Life Cycle Assessment (LCA) in Earth Construction: A Systematic Literature Review Considering Five Construction Techniques

Abstract

:1. Introduction

2. Materials and Methods

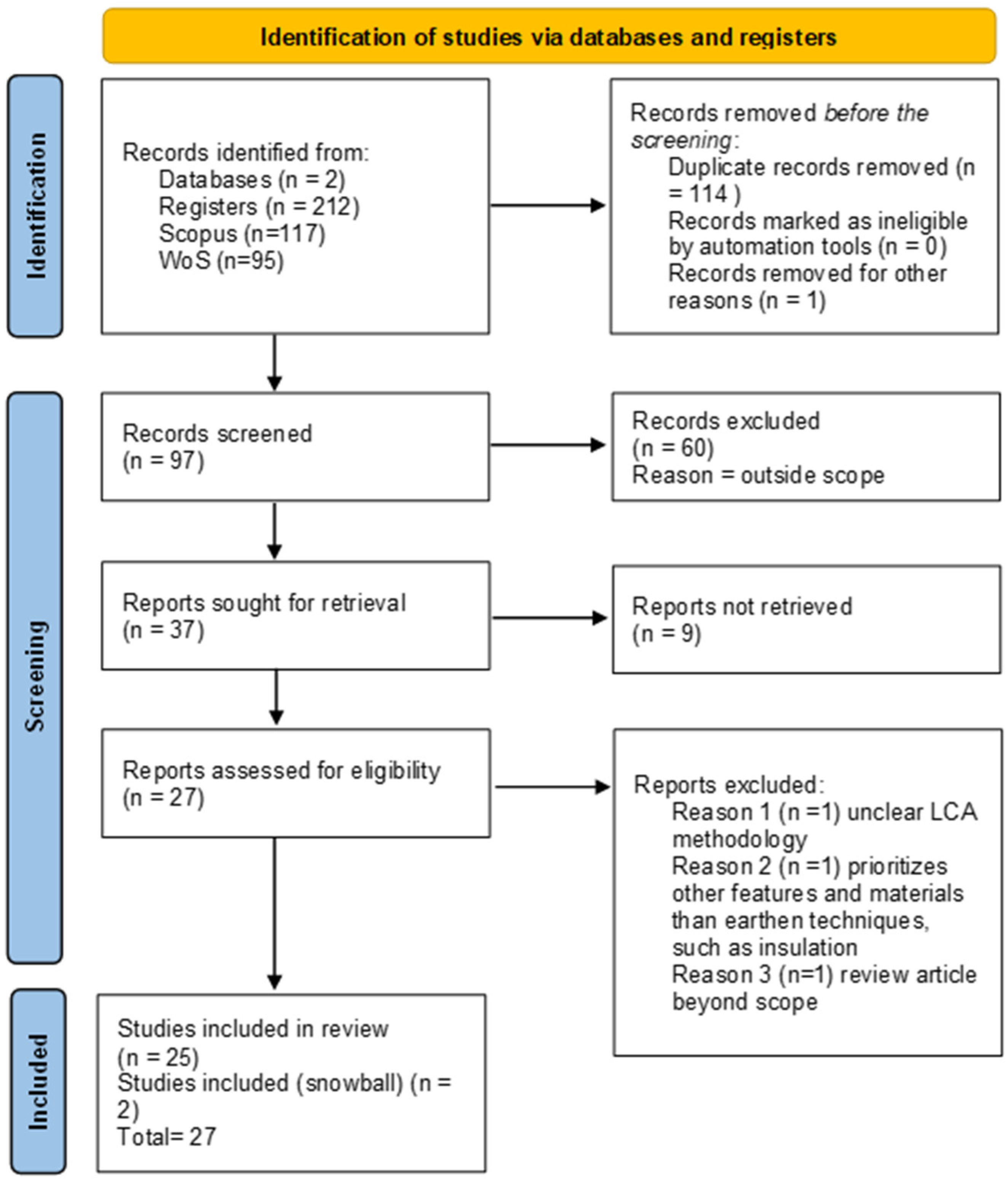

2.1. Systematic Literature Review (SLR)

2.2. Data Analysis

3. Results

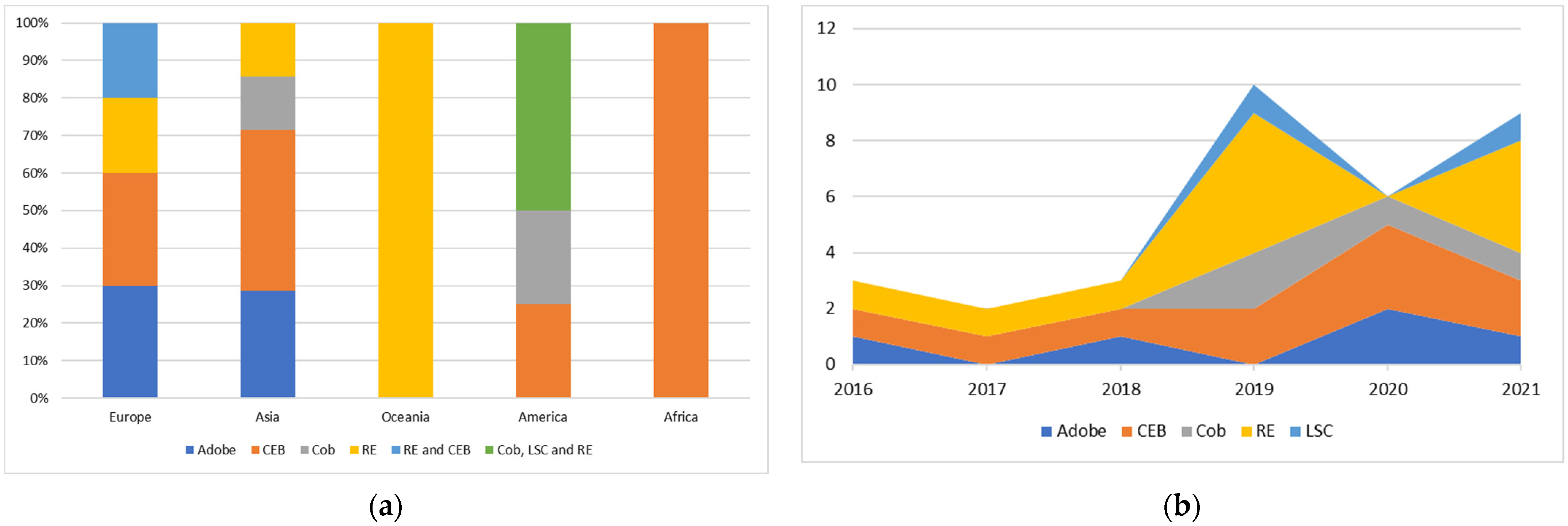

3.1. General Features

3.2. LCA Methodology Framework

3.2.1. Goal and Scope

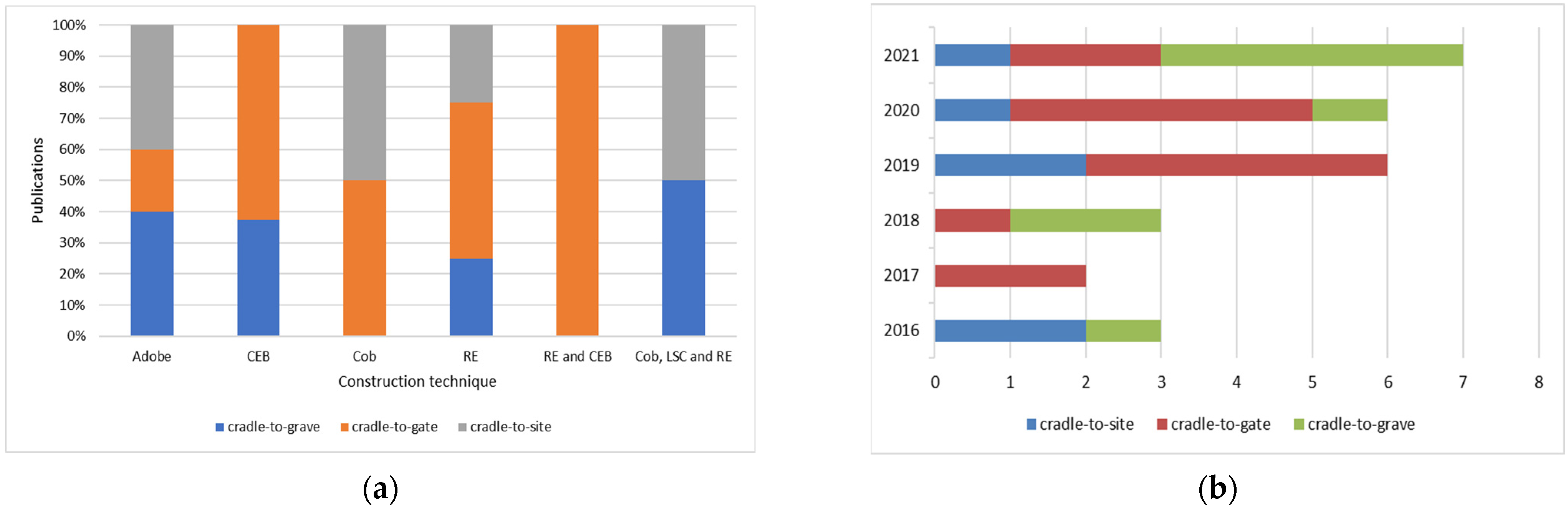

3.2.2. System Boundaries

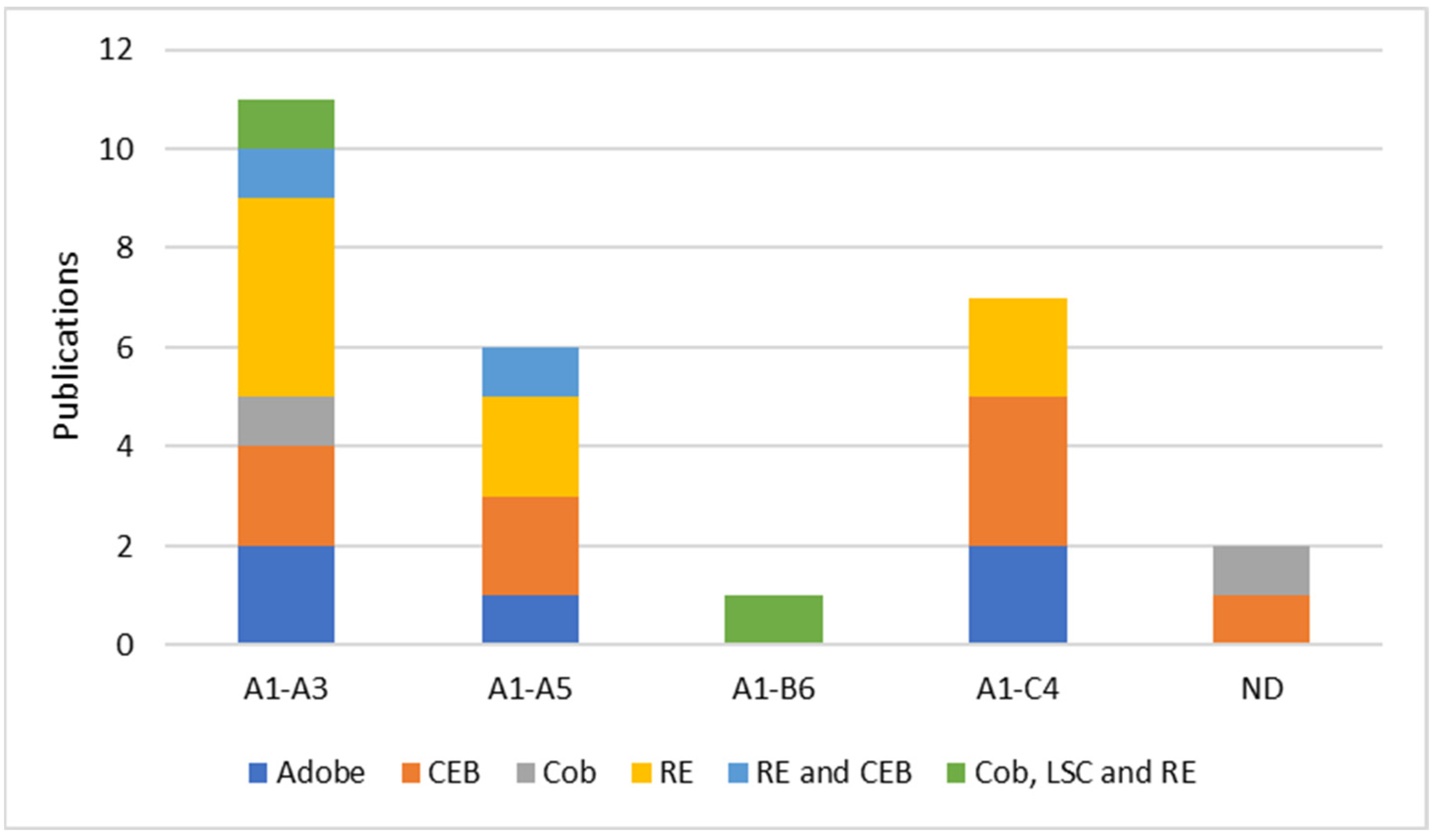

3.2.3. Life Cycle Stages

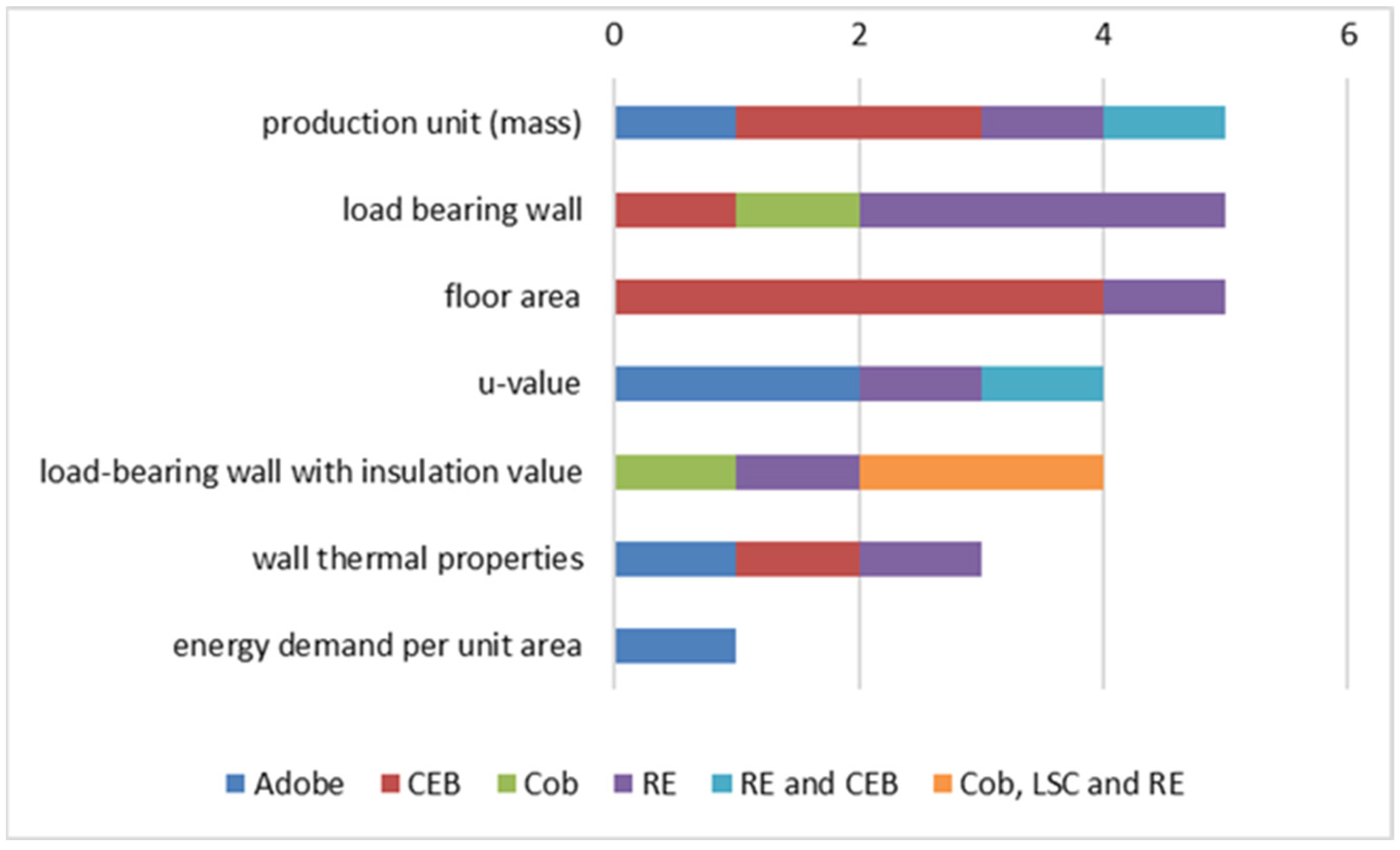

3.2.4. Unit

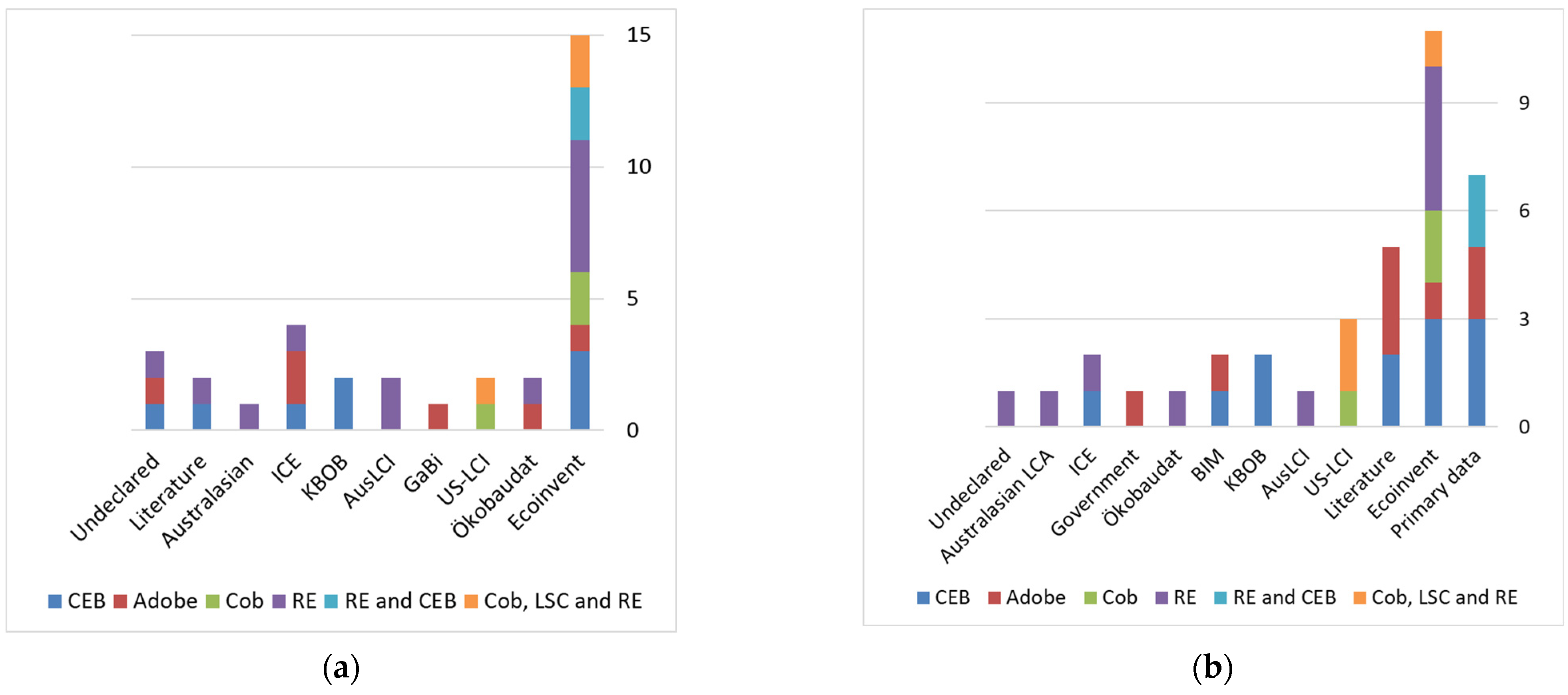

3.2.5. Life Cycle Inventory Analysis (LCI)

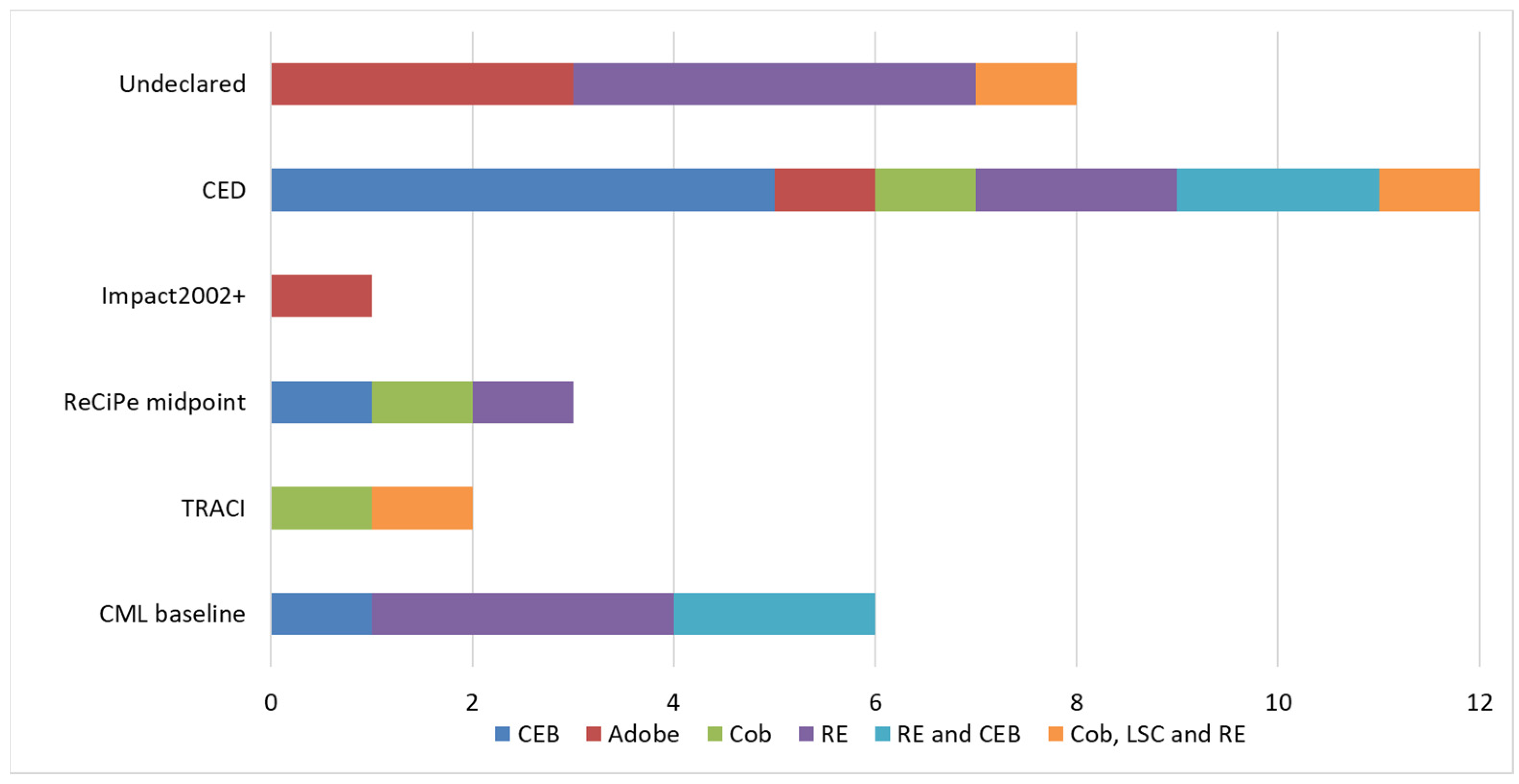

3.2.6. Life Cycle Impact Assessment (LCIA) Methods

3.2.7. Impact Categories

3.2.8. Allocation Procedures

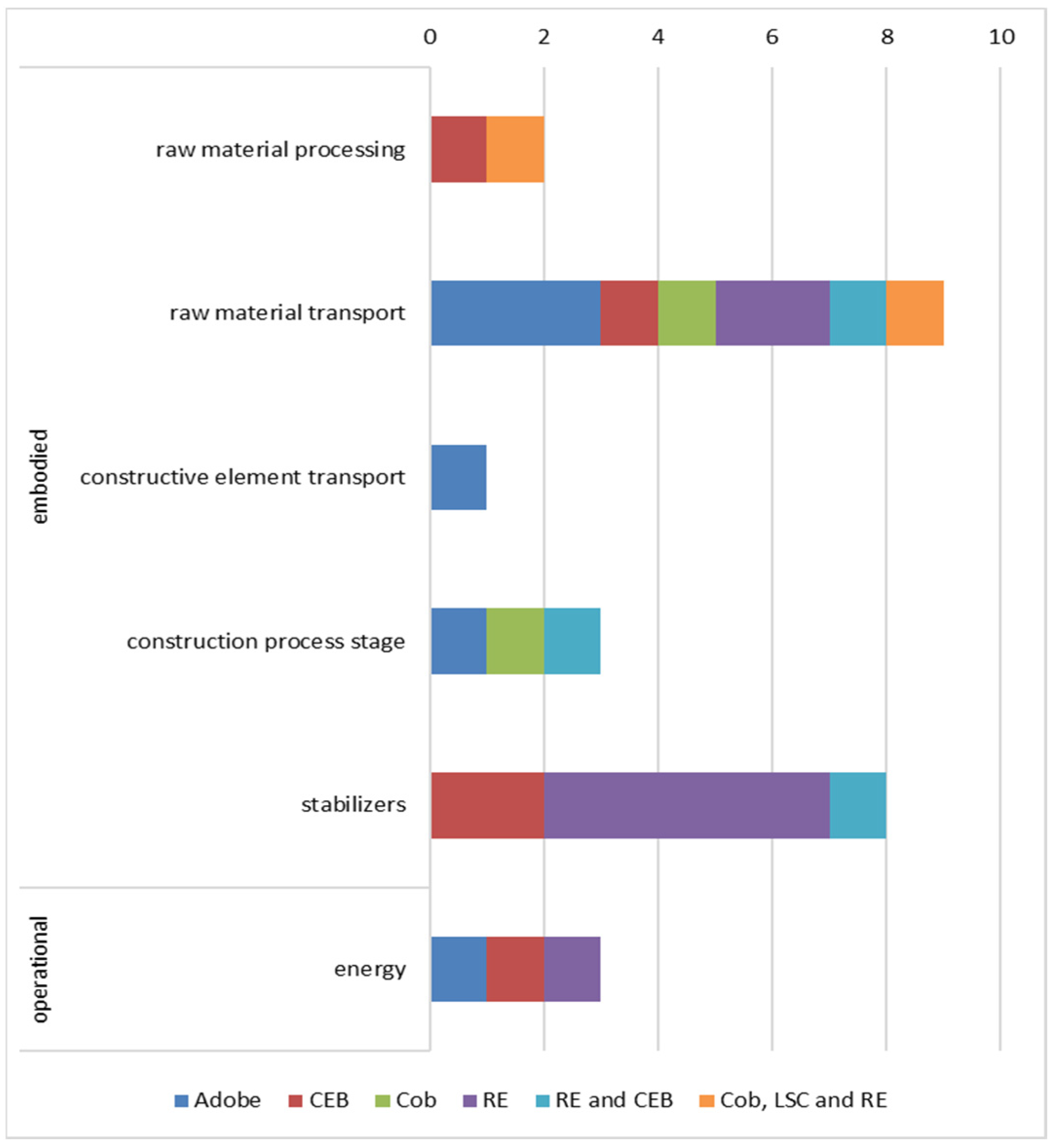

3.3. Embodied Carbon and Embodied Energy

