Logistics and Agri-Food: Digitization to Increase Competitive Advantage and Sustainability. Literature Review and the Case of Italy

Abstract

:1. Introduction

2. Strategic Management in Logistics: A Balance between Connectivity and Sustainability

3. Digitization and New Technologies to Support Logistics and Its Sustainability

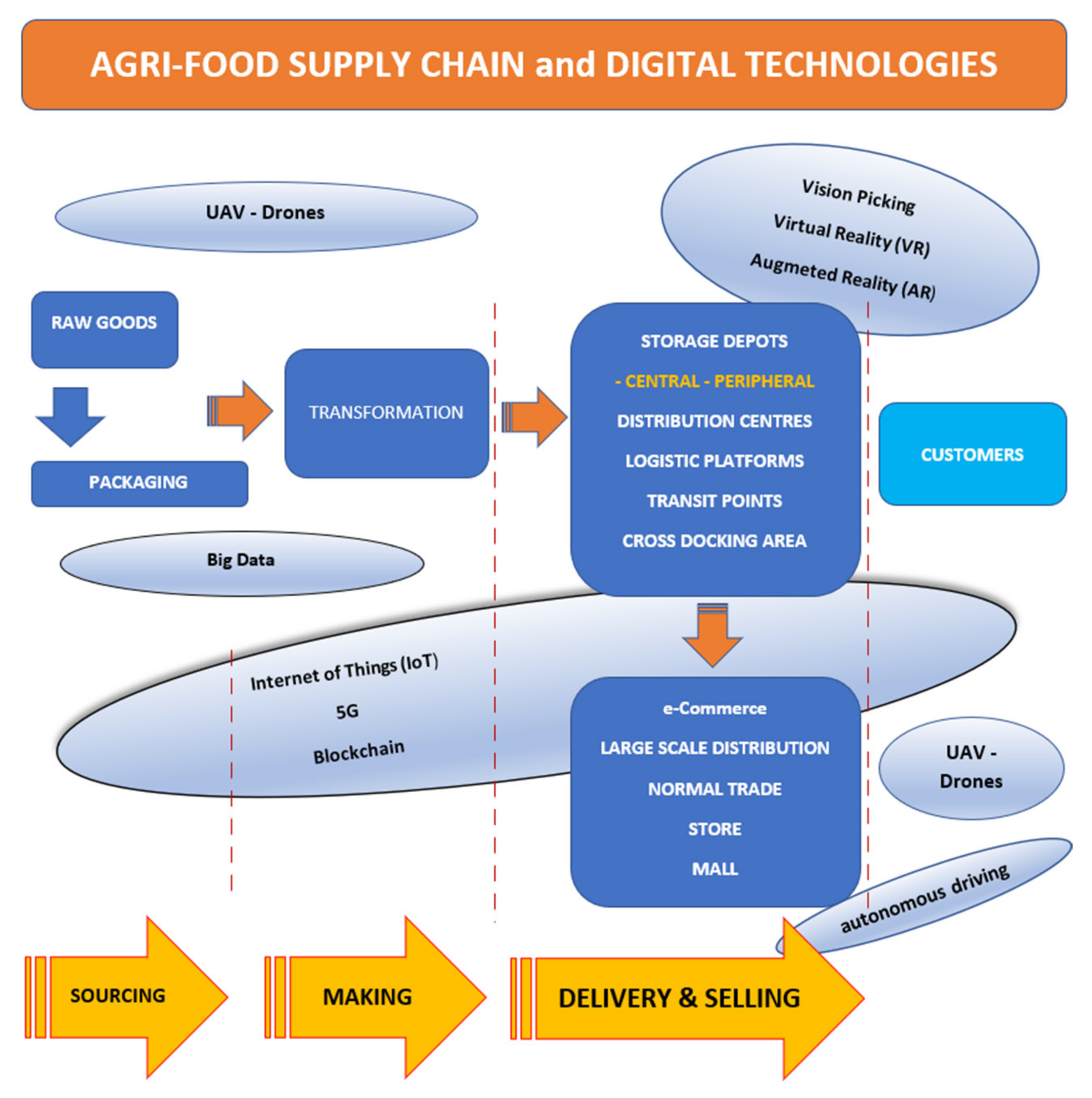

4. Optimizing Processes in the Agri-Food Industry through Digitization and Technology

5. The Case of Italy: Bridging an Infrastructure Gap with Digitization

- -

- there was a sharp increase in business closures in 2020, amounting to 273,000;

- -

- there was a 17% drop in new business start-ups compared to 2019;

- -

- regarding the directors of businesses, between 2011 and 2019 there was an increase in the weight of the age group 70 and over of 6.4% nationally and 2.6% in the South, and at the same time a contraction in the weight of young entrepreneurs (aged under 29) of 1.6% nationally and 2.0% in the South (Source: Infocamere, Italy).

- (1)

- The nature of the products (fresh, dried and frozen);

- (2)

- The complexity of upstream production and food processing chains;

- (3)

- Growing globalization and internationalization of markets, both supply and outlets;

- (4)

- The structure of sales channels (e-commerce, large-scale organized distribution).

6. Results, Discussion and Conclusions

6.1. Digital Technologies Applied to Logistics: Value-Added and Sustainability

6.2. Digitization and New Technologies in the Agri-Food Sector

6.3. Managerial Implications and the Case of Italy

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kovács, G.; Kot, S. New Logistics and Production Trends as the Effect of Global Economy Changes. Pol. J. Manag. Stud. 2016, 14, 115–125. [Google Scholar] [CrossRef]

- Giallombardo, G.; Guerriero, F.; Miglionico, G. Profit Maximization via Capacity Control for Distribution Logistics Problems. arXiv 2020, arXiv:2008.03216. [Google Scholar]

- Bronshtein, E.M.; Gindullin, R.V. Exact Solutions of Some Optimization Problems of Transport Logistics. Math. Models Comput. Simul. 2014, 6, 332–336. [Google Scholar] [CrossRef]

- Roh, S.; Thai, V.V.; Wong, Y.D. Towards Sustainable ASEAN Port Development: Challenges and Opportunities for Vietnamese Ports. Asian J. Shipp. Logist. 2016, 32, 107–118. [Google Scholar] [CrossRef] [Green Version]

- Kuan, S.H.; Ghorbani, Y.; Chieng, S. Narrowing the Gap between Local Standards and Global Best Practices in Bauxite Mining: A Case Study in Malaysia. Resour. Policy 2020, 66, 101636. [Google Scholar] [CrossRef]

- Murray, M.M. Cargo on the Move: Options for Infrastructure and Air Quality Improvements at the San Pedro Bay Ports. Master’s Thesis, California State University, Sacramento, CA, USA, 2012. [Google Scholar]

- Merenkov, A. Digital Economy: Transport Management and Intelligent Transportation Systems. E-Management 2018, 1, 12–18. [Google Scholar] [CrossRef]

- Bobrova, V.V.; Berezhnaya, L.Y. Digitization of the Transport Industry in Russia: Problems and Prospects. In Proceedings of the 1st International Scientific Conference “Modern Management Trends and the Digital Economy: From Regional Development to Global Economic Growth” (MTDE), Institute of International Relations, Yekaterinburg, Russia, 14–15 April 2019; pp. 1–4. [Google Scholar]

- Antonov, A.A. Digitization of Processes of Sea Freight Transportation. 2020. Available online: https://er.nau.edu.ua/handle/NAU/49875?locale=en (accessed on 25 November 2021).

