1. Introduction

According to some estimations, karst regions cover 7–12% of the Earth’s continental area, and their aquifers are at least a partial source of drinking water supply to almost one quarter of the world’s population [

1]. In Slovenia, this percentage is even higher as almost 50% of the surface area is karstified and more than 50% of the drinking water comes from groundwater from karstic aquifers. Globally, stress on groundwater resources has increased dramatically in recent decades in terms of water quantity due to the fact of excessive irrigated agriculture, infrastructure development, and different forms of pollution [

2]. Planning and extensive research may only lessen the risk of the impact but can never totally ensure a positive final result whatever the work we undertake in karsts [

3]. Therefore, a methodology integrating structural, geological, hydrogeological, and karstological data as well as groundwater protection demands was developed to obtain the sustainability of the water resources undermined by the new Divača–Koper railway line. The development of the methodology started in 2007 following the early stages of the planning procedure and continued throughout additional field investigation over the following decade; the need for this was identified by the described method and is extending into and beyond the end of the construction phase, which is currently ongoing. As the method is aimed at finding solutions to sustain human and ecological needs (i.e., drinking water protection) it can be implemented on any given tunnel construction within groundwater protection areas.

It is widely acknowledged that disturbance of the karst aquifer caused by excavation of the tunnel is to a certain degree inevitable. Tunneling in interaction with the aquifer is based on the principle of “the combination of drainage and interception”, which means that tunnel drainage can effectively reduce water pressure on the structure; thus, destruction of the groundwater environment and the loss of groundwater resources cannot be ignored [

4] and must be prevented up to the required level.

Apart from the classical works of Milanović [

5] and Bonacci [

6] on the topic of tunnel construction in karstic conditions and the impact it has on karst hydrology, there have been a significant number of contributions to this topic over the last two decades, adding up to a relevant source of tested knowledge. They can be divided into several categories: (a) the descriptive, (b) those that deal with water inrush and the prevention of ground collapse accidents during tunneling, and (c) those that deal with the environmental impact. In the first category, relevant to this work are the contributions of Knez and Slabe [

7], who provided a description of the types and frequency of occurrence of karstic phenomena found in Slovenian karst, and Garašić [

8], who gave a comprehensive description of the construction problems with caves during tunneling in Dinaric Karst in Croatia. In the second category, dealing with the hazards of water inrush and ground collapse, which pose serious threats to the safety of the tunnel, are the works of Kang et al. [

9], among others, on the karst cave treatment and waterproofing strategy for the TBM tunneling in the urban metro tunnel in Jinan City in China, and Zhang et al. [

10] on the risk assessment of water inrush in tunnels in carbonate karst terrain. In the same category are the works of Day [

11], on the karstic problems in the construction of Milwaukee’s deep tunnels, and Alija et al. [

12] on the systematization of the problems and design solutions associated with tunnel construction in karst rock masses in the case of the Gavarres tunnel in Spain. As the solution methods found in the literature are often only locally applicable or are too general, the issue of karst hydraulic hazards needs to be controlled by carrying out an investigation during tunnel construction, comprising predrilling along the whole karst route and extensive use of borehole geo-radar for early detection of water-bearing karst features. In the category of the environmental impact of tunnels constructed in karsts affecting the saturated zone and the conduit system are the contributions of Gisbert et al. [

13] and Shen et al. [

14], on different case examples dealing with the environmental and hydrogeological impact, and Neukomm et al. [

15] on the adaptation of the tunnel construction to hydrogeological conditions in a karst region. Jeannin et al. [

16] and Malard et al. [

17] used the case example of the karstic Brunnmühle spring system in Bernese Jura, Switzerland, to develop a methodology to assess the karst hydraulic hazards in tunneling and to determine the impact of a tunnel on a karst aquifer. The majority of this research was presented through case studies as the tremendous heterogeneity of karst systems does not provide much room for generalization. In spite of this, Jeannin at al. [

18] gave a valid contribution for the conceptualization of karst hydrogeological systems, and Filipponi et al. [

19] provided comprehensive recommendations, known as the KarstALEA approach, for the prediction of karst-related hazards in underground work. It can be observed that the vulnerability of a karst aquifer, which stems from its hydrogeological complexity and the fact that it can be significantly undermined by tunneling, is a well-studied topic. However, there is a lack of scientific and technical literature that addresses the impact of tunneling on potential long-term groundwater losses in terms of the sustainability of water resources, which is the topic of this paper.