3.4. Technical Features Considered in LCA Studies

4. Research Outlooks and Recommendations

5. Research Limitations

6. Conclusions and Final Remarks

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Authors | Ref | Technique | Geographic Distribution | Goal and Scope | System Boundaries | Life Cycle Stages | Unit | LCI Data Source | LCIA Methods | Allocation Procedures | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Background | Foreground | ||||||||||

| Pereira, 2017 | [53] | CEB | Portugal | to assess the potential environmental impacts | cradle-to-gate | A1–A3 | m2 wall | Ecoinvent 2013 v3.4 | Primary | CML, CED | Not considered: CEB as single product |

| Florescu and Bica, 2020 | [47] | Adobe | Romania | to assess the potential environmental impacts | cradle-to-gate | A1–A5 | m2 wall | Ökobaudat database | Primary data | undeclared | undeclared |

| Mateus, R., Fernandes, J., and Teixeira, E. R., 2019 | [35] | RE and CEB | Portugal | to compare the environmental impact of different earth-based assemblies | cradle-to-gate | A1–A3 | m2 wall | Ecoinvent v3.3 database | Primary data company/manufacturer | CML, CED | undeclared |

| Fernandes et al., 2019 | [40] | RE and CEB | Portugal | to compare the environmental impact of different earth-based assemblies | cradle-to-gate | A1–A5 | m2 wall | Ecoinvent v3.3 database | Primary data—company and manufacturers | CML, CED | Attributional: ordinary allocation by-products |

| Ben-Alon et al., 2019a | [19] | Cob | USA | to assess the potential environmental impacts | cradle-to-gate | A1–A3 | m2 wall | US-LCI and Ecoinvent for North America | US-LCI and Ecoinvent for North America | CML, TRACI | Attributional: ordinary allocation between by-products |

| Ben-Alon et al., 2021 | [20] | Cob, LSC, RE | USA | to compare the environmental impact of different earth-based assemblies | cradle-to-grave | A1–B6 | m2 wall | EcoInvent inventory data North America” | US-LCI. | Operational LCIA | Consequential: system expansion |

| Christoforou et al., 2016 | [32] | Adobe | Cyprus | to compare different scenarios of raw material or transport | cradle-to-site | A1–A3 | kg | GaBi database; ICE | Primary data and the literature | Undeclared | by-products |

| Arrigoni et al., 2017 | [39] | RE | Australia | to compare different scenarios of raw material or transport | cradle-to-gate | A1–A3 | m2 wall | Ecoinvent | Ecoinvent and real distances | CML, CED | Attributional: cut off system model as wasteConsequential: system expansion |

| Meek et al., 2021 | [51] | RE | Australia | to assess the potential environmental impacts | cradle-to-gate | A1-A5 | m2 wall | Ecoinvent v3.4, AusLCI database v2.8 | AusLCI database v2.8; updated where more accurate or current data was available. | - | EN15804 |