- Anwar, M.; Henesey, L.; Casalicchio, E. Digitalization in Container Terminal Logistics: A Literature Review. In Proceedings of the 27th Annual Conference of International Association of Maritime Economists, Athens, Greece, 25–28 June 2019; pp. 1–25. [Google Scholar]

- Fruth, M.; Teuteberg, F. Digitization in Maritime Logistics—What Is There and What Is Missing? Cogent Bus. Manag. 2017, 4, 1411066. [Google Scholar] [CrossRef]

- Remondino, M. Information Technology in Healthcare: HHC-MOTES, a Novel Set of Metrics to Analyse IT Sustainability in Different Areas. Sustainability 2018, 10, 2721. [Google Scholar] [CrossRef] [Green Version]

- Kahn, K.B.; Mentzer, J.T. Logistics and Interdepartmental Integration. Int. J. Phys. Distrib. Logist. Manag. 1996, 6, 6–14. [Google Scholar] [CrossRef]

- Shibasaki, R.; Watanabe, D.; Kawasaki, T. Global and International Logistics. Sustainability 2021, 13, 5610. [Google Scholar] [CrossRef]

- De Andres Gonzalez, O.; Koivisto, H.; Mustonen, J.M.; Keinänen-Toivola, M.M. Digitalization in Just-In-Time Approach as a Sustainable Solution for Maritime Logistics in the Baltic Sea Region. Sustainability 2021, 13, 1173. [Google Scholar] [CrossRef]

- Parfenov, A.; Shamina, L.; Niu, J.; Yadykin, V. Transformation of Distribution Logistics Management in the Digitalization of the Economy. J. Open Innov. Technol. Mark. Complex. 2021, 7, 58. [Google Scholar] [CrossRef]

- Todorovic, V.; Maslaric, M.; Bojic, S.; Jokic, M.; Mircetic, D.; Nikolicic, S. Solutions for More Sustainable Distribution in the Short Food Supply Chains. Sustainability 2018, 10, 3481. [Google Scholar] [CrossRef]

- Pernestål, A.; Engholm, A.; Bemler, M.; Gidofalvi, G. How Will Digitalization Change Road Freight Transport? Scenarios Tested in Sweden. Sustainability 2021, 13, 304. [Google Scholar] [CrossRef]

- Omta, S.W.F.; Folstar, P. Integration of Innovation in the Corporate Strategy of Agri-Food Companies. Innov. Agri-Food Syst. 2005, 1, 223–246. [Google Scholar]

- Paciarotti, C.; Torregiani, F. The Logistics of the Short Food Supply Chain: A Literature Review. Sustain. Prod. Consum. 2021, 26, 428–442. [Google Scholar] [CrossRef]

- Majewski, E.; Komerska, A.; Kwiatkowski, J.; Malak-Rawlikowska, A.; Wąs, A.; Sulewski, P.; Gołaś, M.; Pogodzińska, K.; Lecoeur, J.-L.; Tocco, B. Are Short Food Supply Chains More Environmentally Sustainable than Long Chains? A Life Cycle Assessment (LCA) of the Eco-Efficiency of Food Chains in Selected EU Countries. Energies 2020, 13, 4853. [Google Scholar] [CrossRef]

- Saitone, T.L.; Sexton, R.J. Agri-Food Supply Chain: Evolution and Performance with Conflicting Consumer and Societal Demands. Eur. Rev. Agric. Econ. 2017, 44, 634–657. [Google Scholar] [CrossRef]

- Gandino, F.; Montrucchio, B.; Rebaudengo, M.; Sanchez, E.R. Analysis of an RFID-Based Information System for Tracking and Tracing in an Agri-Food Chain. In Proceedings of the 2007 1st Annual RFID Eurasia, Istanbul, Turkey, 5–6 September 2007; IEEE: Piscataway, NJ, USA, 2007; pp. 1–6. [Google Scholar]

- Carlucci, F.; Cirà, A.; Forte, E.; Siviero, L. Infrastructure and Logistics Divide: Regional Comparisons between North Eastern & Southern Italy. Technol. Econ. Dev. Econ. 2017, 23, 243–269. [Google Scholar]

- Ivanov, D.; Tsipoulanidis, A.; Schönberger, J. Global Supply Chain and Operations Management. Decis.-Oriented Introd. Creat. Value 2017, 2, 203–245. [Google Scholar]

- Chen, H.-M.; Kazman, R.; Garbajosa, J.; Gonzalez, E. Toward Big Data Value Engineering for Innovation. In Proceedings of the 2nd International Workshop on BIG Data Software Engineering, Austin, TX, USA, 16 May 2016; ACM: New York, NY, USA, 2016; pp. 44–50. [Google Scholar]

- Patil, M.A.L.; Rane, B.V. Analyzing the Importance of Logistics in Supply Chain Management. PalArchs J. Archaeol. Egypt/Egyptol. 2021, 18, 2196–2202. [Google Scholar]

- Mir, A.; Lazaar, S.; Balambo, M.A. The Logistics Service Provider as an Integrator of Supply Chain. Evidences from an Emerging Market. Rev. Eur. D’économie Et Manag. Des Serv. 2021, 2021, 69–91. [Google Scholar]

- Sahay, B.S. Supply Chain Collaboration: The Key to Value Creation. Work Study 2003, 52, 76–83. [Google Scholar] [CrossRef]

- Indriastiwi, F.; Hadiwardoyo, S.P. Port Connectivity Model in The Perspective of Multimodal Transport: A Conceptual Framework. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Sanya, China, 12–14 November 2021; IOP Publishing: Bristol, UK, 2021; Volume 1052, p. 012008. [Google Scholar]

- Yang, Y.-C.; Chen, S.-L. Determinants of Global Logistics Hub Ports: Comparison of the Port Development Policies of Taiwan, Korea, and Japan. Transp. Policy 2016, 45, 179–189. [Google Scholar] [CrossRef]

- Berli, J.; Bunel, M.; Ducruet, C. Sea-Land Interdependence in the Global Maritime Network: The Case of Australian Port Cities. Netw. Spat. Econ. 2018, 18, 447–471. [Google Scholar] [CrossRef] [Green Version]

