Investigation of Pressed Solid Biofuel Produced from Multi-Crop Biomass

Abstract

:1. Introduction

2. Materials and Methods

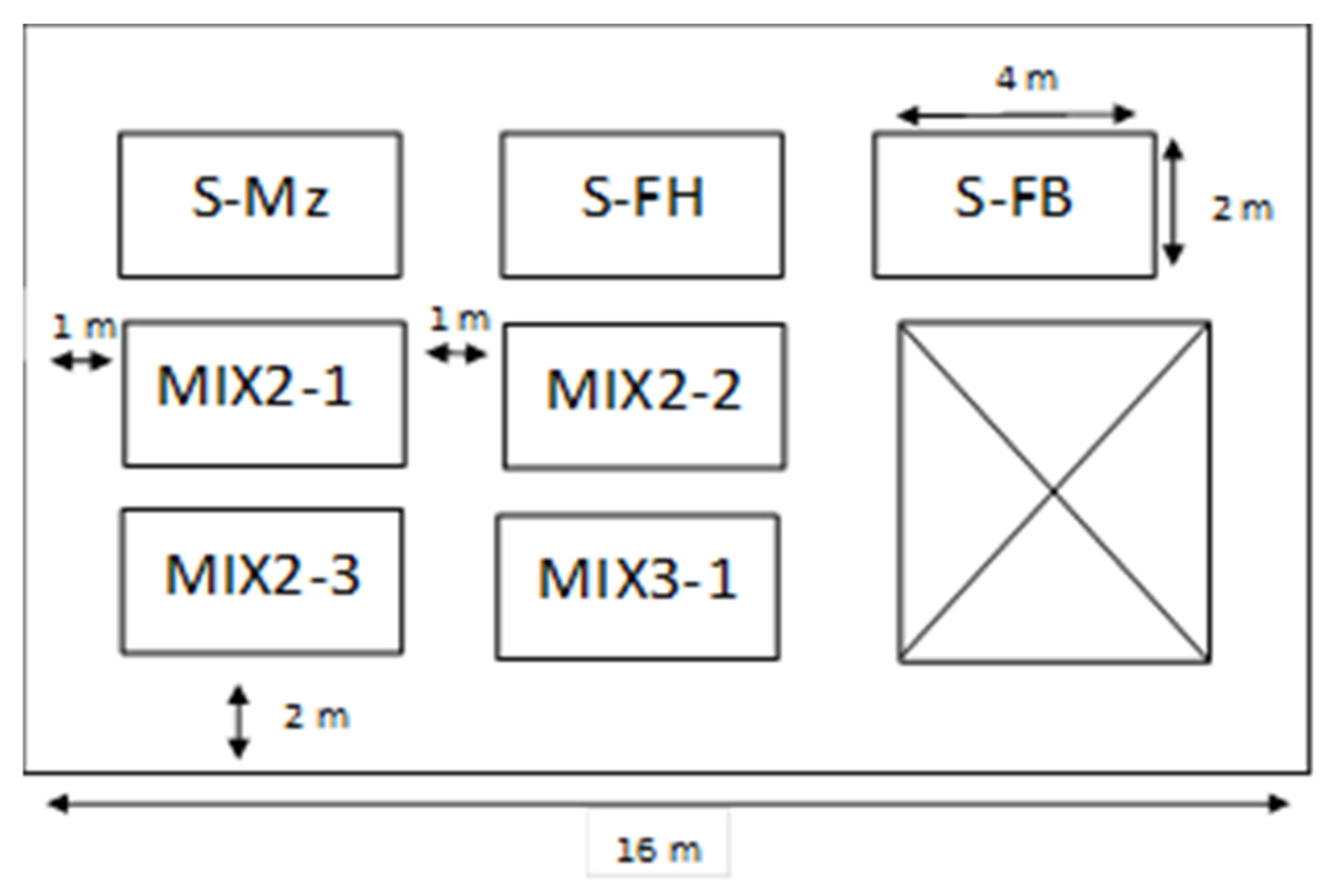

2.1. Selection and Preparation of Biomass for Granulation

2.2. Investigation of Biofuel Pellets and Determination of Their Properties

2.3. Determination of Ash Content and Essential Properties

3. Results and Discussion

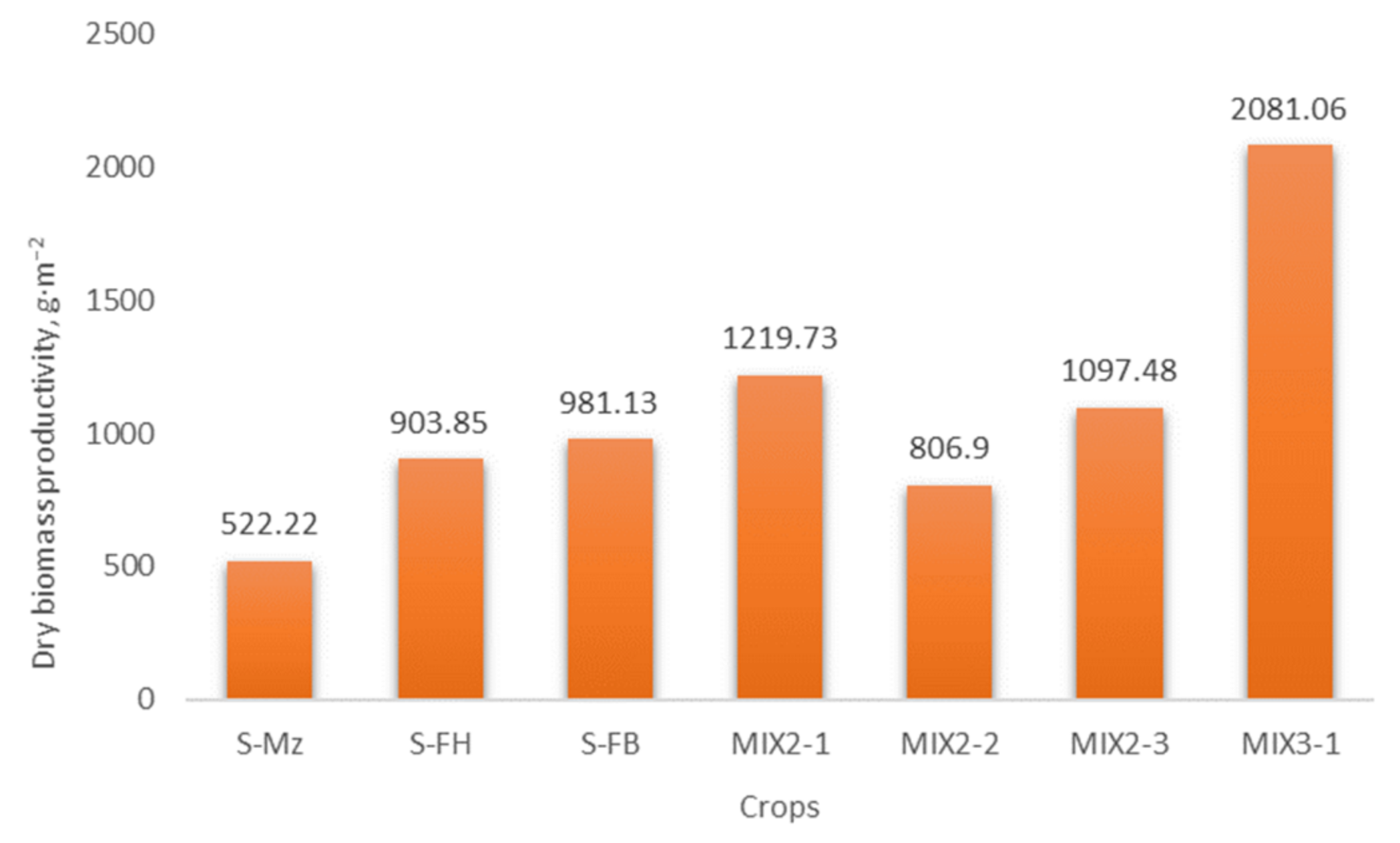

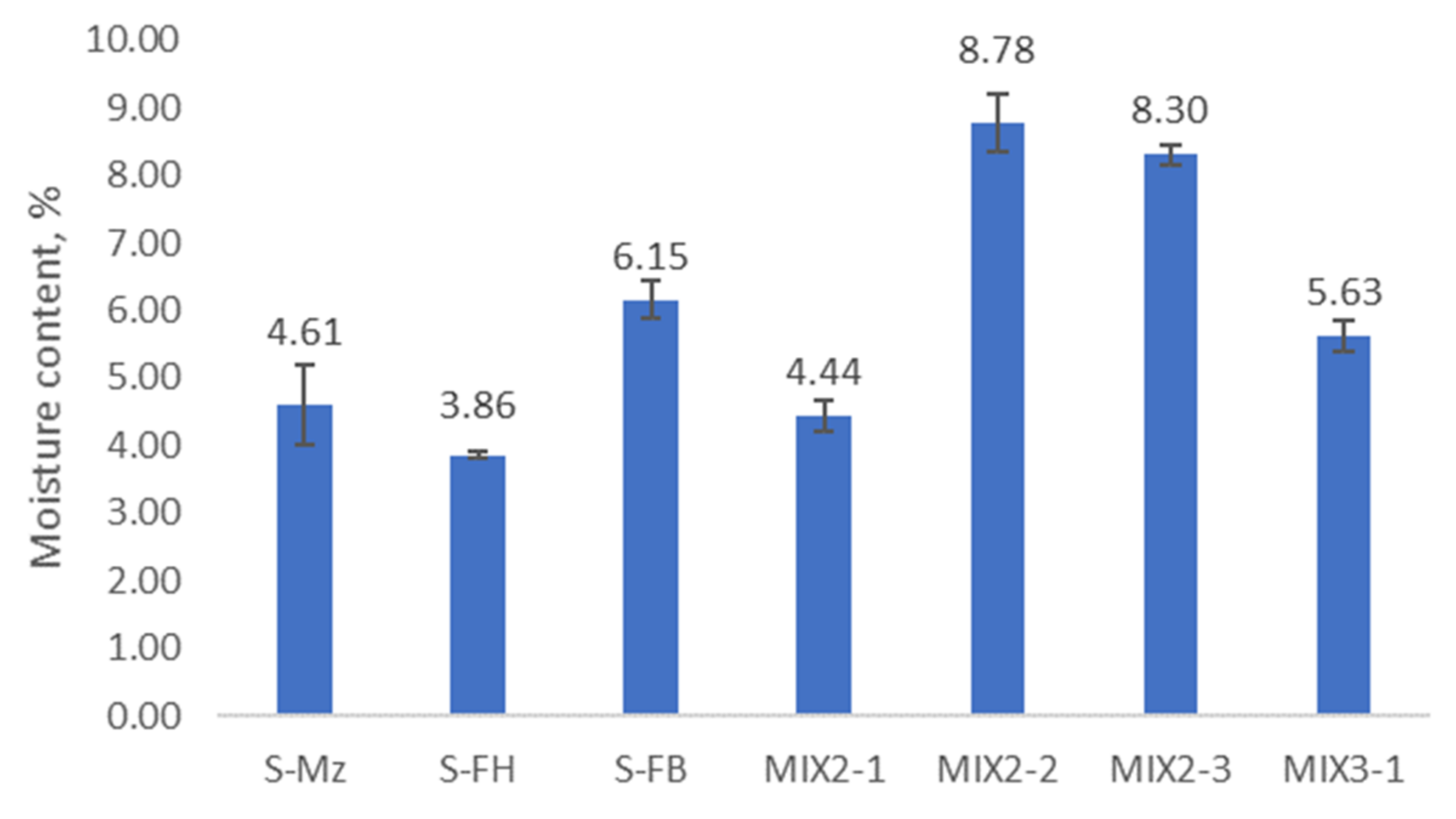

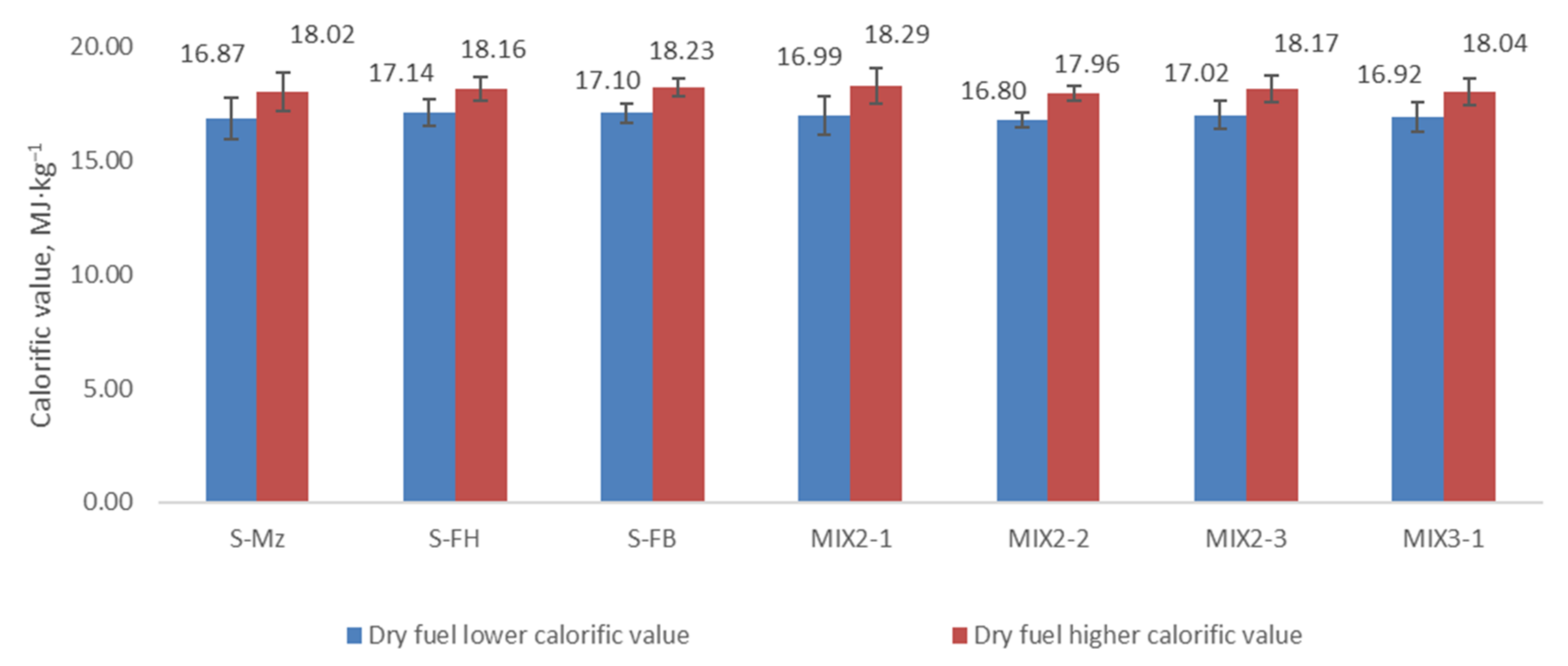

3.1. Physical–Mechanical, Chemical and Thermal Properties of Multi-Crop Mill and Pellets

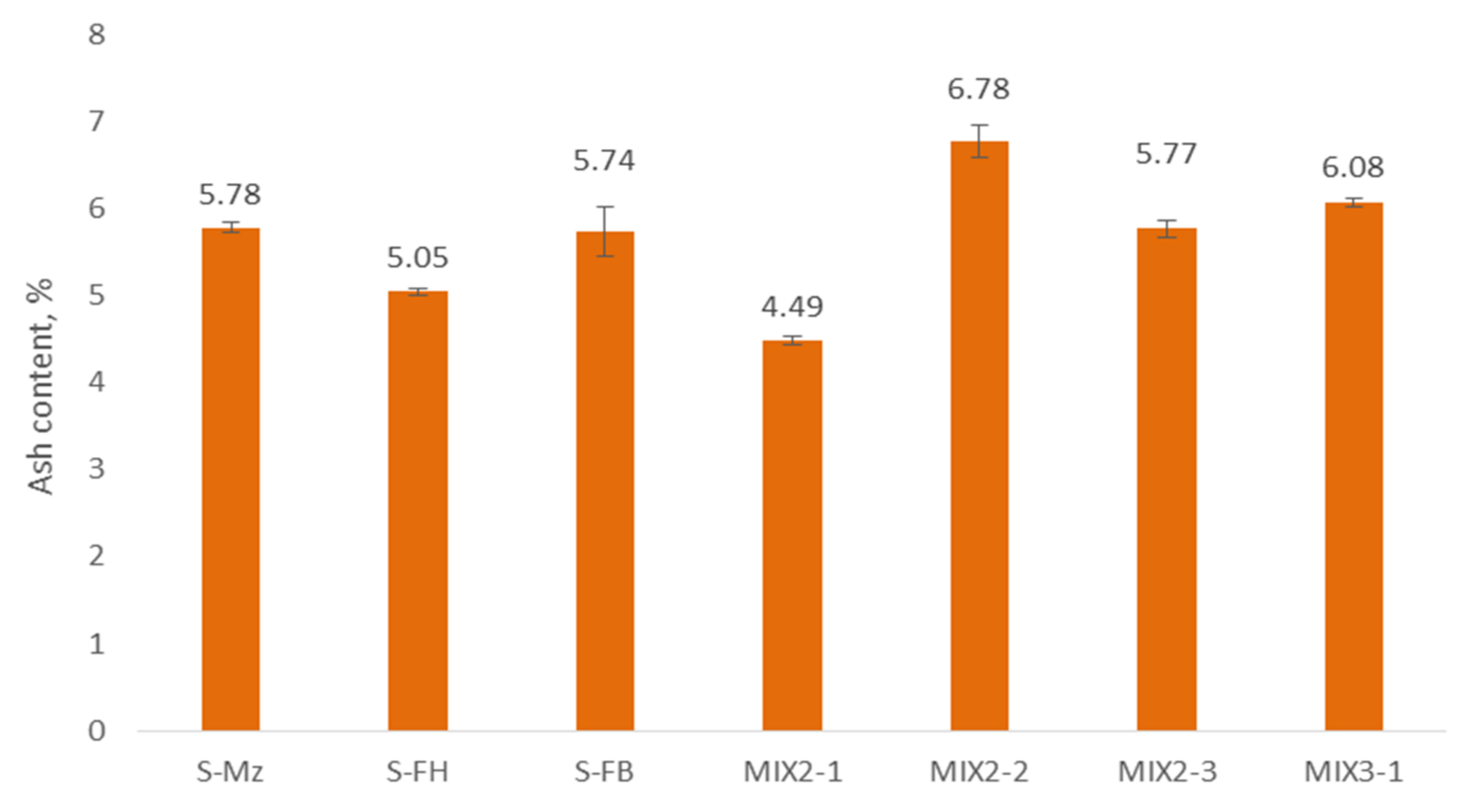

3.2. Ash Content of Burned Biomass Pellets, Elemental Composition and Melting Temperatures

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Wang, J.; Zhang, X.; Grushecky, S. Environmental and Economic Assessments and Uncertainties of Multiple Lignocellulosic Biomass Utilization for Bioenergy Products: Case Studies. Energies 2020, 13, 6277. [Google Scholar] [CrossRef]