| Asman et al., 2020 | [34] | Interlocked CEB (ICEB) | Malaysia | to compare the environmental impact with conventional assemblies | cradle-to-gate | A1–A5 (without A4) | m2 house | - | primary data: Bill of Quantities (BQ) in the contract document and construction data | - | undeclared |

| Elahi et al., 2021 | [31] | CEB | Bangladesh | to compare the environmental impact with conventional assemblies | cradle-to-gate | A1–A3 | m3 wall | literature | Direct data and literature; Based on the local market price for cost analysis. | - | undeclared |

| Alhumayani et al., 2020 | [33] | Cob | Saudi Arabia | to compare the environmental impact with conventional assemblies | cradle-to-site | ND | m2 wall | Ecoinvent v3.1 | Ecoinvent v3.1 | ReCiPe Midpoint | undeclared |

| Nanz et al., 2019 | [37] | RE | Germany | to compare different scenarios of raw material or transport | cradle-to-site | A1–A5 | m2 wall | Ökobaudat (2017), literature and (ÖNORM B 8119-7, 2013) | Ökobaudat (2017); Austrian brick association Initiative Ziegel (2015) | - | undeclared |

| Meek and Elchalakani, 2019. | [50] | RE | Australia | to compare the environmental impact with conventional assemblies | cradle-to-gate | A1–A3 | m2 wall | AusLCI database v2.8, Ecoinventv3.4 when AusLCI data was unavailable | Ecoinvent | - | EN15804 |

| Shrestha 2021 | [44] | Compressed stabilized earth block (CSEB) | Nepal | to assess the potential environmental impacts | cradle-to-grave | A1–C4 | m2 house | Ecoinvent dataset version 3.5 | Ecoinvent dataset version 3.5 | CED, ReCiPe Midpoint | undeclared |

| Arrigoni et al., 2018 | [54] | RE | Australia | to assess the potential environmental impacts | cradle to gate | A1–A3 | m2 wall | ReCiPe Midpoint | waste | ||

| Ansah et al., 2020 | [27] | Stabilized earth blocks façade (SEBF) | Ghana | to compare the environmental impact with conventional assemblies | cradle to gate | A1–A5 | m2 house | The Inventory of Carbon and Energy (ICE) database V2.0; | Primary data (building drawings, etc.) | CED | undeclared |

| Zhang et al., 2020 | [43] | Adobe | China | to compare the environmental impact with conventional assemblies | cradle-to-grave | A1–C4 | m2 house | literature (government data and scientific publications since 1996) | CED | undeclared | |

| Brambilla et al., 2018 | [42] | CEB | Switzerland | to assess the potential environmental impacts | cradle-to-grave | A1–C4 | m2 house | KBOB | KBOB | CED | undeclared |

| Nouri et al., 2021 | [45] | RE | Iran | to compare the environmental impact with conventional assemblies | cradle-to-grave | A1–C4 | 1000 kg | ICE database | ICE and ISIRI7965 code | undeclared | |

| Bonoli et al., 2018 | [28] | Adobe | Italy | to assess the potential environmental impacts | cradle to grave | A1–C4 | m2 wall | Ecoinvent | primary (brick factory); literature data and Ecoinvent | Impact 2002+ | undeclared |

| Arrigoni et al., 2016 | [38] | RE | Australia | to compare different scenarios of raw material or transport | cradle-to-site | A1–A3 | m2 wall | Ecoinvent and the Australasian LCA; | Ecoinvent and the Australasian LCA; | CML | undeclared |

| Cabrera et al., 2020 | [36] | CEB | Argentina | to compare different scenarios of raw material or transport | cradle-to-gate | A1–A3 | kg | Ecoinvent | primary data (Mobak CEB Factory) | undeclared | |

| Brambilla et al., 2016 | [41] | CEB | Switzerland | assess the potential environmental impacts | cradle-to-grave | A1–C4 | m2 house | KBOB | KBOB | CED | undeclared |

| Pakdel et al., 2021 | [48] | Adobe | Iran | to assess the potential environmental impacts | cradle-to-site | A1–A3 | m2 house | ICE | Primary data (contractor and at construction site); Building Information Modelling (BIM) | undeclared | |

| Ben-Alon et al., 2019b | [49] | Cob, LSC, RE | USA | compare the environmental impact of different earth-based assemblies | cradle-to-site | A1–A3 | m2 wall | US-LCI and Ecoinvent for North America | US-LCI and Ecoinvent for North America | CED—Traci | undeclared |

| Mileto et al., 2021 | [46] | RE | Spain | to compare the environmental impact with conventional assemblies | cradle-to-grave | A1–A5, B5, C1–C4 | m2 house | Ecoinvent | Ecoinvent | CML | EN15804 |

References

- Costa, C.; Cerqueira, Â.; Rocha, F.; Velosa, A. The Sustainability of Adobe Construction: Past to Future. Int. J. Archit. Herit. 2018, 13, 639–647. [Google Scholar] [CrossRef]

- Fernandes, J.; Mateus, R.; Bragança, L. Arquitectura Vernácula Portuguesa: Lições de Sustentabilidade Para a Arquitectura Contemporânea. Colóquio Int. Arquit. Pop. 2016, 773–789. Available online: https://hdl.handle.net/1822/43322 (accessed on 2 August 2022).

- Pacheco-Torgal, F.; Jalali, S. Earth Construction: Lessons from the Past for Future Eco-Efficient Construction. Constr. Build. Mater. 2012, 29, 512–519. [Google Scholar] [CrossRef] [Green Version]

- Dobson, S. Rammed Earth in the Modern World. In Rammed Earth Construction: Cutting-Edge Research on Traditional and Modern Rammed Earth; Ciancio, D., Beckett, C., Eds.; CRC Press, Taylor & Francis Group: London, UK, 2015; pp. 3–10. ISBN 978-1-315-69294-4. [Google Scholar]

- Niroumand, H.; Zain, M.F.M.; Jamil, M. Various Types of Earth Buildings. Procedia Soc. Behav. Sci. 2013, 89, 226–230. [Google Scholar] [CrossRef] [Green Version]

- Aguilar, R.; Nakamatsu, J.; Ramírez, E.; Elgegren, M.; Ayarza, J.; Kim, S.; Pando, M.A.; Ortega-San-Martin, L. The Potential Use of Chitosan as a Biopolymer Additive for Enhanced Mechanical Properties and Water Resistance of Earthen Construction. Constr. Build. Mater. 2016, 114, 625–637. [Google Scholar] [CrossRef]

- Bogas, J.A.; Silva, M.; Glória Gomes, M. Unstabilized and Stabilized Compressed Earth Blocks with Partial Incorporation of Recycled Aggregates. Int. J. Archit. Herit. 2019, 13, 569–584. [Google Scholar] [CrossRef]

- Cuitiño-Rosales, M.G.; Rotondaro, R.; Esteves, A. Comparative Analysis of Thermal Aspects and Mechanical Resistance of Building Materials and Elements with Earth. Rev. Arquit. 2020, 22, 138–151. [Google Scholar]

- Millogo, Y.; Aubert, J.-E.; Séré, A.D.; Fabbri, A.; Morel, J.-C. Earth Blocks Stabilized by Cow-Dung. Mater. Struct. 2016, 49, 4583–4594. [Google Scholar] [CrossRef]

- Nakamatsu, J.; Kim, S.; Ayarza, J.; Ramírez, E.; Elgegren, M.; Aguilar, R. Eco-Friendly Modification of Earthen Construction with Carrageenan: Water Durability and Mechanical Assessment. Constr. Build. Mater. 2017, 139, 193–202. [Google Scholar] [CrossRef]

- Olacia, E.; Pisello, A.L.; Chiodo, V.; Maisano, S.; Frazzica, A.; Cabeza, L.F. Sustainable Adobe Bricks with Seagrass Fibres. Mechanical and Thermal Properties Characterization. Constr. Build. Mater. 2020, 239, 117669. [Google Scholar] [CrossRef]