- Bensassi, S.; Márquez-Ramos, L.; Martínez-Zarzoso, I.; Suárez-Burguet, C. Relationship between Logistics Infrastructure and Trade: Evidence from Spanish Regional Exports. Transp. Res. Part A Policy Pract. 2015, 72, 47–61. [Google Scholar] [CrossRef]

- Nam, H.-S.; Song, D.-W. Defining Maritime Logistics Hub and Its Implication for Container Port. Marit. Policy Manag. 2011, 38, 269–292. [Google Scholar] [CrossRef]

- Rimienė, K.; Grundey, D. Logistics Centre Concept through Evolution and Definition. Eng. Econ. 2007, 54, 87–95. [Google Scholar]

- Porter, M.E.; Kramer, M.R. Creating Shared Value. In Managing Sustainable Business; Springer: Berlin/Heidelberg, Germany, 2019; pp. 323–346. [Google Scholar]

- Dolan, C.; Humphrey, J. Governance and Trade in Fresh Vegetables: The Impact of UK Supermarkets on the African Horticulture Industry. J. Dev. Stud. 2000, 37, 147–176. [Google Scholar] [CrossRef]

- Roche, I.C.; Barbolla, J.O.; Guillén, M.J.Y. Price Differences in Consumer Goods in Retail Markets: Spatial and Vertical Competition Analysis. J. Mark. Channels 2006, 13, 49–67. [Google Scholar] [CrossRef]

- Lehmacher, W. Digitizing and Automating Processes in Logistics. In Disrupting Logistics; Springer: Berlin/Heidelberg, Germany, 2021; pp. 9–27. [Google Scholar]

- Dehmer, J.; Niemann, J. Value Chain Management through Cloud-Based Platforms. Procedia-Soc. Behav. Sci. 2018, 238, 177–181. [Google Scholar] [CrossRef]

- Kiel, D.; Müller, J.M.; Arnold, C.; Voigt, K.-I. Sustainable Industrial Value Creation: Benefits and Challenges of Industry 4.0. In Digital Disruptive Innovation; World Scientific: Singapore, 2020; pp. 231–270. [Google Scholar]

- Avetisyan, M.; Hertel, T.; Sampson, G. Is Local Food More Environmentally Friendly? The GHG Emissions Impacts of Consuming Imported versus Domestically Produced Food. Environ. Resour. Econ. 2014, 58, 415–462. [Google Scholar] [CrossRef]

- Memari, A.; Rahim, A.R.A.; Ahmad, R.B. An Integrated Production-Distribution Planning in Green Supply Chain: A Multi-Objective Evolutionary Approach. Procedia Cirp 2015, 26, 700–705. [Google Scholar] [CrossRef] [Green Version]

- McKinnon, A. Decarbonizing Logistics: Distributing Goods in a Low Carbon World; Kogan Page Publishers: London, UK, 2018. [Google Scholar]

- Hesse, M.; Rodrigue, J.-P. The Transport Geography of Logistics and Freight Distribution. J. Transp. Geogr. 2004, 12, 171–184. [Google Scholar] [CrossRef]

- Avram, D.O.; Kühne, S. Implementing Responsible Business Behavior from a Strategic Management Perspective: Developing a Framework for Austrian SMEs. J. Bus. Ethics 2008, 82, 463–475. [Google Scholar] [CrossRef]

- Carayannis, E.G.; Sindakis, S.; Walter, C. Business Model Innovation as Lever of Organizational Sustainability. J. Technol. Transf. 2015, 40, 85–104. [Google Scholar] [CrossRef]

- Elkington, J. Towards the Sustainable Corporation: Win-Win-Win Business Strategies for Sustainable Development. Calif. Manag. Rev. 1994, 36, 90–100. [Google Scholar] [CrossRef]

- Piecyk, M.I.; Björklund, M. Logistics Service Providers and Corporate Social Responsibility: Sustainability Reporting in the Logistics Industry. Int. J. Phys. Distrib. Logist. Manag. 2015, 45, 459–485. [Google Scholar] [CrossRef]

- Pawlik, T.; Gaffron, P.; Drewes, P.A. Corporate Social Responsibility in Maritime Logistics. In Maritime Logistics; Emerald Group Publishing Limited: Bingley, UK, 2012. [Google Scholar]

- Notteboom, T.; Rodrigue, J.-P. Re-Assessing Port-Hinterland Relationships in the Context of Global Commodity Chains. In Ports, Cities, and Global Supply Chains; Routledge: London, UK, 2017; pp. 67–82. [Google Scholar]

- Rodrigue, J.-P.; Notteboom, T. The Terminalization of Supply Chains: Reassessing the Role of Terminals in Port/Hinterland Logistical Relationships. Marit. Policy Manag. 2009, 36, 165–183. [Google Scholar] [CrossRef]

- Emmett, S.; Sood, V. Green Supply Chains: An Action Manifesto; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Maliza Delima, K.Z. Environmental Ethical Commitment of the Business Corporations in Malaysia/Maliza Delima Binti Kamarul Zaman. Ph.D. Thesis, Universiti Malaya, Kuala Lumpur, Malaysia, 2011. [Google Scholar]

- Xie, Y.; Breen, L. Greening Community Pharmaceutical Supply Chain in UK: A Cross Boundary Approach. Supply Chain Manag. Int. J. 2012, 17, 40–53. [Google Scholar] [CrossRef]

- Bouklata, A.; Bensfia, C. Digitalization of Port Passage Procedures: Focus on the Transit Time of Goods. In Proceedings of the 2020 IEEE 13th International Colloquium of Logistics and Supply Chain Management (LOGISTIQUA), Fez, Morocco, 2–4 December 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–6. [Google Scholar]

- Errico, F.; Corallo, A.; Barriera, R.; Prato, M. Dematerialization, Archiving and Recovery of Documents: A Proposed Tool Based on a Semantic Classifier and a Semantic Search Engine. In Proceedings of the 2020 9th International Conference on Industrial Technology and Management (ICITM), Oxford, UK, 11–13 February 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 297–301. [Google Scholar]

- Dörr, S. Watch It! Thinking Digitalization and Sustainability Together. In Corporate Digital Responsibility; Springer: Berlin/Heidelberg, Germany, 2021; pp. 53–83. [Google Scholar]

- Colombo, B.; Gaiardelli, P.; Dotti, S.; Boffelli, A. Business Models in Circular Economy: A Systematic Literature Review. In Proceedings of the IFIP International Conference on Advances in Production Management Systems, Nantes, France, 5–9 September 2021; Springer: Berlin/Heidelberg, Germany, 2021; pp. 386–393. [Google Scholar]

- David, B.G.; Trautrims, A.; Wong, C.Y. Sustainable Logistics and Supply Chain Management 2021. Available online: http://dspace.vnbrims.org:13000/jspui/bitstream/123456789/4493/1/Sustainable%20Logistics%20and%20Supply%20Chain%20Management.pdf (accessed on 25 November 2021).

