exploring the role of building information modeling in construction safety through science mapping. Saf. Sci. 2019, 120, 456–470. [Google Scholar] [CrossRef]

- Park, C.-S.; Kim, H.-J. A framework for construction safety management and visualization system. Autom. Constr. 2013, 33, 95–103. [Google Scholar] [CrossRef]

- Azhar, S. Role of visualization technologies in safety planning and management at construction jobsites. Procedia Eng. 2017, 171, 215–226. [Google Scholar] [CrossRef]

- Arayici, Y.; Coates, P.; Koskela, L.; Kagioglou, M.; Usher, C.; O’Reilly, K. BIM adoption and implementation for architectural practices. Struct. Surv. 2011, 29, 7–25. [Google Scholar] [CrossRef] [Green Version]

- Gu, N.; London, K. Understanding and facilitating BIM adoption in the AEC industry. Autom. Constr. 2010, 19, 988–999. [Google Scholar] [CrossRef]

- Sami Ur Rehman, M.; Thaheem, M.J.; Nasir, A.R.; Khan, K.I.A. Project schedule risk management through building information modelling. Int. J. Constr. Manag. 2020, 22, 1489–1499. [Google Scholar] [CrossRef]

- Khosrowshahi, F.; Arayici, Y. Roadmap for implementation of BIM in the UK construction industry. Eng. Constr. Archit. Manag. 2012, 19, 610–635. [Google Scholar] [CrossRef] [Green Version]

- Kouch, A.M.; Illikainen, K.; Perälä, S. Key Factors of an Initial BIM Implementation Framework for Small and Medium-Sized Enterprises (SMEs). In Proceedings of the ISARC—International Symposium on Automation and Robotics in Construction, Berlin, Germany, 20–25 July 2018; pp. 1–9. [Google Scholar]

- Arshad, M.F.; Thaheem, M.J.; Nasir, A.R.; Malik, M.S.A. Contractual Risks of Building Information Modeling: Toward a Standardized Legal Framework for Design-Bid-Build Projects. J. Constr. Eng. Manag. 2019, 145, 04019010. [Google Scholar] [CrossRef]

- Olanrewaju, O.I.; Chileshe, N.; Babarinde, S.A.; Sandanayake, M. Investigating the barriers to building information modeling (BIM) implementation within the Nigerian construction industry. Eng. Constr. Archit. Manag. 2020, 27, 2931–2958. [Google Scholar] [CrossRef]

- Hire, S.; Sandbhor, S.; Ruikar, K.; Amarnath, C. BIM usage benefits and challenges for site safety application in Indian construction sector. Asian J. Civ. Eng. 2021, 22, 1249–1267. [Google Scholar] [CrossRef]

- Chan, Y.; Leung, H.; Fung, W.; Leung, M. How can BIM support construction safety management? Development of SIM. In Proceedings of the MATEC Web of Conferences, Kuala Lumpur, Malaysia, 7–8 March 2016. [Google Scholar]

- Zhang, S.; Boukamp, F.; Teizer, J. Ontology-based semantic modeling of safety management knowledge. In Proceedings of the 2014 International Conference on Computing in Civil and Building Engineering, American Society of Civil Engineers, Orlando, FL, USA, 23–25 June 2014; pp. 2254–2262. [Google Scholar]

- Zhang, S.; Sulankivi, K.; Kiviniemi, M.; Romo, I.; Eastman, C.M.; Teizer, J. BIM-based fall hazard identification and prevention in construction safety planning. Saf. Sci. 2015, 72, 31–45. [Google Scholar] [CrossRef]

- Rüppel, U.; Schatz, K. Designing a BIM-based serious game for fire safety evacuation simulations. Adv. Eng. Inform. 2011, 25, 600–611. [Google Scholar] [CrossRef]

- Zulkifli, M.H.; Takim, R.; Nawawi, A.H. A proposed initial framework of ASRC system for BIM-based projects in Malaysia. J. Teknol. 2016, 78, 61–67. [Google Scholar] [CrossRef]

- Wetzel, E.M.; Thabet, W.Y. The use of a BIM-based framework to support safe facility management processes. Autom. Constr. 2015, 60, 12–24. [Google Scholar] [CrossRef] [Green Version]