- ISO. ISO 14040; International Standard. In Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Schroeder, H.; Lemke, M. Sustainability of Earth Building Materials—Environmental Product Declarations as an Instrument of Competition in Building Material Industry. VITRUVIO—Int. J. Archit. Technol. Sustain. 2015, 1, 45–55. [Google Scholar] [CrossRef]

- Paiva, R.L.M.; Caldas, L.R.; de Souza Martins, A.P.; Toledo Filho, R.D. Potentiality of Earth-Based Mortar Containing Bamboo Particles for GHG Emissions Reduction. Constr. Build. Mater. 2022, 317, 125971. [Google Scholar] [CrossRef]

- Paiva, R.d.L.M.; Caldas, L.R.; Martins, A.P.d.S.; de Sousa, P.B.; de Oliveira, G.F.; Filho, R.D.T. Thermal-Energy Analysis and Life Cycle Ghg Emissions Assessments of Innovative Earth-Based Bamboo Plastering Mortars. Sustainability 2021, 13, 429. [Google Scholar] [CrossRef]

- Santos, T.; Almeida, J.; Silvestre, J.D.; Faria, P. Life Cycle Assessment of Mortars: A Review on Technical Potential and Drawbacks. Constr. Build. Mater. 2021, 288, 123069. [Google Scholar] [CrossRef]

- Ventura, A.; Ouellet-Plamondon, C.; Röck, M.; Hecht, T.; Roy, V.; Higuera, P.; Lecompte, T.; Faria, P.; Hamard, E.; Moreal, J.-C.; et al. Environmental Potential of Earth-Based Materials: Key Facts and Issues from a Life Cycle Assessment Perspective. In Testing and Characterisation of Earth-Based Building Materials and Elements. State-Of-The-Art Report of the RILEM TC 274-TCE; Fabbri, A., Morel, J.-C., Aubert, J.-E., Bui, Q.-B., Gallipoli, D., Reddy, B.V.V., Eds.; RILEM State-of-the-Art Reports; Springer International Publishing: Cham, Switzerland, 2022; Volume 35, pp. 261–296. ISBN 978-3-030-83296-4. [Google Scholar]

- Fernandes, M.; Tavares, A. O Adobe; Argumentum: Lisboa, Portugal, 2016; ISBN 9789728479954. [Google Scholar]

- Ben-Alon, L.; Loftness, V.; Harries, K.A.; DiPietro, G.; Hameen, E.C. Cradle to Site Life Cycle Assessment (LCA) of Natural vs Conventional Building Materials: A Case Study on Cob Earthen Material. Build. Environ. 2019, 160, 106150. [Google Scholar] [CrossRef]

- Ben-Alon, L.; Loftness, V.; Harries, K.A.; Cochran Hameen, E. Life Cycle Assessment (LCA) of Natural vs Conventional Building Assemblies. Renew. Sustain. Energy Rev. 2021, 144, 110951. [Google Scholar] [CrossRef]

- CEN (European Committee for Standardization). Sustainability of Construction Works. Environmental Product Declarations. Core Rules for the Product Category of Construction Products; Technical Committee B/558, Ed.; EN15804:2012+A1:2013; BSI British Standards Institution: Brussels, Belgium, 2013; ISBN 9780580822322. [Google Scholar]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Seol, Y.; Lee, S.; Lee, J.-Y. Excavation Method Determination of Earth-Retaining Wall for Sustainable Environment and Economy: Life Cycle Assessment Based on Construction Cases in Korea. Sustainability 2021, 13, 2974. [Google Scholar] [CrossRef]

- Damians, I.P.; Bathurst, R.J.; Adroguer, E.G.; Josa, A.; Lloret, A. Environmental Assessment of Earth Retaining Wall Structures. Environ. Geotech. 2017, 4, 415–431. [Google Scholar] [CrossRef]

- Zastrow, P.; Molina-Moreno, F.; García-Segura, T.; Martí, J.V.; Yepes, V. Life Cycle Assessment of Cost-Optimized Buttress Earth-Retaining Walls: A Parametric Study. J. Clean. Prod. 2017, 140, 1037–1048. [Google Scholar] [CrossRef]

- Vyncke, J.; Kupers, L.; Denies, N. Earth as Building Material—An Overview of RILEM Activities and Recent Innovations in Geotechnics. MATEC Web Conf. 2018, 149, 02001. [Google Scholar] [CrossRef]

- Ansah, M.K.; Chen, X.; Yang, H.; Lu, L.; Lam, P.T.I. An Integrated Life Cycle Assessment of Different Façade Systems for a Typical Residential Building in Ghana. Sustain. Cities Soc. 2020, 53, 101974. [Google Scholar] [CrossRef]

- Bonoli, A.; Rizzo, S.; Tomasi, M.; Vado, A. Life Cycle Assessment for the Earthen Heritage Center (Pabillonis, Sardinia). In Vernacular and Earthen Architecture: Conservation and Sustainability, Proceedings of Sostierra 2017, Valencia, Spain, 14-16 September 2017; CRC Press: Boca Raton, FL, USA, 2018; pp. 545–549. [Google Scholar]

- Watson, L.; McCabe, K. The Cob Building Technique: Past, Present and Future. Inf. Constr. 2011, 63, 59–70. [Google Scholar] [CrossRef] [Green Version]

- Baker-Laporte, P.; Laporte, R. The EcoNest Home: Designing and Building a Light Straw Clay House; New Society Publishers: Gabriola Island, BC, Canada, 2015. [Google Scholar]

- Elahi, T.E.; Shahriar, A.R.; Islam, M.S. Engineering Characteristics of Compressed Earth Blocks Stabilized with Cement and Fly Ash. Constr. Build. Mater. 2021, 277, 122367. [Google Scholar] [CrossRef]

- Christoforou, E.; Kylili, A.; Fokaides, P.A.; Ioannou, I. Cradle to Site Life Cycle Assessment (LCA) of Adobe Bricks. J. Clean. Prod. 2016, 112, 443–452. [Google Scholar] [CrossRef]

- Alhumayani, H.; Gomaa, M.; Soebarto, V.; Jabi, W. Environmental Assessment of Large-Scale 3D Printing in Construction: A Comparative Study between Cob and Concrete. J. Clean. Prod. 2020, 270, 122463. [Google Scholar] [CrossRef]

- Asman, N.S.A.; Bolong, N.; Mirasa, A.K.; Asrah, H.; Saad, I. Interlocking Compressed Earth Bricks as Low Carbon Footprint Building Material. IOP Conf. Ser. Earth Environ. Sci. 2020, 476, 012086. [Google Scholar] [CrossRef]

- Mateus, R.; Fernandes, J.; Teixeira, E.R. Environmental Life Cycle Analysis of Earthen Building Materials. In Encyclopedia of Renewable and Sustainable Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 63–68. [Google Scholar]

- Cabrera, S.P.; Jiménez, Y.G.A.; Domínguez, E.J.S.; Rotondaro, R. Compressed Earth Blocks (CEB) Stabilized with Lime and Cement. Evaluation of Both Their Environmental Impact and Compressive Strength. Habitat Sustentable 2020, 10, 70–81. [Google Scholar] [CrossRef]

- Nanz, L.; Rauch, M.; Honermann, T.; Auer, T. Impacts on the Embodied Energy of Rammed Earth Façades during Production and Construction Stages. J. Facade Des. Eng. 2019, 7, 75–88. [Google Scholar] [CrossRef]

- Arrigoni, A.; Ciancio, D.; Beckett, C.T.S.; Dotelli, G. Improving Rammed Earth Walls’ Sustainability through Life Cycle Assessment (LCA). In Proceedings of the Expanding Boundaries: Systems Thinking in the Built Environment. Sustainable Built Environment (SBE) Regional Conference, Zurich, Switzerland, 13–17 June 2016. [Google Scholar] [CrossRef]