- Ibitoye, S.E.; Jen, T.C.; Mahamood, R.M.; Akinlabi, E.T. Densification of agro-residues for sustainable energy generation: An overview. Bioresour. Bioprocess 2021, 8, 75. [Google Scholar] [CrossRef]

- Picchio, R.; Francesco Latterini, F.; Venanzi, R.; Stefanoni, W.; Suardi, A.; Tocci, D.; Pari, L. Pellet Production from Woody and Non-Woody Feedstocks: A Review on Biomass Quality Evaluation. Energies 2020, 13, 2937. [Google Scholar] [CrossRef]

- Whittaker, C.; Shield, I. Factors affecting wood, energy grass and straw pellet durability—A review. Renew. Sustain. Energy Rev. 2017, 71, 1–11. [Google Scholar] [CrossRef]

- Ţîţei, V.; Gadibadi, M.; Guţu, A.; Daraduda, N.; Mazăre, V.; Armaş, A.; Cerempei, V. Biomass quality of hemp, Cannabis sativa L. and prospects of its use for various energy purposes. Agronomy 2020, LXIII, 2. [Google Scholar]

- Tulmuru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densification systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Bioref. 2011, 5, 683–707. [Google Scholar]

- Miranda, M.T.; Sepúlveda, F.J.; Arranz, J.I.; Montero, I.; Rojas, C.V. Analysis of pelletizing from corn cob waste. J. Environ. Manag. 2018, 228, 303–311. [Google Scholar] [CrossRef] [PubMed]

- Pradhan, P.; Mahajani, S.M.; Arora, A. Production and utilization of fuel pellets from biomass: A review. Fuel Process. Technol. 2018, 181, 215–232. [Google Scholar] [CrossRef]

- Miao, Z.; Grift, T.E.; Hansen, A.C.; Ting, K.C. Energy requirement for comminution of biomass in relation to particle physical properties. Ind. Crop. Prod. 2011, 33, 504–513. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Grinding performance and physical properties of wheat and barley straws, corn stover and switchgrass. Biomass Bioenergy 2004, 27, 339–352. [Google Scholar] [CrossRef]

- Wu, Y.; He, D.; Wang, E.; Liu, X.; Huth, N.I.; Zhao, Z.; Gong, W.; Yang, F.; Wang, X.; Yong, T.; et al. Modelling soybean and maize growth and grain yield in strip intercropping systems with different row configurations. Field Crops Res. 2021, 265, 108122. [Google Scholar] [CrossRef]

- Lithourgidis, A.S.; Dordas, C.A.; Damalas, C.A.; Vlachostergios, D.N. Annual intercrops: An alternative pathway for sustainable agriculture. Aust. J. Crop Sci. 2011, 5, 396–410. [Google Scholar]

- Brooker, R.W.; Alison, E.; Bennett, A.E.; Cong, W.F.; Tim, J.; Daniell, T.J.; George, T.S.; Paul, D.; Hallett, P.D.; Hawes, C.; et al. Improving intercropping: A synthesis of research in agronomy, plant physiology and ecology. New Phytol. 2015, 206, 107–117. [Google Scholar] [CrossRef]

- Sharma, G.; Shrestha, S.; Kunwar, S.; Tseng, T.M. Crop Diversification for Improved Weed Management: A Review. Agriculture 2021, 11, 461. [Google Scholar] [CrossRef]

- He, H.M.; Liu, L.N.; Munir, S.; Bashir, N.H.; Wang, Y.; Yang, J.; Li, C.Y. Crop diversity and pest management in sustainable agriculture. J. Integr. Agric. 2019, 18, 1945–1952. [Google Scholar] [CrossRef]