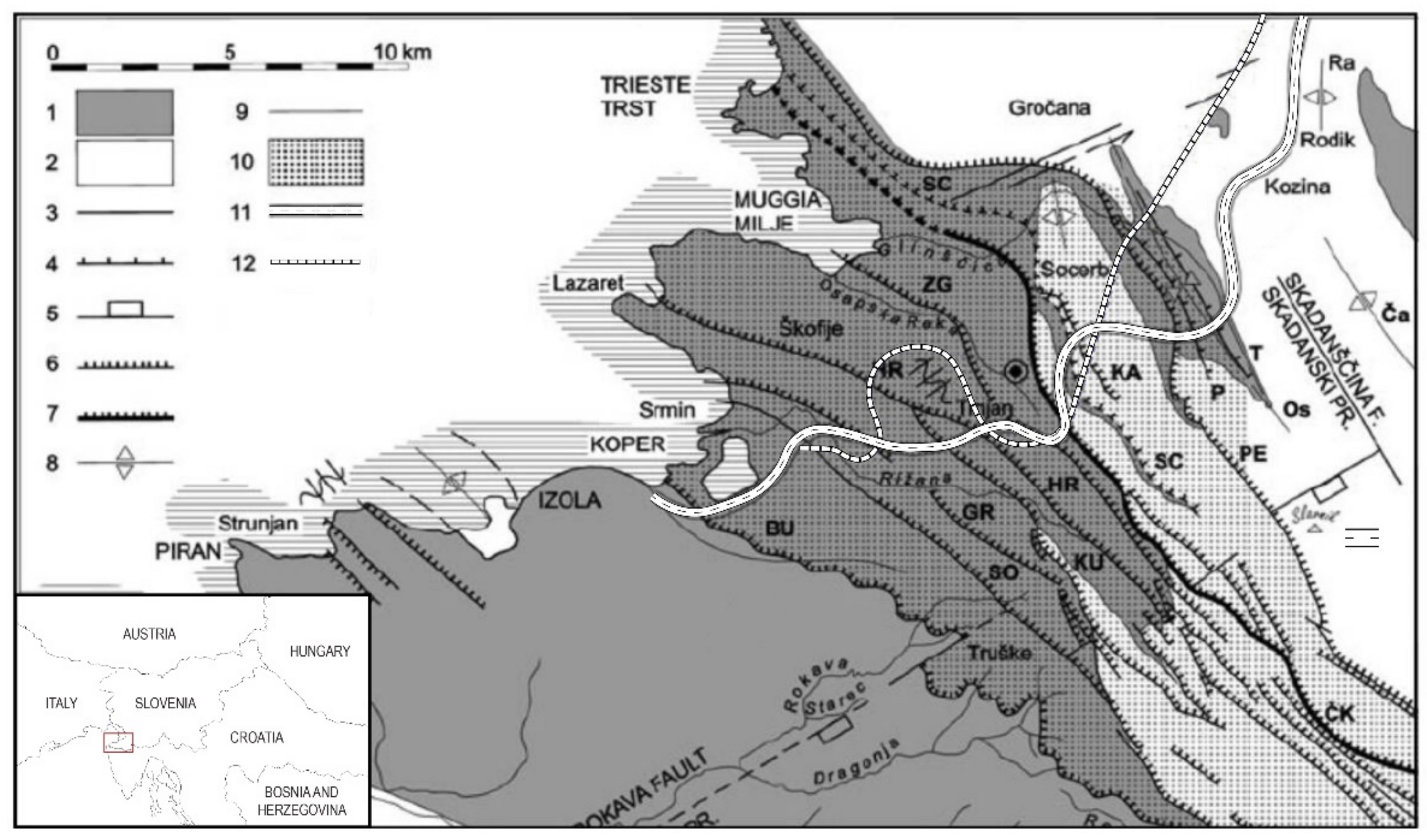

The research presented here is intended to address this deficiency by presenting a method developed for the presented case example, which was studied for the protection of a classic karst aquifer, Rižana, intersected by the tunnels of the new Divača–Koper railway line. An overwhelming majority of the water supply for the 44 km-long Slovenian Adriatic Sea shore, narrowly constricted between Croatia in the south and Italy in the north, comes from a karstic aquifer located in the mainland. The city of Koper, home of the only Slovenian seaport and an important industrial, cultural, and tourist center, is supplied by the Rižana water supply network. The number of water consumers in the network is approximately 85,000 people, but it is highly dependent on the tourist season, when it increases up to 120,000. The Rižana water supply system mainly faces supply problems in the summer months when water consumption is at its highest while the abundance of the Rižana water source is at its lowest. As a result, there is a negative water balance, leading to emptying of the water reservoirs, which is reflected in low water quality and interruptions in water supply to consumers. For the given situation, sustainability of the water resources in the Slovenian karsts is the key issue for the coastal region, bearing a major societal impact. The construction of the new railway line Divača–Koper was therefore carefully assessed in terms of the interaction between the tunnel construction and the karst water resources.

The new railway route overcomes a 400 m height difference between the karst plateau and sea level along the 27.1 km-long route. The required maximum inclination of the railway track of 1.7% dictates that almost 75% of the railway line runs underground. The main challenge presents the construction of the two twin tunnels, T1 (6.7 km) and T2 (6.0 km). The total length of the main and service tubes for both tunnels is some 25.4 km, while some 21 km runs through the karstic aquifer. The size of the excavation profile for both the main and the service tubes is approximately 75 m2. There are also 13 cross-passages along tunnel T1 and 12 along tunnel T2, which are distributed at approximate distances of 500 m. The passages are necessary to allow access to rescue vehicles and to host power supply stations. It was recognized that a substantial network of new channels introduced by tunnels T1 and T2 to the karstic aquifer poses a considerable threat to the existing groundwater flow regime, with potential detrimental effects on the water supply of the coastal region in the long term.