- Arrigoni, A.; Beckett, C.; Ciancio, D.; Dotelli, G. Life Cycle Analysis of Environmental Impact vs. Durability of Stabilised Rammed Earth. Constr. Build. Mater. 2017, 142, 128–136. [Google Scholar] [CrossRef]

- Fernandes, J.; Peixoto, M.; Mateus, R.; Gervásio, H. Life Cycle Analysis of Environmental Impacts of Earthen Materials in the Portuguese Context: Rammed Earth and Compressed Earth Blocks. J. Clean. Prod. 2019, 241, 118286. [Google Scholar] [CrossRef]

- Brambilla, A.; Hoxha, E.; Jusselme, T.; Andersen, M.; Rey, E. LCA as Key Factor for Implementation of Inertia in a Low Carbon Performance Driven Design: The Case of the Smart Living Building in Fribourg, Switzerland. In Proceedings of the Sustainable Built Environment (SBE) Regional Conference, Zurich, Switzerland, 13–17 June 2016. [Google Scholar]

- Brambilla, A.; Bonvin, J.; Flourentzou, F.; Jusselme, T. Life Cycle Efficiency Ratio: A New Performance Indicator for a Life Cycle Driven Approach to Evaluate the Potential of Ventilative Cooling and Thermal Inertia. Energy Build. 2018, 163, 22–33. [Google Scholar] [CrossRef]

- Zhang, T.; Ding, Q.; Hu, Q.; Liu, B.; Gao, W.; Zhou, D.; Fukuda, H. Towards Rural Revitalization Strategy for Housing in Gully Regions of the Loess Plateau: Environmental Considerations. Energies 2020, 13, 3109. [Google Scholar] [CrossRef]

- Shrestha, J.K. Assessment of Energy Demand and Greenhouse Gas Emissions in Low Rise Building Systems: Case Study of Five Building Systems Built after the Gorkha Earthquake in Nepal. J. Build. Eng. 2021, 34, 101831. [Google Scholar] [CrossRef]

- Nouri, H.; Safehian, M.; Mir Mohammad Hosseini, S.M. Life Cycle Assessment of Earthen Materials for Low-Cost Housing a Comparison between Rammed Earth and Fired Clay Bricks. Int. J. Build. Pathol. Adapt. 2021; ahead-of-print. [Google Scholar] [CrossRef]

- Mileto, C.; Vegas, F.; Llatas, C.; Soust-Verdaguer, B. A Sustainable Approach for the Refurbishment Process of Vernacular Heritage: The Sesga House Case Study (Valencia, Spain). Sustainability 2021, 13, 9800. [Google Scholar] [CrossRef]

- Florescu, E.R.; Bica, S.M. Earth as an Alternative Indicator Regarding the Ecological Character of Building Materials. In Proceedings of the INTCESS 2020 7th Conference on Education and Social Sciences, Dubai, United Arab Emirates, 20 January 2020; pp. 205–212. [Google Scholar]

- Pakdel, A.; Ayatollahi, H.; Sattary, S. Embodied Energy and CO2 Emissions of Life Cycle Assessment (LCA) in the Traditional and Contemporary Iranian Construction Systems. J. Build. Eng. 2021, 39, 102310. [Google Scholar] [CrossRef]

- Ben-Alon, L.; Loftness, V.; Harries, K.A.; Hameen, E.C. The Biophilic Power and Environmental Urgency of Earthen Construction. IOP Conf. Ser. Earth Environ. Sci. 2019, 290, 012006. [Google Scholar] [CrossRef]

- Meek, A.H.; Elchalakani, M. Life Cycle Assessment of Rammed Earth Made Using Alkaline Activated Industrial By-Products. In Proceedings of the IOP Conference Series: Earth and Environmental Science; Institute of Physics Publishing: Bristol, UK, 2019; Volume 323. [Google Scholar]

- Meek, A.H.; Elchalakani, M.; Beckett, C.T.S.; Grant, T. Alternative Stabilised Rammed Earth Materials Incorporating Recycled Waste and Industrial By-Products: Life Cycle Assessment. Constr. Build. Mater. 2021, 267, 120997. [Google Scholar] [CrossRef]

- Bahramian, M.; Yetilmezsoy, K. Life Cycle Assessment of the Building Industry: An Overview of Two Decades of Research (1995–2018). Energy Build. 2020, 219, 109917. [Google Scholar] [CrossRef]

- Pereira, H.F.N. Desenvolvimento Da Declaração Ambiental Do Produto (DAP) Do Bloco de Terra Comprimida (BTC). Ph.D. Thesis, University of Minho, Braga, Portugal, 2017. [Google Scholar]

- Arrigoni, A.; Beckett, C.T.S.; Ciancio, D.; Pelosato, R.; Dotelli, G.; Grillet, A.C. Rammed Earth Incorporating Recycled Concrete Aggregate: A Sustainable, Resistant and Breathable Construction Solution. Resour. Conserv. Recycl. 2018, 137, 11–20. [Google Scholar] [CrossRef]

- Asman, N.S.A.; Bolong, N.; Mirasa, A.K.; Asrah, H. Life Cycle Assessment of Interlocking Compressed Earth Brick and Conventional Fired Clay Brick for Residential House. J. Phys. Conf. Ser. 2020, 1529, 042012. [Google Scholar] [CrossRef]

- Frischknecht, R.; Wyss, F.; Büsser Knöpfel, S.; Lützkendorf, T.; Balouktsi, M. Cumulative Energy Demand in LCA: The Energy Harvested Approach. Int. J. Life Cycle Assess. 2015, 20, 957–969. [Google Scholar] [CrossRef]

- Hischier, R.; Weidema, B.; Althaus, H.-J.; Bauer, C.; Doka, G.; Dones, R.; Frischknecht, R.; Hellweg, S.; Humbert, S.; Jungbluth, N.; et al. Implementation of Life Cycle Impact Assessment Methods. Ecoinvent Report No. 3; Hischier, R., Weidema, B., Eds.; Swiss Centre for Life Cycle Inventories, Ecoinvent: Dübendorf, Switzerland, 2010. [Google Scholar]

- Meek, A.H.; Elchalakani, M.; Beckett, C.T.S.; Dong, M. Alternative Stabilised Rammed Earth Materials Incorporating Recycled Waste and Industrial By-Products: A Study of Mechanical Properties, Flexure and Bond Strength. Constr. Build. Mater. 2021, 277, 122303. [Google Scholar] [CrossRef]

- Aubert, J.-E.; Faria, P.; Maillar, P.; Ouedraogo, K.A.J.; Ouellet-Plamondon, C.; Prud’homme, E. Characterization of Earth Used in Earth Construction Materials. In Testing and Characterisation of Earth-Based Building Materials and Elements, RILEM State-of-the-Art Reports; Fabri, A., Morel, J.-C., Aubert, J.-E., Bui, Q.-B., Gallipoli, D., Ventakarama Reddy, B., Eds.; Springer: Berlin/Heidelberg, Germany, 2022; Volume 35, pp. 17–82. [Google Scholar]

- Caldas, L.R.; Saraiva, A.B.; Lucena, A.F.P.; da Gloria, M.Y.; Santos, A.S.; Filho, R.D.T. Building Materials in a Circular Economy: The Case of Wood Waste as CO2-Sink in Bio Concrete. Resour. Conserv. Recycl. 2021, 166, 105346. [Google Scholar] [CrossRef]

- Caldas, L.R.; Pittau, F.; Schaeffer, R.; Saraiva, A.K.E.B.; Paiva, R.d.L.M.; Toledo Filho, R.D. Concrete vs. Ceramic Blocks: Environmental Impact Evaluation Considering a Country-Level Approach. World 2021, 2, 482–504. [Google Scholar] [CrossRef]

- Caldas, L.R.; Paiva, R.D.L.M.; Martins, A.P.d.S.; Toledo Filho, R.D. Argamassas de Terra versus Convencionais: Avaliação Do Desempenho Ambiental Considerando o Ciclo de Vida. MIX Sustentável 2020, 6, 115–128. [Google Scholar] [CrossRef]