- Azhar, S.; Behringer, A. A BIM-based approach for communicating and implementing a construction site safety plan. In Proceedings of the 49th ASC Annual International Conference Proceedings, San Luis, CA, USA, 10–13 April 2013. [Google Scholar]

- Hayne, G.; Kumar, B.; Hare, B. The development of a framework for a design for safety BIM tool. In Computing in Civil and Building Engineering (2014); American Society of Civil Engineers: Reston, VA, USA, 2014; pp. 49–56. [Google Scholar]

- Zhang, S.; Teizer, J.; Lee, J.-K.; Eastman, C.M.; Venugopal, M. Building information modeling (BIM) and safety: Automatic safety checking of construction models and schedules. Autom. Constr. 2013, 29, 183–195. [Google Scholar] [CrossRef]

- Getuli, V.; Capone, P.; Bruttini, A. Planning, management and administration of HS contents with BIM and VR in construction: An implementation protocol. Eng. Constr. Archit. Manag. 2020, 28, 603–623. [Google Scholar] [CrossRef]

- Akram, R.; Thaheem, M.J.; Khan, S. Hazard Identification in Construction Safety: A Visualization-based Approach. In Proceedings of the Technological Transformation of Civil Engineering, 10th International Civil Engineering Conference (ICEC-2019), Karachi, Pakistan, 23–24 February 2019. [Google Scholar]

- Golparvar-Fard, M.; Peña-Mora, F.; Arboleda, C.A.; Lee, S. Visualization of construction progress monitoring with 4D simulation model overlaid on time-lapsed photographs. J. Comput. Civ. Eng. 2009, 23, 391–404. [Google Scholar] [CrossRef] [Green Version]

- Afzal, M.; Shafiq, M.T. Evaluating 4D-BIM and VR for effective safety communication and training: A case study of multilingual construction job-site crew. Buildings 2021, 11, 319. [Google Scholar] [CrossRef]

- Arif, M.; Nasir, A.R.; Thaheem, M.J.; Khan, K.I.A. ConSafe4All: A framework for language friendly safety training modules. Saf. Sci. 2021, 141, 105329. [Google Scholar] [CrossRef]

- Kim, H.; Lee, H.-S.; Park, M.; Chung, B.; Hwang, S. Automated hazardous area identification using laborers’ actual and optimal routes. Autom. Constr. 2016, 65, 21–32. [Google Scholar] [CrossRef]

- Ikpe, E.; Hammon, F.; Oloke, D. Cost-benefit analysis for accident prevention in construction projects. J. Constr. Eng. Manag. 2012, 138, 991–998. [Google Scholar] [CrossRef]

- Clevenger, C.; Lopez del Puerto, C.; Glick, S. Interactive BIM-Enabled Safety Training Piloted in Construction Education. Adv. Eng. Educ. 2015, 4, n3. [Google Scholar]

- Benjaoran, V.; Bhokha, S. An integrated safety management with construction management using 4D CAD model. Saf. Sci. 2010, 48, 395–403. [Google Scholar] [CrossRef]

- Cheng, T.; Teizer, J. Real-time resource location data collection and visualization technology for construction safety and activity monitoring applications. Autom. Constr. 2013, 34, 3–15. [Google Scholar] [CrossRef]

- Zhang, S.; Teizer, J.; Pradhananga, N.; Eastman, C.M. Workforce location tracking to model, visualize and analyze workspace requirements in building information models for construction safety planning. Autom. Constr. 2015, 60, 74–86. [Google Scholar] [CrossRef]

- Li, H.; Chan, G.; Wong, J.K.W.; Skitmore, M. Real-time locating systems applications in construction. Autom. Constr. 2016, 63, 37–47. [Google Scholar] [CrossRef] [Green Version]

- Asadzadeh, A.; Arashpour, M.; Li, H.; Ngo, T.; Bab-Hadiashar, A.; Rashidi, A. Sensor-based safety management. Autom. Constr. 2020, 113, 103128. [Google Scholar] [CrossRef]

- Dong, S.; Li, H.; Yin, Q. Building information modeling in combination with real time location systems and sensors for safety performance enhancement. Saf. Sci. 2018, 102, 226–237. [Google Scholar] [CrossRef]

- Mok, K.Y.; Shen, G.Q.; Yang, J. Stakeholder management studies in mega construction projects: A review and future directions. Int. J. Proj. Manag. 2015, 33, 446–457. [Google Scholar] [CrossRef]