- Ntuchu, R.G. Efficient Logistics Operation in a Supply Chain. 2019. Available online: https://www.theseus.fi/bitstream/handle/10024/264784/Ntuchu_RexdonaldGweko.pdf?sequence=2&isAllowed=y (accessed on 25 November 2021).

- Matopoulos, A.; Vlachopoulou, M.; Manthou, V.; Manos, B. A Conceptual Framework for Supply Chain Collaboration: Empirical Evidence from the Agri-Food Industry. Supply Chain Manag. Int. J. 2007, 12, 177–186. [Google Scholar] [CrossRef] [Green Version]

- Solarte-Montufar, J.G.; Zartha-Sossa, J.W.; Osorio-Mora, O. Open Innovation in the Agri-Food Sector: Perspectives from a Systematic Literature Review and a Structured Survey in MSMEs. J. Open Innov. Technol. Mark. Complex. 2021, 7, 161. [Google Scholar] [CrossRef]

- Jałowiecki, P. Dupont Analysis of Polish Agri-Food Industry Selected Sectors–Logistic Aspects. Res. Logist. Prod. 2018, 8, 217–227. [Google Scholar]

- Raźniewska, M. Meeting the Challenges of Food Sector Using Supplier Relationship Management. Available online: https://www.researchgate.net/profile/Marta-Razniewska/publication/336929843_Meeting_the_Challenges_of_Food_Sector_using_Supplier_Relationship_Management/links/60381a61299bf1cc26efa7d0/Meeting-the-Challenges-of-Food-Sector-using-Supplier-Relationship-Management.pdf (accessed on 25 November 2021).

- Fang, Y.; Jiang, Y.; Sun, L.; Han, X. Design of Green Cold Chain Networks for Imported Fresh Agri-Products in Belt and Road Development. Sustainability 2018, 10, 1572. [Google Scholar] [CrossRef] [Green Version]

- Gössling, S. ICT and Transport Behavior: A Conceptual Review. Int. J. Sustain. Transp. 2018, 12, 153–164. [Google Scholar] [CrossRef]

- Ülkü, M.A.; Engau, A. Sustainable Supply Chain Analytics. Ind. Innov. Infrastruct. 2021, 1123–1134. [Google Scholar] [CrossRef]

- Nikitas, A.; Michalakopoulou, K.; Njoya, E.T.; Karampatzakis, D. Artificial Intelligence, Transport and the Smart City: Definitions and Dimensions of a New Mobility Era. Sustainability 2020, 12, 2789. [Google Scholar] [CrossRef] [Green Version]

- Leurent, F.; Haxaire, O.; Lesteven, G. Smart Mobility: A Landscape Under Development. In Eco-Design of Buildings and Infrastructure; CRC Press: Boca Raton, FL, USA, 2020; pp. 449–496. [Google Scholar]

- Xu, Z.; Li, J.; Zhao, X.; Li, L.; Wang, Z.; Tong, X.; Tian, B.; Hou, J.; Wang, G.; Zhang, Q. A Review on Intelligent Road and Its Related Key Technologies. China J. Highw. Transp. 2019, 32, 1–24. [Google Scholar]

- Fiedler, R.; Bosse, C.; Gehlken, D.; Brümmerstedt, K.; Burmeister, H.S. Autonomous Vehicles’ Impact on Port Infrastructure Requirements; Fraunhofer—Center für Maritime Logistik und Dienstleistungen CML: Hamburg, Germany, 2019; Available online: https://safety4sea.com/wp-content/uploads/2019/06/IAPHPort-of-Hamburg-Autonomous-vehicles-impact-on-port-infrastructure-requirements-2019_06.pdf (accessed on 25 November 2021).

- Novikova, O. The Sharing Economy and the Future of Personal Mobility: New Models Based on Car Sharing. Technol. Innov. Manag. Rev. 2017, 7, 27–31. [Google Scholar] [CrossRef]

- Wong, Y.Z.; Hensher, D.A.; Mulley, C. Mobility as a Service (MaaS): Charting a Future Context. Transp. Res. Part A Policy Pract. 2020, 131, 5–19. [Google Scholar] [CrossRef]

- Chen, C.; Wang, J.; Xu, Q.; Wang, J.; Li, K. Mixed Platoon Control of Automated and Human-Driven Vehicles at a Signalized Intersection: Dynamical Analysis and Optimal Control. Transp. Res. Part C Emerg. Technol. 2021, 127, 103138. [Google Scholar] [CrossRef]

- Varaldo, R. La Nuova Partita Dell’innovazione: Il Futuro Dell’industria in Italia; Saggi Il Mulino: Bologna, Italy, 2014; ISBN 978-88-15-25375-0. [Google Scholar]

- Ye, L.; Yamamoto, T. Modeling Connected and Autonomous Vehicles in Heterogeneous Traffic Flow. Phys. A Stat. Mech. Its Appl. 2018, 490, 269–277. [Google Scholar] [CrossRef]

- Flämig, H. Autonomous Vehicles and Autonomous Driving in Freight Transport. In Autonomous Driving; Springer: Berlin/Heidelberg, Germany, 2016; pp. 365–385. [Google Scholar]

- Nie, J.; Zhang, J.; Ding, W.; Wan, X.; Chen, X.; Ran, B. Decentralized Cooperative Lane-Changing Decision-Making for Connected Autonomous Vehicles. IEEE Access 2016, 4, 9413–9420. [Google Scholar] [CrossRef]

- Shengdong, M.; Zhengxian, X.; Yixiang, T. Intelligent Traffic Control System Based on Cloud Computing and Big Data Mining. IEEE Trans. Ind. Inform. 2019, 15, 6583–6592. [Google Scholar] [CrossRef]

- Givoni, M.; Perl, A. Rethinking Transport Infrastructure Planning to Extend Its Value over Time. J. Plan. Educ. Res. 2020, 40, 82–91. [Google Scholar] [CrossRef]

- Di Carlo, F.; Mazzuto, G.; Bevilacqua, M.; Ciarapica, F.E. Retrofitting a Process Plant in an Industry 4.0 Perspective for Improving Safety and Maintenance Performance. Sustainability 2021, 13, 646. [Google Scholar] [CrossRef]

- Bahers, J.-B.; Tanguy, A.; Pincetl, S. Metabolic Relationships between Cities and Hinterland: A Political-Industrial Ecology of Energy Metabolism of Saint-Nazaire Metropolitan and Port Area (France). Ecol. Econ. 2020, 167, 106447. [Google Scholar] [CrossRef]

- Jugović, A.; Sirotić, M.; Peronja, I. Sustainable Development of Port Cities from the Perspective of Transition Management. Trans. Marit. Sci. 2021, 10, 466–476. [Google Scholar] [CrossRef]

- Serry, A.; Loubet, L. Developing the City, Developing the Port: Comparison of the Governance in Medium-Size Port-Cities in Europe. TransNav Int. J. Mar. Navig. Saf. Sea Transp. 2019, 13, 607–614. [Google Scholar] [CrossRef]

- Alicke, K.; Rexhausen, D.; Seyfert, A. Supply Chain 4.0 in Consumer Goods; Mckinsey Co: New York, NY, 2017; pp. 1–11. Available online: https://www.mckinsey.com/~/media/McKinsey/Industries/Consumer%20Packaged%20Goods/Our%20Insights/Supply%20Chain%204%200%20in%20consumer%20goods/Supply-Chain-4-0-in-consumer-goods-vf.pdf (accessed on 25 November 2021).