The Rižana catchment was protected by Slovenian legislation in 2005 by a separate Decree [

20], which initially did not allow the drainage of water from the karst aquifer by construction of transport infrastructure. This effectively meant that fully watertight tunnels had to be built along their entire lengths. However, this was regarded as unfeasible as watertight tunnel lining must withstand the full hydrostatic groundwater pressures, which can compromise buildability. In that sense, the junctions between the cross-passages and main tunnel tubes are particularly vulnerable. It was recognized that for expected water pressures in excess of 15 bars, it was practically impossible to achieve reasonable construction costs and technical feasibility at the critically affected parts of tunnels T1 and T2.

In order to meet the groundwater protection needs and at the same time be able to construct a tunnel, further technical solutions were sought to limit the outflow of groundwater with sufficient water pressure reduction to assure tunnel safety. A hydrogeological risk analysis was carried out to assess the degree of impact of the tunnels on groundwater balance and quality. The basis for the adjustment of the legislative amendments from 2014 and 2015 was the determination of the level of groundwater protection, which was proven to be sufficient by the risk assessment. This resulted in the formulation of a new decree which allowed groundwater drainage in areas of low aquifer transmissivity. Thus, a compromise was achieved for tunnels to be constructed in watertight forms only in areas in which the outsourcing of the karstic aquifer would otherwise be unacceptably high. There are examples of watertight tunnels, such as the Hallandsas in Sweden [

21], which were built at significant costs and at prolonged construction times. In the case of the Hallandsas tunnels, a balance of the feasibility of the tunnel construction and the sustainability of the water resources was not achieved, resulting in profound financial and societal impact [

22].