- Chong, H.-Y.; Fan, S.-L.; Sutrisna, M.; Hsieh, S.-H.; Tsai, C.-M. Preliminary contractual framework for BIM-enabled projects. J. Constr. Eng. Manag. 2017, 143, 04017025. [Google Scholar] [CrossRef] [Green Version]

- Farooq, M.U.; Thaheem, M.J.; Arshad, H. Improving the risk quantification under behavioural tendencies: A tale of construction projects. Int. J. Proj. Manag. 2018, 36, 414–428. [Google Scholar] [CrossRef]

- Cochran, W.G. Sampling Techniques; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Hafeez, M.A.; Vukovic, V.; Chahrour, R.; Kassem, M.; Dawood, N. Identifying Current BIM Practices in Qatar and Proposing a Framework for Whole Life Cycle BIM Processes. In Proceedings of the Qatar Foundation Annual Research Conference Proceedings, Ar-Rayyan, Qatar, 22–23 March 2016; Volume 2016, p. EEPP3066. [Google Scholar]

- Al Mohannadi, F.; Arif, M.; Aziz, Z.; Richardson, P.A. Adopting BIM standards for managing vision 2030 infrastructure development in Qatar. Int. J. 3-D Inf. Model. 2013, 2, 64–73. [Google Scholar] [CrossRef]

- Ahuja, R.; Sawhney, A.; Jain, M.; Arif, M.; Rakshit, S. Factors influencing BIM adoption in emerging markets–the case of India. Int. J. Constr. Manag. 2020, 20, 65–76. [Google Scholar] [CrossRef]

- Eastman, C.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers and Contractors; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Ding, L.; Zhou, Y.; Akinci, B. Building Information Modeling (BIM) application framework: The process of expanding from 3D to computable nD. Autom. Constr. 2014, 46, 82–93. [Google Scholar] [CrossRef]

- Moon, H.; Dawood, N.; Kang, L. Development of workspace conflict visualization system using 4D object of work schedule. Adv. Eng. Inf. 2014, 28, 50–65. [Google Scholar] [CrossRef]

- Jin, Z.; Gambatese, J.; Liu, D.; Dharmapalan, V. Using 4D BIM to assess construction risks during the design phase. Eng. Constr. Archit. Manag. 2019, 26, 2637–2654. [Google Scholar] [CrossRef]

- Protocol, A.B. AEC (UK) BIM Technology Protocol. 2012. Available online: https://aecuk.files.wordpress.com/2012/09/aecukbimprotocol-v2-0.pdf (accessed on 30 January 2022).

- Construction Industry Council. Building Information Model (BIM) Protocol. CIC/BIM Pro, Standard Protocol for Use in Projects Using Building Information Models; Construction Industry Council: London, UK, 2013. [Google Scholar]

- Eadie, R.; Odeyinka, H.; Browne, M.; McKeown, C.; Yohanis, M. Building information modelling adoption: An analysis of the barriers to implementation. J. Eng. Archit. 2014, 2, 77–101. [Google Scholar]

- Taber, K.S. The use of Cronbach’s alpha when developing and reporting research instruments in science education. Res. Sci. Educ. 2018, 48, 1273–1296. [Google Scholar] [CrossRef] [Green Version]

- Hanusz, Z.; Tarasińska, J. Normalization of the Kolmogorov–Smirnov and Shapiro–Wilk tests of normality. Biom. Lett. 2015, 52, 85–93. [Google Scholar] [CrossRef] [Green Version]

- Ostertagová, E.; Ostertag, O.; Kováč, J. Methodology and Application of the Kruskal-Wallis Test. Appl. Mech. Mater. 2014, 611, 115–120. [Google Scholar] [CrossRef]

- Šiljeg, S.; Milošević, R.; Panđa, L. Public perception of the urban pluvial floods risk-case study of Poreč (Croatia). J. Geogr. Inst. Jovan Cvijic SASA 2022, 72, 147–158. [Google Scholar] [CrossRef]

- Aibinu, A.; Venkatesh, S. Status of BIM adoption and the BIM experience of cost consultants in Australia. J. Prof. Issues Eng. Educ. Pract. 2013, 140, 04013021. [Google Scholar] [CrossRef]