- Jensen, E.S.; Carlsson, G.; Hauggaard-Nielsen, H. Intercropping of grain legumes and cereals improves the use of soil N resources and reduces the requirement for synthetic fertilizer N: A global-scale analysis. Agron. Sustain. Dev. 2020, 40, 5. [Google Scholar] [CrossRef] [Green Version]

- Haug, B.; Messmer, M.M.; Enjalbert, J.; Goldringer, I.; Forst, E.; Flutre, T.; Mary-Huard, T.; Hohmann, P. Advances in Breeding for Mixed Cropping—Incomplete Factorials and the Producer/Associate Concept. Front. Plant Sci. 2021, 11, 620400. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Hoffland, E.; Kuyper, T.W.; Yu, Y.; Zhang, C.; Li, H.; Zhang, F.; van der Werf, W. Syndromes of production in intercropping impact yield gains. Nat. Plants 2020, 6, 653–660. [Google Scholar] [CrossRef] [PubMed]

- Kraszkiewicz, A.; Kachel, M.; Parafiniuk, S.; Zajac, G.; Niedziółka, I.; Sprawka, M. Assessment of the Possibility of Using Hemp Biomass (Cannabis sativa L.) for Energy Purposes: A Case Study. Appl. Sci. 2019, 9, 4437. [Google Scholar] [CrossRef] [Green Version]

- Prade, T.; Svensson, S.E.; Andersson, A.; Mattsson, J.E. Biomass and energy yield of industrial hemp grown for biogas and solid fuel. Biomass Bioenergy 2011, 35, 3040–3049. [Google Scholar] [CrossRef]

- Parvez, A.M.; Lewis, J.D.; Afzal, M.T. Potential of industrial hemp (Cannabis sativa L.) for bioenergy production in Canada: Status, challenges and outlook. Renew. Sustain. Energy Rev. 2021, 141, 110784. [Google Scholar] [CrossRef]

- Miedaner, T.; Juroszek, P. Global warming and increasing maize cultivation demand comprehensive efforts in disease and insect resistance breeding in north-western Europe. Plant Pathol. 2021, 70, 1032–1046. [Google Scholar] [CrossRef]

- Bajwa, D.S.; Peterson, T.; Sharma, N.; Shojaeiarani, J.; Bajwa, S.G. A review of densified solid biomass for energy production. Renew. Sustain. Energy Rev. 2018, 96, 296–305. [Google Scholar] [CrossRef]

- Jasinskas, A.; Streikus, D.; Vonžodas, T. Fibrous hemp (Felina 32, USO 31, Finola) and fibrous nettle processing and usage of pressed biofuel for energy purposes. Renew. Energy 2020, 149, 11–21. [Google Scholar] [CrossRef]

- Šarauskis, E.; Romaneckas, K.; Jasinskas, A.; Kimbirauskienė, R.; Naujokienė, V. Improving energy efficiency and environmental mitigation through tillage management in faba bean production. Energy 2020, 209, 118453. [Google Scholar] [CrossRef]

- Okot, D.K.; Bilsborrow, P.E.; Phan, A.N. Briquetting characteristics of bean straw-maize cob blend. Biomass Bioenergy 2019, 126, 150–158. [Google Scholar] [CrossRef]

- Cui, X.; Yang, J.; Wang, Z.; Shi, X. Better use of bioenergy: A critical review of co-pelletizing for biofuel manufacturing. Carbon Capture Sci. Technol. 2021, 1, 100005. [Google Scholar] [CrossRef]

- García-Maraver, A.; Popov, V.; Zamorano, M. A review of European standards for pellet quality. Renew. Energy 2011, 36, 3537–3540. [Google Scholar] [CrossRef]

- Zhai, J.; Burke, I.T.; Stewart, D.I. Beneficial management of biomass combustion ashes. Renew. Sustain. Energy Rev. 2021, 151, 111555. [Google Scholar] [CrossRef]

- Silva, F.C.; Cruz, N.C.; Tarelho, L.A.C.; Rodrigues, S.M. Use of biomass ash-based materials as soil fertilisers: Critical review of the existing regulatory framework. J. Clean. Prod. 2019, 214, 112–124. [Google Scholar] [CrossRef]

- Voshell, S.; Mäkelä, M.; Dahla, O. A review of biomass ash properties towards treatment and recycling. Renew. Sustain. Energy Rev. 2018, 96, 479–486. [Google Scholar] [CrossRef]

- ISO 18847:2016; Solid Biofuels—Determination of Particle Density of Pellets and Briquettes. Available online: https://www.iso.org/standard/63560.html (accessed on 10 December 2021).

- ISO 16967:2015; Solid biofuels—Determination of major elements—Al, Ca, Fe, Mg, P, K, Si, Na and Ti. Available online: https://www.iso.org/standard/58065.html (accessed on 10 December 2021).

- Kleinhans, U.; Wieland, C.; Frandsen, F.J.; Spliethoff, H. Ash formation and deposition in coal and biomass fired combustion systems: Progress and challenges in the field of ash particle sticking and rebound behavior. Prog. Energy Combust. Sci. 2018, 68, 65–168. [Google Scholar] [CrossRef]

- Praspaliauskas, M.; Pedišius, N. A review of sludge characteristics in Lithuania’s wastewater treatment plants and perspectives of its usage in thermal processes. Renew. Sustain. Energy Rev. 2017, 67, 899–907. [Google Scholar] [CrossRef]

- Mostafa, M.E.; Hu, S.; Wang, Y.; Su, S.; Hu, X.; Elsayed, S.A.; Xiang, J. The significance of pelletization operating conditions: An analysis of physical and mechanical characteristics as well as energy consumption of biomass pellets. Renew. Sustain. Energy Rev. 2019, 105, 332–348. [Google Scholar] [CrossRef]