- Wang, J.; Lim, M.K.; Zhan, Y.; Wang, X. An Intelligent Logistics Service System for Enhancing Dispatching Operations in an IoT Environment. Transp. Res. Part E: Logist. Transp. Rev. 2020, 135, 101886. [Google Scholar] [CrossRef]

- Heilig, L.; Lalla-Ruiz, E.; Voß, S. Digital Transformation in Maritime Ports: Analysis and a Game Theoretic Framework. Netnomics Econ. Res. Electron. Netw. 2017, 18, 227–254. [Google Scholar] [CrossRef]

- Dobrovnik, M.; Herold, D.M.; Fürst, E.; Kummer, S. Blockchain for and in Logistics: What to Adopt and Where to Start. Logistics 2018, 2, 18. [Google Scholar] [CrossRef] [Green Version]

- Ranieri, L.; Digiesi, S.; Silvestri, B.; Roccotelli, M. A Review of Last Mile Logistics Innovations in an Externalities Cost Reduction Vision. Sustainability 2018, 10, 782. [Google Scholar] [CrossRef] [Green Version]

- Wong, Y.Z.; Hensher, D.A.; Mulley, C. Emerging Transport Technologies and the Modal Efficiency Framework: A Case for Mobility as a Service (MaaS). 2018. Available online: https://ses.library.usyd.edu.au/handle/2123/19100 (accessed on 25 November 2021).

- Remondino, M.; Cappellini, A. Minority Game with Communication of Statements and Memory Analysis: A Multi Agent Based Model. Int. J. Simul. Syst. Sci. Technol. 2005, 6, 42–53. [Google Scholar]

- Anderluh, A.; Nolz, P.C.; Hemmelmayr, V.C.; Crainic, T.G. Multi-Objective Optimization of a Two-Echelon Vehicle Routing Problem with Vehicle Synchronization and ‘Grey Zone’Customers Arising in Urban Logistics. Eur. J. Oper. Res. 2021, 289, 940–958. [Google Scholar] [CrossRef]

- Bac, U.; Erdem, M. Optimization of Electric Vehicle Recharge Schedule and Routing Problem with Time Windows and Partial Recharge: A Comparative Study for an Urban Logistics Fleet. Sustain. Cities Soc. 2021, 70, 102883. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, Z.; Ai, H.; Guo, X.; Luo, F. The Impact of GIS/GPS Network Information Systems on the Logistics Distribution Cost of Tobacco Enterprises. Transp. Res. Part E Logist. Transp. Rev. 2021, 149, 102299. [Google Scholar] [CrossRef]

- Remondino, M. Augmented Reality in Logistics: Qualitative Analysis for a Managerial Perspective. Int. J. Logist. Syst. Manag. 2020, 35, 1. [Google Scholar] [CrossRef] [Green Version]

- Kraft, P.; Helm, R.; Dowling, M. New Business Models with Industrie 4.0 in the German Mittelstand. Int. J. Technol. Policy Manag. 2021, 21, 47–68. [Google Scholar] [CrossRef]

- Rodrigue, J.-P.; Slack, B.; Comtois, C. Green Logistics. In Handbook of Logistics and Supply-Chain Management; Emerald Group Publishing Limited: Bingley, UK, 2017. [Google Scholar]

- Botti, A.; Monda, A.; Pellicano, M.; Torre, C. The Re-Conceptualization of the Port Supply Chain as a Smart Port Service System: The Case of the Port of Salerno. Systems 2017, 5, 35. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Huang, T.; Xie, X.; Lee, P.T.-W.; Hua, C. Constructing Governance Framework of a Green and Smart Port. J. Mar. Sci. Eng. 2019, 7, 83. [Google Scholar] [CrossRef] [Green Version]

- Zis, T.P. Green Ports. In Sustainable Shipping; Springer: Berlin/Heidelberg, Germany, 2019; pp. 407–432. [Google Scholar]

- Klumpp, M. Automation and Artificial Intelligence in Business Logistics Systems: Human Reactions and Collaboration Requirements. Int. J. Logist. Res. Appl. 2018, 21, 224–242. [Google Scholar] [CrossRef]

- Haddud, A.; DeSouza, A.; Khare, A.; Lee, H. Examining Potential Benefits and Challenges Associated with the Internet of Things Integration in Supply Chains. J. Manuf. Technol. Manag. 2017, 28, 1055–1085. [Google Scholar] [CrossRef]

- Govindan, K.; Cheng, T.E.; Mishra, N.; Shukla, N. Big Data Analytics and Application for Logistics and Supply Chain Management. Transp. Res. Part E Logist. Transp. Rev. 2018, 114, 343–349. [Google Scholar] [CrossRef]

- Lee, P.T.-W.; Kwon, O.K.; Ruan, X. Sustainability Challenges in Maritime Transport and Logistics Industry and Its Way Ahead. Sustainability 2019, 11, 1331. [Google Scholar] [CrossRef] [Green Version]

- Lipych, L.; Bortnik, S.; Tovsteniuk, O.; Kchilycha, O.; Kushnir, M. Prospects for the Introduction of Innovations by Agricultural Enterprises in Ukraine. Probl. Perspect. Manag. 2017, 15, 53–63. [Google Scholar] [CrossRef] [Green Version]

- Arvis, J.-F.; Ojala, L.; Wiederer, C.; Shepherd, B.; Raj, A.; Dairabayeva, K.; Kiiski, T. Connecting to Compete 2018; World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Agrawal, M.; Eloot, K.; Mancini, M.; Patel, A. Industry 4.0: Reimagining Manufacturing Operations after COVID-19; McKinsey & Company: New York, NY, USA, 2020; Available online: https://www.mckinsey.com/business-functions/operations/our-insights/industry-40-reimagining-manufacturing-operations-after-covid-19 (accessed on 20 August 2020).