For tunneling in the Slovenian karst aquifer, apart from overcoming the integrated risks and hazards in the short term, the real challenge was to find solutions to simultaneously protect the tunnel from high groundwater pressures and to achieve sustainability by draining the aquifer up to the allowable level in the long term. The methodology to determine the appropriate construction measures presented in the continuation was based on extensive works that incorporated input from geological, hydrogeological, and speleological site investigations, which were acquired as part of the project study [

23]. The presented methodology is based on the recognition that the nature of the hydrogeological data and of new karstic information evolves continuously as real facts are revealed by the tunnel construction in progress. As will be explained later, the purpose of this concept is to aid the process of decision making so that previously defined tunnel-construction measures are subjected to change in order to solve newly recognized problems. In that sense, the methodology presented here follows the philosophy of the third stage of the KarstALEA approach [

19], with a distinction that is not only used to reduce hazard but primarily to obtain the sustainability of water resources in the long term, while assuring tunnel safety.

5. Methodology for Hydrogeological Investigation and Simultaneous Decision-Making during Tunnel Construction

Hydrologic models require an adequate representation of the strong subsurface hydraulic heterogeneity of the karstified rocks [

26]. It is widely recognized that this heterogeneity cannot be properly characterized due to the tremendous spatial variations of the karst systems; thus, reliable simulations for the sustainable protection and management of karst water resources are challenging, both scientifically and operationally [

2]. Given that no fully reliable and sufficiently accurate hydrological model could have been developed, a set of rules was developed to enable continuous hydrological investigation and obtain real facts as the tunnel construction progresses. The newly acquired knowledge was then used to procure a decision-making process so that each karst phenomenon is resolved with the appropriate technical measures in order to achieve minimum threshold values of the permanent water intakes.

The methodology, which encompasses the development of the hydrogeological criteria and decision charts for the choice of tunnel variant, was based on the permitted groundwater intakes along certain sections of the tunnel route. These were estimated relative to the amount of predicted water intake from the combined drained/undrained tunnel variant in a cumulative sense. The threshold values of specific groundwater ingress were assessed based on the values allowed by the risk assessment [

34], which was the foundation document for the new decree. To estimate the threshold values of permissive groundwater ingress, a hydrogeological inflow model was formed on the basis of the following premises: (a) the karst aquifer was divided along the length of the tunnel routes according to the geological structure and representative hydrogeological properties, based on the interpretation of the data measured in piezometers; (b) the zones in which more substantial karstification was probable were excluded from the inflow model (i.e., the groundwater flow will be fully preserved by the bypasses constructed around the tunnels); and (c) a continuous flow model was used for the rest of the aquifer. Within the above-defined boundaries, the inflow model was used to determine the zones in which the undrained tunnel variant was mandatory and the zones in which the drained tunnel variant was permissible.

The inflow model was used to estimate the total allowable outflow to the tunnel sections in the Water Protection Zone, ranging from 5 to 11 L/s (for some 4600 m of tunnel length this gives on average a threshold of just over 10 L/min per 100 m of tunnel length). In the tunnel sections outside of the water protection zone, the estimated total allowable outflow was limited to 20 L/s (for some 4500 m of tunnel, this gives, on average, a threshold of 26 L/min per 100 m of tunnel length). This value was reduced to a final obligatory value of 20 L/min per 100 m of tunnel length due to the uncertainties in the prediction of the future water flow and the preventive nature of drinking water protection.

The process of decision making to choose the most suitable tunnel variant at a given location was involved as it must be driven by reliable geological and hydrogeological data collected during the construction. It must be based on regular geotechnical monitoring comprising geological, hydrogeological, and karstological input. A 100 m-long pre-drilling borehole, seismic reflection, and georadar in the pre-boreholes were among the several investigation activities which were to be used during the construction of the tunnel to detect relevant geological and hydrogeological features and manifestations along the tunnel route and reduce hazards.

The logistics of the tunnel construction and geotechnical monitoring must be fully coordinated for the successful application of the method. The methodology considers four governing criteria: (a) the type of rock porosity, (b) the possibility of water withdrawal from the aquifer, (c) the presence of karst formations, and (d) the magnitude of the water pressures. As this information cannot be reliably assessed at a single stage of tunnel construction (ideally it would be at the top heading of the excavation), the decision-making procedure must be carried out in phases of the different stages of construction to confirm the increasing reliability of the data. The real challenge for the determination of the suitable tunnel variant lies in the intermediate zones among the different types of porosity, as phenomena often overlap. The methodology decision chart shown in

Figure 7 deals with individual cases of tunnel variants numbered 1 to 4, considering the different types of rock–mass porosities (matrix, fracture, and conduit), indicated in

Figure 5, and their interplay. The flow of the decision chart is determined by six hydrogeological criteria, which will be explained in detail below.