- Anukam, A.; Berghel, J.; Henrikson, G.; Frodeson, S.; Ståhl, M. A review of the mechanism of bonding in densified biomass pellets. Renew. Sustain. Energy Rev. 2021, 148, 111249. [Google Scholar] [CrossRef]

- Fusi, A.; Bacenetti, J.; Proto, A.R.; Tedesco, D.E.A.; Pessina, D.; Facchinetti, D. Pellet Production from Miscanthus: Energy and Environmental Assessment. Energies 2021, 14, 73. [Google Scholar] [CrossRef]

- Jasinskas, A.; Minajeva, A.; Šarauskis, E.; Romaneckas, K.; Kimbirauskienė, R.; Pedišius, N. Recycling and utilisation of faba bean harvesting and threshing waste for bioenergy. Renew. Energy 2020, 162, 257–266. [Google Scholar] [CrossRef]

- Sulaiman, M.A.; Adetifa, B.O.; Adekomaya, S.O.; Lawal, N.S.; Adama, O.O. Experimental characterization of maize cob and stalk based pellets for energy use. Eng. J. 2019, 23, 6. [Google Scholar] [CrossRef]

- Said, N.; Abdel Daiem, M.M.; García-Maraver, A.; Zamorano, M. Influence of densification parameters on quality properties of rice straw pellets. Fuel Processing Technol. 2015, 138, 56–64. [Google Scholar] [CrossRef]

- DIN 51731. Testing of solid fuels, compressed untreated wood. In Requirements and Testing; Deutsches Institut für Normung: Berlin, Germany, 1996. [Google Scholar]

- Nunes, L.J.R.; Matias, J.C.O.; Catalão, J.P.S. Mixed biomass pellets for thermal energy production: A review of combustion models. Appl. Energy 2014, 127, 135–140. [Google Scholar] [CrossRef]

- Osman, A.I.; Mehta, N.; Elgarahy, A.M.; Al-Hinai, A.; Al-Muhtaseb, A.H.; Rooney, D.W. Conversion of biomass to biofuels and life cycle assessment: A review. Environ. Chem. Lett. 2021, 19, 4075–4118. [Google Scholar] [CrossRef]

- Lavergne, S.; Larsson, S.H.; Perez, D.S.; Marchand, M.; Campargue, M.; Dupont, C. Effect of process parameters and biomass composition on flat-die pellet production from underexploited forest and agricultural biomass. Fuel 2021, 302, 121076. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Gołębiowski, W.; Szczepanik, M. Chemical Characteristics of Biomass Ashes. Energies 2018, 11, 2885. [Google Scholar] [CrossRef] [Green Version]

- Serrano, C.; Monedero, E.; Portero, H.; Jiménez, E.; Ordás, B. Efficient biofuel production from traditional maize under low input. Agron. Sustain. Dev. 2014, 34, 561–567. [Google Scholar] [CrossRef] [Green Version]

- Vassilev, S.V.; Vassileva, C.G.; Song, Y.C.; Li, W.Y.; Feng, J. Ash contents and ash-forming elements of biomass and their significance for solid biofuel combustion. Fuel 2017, 208, 377–409. [Google Scholar] [CrossRef]

- Manić, N.; Janković, B.; Milović, L.; Komatina, M.; Stojiljković, D. The impact of production operating parameters on mechanical and thermophysical characteristics of commercial wood pellets. Biomass Conv. Bioref. 2021, 1–17. [Google Scholar] [CrossRef]

- Platace, R.; Adamovics, A.; Ivanovs, S.; Gulbe, I. Assessment of ash melting temperature of birch and grass biomass pellet mixtures. Engineering for rural development. Jelgava 2017, 24, 103–107. [Google Scholar]

- Radačovská, L.; Holubčík, M.; Noseka, R.; Jandačka, J. Influence of bark content on ash melting temperature. Procedia Eng. 2017, 192, 759–764. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the composition and application of biomass ash. Part 2. Potential utilisation, technological and ecological advantages and challenges. Fuel 2013, 105, 19–39. [Google Scholar] [CrossRef]

- Wierzbowska, J.; Sienkiewicz, S.; Żarczyńki, P.; Krzebietke, S. Environmental Application of Ash from Incinerated Biomass. Agronomy 2020, 10, 482. [Google Scholar] [CrossRef] [Green Version]

- Cruz-Paredes, C.; López-García, Á.; Rubæk, G.H.; Hovmand, M.F.; Sørensen, P.; Kjøller, R. Risk assessment of replacing conventional P fertilizers with biomass ash: Residual effects on plant yield, nutrition, cadmium accumulation and mycorrhizal status. Sci. Total Environ. 2017, 575, 1168–1176. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; He, F.; Zhang, Y.; Yu, R.; Li, Y.; Zheng, Z.; Gao, Z. Experiments and modelling of potassium release behaviour from tablet biomass ash for better recycling of ash as eco-friendly fertilizer. J. Clean. Prod. 2018, 170, 379–387. [Google Scholar] [CrossRef]

| Type of Biomass | Average Fraction Remaining on Sieve, with Error, % (Diameter of Sieve Holes, mm) | ||||||

|---|---|---|---|---|---|---|---|

| 2.0 | 1.0 | 0.63 | 0.5 | 0.25 | 0.1 | 0.0 | |

| S-Mz | 0.23 ± 0.04 | 42.90 ± 17.10 | 18.64 ± 14.60 | 8.46 ± 4.68 | 18.91 ± 1.52 | 5.34 ± 1.51 | 5.52 ± 0.34 |