- Mohamed, M. Challenges and Benefits of Industry 4.0: An Overview. Int. J. Supply Oper. Manag. 2018, 5, 256–265. [Google Scholar]

- Bastas, A.; Liyanage, K. Setting a Framework for Organisational Sustainable Development. Sustain. Prod. Consum. 2019, 20, 207–229. [Google Scholar] [CrossRef]

- Parida, V.; Sjödin, D.; Reim, W. Reviewing Literature on Digitalization, Business Model Innovation, and Sustainable Industry: Past Achievements and Future Promises. Sustainability 2019, 11, 391. [Google Scholar] [CrossRef] [Green Version]

- Ordieres-Meré, J.; Prieto Remon, T.; Rubio, J. Digitalization: An Opportunity for Contributing to Sustainability from Knowledge Creation. Sustainability 2020, 12, 1460. [Google Scholar] [CrossRef] [Green Version]

- Manuel Maqueira, J.; Moyano-Fuentes, J.; Bruque, S. Drivers and Consequences of an Innovative Technology Assimilation in the Supply Chain: Cloud Computing and Supply Chain Integration. Int. J. Prod. Res. 2019, 57, 2083–2103. [Google Scholar] [CrossRef]

- Wu, Y.U.N.; Cegielski, C.G.; Hazen, B.T.; Hall, D.J. Cloud Computing in Support of Supply Chain Information System Infrastructure: Understanding When to Go to the Cloud. J. Supply Chain Manag. 2013, 49, 25–41. [Google Scholar] [CrossRef]

- Kundu, N. Predictive Analytics to Offer Profitable Anticipatory Shipping for E-Commerce Companies. Int. J. Mod. Agric. 2021, 10, 127–136. [Google Scholar]

- Tang, C.S.; Veelenturf, L.P. The Strategic Role of Logistics in the Industry 4.0 Era. Transp. Res. Part E Logist. Transp. Rev. 2019, 129, 1–11. [Google Scholar] [CrossRef]

- Barreto, L.; Amaral, A.; Pereira, T. Industry 4.0 Implications in Logistics: An Overview. Procedia Manuf. 2017, 13, 1245–1252. [Google Scholar] [CrossRef]

- Kayikci, Y. Sustainability Impact of Digitization in Logistics. Procedia Manuf. 2018, 21, 782–789. [Google Scholar] [CrossRef]

- Strandhagen, J.O.; Vallandingham, L.R.; Fragapane, G.; Strandhagen, J.W.; Stangeland, A.B.H.; Sharma, N. Logistics 4.0 and Emerging Sustainable Business Models. Adv. Manuf. 2017, 5, 359–369. [Google Scholar] [CrossRef]

- Brouer, B.D.; Karsten, C.V.; Pisinger, D. Big Data Optimization in Maritime Logistics. In Big Data Optimization: Recent Developments and Challenges; Springer: Berlin/Heidelberg, Germany, 2016; pp. 319–344. [Google Scholar]

- Al-Rakhami, M.S.; Al-Mashari, M. A Blockchain-Based Trust Model for the Internet of Things Supply Chain Management. Sensors 2021, 21, 1759. [Google Scholar] [CrossRef] [PubMed]

- Rodrigue, J.-P.; Notteboom, T. Dry Ports in European and North American Intermodal Rail Systems: Two of a Kind? Res. Transp. Bus. Manag. 2012, 5, 4–15. [Google Scholar] [CrossRef]

- Reis, V.; Meier, J.F.; Pace, G.; Palacin, R. Rail and Multi-Modal Transport. Res. Transp. Econ. 2013, 41, 17–30. [Google Scholar] [CrossRef]

- Aregall, M.G.; Bergqvist, R.; Monios, J. A Global Review of the Hinterland Dimension of Green Port Strategies. Transp. Res. Part D: Transp. Environ. 2018, 59, 23–34. [Google Scholar] [CrossRef]

- Warshauer, E.; Krosinsky, C. Financing the Transition to Green Infrastructure. In Values at Work; Springer: Berlin/Heidelberg, Germany, 2020; pp. 111–125. [Google Scholar]

- Partridge, T. “Power Farmers” in North India and New Energy Producers around the World: Three Critical Fields for Multiscalar Research. Energy Res. Soc. Sci. 2020, 69, 101575. [Google Scholar] [CrossRef]

- Li, R.; Su, M. The Role of Natural Gas and Renewable Energy in Curbing Carbon Emission: Case Study of the United States. Sustainability 2017, 9, 600. [Google Scholar] [CrossRef] [Green Version]

- Ahjum, F. SADC E-Mobility Outlook: Accelerating Low Carbon Transport Futures. 2020. Available online: https://media.africaportal.org/documents/Working-Paper_OP_Fadiel_Transport-and-Energy_20201103_1.pdf (accessed on 25 November 2021).

- Mete, G. Energy Transitions and the Future of Gas in the EU; Palgrave Macmillan: London, UK, 2019. [Google Scholar]

- Jakimowicz, A.; Rzeczkowski, D. The Impact of Public Administration Digitalization on the Decarbonization of the Economy. Energies 2021, 14, 5739. [Google Scholar] [CrossRef]

- Borowski, P.F. Digitization, Digital Twins, Blockchain, and Industry 4.0 as Elements of Management Process in Enterprises in the Energy Sector. Energies 2021, 14, 1885. [Google Scholar] [CrossRef]

- Lee, K.; Cha, J. Towards Improved Circular Economy and Resource Security in South Korea. Sustainability 2020, 13, 17. [Google Scholar] [CrossRef]

- García-Muiña, F.E.; Medina-Salgado, M.S.; Ferrari, A.M.; Cucchi, M. Sustainability Transition in Industry 4.0 and Smart Manufacturing with the Triple-Layered Business Model Canvas. Sustainability 2020, 12, 2364. [Google Scholar] [CrossRef] [Green Version]

- Albano, G.L.; Santocchia, M.G. A Case Study on Bid Rigging in Centralized Procurement of Audit Consulting Services in Italy. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3905749 (accessed on 25 November 2021).

- Lajoie-O’Malley, A.; Bronson, K.; van der Burg, S.; Klerkx, L. The Future (s) of Digital Agriculture and Sustainable Food Systems: An Analysis of High-Level Policy Documents. Ecosyst. Serv. 2020, 45, 101183. [Google Scholar] [CrossRef]

- Jellason, N.P.; Robinson, E.J.; Ogbaga, C.C. Agriculture 4.0: Is Sub-Saharan Africa Ready? Appl. Sci. 2021, 11, 5750. [Google Scholar] [CrossRef]

- Rose, D.C.; Chilvers, J. Agriculture 4.0: Broadening Responsible Innovation in an Era of Smart Farming. Front. Sustain. Food Syst. 2018, 2, 87. [Google Scholar] [CrossRef] [Green Version]

- Tal, A. Making Conventional Agriculture Environmentally Friendly: Moving beyond the Glorification of Organic Agriculture and the Demonization of Conventional Agriculture. Sustainability 2018, 10, 1078. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, R.; Kirchner, K.; Razmerita, L. Understanding the Business Value of Social Information Systems. In Proceedings of the 53rd Hawaii International Conference on System Sciences (HICSS), Honolulu, HI, USA, 7–10 January 2020. [Google Scholar] [CrossRef] [Green Version]