- Sulankivi, K.; Teizer, J.; Kiviniemi, M.; Eastman, C.M.; Zhang, S.; Kim, K. Framework for integrating safety into building information modeling. In Proceedings of the CIB W099 International Conference on “Modelling and Building Health and Safety”, Singapore, 10–11 September 2012; pp. 10–12. [Google Scholar]

- Hadikusumo, B.; Rowlinson, S. Capturing safety knowledge using design-for-safety-process tool. J. Constr. Eng. Manag. 2004, 130, 281–289. [Google Scholar] [CrossRef]

- Zhang, S.; Boukamp, F.; Teizer, J. Ontology-based semantic modeling of construction safety knowledge: Towards automated safety planning for job hazard analysis (JHA). Autom. Constr. 2015, 52, 29–41. [Google Scholar] [CrossRef]

| Reference | Project Lifecycle | Summary | |||

|---|---|---|---|---|---|

| Initiation | Design and Planning | Execution | Closure/O&M | ||

| Azhar and Behringer [29] | ✔ | A framework to explore the advantages of BIM in providing site safety plans and communicating them using 4D simulations and 3D rendering and walkthrough. | |||

| Park and Kim [13] | ✔ | A safety management framework to integrate BIM, AR, location tracking, and game technologies to improve the identification of field safety risks. | |||

| Hayne, Kumar, and Hare [30] | ✔ | An interactive digital teaching tool to educate and disseminate design for safety knowledge using BIM. | |||

| Zhang, Sulankivi, Kiviniemi, Romo, Eastman, and Teizer [25]; Zhang, Teizer, Lee, Eastman, and Venugopal [31] | ✔ | A safety rule-checking system to identify fall-related hazards during the design and planning stage. | |||

| Wetzel and Thabet [28] | ✔ | A framework to support safety maintenance and repair practices through hazard identification, processing the identified data, and rule-based decision-making. | |||

| Zulkifli, Takim, and Nawawi [27] | ✔ | ✔ | A basic theoretical framework for the Malaysian construction industry for automated rule-based checking during the planning and execution phases. | ||

| Getuli, Capone, and Bruttini [32] | ✔ | Standardized protocols using BIM and VR integration for providing safety training to workers on construction sites. | |||

| Factor–Feature Matrix | Features of BIM | 3D Imaging/Rendering | Real-time Monitoring | Clash Detection | 3D Walkthroughs | 4D Simulations | Visualization | Automated Rule-based Checking System | Constructability Review | Facility Management | Location-based Sensing | 3D Animation | Databases | 5D Simulation | Data Sharing/Coordination | Design Review | Structural Analysis | Risk Management | Cost Estimate/Quantity Takeoff |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Factors of Safety | Frequency of Occurrence | ||||||||||||||||||

| Hazard Recognition | Frequency of Occurrence | 3 | 5 | 4 | 2 | 5 | 9 | 6 | 0 | 1 | 3 | 2 | 1 | 0 | 1 | 1 | 1 | 2 | 0 |

| Coordination of Work Tasks | 1 | 1 | 0 | 1 | 2 | 2 | 0 | 0 | 0 | 2 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | |

| Conformance to Standards | 1 | 0 | 0 | 0 | 0 | 1 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | |

| Safety Training | 2 | 1 | 0 | 1 | 0 | 4 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Safety Planning | 1 | 0 | 1 | 0 | 2 | 2 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Worksite Safety | 0 | 2 | 1 | 0 | 2 | 3 | 1 | 0 | 0 | 3 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | |

| Facility and Maintenance Phase Safety | 1 | 0 | 0 | 0 | 0 | 2 | 1 | 0 | 3 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | |

| Design for Safety | 1 | 0 | 1 | 0 | 0 | 2 | 2 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | |

| Accident Investigation | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | |

| Job Hazard Analysis | 0 | 0 | 0 | 0 | 0 | 1 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Hazard Prevention | 1 | 4 | 3 | 0 | 1 | 4 | 4 | 0 | 1 | 3 | 2 | 1 | 0 | 2 | 1 | 1 | 2 | 0 | |

| Safety Codes and Regulations | 0 | 1 | 1 | 0 | 0 | 2 | 5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | |

| Safety Cost | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | |

| Structural Safety Analysis | 1 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 3 | 0 | 0 | ||

| Safety Risk Analysis | 1 | 1 | 2 | 0 | 3 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | |

| Activity Execution Workspace Management | 0 | 1 | 1 | 0 | 1 | 1 | 2 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | |

| Behavior-based Safety | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 1 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Environmental Monitoring | 0 | 1 | 0 | 0 | 1 | 1 | 3 | 0 | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Nature of Organization | Client | Architecture | Contractor | Consulting | Academia |

|---|---|---|---|---|---|

| Response | 5% | 15% | 30% | 42% | 8% |

| Experience | 1–5 | 6–10 | 11–15 | 16–20 | 21 and above |

| Response | 23.30% | 33.33% | 21.66% | 13.33% | 8.33% |

| Qualification | BSc/BEng | MS/MSc | PhD | Others | |

| Response | 53.33% | 35% | 11.67% | 0% | |

| Level of Understanding of BIM | Advanced | Good | Basic | No understanding | |

| Response | 65% | 28.30% | 6.70% | 0% |

| Code | Associated BIM Features | Strategies | Selected References |

|---|---|---|---|

| S1 | Risk Management | Provide BIM-based contracts in the project | [47] |

| S2 | Risk Management, Data Sharing/Coordination | Define BIM goals based on project scope and information exchange procedures | [53] |

| S3 | Risk Management | Set up a BIM team with well-defined tasks (BIM manager, coordinators, and modelers) | [10] |

| S4 | Risk Management, Data Sharing/Coordination | Define strategy for BIM implementation to achieve the scope | [53] |

| S5 | Data Sharing/Coordination | Clarify the cost for tools (BIM) and safety equipment in the early project stages | [10,21] |

| S6 | Risk Management, Data Sharing/Coordination | Hire safety professionals well acquainted with the BIM process and workflow | [10] |

| S7 | 3D Imaging/Rendering, Visualization, Design Review | Generate a preliminary BIM model in the schematic design phase to visualize the project in the early stages | [17,54] |

| S8 | Visualization, 3D Walkthroughs, 3D Animations, 3D Imaging/Rendering | Identify and prevent hazards through BIM-based visualization | [25] |

| S9 | Clash Detection, 4D Simulations | Remove activity timeline conflicts by linking the 3D BIM model with the schedule to improve workspace management for executing activities | [17,55] |

| S10 | 3D Walkthroughs, 3D Animations | Prepare safety evacuation plans for the worksite through BIM | [26] |

| S11 | Visualization, 3D Walkthroughs, 3D Animations, 4D simulations | Provide safety training demonstrating safety concerns using digital models, walkthroughs, and 4D simulations | [14] |

| S12 | 3D Imaging/Rendering, 4D Simulations, Risk Management | Perform appropriate execution planning for high-risk construction activities using 3D models and 4D simulation | [56] |

| S13 | 3D Imaging/Rendering, 4D Simulations, Data Sharing/Coordination | Explain, distribute, and communicate work tasks within the project team in 3D and 4D environments | [10,14] |

| S14 | 3D Walkthroughs | Prepare 3D walkthroughs for hazard identification in congested spaces on a worksite | [14] |

| S15 | Visualization | Deliver BIM-based visual presentations for promoting effective communication throughout the project | [54] |

| S16 | Visualization, Real-time monitoring | Perform safety monitoring through BIM-based visualization | [44] |

| S17 | Data sharing/Coordination | Prepare and disseminate BIM-based safety completion reports to observe and record safety performance | [14] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akram, R.; Thaheem, M.J.; Khan, S.; Nasir, A.R.; Maqsoom, A. Exploring the Role of BIM in Construction Safety in Developing Countries: Toward Automated Hazard Analysis. Sustainability 2022, 14, 12905. https://doi.org/10.3390/su141912905

Akram R, Thaheem MJ, Khan S, Nasir AR, Maqsoom A. Exploring the Role of BIM in Construction Safety in Developing Countries: Toward Automated Hazard Analysis. Sustainability. 2022; 14(19):12905. https://doi.org/10.3390/su141912905

Chicago/Turabian StyleAkram, Ramsha, Muhammad Jamaluddin Thaheem, Shamraiza Khan, Abdur Rehman Nasir, and Ahsen Maqsoom. 2022. "Exploring the Role of BIM in Construction Safety in Developing Countries: Toward Automated Hazard Analysis" Sustainability 14, no. 19: 12905. https://doi.org/10.3390/su141912905