| S-FH | 75.20 ± 14.19 | 1.44 ± 2.07 | 6.00 ± 3.58 | 4.54 ± 3.35 | 7.86 ± 3.68 | 2.32 ± 1.12 | 2.66 ± 0.70 |

| S-FB | 3.96 ± 2.15 | 36.92 ± 6.41 | 28.53 ± 4.24 | 5.45 ± 2.19 | 13.76 ± 1.85 | 4.31 ± 0.62 | 7.07 ± 0.77 |

| MIX2-1 | 41.81 ± 2.94 | 6.49 ± 2.27 | 25.66 ± 10.07 | 5.41 ± 3.48 | 13.83 ± 2.55 | 2.96 ± 0.65 | 3.84 ± 0.51 |

| MIX2-2 | 66.95 ± 8.92 | 2.16 ± 0.83 | 9.10 ± 3.79 | 5.21 ± 1.09 | 9.87 ± 1.47 | 2.75 ± 1.44 | 3.95 ± 0.67 |

| MIX2-3 | 0.23 ± 0.08 | 32.41 ± 7.68 | 32.15 ± 14.50 | 5.12 ± 1.87 | 20.02 ± 4.13 | 5.21 ± 1.90 | 4.86 ± 1.16 |

| MIX3-1 | 20.59 ± 10.58 | 23.14 ± 12.02 | 29.02 ± 0.89 | 4.56 ± 0.49 | 14.18 ± 1.23 | 3.75 ± 0.70 | 4.77 ± 0.22 |

| Type of Biomass | Chemical Composition, % | |||||

|---|---|---|---|---|---|---|

| C | O | H | S | N | Cl | |

| S-Mz | 45.61 ± 1.13 | 42.21 | 5.59 ± 0.46 | 0.06 ± 0.46 | 0.81 ± 0.32 | 0.17 ± 0.04 |

| S-FH | 42.47 ± 2.15 | 47.11 | 4.96 ± 0.05 | 0.04 ± 0.01 | 0.41 ± 0.18 | 0.20 ± 0.02 |

| S-FB | 46.57 ± 0.56 | 41.32 | 5.47 ± 0.05 | 0.06 ± 0.03 | 0.91 ± 0.16 | 0.22 ± 0.02 |

| MIX2-1 | 45.88 ± 1.13 | 43.32 | 5.66 ± 0.45 | 0.04 ± 0.33 | 0.65 ± 0.31 | 0.12 ± 0.02 |

| MIX2-2 | 45.80 ± 0.67 | 41.05 | 5.60 ± 0.05 | 0.04 ± 0.01 | 0.76 ± 0.16 | 0.10 ± 0.02 |

| MIX2-3 | 45.88 ± 0.67 | 41.88 | 5.59 ± 0.05 | 0.06 ± 0.01 | 0.88 ± 0.16 | 0.12 ± 0.02 |

| MIX3-1 | 45.35 ± 1.31 | 42.33 | 5.41 ± 0.09 | 0.05 ± 0.01 | 0.82 ± 0.30 | 0.11 ± 0.02 |

| Type of Biomass | Moisture Content, % | Length, mm | Diameter, mm | Weight, g | Density, kg·m−3 | Density, kg·m−3 (DM) |

|---|---|---|---|---|---|---|

| S-Mz | 4.61 ± 0.59 | 26.78 ± 1.31 | 6.18 ± 0.05 | 0.98 ± 0.06 | 1215.60 ± 30.48 | 1159.57 ± 29.08 |

| S-FH | 3.86 ± 0.05 | 26.05 ± 1.20 | 6.17 ± 0.16 | 0.97 ± 0.06 | 1243.75 ± 48.94 | 1195.75 ± 47.05 |

| S-FB | 6.15 ± 0.28 | 23.69 ± 1.13 | 6.08 ± 0.06 | 0.88 ± 0.05 | 1273.77 ± 36.40 | 1195.42 ± 34.16 |

| MIX2-1 | 4.44 ± 0.22 | 26.36 ± 1.48 | 6.14 ± 0.03 | 0.95 ± 0.06 | 1215.27 ± 37.03 | 1161.30 ± 37.30 |

| MIX2-2 | 8.78 ± 0.43 | 25.93 ± 1.64 | 6.10 ± 0.13 | 0.92 ± 0.08 | 1212.90 ± 46.70 | 1106.46 ± 42.60 |

| MIX2-3 | 8.30 ± 0.15 | 23.43 ± 1.94 | 6.13 ± 0.08 | 0.85 ± 0.09 | 1230.30 ± 58.80 | 1128.12 ± 53.88 |

| MIX3-1 | 5.63 ± 0.23 | 26.30 ± 1.56 | 6.18 ± 0.07 | 0.95 ± 0.06 | 1211.44 ± 31.87 | 1143.26 ± 30.08 |

| Type of Biofuel | Melting Temperature, °C | |||

|---|---|---|---|---|

| Ash Softening Temperature (ST) | Initial Ash Deformation Temperature (DT) | Ash Hemisphere Temperature (HT) | Ash Fusibility Temperature (FT) | |

| S-Mz | 940 ± 0.30 | 976 ± 0.29 | 1070 ± 0.20 | 1089 ± 1.69 |

| S-FH | 741 ± 0.57 | 1322 ± 1.07 | 1408 ± 0.40 | 1432 ± 0.20 |

| S-FB | 1062 ± 1.60 | 1141 ± 0.87 | 1163 ± 0.12 | 1178 ± 0.72 |

| MIX2-1 | 1007 ± 0.63 | 1061 ± 0.93 | 1118 ± 0.76 | 1135 ± 0.37 |

| MIX2-2 | 1029 ± 0.27 | 1051 ± 0.13 | 1137 ± 0.37 | 1177 ± 0.36 |

| MIX2-3 | 935 ± 0.76 | 969 ± 0.73 | 1104 ± 0.26 | 1184 ± 0.96 |

| MIX3-1 | 968 ± 0.58 | 1007 ± 1.12 | 1129 ± 0.88 | 1199 ± 0.83 |

| Chemical Element | Types of Multi-Crops | ||||||

|---|---|---|---|---|---|---|---|

| S-Mz | S-FH | S-FB | MIX2-1 | MIX2-2 | MIX2-3 | MIX3-1 | |

| Chemical Composition of Multi-Crop Ash, mg kg−1 | |||||||

| Cd | <0.51 | <0.51 | <0.51 | <0.51 | <0.51 | <0.51 | <0.51 |

| Pb | <1.20 | <1.20 | <1.20 | <1.20 | 2.68 ± 0.95 | <1.20 | <1.20 |

| Cu | 67.40 ± 3.21 | 85.06 ± 0.91 | 64.82 ± 3.45 | 80.63 ± 1.86 | 71.88 ± 3.74 | 63.17 ± 1.55 | 66.62 ± 7.44 |