- Pérez-Lara, M.; Saucedo-Martínez, J.A.; Marmolejo-Saucedo, J.A.; Salais-Fierro, T.E.; Vasant, P. Vertical and Horizontal Integration Systems in Industry 4.0. Wirel. Netw. 2020, 26, 4767–4775. [Google Scholar] [CrossRef]

- Ciruela-Lorenzo, A.M.; Del-Aguila-Obra, A.R.; Padilla-Meléndez, A.; Plaza-Angulo, J.J. Digitalization of Agri-Cooperatives in the Smart Agriculture Context. Proposal of a Digital Diagnosis Tool. Sustainability 2020, 12, 1325. [Google Scholar] [CrossRef] [Green Version]

- Khanna, A.; Kaur, S. Evolution of Internet of Things (IoT) and Its Significant Impact in the Field of Precision Agriculture. Comput. Electron. Agric. 2019, 157, 218–231. [Google Scholar] [CrossRef]

- Mogili, U.R.; Deepak, B. Review on Application of Drone Systems in Precision Agriculture. Procedia Comput. Sci. 2018, 133, 502–509. [Google Scholar] [CrossRef]

- Shafi, U.; Mumtaz, R.; García-Nieto, J.; Hassan, S.A.; Zaidi, S.A.R.; Iqbal, N. Precision Agriculture Techniques and Practices: From Considerations to Applications. Sensors 2019, 19, 3796. [Google Scholar] [CrossRef] [Green Version]

- De Clercq, M.; Vats, A.; Biel, A. Agriculture 4.0: The Future of Farming Technology. Proc. World Gov. Summit Dubai UAE 2018, 1, 11–13. [Google Scholar]

- Eashwar, S.; Chawla, P. Evolution of Agritech Business 4.0–Architecture and Future Research Directions. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Surakarta, Indonesia, 24–25 August 2021; IOP Publishing: Bristol, UK, 2021; Volume 775, p. 012011. [Google Scholar]

- Reklitis, P.; Sakas, D.P.; Trivellas, P.; Tsoulfas, G.T. Performance Implications of Aligning Supply Chain Practices with Competitive Advantage: Empirical Evidence from the Agri-Food Sector. Sustainability 2021, 13, 8734. [Google Scholar] [CrossRef]

- Remondino, M. Agent Based Virtual Tutorship and E-Learning Techniques Applied to a Business Game Built on System Dynamics. In Proceedings of the 8th International Conference on Intelligent Games and Simulation, GAME-ON 2007, Bologna, Italy, 20–22 November 2007; pp. 157–161. [Google Scholar]

- Wolfert, S.; Ge, L.; Verdouw, C.; Bogaardt, M.-J. Big Data in Smart Farming—A Review. Agric. Syst. 2017, 153, 69–80. [Google Scholar] [CrossRef]

- Mageto, J. Big Data Analytics in Sustainable Supply Chain Management: A Focus on Manufacturing Supply Chains. Sustainability 2021, 13, 7101. [Google Scholar] [CrossRef]

- Cravero, A.; Sepúlveda, S. Use and Adaptations of Machine Learning in Big Data—Applications in Real Cases in Agriculture. Electronics 2021, 10, 552. [Google Scholar] [CrossRef]

- Alem, H. The Role of Technical Efficiency Achieving Sustainable Development: A Dynamic Analysis of Norwegian Dairy Farms. Sustainability 2021, 13, 1841. [Google Scholar] [CrossRef]

- Jin, X.-B.; Yu, X.-H.; Wang, X.-Y.; Bai, Y.-T.; Su, T.-L.; Kong, J.-L. Deep Learning Predictor for Sustainable Precision Agriculture Based on Internet of Things System. Sustainability 2020, 12, 1433. [Google Scholar] [CrossRef] [Green Version]

- Rossel, R.A.V.; Bouma, J. Soil Sensing: A New Paradigm for Agriculture. Agric. Syst. 2016, 148, 71–74. [Google Scholar] [CrossRef]

- Lu, Y. The Current Status and Developing Trends of Industry 4.0: A Review. Inf. Syst. Front. 2021, 1, 1–20. [Google Scholar] [CrossRef]

- Lezoche, M.; Hernandez, J.E.; del Mar Eva Alemany Díaz, M.; Panetto, H.; Kacprzyk, J. Agri-Food 4.0: A Survey of the Supply Chains and Technologies for the Future Agriculture. Comput. Ind. 2020, 117, 103187. [Google Scholar] [CrossRef]

- Fritter, M.S. Development of the Canadian Agri-Food Lifecycle Data Centre with Data Format Interoperability Requirements. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2020. [Google Scholar]

- Sharma, S.; Solanki, S.; Aswal, K.; Thakur, E.; Malhotra, I. Review on Application of Drone Systems in Agriculture. In Proceedings of the 2021 6th International Conference on Signal Processing, Computing and Control (ISPCC), Solan, India, 7–9 October 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 40–45. [Google Scholar]

- Hallett, S.; Hoagland, L.; Toner, E.; Gradziel, T.M.; Mitchell, C.A.; Whipkey, A.L. Urban Agriculture: Environmental, Economic, and Social Perspectives. Hortic. Rev. 2016, 44, 65–120. [Google Scholar]

- Kariapper, R.; Razeeth, M.S.S. Internet of Farming (IOF) and Internet of Things (IoT). J. Inf. Syst. Inf. Technol. 2018, 3, 23–35. [Google Scholar]

- Pescosolido, G. Italy’s Southern Question: Long-Standing Thorny Issues and Current Problems. J. Mod. Ital. Stud. 2019, 24, 441–455. [Google Scholar] [CrossRef]

- Adamashvili, N.; Fiore, M.; Contò, F.; Sala, P.L. Ecosystem for Successful Agriculture. Collaborative Approach as a Driver for Agricultural Development. Eur. Countrys. 2020, 12, 242–256. [Google Scholar] [CrossRef]

- Coluccia, B.; Agnusdei, G.P.; Miglietta, P.P.; De Leo, F. Effects of COVID-19 on the Italian Agri-Food Supply and Value Chains. Food Control 2021, 123, 107839. [Google Scholar] [CrossRef] [PubMed]

- Nyamah, E.Y.; Jiang, Y.; Feng, Y.; Enchill, E. Agri-Food Supply Chain Performance: An Empirical Impact of Risk. Manag. Decis. 2017, 55, 872–891. [Google Scholar] [CrossRef]

- Caracciolo, F.; Amani, P.; Cavallo, C.; Cembalo, L.; D’Amico, M.; Del Giudice, T.; Freda, R.; Fritz, M.; Lombardi, P.; Mennella, L. The Environmental Benefits of Changing Logistics Structures for Fresh Vegetables. Int. J. Sustain. Transp. 2018, 12, 233–240. [Google Scholar] [CrossRef]

- Castro, J.A.O.; Jaimes, W.A. Dynamic Impact of the Structure of the Supply Chain of Perishable Foods on Logistics Performance and Food Security. J. Ind. Eng. Manag. 2017, 10, 687–710. [Google Scholar]