- van Damme, H.; Houben, H. Earth Concrete. Stabilization Revisited. Cem. Concr. Res. 2018, 114, 90–102. [Google Scholar] [CrossRef]

- Elert, K.; Pardo, E.S.; Rodriguez-Navarro, C. Alkaline Activation as an Alternative Method for the Consolidation of Earthen Architecture. J. Cult. Herit. 2015, 16, 461–469. [Google Scholar] [CrossRef]

- Costa, C.; Arduin, D.; Sequeira, C.; Terroso, D.; Moutinho, S.; Cerqueira, Â.; Velosa, A.; Rocha, F. Alkaline Activation of Rammed Earth Material—“New Generation of Adobes”. In International Congress on Applied Mineralogy; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Silva, R.A.; Soares, E.; Oliveira, D.V.; Miranda, T.; Cristelo, N.M.; Leitão, D. Mechanical Characterisation of Dry-Stack Masonry Made of CEBs Stabilised with Alkaline Activation. Constr. Build. Mater. 2015, 75, 349–358. [Google Scholar] [CrossRef] [Green Version]

- Cristelo, N.; Glendinning, S.; Miranda, T.; Oliveira, D.; Silva, R. Soil Stabilisation Using Alkaline Activation of Fly Ash for Self Compacting Rammed Earth Construction. Constr. Build. Mater. 2012, 36, 727–735. [Google Scholar] [CrossRef]

- Elert, K.; Jroundi, F.; Benavides-Reyes, C.; Correa Gómez, E.; Gulotta, D.; Rodriguez-Navarro, C. Consolidation of Clay-Rich Earthen Building Materials: A Comparative Study at the Alhambra Fortress (Spain). J. Build. Eng. 2022, 50, 104081. [Google Scholar] [CrossRef]

- Silva, L.C.; Caldas, L.R.; Paiva, R.L.; Toledo Filho, R.D. Role of Bio-Based Building Materials in Climate Change Mitigation: Special Report of the Brazilian Panel on Climate Change; Kahn Ribeiro, S., Ed.; COPPE/UFRJ: Rio de Janeiro, Brazil, 2018. [Google Scholar]

- Caldas, L.R.; da Gloria, M.Y.R.; Pittau, F.; Andreola, V.M.; Habert, G.; Toledo Filho, R.D. Environmental Impact Assessment of Wood Bio-Concretes: Evaluation of the Influence of Different Supplementary Cementitious Materials. Constr. Build. Mater. 2021, 268, 121146. [Google Scholar] [CrossRef]

- Passuello, A.; Rodríguez, E.D.; Hirt, E.; Longhi, M.; Bernal, S.A.; Provis, J.L.; Kirchheim, A.P. Evaluation of the Potential Improvement in the Environmental Footprint of Geopolymers Using Waste-Derived Activators. J. Clean. Prod. 2017, 166, 680–689. [Google Scholar] [CrossRef]

| Construction Technique | Description | Representation |

|---|---|---|

| Adobe | Adobe is the most simple and ancient brickwork technique. It is a mix of soil and water in a plastic physical state (stabilized or not) in wooden molds shaped like bricks, without compaction, and dried in the sun [18] |  |

| Cob | Cob or stacked earth techniques require mixing earth with straw and water to build layer-by-layer load-bearing masonry walls. It is produced in a plastic state and implemented wet. It is also known as monolithic adobe and “Bauge” in France [19]. |  |

| Rammed earth (RE) | RE, “pies de terre” or “Taipa” uses moist soil (stabilized or not), compacted inside a formwork (traditionally made of wood, and nowadays made of steel) [3] |  |

| Compressed Earth Block (CEB) | CEB is masonry manufactured using the compression or pressing of stabilized soil inside a mechanical or hydraulic press [20]. Interlocking compressed earth brick (ICEB) or stabilized earth brick (SCEB). ICEB does not require a mortar bed between the bricks since they are assembled dry and stacked on one another. Its size and shape depend on the construction purpose, but they all have three hollow sections in the middle of the bricks [21]. |  |

| Light Straw Clay (LSC). | LSC, light clay, straw-clay, slip straw, or rammed straw composed of fiber (usually straw) coated in very wet clay. The mix can be packed into temporary or permanent frameworks. It’s used as insulation due to its workability and compatibility with other wall assemblies, but not as loadbearing [20]. |  |

| Keywords | WOS | Scopus | Total |

|---|---|---|---|

| LCA Earth Construction | 34 | 47 | 81 |

| LCA Adobe | 3 | 3 | 6 |

| LCA CEB | 3 | 3 | 6 |

| LCA Cob | 3 | 5 | 8 |

| LCA Rammed Earth | 7 | 10 | 17 |

| LCA Earthen Material | 3 | 8 | 11 |

| LCA Earth Building | 42 | 40 | 82 |

| Total | 95 | 116 | 211 |

| Theme | Categories |

|---|---|

| General Features | Geographic Distribution Publication year |

| Goal and Scope | Assess potential impact Compare the impact of earth-based assemblies Compare the impact of earth-based assemblies to conventional assemblies Compare scenarios Compare assemblies |

| System boundaries | Cradle-to-gate Cradle-to-site Cradle-to-grave |

| Life Cycle Stages (EN 15804:2012 + A1) | Product stage Construction stage Use stage End-of-life stage |

| Unit | Functional unit Declared unit Reference flow |

| Life Cycle Inventory Analysis (LCI) | Background and foreground data sources |

| Life Cycle Impact Assessment (LCIA) | Impact assessment methods Impact categories Allocation procedures |

| Embodied Carbon an dEmbodied energy | Hotspots Benchmarks |

| Other material features | Thermal, mechanical and durability |

| Strategies | Description | Construction Techniques | ||||

|---|---|---|---|---|---|---|

| Adobe | CEB | Cob | LSC | RE | ||

| Use local earth and aggregates | Using local materials results in smaller carbon emissions; the higher the proportion (usually earth and mineral aggregates) in the mixture, the more relevant the transportation’s environmental impact due to fossil fuel burning. | x | x | x | x | x |

| Reuse of excavated earth | Other sources should be considered if the soil needs great amounts of aggregates or clays to enable the technique. Regarding the distance from the construction site, using excavated soils can reduce the environmental impact. | x | x | x | x | x |

| Decrease the amount of binder | Cement as a stabilizer has a higher impact regarding the indicator; hence it should be used in small amounts (around 5% wg). | x | x | x | x | x |

| Use of SCMs replacing conventional binders | SCMs such as fly ash, blast furnace slag, and other by-products should be used to provide the required features for the earthen material. | x | x | x | x | x |

| Use of alkaline activators (in small concentrations) to replace conventional binders | Alkaline activators as chemical stabilizers should be used in the less concentration possible to give the required features for the earthen material. | - | - | - | - | x |

| Use bio-based materials as reinforcement. | Bio-based reinforcements are renewable sources and can absorb and store CO2. Additionally, they can improve some materials’ properties, such as thermal resistance. | x | - | - | - | x |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arduin, D.; Caldas, L.R.; Paiva, R.d.L.M.; Rocha, F. Life Cycle Assessment (LCA) in Earth Construction: A Systematic Literature Review Considering Five Construction Techniques. Sustainability 2022, 14, 13228. https://doi.org/10.3390/su142013228

Arduin D, Caldas LR, Paiva RdLM, Rocha F. Life Cycle Assessment (LCA) in Earth Construction: A Systematic Literature Review Considering Five Construction Techniques. Sustainability. 2022; 14(20):13228. https://doi.org/10.3390/su142013228

Chicago/Turabian StyleArduin, Deborah, Lucas Rosse Caldas, Rayane de Lima Moura Paiva, and Fernando Rocha. 2022. "Life Cycle Assessment (LCA) in Earth Construction: A Systematic Literature Review Considering Five Construction Techniques" Sustainability 14, no. 20: 13228. https://doi.org/10.3390/su142013228