| Zn | 522.00 ± 20.44 | 679.83 ± 17.49 | 154.64 ± 19.06 | 581.38 ± 3.74 | 721.02 ± 19.08 | 1339.21 ± 14.71 | 400.17 ± 40.65 |

| Mg | 31,638.10 ± 16.11 | 27,555.96 ± 10.77 | 21,018.50 ± 9.33 | 37,380.16 ± 24.94 | 23,870.85 ± 12.64 | 27,882.13 ± 6.70 | 27,466.08 ± 11.20 |

| Fe | 8848.28 ± 14.30 | 9029.58 ± 10.71 | 11,672.95 ± 10.39 | 8880.02 ± 16.22 | 21,934.71 ± 11.53 | 15,869.02 ± 8.71 | 7671.48 ± 12.28 |

| Ca | 51,549.95 ± 18.09 | 156,890.20 ± 13.41 | 117,840.35 ± 10.63 | 96,122.58 ± 17.03 | 118,996.52 ± 12.50 | 89,728.14 ± 8.79 | 104,086.17 ± 14.26 |

| K | 265,865.78 ± 2.00 | 197,921.93 ± 10.99 | 85,964.19 ± 13.62 | 231,545.58 ± 7.87 | 123,579.76 ± 14.39 | 159,210.76 ± 13.98 | 144,021.32 ± 12.11 |

| Si | 95,668.66 ± 8.98 | 62,609.65 ± 11.40 | 248,960.29 ± 33.63 | 81,779.35 ± 25.03 | 216,689.14 ± 17.04 | 260,773.74 ± 9.22 | 228,605.42 ± 20.63 |

| Al | 1375.16 ± 8.24 | 1551.06 ± 2.68 | 6482.69 ± 7.98 | 1520.43 ± 7.34 | 4836.99 ± 8.60 | 4207.60 ± 6.26 | 4650.34 ± 7.22 |

| Na | 630.64 ± 5.73 | 2082.72 ± 15.08 | 1604.98 ± 6.94 | 1080.55 ± 26.39 | 9302.97 ± 9.58 | 8454.99 ± 2.20 | 5878.78 ± 16.30 |

| P | 28,847.45 ± 18.81 | 30,359.01 ± 13.92 | 16,922.97 ± 11.41 | 30,771.96 ± 33.61 | 22,088.97 ± 15.92 | 26,305.29 ± 23.73 | 24,665.83 ± 16.71 |

| Chemical Composition of Multi-Crop Ash, % | |||||||

| Cl | 0.27 ± 0.05 | 1.07 ± 0.21 | 0.40 ± 0.11 | 2.41 ± 0.47 | 0.70 ± 0.12 | 2.47 ± 0.74 | 1.76 ± 0.27 |

| S | 0.08 ± 0.02 | 0.62 ± 0.11 | 0.55 ± 0.11 | 0.67 ± 0.12 | 0.49 ± 0.08 | 0.87 ± 0.18 | 0.63 ± 0.13 |

| Chemical Element | In Forestry | In Agriculture/Remediation of Damaged Areas |

|---|---|---|

| Concentration, mg kg−1 in Dry Matter | ||

| Boron (B) | 200 | 250 |

| Vanadium (V) | 150 | 150 |

| Nickel (Ni) | 20 | 30 |

| Chrome (Cr) | 20 | 30 |

| Cadmium (Cd) | 3 | 5 |

| Lead (Pb) | 40 | 50 |

| Copper (Cu) | 100 | 200 |

| Zinc (Zn) | 1000 | 1500 |

| Arsenic (As) | 3 | 3 |

| Mercury (Hg) | 0.2 | 0.2 |

| Benz(a)pyrene, μg·kg−1 | 0.5 | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petlickaitė, R.; Jasinskas, A.; Mieldažys, R.; Romaneckas, K.; Praspaliauskas, M.; Balandaitė, J. Investigation of Pressed Solid Biofuel Produced from Multi-Crop Biomass. Sustainability 2022, 14, 799. https://doi.org/10.3390/su14020799

Petlickaitė R, Jasinskas A, Mieldažys R, Romaneckas K, Praspaliauskas M, Balandaitė J. Investigation of Pressed Solid Biofuel Produced from Multi-Crop Biomass. Sustainability. 2022; 14(2):799. https://doi.org/10.3390/su14020799

Chicago/Turabian StylePetlickaitė, Rita, Algirdas Jasinskas, Ramūnas Mieldažys, Kęstutis Romaneckas, Marius Praspaliauskas, and Jovita Balandaitė. 2022. "Investigation of Pressed Solid Biofuel Produced from Multi-Crop Biomass" Sustainability 14, no. 2: 799. https://doi.org/10.3390/su14020799

APA StylePetlickaitė, R., Jasinskas, A., Mieldažys, R., Romaneckas, K., Praspaliauskas, M., & Balandaitė, J. (2022). Investigation of Pressed Solid Biofuel Produced from Multi-Crop Biomass. Sustainability, 14(2), 799. https://doi.org/10.3390/su14020799