In Case 1, the intake of water quantities at an individual section is permissible, and the tunnel can be built as drained (low, predominantly matrix porosity). In Case 2, there will be karst channels to deal with (conduit porosity) and installation of bypasses, if necessary. In Case 3, in which the water pressure is higher than 10 bar, the tunnel will also be built as drained, with the low intake of water provided by pre-grouting and post-grouting measures (change between drained/undrained). In all other cases, the tunnel will be built as undrained, as in Case 4.

Figure 3 also presents the prognosis for the tunnel variants according to the criteria given in the decision chart for Cases 1 to 4, as shown in

Figure 7.

Cases 1–4 are all elaborated with respect to six hydrogeological criteria (HGC 1–5 and HGC permanent). The hydrogeological criteria represent partial quantitative norms for determining the acceptability of a variant on a given section. They are divided into six categories according to the type of hydrogeological manifestations. In all phases of the tunnel construction, from pre-drilling to installation of the inner lining, the hydrogeological criteria are also the basis for the determination of the technical measures to protect the quantitative state and the sustainability of the aquifer (i.e., pre-grouting, post-grouting, and construction of the karst channel bypasses).

Hydrogeological data must be obtained in the different phases of tunnel construction due to the different reliabilities of the data obtained from the different sources that occur during pre-drilling, excavation, excavation of bench and invert, and continuous monitoring outside the tunnel. This permits flexibility in decision-making so that certain changes in categorization are possible until the final decision. In the case that the manifestation is incorrectly recognized due to the previous low reliability of the obtained data, it can be reclassified and then addressed through the new branch of the decision diagram, as shown in

Figure 7.

Hydrogeological criterion 1 (HGC 1) is related to the basic assessment of the rock mass porosity (i.e., matrix, fissure, or conduit). If the presence of karstic channels or conduits, which can represent a significant groundwater conductor, is detected, an assessment of possible transmissivity reduction is carried out. If the clash with the tunnel can reduce the transmissivity by more than 10%, a bypass must be excavated to preserve approximately the same conductivity regime as before the tunnel construction. HGC 1 is determined during excavation of the top heading and bench, while some valuable information (detected gaps in drilling, their distance from the top heading, pressure, and high fluid loss during drilling) can be collected from pre-drilling.

Hydrogeological criterion 2 (HGC 2) defines the acceptability of the rate of the reduction in groundwater flow based on pre-drilling at the top heading. It is met only if the measured flow Q does not exceed 20 L/min (within the water protection area it must not exceed 10 L/min) and if the initial flow rate from the pre-drilling borehole is halved in three hours (Q after 3 h < 50% Qinitial). If groundwater is not currently present during pre-drilling, but other indications suggest that it may occur at higher seasonal water levels (e.g., within the epiphreatic zone), a Lugeon test is performed to assess the permeability and the potential inflow for estimated hydrostatic pressures.

Hydrogeological criterion 3 (HGC 3) is related to the highest possible water pressures on the considered section and can be reliably determined only during pre-drilling, when the impact of the tunnel construction on the aquifer is the smallest. HGC 3 is met if the maximum groundwater pressure is greater than 10 bars (pmax > 10 bars). The measurement is analyzed in the context of simultaneous measurements of the levels in piezometers on the surface and the surrounding cave interiors, if accessible.

Hydrogeological criterion 4 (HGC 4) defines the acceptability of the volume of the inflow during the excavation of the top heading. The criterion is met if the measured flow Q does not exceed 20 L/min per 100 m length of the top heading. The measurement of the flow is superimposed with the measurements of the inflow variations, depending on the timing of the precipitation events. The water flow is measured at the points of inflow to the tunnel at the drainage boreholes and larger drainage areas at 100 m-long sections. At the same time, the groundwater levels in the surrounding piezometers are monitored so that this criterion, together with HGC 3, specifies the need for local grouting and enables a preliminary decision on the drained/undrained tunnel section used for the excavation of the bench and invert.