- Haji, M.; Kerbache, L.; Muhammad, M.; Al-Ansari, T. Roles of Technology in Improving Perishable Food Supply Chains. Logistics 2020, 4, 33. [Google Scholar] [CrossRef]

- Li, X. Operations Management of Logistics and Supply Chain: Issues and Directions. Discret. Dyn. Nat. Soc. 2014, 2014, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Mentzer, J.T.; DeWitt, W.; Keebler, J.S.; Min, S.; Nix, N.W.; Smith, C.D.; Zacharia, Z.G. Defining Supply Chain Management. J. Bus. Logist. 2001, 22, 1–25. [Google Scholar] [CrossRef]

- Musolino, G.; Trecozzi, M.R. Structural Factors for a Third-Generation Port: Planning Interventions for Agri-Food Logistics in Gioia Tauro, Italy. Urban Marit. Transp. XXVII 2021, 204, 43. [Google Scholar]

- Malaspina, M. The Agri-Foodstuffs Market and the Value Chain: Proposals for an Integrated System of Multifunction Logistic Centres in the Metropolitan City of Reggio Calabria. In Advanced Engineering Forum; Trans Tech Publication: Stäfa, Switzerland, 2014; Volume 11, pp. 402–409. [Google Scholar]

- Russo, F.; Panuccio, P.; Rindone, C. Structural Factors for a Third-Generation Port: Between Hinterland Regeneration and Smart Town in Gioia Tauro, Italy. Urban Marit. Transp. XXVII 2021, 204, 79. [Google Scholar]

- Figiel, S.; Gospodarowicz, M.; Grochowska, R.; Kuberska, D.; Kufel-Gajda, J.; Oliński, M.; Wasilewski, A. Innovation Performance of the Polish Agri-Food Sector: Key Determinants and Prospects for Improvements. Monogr. Multi-Annu. Programme 2017. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3604974 (accessed on 25 November 2021).

- Akter, S.; Wamba, S.F.; Gunasekaran, A.; Dubey, R.; Childe, S.J. How to Improve Firm Performance Using Big Data Analytics Capability and Business Strategy Alignment? Int. J. Prod. Econ. 2016, 182, 113–131. [Google Scholar] [CrossRef] [Green Version]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Lu, S.C.-Y.; Nee, A.Y.C. Digital Twin-Driven Product Design Framework. Int. J. Prod. Res. 2018, 57, 3935–3953. [Google Scholar] [CrossRef] [Green Version]

- Adamashvili, N.; State, R.; Tricase, C.; Fiore, M. Blockchain-Based Wine Supply Chain for the Industry Advancement. Sustainability 2021, 13, 13070. [Google Scholar] [CrossRef]

- De Raeve, P.; Gomez, S.; Hughes, P.; Lyngholm, T.; Sipilä, M.; Kilanska, D.; Hussey, P.; Xyrichis, A.; ENS4Care Project. Enhancing the Provision of Health and Social Care in Europe through EH Ealth. Int. Nurs. Rev. 2017, 64, 33–41. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guttentag, D.A. Virtual Reality: Applications and Implications for Tourism. Tour. Manag. 2010, 31, 637–651. [Google Scholar] [CrossRef]

- Remondino, M. Virtual Reality and Immersive Simulation Technology Outside Video Gaming: Enterprise Applications and Potential Implications. Int. J. Simul. Syst. Sci. Technol. 2017, 18, 11.1–11.12. [Google Scholar] [CrossRef]

- Karlin, S.; Karlin, S.; Karlin, S. Jared Leto Tours the Arctic in A New Virtual Reality Climate Change Campaign. Available online: https://www.fastcompany.com/3052044/jared-leto-tours-the-arctic-in-a-new-virtual-reality-climate-change-campaign (accessed on 23 March 2018).

- Remondino, M. A Managerial Perspective of Technological Cloud Paradigms: Its Effects on Enterprise Business, Costs and Strategies. Int. J. Simul. Syst. Sci. Technol. 2017, 18, 1–12. [Google Scholar] [CrossRef]

- Spanaki, K.; Karafili, E.; Sivarajah, U.; Despoudi, S.; Irani, Z. Artificial Intelligence and Food Security: Swarm Intelligence of AgriTech Drones for Smart AgriFood Operations. Prod. Plan. Control 2021, 1–19. Available online: https://bradscholars.brad.ac.uk/bitstream/handle/10454/17961/Acceptedversion-PPCFinalSwarmintelligence.pdf?sequence=7&isAllowed=y (accessed on 25 November 2021).

- Daponte, P.; De Vito, L.; Glielmo, L.; Iannelli, L.; Liuzza, D.; Picariello, F.; Silano, G. A Review on the Use of Drones for Precision Agriculture. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Malang City, Indonesia, 12–13 March 2019; IOP Publishing: Bristol, UK, 2019; Volume 275, p. 012022. [Google Scholar]

- Iost Filho, F.H.; Heldens, W.B.; Kong, Z.; de Lange, E.S. Drones: Innovative Technology for Use in Precision Pest Management. J. Econ. Entomol. 2020, 113, 1–25. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stehr, N.J. Drones: The Newest Technology for Precision Agriculture. Nat. Sci. Educ. 2015, 44, 89–91. [Google Scholar] [CrossRef]

| Technology | Applications in Logistics | Managerial Sustainable Improvements |

|---|---|---|

| IoT [103,121,142,153,160] |

|

|

| Big Data [104,120,149,150,151,174] |

|

|

| Digital Twins [131,175] |

|

|

| Blockchain [89,121,131,176] |

|

|

| Vision Picking [96,177] |

|

|

| Virtual Reality (VR) & Augmented Reality (VR) [96,178,179,180] |

|

|

| Cloud Computing [40,80,113,114,181] |

|

|

| Unmanned Aerial Vehicles (UAV)—Drones [182,183,184,185] |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Remondino, M.; Zanin, A. Logistics and Agri-Food: Digitization to Increase Competitive Advantage and Sustainability. Literature Review and the Case of Italy. Sustainability 2022, 14, 787. https://doi.org/10.3390/su14020787

Remondino M, Zanin A. Logistics and Agri-Food: Digitization to Increase Competitive Advantage and Sustainability. Literature Review and the Case of Italy. Sustainability. 2022; 14(2):787. https://doi.org/10.3390/su14020787

Chicago/Turabian StyleRemondino, Marco, and Alessandro Zanin. 2022. "Logistics and Agri-Food: Digitization to Increase Competitive Advantage and Sustainability. Literature Review and the Case of Italy" Sustainability 14, no. 2: 787. https://doi.org/10.3390/su14020787

APA StyleRemondino, M., & Zanin, A. (2022). Logistics and Agri-Food: Digitization to Increase Competitive Advantage and Sustainability. Literature Review and the Case of Italy. Sustainability, 14(2), 787. https://doi.org/10.3390/su14020787