Hydrogeological criterion 5 (HGC 5) is critical for the final decision on the tunnel variant. It is related to the longest available period of flow measurements on a dam installation equipped with overflows every 100 m at the tunnel invert. The dams have to be carefully prepared and sealed at the invert to prevent water bypassing them and equipped with an overflow V-notch to calculate the flow rate. The criterion is met if the measured flow Q does not exceed 20 L/min per 100 m length of the top heading (within the water protection area it must not exceed 10 L/min). The implementation period for HGC 5 is estimated at 4 months, or longer, depending on the schedule in the construction of the secondary lining. To determine reliably the outflow of water from the aquifer, considering precipitation events, the measurement of the flows at the dams is performed at every 6 and 12 h. The capacity of a proven-effective downstream outflow can be deducted from the measured upstream intake.

Hydrogeological criterion 6, or HGC permanent, is related to the permanent monitoring outside the tunnel and in principle can override other criteria. Such monitoring makes an important contribution to the interpretations of the hydrogeological measurements in the tunnel and is the basis of the final decision on the tunnel variant. The HGC permanent criterion is related to the measurements of the total outflows from the tunnel tubes (to determine the long-term exceedances of permissible values), precipitation measurements to determine the correlation with groundwater levels and inflows, measurements of water levels in piezometers on the surface and in cave interiors (notifies significant declines as a direct impact on the quantitative status of the aquifer), surface water flows (notifies significant reductions in flows as an indirect indicator of the tunnel construction impact), and also changes in the chemical status of the groundwater at the aquifer outflows.

Figure 8 shows the scheme of the flow of hydrogeological monitoring and the utilization of the hydrogeological criteria for the protection of groundwater and karst conduits, including: (a) timing of measurement relative to the schedule and location of the tunnel construction (top heading, bench, invert, and secondary lining), (b) reliability of measurement, and (c) duration of the measured impact on the aquifer. The hydrogeological criteria are the same as shown in

Figure 7 so that the diagrams are fully aligned in this regard. The possible delays in the schedules of tunnel construction can originate only by the measurement related to criteria HGC 2 and HGC 3, which are part of the pre-drilling investigations and are expected to last up to 6 h.

As can be seen from the decision diagram shown in

Figure 7 and the scheme of hydrogeological investigation shown in

Figure 8, the decision-making process must be multi-stage, following the timing of the hydrogeological monitoring relative to the tunnel excavation. It begins with the pre-drilling process in front of the top heading (i.e., HGC1, HGC2, and HGC3) and the measurements of flow obtained during the excavation of the top heading (i.e., HGC4) and continues during the period following the excavation of the bench and invert (i.e., HGC5). At the same time, the hydrogeological observation outside the tunnel is continuously checked (HGC permanent) and used. The decision methodology was developed to be both thorough and flexible and in coordination with the tunnel excavation sequence. The methodology considers that the preliminary decision on the tunnel variant can be made at any significant stage of the evaluation, but the final decision can be made only after the excavation of the invert and after additional in situ geological, hydrogeological, and karst analyses based on permanent monitoring outside the tunnel. This is critical for the areas either close to the karst formations or strongly fractured rock or the areas with the interplay of both.

6. Discussion

The specificity of the karstic aquifer is that the estimated mean effective porosity is very low (in the case of Slovenian Kras only 0.3%), implying that most of the groundwater flow takes place in a very localized manner. In these conditions, even the cross-sectional area of limited size perpendicular to the water flow can potentially induce significant water level rises/drops, both in magnitude and rapidness in the times of recharge/discharge, as clearly seen in the presented observational data. The drops in water level and consequent losses, once the tunnel reaches one or more of the interconnected fissures or channels, are also expected to be significant and fast in these conditions.

The potential losses depend on several key hydrogeological features that might clash with the tunnel in a cumulative sense, such as the total volume of the interconnected cracks and fractures, the apertures of both the major and the limited karstic features (e.g., bottleneck effects), the changes in effective hydraulic conductivity, the recharge conditions in the epiphreatic zone due to the oscillation of the water table, and others. For this reason, the emphasis was given to the determination of the temporal development of each individual water inflow in the karst aquifer, which is just as important as its magnitude.

As the karst aquifer presents a highly dynamic system, the timing of the tunnel construction plays an important role in the overall complexity of the interaction with groundwater flow. It is estimated that the predictability of the current water levels ahead of the top heading during the excavation is relatively low, usually up to 5–10 m in accuracy. Extrapolating from these data to a maximum expected water level and the estimated possible inflows in the entire tunnel lifetime presents a significant challenge given the limited time available and the possibilities for the hydrogeological investigation during construction. It was therefore important to assess as precisely as possible the long-term groundwater-level fluctuations in the available piezometers along the tunnel prior to their construction. These data are critical for the presented methodology and will be used as a benchmark for the final decision on the variant of the tunnel construction (drained/undrained) at the given section.

The presented methodology and decision-making charts for the tunnel variants are developed on the basis of six hydrogeological criteria, which are categorized by their reliability, importance, and timing relative to the schedule of the tunnel construction. Due to its sporadic nature, pre-drilling (a valuable indication of the groundwater pressure in the unperturbed aquifer) can frequently miss a conductive feature that will later intercept the tunnel tube. For this reason, HGC2, which is evaluated during pre-drilling, is primarily aimed at determining a deviation from the benchmark groundwater pressure (obtained by the long-term hydrogeological monitoring that took place prior to the construction). Additional consideration and adaptation must be given for the current water levels in the wider aquifer at the time of measurement, especially the unperturbed part, considering the entire span of water levels measured in that area in the long term. If the water levels are low during tunnel construction, dropping under the tunnel level for example, HGC2 is supplemented by Lugeon tests to assess the available maximum water levels considering the previous measurements.

HGC2 sets the criteria to decline in flow rate from a pre-drilled borehole to 50% of the initial flow in 3 h. This rate is set to distinguish the small separate inflows, related mainly to poorly interconnected fissures with limited accumulation, from the main inflows, which are connected to more significant bodies of groundwater that need to be prevented from permanently flowing into the tunnel. The reliability of the HGC2 in the given methodology is nevertheless relatively low due to the limited area of the borehole with respect to the area of the tunnel and the irregular shapes of the karst features. The reliability somewhat increases in cases of evident high-water ingress through pre-drilling, i.e., in the case of high-water levels hitting a conduit via a pre-borehole.

HGC4 and HGC5 are very similar in terms of the threshold values but differ substantially in terms of the available means and times for the inflow measurements as well as the purpose of each of the criteria. While HGC4 aims at assessment of the short-term response and, thus, supporting a preliminary decision on the drained or undrained variant, HGC5 is used for the final decision on the drained/undrained tunnel just before the beginning of the construction of the secondary lining. Significant weight is therefore given to HGC5, with overflows measured every 100 m at the tunnel invert at purposefully built dams as the most important indicator of the expected short- and mid-term inflows. The reliability of HGC5 is high if the aquifer recharge conditions are long-term representative, otherwise it is low in times of droughts and consequent interim water level drawdowns.

The threshold values of the specific groundwater ingress of 20 L/min per 100 m of the tunnel (and 10 L/min per 100 m of tunnel in the water protection zone) represent a measured balance between the sustainability of water resources and the feasibility of the tunnel construction. The threshold values significantly surpass the less strict criteria usually set at 30 L/min per 100 m of tunnel, which are aimed at concave tunnels where the pumping costs are to be controlled. On the other hand, the ingress values of 5 L/min per 100 m of tunnel or less were avoided as those are generally used for tunnels in the areas of risk of subsidence or immediate threat to the water supply in water-scarce regions [

35].

A final water protection safety measure is incorporated in HGC permanent (i.e., HGC 6), which considers the impacts of the allowed inflows to the tunnels on the surrounding aquifer from the normalized data relative to the existing long-term, on-going measurements. This, in turn, gives a basis for the decision to make the threshold values stricter on a certain section that proves to be more susceptible to the water level drawdown due to the limited conduit volumes and the groundwater accumulation.